Page 1

MoviTHERM MIO Series of Intelligent I/O Modules

Intelligent I/O Module for FLIR® AX8 Cameras

User Manual

September 2016

Page 2

Revision 1.4

Support

Thank you for selecting MoviTHERM Products.

For product updates and web support, visit:

http://www.movitherm.com

General Disclaimer

MoviTHERM temperature monitoring solutions (hardware and software) are intended for

supplemental thermal monitoring. The device described in this document is only intended to

alert human operators of an emergency situation. The MoviTHERM device is not intended as a

substitute for prudent fire prevention practices and conventional fire prevention equipment,

nor is it a substitute for life and property insurance. The MoviTHERM device must be installed

and serviced by qualified professionals who, along with this documentation package, will

provide information about the capabilities and limitations of the device. While generally very

reliable, the device may not work under all conditions such as (but not limited to) interruptions

to power, component failure, and/or other unanticipated operational conditions that were not

present during installation, testing and validation. When correctly installed and maintained, the

MoviTHERM device explained in this document should reliably provide years of trouble-free

service. All MoviTHERM systems and devices must be used in combination with redundant fire

detection and response systems.

Compliance

The MIO I/O module is CE/FCC compliant. Refer to the MoviTHERM MIO Compliance

documentation supplied with the device.

Trademarks

FLIR, the FLIR logo, and all FLIR product names referenced in this document are trademarks

and/or registered trademarks of FLIR Systems, Inc. and/or its subsidiaries.

Information is subject to change without notice. ©2016 MoviTHERM - All rights reserved.

Page 3

Table of Contents

1 Foreword .............................................................................................................................. 1

2 Device Overview .................................................................................................................. 2

3 Unpacking ............................................................................................................................ 2

4 Connecting the MIO I/O Module ......................................................................................... 3

5 Specifications ....................................................................................................................... 6

6 System Installation and Set-up ............................................................................................ 6

6.1 Configuration Procedure .................................................................................................. 7

6.1.1 IP Configuration ........................................................................................................ 8

6.2 Preparing MIO for Configuration ..................................................................................... 9

6.3 Assigning Actions to Camera Regions: The MIO Controller Utility .................................. 9

6.3.2 The Camera Settings Tab ........................................................................................ 15

6.3.3 The Debug Tab ........................................................................................................ 22

6.4 Recovery Mode .............................................................................................................. 23

6.4.1 Password Reset ....................................................................................................... 25

7 Operations ......................................................................................................................... 25

7.1 I/O Connections .............................................................................................................. 25

7.1.1 Digital Output Pin Definitions ................................................................................. 26

7.1.2 Analog Output Pin Definitions ................................................................................ 26

8 Troubleshooting Common Issues ...................................................................................... 29

9 Appendix A: Default Settings ............................................................................................. 31

10 Appendix B: Technical Specifications ................................................................................. 31

10.1 Absolute Maximum Ratings ........................................................................................... 31

10.2 Operating Specifications ................................................................................................ 31

Page 4

MoviTHERM MIO-AX8-1 Manual

MoviTHERM – Advanced Thermography Solutions| 15540 Rockfield Blvd., Suite C110, Irvine, CA, USA| www.movitherm.com

1

1 Foreword

Congratulations on your purchase of the MoviTHERM MIO Series Intelligent I/O Module. We appreciate

your business and want to make sure that your installation is successful. This manual provides important

information for installation, setup, configuration and care of your new product.

PLEASE MAKE SURE TO READ THE ENTIRE MANUAL CAREFULLY BEFORE OPERATING THIS DEVICE.

Whenever you see the symbol to the left, please pay special attention. This is a warning

symbol. Carefully consider all warnings in this document in order to prevent any mistakes.

The blue light bulb and checkmark symbol indicates a useful tip or information.

We invite any suggestions that you might have for improving our products or this user manual. Please

feel free to contact us at any time with your questions, suggestions or concerns:

MoviTHERM – Advanced Thermography Solutions

15540 Rockfield Blvd., Suite C110

Irvine, CA, USA

Phone: +1 949.699.6600

Fax: +1 949.699.6601

Email: info@movitherm.com

Website: http://www.movitherm.com

Twitter: www.twitter.com/movitherm

Page 5

MoviTHERM MIO-AX8-1 Manual

MoviTHERM – Advanced Thermography Solutions| 15540 Rockfield Blvd., Suite C110, Irvine, CA, USA| www.movitherm.com

2

2 Device Overview

This User’s Guide describes how to install, configure, and use the MoviTHERM MIO Intelligent I/O

device. For detailed device specifications, refer to the specifications section at the end of this document.

The single camera version of the MoviTHERM MIO Intelligent I/O device provides TCP/IP connectivity

for 1 camera over a 100Base-T Ethernet connection. Each unit provides two channels of isolated, looppowered analog (4-20mA) outputs, and two solid state (24VDC) relay outputs.

3 Unpacking

The MoviTHERM MIO Intelligent I/O device ships in a custom printed cardboard box, as shown in the

photo below.

After removing the device from the packaging, inspect for damage that may have occurred

during shipping. Damaged devices should not be put into service. Contact your distributor

and/or MoviTHERM immediately if the device appears damaged in any way. If the damages

occurred during shipping, please file a claim with your shipping company.

Page 6

MoviTHERM MIO-AX8-1 Manual

MoviTHERM – Advanced Thermography Solutions| 15540 Rockfield Blvd., Suite C110, Irvine, CA, USA| www.movitherm.com

3

4 Connecting the MIO I/O Module

Inspect the device to locate the various ports and connectors. (See Figure 1.)

Figure 1: MIO Device Connections

The power terminals shown in Figure 1 must be connected to an industrial power supply, or other 1030VDC source. Although the unit is designed to work with a standard 24VDC industrial supply, it will also

work with a 12VDC supply. The input voltage needs to be between 10VDC and 30VDC, so any supply

within this range should be suitable. The selected power source must be regulated and stabilized to

assure reliable performance.

NOTE: No power supply is included with the MIO module. However, power supplies are available, and a

suitable unit can be added as an accessory.

Connect the positive lead of the power supply to the screw terminal marked “V+” and the negative or

ground lead to the terminal marked “V- “. Please make sure not to reverse the polarity. The unit has a

reverse polarity protection built in. However, the unit will not power up if the polarity is reversed.

Under full load conditions, the unit draws about 0.125A (3W). This does not include the current needed

to supply the digital outputs. The digital outputs can source 0.5A each, but will not exceed 1.0A total for

all outputs

Page 7

MoviTHERM MIO-AX8-1 Manual

MoviTHERM – Advanced Thermography Solutions| 15540 Rockfield Blvd., Suite C110, Irvine, CA, USA| www.movitherm.com

4

You can connect the Ethernet RJ-45 port directly to the camera, however it is recommended that you

connect it to a camera network or an Ethernet switch, particularly if you have multiple MIO units and

multiple cameras. You will also need to connect the MIO unit to a PC or laptop for configuring the unit.

