Page 1

Fluke 123/124

Industrial ScopeMeter

Users Manual

®

GB

Sep 2002

© 2002 Fluke Corporation. All rights reserved.

All product names are trademarks of their respective companies.

Page 2

LIMITED WARRANTY & LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under normal use and service. The warranty period is three years for the

Test Tool and one year for its accessories. The warranty period begins on the date of shipment. Parts, product repairs and services are warranted for 90 days.

This warranty extends only to the original buyer or end-user customer of a Fluke authorized reseller, and does not apply to fuses, disposable batteries or to any

product which, in Fluke's opinion, has been misused, altered, neglected or damaged by accident or abnormal conditions of operation or handling. Fluke warrants

that software will operate substantially in accordance with its functional specifications for 90 days and that it has been properly recorded on non-defective media.

Fluke does not warrant that software will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user customers only but have no authority to extend a greater or different

warranty on behalf of Fluke. Warranty support is available if product is purchased through a Fluke authorized sales outlet or Buyer has paid the applicable international

price. Fluke reserves the right to invoice Buyer for importation costs of repair/replacement parts when product purchased in one country is submitted for repair in another

country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the purchase price, free of charge repair, or replacement of a defective product which is returned to a

Fluke authorized service center within the warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center or send the product, with a description of the difficulty, postage and insurance prepaid

(FOB Destination), to the nearest Fluke authorized service center. Fluke assumes no risk for damage in transit. Following warranty repair, the product will be returned to

Buyer, transportation prepaid (FOB Destination). If Fluke determines that the failure was caused by misuse, alteration, accident or abnormal condition of operation or

handling, Fluke will provide an estimate of repair costs and obtain authorization before commencing the work. Following repair, the product will be returned to the Buyer

transportation prepaid and the Buyer will be billed for the repair and return transportation charges (FOB Shipping Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE FOR ANY

SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING LOSS OF DATA, WHETHER ARISING FROM BREACH OF

WARRANTY OR BASED ON CONTRACT, TORT, RELIANCE OR ANY OTHER THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or limitation of incidental or consequential damages, the limitations

and exclusions of this warranty may not apply to every buyer. If any provision of this Warranty is held invalid or unenforceable by a court of competent jurisdiction, such

holding will not affect the validity or enforceability of any other provision.

Fluke Corporation, P.O. Box 9090, Everett, WA 98206-9090 USA, or

Fluke Industrial B.V., P.O. Box 90, 7600 AB, Almelo, The Netherlands

Page 3

SERVICE CENTERS

To locate an authorized service center, visit us on the W orld Wide Web:

http://www.fluke.com

or call Fluke using any of the phone numbers listed below:

+1-888-993-5853 in U.S.A. and Canada

+31-402-675-200 in Europe

+1-425-446-5500 from other countries

Page 4

Table of Contents

Chapter Title Page

Declaration of Conformity ....................................................................................................... 1

Unpacking the Test Tool Kit........................................................................................... 2

Safely Using the Test Tool............................................................................................. 4

1 Using The Test Tool..................................................................................................... 7

Goal of this Chapter ....................................................................................................... 7

Powering the Test Tool .................................................................................................. 7

Resetting the Test Tool.................................................................................................. 8

Changing Backlight ........................................................................................................ 9

Reading the Screen ....................................................................................................... 10

Making Selections in a Menu ......................................................................................... 11

Looking at the Measurement Connections..................................................................... 12

Displaying an Unknown Signal with Connect-and View™ ............................................. 13

Making Measurements................................................................................................... 14

i

Page 5

Fluke 123/124

Users Manual

Freezing the Screen....................................................................................................... 16

Holding a Stable Reading .............................................................................................. 16

Making Relative Measurements..................................................................................... 17

Selecting Auto/Manual Ranges...................................................................................... 18

Changing the Graphic Representation on the Screen ................................................... 18

TrendPlotting a Waveform ............................................................................................. 22

Acquiring the Waveform ................................................................................................ 23

Triggering on a Waveform ............................................................................................. 27

Saving and Recalling a Setup and a Screen ................................................................. 32

Making Cursor Measurements....................................................................................... 35

Using the 10:1 Probe for High Frequency Measurements............................................. 38

Using a Printer ............................................................................................................... 39

Using FlukeView

®

Software ........................................................................................... 41

2 Maintaining the Test Tool............................................................................................ 43

About this Chapter ......................................................................................................... 43

Cleaning the Test Tool................................................................................................... 43

Storing the Test Tool...................................................................................................... 43

Charging the Rechargeable Battery Pack...................................................................... 44

Keeping Batteries in Optimal Condition ......................................................................... 45

Replacing and Disposing of the Rechargeable Battery Pack ........................................ 46

Using and Adjusting 10:1 Scope Probes ....................................................................... 47

Calibrating the Test Tool................................................................................................ 49

Parts and Accessories ................................................................................................... 49

3 Tips and Troubleshooting........................................................................................... 53

ii

Page 6

Contents (continued)

Goal of this Chapter ....................................................................................................... 53

Using the Tilt Stand........................................................................................................ 53

Resetting the Test Tool.................................................................................................. 54

Changing the Information Language.............................................................................. 54

Changing the Display..................................................................................................... 55

Changing Date and Time ............................................................................................... 56

Saving Battery Life ......................................................................................................... 57

Changing the Auto Set Options...................................................................................... 58

Using Proper Grounding ................................................................................................ 59

Solving Printing and Other Communication Errors ........................................................ 60

Battery Testing of Fluke Accessories............................................................................. 60

4 Specifications............................................................................................................... 61

Introduction ....................................................................................................................61

Dual Input Oscilloscope ................................................................................................. 62

Dual Input Meter............................................................................................................. 65

Cursor readout (Fluke 124)............................................................................................ 68

Miscellaneous ................................................................................................................ 69

Environmental ................................................................................................................ 70

Safety ...................................................................................................................... 70

iii

Page 7

Declaration of Conformity

Declaration of Conformity

for

Fluke 123/124

®

ScopeMeter

Manufacturer

Fluke Industrial B.V.

7602 EA Almelo

The Netherlands

Statement of Conformity

Based on test results using appropriate standards,

the product is in conformity with

Electromagnetic Compatibility Directive 89/336/EEC

Low Voltage Directive 73/23/EEC

test tool

Lelyweg 1

Sample tests

Standards used:

EN 61010.1 (1993)

Safety Requirements for Electrical Equipment for

Measurement, Control, and Laboratory Use

EN 50081-1 (1992)

Electromagnetic Compatibility.

Generic Emission Standard:

EN55022 and EN60555-2

EN 50082-2 (1992)

Electromagnetic Compatibility.

Generic Immunity Standard:

IEC1000-4 -2, -3, -4, -5

The tests have been performed in a

typical configuration.

This Conformity is indicated by the symbol

i.e. “Conformité Européenne”.

,

1

Page 8

Fluke 123/124

Users Manual

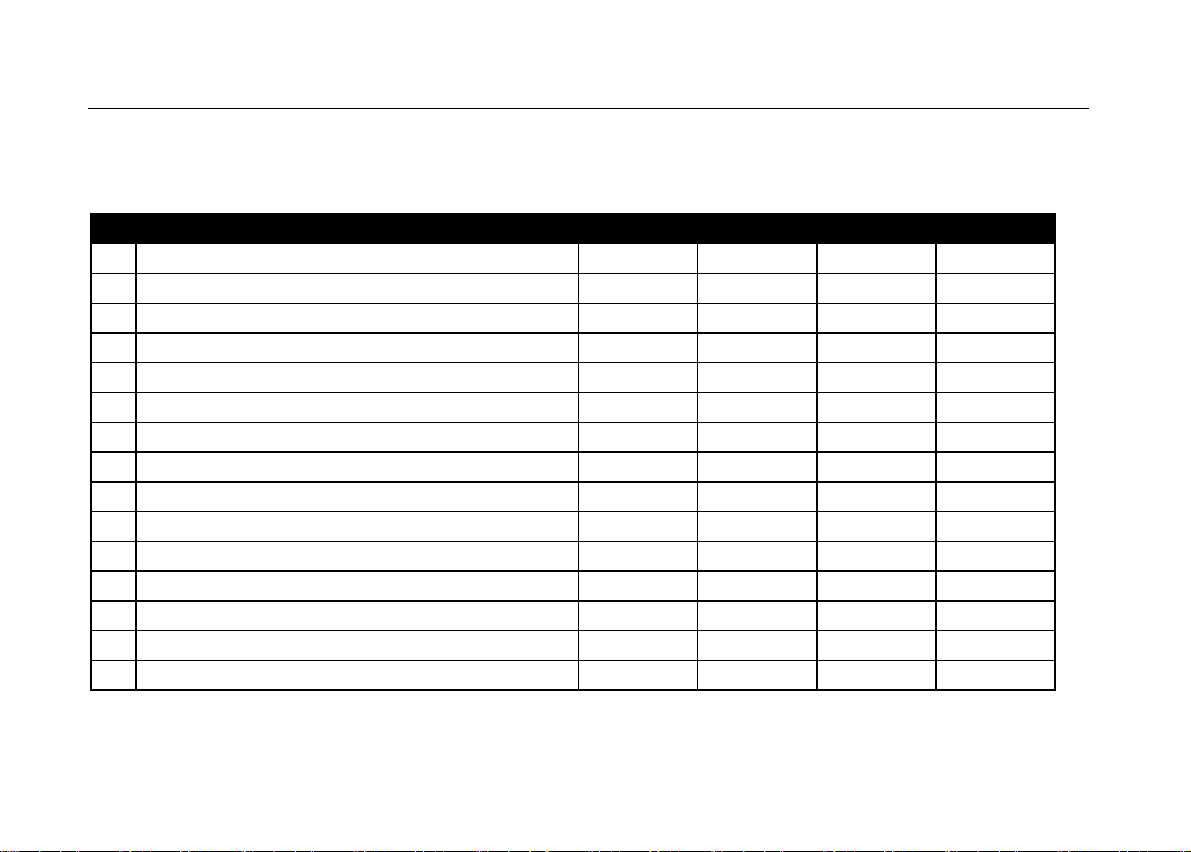

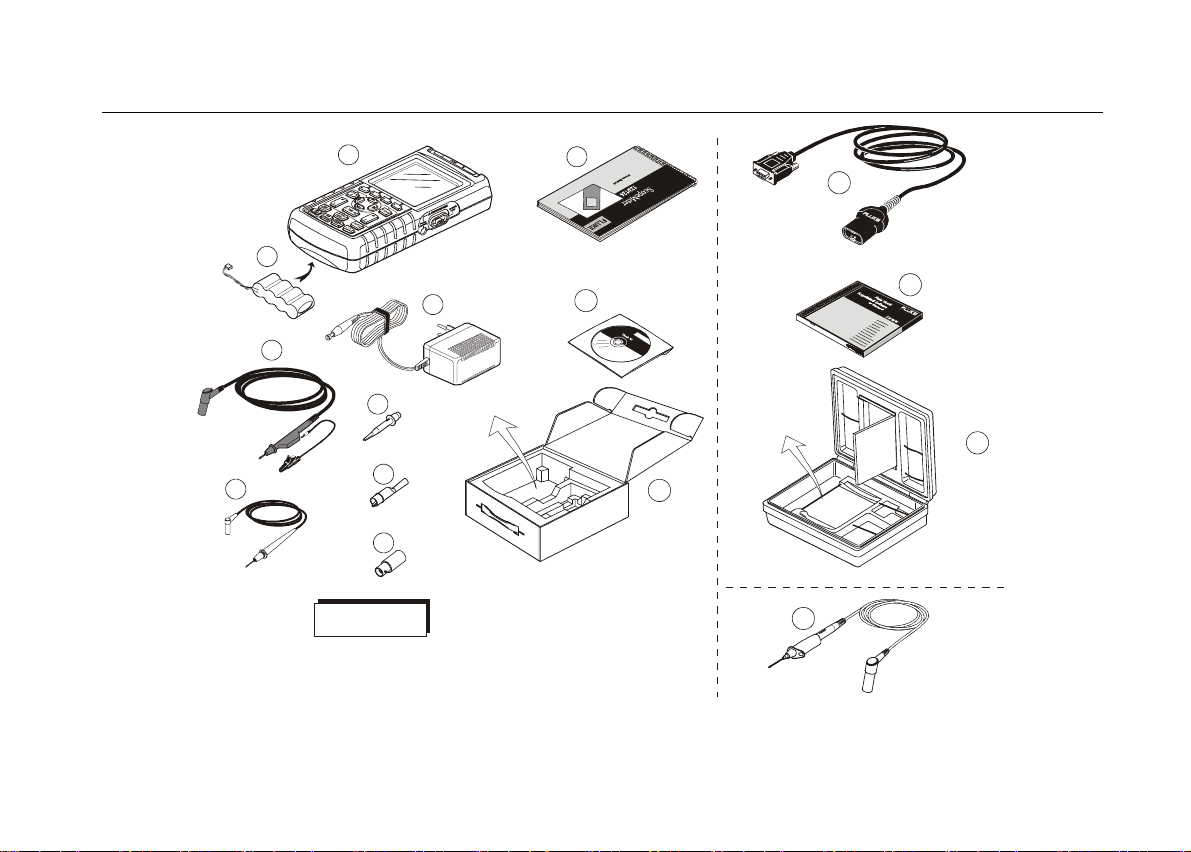

Unpacking the Test Tool Kit

The following items are included in your test tool kit. (see

Figure 1.):

# Description Fluke 123 Fluke 123/S Fluke 124 Fluke 124/S

1 Fluke Test Tool Model 123 Model 123 Model 124 Model 124

2 Rechargeable Battery Pack NiCd NiCd NiMH NiMH

3 Power Adapter/Battery Charger ••••

4 Shielded Test Leads with Black Ground Leads ••••

5 Test Lead Black (for Grounding) ••••

6 Hook Clips (red, gray) ••••

7 Alligator Clips (red, gray, black) ••••

8 Banana-to-BNC Adapters (black) • (1x) • (2x) • (1x) • (2x)

9 Getting Started Manual (this book) ••••

10 CD-ROM with Users Manuals ••••

11 Shipment Box ••

12 Optically Isolated RS-232 Adapter/Cable ••

13 FlukeView ScopeMeter Software for Windows ••

14 Hard Carrying Case ••

15 10:1 Voltage Probe ••

When new, the rechargeable battery pack is not

fully charged. See Chapter 2.

