Page 1

Installation

Manual

D-Series

Page 2

© 2018 FLIR Systems, Inc. All rights reserved worldwide. No parts of thi s manual, in whole or in part, may be copied,

photocopied, translated, or transmitted to any electronic medium or machine readable form without the prior written

permission of FLIR Systems, Inc.

Names and marks appearing on the products herein are either registered trademarks or trademarks of FLIR Systems,

Inc. and/or its subsidiaries. All other trademarks, trade names, or company names referenced herein are used for

identification only and are the property of their respective owners.

This product is protected by patents, design patents, patents pending, or design patents pending.

The contents of this document are subject to change without notice.

FLIR Systems, Inc.

6769 Hollister Avenue

Goleta, CA 93117

Support: https://www.flir.com/support-center/support-hq/

Important Instructions and Notices to the User:

Modification of this device without the express authorization of FLIR Commercial Systems, Inc. may void the user’s

authority under FCC rules to operate this device.

Note 1: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to

Part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio communications. However,

there is no guarantee that the interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna;

• Increase the separation between the equipment and receiver;

• Connect the equipment into an outlet on a circuit different from that of the receiver; and/or

• Consult the dealer or an experienced radio/television technician for help.

Note 2: This equipment was tested for compliance with the FCC limits for a Class B digital device using a shielded

cable for connecting the equipment to an analog video output to a monitor and using a shielded USB cable for

connecting the equipment to a personal computer. When making such connections, shielded cables must be used

with this equipment.

Industry Canada Notice:

This Class B digital apparatus complies with Canadian ICES-003.

Avis d’Industrie Canada:

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

Proper Disposal of Electrical and Electronic Equipment (EEE)

The European Union (EU) has enacted Waste Electrical and Electronic Equipment Directive 2002/96/EC (WEEE),

which aims to prevent EEE was te fr om ar ising; to en courag e reu se, rec ycli ng, and reco very of EEE w aste ; and to

promote environmental responsibility.

In accordance with these regulations, all EEE products labeled with the “crossed out wheeled bin” either on the

product itself or in the product literature must no t be d ispo sed of i n reg ular ru bbis h bin s, mi xed wit h regul ar

household or other commercial waste, or by other regular municipal waste collection means.

with the product) should be responsibly discarded or recycled.

To identify a responsible disposal method where you live, please contact your local waste collection or recycling service, your

original place of purchase or product supplier, or the responsible government authority in your area. Business users should contact

their supplier or refer to their purchase contract.

to prevent possible harm to the environment or human health, all EEE products (including any cables that came

Instead, and in order

427-9030-01-12 Version 140 March 2018 2

Page 3

Contents

Contents

D-Series Camera Installation

1.1 Warnings and Cautions .................................................................................................. 4

1.2 References .................................................................................................................... 4

1.3 Camera Overview .......................................................................................................... 5

1.4 Installation Overview ......................................................................................................5

1.5 Camera Connection Options ......................................................................................... 6

1.5.1 Supplied Components .......................................................................................... 6

1.5.2 Required Supplies ................................................................................................6

1.5.3 Bench Testing ....................................................................................................... 6

1.6 Location Considerations ................................................................................................7

1.6.1 Prior to Cutting/Drilling Holes ................................................................................8

1.7 Camera Mounting ..........................................................................................................8

1.8 Camera Connections ..................................................................................................... 9

1.8.1 Connecting Power ................................................................................................ 9

1.8.2 Camera Grounding ............................................................................................. 10

1.8.3 Analog Video Connections .................................................................................. 10

1.8.4 Ethernet ..............................................................................................................10

1.8.5 Serial Connection ............................................................................................... 10

1.9 D-Series Camera Specifications .................................................................................. 11

Basic Operation and Configuration

2.1 IP Camera, ONVIF Profile S Compliant ........................................................................ 13

2.1.1 Serial and/or IP Communications ........................................................................ 13

2.1.2 Server Configuration ........................................................................................... 13

2.2 Camera Bench Test ..................................................................................................... 13

2.2.1 Set IP Address using the FLIR Discovery Network Assistant (DNA) ................... 14

2.3 Log into the Camera Web Page ................................................................................... 15

2.3.1 Live Video Page .................................................................................................. 16

2.3.2 Camera Control and Status ................................................................................. 17

2.3.3 Web Control Panel ..............................................................................................17

2.4 Camera Configuration .................................................................................................. 19

2.4.1 Expert and Admin Accounts ................................................................................ 19

2.4.2 Setup Menu ........................................................................................................19

2.4.3 Maintenance Menu ............................................................................................. 24

2.5 Thermal Imaging Overview ..........................................................................................38

2.6 Troubleshooting Tips ...................................................................................................39

427-9030-01-12, Version 140 March 2018 3

Page 4

1 D-Series Camera Installation

The D-Series Camera is a multi-sensor camera system on a pan/tilt platform. The system combines an

infrared thermal imaging camera and a visible-light video camera, and is intended for outdoor

installations.

This manual describes the installation of the D-Series cameras. If help is needed during the installation

process, please refer to https://www.flir.com/support-center/support-hq/ for support. All installers and

integrators are encouraged to take advantage of the training offered by FLIR; visit

https://www.flir.com/support-center/training/ for more information.

This manual includes the following topics:

• Installation overview

• Mounting the camera and its components

• Connecting the electronics

• Bench testing the camera

• Basic configuration and operation of the camera

• Camera Specifications

For safety, and to achieve the highest levels of performance from the D-Series camera system, always

follow the warnings and cautions in this manual when handling and operating the camera.

1.1 Warnings and Cautions

Warning!

If mounting the D-Series camera on a pole, tower or any elevated location, use industry standard safe

practices to avoid injuries.

Caution!

Except as described in this manual, do not open the D-Series camera for any reason. Damage to the

camera can occur as the result of careless handling or electrostatic discharge (ESD). Always handle

the camera with care to avoid damage to electrostatic-sensitive components.

Prior to making any connections, ensure the power supply or circuit breaker is switched off.

Be careful not to leave fingerprints on the D-Series camera’s infrared optics.

Operating the camera outside of the specified input voltage range or the specified operating

temperature range can cause permanent damage.

Be sure to use a water-tight enclosure for the pigtail connections (rated IP 67 or higher).

1.2 References

D-SERIES Interface Control Drawing (ICD) (FLIR Doc # 427-9XXX-XX-19)

Available from the FLIR website, provides further details regarding mechanical dimensions and

mounting for the D-Series camera.

427-9030-01-12, Version 140 March 2018 4

Page 5

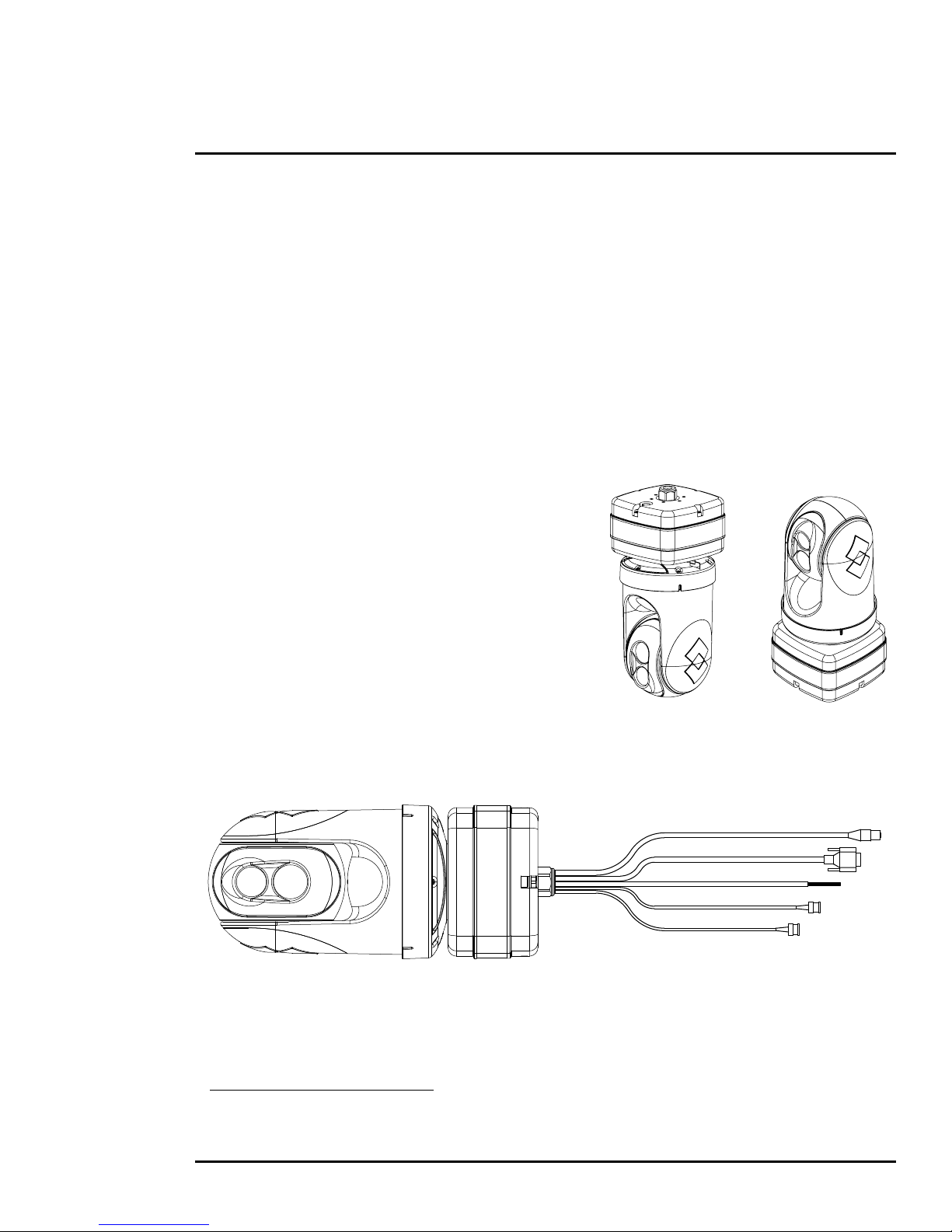

1 D-Series Camera Installation

Figure 1-1: Pigtail Cable Assembly

1.3 Camera Overview

The D-Series camera is both an analog and an IP camera. The video from the camera can be viewed

over a traditional analog video network or it can be viewed by streaming it over an IP network using

MPEG-4, M-JPEG, and H.264 encoding. Analog video will require a connection to a video monitor or

an analog matrix/switch. The IP video will require a connection to an Ethernet network switch and a

computer with the appropriate software for viewing the video stream.