Connecting the MIO, the camera, and the PC to an Ethernet switch permits you to configure both the

camera and the MIO module at the same time.

Connect the 4-20mA analog outputs to any device with 4-20mA signal inputs, such as industrial PLCs, 420mA data loggers, 4-20mA signal monitoring/alarm devices, etc. Keep in mind that from the

perspective of the MoviTHERM MIO I/O module, these are outputs. The 4 to 20mA outputs are active, or

loop powered. This indicates that they will provide a loop voltage to the connected device. No additional

power source is necessary or should be added. Make sure to observe the connection polarity of the 4 to

20mA device.

Connect the digital outputs to discrete signal inputs on alarms, warning lamps, auto-dialers, PLCs, etc.

For more details on how to connect devices, please go to Section 7.1 – I/O Connections.

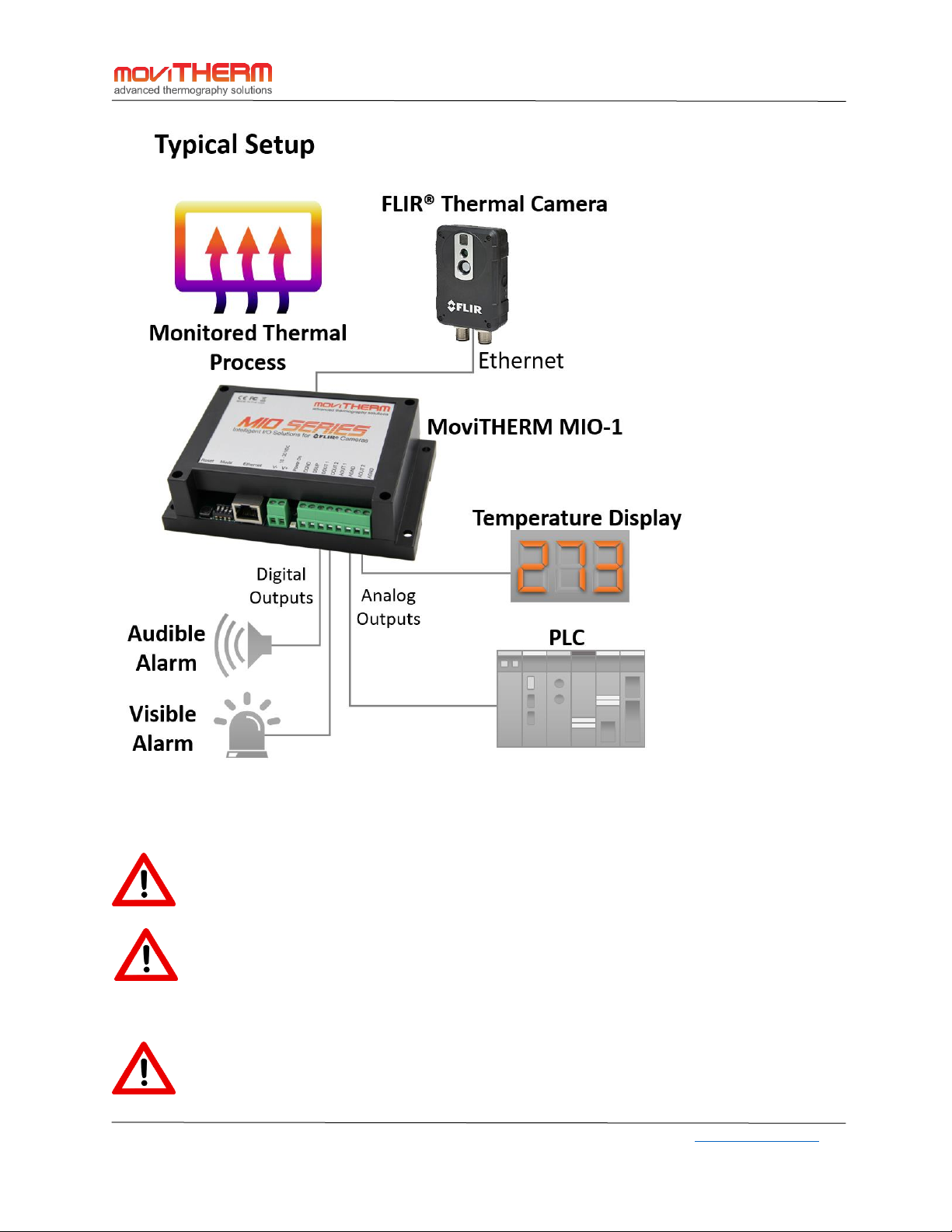

Any number of connection scenarios are possible using the MIO signal outputs. Figure 2 illustrates a

typical installation scenario, and offers some examples of the types of industrial devices that can be

connected to the MIO.

Page 8

MoviTHERM MIO-AX8-1 Manual

MoviTHERM – Advanced Thermography Solutions| 15540 Rockfield Blvd., Suite C110, Irvine, CA, USA| www.movitherm.com

5

Figure 2: A typical MoviTHERM MIO-AX8-1 Monitoring Installation

Do not operate the device in a manner that is not specified in this document. Misuse of the

device may result in a malfunction or safety hazard. It will also void the warranty.

Never operate this device in an explosive environment where flammable gases, dust, fumes

or other volatile materials may be present. If you must operate this device in a hazardous or

explosive environment, it must be installed in a suitably rated enclosure with the necessary

provisions.

To ensure proper performance consistent with the specifications of this device, please

carefully read this user manual and observe all cautions, operating conditions and limits.

Page 9

MoviTHERM MIO-AX8-1 Manual

MoviTHERM – Advanced Thermography Solutions| 15540 Rockfield Blvd., Suite C110, Irvine, CA, USA| www.movitherm.com