Note

2

Page 9

Unpacking the Test Tool Kit

(2x)

1

9

12

2

3

10

13

4

6

(2x)

14

(3x)

5

*

7

8

*

Fluke 123/ 124 : 1x

Fluke 123-S/ 124-S : 2x

Fluke 123/ 124

11

Fluke 123-S/ 124-S

15

Fluke 124/ 124-S

Figure 1. ScopeMeter Test Tool Kit

3

Page 10

Fluke 123/124

Users Manual

Safely Using the Test Tool

Attention

Carefully read the following safety

information before using the test tool.

Safety Precautions

Specific warning and caution statements, where they

apply, will be found throughout the manual.

A Caution identifies conditions and actions that may

damage the test tool.

A Warning identifies conditions and actions that pose

hazard(s) to the user.

Symbols used on the test tool and in this manual are

explained in the next table.

Warning

To avoid electrical shock, use only Fluke

power supply, Model PM8907 (Power

Adapter/Battery Charger).

See explanation in

manual

Disposal information Earth

Recycling

information

Double Insulation

(Protection Class)

Equal potential

inputs

Conformité

Européenne

UL listed

Warning

Should this test tool be used with AC

coupling selected, or manual operation of

amplitude or time base ranges, the measuring

results displayed on the screen may not be

representative of the total signal. This can

result in the presence of dangerous voltages

of more than 42V peak (30V rms), not being

detected. To guarantee user safety, all signals

should first be measured with DC coupling

selected and in fully automatic mode. This

ensures that the full signal content is

measured.

4

Page 11

Safely Using the Test Tool

Warning

To avoid electrical shock or fire:

• Use only the power supply, Model PM8907

(Battery Charger / Power Adapter).

• Before use check that the selected/indicated

voltage range on the PM8907 matches the

local line power voltage and frequency.

• For the PM8907/808 universal Battery

Charger/Power Adapter use only line cords

that comply with the local safety regulations.

Note

To accommodate connection to various line

power sockets, the PM8907/808 universal

Battery Charger / Power Adapter is equipped

with a male plug that must be connected to a line

cord appropriate for local use. Since the adapter

is isolated, the line cord does not need to be

equipped with a terminal for connection to

protective ground. Since line cords with a

protective grounding terminal are more

commonly available you might consider using

these anyhow.

Warning

To avoid electrical shock or fire if a Test Tool

input is connected to more than 42 V peak (30

Vrms) or on circuits of more than 4800 VA:

• Use only insulated voltage probes, test leads

and adapters supplied with the Test Tool, or

indicated as suitable for the Fluke 123/124

Test Tool.

• Before use, inspect voltage probes, test leads

and accessories for mechanical damage and

replace when damaged.

• Remove all probes, test leads and

accessories that are not in use.

• Always connect the battery charger first to

the ac outlet before connecting it to the Test

Tool.

• Do not connect the ground wire (Figure 1,

item 5) to voltages higher than 42 V peak (30

Vrms) from earth ground.

• Do not apply input voltages above the rating

of the instrument. Use caution when using

1:1 test leads because the probe tip voltage

will be directly transmitted to the Test Tool.

• Do not use exposed metal BNC or banana

plug connectors.

5

Page 12

Fluke 123/124

Users Manual

• Do not insert metal objects into connectors.

• Always use the Test Tool only in the manner

specified.

Max. Input Voltages

Input A and B directly............................... 600 V CAT III

Input A and B via BB120 .......................... 300 V CAT III

Input A and B via STL120 ........................ 600 V CAT III

Max. Floating Voltage

From any terminal to ground.................... 600 V CAT III

Voltage ratings are given as “working voltage”. They

should be read as Vac-rms (50-60 Hz) for AC sinewave

applications and as Vdc for DC applications.

Overvoltage Category III refers to distribution level and

fixed installation circuits inside a building.

The terms ‘Isolated’ or ‘Electrically floating’ are used in

this manual to indicate a measurement in which the Test

Tool’s Shielded Banana inputs or banana jack is

connected to a voltage different from earth ground.

If Safety Features are Impaired

Use of the Test Tool in a manner not specified may

impair the protection provided by the equipment.

Before use, inspect the test leads for mechanical damage

and replace damaged test leads!

Whenever it is likely that safety has been impaired, the

Test Tool must be turned off and disconnected from the

line power. The matter should then be referred to qualified

personnel. Safety is likely to be impaired if, for example,

the Test Tool fails to perform the intended measurements

or shows visible damage.

The isolated input connectors have no exposed metal and

are fully insulated to protect against electrical shock.

6

Page 13

Goal of this Chapter

This Chapter provides a step-by-step introduction to the

test tool. The introduction does not cover all of the

capabilities of the test tool but gives basic examples to

show how to use the menus perform basic operations.

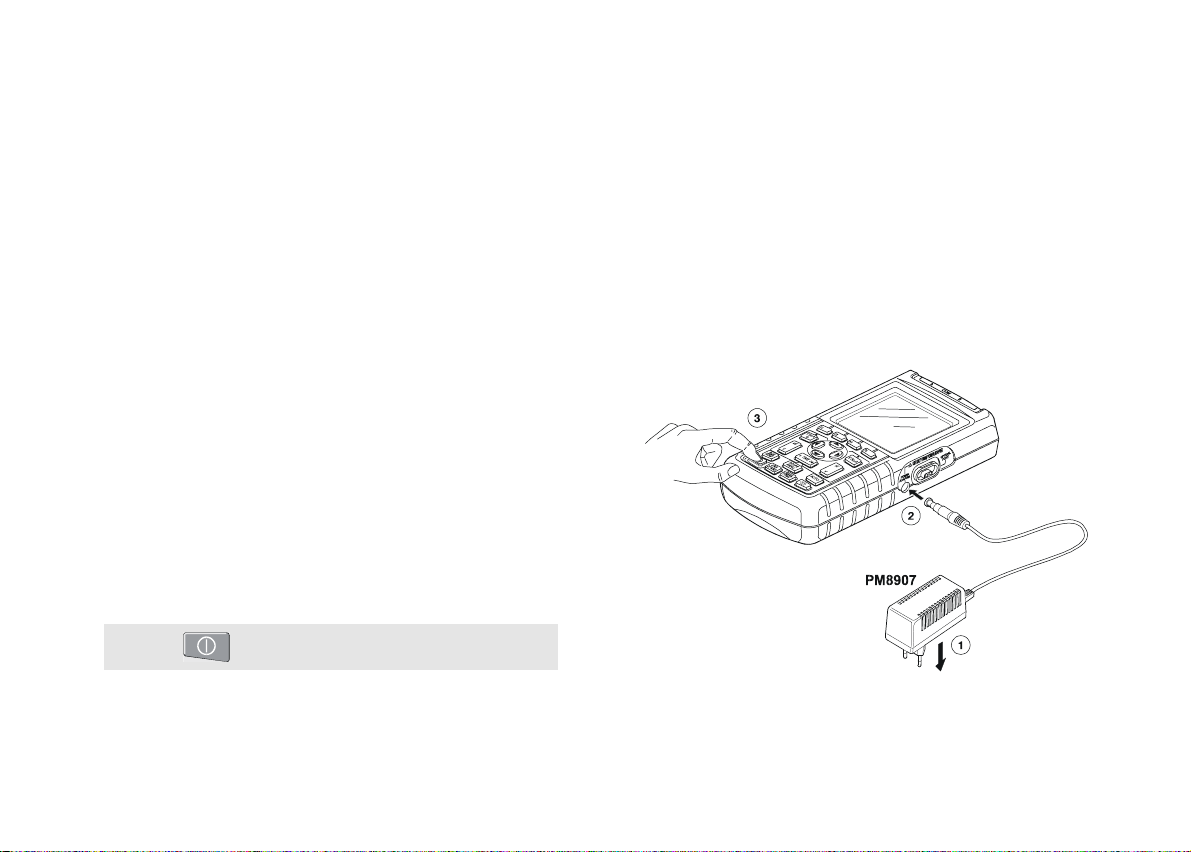

Powering the Test Tool

Follow the procedure (step 1 to 3) in Figure 1-1 to power

the test tool from a standard ac outlet. See Chapter 2 for

battery power instructions.

Turn the test tool on.

Chapter 1

Using The Test Tool

The test tool powers up in its last setup configuration.

Figure 1-1. Powering the Test Tool

7

Page 14

Fluke 123/124

Users Manual

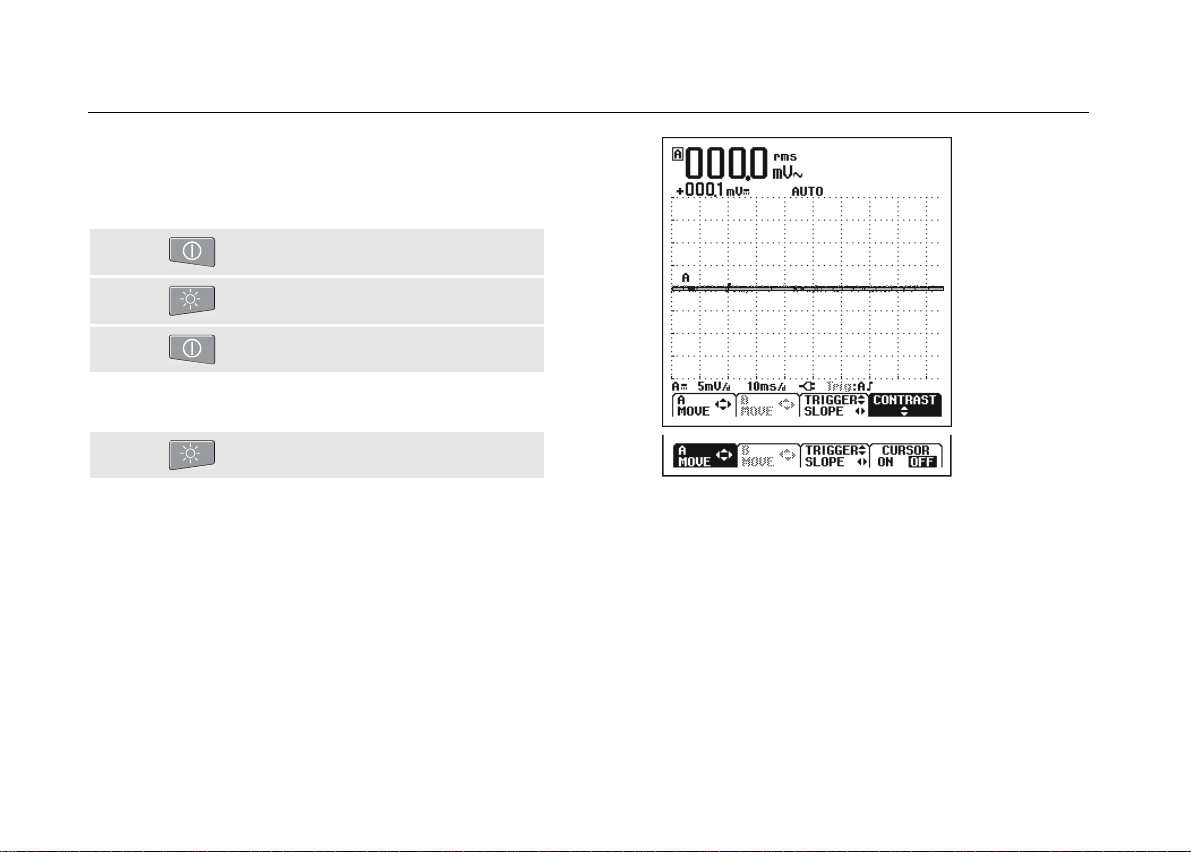

Resetting the Test Tool

If you want to restore the test tool settings as delivered from

the factory, do the following:

Turn the test tool off.

Press and hold.

Press and release.

The test tool turns on, and you should hear a double

beep, indicating the Reset was successful.

Release.

Now look at the display; you will see a screen that looks

like Figure 1-2.

The F4 key of Fluke 123 is used to control the contrast; in

Fluke 124 this key is used to switch the cursors on.

