Page 1

www.flir.com

D--

D

S

S

errii

e

ess

e

T

T

h

h

err

IInnssttaallllaattiioonn aanndd O

e

m

m

all

a

C

C

a

a

Oppeerraattiioonn

m

Maannuuaall

m

M

err

e

a

a

444-00001-00-10 Revision 110 Copyright © 2008 FLIR Systems, Inc. Page 1 of 33

FLIR Systems, Inc.

70 Castilian Drive

Goleta, CA 93117

Phone: 888.747.FLIR

(888.747.3547)

International: +1.805.964.9797

Page 2

FLIR Systems Inc.

70 Castilian Dr.

Goleta, CA 93117-3027

888.747.FLIR (888.747.3547)

Intl.: +1.805.964.9797

FAX 805 685-2711

www.flir.com

Document Number: 444-00001-00-10 Revision 110

Revision Number: 110

Date: November 21, 2008

Revision Date Notes

100 11/7/2008 Initial release

110 11/21/2008 Minor corrections

EXPORT RESTRICTIONS

This document is controlled to FLIR Technology Level 2. The information contained in

this document pertains to a dual use product controlled for export by the Export

Administration Regulations (EAR). FLIR trade secrets contained herein are subject to

disclosure restrictions as a matter of law. Diversion contrary to US law is prohibited. US

Department of Commerce authorization is not required prior to export or transfer to

foreign persons or parties unless otherwise prohibited.

PROPRIETARY

The data in this publication shall not be disclosed without permission and shall not be

duplicated, used, or disclosed in whole or in part except to the extent provided in any

contract of which this document is made a part. This restriction does not limit the

customer’s right to use information contained in this document if it is obtainable from

another source without restriction. The data subject to this restriction are contained in all

sheets of this document and related drawings and document specifications herein. FLIR

reserves the right to make changes to its products or specifications at any time, without

notice, in order to improve design or performance and to supply the best possible

product.

COPYRIGHT

Copyright © 2008 by FLIR Systems, Inc. All rights reserved. This publication, or any

parts thereof, may not be reproduced in any form without the express written permission

of FLIR Systems, Inc.

Pelco is a registered trademark of Pelco. Windows is a registered trademark of Microsoft Corporation.

444-00001-00-10 Revision 110 Copyright © 2008 FLIR Systems, Inc. Page 2 of 33

Page 3

Table of Contents

Legal Considerations .............................................................................................................. 4

Support ................................................................................................................................... 4

1. Warnings and Cautions .......................................................................................................... 5

2. Introduction ............................................................................................................................ 6

2.1 Advantages of Thermal Imaging ....................................................................................... 6

2.2 Pan/Tilt Mechanism .......................................................................................................... 7

2.3 Connections and Communication Protocol ....................................................................... 7

2.4 Mounting Options ............................................................................................................. 8

3. Getting Sta rted ....................................................................................................................... 9

3.1 Package Contents ............................................................................................................ 9

3.2 Installation Requirements ................................................................................................10

3.2.1 Power On Self-Test ...................................................................................................11

3.3 D-Series Camera Connections ........................................................................................12

3.4 Drop Ceiling Installation (Typical Installation) ..................................................................12

4. Removing the main camera assembly from the housing enclosure .......................................17

4.1. Disassembling the Dome ................................................................................................17

4.2. Steps to removing the camera base for installation .........................................................19

4.3. Steps to install the base cover ........................................................................................19

4.4 Hard Ceiling Installation (Pendant Mount) ........................................................................21

5. Configuration Options ...........................................................................................................23

5.1 Changing the Electronic Connections ..............................................................................23

5.2 Changing DIP Switch Settings .........................................................................................24

5.3 Changing the Pelco Address ...........................................................................................24

5.4 Changing the Baud Rate .................................................................................................24

5.5 RS-485 Termination Resistor DIP Switch ........................................................................25

5.6 Reassembling and Running Self-Check ..........................................................................25

6. Using Your D-Series Camera ................................................................................................25

6.1. IR Imaging Views ............................................................................................................25

6.2 Pelco D and Keyboard Commands ..................................................................................26

7. Troubleshooting ....................................................................................................................27

7.1 Caring for your FLIR D-Series Camera ............................................................................27

8. Performance Specifications ...................................................................................................28

8.1 FLIR D-Series Camera Dimensions .................................................................................29

8.2 Default Settings ...............................................................................................................30

8.3 Baud Rate Settings ..........................................................................................................31

9. Mounting Templates ..............................................................................................................31

9.1. Drop Ceiling Mounting Templates ...................................................................................31

9.2 Hard Ceiling Mounting Template .....................................................................................32

10. Fundamentals of Infrared ....................................................................................................33

444-00001-00-10 Revision 110 Copyright © 2008 FLIR Systems, Inc. Page 3 of 33

Page 4

List of Figures

Figure 1: Differences in imagery obtained with a standard CCTV camera (left) and the FLIR D-

Series Camera (right) ................................................................................................................. 7

Figure 2: Types of installation …………………………………………………………………………..8

Figure 3: D-Series external components ………………………………………………………………9

Figure 4: D-Series camera wiring connections ..........................................................................12

Figure 5: Installation templates (not to scale) ............................................................................14

Figure 6: Proper alignment of standoffs for installation of dome enclosure ................................16

Figure 7: Ring installation (left); D-Series Dome camera installed in ceiling (right) ....................16

Figure 8: PC Board with DIP Switch Bank .................................................................................24

Figure 9: Areas radiating heat appear brighter. .........................................................................26

Figure 10: FLIR D-Series Camera Dimensions (in mm) ............................................................30

Figure 11: Drop Ceiling Mounting Template (not to scale)... ………………………………………31

Figure 12: Hard Ceiling Mounting Template (not to scale) .........................................................32

List of Tables

Table 1: Shipping Contents ........................................................................................................ 9

Table 2: Pelco D and Keyboard Commands .............................................................................27

Table 3: Troubleshooting Guidelines .........................................................................................27

Table 4: Performance Specifications .........................................................................................29

Table 5: Address Settings .........................................................................................................30

Table 6: Baud Rate Settings .....................................................................................................31

Legal Considerations

Camera and audio surveillance may be prohibited by laws that vary from country to country.