6

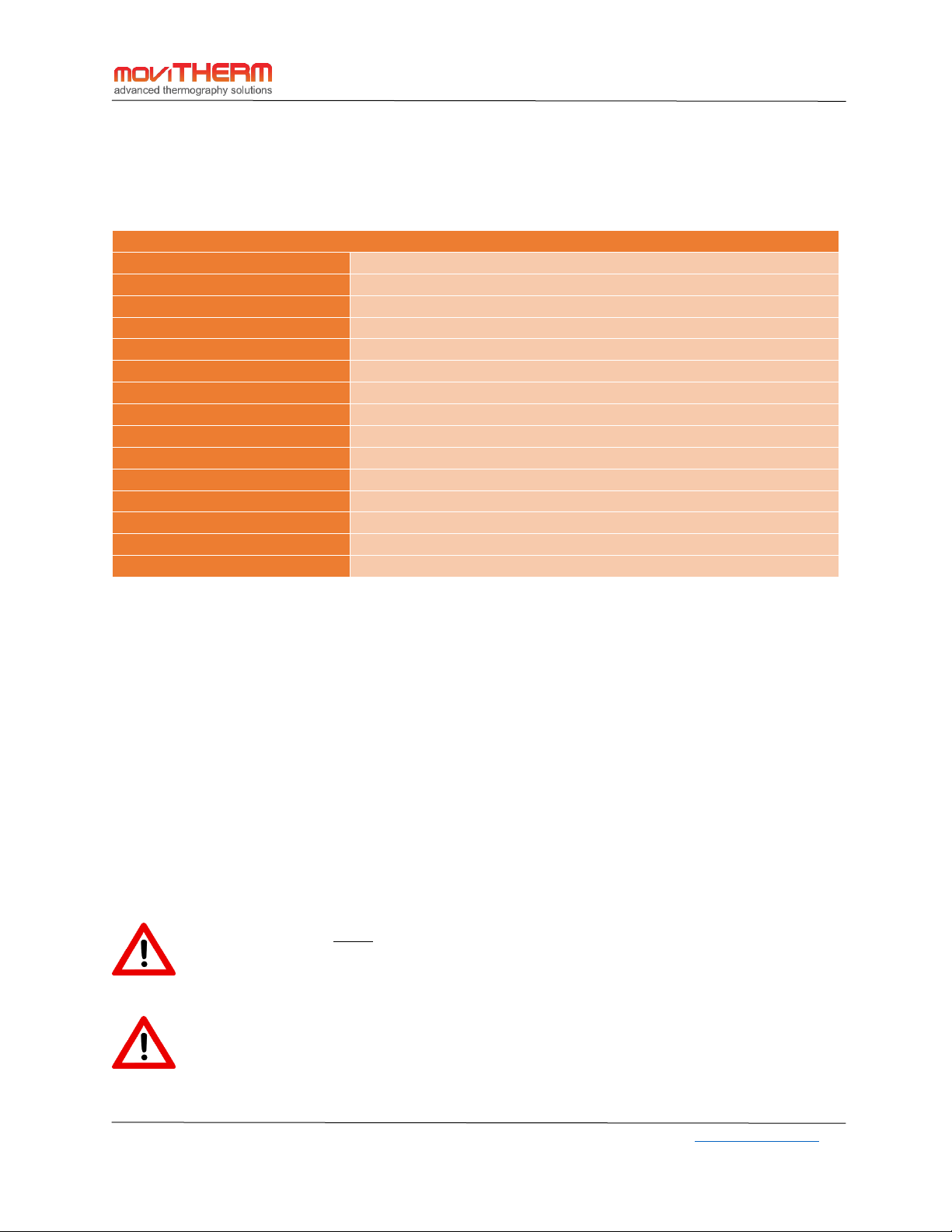

5 Specifications

Model

MIO-AX8-1

Compatible Cameras

FLIR® AX8

Maximum Cameras Supported

1

Ethernet Connection

100Base-T

Communication Protocol

Modbus TCP/IP

4-20mA Transmitter Channels

2 CH, Group Isolated, Self-Powered

Digital Output Channels

2

Digital Output Current

0.5A per Channel, 1.0A all Channels

Digital Output Voltage

10-30VDC

Power Supply Voltage

24 VDC

Maximum Power Consumption

3W

Dimensions

5.7 x 3.6 x 1.6 in (145 x 90 x 40 mm)

Weight

0.5 lbs. (0.23 kg)

Enclosure Material

ABS Plastic

Operating Temperature

0°C to 50°C (32°F to 122°F)

Relative Humidity

0% to 95% RH, non-condensing

6 System Installation and Set-up

The MoviTHERM MIO Series of Intelligent I/O modules are built into rugged ABS plastic enclosures. The

ABS enclosures are intended to protect the internal electronics for general handling and from minor

impact, but are not designed to protect the device from harsh industrial environments, or exposure in

outdoor installations. Like most industrial devices of this nature, the MIO I/O module is intended to be

mounted inside an existing electrical cabinet or other protective enclosure.

The MIO I/O Module is rated NEMA1 / IP20

Enclosures are constructed for indoor use. They provide a degree of protection to personnel against

incidental contact with the enclosed equipment and to provide a degree of protection against falling

dirt. Internal electronics are protected against solid foreign objects of 12mm in diameter and greater.

The device is NOT protected against water.

The MIO I/O module is not protected against ingress of dust, conductive particles, moisture

or liquid splashing.

For installations in dirty, dusty, hot, wet, freezing or otherwise harsh or hazardous areas,

provisions must be made to adequately protect the MIO I/O module.

Page 10

MoviTHERM MIO-AX8-1 Manual

MoviTHERM – Advanced Thermography Solutions| 15540 Rockfield Blvd., Suite C110, Irvine, CA, USA| www.movitherm.com

7

Please do not stick any tools or metal objects inside the MIO module. This may create an

electrical shortcut and permanently damage the unit. This will also void the warranty.

For indoor industrial or outdoor environments, we recommend placing the MIO I/O module inside an

electrical enclosure rated at least NEMA4 or NEMA4x. No cooling is required, provided the inside

temperature of the protective enclosure does not exceed the max allowable operating temperature of

the MIO module. If the expected internal enclosure temperature may exceed the max operating

temperature, active cooling is recommended to ensure trouble-free operations.

To ensure proper operation and continuing reliability, all set-up and configuration tasks should be

completed by qualified engineers or service technicians. The information in this manual provides some

direction, but should not be considered a substitute for extensive experience.

If you are unsure how to proceed, contact your distributor or MoviTHERM technical

support (support@movitherm.com) for further direction. Please include the serial number

of your MoviTHERM MIO unit. Alternatively, visit the MoviTHERM Website

www.movitherm.com and use the contact methods provided on the contact page.

6.1 Configuration Procedure

After the electrical connections have been made and verified, it is time to configure the camera and the

MoviTHERM MIO device. FLIR AX8 cameras are configured using FLIR IP Config and the camera’s built in

web server. (Additional information about configuring the FLIR cameras can be found in the camera

documentation.)

The MIO device is configured using the browser-based MoviTHERM MIO Configuration Utility, as

discussed later in the manual.

System Configuration is a four step process:

1) Set the camera to a fixed IP addresses using the FLIR IP Config application or the built-in web

browser interface.

2) Set up the inspection regions (Regions of Interest or “ROIs”) using the camera’s built it web

server.

3) Define the thresholds and action criteria for each ROI using the browser-based MoviTHERM

MIO Configuration Utility.

4) Configure the MIO board response using the MoviTHERM MIO Configuration Utility.