1.4 Installation Overview

The D-Series Camera is a multi-sensor thermal imaging camera system intended for outdoor security

applications. The system has a pan/tilt gimbal assembly with a dual payload that includes:

• An uncooled thermal imaging camera with fixed Field of View (FOV)

• A daylight camera with continuous zoom

It is shipped from the factory in one of two configurations,

either ball up

1

or ball down, depending on the model

number ordered. The D-Series camera is intended to be

mounted on a heavy-duty fixed pedestal or wall mount

commonly used in the security industry. The camera

mount must support at least 11.4 kg (25 lbs).

The camera can be attached to the mount with a single

1.5” NPT stainless steel threaded coupler which is

supplied with the camera. Optionally the camera can also

be mounted to a surface with M5 fasteners (quantity 6).

The electrical connections can be made with a short pigtail

cable assembly which exits the base of the camera. The

camera will typically be mounted (either directly or via a

short coupler) to a water-tight enclosure for the pigtail

connections. In order to install the camera, it is not

necessary to open the camera’s electronics enclosure.

The pigtail connectors range in length from 300 mm (11.8 in) minimum to 450 mm (17.7 in) maximum.

1. A camera mounted in the ball up position has a limited range of downward tilt. The range of

tilt motion is 25° to -90° when ball down, -25° to 90° when ball up.

427-9030-01-12 Version 140 March 2018 5

Page 6

1 D-Series Camera Installation

1.5 Camera Connection Options

The camera can be powered with a conventional 24 Vac/Vd c powe r supply:

21 Vac to 30 Vac, or

21 Vdc to 30 Vdc.

The D-Series Camera produces analog or digital (IP) video output (or both). Analog video will require

at least one connection to a video monitor or an analog video matrix switch. In most analog

installations, two video connections will be used—one for the thermal camera video, and one for the

daylight camera video. The camera pigtail provides two BNC connectors for these video channels.

An Ethernet connection is provided for IP video streaming and for command and control

communications (pan/tilt/zoom/etc.). A PC or laptop with a web browser is also required for camera

configuration and maintenance (software/firmware updates).

For analog installations that are not using Ethernet/IP, a serial cable (RS232 or RS422) can optionally

be connected and used for command and control communications, supporting either Pelco D or Bosch

protocols. In installations using analog video and serial communications, it is recommended an

Ethernet cable is installed for camera configuration and troubleshooting using a PC with a web

browser.

For installations where the camera is mounted on a tower or pole or other location that may be difficult

to access, it is recommended the Ethernet connection should be installed from the camera down to

ground level at a minimum, to allow easier access.

1.5.1 Supplied Components

The D-Series camera package includes these standard components:

• Multi-sensor Pan/Tilt Camera Gimbal Assembly

• Stainless Steel threaded coupler (1.5” OD)

• Power connectors (qty 3)

• Ethernet coupler (RJ-45 jacks at each end)

Accessories are available from FLIR Systems, Inc. Contact your FLIR Dealer or integrator for up-todate information.

1.5.2 Required Supplies

The installer will supply the following items, as needed (specific to the installation).

• Water-tight enclosure for the connections

• 24 Vac or 24 Vdc power supply

• Power cable for system power; 3-conductor, shielded, gauge determined by cable length and

supply voltage

• Cat5e Ethernet cable for digital video and/or communications

• Coaxial RG59U cables for analog video (up to 2, with BNC male connector at the camera end)

• Serial cable for serial communications

• Camera grounding strap, camera mount, miscellaneous connectors and tools

1.5.3 Bench Testing

Connect the power, video, serial, and Ethernet connections and confirm that the video is displayed on

a monitor when the power is turned on. Confirm the camera can be controlled by moving it (pan/tilt).

Refer to

427-9030-01-12 Version 140 March 2018 6

Basic Operation and Configuration, pg. 13.

Page 7

1 D-Series Camera Installation

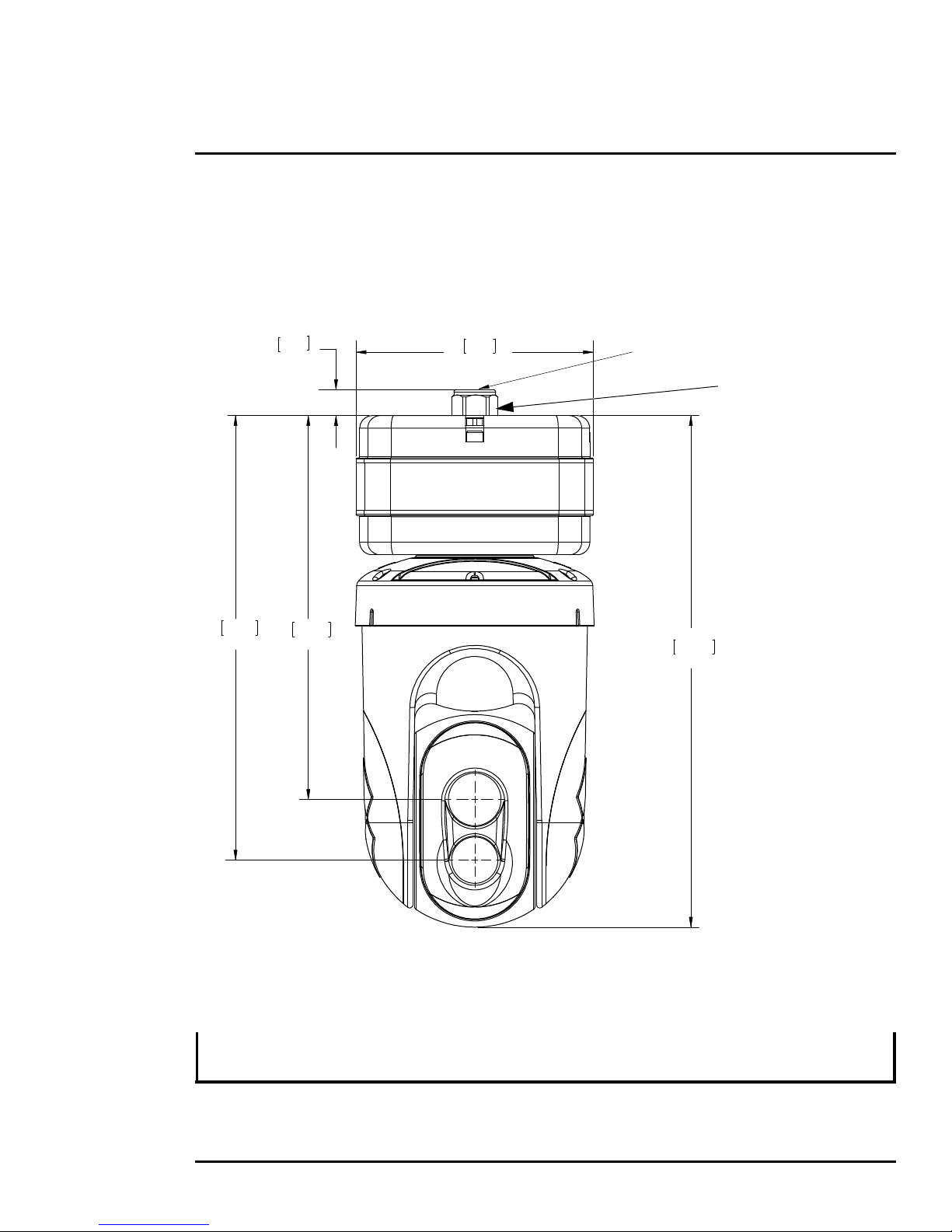

7.38

187.5

15.92

404.4

0.81

20.6

11.94

303.4

13.83

351.4

Cables (not shown)

exit at center of base

All dimensions are

in mm and (inches)

Cable Gland

Do not loosen

or remove

1.6 Location Considerations

The camera will require connections for power, video and communications. Ensure that cable

distances do not exceed the specifications and that cables adhere to all local and industry standards,

codes, and best practices. The D-Series camera should be mounted upright (ball up) or upside down

(ball down), depending on the model ordered. The camera should be mounted such that the FLIR logo

on the side of the camera is right-side up and readable.

A ball-up camera model can be mounted on top of the mounting surface. A ball-down camera model

can be mounted under an overhanging mounting arm, or underneath an overhanging mounting

surface such as eaves or an awning.

Note

If the camera is to be mounted on a pole or tower or other hard-to-reach location, connect and operate

the camera as a bench test at ground level prior to mounting the camera in its final location.

427-9030-01-12 Version 140 March 2018 7

Page 8

1 D-Series Camera Installation

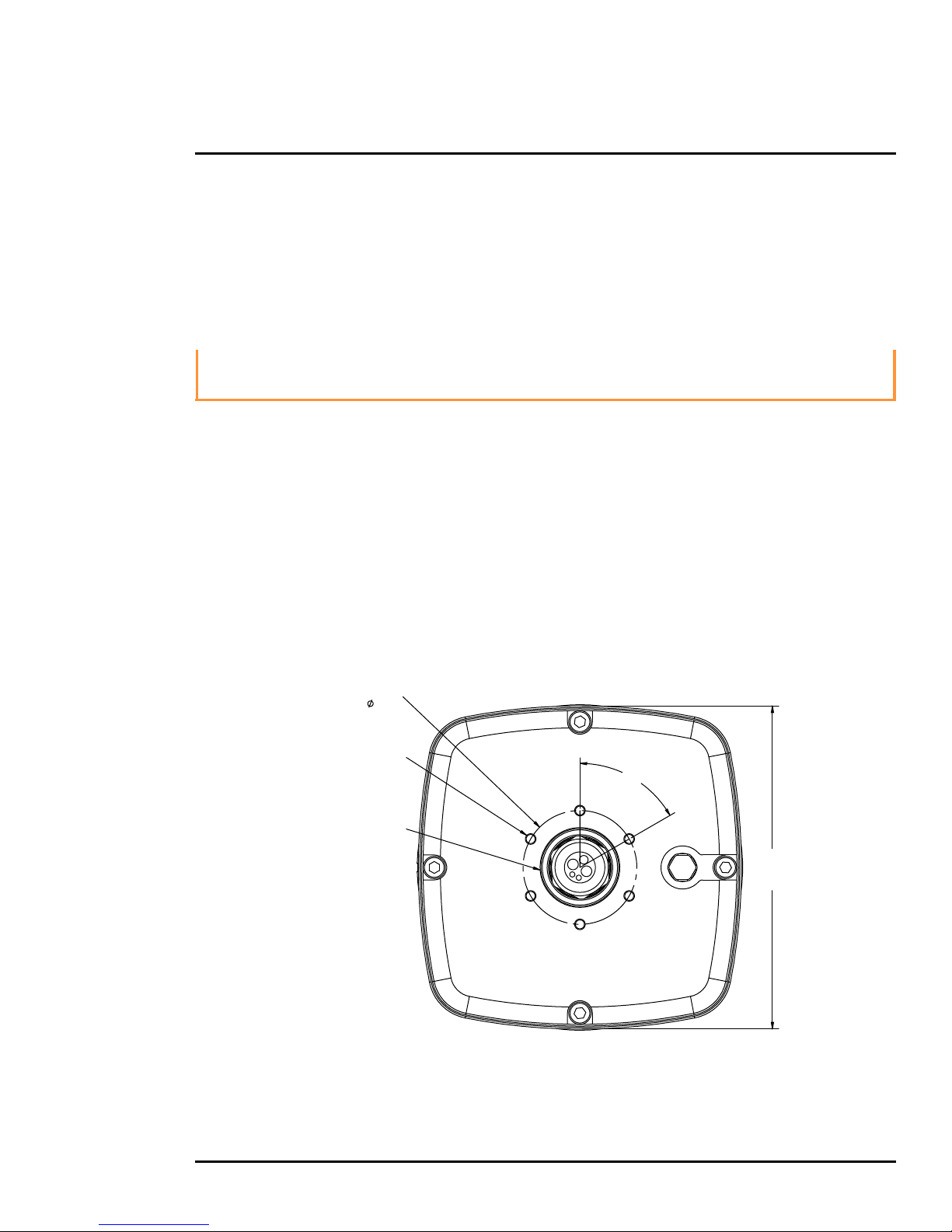

Figure 1-2: D-Series Camera Bottom Mounting Holes

(7.38)