8

Fluke 123

Fluke 124

Figure 1-2. The Screen After Reset

Page 15

Using The Test Tool

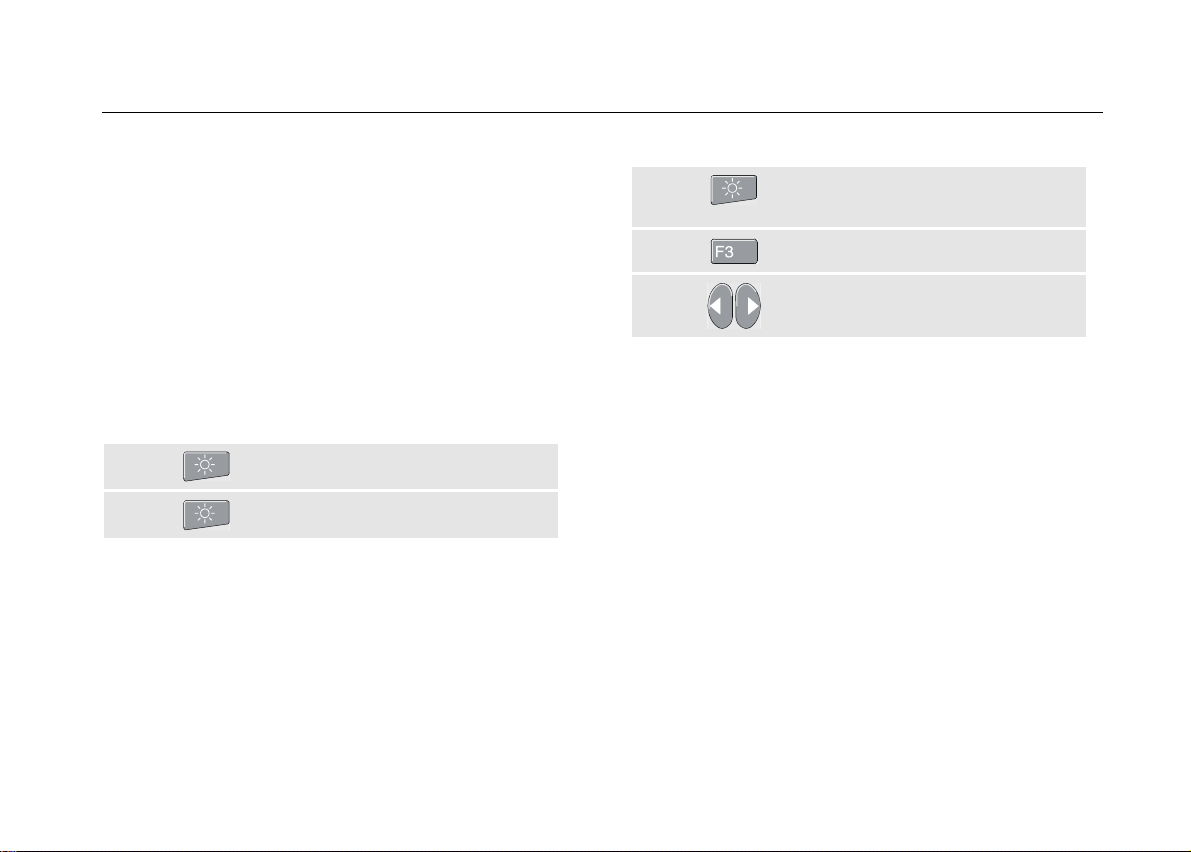

Changing Backlight

1

Changing Backlight

After power-up, the screen has a high bright display.

To save battery power, the screen has an economic

brightness display when operated on the battery pack (no

power adapter connected).

Note

Using dimmed display lengthens maximum

battery power operation time.

To change the brightness of the display in Fluke 123, do

the following:

Dim the backlight.

Brighten the backlight again.

In Fluke 124, do the following:

Press to get access to the display

functions.

Select LIGHT

Dim or brighten the backlight.

The high brightness increases when you connect the

power adapter.

.

9

Page 16

Fluke 123/124

Users Manual

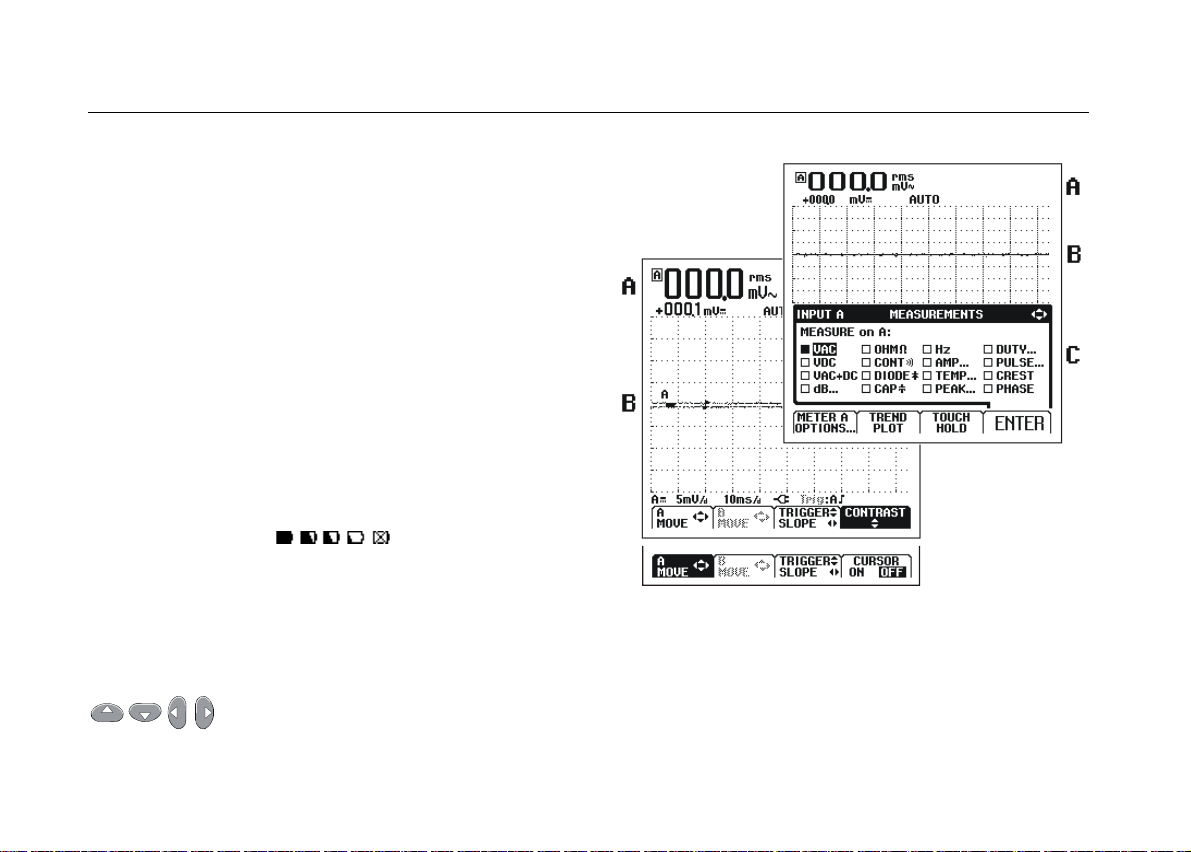

Reading the Screen

The screen is divided into three areas: Reading area,

Waveform area, and Menu area. Refer to Figure 1-3

during the following.

Reading area

Because only input A is on, you will see the input A

readings only.

Waveform area

bottom line displays the ranges/div and the power

indicator (line or battery). Because only input A is on, you

will see the input A waveform only.

When battery powered, the battery indicator

informs you about the condition of the battery

from full to empty:

Menu area (C): Displays the menu that provides choices

available through the blue function keys.

When you change a setup, a part of the screen is used to

display the choices. The area displays one or more

menus with choices accessed with the arrow keys:

(A): Displays the numeric readings.

(B): Displays the input A waveform. The

Note

.

.

10

Fluke 123

Fluke 124

Figure 1-3. The Screen Area's

Page 17

Using The Test Tool

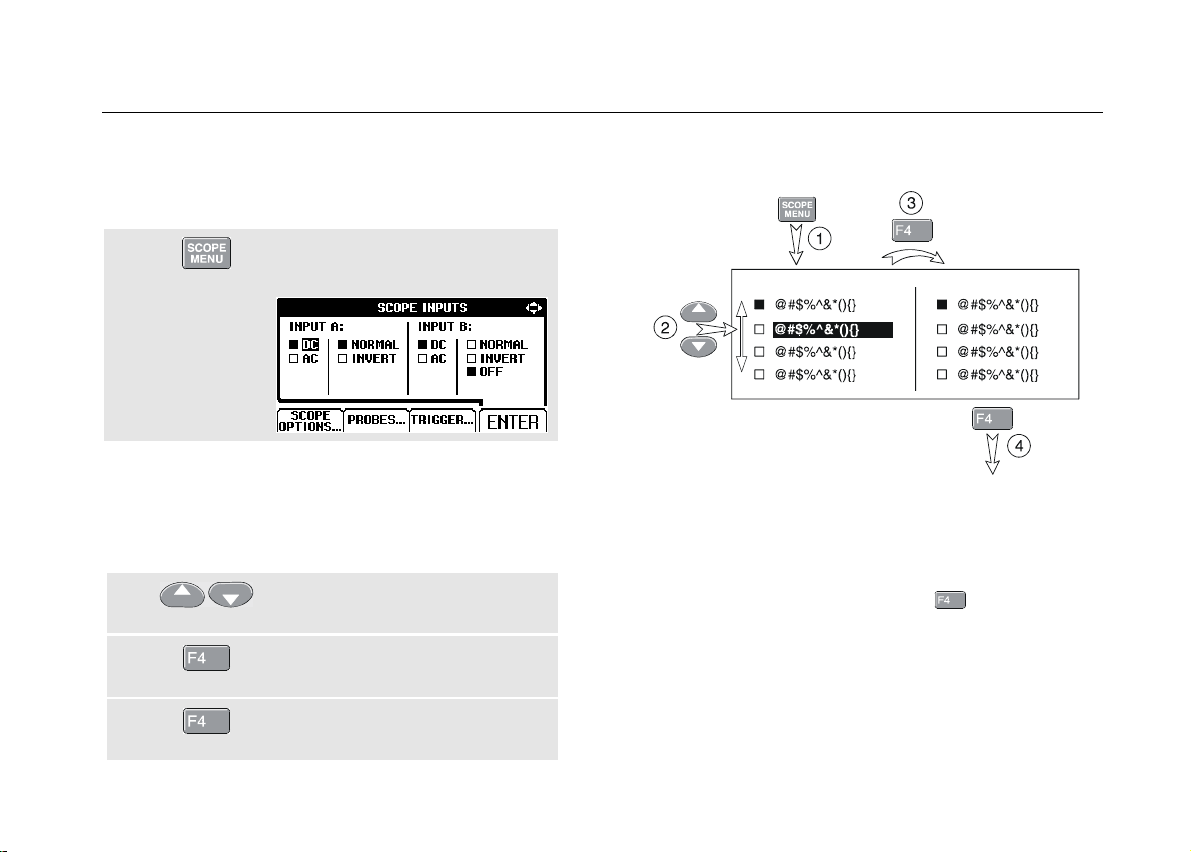

Making Selections in a Menu

1

Making Selections in a Menu

Subsequently follow steps to to open a menu and to

choose an item.

Press the SCOPE MENU key to

open the Scope menu.

Note

Pressing the SCOPE MENU key a second time

closes this menu and resumes normal

measurement. This toggling enables you to

check the menu without destroying your settings.

Use the blue arrow keys to

highlight the item.

Press the blue ‘ENTER’ function

key to confirm selection

Press ‘ENTER’ until you return to

normal mode.

Figure 1-4 shows the basic navigation of the test tool.

Figure 1-4. Basic Navigation

Note

When you do not change an item with the blue

arrow keys, repeatedly pressing

you to step through a menu without changing the

setup of the test tool.

enables

11

Page 18

Fluke 123/124

Users Manual

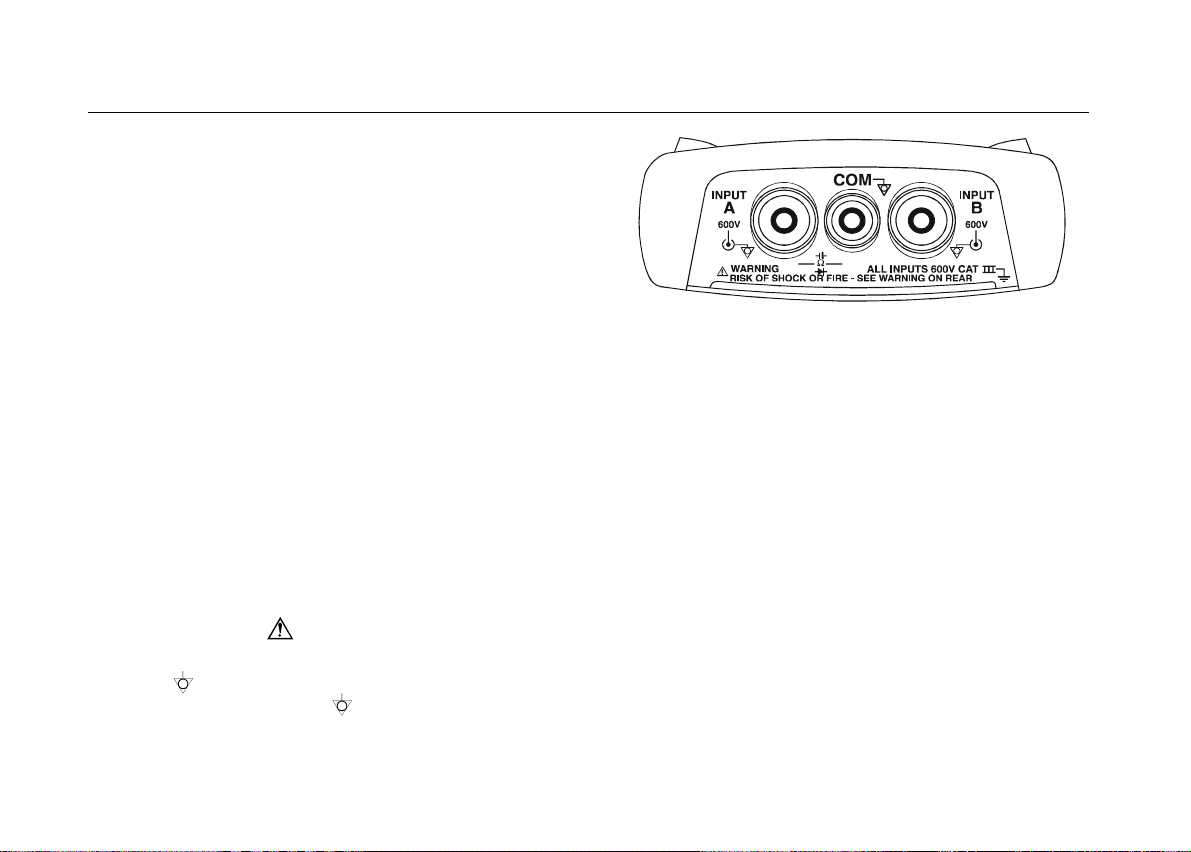

Looking at the Measurement

Connections

Look at the top of the test tool. The test tool provides two

4-mm safety shielded banana jack inputs (red input A and

gray input B) and a safety 4-mm banana jack input

(COM). (See Figure 1-5.)