Page 11

MoviTHERM MIO-AX8-1 Manual

MoviTHERM – Advanced Thermography Solutions| 15540 Rockfield Blvd., Suite C110, Irvine, CA, USA| www.movitherm.com

8

Steps 3 & 4 cannot be completed until Steps 1 and 2 are complete. Step 1 requires the FLIR

IP Config software utility (bundled with the camera or available online at www.flir.com).

Step 2 requires the built-in AX8 configuration application, deployable using any standardscompliant Internet web browser (Microsoft Edge, IE, Google Chrome, Firefox). Steps 3 & 4

also use the web browser interface to access the MoviTHERM MIO Configuration Utility.

Configuring the FLIR AX8 “ROIs” requires the camera’s built in web browser. Consult the

appropriate FLIR camera user manual for more details on how to setup the camera.

6.1.1 IP Configuration

It is important to understand that although the MIO device, the configuration computer (PC), and the

camera share an Ethernet connection, the camera, the MIO device, and the PC must have separate and

unique TCP/IP addresses. The camera, MIO, and PC must also be configured to use a static IP addresses.

Use the FLIR IP Config utility software to set the AX8 IP address.

The MoviTHERM MIO Configuration Utility will be used to set up the IP address on the MIO device (as

discussed in the next chapter).

IP SUBNET CONFIGURATION - IMPORTANT NOTE:

The camera, the MIO device, and the PC must each be assigned a unique IP address. However,

in order to share the same Ethernet cable connection, all of the IP addresses must reside within

the same subnet. This is most easily accomplished by ensuring that the 1st, 2nd, and 3rd IP

address fields are common for all devices, while the 4th field is unique for each device.

For example, the default IP address for the MIO device is defined as follows:

MIO IP address: 192.168.1.2

Subnet mask: 255.255.255.0

If this default is left unchanged, suitable camera IP addresses might be:

Camera IP address 1: 192.168.1.3

Camera IP address 2: 192.168.1.4

Camera IP address 3: 192.168.1.89 (etc.)

If the MIO device IP is modified (as outlined later in this document), the camera and PC’s IP

addresses may need to be updated accordingly.

Page 12

MoviTHERM MIO-AX8-1 Manual

MoviTHERM – Advanced Thermography Solutions| 15540 Rockfield Blvd., Suite C110, Irvine, CA, USA| www.movitherm.com

9

After the camera, PC, and MIO IP addresses have been assigned, you will be ready to define the Regions

of Interest that will be used by the MIO device. Refer to the FLIR AX8 User Manual for detailed

information about defining the regions of interest for the FLIR AX8 camera.

You must complete the Region of Interest configuration in the camera before moving on to configure

the MoviTHERM MIO device.

6.2 Preparing MIO for Configuration

You will need to have the camera’s regions of interest defined before you can configure the MIO. The

MIO needs to find the configured regions of interest in the camera in order to perform the selected

actions. You can configure one or many ROIs. You are limited only by the number of regions available in

the camera, and the available outputs on the MIO I/O. If more outputs are needed, or you need to

monitor more than one camera in your application, simply add additional single-channel or a multichannel MIO I/O modules to your network.

Supported Web Browsers - The following web browsers are supported by the MIO. If you

are using an older version than the supported version and are experiencing issues, update

to the latest version or use another supported browser.

Microsoft Edge – 38.0

Google Chrome – 53.0

Firefox – 48.0

6.3 Assigning Actions to Camera Regions: The MIO Controller Utility

Once Regions have been defined in the camera, you are ready to assign actions based on temperatures

detected. Start by launching a web browser (Google Chrome, Microsoft Edge, Firefox) from your

Windows Desktop or Start Menu. When the browser window opens, type the MIO Controller Board IP

address into the Address (URL) field at the top of the browser window, as shown in Figure 4.

The MIO’s default IP address is: 192.168.1.2

The MIO’s IP address is user-configurable. If you are uncertain about the MIO’s IP address setting, start

with the default. If this doesn’t provide access, refer to the notes on the next page.

Page 13

MoviTHERM MIO-AX8-1 Manual

MoviTHERM – Advanced Thermography Solutions| 15540 Rockfield Blvd., Suite C110, Irvine, CA, USA| www.movitherm.com

10

Figure 4: MIO Access Log-in Dialog

If the correct IP address is entered, the Password Login dialog will appear in the browser window as

shown here.

Enter the Administrator log-in password in the field provided, and click the Log In button to continue.

When the correct password has been entered, the Device Settings Tab will open in the browser window,

as shown in Figure 5.

For simplicity, the default log-in password is set to “password”. After system installation,

you may want to change the password to reduce the potential for unauthorized system

access. (Additional information about changing the password can be found in the section

that discusses Recovery Mode.)

The MoviTHERM MIO Device IP Address is pre-configured to 192.168.1.2. This is the factory

default IP setting, but this address is configurable. If the IP address has been changed, you will

need to provide a different address. If you know the correct address, enter it into the Address

(URL) field. If you are uncertain, try the default IP (192.168.1.2) first. If you are unable to

connect, you may need to perform a Network Reset. (Refer to the IP Address Reset section

later in this chapter.)

Page 14

MoviTHERM MIO-AX8-1 Manual

MoviTHERM – Advanced Thermography Solutions| 15540 Rockfield Blvd., Suite C110, Irvine, CA, USA| www.movitherm.com

11

Figure 5: The MIO Controller Utility opens to the Device Settings tab after the correct password has been entered.

The contents of the Device Information fields will depend on the MIO device and camera.

6.3.1.1 The Device Settings Tab

The Device Settings tab (shown in Figure 5) is the default start-up page. When you access the MIO Board

Configuration from your browser, this is the tab that will appear after entering the correct log-in

password. The text fields with a white background are editable fields. The text fields with a grey

background display current system parameters, but are not user-editable.

The Device Settings tab is used to:

1) set the Network Configuration (IP Address and Subnet),

2) enter an optional user-defined Device Name

3) execute a firmware update

Page 15

MoviTHERM MIO-AX8-1 Manual

MoviTHERM – Advanced Thermography Solutions| 15540 Rockfield Blvd., Suite C110, Irvine, CA, USA| www.movitherm.com

12

6.3.1.2 Network Configuration

To change the Network Configuration, simply type the new Device IP address and Subnet mask in the

fields provided. Similarly, to change the Device name, simply type a user-specified name into the Device

name field provided. Click “Save Settings and Reboot” to save the changes.

Note: If you change the IP address and then click “Save Settings and Reboot”, the board will run through

a short reset cycle before opening a link to the new IP address. When the browser page updates, the

Device IP address and Subnet mask fields will reflect the changes. (See Figure 6.)