187.5

square

(2.598)

66.00

bolt circle

60.0°

6X M5 X 0.8

equal spacing

10 mm (0.394 in.) max

fastener engagement

1-1/2 NPT

All dimensions are

in mm and (inches)

1.6.1 Prior to Cutting/Drilling Holes

When selecting a mounting location for the D-Series camera, consider cable lengths and cable routing.

Ensure the cables are long enough, given the proposed mounting locations and cable routing

requirements, and route the cables before you install the components.

Use cables that have sufficient dimensions to ensure safety (for power cables) and adequate signal

strength (for video and communications).

Caution!

There is no need to open the electronics enclosure. All settings and adjustments are done through

software. There are no user-serviceable parts inside the camera enclosure.

1.7 Camera Mounting

The camera mount must nominally be rated to support at least 11.4 kg (25 lbs). For some installations,

the mount must support even greater weights. Use a mount which will provide adequate support in

adverse weather and environmental conditions. The D-Series camera can be secured to the mount

two ways:

• 1.5 in. NPT threaded coupler

Intended for rigid mounting with the supplied NPT stainless steel coupler, or equivalent.

Use PTFE pipe seal tape or equivalent on the coupler.

• M5 x 0.8 fasteners (quantity 6)

If using four M5 x 0.8 fasteners, the maximum depth of the fastener should not exceed 10.0 mm

(0.394 in). Use Loctite 222 low strength threadlocker for the M5 fasteners.

Refer to the ICD for additional information (FLIR Doc. # 427-9XXX-XX-19).

427-9030-01-12 Version 140 March 2018 8

Page 9

1 D-Series Camera Installation

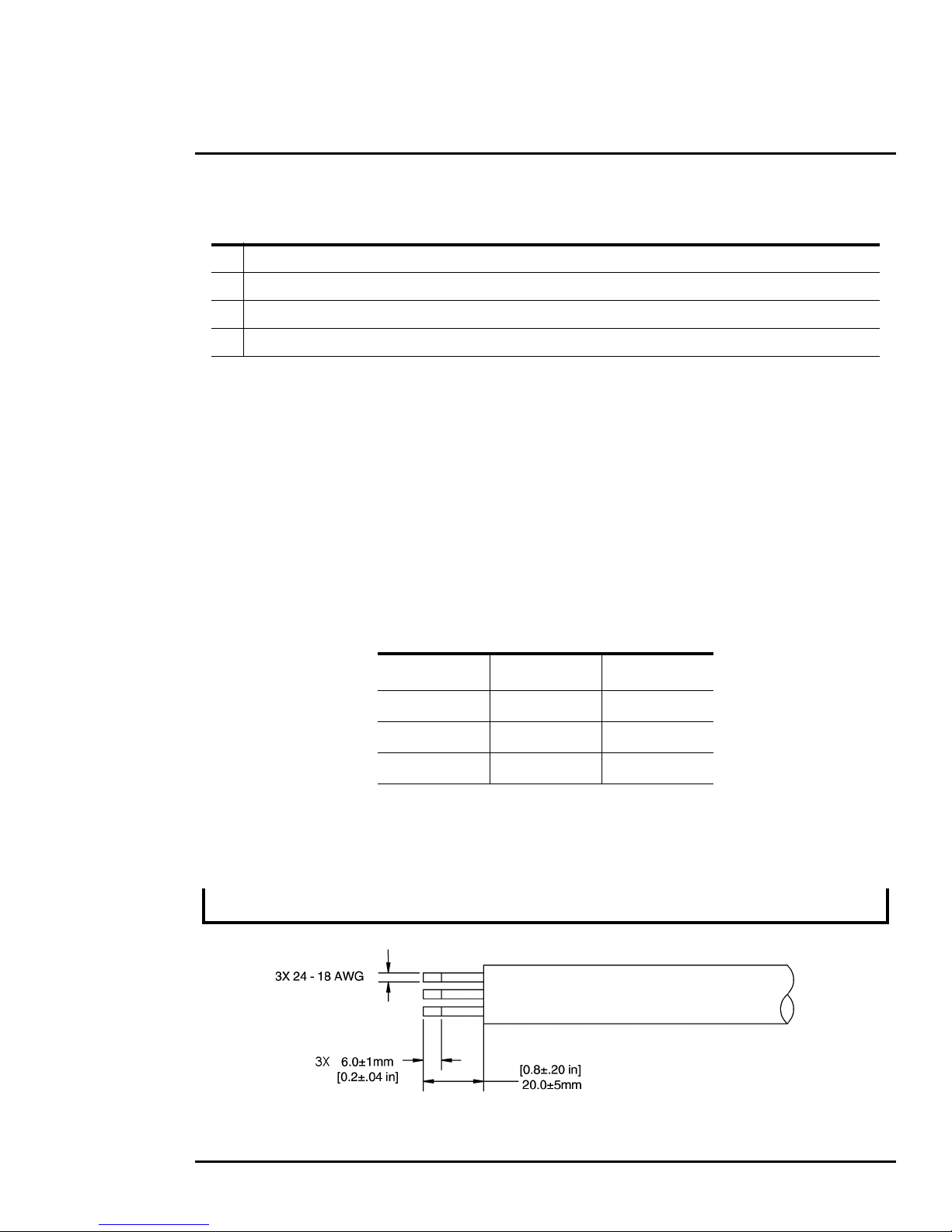

Figure 1-3: Power Cable (3 conductor)

1 M5 bolt circle diameter 66 mm (2.598 in)

2 6X M5 X 0.8 fasteners, equally spaced at 60°; maximum fastener engagement 10 mm (.394 in)

3 1-1/2 in NPT threaded opening

4 Do not loosen or remove the cable gland nut; doing so could result in damage to the camera unit

Select a water-tight enclosure for the connections that allows adequate space for the cable

connections. This requirement may vary, depending on the installation. Do not exceed the bend radius

per the recommendation of the cable manufacturer. The typical cable bend radius is 50 mm to 75 mm

(2-3 in).

1.8 Camera Connections

Do not disassemble the camera, as it will void the camera warranty and could lead to damage if the

camera is not resealed properly.

Tabl e 1-1: Mounting Specifications

1.8.1 Connecting Power

The camera can be powered with a conventional AC or DC power supply. Prior to making any

connections, ensure the power supply or circuit breaker is switched off.

Tabl e 1-2: Power Connections

Wire Color Vac Vdc

Red Line DC +

Black Neutral DC -

Clear Chassis Chassis

The power cable supplied by the installer must use wires that are sufficient size gauge for the supply

voltage and length of the cable run, to ensure adequate current carrying capacity (for most installations

18 AWG is recommended). Always follow local building/safety codes.

Note

The supplied connectors for the power connections will accept 16 AWG to 24 AWG wire size.

427-9030-01-12 Version 140 March 2018 9

Page 10

1 D-Series Camera Installation

The camera itself does not have an on/off switch. Generally the D-Series camera may be connected to

a circuit breaker and the circuit breaker will be used to apply or remove power to the camera. If power

is supplied to it, the camera will be powered on and operating.

1.8.2 Camera Grounding

Ensure the camera is properly grounded. Failure to properly ground the camera can lead to permanent

damage to the camera. Typical to good grounding practices, the camera chassis ground should be

connected to the lowest resistance path possible.

Grounding of the camera is accomplished by terminating the ground wire (clear wire of the power

cable pigtail). Additional grounding can be accomplished by connecting a grounding strap to one of the

6X bolt locations on the unit's mounting surface, with the other end connected to the nearest earthgrounding point.

1.8.3 Analog Video Connections

The analog video connections from the camera use female BNC connectors. The video cable supplied

by the installer should be rated as RG-59/U or better to ensure a quality video signal and should be

terminated with male BNC connectors.

1.8.4 Ethernet

The Ethernet pigtail cable is terminated with an RJ-45 plug. Connect the supplied Ethernet coupler to

the pigtail cable, then connect a shielded cat5e/6 Ethernet cable to the other end of the Ethernet

coupler. Connect the far end of the Ethernet cable to a network switch.

