FloCat MFE Operating Manual

FloCatMFEElectromagneticFlowMeter

INSTALLATION AND

WIRING MANUAL

MFE Electromagnetic Flowmeter

Installation and Wiring Manual

Table of Contents

Inspection upon Receipt..…………………………………….…………… 2

Storage…….…..……………………………………………………………… 2

Before Installation ………………………………………………………… 2

Installation of Flowmeter on Pipeline ….……………….………………… 2

Wiring ……………………………………………………………………….. 5

1. Cable …………………………………………………………………………...

2. Wiring in Regular Transmitter...………………………………………………..

3. Wiring in Explosion Proof Transmitter ………….…………………………….

Spec Sheet …………………………….…….…….………….……………... 15

1. Dimensions and Weight of Sensor …….……………………………………….

2. Technical Specifications ……………………………………………………….

5

6

9

15

17

1

Inspection upon Receipt

Every electromagnetic flowmeter passed strict calibration testing and inspection before leaving factory. Please

follow the guidelines below when receiving your order.

If the sh ipping box shows sign of damage, have the carrier unpack the flowmeter. If the meter was

damaged during shipping, file a claim with the carrier, and contact your vendor as soon as possible.

Open the shipping box, find the Packing List, and check if the items in the box match the list. If anything

is missing, contact your vendor.

Verify that the model number on the nameplate matches that on your purchase order. If it is different,

do NOT proceed or install the meter, and contact your vendor as soon as possible.

If you have a ny doubts about the meter you received, DO NOT proceed or install the meter. Contact

your vendor as soon as possible.

Storage

If you need to store flowmeter for an extended period after receipt:

Keep flowmeter in the original box.

Do not put flowmeter under the rain.

Do not put flowmeter in place with continuous vibration.

Do not open junction box on sensor and transmitter in order to avoid moisture.

Ambient temperature: -20 to 60°C

Relative humidity: 5 to 90%

Before Installation

Please read following carefully before installing flowmeter:

Be careful to not damage meter when opening the box. It is suggested you open the box at the job site.

Hang the flowmeter by the installation rings.

Do not press or damage the liner. If the lining is damaged, the flowmeter may not work properly.

Protect the flange surface. Do not place the flange on the ground without any protection.

Do not open wire connection box before wiring.

Preparing pipeline: dross usually exists inside new pipeline (for example welding dross). It is important

to remove dross before installing flowmeter to avoid damage to lining and causing measuring errors.

Installation of Flowmeter on Pipeline

1. Install the flowmeter in a place where there is no direct sunshine and ambient temperature is -20 to 60°C.

If the meter is installed close to a heat source, protect with insulation or use a ventilation device.

Do NOT install the meter in an environment filled with strong corrosive air or explosive air

(for non-explosion-proof type flowmeter).

Do NOT install the meter near an electromagnetic field, such as electromotor or transformer.

2

If the meter’s protection rating is IP65, do NOT install meter under water; For IP67, do NOT

install under water over 1 meter; for IP68, do NOT install under water over 5 meters.