Figure 6: IP Address changed - view after Save and Reboot

6.3.1.3 IP Address Reset

If you changed the IP Address, but have forgotten the new setting, an IP Address Reset operation will

temporarily reset the IP address to the factory default. To reset the IP address, you will need to access

the DIP switches on the MIO device. (The DIP switches can be accessed through the cut-out port located

to the left of the MIO Ethernet port.)

DIP Switches and Reset Button

locations

Page 16

MoviTHERM MIO-AX8-1 Manual

MoviTHERM – Advanced Thermography Solutions| 15540 Rockfield Blvd., Suite C110, Irvine, CA, USA| www.movitherm.com

13

When you have located the DIP switches, follow these steps to reset the IP address to the factory

default setting: 192.168.1.2 (Subnet Mask: 255.255.255.0)

While the unit is powered on:

Step 1: Turn on the IP Reset DIP switch

(see Figure 7)

Step 2: Reset the device by either:

a) Powering module off, waiting 10 seconds,

then powering back on

Or

b) Pressing the reset button. The reset button is located to the immediate left of the DIP Switches.

(See blue highlighted area and arrow in the image above.)

Step 3: After the device reboots, log in to the device using the default IP address: 192.168.1.2

Step 4: Turn off the IP Reset DIP switch

(see Figure 8)

For setting the IP Address back to a user-defined value, return to the previous Network

Configuration section of this document. Keep in mind that every time you are changing

the IP address of the device, the connection in your browser (and all other connected

devices) may be lost. Make sure to change the IP address in the browser to the newly

configured IP address to re-establish the connection.

Figure 7: Set the IP reset DIP Switch to ON

Figure 8: Clear the IP reset DIP Switch (OFF)

Page 17

MoviTHERM MIO-AX8-1 Manual

MoviTHERM – Advanced Thermography Solutions| 15540 Rockfield Blvd., Suite C110, Irvine, CA, USA| www.movitherm.com

14

6.3.1.4 Firmware Update

The Firmware Update option at the top of the Device Settings tab is an advanced feature that allows you

to quickly and easily upgrade the Firmware (embedded software) running on the board. Under normal

conditions, you will rarely need to update the Firmware. (MoviTHERM may release firmware updates

from time to time to add new functionality to the MIO, or to address firmware changes in the FLIR

camera.) You will not be required to perform this operation under normal, everyday operating

conditions, but if an update is required, the Firmware Update process involves the following steps:

1) Download the Firmware file to your PC

2) Click the “Choose File” button under “Firmware Update” on the “Device Settings” tab (Fig. 9)

3) Navigate to the Firmware file (from Step 1) using the file browser, and select it. The filename will

appear next to the “Choose File” button.

4) Click the “Update” button under “Firmware Update” on the “Device Settings” tab (Fig. 9)

5) The firmware update will be loaded into the MIO Device. The device will reboot and reconnect.

When the Firmware update cycle is complete, you will be returned the Device Settings Tab.

Figure 9: Buttons for initiating the Firmware Update

Page 18

MoviTHERM MIO-AX8-1 Manual

MoviTHERM – Advanced Thermography Solutions| 15540 Rockfield Blvd., Suite C110, Irvine, CA, USA| www.movitherm.com

15

6.3.2 The Camera Settings Tab

The Camera Settings Tab is used to link the camera IP addresses to the MIO Controller board. This step

permits the cameras to communicate with the board, enabling its functionality. When you click on the

Camera Settings tab, the tab depicted in Figure 10 loads into the browser window.

Figure 10: The Camera Settings Tab - awaiting configuration

Enter a name or alias for the camera in the field provided, along with the corresponding IP

address for the camera, as illustrated in Figure 11, and press the “Save Configuration”

button. As the MIO Board connects to the cameras, the green “Connected” text will

replace the red “Not Connected” text to the right of the camera specification, as shown in

Figure 11.

The “Alias” allows the user to provide a more meaningful name or reference to the camera, rather than

having to memorize a cryptic IP address number. The alias name has no other use than that and will not

affect any functionality.

Page 19

MoviTHERM MIO-AX8-1 Manual

MoviTHERM – Advanced Thermography Solutions| 15540 Rockfield Blvd., Suite C110, Irvine, CA, USA| www.movitherm.com

16

Figure 11: Sample Camera Configuration

6.3.2.1 Saving and Loading Configurations

The MIO device maintains one complete configuration in non-volatile memory. You can use the “Save

Configuration” button to store the current configuration as displayed on the Camera Settings tab into

the device memory. On power reset, the most recently saved configuration is used by the device. You

can also use the “Get Current Settings” button to load the most recently saved configuration from the

device memory into the Camera Settings tab for inspection or further editing.

6.3.2.2 The Script Commands Tab

After the camera settings have been set up, the next task is to set up the script commands that create

the intended system responses. The Script Commands tab is used to configure the commands

configuration. (See Figure 12.)

Page 20

MoviTHERM MIO-AX8-1 Manual

MoviTHERM – Advanced Thermography Solutions| 15540 Rockfield Blvd., Suite C110, Irvine, CA, USA| www.movitherm.com

17

Figure 12: The Script Commands tab - prior to configuration.

The configuration procedure is straight-forward:

1) Select a Command from the left-most pull-down menu (as shown in Figure 13)

2) Assign the selected Command to a Region of Interest by selecting it using the pull-down menu.

(The Regions of Interest must be predefined in the camera using FLIR AX8 web browser

interface as discussed previously.)

3) In the case of an Analog Output command, assign the Analog Output Mode, “Linear” or

“Threshold” (information about these modes is provided below).

4) If “Threshold” mode is used, set the Temperature Threshold(s) needed to initiate the specified

action in the Low Temperature box. If “Linear” mode is used, enter the value which should

correspond to 4 mA in the Low Temperature box and the value which should correspond to 20

mA in the High Temperature box.

Repeat these steps for the Analog and/or Digital channels as needed, then save the configuration by

clicking the “Save Configuration” button.

Page 21

MoviTHERM MIO-AX8-1 Manual

MoviTHERM – Advanced Thermography Solutions| 15540 Rockfield Blvd., Suite C110, Irvine, CA, USA| www.movitherm.com

18

Figure 13: Command pull-down menu options

You can assign multiple outputs (digital and analog) to the same camera, if needed. For

example, if you have four regions of interest configured within one and the same

camera, you can also assign two separate analog outputs and two separate digital

outputs to each of these four regions, each with their own alarm threshold. Or

alternatively, you could assign the analog 4 to 20mA outputs to the same regions as the

digital outputs for external monitoring or control. It is entirely up to you, how you utilize

the resources in the MIO I/O module. If you run out of outputs, you can add another

MIO I/O module to the network and expand your system that way.