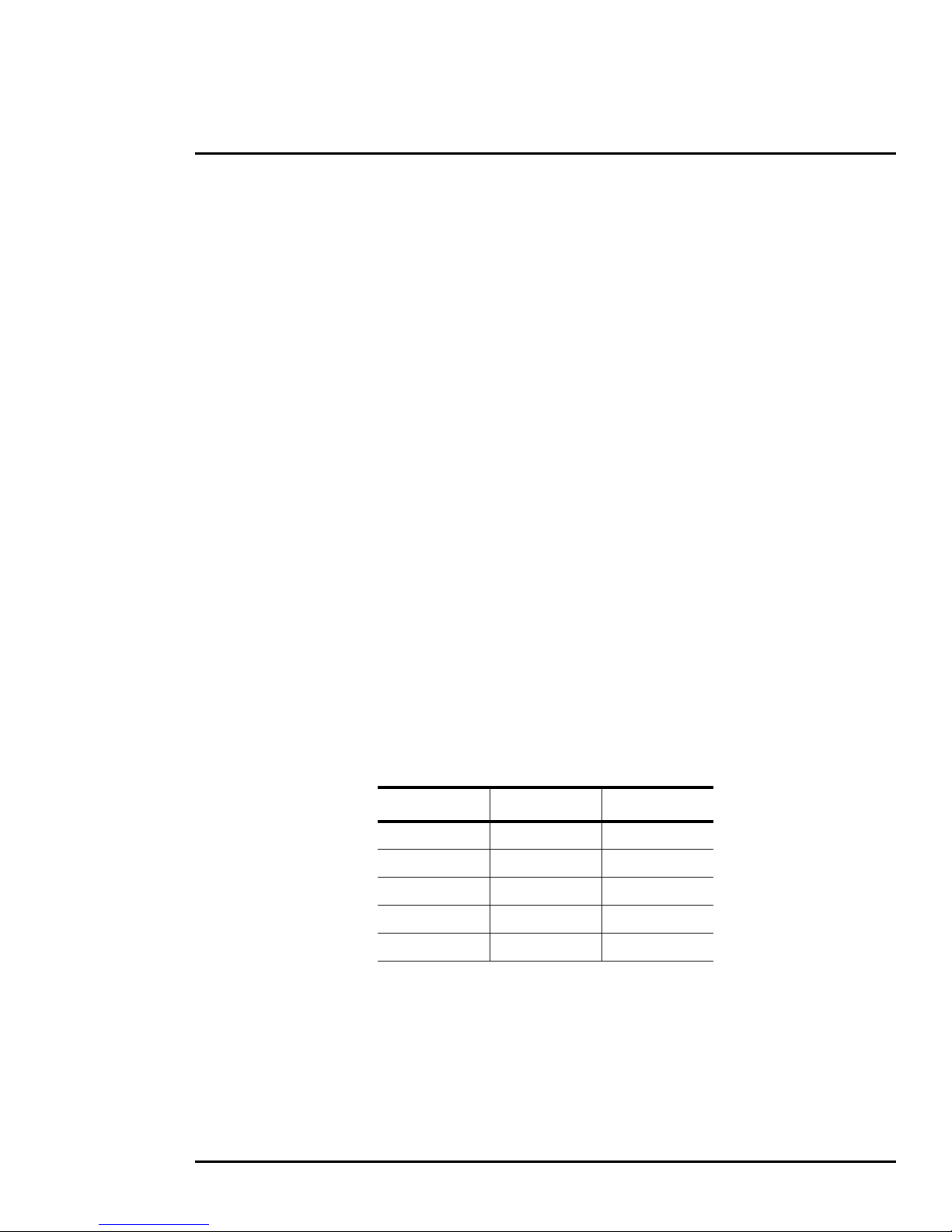

1.8.5 Serial Connection

By default, the serial interface uses the Pelco D protocol, RS-422 standard, 9600 baud rate (8/none/1),

and address 1. The pigtail serial connection provides a female DB9 connector. The pinouts are as

follows:

Tabl e 1-3: Serial Connector

Signal DB9F Pin Color wire

TxA 2 Green

TxB 7 White

RxA 8 Black

RxB 3 Red

Ground 4 Brown

427-9030-01-12 Version 140 March 2018 10

Page 11

1 D-Series Camera Installation

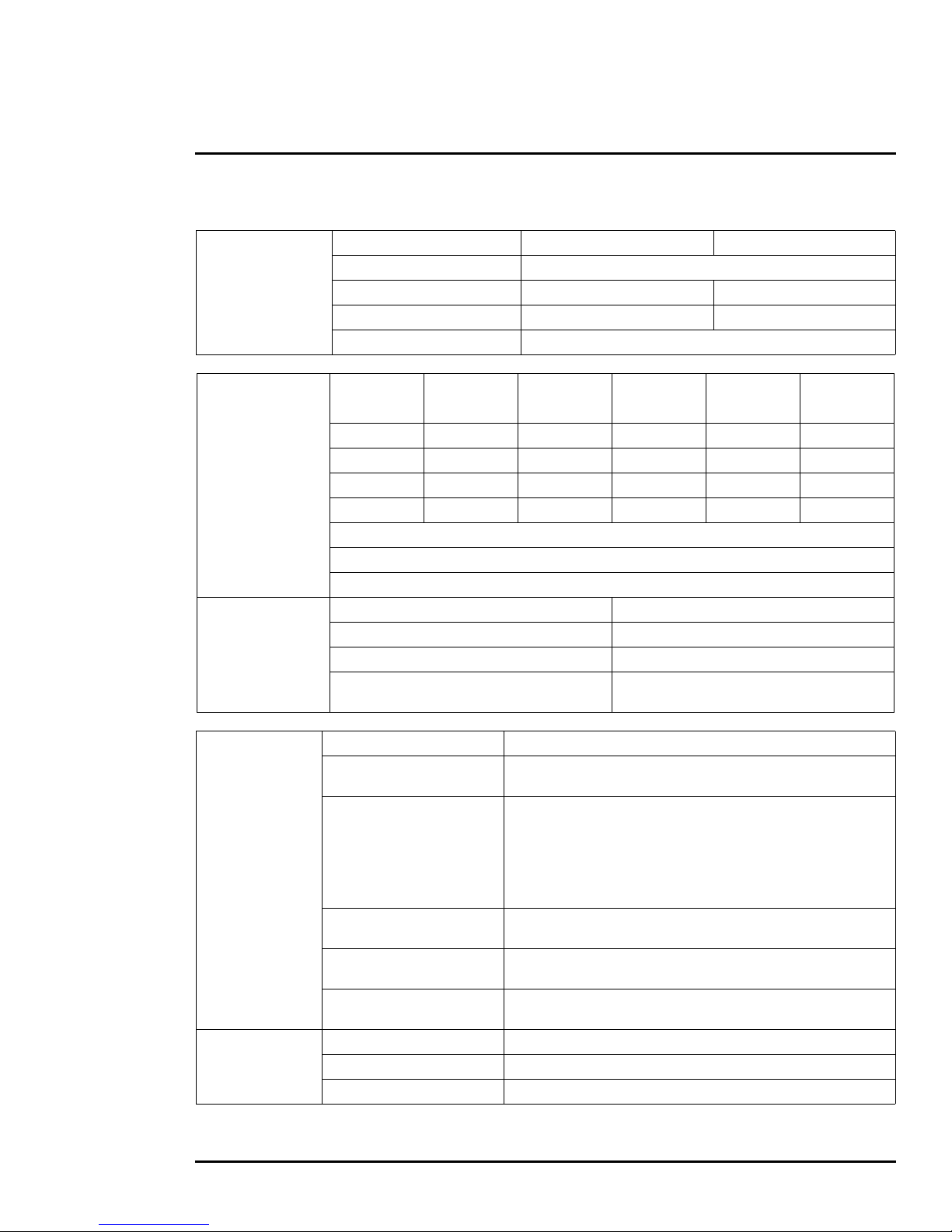

1.9 D-Series Camera Specifications

Array Format 320 × 240 640 × 480

Detector Type Long-Life, Uncooled VOx Microbolometer

Thermal Camera

Specifications

Effective Resolution 76,800 307,200

Pixel Pitch 25 µm 17 µm

Thermal Frame Rate NTSC: 30 Hz or 7.5 Hz or PAL: 25 Hz or 8.33 Hz

Optical

Characteristics

Visible Camera

Specifications

Video

Model FOV

D-348 48° × 39° 9 mm D-645 45° × 37° 13 mm

D-334 34° × 28° 13 mm D-625 25° × 20° 25 mm

D-324 24° × 19° 19 mm D-618 18° × 14° 35 mm

D-313 13° × 10° 35 mm

Zoom 2× & 4x E-zoom

Spectral Range 7.5 μm to 13.5 μm

Focus Range Athermalized, Focus-Free

Detector Type 1/4” Exview HAD CCD

Effective resolution 380,000 (NTSC), 444,000 (PAL)

Field Of View Field of view: 57.8° (H) to 1.7° (H)

Lens

Composite Video NTSC or PAL Standard

Video Compression

Focal

Length

Two independent channels of streaming MPEG-4, H.264, or

M-JPEG; for each camera.

Model FOV

3.4 mm (wide) to 122.4 mm (narrow),

F1.6 to F4.5

NTSC:

D1 (720 × 480), 4SIF (704 × 480), VGA (640 × 480),

Strea mi ng Resol ution

SIF (352 ×240), QVGA (320 × 240)

PAL :

D1 (720 ×576), 4CIF (704 × 576), VGA (640 × 480),

CIF (352 × 288), QVGA (320 × 240)

Focal

Length

System

Integration

427-9030-01-12 Version 140 March 2018 11

Thermal AGC Modes

Thermal AGC Region of

Interest (ROI)

Image Uniformity

Optimization

Ethernet Ye s

Serial Control Interfaces RS-232/-422; Pelco D, Bosch

External Analytics Compatible Ye s

Preset AGC modes and manual Brightness (ITT Mean), Contrast

(Max Gain), Sharpness (DDE Gain), and AGC Filter controls.