Check the laws in your local region before using this product for surveillance purposes.

Support

If you have questions that are not covered in this manual, or need service, contact FLIR

Customer Support at (805) 964-9797 for additional information prior to returning your D-Series

Camera. In the US, you can also reach FLIR Customer Support at (888) 747-FLIR (747-3547).

444-00001-00-10 Revision 110 Copyright © 2008 FLIR Systems, Inc. Page 4 of 33

Page 5

CAUTION!

Caution

NOTE: This guide uses blue Note boxes to provide extra information on a topic.

1. Warnings and Cautions

This guide uses a yellow box with the word

hazardous situation, which, if not avoided, may result in injury or damage to the device.

1. A trained professional should install the camera in accordance with local codes and

industry-standard safe practices.

2. Disassembling the D-Series Camera for reasons other than installation, ordinary

maintenance or configuration can cause permanent damage and will void the warranty.

3. Operating the camera outside of the specified input voltage range or the specified

operating temperature range can cause permanent damage.

4. Follow the environmental guidelines included in the technical specifications required for

installation. Avoid exposure to dust and moisture.

5. Do not image extremely high intensity radiation sources, such as the sun, lasers, arc

welders, etc. This warning applies whether or not the system is powered.

6. The camera is a precision optical instrument and should not be exposed to excessive

shock and/or vibration.

7. This camera contains static-sensitive electronics and should be handled appropriately.

8. Do not install or operate the device in locations that contain flammable and/or explosive

objects.

to indicate a potentially

9. Do not try to repair the unit by yourself. FLIR Systems shall not be responsible for any

problem caused by unauthorized amendment or repairing.

10. Take great care when handling your camera optics. They are delicate and can be

damaged by improper cleaning. Clean the lens in the manner described in Section 7.1

Caring for your FLIR D-Series Camera

WARNING: All thermal imaging systems are subject to export control. Please contact FLIR

for export compliance information concerning your application or geographic area.

444-00001-00-10 Revision 110 Copyright © 2008 FLIR Systems, Inc. Page 5 of 33

.

Page 6

2. Introduction

Congratulations! You have purchased one of the most important instruments you can have as

part of your security system. The D-Series Thermal Camera is a state -of-the-art thermal imaging

system especially suited to accommodate security surveillance of moving objects within a large

area.

The D-Series camera is a compact, all-in-one thermal imager with outstanding sensitivity and

image quality. T he on-focal-plane circuitry, combined with FLIR’s advanced signal processing

electronics, enables the camera to maintain excellent dynamic range and image uniformity over

a wide temperature range. The dome casing allows easy ceiling installation in a variety of indoor

locations to provide round-the-clock, high quality analog video (NTSC or PAL) with full pan, tilt

and zoom control.

Designed specifically for indoor use, the FLIR D-Series Camera is ideal for demanding security

surveillance installations at airports, railway stations, supermarkets, judicial buildings, prisons,

banks, casinos, etc.

The D-Series camera is designed for simple, intuitive installation and operation. Each camera is

based on FLIR’s widely-deployed uncooled microbolometer imaging core. All cameras include

FLIR’s advanced image processing techniques which deliver excellent contrast regardless of

scene dynamics.