Input A

You can always use the red input A for all single input

measurements possible with the test tool.

Input B

For measurements on two different signals you can use

the gray input B together with the red input A .

COM

You can use the black COMmon as single ground for low

frequency measurements, and for Continuity, Ohm (Ω),

Diode, and Capacitance measurements.

Warning

To avoid electrical shock or fire, use only one

COM

all connections to COM

potential.

(common) connection, or ensure that

are at the same

Figure 1-5. Measurement Connections

12

Page 19

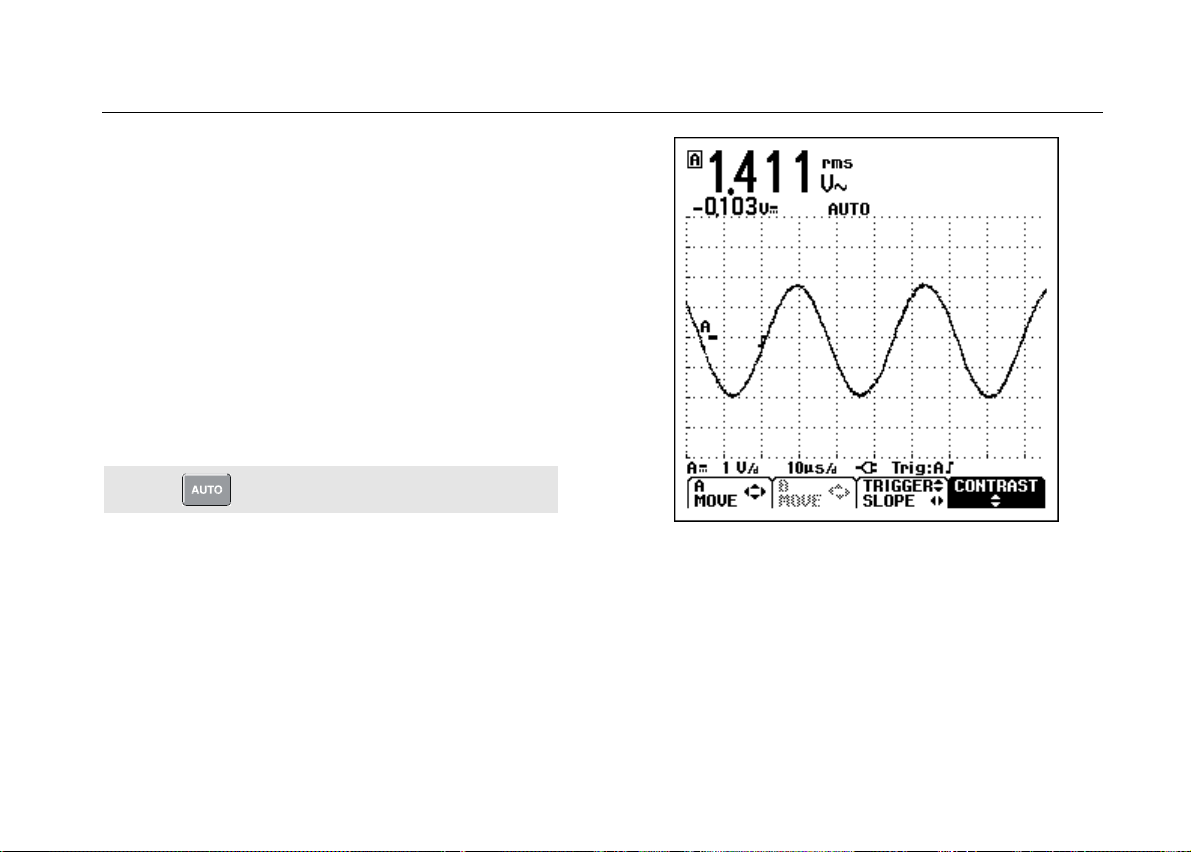

Displaying an Unknown Signal with

Connect-and View™

The Connect-and-View™ function enables hands-off

operation to display complex unknown signals. This

function optimizes the position, range, time base, and

triggering and assures a stable display on nearly all

waveforms. If the signal changes, the setup will track

these changes.

To enable the Connect-and-View™ function, do the

following:

• Connect the red test lead from red input A to the

unknown signal to be measured .

Perform an Auto Set.

Using The Test Tool

Displaying an Unknown Signal with Connect-and View™

1

In the next example, the screen displays “1.411” in large

numbers and “-0.103” in smaller numbers. A scope trace

gives a graphical representation of the waveform.

The trace identifier (A) is visible on left of the waveform

area. The zero icon (

waveform.

-) identifies the ground level of the

Figure 1-6. The Screen After an Auto Set

13

Page 20

Fluke 123/124

Users Manual

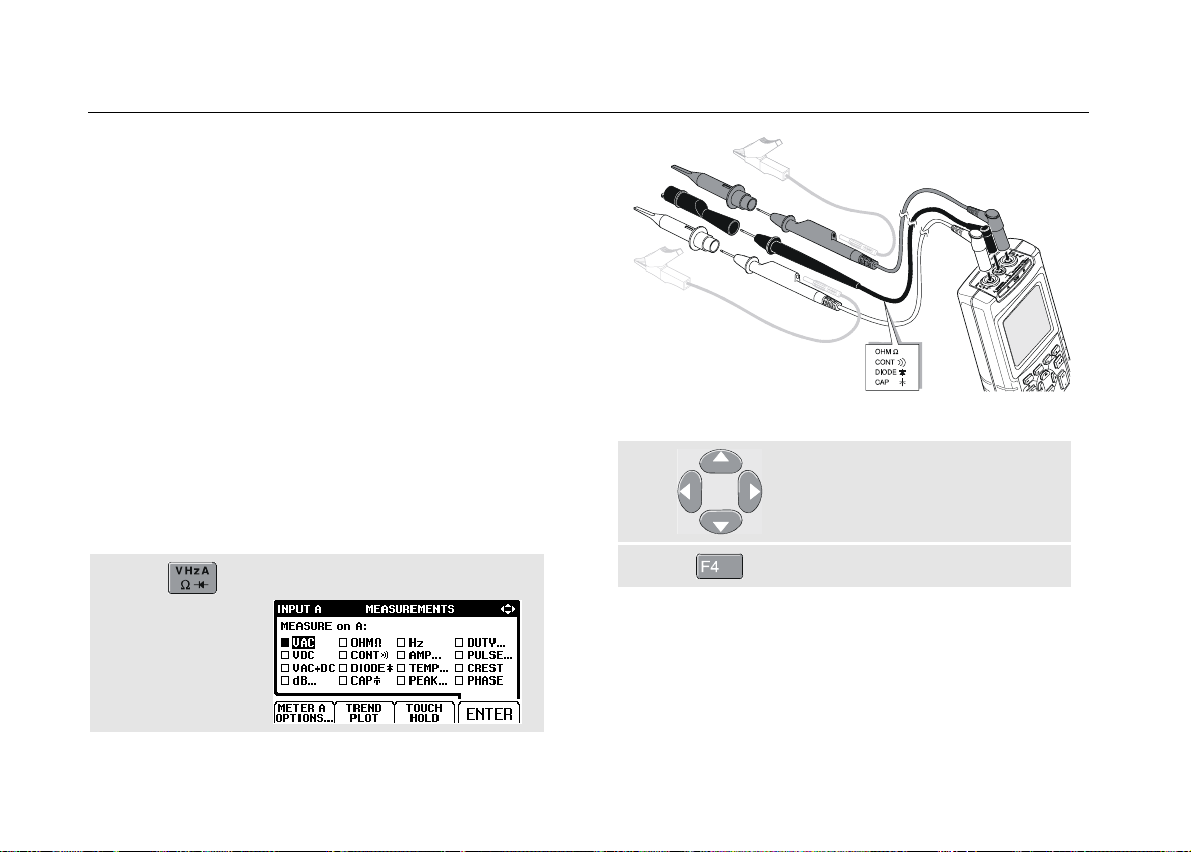

Making Measurements

The reading area displays the numeric readings of the

chosen measurements on the waveform that is applied to

the input jack.

• First connect the red shielded test lead from input A,

and the gray shielded test lead from input B to the

signals to be measured. Connect the short ground

leads to the same ground potential. (See Figure 1-7.)

Note

Ω

For Ohm (

measurements, use the red shielded test lead

from input A and the black unshielded ground

lead from COM (common). (See Figure 1-7.)

To choose a frequency measurement for Input A, do the

following:

Open the INPUT A menu.

), continuity, diode, and capacitance

Figure 1-7. Measurement Setup

Highlight Hz.

Select Hz.

Observe that Hz is now the main reading. The former

main reading has now moved to the smaller secondary

reading position. (See Figure 1-8.)

14

Page 21

Using The Test Tool

Making Measurements

1

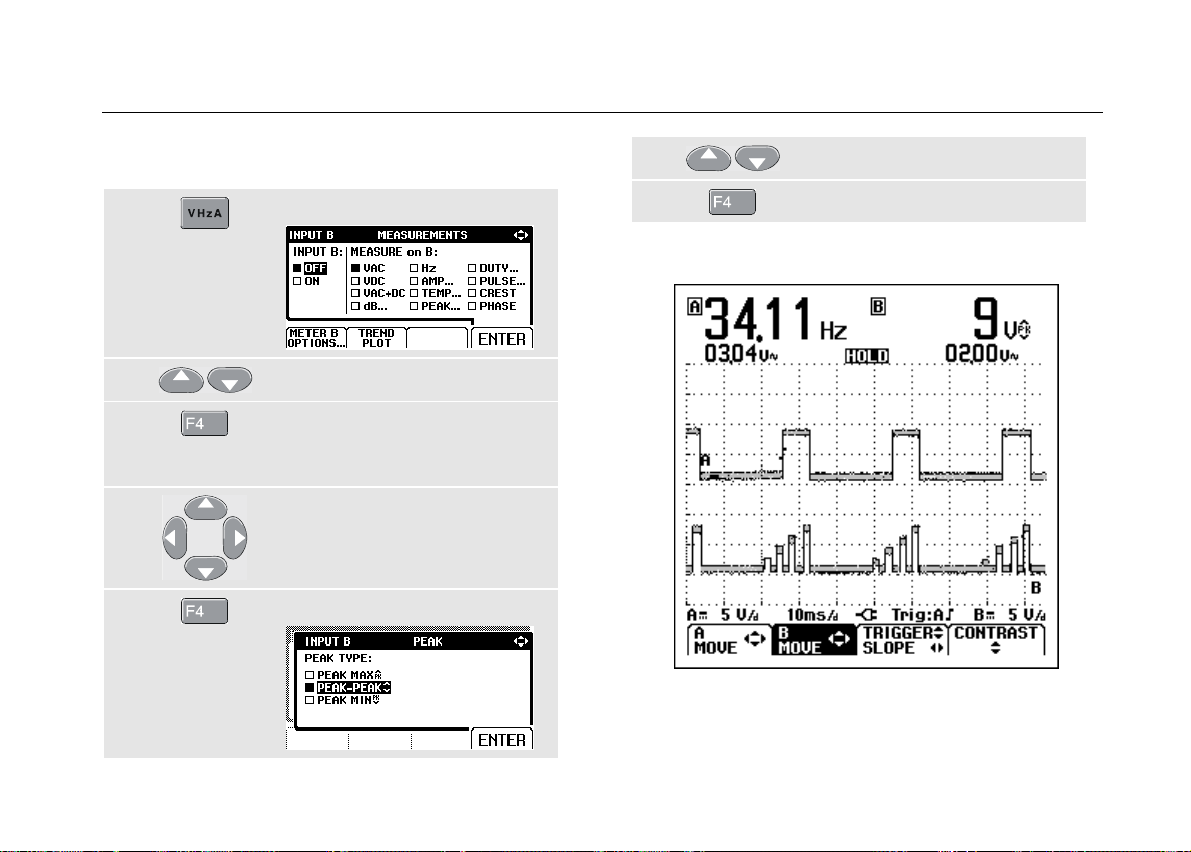

To choose also a Peak-to-Peak measurement for Input B,

do the following:

Open the INPUT B menu.

Highlight ON.

Turn Input B on. Observe that the

highlight jumps to the present

main measurement.

Highlight PEAK...

Open the PEAK submenu.

Now, you will see a screen like Figure 1-8.

Figure 1-8. Hz and Vpp as Main Readings

Highlight PEAK-PEAK.

Accept the pk-pk measurement.