Default Presets and User definable to insure optimal image quality for

subjects of interest

Automatic Flat Field Correction (FFC) - Thermal and Temporal

Tr i g g e r s

Page 12

1 D-Series Camera Installation

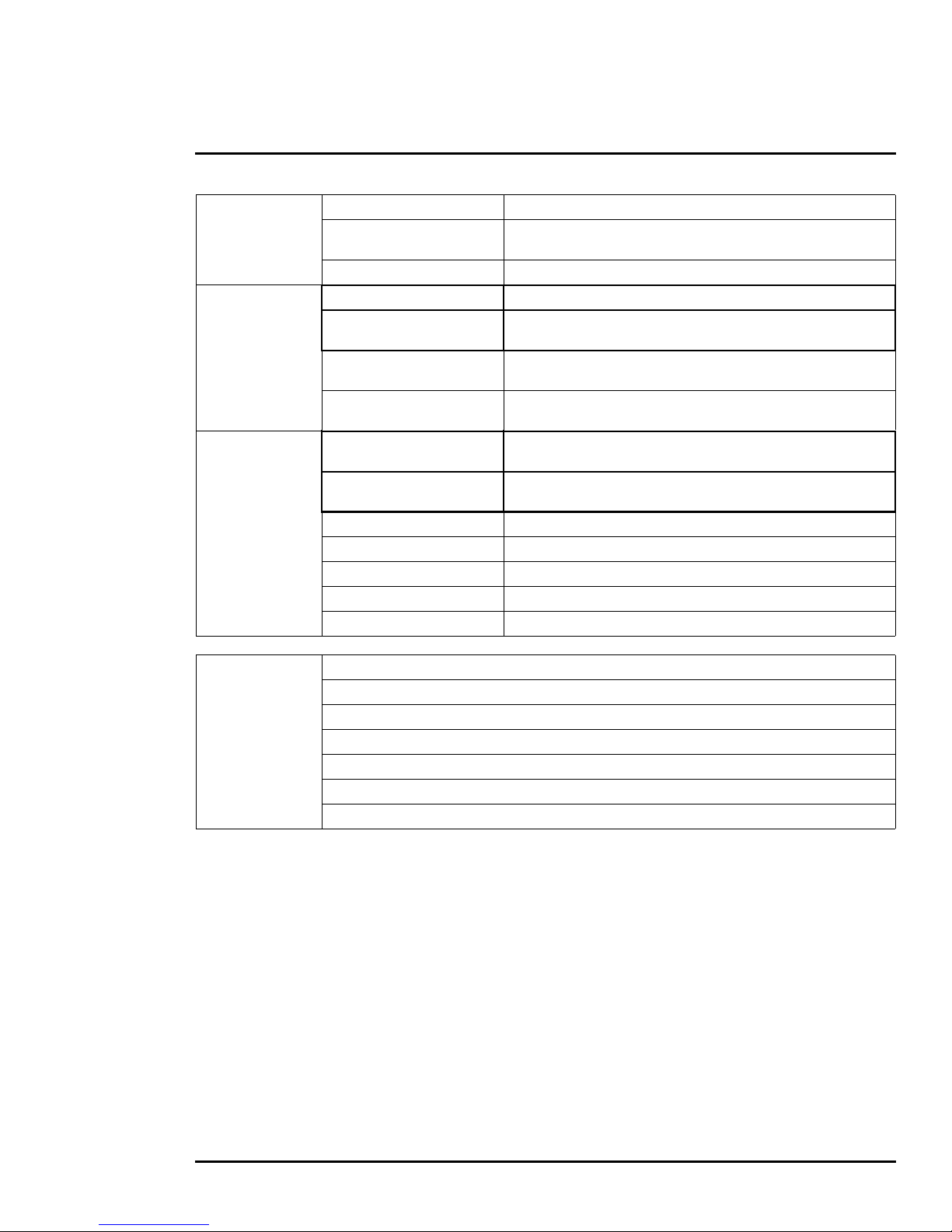

Pan Angle/Speed Continuous 360°; 0.5° to 60°/sec

Pan/Tilt

General

Environmental

Tilt Angle/Speed

Programmable presets 128

Weight 18.2 lb (8.3 kg)

Dimensions (L,W,H)

Input Voltage

Power Consumption

IP rating (dust and water

ingress)

Operating temperature range

Storage Temperature Range -55 °C to 85 °C

Humidity 0-95% relative

Shock MIL-STD-810F Transportation

Vibe IEC 60068-2-27

De-Icing / Anti-Icing MIL-STD-810F, Method 521.1

Tilt from horizontal: 25° to -90° when ball down,

-25° to 90° when ball up/0.5° to 30°/sec

8” x 8” x 17" (Nominal)

(203mm x 203mm x 432mm)

24 Vac (21-30 Vac)

24 Vdc (21-30 Vdc)

Maximum power at 24 Vdc = 75 W

Maximum power at 24 Vac = 85 VA

IP56

-25 °C to 70 °C (-13 °F to 158 °F)

-25 °C to 58 °C (-13 °F to 136 °F) black finish

Compliance &

Certifications

EN 61000-6-4: 2007 Class A/CISPR 22: 2005 Class A

EN 61000-3-3: 1995+A1:2001+A2:2005

EN 61000-3-2: 2006

EN 50130-4: 1996+A1:1998+A2:2003

FCC Part 15, Subpart B, Class A

IP 66 (IEC 60529)

IEC 60068-2-27)

427-9030-01-12 Version 140 March 2018 12

Page 13

2 Basic Operation and Configuration

This chapter provides basic information on how to operate the D-Series camera. A bench test can be

used to verify camera operation before the camera is configured for the local network. This chapter

also provides general configuration information.

2.1 IP Camera, ONVIF Profile S Compliant

When the camera is connected to the network it functions as a server; providing services such as

camera control, video streaming, network communications, and geo-referencing capabilities. The

communications protocol used is an open, standards-based protocol that allows the server to

communicate with a video management client, such as FLIR Latitude or with a third-party VMS client,

including systems that are compatible with ONVIF Profile S. These clients can be used to control the

camera and stream video during day-to-day operations. Refer to the individual product web page at

https://www.flir.com/browse/security/thermal-security-cameras/ for a listing of supported VMS clients.

2.1.1 Serial and/or IP Communications

For a camera that is installed in a legacy-type CCTV network using analog video, the camera may

commonly be controlled with serial communications. The serial cable from the camera will be

connected to a keyboard/joystick device, or to a video switch, encoder, or DVR that has a serial

communication port. In this case the installer may want to configure parameters such as the address of

the camera, the baud rate, and so on. These parameters can be set through software using a web

browser. The parameters can also be set using DIP switches when IP communications are not used.

2.1.2 Server Configuration

It may be necessary for the installer to make a limited number of configuration changes to the camera

server, such as setting the IP communication parameters, setting new login passwords, as well as

some scene specific parameters. For example, each camera comes from the factory with the same

default IP address, so adding more than one camera to an IP network requires each camera to be

configured with a different IP address. On the other hand, many of the configuration parameters will

remain unchanged from the factory default settings.

2.2 Camera Bench Test

Since the camera offers both analog video and IP video, it is recommended that the installer test the

camera using the same type of connections as the final installation. If using analog video and serial

communications in the final installation, also test the IP communications when performing the bench

test. If any image adjustments are necessary, they can be done using a web browser over the IP

connection, and saved as power-on default settings.

Test serial communications by connecting a serial device such as a keyboard and confirm the camera

is responding to serial commands. It may be necessary to configure the serial device interface to

operate with the camera.

Once the camera is connected to a network and powered on, set camera network parameters using

the FLIR Discovery Network Assistant (DNA) software, perform a bench test by using a web browser to

view the video and control the camera, or view video in the local Network Video Management System

(for example, FLIR Latitude

require a license to use and is a free download from the individual product web page at:

https://www.flir.com/browse/security/thermal-security-cameras/.

tm

). The FLIR Discovery Network Assistant (DNA) software does not

427-9030-01-12, Version 140 March 2018 13

Page 14

2 Basic Operation and Configuration

Online manual

Select a filter

Click to sort

Select Assign IP

Right-click

2.2.1 Set IP Address using the FLIR Discovery Network Assistant (DNA)

The D-Series camera is shipped with a static IP address: 192.168.250.116. Assuming the existing

network uses IP addresses that are unique and different than the default address on the camera,

configuring the camera for IP communications generally involves the following steps:

Step 1 Connect the Ethernet port of the camera to the existing IP camera network.

Step 2 Connect a PC or laptop to the same network.

Step 3 From the PC connected to the camera network, use the DNA utility to discover and display

the camera’s current IP address.

a Download the DNA utility.

b Unzip the utility, then double-click to run the executable file ( DNA.exe). All the units on

the VLAN are discovered.

c For additional instructions on using DNA, refer to the DNA User’s Manual available in the

Help (

) link while the software is running.

Step 4 Select Assign IP to change the IP

address or to set IP addressing to DHCP.

Step 5 Double-click the camera in DNA’s

Discovery List to open the camera’s web

server Login page in Internet Explorer or

point your web browser to the camera’s IP

address.

Step 6 Using a web browser, configure the camera

settings, such as camera date/time, and

other parameters, so the camera is

compatible with the existing network.

427-9030-01-12 Version 140 March 2018 14

Page 15

2 Basic Operation and Configuration

Figure 2-1: Camera Web Page Login Screen

2.3 Log into the Camera Web Page

Use a web browser to connect to the camera’s web server using one of three User Names: user,

expert, or admin (the default passwords are user, expert, and admin respectively). The user login

can be used to do the initial bench test of the camera. The expert login may be used to make

configuration changes such as setting the IP address and other server settings. The admin login has

access to all configuration, setup, and maintenance settings. The login passwords should be changed

(admin login required) to prevent unauthorized access. Two web sessions can be active at once. An

inactive session will be logged out after 20 minutes.

For information on how to change the passwords, refer to Server > Security Options, pg. 27.

Note

A VMS Remote to the camera, ONVIF or Nexus CGI, uses the same password as the web interface.

Refer to

Open a web browser and enter the camera IP address. The login screen with a picture of the camera

will appear. Enter user for the User Name and user for the Password, and click Log in.

Sensor > Communications > VMS Remote, pg. 32.

427-9030-01-12 Version 140 March 2018 15

Page 16

2 Basic Operation and Configuration

Figure 2-2: Live Video Web Page – user login

Toggle Time

2.3.1 Live Video Page

The Live Video page displays a live image from the camera on the left part of the screen. Along the

top of the screen are some menu choices, including Live Video (the red text indicates it is selected),

Help and Log out.

On the right side are some control buttons.

In the lower right corner of the web page there is a frame rate selector. This selector allows the user to

change the rate at which the frames are displayed in the browser from the default 8 fps up to 16 fps.

This controls the frame rate of the user’s own web browser only, and does not affect the video streams

to other users or to an NVR. If the live video is not displayed, refer to

Help

Troubleshooting Tips, pg. 39.

The Help menu displays software version information. If it is necessary to contact FLIR Technical

Support for assistance, it will be helpful to have the information from this page on hand.

Log out

Use this button to disconnect from the camera and stop the display of the video stream. If a web

session is inactive for 20 minutes, it will be stopped and it will be necessary to log in again.

Toggle PC/Camera time

Use this button to display either the PC time or the camera time.

427-9030-01-12 Version 140 March 2018 16

Page 17

2 Basic Operation and Configuration

Save snapshot

Video stream

or

Go to Preset position.

Refer to Surveillance > Scan List, pg. 23

Thermal Control Keypad Visible Control Keypad

2.3.2 Camera Control and Status

In the lower left of the screen are two indicator lights: Control and Status.

Initially the Control light is off, as in the image above, indicating the user is not

able to control the camera immediately. When multiple users are connected to

a camera, only one user at a time can issue commands to the camera. If

another user has control of the camera, the Control light is yellow.

A user is able to request control of the camera by clicking on the yellow or black

light, or simply by sending a command to the camera. After a short pause, the

Control light should turn green. Be patient, there may be a slight delay between

each command while the browser waits for a response from the camera.

If a command is sent to the camera when the user does not have control, the command will not be

executed, and it is necessary to send the command again once the light is green.

2.3.3 Web Control Panel

The control buttons on the right side of the page can control the camera. When the mouse cursor is

positioned over a button, a tool tip is displayed which explains the function of the button.

When the mouse is positioned over the video window, the video stream source is shown in the upper

left corner of the video image and a snapshot button is shown in the upper right corner of the video

image. The snapshot button will save an image as a .jpg file to the selected destination folder or as

determined by the web browser.

This same web interface is used with various FLIR thermal cameras, some of which have different

capabilities. As a result, different buttons in the control panel will appear for different FLIR cameras.

The functions of the buttons appearing for the D-Series cameras are described below:

Zoom In/Zoom Out

These buttons zoom the active camera (IR or daylight). On cameras with zoom

427-9030-01-12 Version 140 March 2018 17

lenses, digital zoom or E-Zoom extends the ability to zoom in, but at the expense of

resolution. Also, refer to

Sensor > Devices > IR > Zoom Slave, pg. 33.