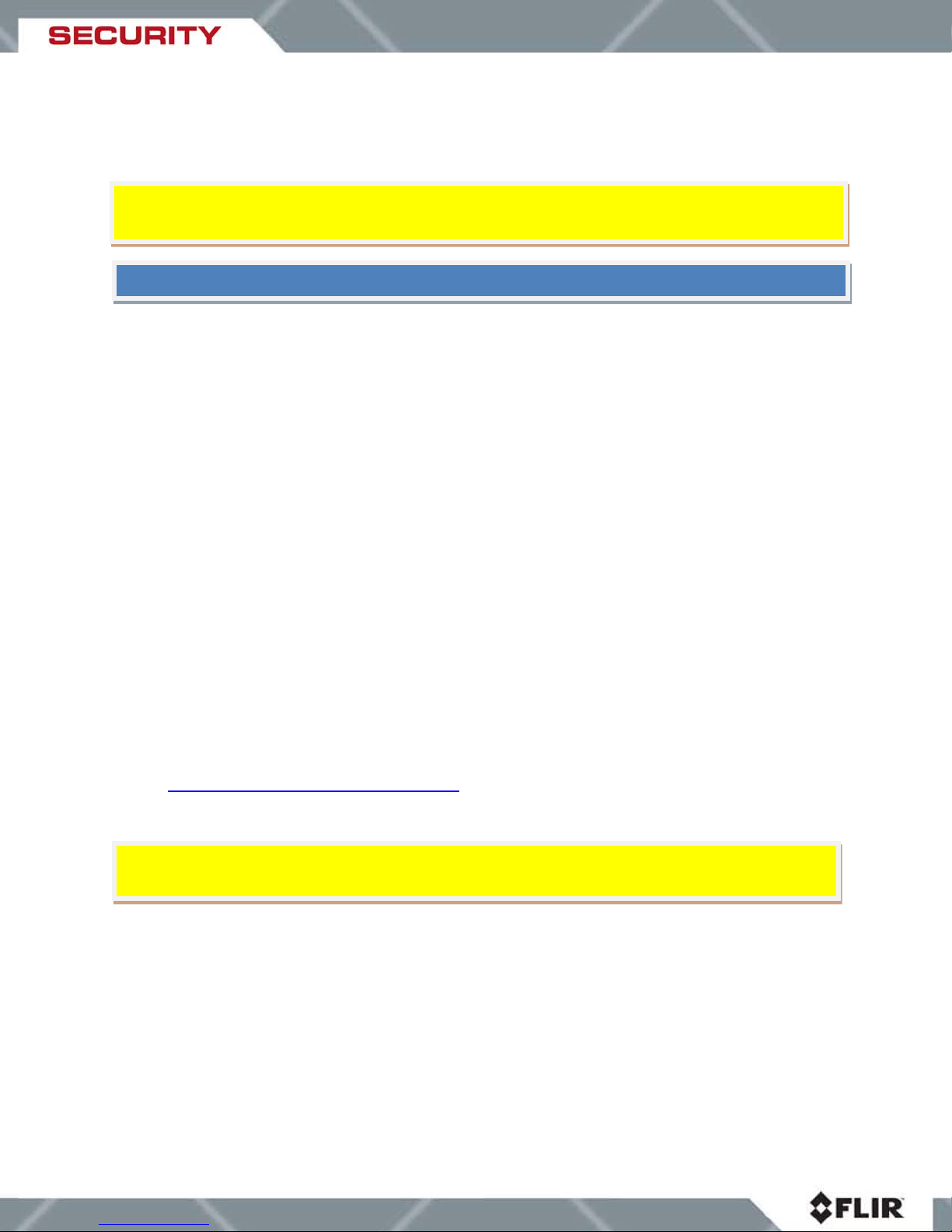

2.1 Advantages of Thermal Imaging

FLIR’s powerful D-6 and D-19 indoor thermal dome cameras compliment and complete your

security camera network. They turn night into day, letting you see through smoke and in total

darkness. When the lights go out, or smoke renders conventional CCTV cameras useless, DSeries cameras still see clearly.

Originally developed for the military, thermal imaging cameras are now deployed in numerous

commercial applications where it is impractical or too expensive to use active illumination

(lights). They are perfect for wide-area surveillance in critical infrastructure or high-value

residence installations where lighting is unwelcome or impractical. The cameras also provide

improved daytime surveillance in environments where traditional CCTV security camera

performance suffers, such as in shadows, backlit scenes or through foliage.

Low-cost infrared illuminated cameras rely on near infrared (NIR) lamps to illuminate threats,

resulting in shadows, reflections, backscatter, higher power consumption, narrow areas of

illumination and much shorter ranges than passive thermal camera technology.

Unlike other night vision systems that require low amounts of light to generate an image, the DSeries Camera thermal imager needs no light at all.

The D-Series Camera is designed to be compatible with standard security systems employing

ordinary daylight cameras, with a variety of connection options available. Installation is straight

forward with standard interfaces for power, video (NTSC or PAL), and serial control (Pelco D

protocol over RS-485). The choice of lenses for the cameras (6.3mm and 19mm) allows for

short- or medium-range surveillance capability.

444-00001-00-10 Revision 110 Copyright © 2008 FLIR Systems, Inc. Page 6 of 33

Page 7

The D-Series Camera features a wide field of view and is capable of providing an image even in

absolute darkness. Figure 1 shows the limitations of images obtained with a standard CCTV

camera and the advantages provided by the D-Series camera in extreme conditions.

Figure 1: Differences in imagery obtained with a standard CCTV camera (left) and the FLIR DSeries Camera (right)

2.2 Pan/Tilt Mechanism

The FLIR D-Series Camera provides a continuous 360° pan operation and a 90° tilt operation

with automatic flip to provide complete 180° tilt coverage. The pan and tilt speeds range from

0.5° per second to 100° per second. To accommodate typical security surveillance operations,

up to 80 preset locations can be configured on the camera. The camera can also be set to

continuously auto scan between two positions or up to 200 points can be set in a repeating

pattern.

2.3 Connections and Communication Protocol

The D-Series camera provides standard video format output via a BNC connector. The camera

is controlled using the Pelco-D protocol over RS485 serial communications, and is powered

using a 24V AC power supply. The camera is provided with a 6 foot bundled cable system that

includes the connections for video, power and serial control.

444-00001-00-10 Revision 110 Copyright © 2008 FLIR Systems, Inc. Page 7 of 33

Page 8

standard safe practices.

Any device that communicates with the Pelco-D protocol can be used as a control unit, including

a commonly-used joystick keyboard such as the Pelco KBD300A or a more sophisticated device

such as an IP-encoder with serial control. The control unit can be used to operate the following

functions or features:

• Pan/Tilt operation

• Set or activate preset location

• Set or Initiate auto scan or pattern scan sequence

• Zoom (2x digital zoom, available on D-19 camera only)

• Video palette (white hot by default, black hot and rainbow palettes available also)

• Scene setting (user-selectable automatic gain control settings)