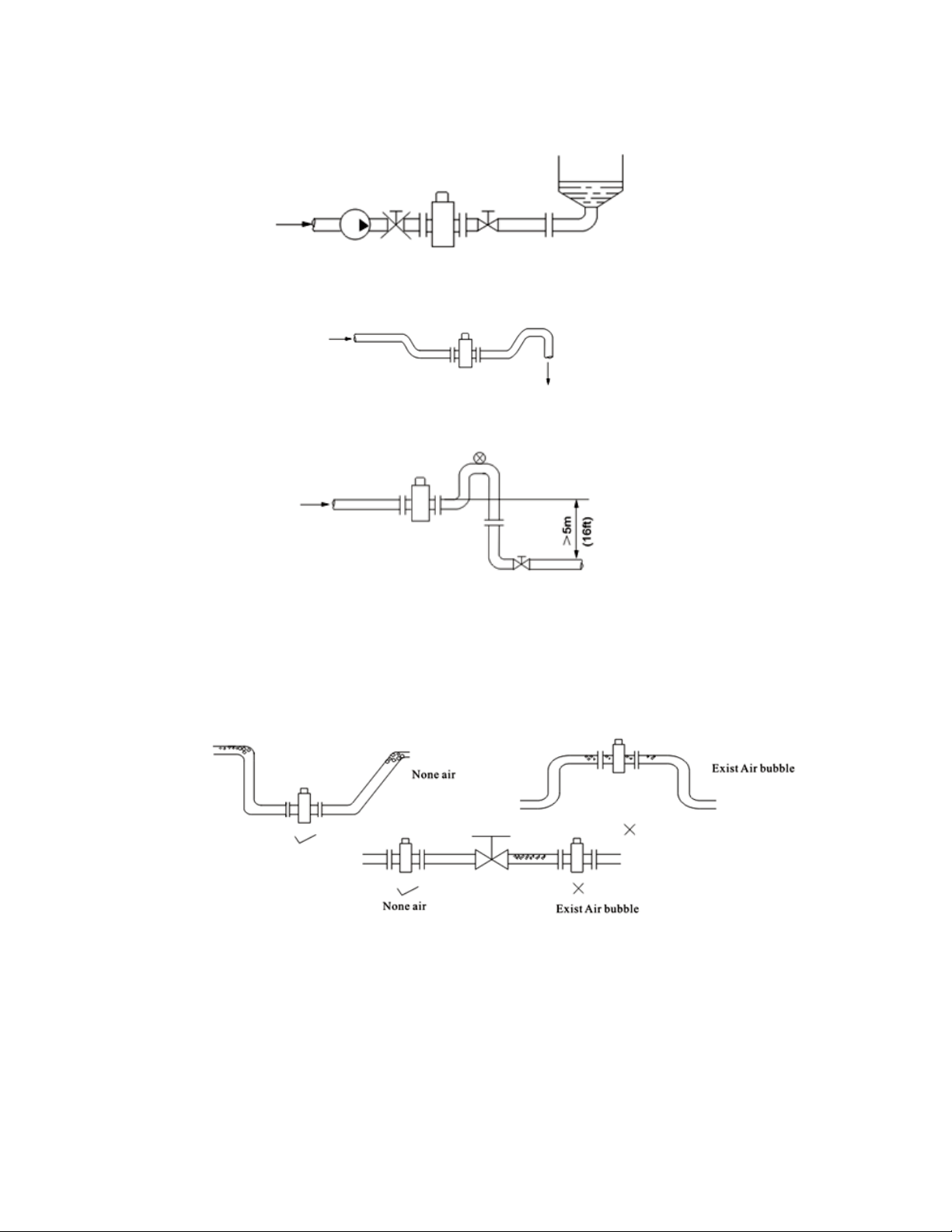

2. To ensure measurement accuracy, the upstream pipe of flowmeter must be straight for at least 5D, and

the downstream must be straight for at least 2D, where D is the diameter of the pipe.

3. Do not install the flowmeter on a vibrating pipe. Pipes should be fixed with an installation foundation.

For underground installation, supports are required at the two ends of the pipeline.

4. Flow direction: the flowmeter can self-check forward/reverse flow, and the flow arrow on sensor

indicates forward flow direction. User should ensure the flow arrow is the same as the actual flow

direction when installing the meter.

5. Installation orientation: sensor can be installed horizontally or vertically.

6. Pipes must be fully filled with fluid. Ensure electrodes are completely immersed into the flow liquid to

achieve good measurement accuracy.

7. Do not install the flowmeter on the pumping side.

3

8. For long pipelines, the control valve is usually installed downstream of the flowmeter.

9. For pipes with an open end, the flowmeter should be installed at the lower section on pipeline.

10. For pipes exceeding 5 meters vertically, air valve (vacuum) should be installed at downstream flowmeter.

11. No air bubbles in the pipeline

Flowmeters should be installed on the upstream before the valve. Due to the action of valve,

the pressure inside the pipeline may decrease and cause air bubbles.

Flowmeters should be installed on the lower section of pipeline to prevent air bubbles

12. Liquid conductance

• Don't install the flowmeter at a place where conductance fluctuates.

• Filling chemical liquid on the upstream from flowmeter will easily cause liquid conductance to

vary irregularly, which may result in false reading on flowmeter. It’s suggested to fill chemical

liquid on the down-stream. If filling chemical liquid on the upstream cannot be avoided, ensure

that the length of the straight pipe before flowmeter is at least 5 times of the upstream section,

so that liquid can be adequately mixed on the upstream.