Page 18

2 Basic Operation and Configuration

Toggle Video Source

This button causes the active video source to be switched between the thermal IR camera

and the daylight camera. Also, refer to

Toggle Polarity—IR only

This button changes the way various objects are displayed in the image, for example, with

hot objects displayed as white and cold objects as black, or vice versa.

Toggle Palette—IR only

This button causes the IR camera to cycle through different color palettes. Each of the

palettes presents the IR image using a different color scheme. Use the Toggle Polarity

button to invert the palette, for example, between white hot and black hot.

Perform IR NUC Calibration—IR only

Sensor > Devices > IR > Zoom Slave, pg. 33.

This button causes the camera to do a manual Non-Uniformity Correction (NUC) operation.

The D-Series camera, by default, does an automatic NUC calibration as required based on

changes in temperature.

Toggle Scene Preset—IR only

This button causes the IR camera to cycle through different image settings. The Scene

Presets cause the image brightness and contrast to adjust. Depending on the time of day,

weather, and other conditions, one Scene Preset may be preferable to the others.

Toggle Automatic Gain Control (AGC)

This button causes the camera to cycle through different AGC options that use a

combination of settings to produce different configurations that could improve the video

image for a given set of conditions.

Freeze Video

This button stops the video on a single frame. Click again to start the video.

Autofocus

This button causes the DLTV camera to toggle the autofocus mode. Clicking the button a

second time reinstates the autofocus mode and causes an autofocus operation.

Function

When the Function button is selected, the keypad changes to a

numeric keypad. A tool tip can be shown when a function has

been assigned to a number. Use the back (

return to the Control Panel.

427-9030-01-12 Version 140 March 2018 18

) arrow to

Page 19

2 Basic Operation and Configuration

Pan/Tilt Home

This button causes the camera to go to the Home position. To set a new Home position,

hold the button for approximately 3 seconds.

Go to Preset

The D-Series camera can have a set of predetermined pan/tilt locations, each of which is

known as a preset. For example, a preset may be set for each of the locations where

security surveillance is most needed, a gate, doorway, and other points of access.

When the Go to Preset button is selected,

the keypad changes to a numeric keypad.

To cause the camera to go to a predefined location

view (Preset) select a number.

Use the back ( ) arrow to return to the Control Panel.

2.4 Camera Configuration

The following procedures describe how to do the most common camera configuration steps, such as

setting the camera IP address and hostname and changing the user passwords. To make these

changes, it is necessary to log in using the admin account.

Note

In most installations, the only camera settings needed are available from the Live Video page

(using Scene Presets or Polarity). Use caution when modifying the camera settings described in

this section. Some settings may adversely affect the thermal image over time or may completely

disable the camera or the network interface.

2.4.1 Expert and Admin Accounts

When a user logs in as expert or admin, additional menus, Setup

and Maintenance are available. The Setup menu is used to make

advanced adjustments to the thermal camera, the daylight camera,

and the pan/tilt platform.

The basic camera configuration steps are accessed through the Maintenance > Server menu, using

the menus on the left side of the page. The LAN Settings, Services, and Security Options

selections are described below (

Server pages. The admin login provides access to all configuration options. The login passwords

should be changed (admin login required) to prevent unauthorized access.

2.4.2 Setup Menu

Maintenance Menu, pg. 24). The expert login has access to the

The Setup menu is used for GEO Settings, camera setup, and defining parameters for surveillance

zones.

When configuration changes are made with the web browser, the settings are saved to a configuration

file. It is a good idea to make a backup of the existing configuration file prior to making changes, and

another backup once the changes are finalized. If necessary the camera can be restored to its original

factory configuration or one of the saved configurations (refer to

427-9030-01-12 Version 140 March 2018 19

Files > Configuration, pg. 37).

Page 20

2 Basic Operation and Configuration

Camera Control

It is necessary to have control of the camera to make Setup changes. Changes made through the

Setup menu have an immediate effect (it is not necessary to stop and restart the server). To use these

settings at power up, it is necessary to save the changes.

Adjustments to the IR settings should only be made by someone who has expertise with thermal

cameras and a thorough understanding of how the various settings affect the image. In most

installations, the only camera settings needed are available from the Web Control panel on the Live

Video page (Scene Presets, Polarity, Palettes, and AGC). Haphazard changes can lead to image

problems including a complete loss of video.

427-9030-01-12 Version 140 March 2018 20

Page 21

2 Basic Operation and Configuration

IR > AGC ROI

The IR camera adjustments to the region of interest (ROI) determine what portion of the image is used

by the Automatic Gain Control (AGC) algorithm. By default all of the pixels in the image are

considered; in some cases it may provide an improved image if a portion of the image is excluded. For

example, the sky is generally very cold, so if the ROI excludes the sky it may add more contrast to the

rest of the image. A pull-down list offers some convenient options.

When Custom is selected, a handle is shown

in the center of the screen.

Drag the handle to set

the size of the ROI box.

Drag the ROI box over

the portion of the scene

that will control the AGC.

IR > AGC

The AGC parameters affect how the overall IR video image appears. Using the AGC button on the Live

Video page (refer to

Toggle Automatic Gain Control (AGC), pg. 18), toggle through five AGC algorithms.

The default algorithms are suitable for most installations, but each selection allows a combination of

further adjustments that may provide a more appealing image, depending on personal preferences. Be

aware that the settings that are optimal at one time may be less optimal a short time later, since

conditions such as weather and time of day affect the image and are constantly changing.

Experiment with different AGC parameters to find the settings that work best for the particular

installation. Select Save Settings button at the bottom of the page to keep the settings after a power

cycle or select the Factory Defaults button to return the settings to default values.

• Brightness (ITT Mean) setting determines the temperature that is at the middle of the 256

“shades of gray” produced by the AGC. Positive values allow more detail in hotter scenes, while

negative values allow more detail in lower temperature scenes.

427-9030-01-12 Version 140 March 2018 21

Page 22

2 Basic Operation and Configuration

To move the camera:

enter coordinates,

click Go to

Current camera

coordinates and

pan/tilt mode

• Contrast (Max Gain) can be used to increase contrast, especially for scenes with little

temperature variation (it may also increase noise due to increased gain).

• Sharpness (DDE Gain) is used to enhance image details and/or suppress fixed pattern noise.

Positive values increase Sharpness, while negative values soften the image and filter fixed pattern

noise. A setting of 0 is neutral and will not have any effect.

• AGC Filter determines how quickly a scene will adjust when a hot object appears (or disappears)

within the AGC ROI. If set to a low value, when a hot object enters the ROI, the AGC will adjust

more slowly to the hot object, resulting in a more gradual transition.

Pan and Tilt

The azimuth and elevation angles are measured in degrees. The elevation angle is measured from

horizontal; negative values are down, positive values are up. The Azimuth angle is measured from the

front of the pan/tilt unit; negative values are counter-clockwise, positive values are clockwise.

427-9030-01-12 Version 140 March 2018 22

Page 23

2 Basic Operation and Configuration

Click Set

select Preset ID

position camera,

To setup Presets:

then select Start

select width and speed,

To start Auto Scan:

select limits,

select speed,

Set Autoscan parameters:

click Save

Surveillance > Scan List

Surveillance > Auto Scan

Relative Auto Scan (Surveillance mode) will scan the scene starting with the current position of the

camera. Absolute Auto Scan will scan the scene starting with the zero azimuth position of the camera.

can be started and the parameters set in the web page, note also that Absolute Auto Scan can also be

started as an option in the Startup mode when the camera boots. Refer to

Tilt, pg. 33.

Sensor > Devices > Pan &

427-9030-01-12 Version 140 March 2018 23

Page 24

2 Basic Operation and Configuration

2.4.3 Maintenance Menu

When a user logs in as admin, a complete Maintenance menu is available. The basic camera

configuration steps are accessed through the Maintenance menu, using the Server submenu on the

left side of the page.The LAN Settings, Date and Time, Server Status, and Security Options

selections are described below. Generally with these settings it is necessary to save the changes to

make them effective, but it is not necessary to stop and restart the server.

Server > LAN Settings

If the IP address of the camera is changed, the PC may no longer be on the same network and

therefore may not be able to access the camera until the IP address on the PC is changed also. For

that reason, it may be preferable to change the IP address after making other configuration changes.

When the LAN settings are changed and the Save button is clicked, a

pop-up message will appear to indicate the network interface should

be restarted. Once all the changes have been made and saved, click

on the Restart Network button at the bottom of the page.

427-9030-01-12 Version 140 March 2018 24

Page 25

2 Basic Operation and Configuration

Select

Custom

Set Date

Server > Services > Date and Time

The date, time, and time zone can be obtained from an NTP server, or can be entered manually. If the

NTP mode is selected, the NTP server information can be entered. The NTP server address can be

entered as a static address or can be obtained via DHCP.

Note

The server must be stopped before date and time settings can be changed.

Set the date and time parameters, then select the Save button at the bottom. After saving the settings,

reboot the system. Refer to

Server > Server Status, pg. 26.

If the Custom mode is selected, a pop-up window allows the information to be entered manually.

427-9030-01-12 Version 140 March 2018 25

Page 26

2 Basic Operation and Configuration

Toggle Server

(Stop/Start)

Server > Server Status

The Server Status page provides an indication of the current server status (either running or stopped)

and buttons for starting or stopping the server and for rebooting the system. The Uptime section of the

Server Status page shows how long the camera has been running, number of users, and the load on

the camera processor. All values are updated only when the Server Status page is first accessed.

After making configuration changes, it is necessary to save the changes to the server (there is a Save

button at the bottom of each configuration page). The configuration changes do not take effect

immediately. Generally, it is also necessary to stop and restart the server for the changes to become

effective. The server has a configuration that is active and running, and another configuration that is

saved (and possibly different than the running configuration).

The message at the bottom of the page indicates the

saved configuration is different than the active (running)

configuration, and it is necessary to restart the server.

It may take up to 20 seconds or more to stop the server, especially when there are multiple video

streams open. Be patient when stopping the server.

When the server is stopped and the page is refreshed, the status will show

Server Stopped and the Start button will be enabled.

Click on the Start button to restart the server, and when the page refreshes,

the status will again show Server Running. The Start button will be replaced

by a Stop button when the startup procedure has completed.

427-9030-01-12 Version 140 March 2018 26

Page 27

2 Basic Operation and Configuration

Add IP

address

Select login

Click Edit

Enter new password

Click Save

Confirm password

Server > Security Options

Use the Security Options page to restrict access through the camera web server to specific IP

addresses and to set or change passwords. The admin login can change or set any password. The

expert login can only configure the expert login password.

As an additional security measure, limit which computers have access to the web browser interface.

Simply add a computer’s IP address and click Add. After all the allowed IP addresses are entered,

select the Save button to save the changes.

Note

A VMS Remote to the camera, ONVIF or Nexus CGI, uses the same password as the web interface.