6.3.2.3 Command Options

The Command Options can be summarized in the following categories:

1) System Status

2) Delta Temperature

3) Internal Camera Temperature

4) Spot Temperature

5) Box Temperature (Max, Min, or Average)

6) Alarm trigger

System Status

System Status is a special configuration option that can be used to monitor camera connectivity. When

the System Status Command is assigned to an output channel, the selected channel can be used to

monitor Ethernet connectivity. If all the cameras entered in the “Camera Settings” tab have active

Ethernet connections to the MIO (0.0.0.0 IP address are not considered), the output will be logical

"HIGH" (20mA output). If one or more camera connectivity issues are detected, the selected output

channel will reflect a logical "LOW" (4.0 mA) state.

Page 22

MoviTHERM MIO-AX8-1 Manual

MoviTHERM – Advanced Thermography Solutions| 15540 Rockfield Blvd., Suite C110, Irvine, CA, USA| www.movitherm.com

19

Delta Temperature

The Delta Temperature command enables you to initiate an action based on the difference between two

parameters. For example, an action could be based on the difference between the minimum and

maximum temperature readings within a single region. Alternatively, two regions could be compared, or

the camera’s internal temperature register could even be compared with a region in the image. The

difference between any two eligible camera parameters can be used as the basis for the delta

comparison. (Refer to the FLIR Camera user manual for how to setup delta temperature functions in the

camera)

Internal Camera Temperature

The Internal Camera Temperature option selects the camera’s internal temperature as the data source.

This option can be used to monitor the temperature environment of the camera, and alert the user to

unusual operating conditions.

Spot Temperature

Select the Spot Temperature option to use a predefined spot temperature as the data source. (Refer to

the FLIR Camera manual for more details about configuring a Spot Temperature measurement.)

Box Temperature (Max, Min, or Average)

Select the Box Temperature option to use a predefined Box temperature (max, min or average) as the

data source. . (Refer to the FLIR Camera manual for more details about configuring a Box Temperature

measurement.)

Alarm Trigger

Each camera can be configured to generate Alarm Trigger events in response to a variety of inputs.

Measurement results from within the image, the instantaneous state of a digital input, or even a

camera’s internal temperature could potentially be configured to generate an alarm. Selecting the Alarm

Trigger option assigns the state of the alarm flag as the data source for MIO device operations. (Refer to

the FLIR Camera manual for more details about configuring alarms in the camera.)

6.3.2.4 Region of Interest Selection

The Region of Interest field is located to the right of the Command field. The available Region of

Interest options will depend on the Command option selected. For example, if you select the System

Status, Internal Camera Temperature, Delta Temperature, or Alarm option in the Command pull-down,

the Region of Interest specification is not relevant. The Region of Interest field will be disabled and

unavailable for editing. However, if you select a Spot or Box source in the Command field, it becomes

necessary to specify which of the pre-defined Spots or Boxes applies. In this case, the Region of Interest

field will be enabled and populated with all the available regions (Spots and Boxes). After specifying the

appropriate region, you can move on to specify the Output Mode (in the case of Analog Output

channels), and the temperature threshold(s).

Page 23

MoviTHERM MIO-AX8-1 Manual

MoviTHERM – Advanced Thermography Solutions| 15540 Rockfield Blvd., Suite C110, Irvine, CA, USA| www.movitherm.com

20

6.3.2.5 Analog Output Mode

The Analog Output Mode selection determines the behavior of the specific analog output channel. Two

options are available: Linear Output or Threshold Output. When Linear Output is selected, the specified

output channel will produce a scaled 4-20mA signal based on the selected Command and Region of

Interest. The scaling is based on the values entered in the Low and High Temperature fields (4mA for

values ≤ Low Temperature, 20mA for values ≥ High Temperature). When Threshold Output is selected,

the output channel will produce a discrete low (4mA) or high (20mA) signal, based on the temperature

threshold value(s) set in the Low Temperature field.

You can scale the 4 to 20mA output to either the selected temperature range of the

camera, or a custom scale. For example, if the selected temperature range of the

camera is 0°C to 350°C, then enter ‘0’ in the field “Low Temperature” and ‘350’ in the

field named “High Temperature. In this example, a 4mA output signal equals to 0°C and

20mA equals to 350°C. Setting the low temperature or high temperature outside the

selected camera temperature range is not recommended. However, you may select a

different range within the calibrated temperature range of the camera. This is useful, if

you know that your process temperature may never go below or above a certain value.

For example, your process temperature may be between 70°C and 150°C, while the

temperature range of the camera is 0°C to 350°C. Setting the scaling of the 4 to 20mA

output of the MIO module to your min. and max. range of your expected process

temperature allows you to stretch the range across the entire 4 to 20mA range.

However, this will not increase the accuracy of your system.

It is also possible to use the analog 4 to 20mA outputs as threshold or alarm outputs. In

other words, if you select the “Threshold” option, rather than the “Linear Output”

option. This function allows any analog output to behave like a digital output in a sense.

In this case a 4mA current indicates a logic low signal and a 20mA current signals a logic

high or alarm. This is useful, if you run out of digital outputs and want to extend the I/O

of the module. Some 4 to 20mA controllers also “understand” this sort of signaling as

alarm condition.

Page 24

MoviTHERM MIO-AX8-1 Manual

MoviTHERM – Advanced Thermography Solutions| 15540 Rockfield Blvd., Suite C110, Irvine, CA, USA| www.movitherm.com

21

An example of a completed configuration is shown in Figure 14.

Figure 14: Sample Configuration

To summarize, each output channel is configured via the Script Commands tab (as shown in Figure 14).

The usual procedure is to start by selecting a camera using the pull-down camera selector menu. After

selecting a camera, a Command should be specified. If the selected Command specifies a Spot or Box

temperature, you will also need to select a Region of Interest. For Analog Outputs, an Analog Output

Mode must be selected – either a Linear 4-20 mA analog signal that changes proportionally based on the

selected Region of Interest, or a discrete 4 or 20mA Threshold Output, based on a comparison of the

Region of Interest with the temperature threshold settings. (Note that the Digital Channels behave

similarly to the Analog Threshold Output mode.)

6.3.2.6 Saving and Loading Configurations

Just like the Camera Configuration (discussed previously), the MIO device maintains one complete set of

Script Commands in non-volatile memory. You can use the “Save Configuration” button to store the

current configuration as displayed on the Script Commands tab into the device memory. On power

reset, the most recently saved configuration is used by the device. You can also use the “Get Current

Settings” button to load the most recently saved configuration from the device memory into the Script

Commands tab for inspection or further editing.

Page 25

MoviTHERM MIO-AX8-1 Manual

MoviTHERM – Advanced Thermography Solutions| 15540 Rockfield Blvd., Suite C110, Irvine, CA, USA| www.movitherm.com

22

6.3.3 The Debug Tab

After the configuration has been defined, the Debug Tab (in Figure 15) provides a convenient,

interactive window into the real-time operation of the MIO Board. Using the Debug tab, you can observe

the current status of all output channels and DIP switches at a glance. You can use this tab to validate

output channel operations.