• Invert Image

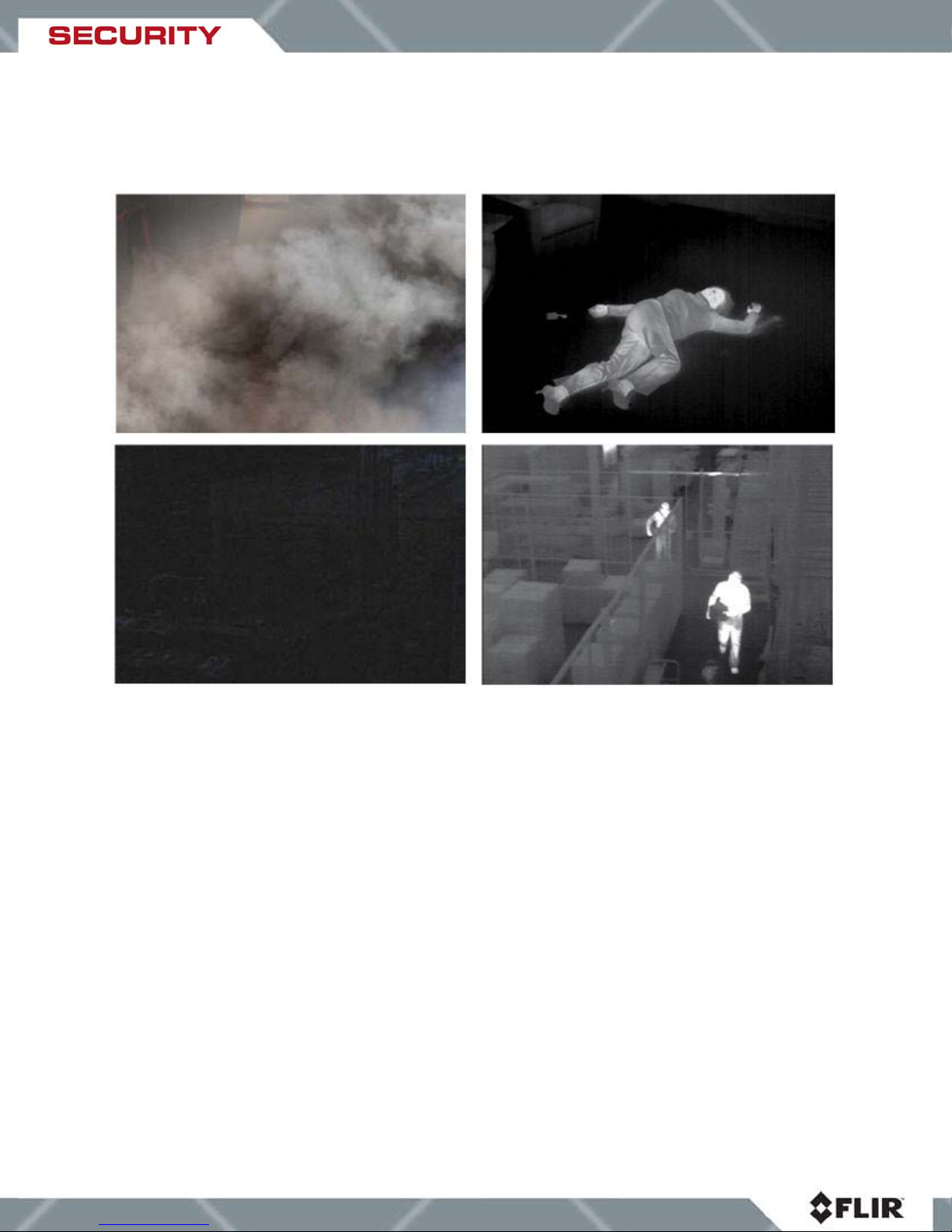

2.4 Mounting Options

The FLIR Thermal Camera is designed to be mounted in the ceiling. The camera is ordinarily

mounted with the main camera assembly above the ceiling, with only the camera dome and trim

ring exposed. During the installation, the main camera assembly is temporarily removed from

the camera housing enclosure. The housing enclosure is installed in the ceiling, then the

camera body is reinstalled in the housing, and finally the trim ring is installed. FLIR recommends

using a mounting board and chain when installing in a drop ceiling.

Alternatively, for locations where there is insufficient clearance above the ceiling, the camera

can be installed hanging from the ceiling (known as a “pendant” mount), in which case the entire

camera body (minus the housing enclosure) hangs below the ceiling. The housing enclosure is

not used with this type of installation. See sections 3 and 4 for detailed installation instructions.

CAUTION! The camera should be installed in accordance with local codes and industry-

444-00001-00-10 Revision 110 Copyright © 2008 FLIR Systems, Inc. Page 8 of 33

Figure 2: Types of installation

Page 9

IR Imager (Photon)

Electrical Connections

3. Getting Started

3.1 Package Contents

Refer to the Shipping Check List that is shipped with each camera for a description of the parts

and components that are included with the camera. If there is any discrepancy between the list

and the contents of your shipment, please contact FLIR Systems Customer Support

immediately using the contact information at the front of this manual. Please retain the original

shipping container and packing materials in case the camera possibly needs to be shipped in

the future.

Item Quantity

D-Series Camera with electrical connectors attached

(Figure 3)