Refer to

Sensor > Communications > VMS Remote, pg. 32.

To maintain security of the system set new passwords for each of the three login accounts.

• user—The user account can only use the Live Video page and controls.

• expert—The expert account can use the Live Video page, the camera Setup page, the Server

pages on the Maintenance menu, and set the password for the expert login.

• admin—The admin account can use all pages and set passwords.

427-9030-01-12 Version 140 March 2018 27

Page 28

2 Basic Operation and Configuration

Save

Select

protocol

Toggle Server (Stop/Start)

Pelco-D

settings

Bosch

settings

Sensor > Communications > Serial Remote

In some installations, a serial device such as a keyboard, joystick, or other device is used to control

camera functions such as pan/tilt or zoom. A serial device can also be used to access functions that

are specific to thermal cameras, such as changing the polarity from white hot to black hot. Refer to

AutoPan Function, pg. 30 for additional information.

The Serial Remote settings are used to configure the serial communication parameters when the

camera is controlled with a serial device. For serial communications, it is necessary to set the

parameters such as the signaling standard (RS-232 or RS-422), baud rate, number of stop bits, parity

and so on. It is also necessary to select the communication protocol used (either Pelco D or Bosch)

and the camera address.

On the Serial Remote configuration page, the buttons at the top of the page allow configuration of

three SerialRemote devices: 0, 1, and 2. SerialRemote 0 is used as a switch to select either Pelco D

or Bosch serial communications protocol. The actual serial parameters (such as baud rate) are

configured for either SerialRemote 1 (for Pelco D) or SerialRemote 2 (for Bosch).

With SerialRemote 0 selected, set the Serial Remote Protocol to either Pelco D Serial Remote or

Bosch Serial Remote. Ensure the Enabled parameter is set to Yes. If necessary, click Save to save the

changes.

427-9030-01-12 Version 140 March 2018 28

Page 29

2 Basic Operation and Configuration

If the Pelco D protocol is to be used, select SerialRemote 1

and wait for the page to refresh, and then configure the Remote

Port Settings such as Speed (baud rate), Data Bits, Parity and

Stop Bits. Set the Address parameter to the appropriate Pelco

address. It may be necessary to use the scroll bar on the right

side of the page to access the settings.

When Use Preset Map File is set to Yes (the default), then

presets (and special functions known as Aux commands) can

be used to access certain settings that are specific to the FLIR

thermal camera, such as switching between White Hot and

Black Hot settings. See

Preset Map File, pg. 31 for information.

The Initial Selected Camera is used to designate which camera

(IR or DLTV) in a multi-sensor camera is selected as the initial

Active camera. When a command such as “Zoom In” is sent to

the camera, it will affect the Active camera, regardless of which

video stream is displayed.

In the Joystick settings, the Mode parameter, when set to FOV

Dependant, allows a pan/tilt camera to adjust the pan speed

automatically, depending on the current field of view (FOV). For

a narrow FOV, the camera moves more slowly. If you do not

want to limit the pan speed according to the FOV, set the

parameter to Absolute.

The Pilot Mode parameter controls the direction of tilt when the

joystick is moved forward or backward. When Pilot Mode is set

to yes, the camera points downward when the joystick is

moved forward, similar to the way an aircraft would move. If the

mode is set to no, the joystick operates as one would expect

with a video game controller.

The parameters in the Advanced Settings are related to Scan

Lists and the AutoPan feature. Refer to

Preset Map File, pg. 31

and AutoPan Function, pg. 30 for more information about these

features.

If any of the parameters for SerialRemote 1 are changed, click

Save to save the changes. Generally most of the other Serial

Remote parameters which were not specifically described

above do not need to be changed (for SerialRemote 1 and

SerialRemote 2, it is OK if the Enabled parameter is set to no).

427-9030-01-12 Version 140 March 2018 29

Page 30

2 Basic Operation and Configuration

Note

Typical Bosch systems operate over a biphase connection. FLIR cameras do not accept biphase

signals directly. It may be necessary to install a biphase converter in order to use Bosch protocol.

If using the Bosch protocol, select SerialRemote 2 and wait for

the page to refresh to configure the Remote Port Settings such

as Speed (baud rate), Data Bits, Parity, and Stop Bits. Select

the appropriate Hardware Protocol (RS-422 or RS-232), and

set the Address parameter to the appropriate Bosch address. If

necessary, click Save to save the changes.

AutoPan Function: In many cases with a pan/tilt camera, it

may be desirable to use a simple back-and-forth (left-right)

scan pattern, rather than a Scan List set of presets. To use the

AutoPan feature (also known as Auto Scan), set the left and

right pan limits and the pan speed, and then start the AutoPan

mode. The functions for setting up the AutoPan limits and for

controlling the AutoPan function are available using presets

and are described in the following table.

Tabl e 2-1: AutoPan functions

PRESET GOTO 90 GoToPanLimitLeft

PRESET GOTO 91 GoToPanLimitRight

PRESET GOTO 92 SetPanLimitLeft

PRESET GOTO 93 SetPanLimitRight

PRESET GOTO 94 IncrementAutoPanSpeed

PRESET GOTO 95 DecrementAutoPanSpeed

PRESET GOTO 96 Stop Aut oPan

PRESET GOTO 99 StartAutoPan

Serial Extensions: In addition to the set of standard commands that would be used on an ordinary

CCTV camera, control commands that allow access to more advanced features, or features that are

specific to a particular type of equipment, are available through extensions to the serial protocol.

These extended commands are quite useful when controlling features that are specific to FLIR thermal

cameras.

In the Pelco D protocol, these additional functions can be accessed using the Aux On and Aux Off

extensions and are available by default. Many keyboards that support Pelco protocols have Aux On

and Aux Off buttons for selecting these functions. As an example, the following functions are typically

supported by default

AUX ON 1 IRPolarityBlackHot

AUX OFF 1 IRPolarityWhiteHot

AUX ON 2 DLTVChangeActiveSource

427-9030-01-12 Version 140 March 2018 30

Tabl e 2-2: Aux Functions

Page 31

2 Basic Operation and Configuration

Table 2-2: Aux Functions (Continued)

AUX OFF 2 IRChangeActiveSource

AUX ON 3 TogglePlateauValue

AUX OFF 3 IRToggleAGCType

AUX ON 4 To g g l e A u t o f o c u s

AUX OFF 4 IRStartNUCCalibration

AUX OFF 5 IRToggleLUTPalette

AUX ON 6 IRToggleDDEGain

AUX OFF 6 IRToggleAGCROI

AUX ON 7 IRToggleFOV

AUX OFF 7 IRToggleAGCMaxGain

AUX ON 8 SwitchCameraOn

AUX OFF 8 SwitchCameraOff

AUX ON 9 InitializePT

AUX OFF 9 GoToParkPositi on

Preset Map File: Most pan/tilt cameras support predetermined pan/tilt locations that are stored as

“presets’. A collection of presets is known as a Scan List (also referred to as a Pattern or Tour), A Scan

List is used to direct the camera to a sequence of locations that are typically viewed, or are considered

important or high-priority. Using video management software (VMS), multiple scan lists for a camera

can be set up and scheduled according to time of day and other factors.

However, presets can also be used to access other functions. The camera is capable of storing up to

128 Presets, but generally not that many are needed, so some presets can be reassigned to access

the other functions. For keyboards that do not have the Aux buttons, camera presets can be used to

accomplish the extended functions described above. For example, if preset 41 is not being used for an

actual preset location, it can be mapped to one of the above functions, such as IRPolarityBlackHot. To

allow mapping of the serial functions, set the “Use Preset Map File” parameter to yes.

On the Files page under PelcoD Map, use the Download link to open the text file that is used for

mapping the functions to Aux commands and Presets. If it is necessary to change the mapped

functions, edit the file and upload the new map file to the camera using the Upload button. Once a file

has been edited and tested, it can also be uploaded to other cameras so that each camera operates

the same way.

427-9030-01-12 Version 140 March 2018 31

Page 32

2 Basic Operation and Configuration

ONVIF-Interface

NTCIP-Interface

Lenel-Interface 2

Sensor > Communications > VMS Remote

If the camera is used with a VMS that is compliant with ONVIF, the parameters can be adjusted (if

needed) to work with the VMS. Refer to the VMS documentation to determine what parameter values

are needed. By default, the camera is configured with a VMS Remote interface with ONVIF 2.0

parameters (Profile S).

Authentication when enabled uses the same passwords set from the Server Security Options page.

Refer to

Server > Security Options, pg. 27. Several types of third-party Video Management Systems

(VMS) are supported by FLIR IP cameras. Because these systems tend to evolve and change over

time, contact the local FLIR representative or FLIR Technical Support to resolve any difficulties or

questions about using this feature.

427-9030-01-12 Version 140 March 2018 32

Page 33

2 Basic Operation and Configuration

Scroll down

to Save

Select zoom mode

Set to Yes

Select camera

controlling zoom

Scroll down

to Save

Select an action

from the menu

Sensor > Devices > IR > Zoom Slave

The Zoom Slave function is set from the IR web page. To slave the IR camera to the DLTV zoom select

the IR web page and scroll down to Zoom Slave.

When the IR camera zoom is slaved to the DLTV camera (Specific Camera), the cameras will only

zoom when the DLTV camera is the active camera.

Sensor > Devices > Pan & Tilt

Scroll down to select an action the camera will perform at startup (power cycle or server reset).

427-9030-01-12 Version 140 March 2018 33

Page 34

2 Basic Operation and Configuration

Sensor > Modules > Video

By default, four video streams are enabled for the camera: Video 0, Video 1, Video 2, and Video 3. The

streams are available for viewing from a client program such as FLIR Latitude, a stand-alone video

player, or a third-party VMS including ONVIF systems. By default, Video 0 and Video 1 are from the IR

sensor, while Video 2 and Video 3 are from the visible camera.

Caution!

Adjustments to these settings should only be made by someone trained with thermal cameras

and a thorough understanding of how the various settings affect the image.

Haphazard changes can lead to image problems including a complete loss of video.

To modify parameters that affect a particular IP Video stream from the camera, select the appropriate

link at the top of the page (for example, Video 0).

The default RTP Settings for connecting to an IP video stream

from the D-Series are shown in the illustration. The RTP Port

and the Stream Name are used when establishing a session

from a client.

Given the camera IP address of 192.168.250.116, the complete

connection string for each of the video streams are as follows:

VIDEO 0 - rtsp://192.168.250.116:554/ch0

VIDEO 1 - rtsp://192.168.250.116:554/ch1

VIDEO 2 - rtsp://192.168.250.116:554/ch2

VIDEO 3 - rtsp://192.168.250.116:554/ch3

427-9030-01-12 Version 140 March 2018 34

Page 35

2 Basic Operation and Configuration

In some networks, the RTP/RTSP traffic is carried (tunneled) over Hypertext Transfer Protocol (HTTP)

as that may allow the traffic to cross network boundaries and firewalls. While this method involves

more overhead due to encapsulation, it may be necessary for clients to access the video streams

when HTTP proxies are used.

