Page 1

Application: VSD failure

Introduction

• A variable speed drive on a critical system, the

fault indicator LED is on

• According to the VSD (variable speed drive), the

error code is F4; this is: the drive has detected an

“under voltage” condition and shuts down

How do you identify if the failure is in the drive,

in the motor or in a distorted supply voltage?

A typical industrial electrical distribution system

with non-linear loads

Page 2

Diagnosing VSD failure

Using a DMM

• Check the input line voltage (figure 1)

– A typical multimeter will display either average

or rms voltage values

– Depending on the type of distortion, the rms or

peak value may not reveal if a problem exists

• Check the VSD dc bus voltage

– The dc bus voltage is directly proportional to the

peak of the input line voltage

– Any distortion or error in peak amplitude of the

line voltage can cause an over- or undervoltage error

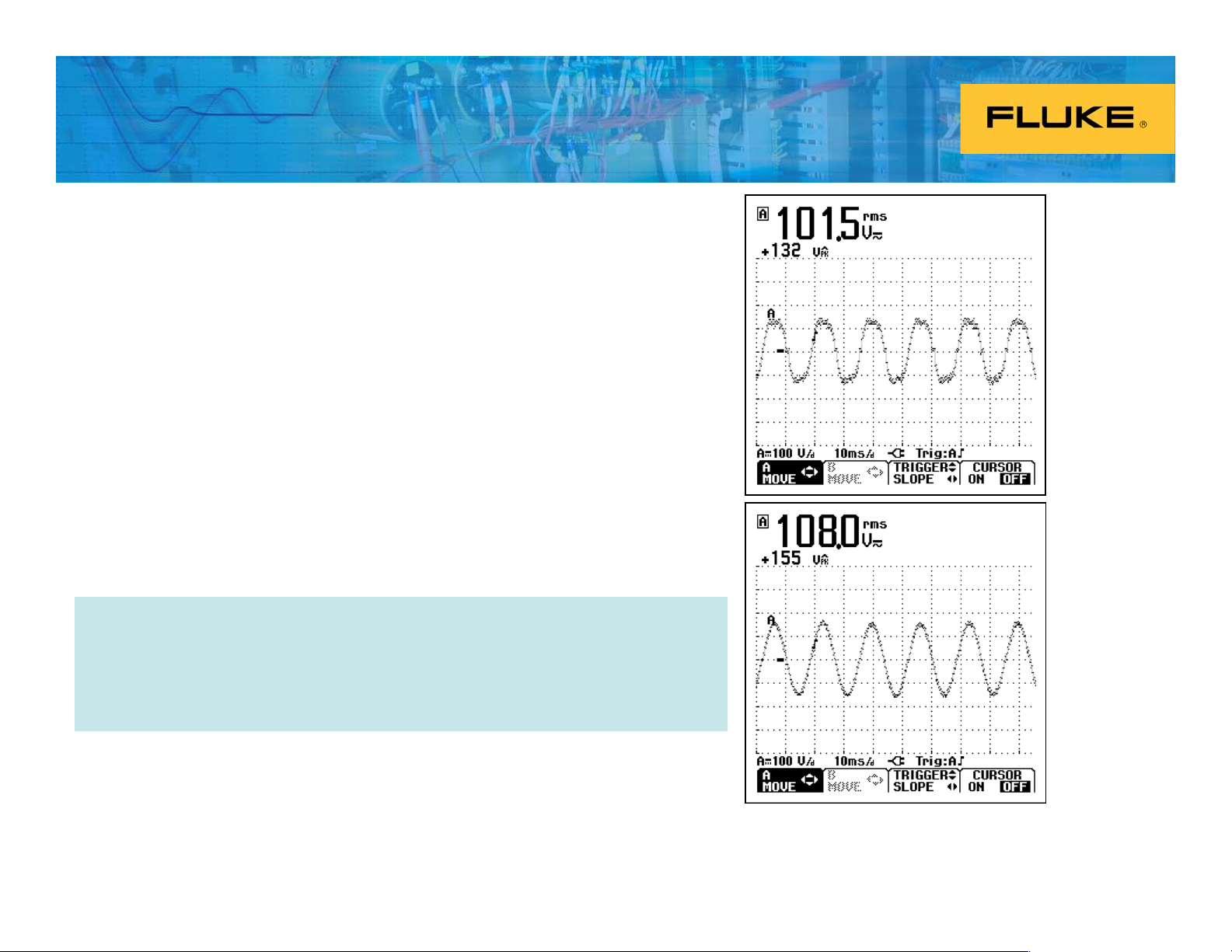

• The drive dc bus voltage in figure 2

shows around 20 % under the nominal

value of 160 V

Do you replace the drive

controller and/or motor?

Figure 1. Measuring the line voltage at

the input to a Pulse Width Modulated

drive, appears to be normal

Figure 2. Checking the dc bus voltage

level is less than nominal revealing a

potential problem

Page 3

Diagnosing line voltage distortion..

Using an Oscilloscope

• Check the input line voltage

– Connect the oscilloscope to Phase and the ground

lead to Neutral

– The waveform reveals sine wave peaks that are

rounded, almost becoming a “flat top” (figure 3)

– When this occurs, the ratio between “peak” versus

“rms” measured values is smaller than 1.4, as it

should be

– Figure 4 shows a circuit with an ideal line voltage

wave shape

The waveform distortion is caused by a

Figure 3.

Oscilloscope

waveform

displaying flat

top input line

voltage

Figure 4.

Ideal line

voltage

sine wave

non-linear load attached to the same feeder

circuit, and not necessarily the VSD or motor

Page 4

Troubleshooting using an oscilloscope

Conclusion

• A DMM can display precise amplitude RMS or

Peak values

• An oscilloscope will graphically show amplitude

(RMS or peak) as well as any distortion,

disturbance and noise that may be present on the

waveform

Fluke 120 Series

ScopeMeter

Dual input oscilloscope

and multimeter makes

troubleshooting as

easy as 123!

A picture is worth more than

a thousand words.

The more you see–the more you can fix!

Loading...

Loading...