Self-Tapping Screw M4×30 with wall anchors 3

Mounting template 1

Pan head screws with cross recessed M4×15 4

Flat Washer • 4 4

Table 1: Shipping Contents

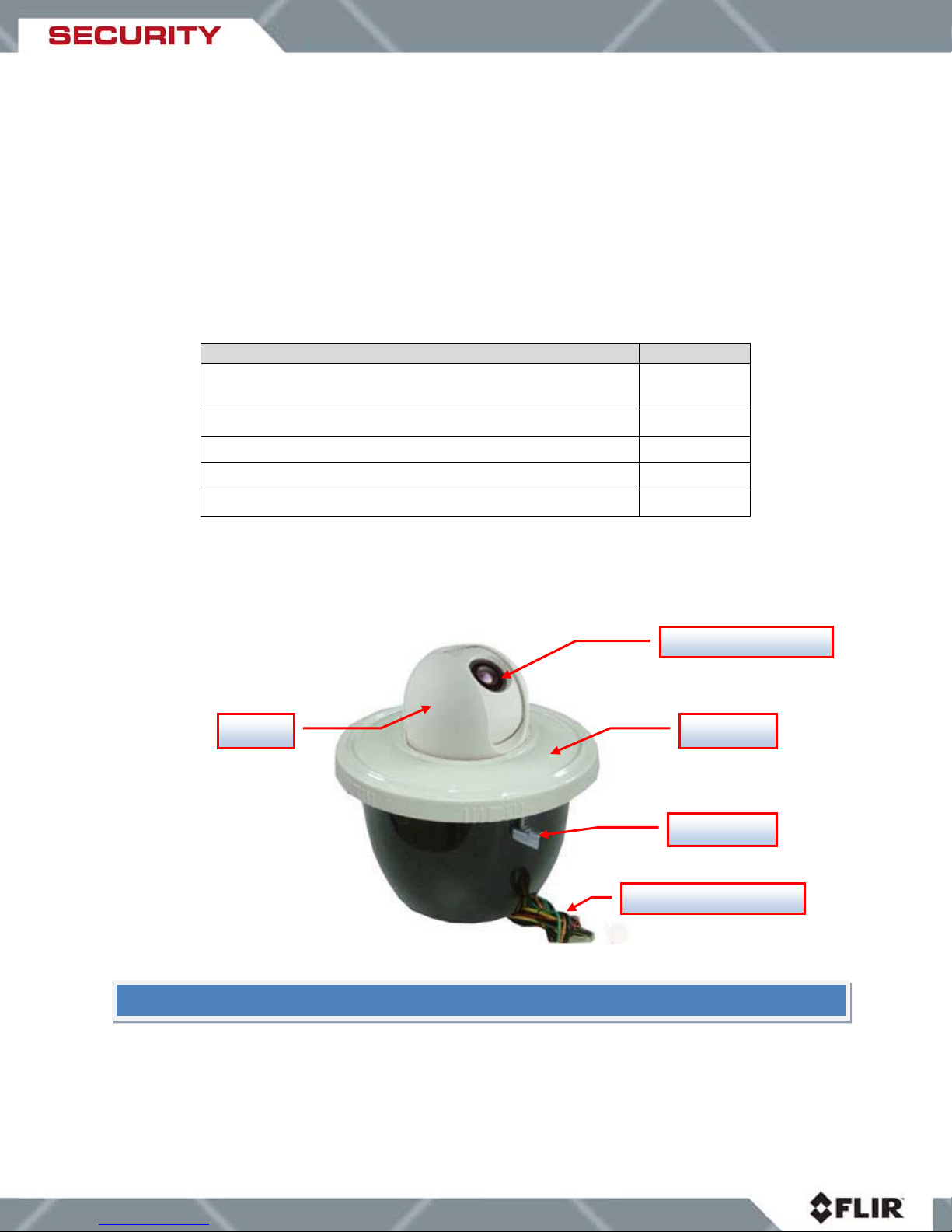

Figure 3 illustrates the outer parts of the FLIR D-Series Camera:

1

Dome

Trim ring

Spring Clip

Figure 3: D-Series external components

NOTE: if any specified materials are missing or damaged, please contact your FLIR dealer

444-00001-00-10 Revision 110 Copyright © 2008 FLIR Systems, Inc. Page 9 of 33

Page 10

CAUTION

CAUTION

3.2 Installation Requirements

Generally, some level of disassembly and reassembly is necessary during the installation

process. If it is necessary to change any of the default settings (for example, the Pelco

address), refer to section

camera assembly prior to installation and access the configuration DIP switches. It is also

necessary to separate the base from the main camera assembly if the cables that are provided

with the camera are to be replaced with other cables.

In order to get familiar with the camer a installation and operation, it may be wise to make the

appropriate connections to the camera while the camera is on a test bench prior to doing the

actual installation. Observe the initial power-on self-test before you install the camera into the

ceiling and ensure that it is supplying video to a monitor and responding to the joystick

controller. The wiring connections are described below.

Shielded Twisted Pair (STP) wiring is recommended for the RS485 cable to avoid problems with

performance, communication or video noise. The shielding wire must be grounded.

! The Dome Camera should be installed by a certified CCTV installer who has

experience working with CCTV system component installation, operation and repair.

Incorrect installation could void your warranty.

4.1. Disassembling the Dome for information on how to take apart the

! The Dome Camera is intended to be mounted in the ceiling with the camera

facing away from the mounting plane. Any other type of installation is not appropriate and

could result in undesirable operation, which will void the warranty.

Tools/Materials Needed:

• Small slotted screw driver

• Phillips screw driver

• Soft lens cloth

• Wire nuts

• Safety chain or cable for in-ceiling installa tion

• Appropriate tool(s) for cutting hole in ceiling

Safety Requirements - the ceiling should meet the following safety requirements:

1. The installation site must have enough clearance to allow for the necessary freedom of

travel for pan and tilt operation over the full range. Refer to the

Specifications section for

specific dimensions.

2. The installation site must be stable and sturdy enough to hold the camera during the

continuous pan and tilt movement.

3. The installation materials must be capable of supporting well in excess of the weight of

the product and accessories. FLIR Systems, Inc. is not responsible for damage or injury

that results from an improperly installed camera.

444-00001-00-10 Revision 110 Copyright © 2008 FLIR Systems, Inc. Page 10 of 33

Page 11

insufficient.

NOTE

The D-Series camera has grounding and surge protection to provide further immunity from high

current transients that can occur in installations that are subject to electrical storms and/or

nearby lightning events. In order to ensure CE and FCC compliance as well as to protect

against these high current events, installers are required to provide an earth connection to

the camera.

NOTE: A ground connection to the exterior of the camera (for example, to the spring clip) is

Caution! The camera must be installed according to industry-standard practices and local

electrical codes. Failure to properly connect the camera to ground could result in damage to

the camera and possible bodily injury.

3.2.1 Power On Self-Test

The D-Series Camera goes through a self-test process after power on. T he camera will tilt up to

the top near the trim ring and the dome will perform a full rotation. The self-test is complete

when the camera tilts to the home position. Although the unit will produce a video signal

during the self-test, it is not possible to operate the camera (pan/tilt or other operations)

until the self-test process is complete.

: if you encounter problems with the self-check process, please refer to the

Troubleshooting section for recommendations.

444-00001-00-10 Revision 110 Copyright © 2008 FLIR Systems, Inc. Page 11 of 33

Page 12

3.3 D-Series Camera Con n ecti on s

Figure 4: D-Series Camera wiring connections

WARNING: The Green/Yellow Gr ound wire must be properly connected in order for the

camera to operate properly.

3.4 Drop Ceiling Installation (Typical Installation)

WARNING! Make sure the Dome Camera and any other related equipment is powered off

during installation.

The FLIR Thermal Camera is designed to be mounted on the ceiling. A typical installation uses

the supplied housing enclosure, which conceals the main body of the camera in the ceiling,

showing only the camera dome. Alternatively, the camera can be installed hanging from the

444-00001-00-10 Revision 110 Copyright © 2008 FLIR Systems, Inc. Page 12 of 33

Page 13

Step 1

ceiling (“pendant” installation), in which case the entire camera body (minus the housing

enclosure mount) hang from the ceiling in plain view. Which mounting type you use depends on

your specific security needs.

When cutting the hole for the camera in the ceiling, be sure to follow the template provided

carefully. If the hole is cut too large or imprecisely, the camera will not fit snugly in the hole and

it will be difficult to secure the camera safely.