15

Page 22

Fluke 123/124

Users Manual

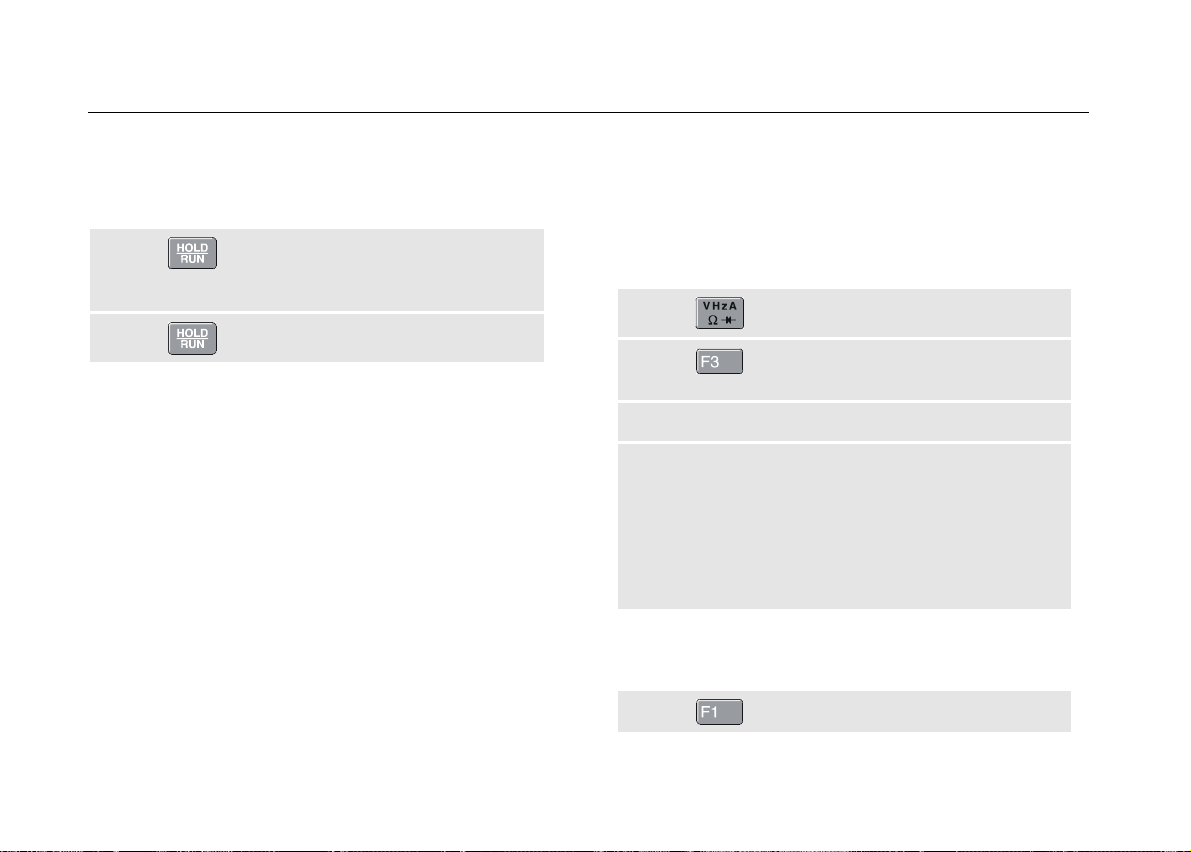

Freezing the Screen

You can freeze the screen (all readings and waveforms)

at any time.

Freeze the screen. HOLD

appears at the bottom of the

reading area.

Resume your measurement.

Holding a Stable Reading

The Touch Hold® function captures and freezes the next

stable measurement result. A beep indicates that a stable

measurement has been made.

Use the following procedure for the Touch Hold function:

Open the INPUT A menu.

TOUCH HOLD OFF appears on

bottom of the screen.

Measure the signal.

BEEP)))

Because no special keys accompany the Touch Hold

function, you can use this function for hands-free

measurements.

Wait until an audible beep: now

you have a stable display.

The screen continues to update

with valid readings (and beeps)

as longs as you maintain the

measurement connections.

Return to normal measurement.

16

Page 23

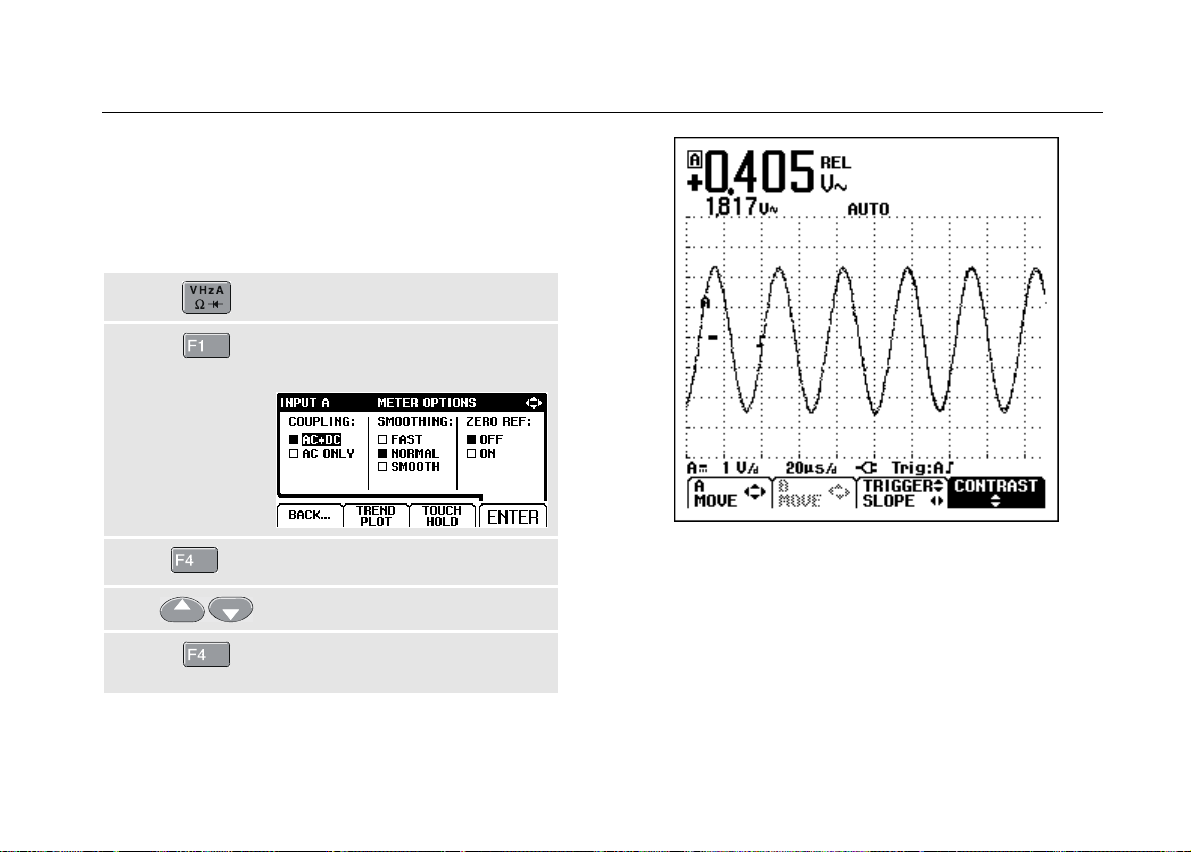

Making Relative Measurements

Zero Reference displays the present measurement result

with respect to the defined value. This feature is useful

when you need to monitor the measured value in relation

to a known good value.

Open the INPUT A menu.

Open the METER A OPTIONS

submenu.

(2x)

Jump to ZERO REF.

Highlight ON.

Activate the relative

measurement.

Using The Test Tool

Making Relative Measurements

Figure 1-9. Making a Relative Measurement

The relative measurement now becomes the main

reading, while the former main measurement has moved

to the smaller secondary reading position. (See Figure

1-9.)

1

17

Page 24

Fluke 123/124

Users Manual

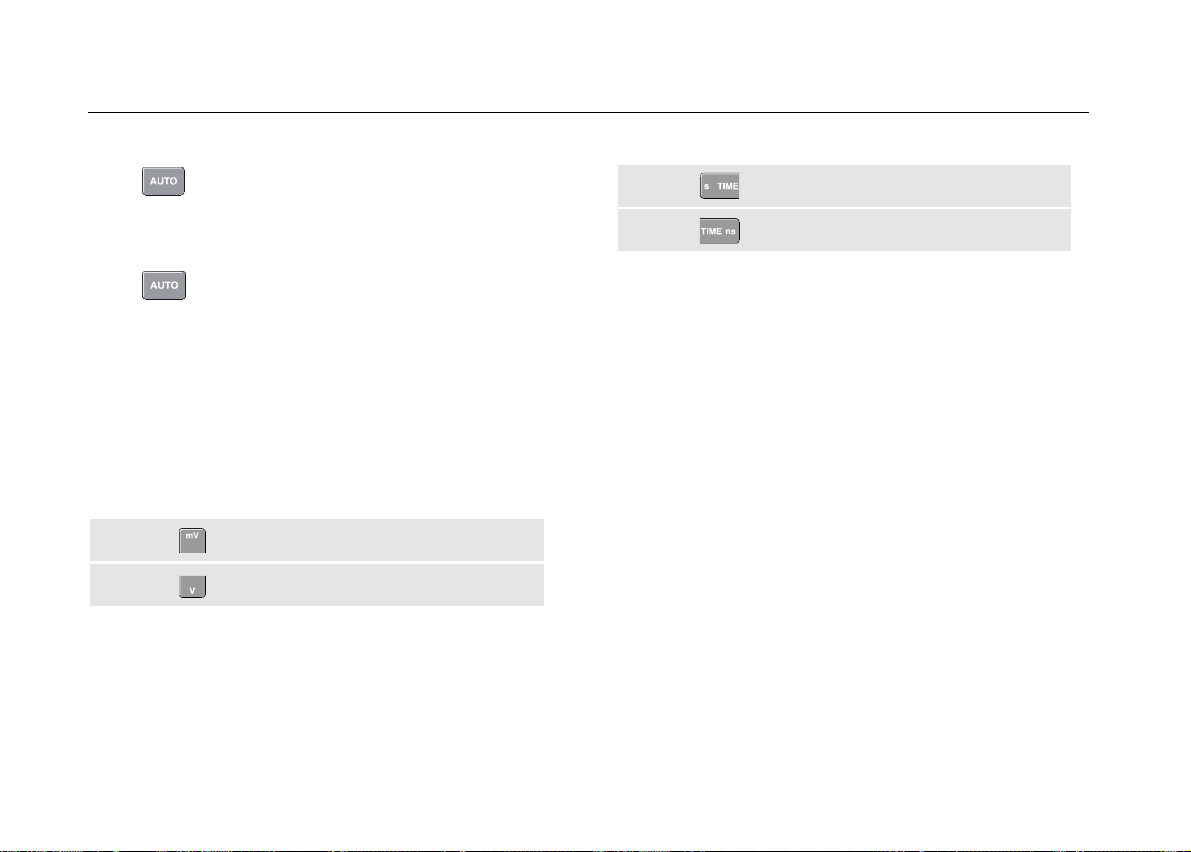

Selecting Auto/Manual Ranges

Press to automatically adjust the position, range,

time base, and triggering. This assures a stable display

on nearly all waveforms. The bottom line shows the range,

the time base for both inputs, and the trigger information.

Press

MANUAL appears at the bottom of the reading area.

a second time to select the manual range.

Changing the Graphic Representation

on the Screen

From Auto range, you can use the light-gray rocker keys

to change the graphic representation on the screen

manually.

Changing the Amplitude

Enlarge the waveform.

Reduce the waveform.

Available settings are from 5 mV/div to 500 V/div when

using the test leads.

Observe that AUTO at the bottom of the reading area

disappears to indicate that the continuous Auto Set

function is not valid anymore.

Changing the Time Base

Increase the number of periods.

Decrease the number of periods.

Available settings are from 20 ns/div (Fluke 123) or 10

ns/div (Fluke 124) to 5 s/div in normal mode.

18

Page 25

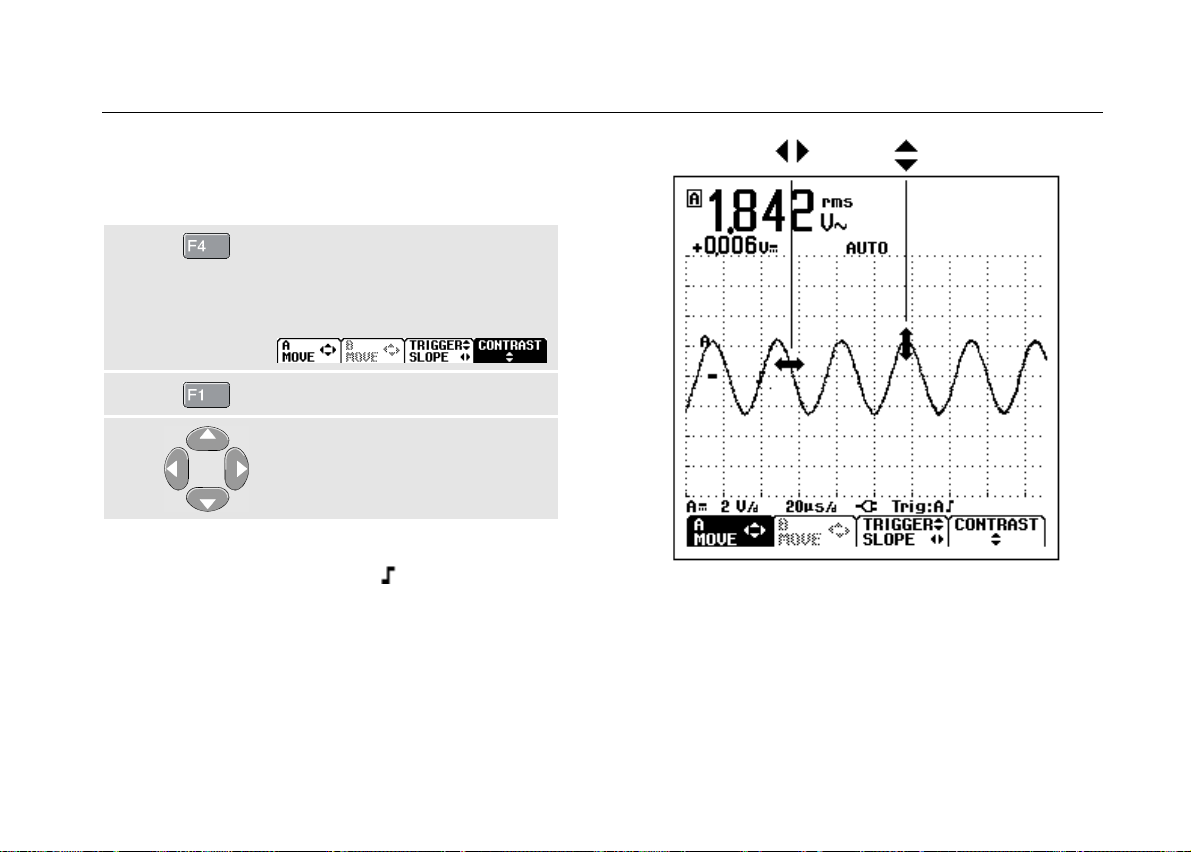

Positioning the Waveform on the Screen

Considerable flexibility is offered in moving the

waveform(s) around the screen.