4

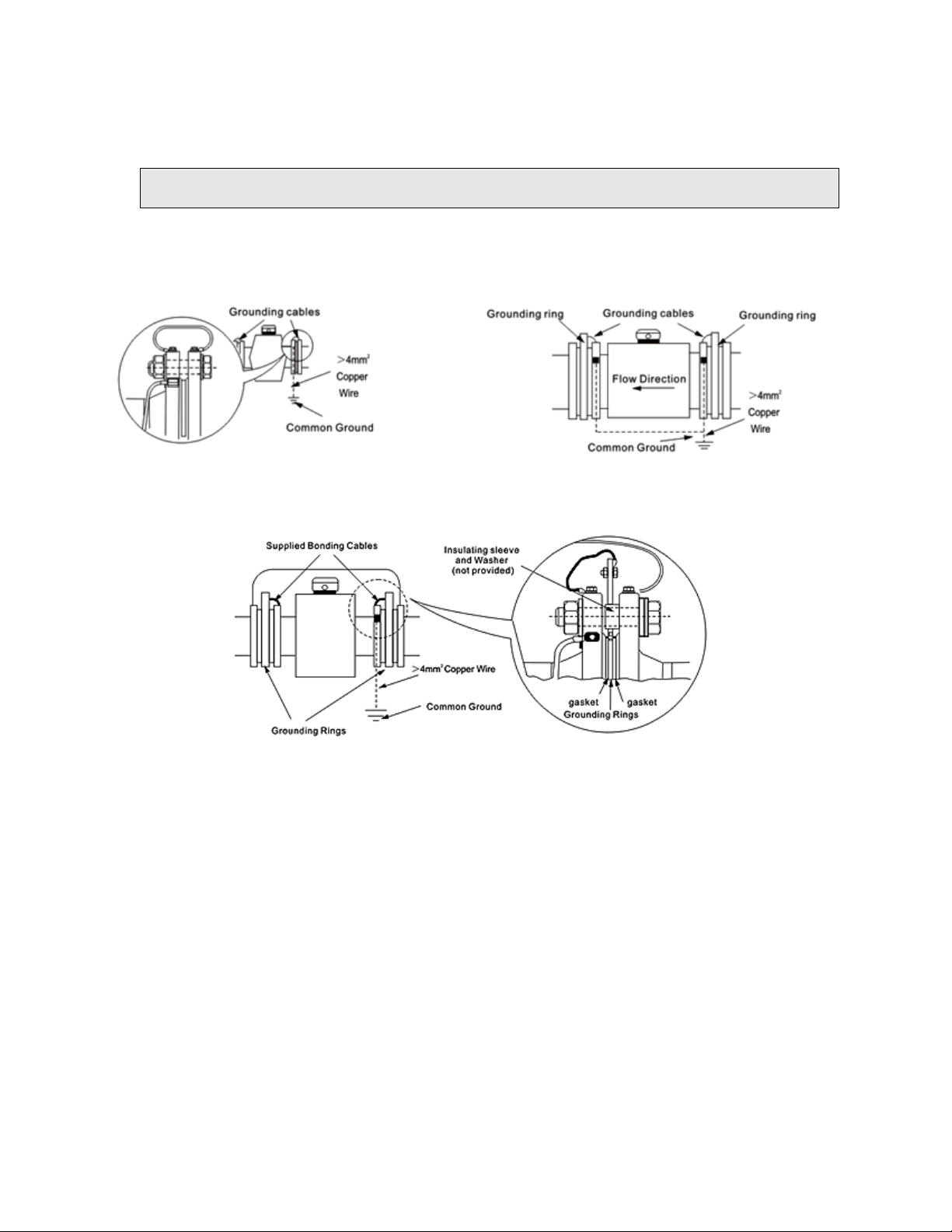

13. Ground Connections for Sensor

★ Notice: Since inductive signal generated from flow is very faint, it is very important to

have a good earth connection, in order to avoid interference.

The following diagrams show the grounding connection methods for sensor in the different conditions:

A. Metal pipe grounding B. Plastic pipe grounding

C. Pipeline with cathode protection

14. Ground Connections for Transmitter

• Just connect the housing of transmitter to earth with copper wire.

Wiring

1. Cable (Cable is for remote version of flowmeter only. No cable wiring is needed for integral version.)

Working temperature:-25 to ~70°C

Cable's specification and colors are as shown below

The diameter of cable is 11.5±0.5mm.

5

Loading...

Loading...