NOTE: It may be useful to have another person hold the camera in place while tightening the

spring clips.

Cut an approximately 9 ½ “ diameter hole in the surface where the dome is to be

mounted using the template provided with the SR-Series camera. A sketch (not to

scale) is shown in Figure 5.

Cutouts

444-00001-00-10 Revision 110 Copyright © 2008 FLIR Systems, Inc. Page 13 of 33

Page 14

In-ceiling mount template

Pendant mount template

Step 2

Trim ring

Step 3

Figure 5: Installation templates (not to scale)

Turn the trim ring on the unit counter-clockwise to remove it, as shown below.

Secure the mounting board and security chain to the bottom of the dome.

444-00001-00-10 Revision 110 Copyright © 2008 FLIR Systems, Inc. Page 14 of 33

Page 15

Mounting Board

Safety Chain/Cable

Spring Clip

Screw

Step 4

Insert the dome into the ceiling hole, making sure you align the retaining clips with the

cutouts on the mounting board.

Upper Dome

Ceiling Tile

Rotate the dome clockwise until the large plastic standoff falls into the center of the

Step 5

cutout and the two small plastic standoffs surrounding the mounting screw rest firmly

against the ceiling board (they should be flush with the ceiling board).

444-00001-00-10 Revision 110 Copyright © 2008 FLIR Systems, Inc. Page 15 of 33

Page 16

Step 6

Mounting screw

Board Cutout

Large plastic standoff

Small plastic standoffs

Step 7

Figure 6: Proper alignment of standoffs for installation of dome enclosure

Tighten the mounting screws until the spring clips make contact with the back of the

mounting board and are secure. Attach the mounting board onto a secure beam or

any other secure platform.

Slide the trim ring into the slots on the dome edge and turn clockwise to tighten it.

Figure 7: Ring installation (left); D-Se ries Dome camera installed in ceiling (right)

444-00001-00-10 Revision 110 Copyright © 2008 FLIR Systems, Inc. Page 16 of 33

Page 17

Trim ring

4. Removing the main camera assembly from the housing

enclosure

With certain installations, including a pendant mount installation, it may be necessary to remove

the camera from the housing enclosure. It may also be necessary to remove the base from the

main camera assembly so the DIP switches are accessible (for example, to change the Pelco

address). The instructions for these disassembly steps are provided below.

4.1. Disassembling the Dome

The PC board and electrical interface board are located within the inner dome cylinder. To

disassemble the dome, follow these steps:

Step 1

Step 2

If the power is on, power off the unit.

Turn the trim ring counter-clockwise and remove it from the unit.

Step 3

444-00001-00-10 Revision 110 Copyright © 2008 FLIR Systems, Inc. Page 17 of 33

Reach inside and lift the catch on the bottom of the inner cylinder. Push down on

the cylinder and turn the cylinder counter-clockwise to release it, then pull the

cylinder up.

Page 18

Catch

Cylinder bottom

Safety cable

Ribbon cable

Step 4

When you lift the inner cylinder, the bottom of the cylinder, which contains the

electronic interface board, remains attached to the dome bottom. The ribbon

cable and safety cable connect the two parts.

NOTE: To make it easier, you may want to disconnect the cables and completely remove the

inner cylinder. The cylinder bottom is attached to the dome by four screws on the bottom of

the dome. You may remove it as well. A safety cable attaches the cylinder to the cylinder

bottom and is designed to keep the cylinder from falling off if the maintenance person were to

accidentally drop it.

444-00001-00-10 Revision 110 Copyright © 2008 FLIR Systems, Inc. Page 18 of 33

Page 19

4.2. Steps to removing the camera base for installation

1. Hold the camera upside down firmly. You may need someone else to hold the camera

housing at this point to keep it from turning.

2. Pull the tab out, being careful not to break it, while at the same time pushing down on

the base. Do not use a screwdriver or any other metal tool to pull the tab out or you may

break it.

2 and 3: Push

down and turn

base counter

clockwise

1. Pull tab out

and hold

3. While pushing the base down and holding the tab out, rotate the base clockwise. This

will release the locking mechanism and you can now pull out the base cover.

4.3. Steps to install the base cover

1. To install the base, align the cutout on the base with the pull out tab

444-00001-00-10 Revision 110 Copyright © 2008 FLIR Systems, Inc. Page 19 of 33

Page 20

2. Turn the base clockwise and make sure the locking mechanism engages (you will hear a

clicking sound when the locking mechanism sets in place.

444-00001-00-10 Revision 110 Copyright © 2008 FLIR Systems, Inc. Page 20 of 33

Page 21

CAUTION!

Step 2

Step 3

Mounting the camera without the locking mechanism properly engaged may

result in the camera falling from its base. Damage to the camera may occur!

4.4 Hard Ceiling Installation (Pendant Mount)

Step 1

Step 1

Cut a 2

template provided with the camera (see sketch in Figure 4). Drill holes for wall

anchors.

Wall anchor holes

3/8

” •diameter hole in the surface where the Dome is to be mounted using the

Attach the base to the ceiling using the three screws and wall anchors provided.

The wires go up through the central hole in the camera base.

Ceiling

mounting holes

Attach the safety cable and ribbon cable.

444-00001-00-10 Revision 110 Copyright © 2008 FLIR Systems, Inc. Page 21 of 33

Page 22

Step 4

Ribbon cable

Safety cable

Attach the dome to the base using the locking mechanism. Make sure the locking

mechanism engages, as indicated by a clicking sound. Failure to properly engage

the locking mechanism may cause the dome to fall from the base, resulting in

damage to the dome and base, and possible personal injury.

444-00001-00-10 Revision 110 Copyright © 2008 FLIR Systems, Inc. Page 22 of 33

Page 23

1 2 6

3

4

5

5. Configuration Options

The D-Series Camera comes with defaults set (see Section 5.4: Default Settings). However, you

can make the following modifications to the FLIR D-Series Camera:

• Change the electronic wiring connections

• Change the dip switch settings on the PC board

To make the changes, you must first disassemble the Dome as described in

should be done by a certified CCTV person only.