Press until you have left any open

menu. Observe that the following

main menu appears on bottom of

the screen.

Choose A MOVE.

Position the waveform of INPUT

A on the screen.

Waveform positioning is demonstrated in Figure 1-10.

Using The Test Tool

Changing the Graphic Representation on the Screen

1

Observe that the trigger identifier (

on the screen.

) moves horizontally

Figure 1-10. Positioning the Waveform

19

Page 26

Fluke 123/124

Users Manual

Smoothing the Waveform

To smooth the waveform, do the following:

Open the SCOPE INPUTS menu.

Open the SCOPE OPTIONS

submenu.

Jump to WAVEFORM MODE.

Highlight SMOOTH.

Accept waveform smooth.

You can use waveform smooth to suppress noise without

loss of bandwidth. Waveform samples with and without

smoothing are shown in Figure 1-11.

Figure 1-11. Smoothing the Waveform

20

Page 27

Displaying the Envelope of a Waveform

The test tool records the envelope (minimum and

maximum) of the live waveforms A and B.

Repeat the first three actions of ‘Smoothing the

Waveform’, and then do the following:

Highlight ENVELOPE.

Start monitoring the envelope of

the waveform.

The screen shows the resultant envelope in a gray

waveform. See Figure 1-12.

You can use ENVELOPE to observe variations in time or

amplitude of input waveforms over a longer period of time.

Using The Test Tool

Changing the Graphic Representation on the Screen

Figure 1-12. Displaying the Envelope of a Waveform

1

21

Page 28

Fluke 123/124

Users Manual

TrendPlotting a Waveform

The TrendPlot™ function plots the digital readings as a

function of time. Date and time stamp shows the time of

the most recent change in a MIN or MAX reading.

Starting a TrendPlot™ function

Open the INPUT A menu.

Start TRENDPLOT.

The test tool records the minimum (MIN) reading as the

main (upper displayed) measurement of input A. The date

and time stamp appear below the MIN reading. (See

Figure 1-13.)

The test tool also continuously logs all readings to

memory and displays these as graphs. Automatic vertical

scaling and horizontal time compression resizes the

TrendPlot to fit on the screen. The TrendPlot is built up on

the screen from left to right until the screen is full. The

automatic time scaling then compresses this information

to about half the screen.

Figure 1-13. TrendPlot Reading

Note

When a new minimum value is detected , a beep

occurs and the new minimum is displayed.

22

Page 29

Using The Test Tool

Acquiring the Waveform

1

Changing the TrendPlot Reading

To toggle the TrendPlot reading between MIN (minimum),

MAX (maximum), and AVERAGE, do the following:

Change MIN into MAX reading.

Change MAX into AVG reading.

Note that the date and time stamp now updates

continuously to indicate the most recent change in a

reading.

Turning Off the TrendPlot Display

Turn TrendPlot off again.

Acquiring the Waveform

Making a Single Acquisition

To catch single events, you can perform a single shot.

(One time screen update.) To set up the test tool for a

single shot on the input A waveform, do the following:

• Connect the probe to the signal to be measured.

Open the SCOPE INPUTS menu.

Open the SCOPE OPTIONS

submenu.

Highlight SINGLE SHOT.

(2x)

Accept the set up for a Single

Shot.

23

Page 30

Fluke 123/124

Users Manual

Wait appears on bottom of the

screen to indicate that the test

tool is waiting for a trigger.

Run appears on bottom of the

screen when the single

acquisition is triggered.

Hold appears on bottom of the

screen when the single

acquisition has been completed.

The test tool will now have a screen like Figure 1-14.

To perform a next single acquisition, do the following:

Wait for another single

acquisition trigger.

Figure 1-14. Making a Single Acquisition

24

Page 31

Recording Slow Signals over a Long Period of

Time

The roll mode function supplies a visual log of waveform

activity and is especially useful when you measure lower

frequency waveforms.

Open the SCOPE INPUTS menu.

Open the SCOPE OPTIONS

submenu.

Using The Test Tool

Acquiring the Waveform

1

Highlight ROLL MODE.

The waveform moves accross the screen from right to left

like a normal chart recorder. Observe that during

recording no measurements are made. (See Figure 1-15.)

(2x)

Start Recording.

Figure 1-15. Recording Waveforms over Longer

Period of Time

Freeze Recording.

Observe that the measurement values are only displayed

after is pressed. (See figure 1-15.)

25

Page 32

Fluke 123/124

A

Users Manual

Selecting AC-Coupling

Use AC-coupling when you wish to observe a small AC

signal that rides on a DC signal.

Open the SCOPE INPUTS menu.

Highlight AC.

(4x)

Accept AC-coupling for INPUT A.

Reversing the Polarity of the Displayed

Waveform

To invert the input A waveform, do the following:

Open the SCOPE INPUTS menu.

Select NORMAL (of INPUT A).

Highlight INVERT.

For example, a negative-going waveform is displayed as

positive-going, providing a more meaningful viewing

perspective in some cases. An inverted display is

identified by trace identifier

area.

(3x)

Accept inverted waveform

display.

on left of the waveform

26

Page 33

Using The Test Tool

Triggering on a Waveform

1

Triggering on a Waveform

Triggering tells the test tool when to begin displaying the

waveform. You can select which input signal should be

used, on which edge this should occur, and you can

define the condition for a new update of the waveform.

Finally you can tell the test tool to trigger on video signals.

The bottom line of the waveform area identifies the trigger

parameters being used. Trigger icons on the screen

indicate the trigger level and slope. (See Figure 1-16.)

Setting Trigger Level and Slope

Perform an AUTO SET.

For quick operation, use the AUTO SET key to

automatically trigger on nearly all signals. To optimize

trigger level and slope manually, do the following:

Press until you have left any open

menu.

Enable the arrow keys for Trigger

Level and Slope adjustment.

Adjust the Trigger Level

continuously. Observe the trigger

icon on the second time division

line indicates the trigger level.

Trigger on either positive Slope or

negative Slope of the chosen

waveform.

Figure 1-16. Screen with all Trigger Information

27

Page 34

Fluke 123/124

Users Manual

Selecting the Trigger Parameters

To trigger on the input A waveform, with automatic screen

update, and to configure the auto range triggering for

waveforms from 1 Hz, do the following:

Open the SCOPE INPUTS menu.

Open the TRIGGER submenu.

Highlight Input ‘A’.

Select Input ‘A’.

Highlight FREE RUN.

Select FREE RUN.

Highlight >1 Hz

Accept all trigger selections and

return to normal measurement.

Note

Setting the automatic triggering to >1Hz will slow

down the auto range.

TRIG:A appears in gray text on bottom of the screen

when no trigger is found.

Note

Gray text in a menu or button bar indicates that

the function is disabled or the status is not valid.

28

Page 35

Using The Test Tool

Triggering on a Waveform

1

Isolated Triggering

Use the optically isolated trigger probe (ITP120, optional)

to trigger on an external source, and to isolate the test tool

from a trigger waveform. See Figure 1-17.

To choose the isolated trigger probe, select ‘EXT’ in point

of the previous example. Trigger level is fixed and is

TTL compatible.

Figure 1-17. Isolated Triggering

Triggering on Video Signals

• Apply an interlaced video signal to the red input A.

To trigger on a random video line, continue from point

of the previous example as follows:

Highlight VIDEO on A.

Open the VIDEO TRIGGER

submenu.

Highlight PAL.

Select PAL.

Highlight RANDOM.

Select RANDOM.

29

Page 36

Fluke 123/124

Users Manual

Trigger level and slope are now fixed. (See Figure 1-18.)

Positive video is indicated as a “+” icon on bottom of the

screen.

Highlight POSITIVE.

Accept the video trigger

selections .

Figure 1-18. Measuring Video Signals

30

Page 37

Using The Test Tool

Triggering on a Waveform

1

Triggering on a Specific Video Line

To view a specific video line in more detail you can select

the line number. To measure on a selected video line,

continue from point of the previous example as follows:

Highlight SELECT

Select SELECT

Highlight POSITIVE.

Accept the video trigger

selections .

Pressing selects the line number function.

To choose line 135, do the following:

Enable video line selection.

Select number 135.

31

Page 38

Fluke 123/124

Users Manual

Saving and Recalling a Setup and a

Screen

You can save Screens and Setups to memory, and recall

them again for later use. Fluke 123 has 10 memories

while Fluke 124 has 20 memories. In each memory you

can save a screen and the related settings.

Saving Screens with Belonging Setups

To save a screen and setups in e.g. memory location 7,

do the following:

Open the SAVE/PRINT menu.

Observe that SAVE ... is already

highlighted and that the screen is

frozen until you leave the

SAVE/PRINT menu again.

Note that free memory locations are indicated by an open

square () in front of the memory number.

Highlight memory location 7.

Save the actual screen and

settings.

The actual screen and settings are saved in memory

location 7 and the instrument returns to normal signal

acquisition again.

Open the SAVE ... submenu.

32

Page 39

Using The Test Tool

Saving and Recalling a Setup and a Screen

1

Recalling Screens and Setups

To recall a screen and setups, do the following:

Open the SAVE/PRINT menu.

Highlight RECALL ...

Open the RECALL ... submenu.

Already filled memory locations

are indicated with a closed

square ().

Highlight memory 7.

View the saved screen and

belonging settings.

Observe that the recalled waveform is displayed and that

HOLD appears on the screen. From this point you can

use cursors for analysis or you can print the recalled

screen. The instrument returns to signal acquisition if you

press the HOLD/RUN key. The settings such as stored in

memory location 7 are used then.

33

Page 40

Fluke 123/124

Users Manual

Deleting Screens and Associated Setups

To delete all or just 1 screen + setups, do the following:

Open the SAVE/PRINT menu.

If you want to clear all memory locations, press F3

DELETE ALL. If you want to clear just 1 memory location

(e.g. memory 7), do the following:

Highlight DELETE ...

Open the DELETE ... submenu.

Filled memory locations are

indicated with a closed square.

Highlight memory 7.

Observe that the settings and

date/time of creation of the

waveform in memory 7 are

displayed now.

The contents of memory 7 are

deleted and the instrument

returns to normal signal

acquisition.

34

Page 41

Using The Test Tool

Making Cursor Measurements

1

Making Cursor Measurements

Fluke 124 has cursors. Cursors allow you to make precise

digital measurements on waveforms. This can be done on

live waveforms and on saved waveforms.

Using Horizontal Cursors on a Waveform

To use the cursors for a voltage measurement, do the

following:

From Scope mode, display the

Cursor Key functions.

Press to highlight . Observe

that two horizontal cursor lines

are displayed.

Highlight the upper cursor.

Move the upper cursor to the

desired position on the screen.

Highlight the lower cursor.

⑥ Move the lower cursor to the

desired position on the screen.

Note

Even when the key labels are not displayed at

the bottom of the screen, you can still use the

arrow keys.

Figure 1-19. Voltage Measurement with Cursors

35

Page 42

Fluke 123/124

Users Manual

The readout shows the voltage difference between the

two cursors and the voltages at the cursors in relation to

the zero icon (-). See Figure 1-19).

Use horizontal cursors to measure the amplitude, high

and low value, or overshoot of a waveform.

Using Vertical Cursors on a Waveform

To use the cursors for a time measurement, do the

following:

From Scope mode, display the

Cursor Key functions.

Press to highlight . Observe

that two vertical cursors are

displayed. Markers (-) identify the

point where the cursors cross the

waveform.

If necessary, choose the trace A

or B.

Highlight the left cursor.

Move the left cursor to the

desired position on the waveform.

⑥ Highlight the right cursor.

⑦ Move the right cursor to the

desired position on the waveform.

Figure 1-20. Time Measurement with Cursors

36

Page 43

Using The Test Tool

Making Cursor Measurements

1

The readout shows the time difference ‘t’ between the

cursors and the voltage difference between the two

markers (See Figure 1-20).

The signal frequency is displayed behind 1/t if exactly 1

signal period is between the cursors.

Making Rise Time Measurements

To measure rise time, do the following:

From Scope mode, display the

Cursor Key functions.

Press to highlight (rise time).

Observe that two horizontal

cursors are displayed.

If only one trace is displayed,

select MANUAL or AUTO. AUTO

automatically does steps 4 to 6.

For multiple traces select the

required trace A or B.

Move the upper cursor to 100%

of the trace height. A marker is

shown at 90%.

Highlight the other cursor.

⑥ Move the lower cursor to 0% of

the trace height. A marker is

shown at 10%.

Figure 1-21. Risetime Measurement with Cursors

37

Page 44

Fluke 123/124

Users Manual

The reading now shows the risetime from 10%-90% of the

trace amplitude and the voltage at the cursors in relation

to the zero icon (-). See Figure 1-21.

⑦ Turn off the cursors.

Using the 10:1 Probe for High Frequency

Measurements.

Fluke 124 is supplied with a model VP40 10:1 Probe. Use

of this Probe is recommended when you measure high

frequency signals in circuits with a high impedance. The

loading of the circuit by a 10:1 Probe is much lower than

that of a 1:1 Shielded Test Lead.

The following aspects must be observed when using a

10:1 Probe:

Probe Attenuation.

The Probe attenuates the signal 10 times. Proceed as

follows to adapt the Test Tool’s voltage readout to this

attenuation. The example below is for a Probe connected

to input B:

Open the Scope menu.