By default, the video streams from the camera are sent using

multicast packets. With Multicast enabled, video packets are

shared by streaming clients, so additional clients do not cause

bandwidth to increase as dramatically.

If more than one camera is providing multicast streams on the

network, be sure to configure each stream with a unique

multicast Destination Network IP address and Destination

Port combination.

The time-to-live field controls the ability of IP packets to

traverse network boundaries. A value of 1 restricts the stream

to the same subnet. Greater values allow increasing access

between networks.

The video streaming is done using a protocol generally referred to as Real-time Transport Protocol

(RTP), but there are actually many protocols involved, including Real-Time Transport Control Protocol

(RTCP) and Real Time Streaming Protocol (RTSP). In the background, a “negotiation” takes place to

establish a session between the client (such as FLIR Latitude, a third party VMS, or video player) and

the camera. The ports which form a session are negotiated using a protocol such as RTSP. A client

typically requests a video stream using its preferred settings, and the camera can respond with its

preferred settings. As a result, many of the details are established dynamically, which may run contrary

to network security requirements.

The parameters in the Settings section will have a

significant impact on the quality and bandwidth

requirements of the video stream. In general it is

recommended that the default values be used initially. Then

individual parameters can be modified and tested

incrementally to determine if the bandwidth and quality

requirements are met.

For video streams, the Codec options are H.264, MJPEG

and MPEG4.

The Bit Rate parameter is used with the CBR (Constant Bit

Rate) setting to attempt to keep the resulting bit rate of the

video at or near the target bit rate.

When the Rate Control parameter is set to CVBR

(Constrained Variable Bit Rate), the Bit Rate parameter is

used as an upper limit bit rate and the system keeps the

stream at or under the target bit rate.

The I-Frame Interval parameter controls the number of P-frames used between I-frames. I-frames are

full frames of video and the P-frames contain the changes that occurred since the last I-frame. A

smaller I-Frame Interval results in higher bandwidth (more full frames sent) and better video quality. A

higher I-Frame Interval number means fewer I-frames are sent and therefore results in lower

bandwidth and possibly lower quality.

427-9030-01-12 Version 140 March 2018 35

Page 36

2 Basic Operation and Configuration

Stop server

The Image Size parameter controls the video resolution and therefore can have a large impact on

bandwidth usage. The higher the resolution, the larger the size of the frame and the higher the

network bandwidth required.

Tabl e 2-3: Image Size Settings

Image Size NTSC PAL

D1 720x480 720x576

4SIF/4CIF 704x480 704x576

VGA/Native 640x480 640x512

SIF/CIF 352x240 352x288

QVGA/QNative 320x240 320x256

Ta bl e 2-3 provides the corresponding resolution for each setting.

If the video will be viewed on its own and on a reasonably large screen, a large image size setting may

look better. On the other hand, if the video is shown as a tile in a video wall, a smaller image size may

look as good and consume less bandwidth.

Files > Firmware

For camera firmware updates, manually install a firmware update file by first stopping the camera

server, browsing to select the update file on your computer, and selecting Upload. The firmware files

will be uploaded and installed.

427-9030-01-12 Version 140 March 2018 36

Page 37

2 Basic Operation and Configuration

Files > Configuration

The Configuration page allows the Nexus Server configuration to be displayed or backed up locally

(on the camera). The configuration file can also be downloaded to another computer for backup, or a

new configuration file can be uploaded from a computer to the camera. Shown at the top of the page is

the configuration script file in a scrollable window. This can be useful if help is ever needed from a

support engineer.

In the Backup & Recovery section, click the Restore link associated with the factory.defaults

configuration to restore the camera to its factory settings. This file can not be modified or deleted, so it

is always available.Use the Backup button to make a backup of the final settings. This will make a

backup copy of the configuration file and store it locally on the camera.

In the Upload & Download section, the Download Configuration File link can be used to save a copy to

a PC for safe keeping. A pop-up window will ask for a file name and destination folder.The Upload

button is used to transfer a configuration file from a PC to the camera.

427-9030-01-12 Version 140 March 2018 37

Page 38

2 Basic Operation and Configuration

Files > Log > Field Support Log

Scroll down and select the Download button under Field Support Log to download a zip file to the

computer for field service evaluation.

2.5 Thermal Imaging Overview

The thermal camera makes an image based on temperature differences. In the thermal image, by

default the hottest item in the scene appears as white and the coldest item is black, and all other items

are represented as a gray scale value between white and black.

It may take some time to get used to the thermal imagery from the camera, especially for someone

who only has experience with normal daylight cameras. Having a basic understanding of the

differences between thermal and daylight cameras can help with getting the best performance from the

thermal camera.

Both thermal and daylight cameras have detectors (pixels) that detect energy. One difference between

thermal and daylight cameras has to do with where the energy comes from to create an image. When

viewing an image with an ordinary camera, there has to be some source of visible light (something hot,

such as the sun or lights) that reflects off the objects in the scene to the camera. The same is true with

human eyesight; the vast majority of what people see is based on reflected light energy.

On the other hand, the thermal camera detects energy that is

directly radiated from objects in the scene. Most objects in

typical surroundings are not hot enough to radiate visible light,

but they easily radiate the type of infrared energy that the

thermal camera can detect. Even very cold objects, like ice

and snow, radiate this type of energy.

The camera is capable of sensing very small temperature

differences, and produces a video image that typically has

dramatic contrast in comparison to daylight cameras. This

high contrast level from the thermal video enables intelligent

video analytic software to perform more reliably.

427-9030-01-12 Version 140 March 2018 38

Page 39

2 Basic Operation and Configuration

The performance of the camera varies throughout the day. Right after sunset, objects warmed by the

sun will appear warmest. Early in the morning, many of these objects will appear cooler than their

surroundings, so be sure to look for subtle differences in the scene, as opposed to just hot targets.

While the imagery on the monitor may at first look similar to ordinary black and white daylight video,

experience with the camera in varying conditions and seasons will lead to an appreciation of the

characteristics that make thermal imaging distinct. A few tips on how to interpret some of the imagery

may help to make the most of the system.

The camera senses small differences in apparent radiation from the objects in view, and displays them

as either white (or lighter shades of gray) for warmer objects, and black (or darker shades of gray) for

colder objects. This is why hot objects such as parts on an engines and exhaust pipes appear white,

while the sky, puddles of water and other cold objects appear dark (or cool). Scenes with familiar

objects will be easy to interpret with some experience. The camera automatically optimizes the image

to provide the best contrast in most conditions.

2.6 Troubleshooting Tips

If help is needed during the installation process, contact a local FLIR representative. FLIR Systems,

Inc. offers a selection of training courses to help get the best performance and value from the thermal

imaging camera.

Find out more at the FLIR training web page: https://www.flir.com/support-center/training/

No video: Check the video connection at the camera and at the display. If the connectors appear to

be properly connected but the camera still does not produce an image, ensure that power has been

properly applied to the camera and the circuit breaker is set properly. If a fuse was used, be sure the

fuse is not blown. If the video cabling is suspected as a possible source of the problem, plug a monitor

into the RCA connection inside the camera and determine if it produces an image.

If the camera still does not produce an image, contact the FLIR dealer or reseller who provided the

camera, or contact FLIR directly (contact information is provided on the rear cover of this manual).

Performance varies with time of day: It may be possible to observe differences in the way the

camera performs at different times of the day, due to the diurnal cycle of the sun. Recall that the

camera produces an image based on temperature differences.

At certain times of the day, such as just before dawn, the objects in the image scene may all be roughly

the same temperature, compared to other times of the day. Compare this to imagery right after sunset,

when objects in the image may be radiating heat energy that has been absorbed during the day due to

solar loading. Greater temperature differences in the scene generally will allow the camera to produce

higher-contrast imagery.

Performance may also be affected when objects in the scene are wet rather than dry, such as on a

foggy day or in the early morning when everything may be coated with dew. Under these conditions, it

may be difficult for the camera to show the temperature the object itself, rather than of the water

coating.

Unable To Communicate Over Ethernet: First check to ensure the physical connections are intact

and that the camera is powered on and providing analog video to the monitor. When the camera is

turned on, confirm the camera IP address is shown on the Analog Visible Video monitor after

approximately 90 seconds.

Confirm that the IP address for the PC is on the same network as the camera.

427-9030-01-12 Version 140 March 2018 39

Page 40

2 Basic Operation and Configuration

By default the camera will broadcast a discovery packet two times per second. Use the FLIR Discovery

Network Assistant (DNA) or a packet sniffer utility such as Wireshark and confirm the packets are

being received by the PC from the camera.

Determine if Windows Personal Firewall is blocking the packets. Turn off the firewall or add an

exception for the client program. Typically when a program runs for the first time, a pop-up notification

may ask for permission to communicate on the network. Select the check boxes (domain/private/

public) that are appropriate for the network.

Unable to View Video Stream: If the video stream from the camera is not displayed in a client

program, it could be that the packets are blocked by the firewall, or there could be a conflict with video

codecs that are installed for other video programs.

When displaying video with FLIR Latitude or a VMS for the first time, the Windows Personal Firewall

may ask for permission to allow the video player to communicate on the network. Select the check

boxes (domain/private/public) that are appropriate for the network.

If necessary, test to make sure the video from the camera can be viewed by a generic video player

such as VLC media player (http://www.videolan.org/vlc/). To view the video stream, specify RTSP port

554 and the appropriate stream name. For example: rtsp://192.168.0.250:554/ch0.

Refer to Sensor > Modules > Video, pg. 34.

Noisy image: A noisy image is usually attributed to a cable problem (too long or inferior quality) or the

cable is picking up electromagnetic interference (EMI) from another device. Although coax cable has

built-in losses, the longer the cable, or the smaller the wire gauge, the more severe the losses

become; and the higher the signal frequency, the more pronounced the losses. Unfortunately this is

one of the most common and unnecessary problems that plagues video systems in general.

Cable characteristics are determined by a number of factors (core material, dielectric material and

shield construction, among others) and must be carefully matched to the specific application.

Moreover, the transmission characteristics of the cable will be influenced by the physical environment

through which the cable is run and the method of installation.

Check cable connector terminations. Inferior quality connections may use multiple adapters which can

cause unacceptable noise. Use a high-quality video distribution amplifier when splitting the signal to

multiple monitors.

Image too dark or too light: By default the D-Series thermal camera uses an Automatic Gain

Control (AGC) setting that has proven to be superior for most applications, and the camera will

respond to varying conditions automatically. The installer should keep in mind that the sky is quite cold

and can strongly affect the overall image. It may be possible to avoid a problem by slightly moving the