5.1 Changing the Electronic Connections

The electronic connections may be changed on the electronic interface as shown below:

Section 4. This

1. Welding point of coaxial cable

2. Fixing point of coaxial cable

3. RS485 Terminal (Left to right: B, A, GND)

4. 10-plug connector for ribbon cable

5. 24VAC Terminal (Left to right: AC24V, AC24V, SAFE-GND)

6. 24VAC (Spare use)

444-00001-00-10 Revision 110 Copyright © 2008 FLIR Systems, Inc. Page 23 of 33

Page 24

Connect the external cables to the electronic interface according to the following guidelines:

Power RS485 Video

Function

AC24V B- A+ GND V+ V-

GND

Cable

Color

Red Yellow Blue Red Black Core

Screen

Olivine

Shield

5.2 Changing DIP Switch Settings

If needed, you may change the dip switch settings on the PC board. Figure 10 shows the

location of the DIP switches:

The default settings are listed on Section 5.4 default Settings.

5.3 Changing the Pelco Address

The Pelco address (001-255) is set using DIP switch S2. See

5.4 Changing the Baud Rate

The baud rate for communication with the D-Seri es camera using the Pelco-D protocol can be

set to 2400, 4800, 9600, or 19200. The factory default is 2400, which is the baud rate used by

444-00001-00-10 Revision 110 Copyright © 2008 FLIR Systems, Inc. Page 24 of 33

Figure 8: PC Board with DIP Switch Bank

section 8.2 for details.

Page 25

for recommendations.

the Pelco 300 keyboard. Use Switch S3, bits 5 and 6 to change this setting as shown in section

8.3 Baud Rate Settings.

5.5 RS-485 Termination Resistor DIP Switch

This is switch 8 on DIP switch S3. The switch is needed for when multiple cameras are wired in

a true RS485 "network", where the Pelco KBD (or similar controller device) uses addressable

commands from one access point. This switch needs to be set to the "On" position for the last

Thermal Dome in the chain. While a small network may work even if this switch is not set to

“On, the system may be unstable and reliability compromised.

For the best reliability, the last camera (certainly for a large installation) should have this RS485

switch set to "On" and the remaining cameras have the switch set to "Off". The default setting of

this switch is “Off”.

5.6 Reassembling and Running Self-Check

Before installation, reassemble the dome and run the self-check.

1. Reconnect the ribbon cable and white cable between the PC board and electronic

interface board.

2. Insert the cylinder into the bottom section and turn clockwise until you hear a click. The

click indicates the cylinder is locked in place.

3. Slide the trim ring into the slots on the Dome edge and turn clockwise to tighten.

4. Before you install the camera into the ceiling, connect the power, video, and serial

cables to your security network and run the self-check.

NOTE: if you encounter a problem or malfunction please refer to the Troubleshooting section

6. Using Your D-Series Camera

6.1. IR Imaging Views

The D-Series Camera is easy to use, but you should take a moment to carefully read this

section so you fully understand what you are seeing on your display. While the imagery you will

see on the monitor may look like black and white daylight video, it isn’t! A few tips on how to

interpret some of the imagery will help you to make the most of your system.

Turn on the camera using the on/off switch on the power supply. After the self-check, you can

use the joystick to control the pan and tilt features of the camera. Controlling the camera’s

direction becomes intuitive after a few minutes of experimenting. The camera automatically

adjusts to changing scene conditions so no additional adjustments of contrast or brightness are

necessary.

The thermal imager inside the camera does not sense light like conventional cameras; it senses

heat or temperature differences. As you experiment with the system during daylight and

444-00001-00-10 Revision 110 Copyright © 2008 FLIR Systems, Inc. Page 25 of 33

Page 26

21 Preset

1 Aux On

Black Hot LUT

Default Settings

Default, Not Inverted

nighttime operation, you will notice differences in the “picture quality”; this is normal. The

camera senses small “differences” in apparent radiation from the objects in view and displays

them as either white (or lighter shades of gray) for warmer objects, and black (or darker shades

of gray) for colder objects. This is why you will see areas of an object or person that appear

white while the rest of the object or person may appear dark (or cool).

Figure 9: Areas radiating heat appear brighter.

Scenes with familiar objects will be easy to interpret with some experience. The camera

automatically optimizes the image to provide you with the best contrast in most conditions.

6.2 Pelco D and Keyboard Commands

The following table shows the commands available to the Thermal Dome. No other commands

are available, and the camera operates in slave mode only. It recognizes and acts on the

commands received immediately but it does not communicate in any way back to the host or

keyboard. Note that the Pelco Commands can either be initiated over the RS-485 command

wires directly from a customer host system, or from the Pelco keyboard by entering “command

number”, then pressing the Preset button.