Open the Probes menu.

Select PROBE on B ...

Press ENTER

Select 10:1 V

38

Page 45

Using The Test Tool

Using a Printer

1

⑥ Press ENTER to confirm the

selection.

Observe that the 10 times attenuation of the Probe is

compensated in the voltage readout.

Probe Adjustment.

The Probe of model VP40 such as supplied with the Test

Tool is always adapted correctly to its inputs: high

frequency adjustment is not necessary.

Other 10:1 Probes however must be adjusted for optimal

High Frequency performance. How to adjust these Probes

is explained in Chapter 2 under ‘Using and Adjusting 10:1

Scope Probes’.

Using a Printer

To print a (graphic) hard copy of the present screen, you

need to use one of the following:

The Optically Isolated RS-232 Adapter/Cable

(PM9080) to connect a serial printer to the OPTICAL

PORT of the test tool. See Figure 1-22.

The Print Adapter Cable (PAC91, optional) to connect

a parallel printer to the OPTICAL PORT of the test

tool. See Figure 1-23.

39

Page 46

Fluke 123/124

Users Manual

Figure 1-22. Connecting a Serial Printer

This example covers how to set up the test tool to print on

a HP Deskjet printer with a baudrate of 9600 baud:

Open the SAVE&PRINT menu.

Observe that the screen is

freezed.

Open the PRINTER SETUP

submenu.

Highlight DESKJET.

Select DESKJET.

Figure 1-23. Connecting a Parallel Printer

40

Highlight 9600.

Accept the print selections.

Page 47

Using The Test Tool

Using FlukeView® Software

1

Now you are ready to print.

To print a live screen, do the following:

Open the SAVE&PRINT menu.

Start printing.

To print a recalled screen, do the following:

Start printing.

A message that indicates that the test tool is printing

appears on bottom of the screen.

Using FlukeView® Software

To connect the test tool to a computer for using the

FlukeView software for Windows

following:

Use the Optically Isolated RS-232 Adapter/Cable

(PM9080) to connect a computer to the OPTICAL

PORT of the test tool. See Figure 1-24.

For all information relating to installing and using the

FlukeView ScopeMeter software, see the SW90W Users

Manual.

A Software & Cable Carrying Case Kit is optional available

as model number SCC 120.

®

(SW90W), do the

41

Page 48

Fluke 123/124

Users Manual

Figure 1-24. Connecting a Computer

42

Page 49

Chapter 2

Maintaining the Test Tool

About this Chapter

This chapter covers basic maintenance procedures that

can be performed by the user. For complete service,

disassembly, repair, and calibration information, see the

Service Manual. You will find the part number of the

Service Manual in the section ‘Parts and Accessories’ in

this manual.

Cleaning the Test Tool

Clean the test tool with a damp cloth and a mild soap to

avoid abrasion of text on the test tool. Do not use

abrasives, solvents, or alcohol.

Storing the Test Tool

If you are storing the test tool for an extended period of

time, charge the rechargeable battery pack before storing.

It is not necessary to remove the battery pack.

43

Page 50

Fluke 123/124

Users Manual

Charging the Rechargeable Battery Pack

At delivery, the batteries may be empty and must be

charged (test tool is off) to fill them completely. Charging

time is 5 hours for Fluke 123 (Ni-Cd battery) and 7 hours

for Fluke 124 (Ni-MH battery). When fully charged, the

batteries typically provide 4 hours of use in Fluke 123 and

6 hours in Fluke 124 at full brightness. Operating time is

extended at normal brightness.

When battery powered, the battery indicator on the

bottom of the screen informs you about the condition of

the battery. The battery symbols are:

battery symbol

minutes of operating time left.

Use the setup as shown in Figure 2-1 to charge the battery

pack and power the instrument.

Turn the test tool off to charge the batteries more quickly.

The test tool uses a trickle charge for the

batteries, so no damage can occur if you leave it

charging for long periods, e.g., through the

weekend.

indicates that there are typically five

Note

. The

Figure 2-1. Charging the Battery Pack

44

Page 51

Maintaining the Test Tool

Keeping Batteries in Optimal Condition

2

Keeping Batteries in Optimal Condition

Always operate the test tool on batteries until an -icon

appears on the bottom line of the screen. This indicates

that the battery level is low and that the batteries need to

be recharged.

Frequent charging of the batteries when they are not

completely empty can reduce the operating time for the

test tool.

You can refresh the battery pack at any time. This battery

refresh cycle fully discharges and charges the battery pack.

A complete refresh cycle takes about 14 hours (Fluke 123

with Ni-Cd battery) or 19 hours (Fluke 124 with Ni-MH

battery) and should be done at least four times a year.

Note

Be sure not to disconnect the Power Adapter

during the complete refresh cycle. Doing so will

interrupt the refresh cycle.

To refresh the battery pack, do the following:

• Be sure that the test tool is line powered.

Open the USER OPTIONS menu.

Open the BATTERY REFRESH

submenu.

Highlight START REFRESH.

Start the refresh cycle.

Note

After start of the refresh cycle, the screen will be

black.The backlight is on during discharging

within the refresh cycle.

45

Page 52

Fluke 123/124

Users Manual

Replacing and Disposing of the

Rechargeable Battery Pack

Warning

To avoid electrical shock, remove the test

leads and probes before replacing the battery

pack.

Note

This instrument contains Ni-Cd or Ni-MH

batteries. Do not dispose of this battery pack with

other solid waste. Used batteries should be

disposed of by a qualified recycler or hazardous

materials handler. Contact your authorized

FLUKE Service Center for recycling information.

To replace the battery pack, do the following: (See Figure

2-2.)

1. Disconnect the test leads and probes both at the

source and at the test tool.

2. Power the test tool with the Power Adapter.This

ensures information stored in memories will not be lost.

3. Locate the battery access cover on the bottom rear.

Loosen the screw with a flat-blade screwdriver.

46

Figure 2-2. Replacing the Battery Pack

4. Lift the battery access cover away from the test tool.

5. Take the battery pack out of the battery compartment.

6. Remove the battery plug from the connector.

7. Install a new battery pack.

Page 53

Maintaining the Test Tool

Using and Adjusting 10:1 Scope Probes

2

Note

Ensure that the battery pack is placed in the

battery compartment as shown in Figure 2-2.

For Fluke 123 use the Fluke BP120 Ni-Cd

(standard) or BP130 Ni-MH (extended operating

time) battery pack.

For Fluke 124 it is recommended to use the

Fluke BP130 Ni-MH battery pack .

8. Reinstall the battery cover and secure the screw.

Using and Adjusting 10:1 Scope Probes

Note

The 10:1 voltage probe that is supplied with

Fluke 124 is always adjusted correctly to the

Test Tool and needs no further adjustment.

You need to adjust other scope probes (e.g. VPS100,

optional) for optimal response.

Warning

To avoid electrical shock use the BB120

Banana-to-BNC adapter (delivered with the

test tool) to connect a 10:1 scope probe to

the input of the test tool.

• Connect the 10:1 scope probe from the gray input B

jack to the red input A jack. Use the red 4-mm

banana adapter (delivered with the probe) and the

banana-to-BNC adapter (BB120). See Figure 2-3.

BB120

To adjust probes, do the following:

Figure 2-3. Adjusting Scope Probes

47

Page 54

Fluke 123/124

Users Manual

Open the SCOPE INPUTS menu.

Open the PROBES submenu.

Highlight PROBE AC ADJUST.

Open the PROBE AC ADJUST

submenu.

Highlight ADJUST 10:1 PROBE.

A square wave appears on the

screen.

Adjust the trimmer screw in the

probe housing to give an

optimum square wave.

Return to normal mode.

48

Page 55

Maintaining the Test Tool

Calibrating the Test Tool

2

Calibrating the Test Tool

You can ask for the model identity (version and calibration

data) at any time. To display the identity, do the following:

Open the USER OPTIONS menu.

Open the

VERSION&CALIBRATION

submenu.

The screen gives you information about the model

number with software version, the calibration number with

latest calibration date, and the latest battery refresh date.

Return to normal mode.

Recalibration must be carried out by qualified personnel

only. Contact your local Fluke representative for

recalibration.

Parts and Accessories

Service Manual

Ordering Number: 4822 872 05389

Standard Accessories

The next tables list the user-replaceable parts for the

various test tool models. To order replacement parts,

contact your nearest service center.

49

Page 56

Fluke 123/124

Users Manual

Standard Accessories (cont)

Item Ordering Code

Ni-Cd Battery Pack (installed in Fluke 123, 123/S) BP120

Ni-MH Battery Pack (installed in Fluke 124, 124/S) BP130

Power Adapter/Battery Charger, available models:

Universal Europe 230V, 50Hz

North America 120V, 60Hz

United Kingdom 240V, 50Hz

Japan 100V, 60Hz

Australia 240V, 50Hz

Universal 115V/230V

*

UL listing applies to PM8907/808 with UL listed line plug adapter

for North America. The 230 V rating of the PM8907/808 is not for

use in North America. For other countries, a line plug adapter

complying with the applicable National Requirements must be

used.

Set of two Shielded Test Leads (Red and Gray), designed for use only

with the Fluke ScopeMeter 120 series test tool.

Set contains the following replaceable part:

Ground Lead with Alligator Clip (Black)

*

PM8907/801

PM8907/803

PM8907/804

PM8907/806

PM8907/807

PM8907/808

STL120

5322 320 11354

50

Page 57

Maintaining the Test Tool

Parts and Accessories

Standard Accessories (cont)

Item Ordering Code

Test Lead for Grounding (Black) TL75

Set of two Hook Clips (Red and Gray) HC120

Set of three Alligator Clips (Red, Gray, and Black) AC120

One Banana-to-BNC Adapter (Black). Supplied with: Fluke 123, 124 BB120 (Set of two)

Two Banana-to-BNC Adapters (Black). Supplied with: Fluke 123/S, 124/S BB120 (set of two)

Getting Started Manual (English, German, French, Spanish)

Getting Started Manual (French, Spanish, Portuguese, Italian, Dutch,

Danish, Norwegian, Swedish, Finnish, Russian)

Getting Started Manual (English, Chinese, Japanese, Korean)

CD-ROM with Users Manual (All languages)

4822 872 30711

4822 872 30712

4822 872 30713

4022 240 12370

2

51

Page 58

Fluke 123/124

Users Manual

Optional Accessories

Item Ordering Code

Software & Cable Carrying Case Kit (Supplied with Fluke 123/S, 124/S)

Set contains the following parts:

Optically Isolated RS-232 Adapter/Cable

Hard Carrying Case. Supplied with Fluke 123/S, 124/S

FlukeView

®

ScopeMeter® Software for Windows

®

10:1 Scope Probe VP40. Supplied with Fluke 124, 124/S VPS40 (Set of two)

Optically Isolated RS-232 Adapter/Cable. PM9080

Hard Carrying Case. C120

Compact Soft Case C125

Soft Carrying Case C789

Isolated Trigger Probe ITP120

Print Adapter Cable for Parallel Printers PAC91

SCC 120

PM9080

C120

SW90W

52

Page 59

Goal of this Chapter

This Chapter gives you information and tips on how you

can make the best use of the test tool.

Using the Tilt Stand

The test tool is equipped with a tilt stand, allowing viewing

from an angle. You can also use the tilt stand to hang the

test tool at a convenient viewing position. Simply tilt the

stand and hang the test tool. Typical positions are shown

in Figure 3-1.

Chapter 3

Tips and Troubleshooting

Figure 3-1. Using the Tilt Stand

53

Page 60

Fluke 123/124

Users Manual

Resetting the Test Tool

Perform a Master Reset to make sure that your test tool is

in the initial settings condition.

Turn the test tool off.

Press and hold.

Press and release.

The test tool turns on, and you should hear a double

beep, indicating the Reset was successful.

Release.

Changing the Information Language

When you operate the test tool, messages appear on the

bottom of the screen. These messages are always

displayed in a box, and can in some test tool versions be

displayed in more languages. In different combinations,

you can choose from 10 languages: English, French,

German, Italian, Spanish, Portuguese, Dutch, Japanese,

Korean, and Chinese.

If you want to change the language of the messages into

e.g. Italian, do the following:

Open the USER OPTIONS menu.

Open the LANGUAGE SELECT

submenu.

Highlight ITALIANO.

Accept ITALIANO (Italian) as

language.

54

Page 61

Tips and Troubleshooting

Changing the Display

3

Changing the Display

Adjusting the Screen Contrast in Fluke 123

From the main menu, choose

CONTRAST.

Adjust the contrast of the screen.

Adjusting the Screen Contrast in Fluke 124

Switch from cursor control to

display control.

From the display control menu,

choose CONTRAST

Adjust the contrast of the screen.

Note

The new contrast adjustment of the screen is

saved in memory until a new adjustment is

made.

Setting the Grid Display

To choose a dotted grid, do the following:

Open the USER OPTIONS menu.

Highlight GRID TYPE.

Open the GRID TYPE submenu.

Choose DOTS.

Accept the new grid display.

Use LINES when you need a cross hatch pattern based

on the horizontal time and vertical divisions on the screen.

Use DOTS when you need vertical and horizontal division

dots as added reference points to the screen.

55

Page 62

Fluke 123/124

Users Manual

Changing Date and Time

The test tool has a date and time clock. To change the

date to (e.g.) 20 June, 2002, do the following:

Open USER OPTIONS menu.

Highlight DATE ADJUST.

Open DATE ADJUST submenu.

Choose 2002.

Jump to MONTH.

Jump to DAY.

Choose 20.

Jump to FORMAT.

Choose DD/MM/YY.

Accept the new date.

You can change the time in a similar way by opening the

TIME ADJUST submenu. (steps

and .)

Choose 06.