Figure 15: The Debug Tab shows the current output state of each MIO Board output channels and the DIP switch states

6.3.3.1 MIO Board DIP Switches

The DIP Switches control advanced board functions. The position of each switch is shown below in

Figure 16.

Figure 16: MIO Board DIP Switches

Page 26

MoviTHERM MIO-AX8-1 Manual

MoviTHERM – Advanced Thermography Solutions| 15540 Rockfield Blvd., Suite C110, Irvine, CA, USA| www.movitherm.com

23

6.3.3.2 DIP Switch Functions

Switch 1 – Filter: Enabling the Filter switch activates a running average filter (10 samples) on the

temperature INPUTS. This function may provide better performance for monitoring applications

involving a constantly variable temperature source such as a flickering flame. The filter is globally

applied to all seven cameras and all configured regions of interest.

Switch 2 – IP Reset: The IP Reset switch is used to reset the IP address to the factory default setting. (For

more information, refer to IP Address Reset under the Device Settings Tab discussions earlier in this

document.)

Switch 3 – 4mA Test: When enabled, all analog channels will output a “logical low” 4mA signal.

Switch 4 – 20mA Test: When enabled, all analog channels will output a “logical high” 20mA signal.

NOTE: When both Switch 3 (4mA Test) and Switch 4 (20mA Test) are enabled, a 12mA half-scale signal

will be output on all analog channels

Switches 5-8: [Reserved for Future Expansion]

All MIO Series I/O modules have a built-in loop calibrator and simulator. The 4 to

20mA signal has 16-bit resolution and is very accurate. By using dip switch 3,4 and 3&4

together you can simulate 4mA, 12mA or 20mA in your setup. The current that the

board outputs is being indicated on the debug page. Therefore, you do not need a

separate instrument such as a loop calibrator or multi-meter to verify your system. This

feature lets you troubleshoot issue and quickly very how your scaling is setup on the

MIO I/O module as well as on the receiving device.

6.4 Recovery Mode

The Recovery Mode (depicted in Figure 17) is an advanced mode that can be used to reset the MIO

device to its original factory settings. Similar in appearance to the Device Settings Tab discussed

previously, the Recovery page includes two key differences:

1) a button to clear camera and script settings

2) a field to enter a new system password.

To enter into Recovery Mode, you must first set all the DIP switches to the ON position and reset the

board. The reset function is activated by pressing the Reset button (located to the left of the DIP

switches), or by power-cycling the unit.

Page 27

MoviTHERM MIO-AX8-1 Manual

MoviTHERM – Advanced Thermography Solutions| 15540 Rockfield Blvd., Suite C110, Irvine, CA, USA| www.movitherm.com

24

Only use the Recovery Mode as a last resort. This function clears all system settings. The

recovery mode is typically only necessary if a firmware update has failed or when you are

unable to access the unit via the web-browser.

Before attempting a system recovery, please make sure to try an IP Address reset first to see

if you can access the MIO I/O module. Sometimes Windows Firewall settings, Virus

Scanners, web browser privacy or Windows security settings may be the issue preventing

you from accessing the unit. Check these first.

Figure 17: Set all DIP switches ON and power-cycle to open the Recovery panel

Page 28

MoviTHERM MIO-AX8-1 Manual

MoviTHERM – Advanced Thermography Solutions| 15540 Rockfield Blvd., Suite C110, Irvine, CA, USA| www.movitherm.com

25

6.4.1 Password Reset

To reset the access password, make sure the unit is already in “Recovery Bootloader Mode”

1. Type a new password into the current password field

2. Switch all DIP switches to the OFF position

3. Click the “Save Settings and Reboot” button

4. When the system restarts, use the new password to log into the Device Settings tab

5. Switch the DIP switches switched to OFF under 2.) back to the desired position.

7 Operations

The MIO-AX8-1 provides two (2) 4 to 20mA analog outputs and two (2) digital outputs. In order to

benefit from this connectivity, the MIO signals must be connected to other devices such as PLCs, dataloggers, warning lamps, alarm equipment, etc. This chapter is devoted to connecting the MIO unit to

external devices.

7.1 I/O Connections

All I/O connections are made via the screw terminal I/O Connectors as denoted in Figure 18.

Figure 18: I/O Mapping and Connectivity

Page 29

MoviTHERM MIO-AX8-1 Manual

MoviTHERM – Advanced Thermography Solutions| 15540 Rockfield Blvd., Suite C110, Irvine, CA, USA| www.movitherm.com

26

The I/O ports are organized into two groups: Digital Outputs and Analog Outputs. When looking at the

side of the MIO enclosure with the I/O port cutouts, the Digital Outputs appear to the left of the Analog

outputs.

7.1.1 Digital Output Pin Definitions

From left to right, the DOUT pins are defined as:

Pin 1: DGND (DOUT Ground)

Pin 2: DSUP (DOUT Supply)

Pin 3: DOUT 1

Pin 4: DOUT 2

Refer to Figure 19 for DOUT channel circuit and connection diagram.

7.1.2 Analog Output Pin Definitions

From left to right, the AOUT pins are defined as:

Pin 5: AOUT 1

Pin 6: AGND

Pin 7: AOUT 2

Pin 8: AGND

Refer to Figure 19 for AOUT channel circuit and connection diagram.

Page 30

MoviTHERM MIO-AX8-1 Manual

MoviTHERM – Advanced Thermography Solutions| 15540 Rockfield Blvd., Suite C110, Irvine, CA, USA| www.movitherm.com

27

Figure 19: DOUT and AOUT Channel Circuit Diagrams

The DOUT signals (DOUT 1 and DOUT 2) when active (turned on) will source the voltage connected to

the DSUP terminal with reference to DGND. Therefore, an external power supply needs to be connected

to the terminal DSUP (‘+’) and DGND (‘-‘). The supplied voltage can be between 9 and 34VDC. Most

common voltages used are either +12VDC or +24VDC.

Each output can source up to 0.5A individually. However, the total sum of all current sourced

through any of the digital outputs cannot and shall not exceed 1.0A. If higher currents are

required, please add a relay or other suitable power switch to protect the output.

If all outputs are turned on, then the following needs to be observed:

1.0A/2 = 0.5A max. per digital output. In other words, if you would like to connect a

relay to each output, please make sure that each relay coil draws <= 0.5A.

Page 31

MoviTHERM MIO-AX8-1 Manual

MoviTHERM – Advanced Thermography Solutions| 15540 Rockfield Blvd., Suite C110, Irvine, CA, USA| www.movitherm.com

28

Example: You are using a 12VDC/1A external power supply for the digital outputs. The

power supply is connected to DSUP (‘+’) and DGND (‘-‘). You have two electromechanical relays with 12VDC coils. The coil resistance is 120Ω.