Pelco Command Keyboard

Command

11 Preset 1 Aux Off White Hot LUT

22 Preset 2 Aux On Set to 2X Zoom Also accessed by rotating

12 Preset 2 Aux Off Set to 1X Zoom Also accessed by rotating

23 Preset 3 Aux On Toggle AGC Toggles through 7 AGC

13 Preset 3 Aux Off Invert Image Repeat to Non-Invert

24 Preset 4 Aux On Set Power-up

14 Preset 4 Aux Off Restore Factory

Thermal Dome

Function

Settings

Comment

the joystick

counterclockwise

the joystick clockwise

settings

White H ot, Zoom 1X, AGC

444-00001-00-10 Revision 110 Copyright © 2008 FLIR Systems, Inc. Page 26 of 33

Page 27

Hot

16 – 20 Prese t

5 Aux On

Reserved

Move joystick to stop

1 – 10 Prese t

----------

Available for use

Hold Preset for >3 seconds

Symptoms

Possible Reasons

Recommendations

connection

Not enough power

Change power supply

Wrong connection

Reconnect

switcher or wrong operation

with manual

of camera serial number and

15 Preset 5 Aux Off Toggle LUT

25 – 29 Prese t 6 – 9 Aux On/Off Reserved

92 Preset ---------- Set Auto Scan Left Hold Preset for >3 seconds

93 Preset ---------- Set Auto Scan Right Hold Preset for >3 seconds

99 Preset ---------- Start Auto Scan Tilt is not set, does not

30 – 52 Prese t ---------- Available for use Hold Preset for >3 seconds

Pattern ---------- Up to 200

programmable

positions

Table 2: Pelco D and Keyboard Commands

Color, White Hot, Black

change

Hold Pattern button for >3

seconds, then move to

desired positions, ACK to

end pattern

7. Troubleshooting

No self-checking or/and

image after power on

No self-checking

or with noise

No image after selfchecking

Incorrect power supply

Power supply problem Change power supply

Mechanical failure Contact FLIR technical support

Bad connection Check connections

Wrong connection of video

Check power supply connections

Connect and operate in accordance

No operation after selfchecking

Image lost during dome

operation

Image instability

No display of camera

chosen

Wrong connection of control

wires

Wrong setup of address,

protocol or baud rate

Not enough power Replace power supply

Bad connection Check connections

Video switcher or electronic

malfunction

Wrong connection position

video switcher

Table 3: Troubleshooting Guidelines

Reconnect

Re-setup

Contact FLIR Technical Support

Reconnection to camera serial

number

7.1 Caring for your FLIR D-Series Camera

For lens cleaning use the following materials:

• Optical-grade tissue (e.g., Edmund Industrial Optics part number 52105 or any similar

product)

• Pure water (de-ionized or other)

444-00001-00-10 Revision 110 Copyright © 2008 FLIR Systems, Inc. Page 27 of 33

Page 28

Outputs

• Isopropyl alcohol (IPA)

Cleaning Procedure:

1. Saturate a piece of the lens tissue with the water and drape it over the lens. Let the

surface tension of the water pull the tissue onto the lens surface; then drag the tissue

across the lens surface. Repeat several times with different pieces of tissue.

2. Repeat the same procedure using IPA instead of water. Drag the final piece of tissue

over the lens several times to prevent pooling, which could leave a residue on the lens.

8. Performance Specifications

Performance

Camera Type Uncooled LWIR Thermal Imager

Sensor Type 324x256 Vox Microbolometer

Pixel Si ze 38 µm

Spectral Band 7.5 – 13.5 µm

Performance < 85mK NE dT at f/1.6

Movement Pan: 0° – 360° Continuous Tilt: 0° – 90° (180° with flip)

Speed Pan: 0.5° – 100°/S Tilt: 0.5° – 100°/S

Max. Preset Speed 100°/S

Preset Point 80

Auto Scan 1 Route

Patterns 1 Route, 200 Instructions

Analog Video

Power

Input Voltage 24VAC±25%

Power Consumption • 20W

Operation

Image Control Invert, 2x digital zoom, AGC

Time to I mage ~2 seconds

Environmental

Storage Temperature -40 – +85 °C external temp

Environment in-ceiling, indoor only

Humidity only non-condensing

Scene Temp Range To 150 °C standard

Shock 70g shock pulse, 11ms half-sine profile

Vibration 4.3 g ms random vibration for 8 hours (three axes)

Operational Temperature -100 C to +500 C

Default Settings

Baud Rate 2400 Baud

Pelco ID Address 01

NTSC @ 30 Hz

PAL @ 25 Hz (optional)

9 Hz option for export (factory set)

444-00001-00-10 Revision 110 Copyright © 2008 FLIR Systems, Inc. Page 28 of 33

Page 29

Shipping Dimensions

Size 15” x 15” x 19” (38 cm x 38 cm x 48 cm)

Weight 10.7 lbs (4.86 kg)

Table 4: Performance Specifications

8.1 FLIR D-Series Camera Dimensions

444-00001-00-10 Revision 110 Copyright © 2008 FLIR Systems, Inc. Page 29 of 33

Page 30

NOTE

Figure 10: FLIR D-Series Camera Dimensions (in mm)

8.2 Default Settings

,

The FLIR D-Series Camera comes with a default address of 001 (Table 6), a Baud rate of 2400,

and default Pelco-D auxiliary command settings (Table 2).

: If you decide to change the settings, FLIR recommends making the change before

installation.

Address 1 2 3 4 5 6 7 8

001

002 OFF ON OFF OFF OFF OFF OFF OFF

003 ON ON OFF OFF OFF OFF OFF OFF

004 OFF OFF ON OFF OFF OFF OFF OFF

005

006 OFF ON ON OFF OFF OFF OFF OFF

ON

ON

OFF OFF OFF OFF OFF OFF OFF

OFF ON OFF OFF OFF OFF OFF

007 ON ON ON OFF OFF OFF OFF OFF

008 OFF OFF OFF ON OFF OFF OFF OFF

…… …………………………………………………………………

254 OFF ON ON ON ON ON ON ON

255 ON ON ON ON ON ON ON ON

444-00001-00-10 Revision 110 Copyright © 2008 FLIR Systems, Inc. Page 30 of 33

Table 5: Address Settings

Page 31

On

On

19200

installation are provided with the SR-Series Camera.

8.3 Baud Rate Settings

The FLIR D-Series Camera comes with the Baud rate set to 2400. Use the table below to set

the Baud rate using S3, bits 5 and 6.

5 6 Baud Rate

Off Off 2400

On Off 4800

Off On 9600

Table 6: Baud Rate Settings

9. Mounting Templates

9.1. Drop Ceiling Mounting Templates

NOTE: for your convenience, full size templates for both drop ceiling and hard ceiling

Figure 11: Drop Ceiling Mounting Template (not to scale)

444-00001-00-10 Revision 110 Copyright © 2008 FLIR Systems, Inc. Page 31 of 33

Page 32

9.2 Hard Ceiling Mounting Template

Figure 12: Hard Ceiling Mounting Template (not to sc ale)

444-00001-00-10 Revision 110 Copyright © 2008 FLIR Systems, Inc. Page 32 of 33

Page 33

10. Fundamentals of Infrared

444-00001-00-10 Revision 110 Copyright © 2008 FLIR Systems, Inc. Page 33 of 33

Loading...

Loading...