56

Page 63

Tips and Troubleshooting

Saving Battery Life

3

Saving Battery Life

When operated on the battery pack (no Power Adapter

connected), the test tool conserves power by shuting itself

down. If you have not pressed a key for at least 30 minutes,

the test tool turns itself off automatically.

Note

If the Power Adapter is connected, there is no

automatic power shutdown.

Although automatic power shutdown will not occur if

TrendPlot is on, the backlight will dim. Recording will

continue even if the battery pack is low, and retention of

memories is not jeopardized.

Setting the Power Down Timer

To extend battery life, the power shutdown time is set to

30 minutes after the last key press. To set the power

shutdown to five minutes, do the following:

Open the USER OPTIONS menu.

Highlight POWER DOWN ...

Open the submenu.

Highlight AFTER 5 MIN.

Accept the new power down time.

57

Page 64

Fluke 123/124

Users Manual

Changing the Auto Set Options

Normally, the Auto Set function captures waveforms from

15 Hz.

To configure Auto Set for waveforms from 1 Hz with

unchanged input coupling, do the following:

Note

Setting the Auto Set adjust to 1 Hz will slow

down the Auto Set response.

Open the User Options menu.

Highlight AUTOSET ADJUST...

Open the AUTOSET ADJUST

submenu.

Highlight SIGNALS > 1 Hz.

Highlight UNCHANGED.

Accept the new Auto Set

configuration.

Select COUPLING.

58

Page 65

Using Proper Grounding

Incorrect grounding can cause various problems. This

Section gives you guidelines for proper grounding.

Use the short ground lead(s) when measuring DC or

AC signals on input A and input B. (See Figure 3-2.)

Warning

To avoid electrical shock or fire, use only one

COM (common) connection

all connections to COM

potential.

Use the unshielded black ground lead to COM

(common) for Ohm (Ω), Continuity, Diode, and

Capacitance measurements. (See Figure 3-3.)

Using the unshielded ground lead is also possible for

single or dual input measurements for waveforms with

a frequency up to 1 MHz. This may add some hum or

noise to the waveform display due to the unshielded

ground lead.

, or ensure that

are at the same

Tips and Troubleshooting

Using Proper Grounding

Figure 3-2. Grounding with Short Ground Lead

3

Figure 3-3. Grounding with Unshielded Ground Lead

59

Page 66

Fluke 123/124

Users Manual

Solving Printing and Other

Communication Errors

RS-232 communication may cause problems. When

experiencing communication problems, try the following

remedies:

Make sure that the interface cable is connected to the

correct port on the printer or computer. If necessary

use the 9 pin to 25 pin adapter or gender changer.

Make sure that you have selected the correct printer

type. (To select printer type, see Chapter 1.)

Make sure that the baud rate matches with the printer

or computer. (To set the baud rate, see Chapter 1.)

Reset the RS-232 parameters to defaults.

Battery Testing of Fluke Accessories

When using battery operated Fluke accessories, always

check the battery condition of the accessory first on a

Fluke multimeter .

60

Page 67

Chapter 4

Specifications

Introduction

Performance Characteristics

FLUKE guarantees the properties expressed in numerical

values with the stated tolerance. Specified non-tolerance

numerical values indicate those that could be nominally

expected from the mean of a range of identical

ScopeMeter test tools.

Environmental Data

The environmental data mentioned in this manual are

based on the results of the manufacturer’s verification

procedures.

Safety Characteristics

The test tool has been designed and tested in accordance

with Standards ANSI/ISA S82.01-1994, EN 61010.1

(1993) (IEC 1010-1), CAN/CSA-C22.2 No.1010.1-92

(including approval), UL3111-1 (including approval) Safety

Requirements for Electrical Equipment for Measurement,

Control, and Laboratory Use.

This manual contains information and warnings that must

be followed by the user to ensure safe operation and to

keep the instrument in a safe condition. Use of this

equipment in a manner not specified by the manufacturer

may impair protection provided by the equipment.

61

Page 68

Fluke 123/124

Users Manual

Dual Input Oscilloscope

Vertical

Frequency Response

DC Coupled:

excluding probes and test leads (via BB120):................

Fluke 123: DC to 20 MHz (-3 dB)

Fluke 124: DC to 40 MHz (-3 dB)

with STL120 1:1 shielded test leads: .............................

DC to 12.5 MHz (-3 dB)

DC to 20 MHz (-6 dB)

with VP40 10:1 probe:....................................................

Fluke 123 (optional accessory): DC to 20 MHz (-3 dB)

Fluke 124 (standard accessory): DC to 40 MHz (-3 dB)

AC Coupled (LF roll off):

excluding probes and test leads............. <10 Hz (-3 dB)

with STL120 ............................................ <10 Hz (-3dB)

with 10 MΩ 10:1 Probe ............................ <1 Hz (-3 dB)

Rise Time

excluding probes, test leads (Fluke 123) .........<17.5 ns

excluding probes, test leads (Fluke 124) .........<8.75 ns

Input Impedance

excluding probes and test leads................ 1 MΩ//12 pF

with BB120 ................................................ 1 MΩ//20 pF

with STL120............................................. 1 MΩ//225 pF

with VP40 10:1 Probe............................. 5 MΩ//15.5 pF

Sensitivity............................................5 mV to 500 V/div

Display Modes .............................................. A, -A, B, -B

Max. Input Voltage A and B

direct, with test leads, or with VP40 Probe..... 600 Vrms

with BB120 .....................................................300 Vrms

(For detailed specifications, see “Safety”, Figs. 4-1/4-2)

Max. Floating Voltage

from any terminal to ground ...........................600 Vrms

up to 400 Hz

Resolution................................................................ 8 bit

Vertical Accuracy .......................±(1% + 0.05 range/div)

Max. Vertical Move .......................................±4 divisions

62

Page 69

Specifications

Dual Input Oscilloscope

4

Horizontal

Scope Modes...................................Normal, Single, Roll

Ranges

Normal:

equivalent sampling (Fluke 123) ..... 20 ns to 500 ns/div

equivalent sampling (Fluke 124) ..... 10 ns to 500 ns/div

real time sampling ................................... 1 µs to 5 s/div

Single (real time) ..................................... 1 µs to 5 s/div

Roll (real time)......................................... 1s to 60 s/div

Sampling Rate (for both channels simultaneously)

Equivalent sampling (repetitive signals)........................

up to 1.25 GS/s

Real time sampling:

1 µs to 5 ms/div .......................................... 25 MS/s

10 ms to 60 s/div .......................................... 5 MS/s

Time Base Accuracy

Equivalent sampling .................. ±(0.4% +0.04 time/div)

Real time sampling.................... ±(0.1% +0.04 time/div)

Glitch Detection..................≥40 ns @ 20 ns to 5 ms/div

≥200 ns @ 10 ms to 60 s/div

Glitch detection is always active.

Horizontal Move ...........................................10 divisions

Trigger point can be positioned anywhere across the

screen.

Trigger

Screen Update ..............................Free Run, On Trigger

Source ..............................................................A, B, EXT

EXTernal via optically isolated trigger probe ITP120

(optional accessory)

Sensitivity A and B (Fluke 123)

@ DC to 5 MHz.............................0.5 divisions or 5 mV

@ 25 MHz.................................................. 1.5 divisions

@ 40 MHz..................................................... 4 divisions

Sensitivity A and B (Fluke 124)

@ DC to 5 MHz.............................0.5 divisions or 5 mV

@ 40 MHz.................................................. 1.5 divisions

@ 60 MHz..................................................... 4 divisions

Slope................................................... Positive, Negative

Video on A.......................... interlaced video signals only

Modes................................................Lines, Line Select

Standards .......................... PAL, NTSC, PAL+, SECAM

Polarity.............................................. Positive, Negative

Sensitivity .........................................0.6 divisions sync.

63

Page 70

Fluke 123/124

Users Manual

Advanced Scope Functions

Display Modes

Normal........Captures up to 40 ns glitches and displays

analog-like persistence waveform.

Smooth.......Suppresses noise from a waveform.

Envelope ....Records and displays the minimum and

maximum of waveforms over time.

Auto Set

Continuous fully automatic adjustment of amplitude,

time base, trigger levels, trigger gap, and hold-off.

Manual override by user adjustment of amplitude, time

base, or trigger level.

64

Page 71

Specifications

Dual Input Meter

4

Dual Input Meter

The accuracy of all measurements is within ± (% of

reading + number of counts) from 18 °C to 28 °C.

Add 0.1x (specific accuracy) for each °C below 18 °C or

above 28 °C. For voltage measurements with 10:1 probe,

add probe uncertainty +1%. More than one waveform

period must be visible on the sceen.

Input A and Input B

DC Voltage (VDC)

Ranges........................ 500 mV, 5V, 50V, 500V, 1250V

Accuracy ..........................................±(0.5% +5 counts)

Normal Mode Rejection (SMR)...........................>60 dB

@ 50 or 60 Hz ±1%

Common Mode Rejection (CMRR)........>100 dB @ DC

>60 dB @ 50, 60, or 400 Hz

Full Scale Reading .................................... 5000 counts

True RMS Voltages (VAC and VAC+DC)

Ranges........................ 500 mV, 5V, 50V, 500V, 1250V

Accuracy for 5 to 100% of range

DC coupled:

DC to 60 Hz (VAC+DC) ...............±(1% +10 counts)

1 Hz to 60 Hz (VAC) ....................±(1% +10 counts)

AC or DC coupled:

60 Hz to 20 kHz ........................ ±(2.5% +15 counts)

20 kHz to 1 MHz .......................... ±(5% +20 counts)

1 MHz to 5 MHz.........................±(10% +25 counts)

5 MHz to 12.5 MHz ................... ±(30% +25 counts)

5 MHz to 20 MHz (excl. test leads or probes) ..........

±(30% +25 counts)

AC coupled with 1:1 (shielded) test leads

60 Hz (6 Hz with 10:1 probe) ......................... -1.5%

50 Hz (5 Hz with 10:1 probe) ............................ -2%

33 Hz (3.3 Hz with 10:1 probe) ......................... -5%

10 Hz (1 Hz with 10:1 probe) .......................... -30%

DC Rejection (only VAC) ................................... >50 dB

Common Mode Rejection (CMRR)....... >100 dB @ DC

>60 dB @ 50, 60, or 400 Hz

Full Scale Reading ....................................5000 counts

The reading is independent of any signal crest factor.

Peak

Modes.........................Max peak, Min peak, or pk-to-pk

Ranges ........................500 mV, 5V, 50V, 500V, 1250V

Accuracy:

Max peak or Min peak........................ 5% of full scale

Peak-to-Peak ................................... 10% of full scale

Full Scale Reading ......................................500 counts

Frequency (Hz)

Ranges ................ 1 Hz, 10 Hz, 100 Hz, 1 kHz, 10 kHz,

100 kHz,1 MHz, 10 MHz, and 50 MHz (Fluke 123) or

70MHz (Fluke 124)

Frequency Range in Continuous Autoset......................

15 Hz (1 Hz) to 50 MHz

65

Page 72

Fluke 123/124

Users Manual

Accuracy:

@1 Hz to 1 MHz............................ ±(0.5% +2 counts)

@1 to 10 MHz ...............................±(1.0% +2 counts)

@10 to 50 MHz (Fluke 123) ..........±(2.5% +2 counts)

@10 to 70 MHz (Fluke 124) ..........±(2.5% +2 counts)

(50 MHz in Autorange)

Full Scale Reading..................................10 000 counts

Duty Cycle (DUTY)

Range...........................................................2% to 98%

Frequency Range in Continuous Autoset .....................

15 Hz (1 Hz) to 30 MHz

Accuracy (Logic or Pulse waveforms):

@1Hz to 1 MHz............................. ±(0.5% +2 counts)

@1 MHz to 10 MHz....................... ±(1.0% +2 counts)

Pulse Width (PULSE)

Frequency Range in Continuous Autoset .....................

15 Hz (1 Hz) to 30 MHz

Accuracy (Logic or Pulse waveforms):

@1 Hz to 1 MHz............................ ±(0.5% +2 counts)

@1 MHz to 10 MHz....................... ±(1.0% +2 counts)

Full Scale Reading ..................................1000 counts

Amperes (AMP) ....................with optional current probe

Ranges......... same as VDC, VAC, VAC+DC, or PEAK

Scale Factor... 1 mV/A, 10 mV/A, 100 mV/A, and 1 V/A

Accuracy ......... same as VDC, VAC, VAC+DC, or PEAK

(add current probe uncertainty)

Temperature (TEMP) ... with optional temperature probe

Range........................................200 °C/div (200 °F/div)

Scale Factor ............................... 1 mV/°C and 1 mV/°F

Accuracy........... as VDC (add temp. probe uncertainty)

Decibel (dB)

0 dBV........................................................................ 1V

0 dBm (600Ω /50Ω) ............................................. 1 mW

referenced to 600Ω or 50Ω

dB on ...................................... VDC, VAC, or VAC+DC

Full Scale Reading .................................... 1000 counts

Crest Factor (CREST)

Range.................................................................1 to 10

Accuracy............................................... ±(5% +1 count)

Full Scale Reading ...................................... 100 counts

Phase

Modes...................................................... A to B, B to A

Range.................................................0 to 359 degrees

Accuracy up to 1 MHz ...................................2 degrees

Accuracy 1 MHz to 5 MHz.............................5 degrees

Resolution .......................................................1 degree

66

Page 73

Specifications

Dual Input Meter

4

Input A

Ohm (ΩΩΩΩ)

Ranges....... 500Ω, 5 kΩ, 50 kΩ, 500 kΩ, 5 MΩ, 30 MΩ

Accuracy: .........................................±(0.6% +5 counts)

Full Scale Reading:

500Ω to 5 MΩ ......................................... 5000 counts

30 MΩ..................................................... 3000 counts

Measurement Current ......................... 0.5 mA to 50 nA

decreases with increasing ranges

Open Circuit Voltage ...............................................<4V