To calculate the required current per each relay, we can use the Ohm’s Law.

Coil Current = Coil Voltage/Coil Resistance

= 12V/120Ω

= 0.1A or 100mA

The above relay would be suitable, since it only draws 0.1A.

0.1A x 2 Channels = 0.2A total.

The digital outputs are protected against thermal overload, over current and transients from inductive

loads. It is good engineering practice to select relays with a coil current less than 0.15A or 150mA.

The positive (+) terminal of the external (load) device is connected to the DOUT channel on the MIO

device, as illustrated in Figure 18. The load’s negative (-) terminal must be connected to the Digital

Ground (Pin 1), which will share a connection to the negative (-) terminal of the 9-34VDC digital power

supply.

The AOUT signal pairs are “self-powered” 4-20mA output signals. Loop power is provided by an on-

board isolated 24VDC power supply. The recommended wiring configuration is depicted in Figures 18

and 19. The positive (+) terminal of the power source should be connected to the lower-numbered pin

of the pair (i.e. Pin 5 for AOUT 1 or Pin 7 for AOUT 2). The negative (-) load terminal should be connected

to the AGRND, which is connected to the negative (-) terminal of the power source.

AOUT(n) channels are group isolated outputs, which is to say that they are isolated from the main 24V

power and all other digital output signals, but not from each other. All AGNDs are connected to each

other internally.

NOTE: If using the digital output to signal a digital input device, a pull-down resistor must be used. A

common value is 10K. This may also be the case for driving SSR (Solid State Relays).

Page 32

MoviTHERM MIO-AX8-1 Manual

MoviTHERM – Advanced Thermography Solutions| 15540 Rockfield Blvd., Suite C110, Irvine, CA, USA| www.movitherm.com

29

8 Troubleshooting Common Issues

Camera Image Issue

Possible Causes

Recommended Action

Unable to connect to

the Thermal Camera

over Ethernet

1) No Camera Power

2) No Ethernet Connection

3) Incorrect IP Settings

4) Camera Hardware Failure

1) Check Power Supply and Cables

2) Check Ethernet cables, switches, etc.

3) Set IP address with FLIR IP Config

4) Check Camera operations

Camera connection lost

during normal operation

after working

previously.

1) Camera Power cable broken

2) Ethernet cable broken

3) Ethernet Bandwidth Limitation

4) Camera Software Fault

5) Camera Hardware Failure

6) Camera thermal issue

(overheating)

1) Check Power Supply and Cables

2) Check Ethernet Cable

3) Check Router/Switch throughput

4) Power-cycle the Camera

5) Check Camera operations

6) Power down and allow to cool.

A) Camera connection

appears to be OK, but

no image appears.

B) Camera image is

blank and/or the

camera temperature

range is much higher

than expected.

1) Camera Start-up underway

2) Camera temperature range is

not properly set*.

3) Camera Software Fault

4) Camera Hardware Failure

*NOTE: This may happen if the

camera Ethernet connection is

unplugged while the camera is

running.

1) Wait until start-up complete

2) Set correct Camera Configuration in

web browser

3) Power-cycle the Camera

4) Check Camera operations

Camera images appear

as expected, but no

output signal is

generated.

1) Camera Region or MIO

Configuration Error

2) Output line connection fault

3) I/O Module Error or hardware

failure

1) Verify Output Channel parameters

are set correctly on the MIO Utility’s

Script Commands tab

2) Check Output signal wiring

3) Verify Output signal using a volt

meter or 4-20mA loop tested

Analog output current is

unaffected by camera

input.

1) Analog channel is reading from

incorrect Region of Interest

2) Camera connection issue (See

above)

3) MIO Device test current dip

switches are enabled

1) Verify proper camera and ROI

selection on the MIO Utility’s Script

Commands tab

2) Verify camera connection on the MIO

Utility’s Camera Settings tab

3) Move dip switches 3 and 4 on the

MIO device to the OFF position

Page 33

MoviTHERM MIO-AX8-1 Manual

MoviTHERM – Advanced Thermography Solutions| 15540 Rockfield Blvd., Suite C110, Irvine, CA, USA| www.movitherm.com

30

MIO Setup Issue

Possible Causes

Recommended Action

Unable to log in to the

MIO Device

Configuration Utility

1) No Ethernet Connection to MIO

Device

2) Incorrect IP Address

3) Incorrect Password

4) Hardware Malfunction

1) Check Ethernet cables, switches, etc.

2) Reset IP address to Default (Recovery

Mode)

3) Reset Access Password

(Recovery Mode)

4) Cycle power. (Replace if defective.)

Unable to access

Camera Configuration

items in the Script

Commands tab

1) No Ethernet Connection to the

camera

2) Camera (Region of Interest)

Configuration not complete

3) Camera (Region of Interest)

Configuration error

1) Check Ethernet cables, switches, etc.

2) Verify Regions are set correctly in the

AX8’s web application

3) Verify Regions are set correctly in the

AX8’s web application

Device is unresponsive

after firmware update

1) Updated firmware is invalid

2) MIO Device was interrupted

during update

3) Firmware binary file is

corrupted

1) Reboot the device in Recovery mode,

and try updating the firmware again.

2) If the device is still unresponsive, try

updating to a previous working

version of the firmware.

3) Contact MoviTHERM support.

Output Issue

Possible Causes

Recommended Action

Digital Output voltage

when off is too high

The attached load’s resistance is

too high

Install a pull down resistor in parallel with

the load

Page 34

MoviTHERM MIO-AX8-1 Manual

MoviTHERM – Advanced Thermography Solutions| 15540 Rockfield Blvd., Suite C110, Irvine, CA, USA| www.movitherm.com

31

9 Appendix A: Default Settings

Default Device Name: “MIO- AX8-1”

Default Password: password

Default Device IP Address: 192.168.1.2

Default Subnet Mask: 255.255.255.0

10 Appendix B: Technical Specifications

10.1 Absolute Maximum Ratings

Parameter

Min

Typ

Max

Unit

Vin – Input Power Voltage Range

10

24

30

VDC

Pin – Input Power

-

1.5 3 W

Vd_in – Digital Voltage In

9

24

30

VDC

Id_out – Digital

Current

Single Channel

- - 0.5 A All Channels

- - 1.0

A

Digital inductive load switch-off

energy dissipation

- - 0.5

J

Operating Temperature

0 - 50

°C

Storage Temperature

-30 - 85

°C

10.2 Operating Specifications

Parameter

Min

Typ

Max

Unit

Output Current Error

vs Temperature (-30°C to 85°C)

±0.3

±98

±0.5

±170 % ppm/°C

Analog Current Output Resolution

16 Bits

Digital Output On-State Resistance

0.16

0.4

Ω

Loading...

Loading...