Page 1

USER MANUAL

True RMS 600A

Solar Clamp

Meter with

METERLiNK®

Model CM65

Page 2

Page 3

USER MANUAL

True RMS 600A Solar Clamp

Meter with METERLiNK®

#NAS100017; r. AB/59644/59644; en-US iii

Page 4

Page 5

Table of contents

1 Advisories............. ................. ............... ................. .. ..........1

1.1 Copyright......... ............. .. ................. ............... .......... 1

1.2 Quality Assurance ............... ............... ................. .......1

1.3 Documentation ............... ............... ................. ...........1

1.4 Disposal of Electronic Waste..... ............... .. ............... .... 1

2 Introduction...... .. ............. .. ................. ............. .. ................. 2

3 Safety ..... ............. .. ................. ............... ................. ...........3

3.1 General Safety Information ............... ................. ...........3

3.2 Safety Terms Used In This Manual ........... ................. .. ...3

3.3 Warning and Caution Statements .. ............... ............... .. .3

3.4 UL Listing Note .... ................. .. ............. .. ................. ...4

3.5 International Electrical Symbols ......... .. ............... ...........4

3.6 CENELEC Directives.............. .. ............... .. ............... ...5

4 Descriptions ...... ............... .. ............... .. ............. .. ............... .6

4.1 Product Description.. .. ............. .. ............... .. ............. .. .. 6

4.2 Control Button Descriptions ...... ............... .. ............... .... 7

4.3 Rotary Switch Positions......... ............... .. ............... .......7

4.4 Display Description ................ .. ............. ................. .. ...8

5 Meter Operation .............. .. ............. .. ............... .. ............... ...9

5.1 Powering the Meter .. ............... ................. ............... .... 9

5.2 Auto Power OFF (APO).......... .. ............... ............... .. .... 9

5.3 Automatic and Manual Ranges .......... ................. ...........9

5.4 Out-of-Range Alert.......... .. ............... .. ............. .. ........ 10

5.5 Display Hold Function.......... ................. ............... .. .... 10

5.6 Display Backlight ............... ............... ................. .. .... 10

5.7 Voltage Measurements ........ ................. .. ............. .. .... 10

5.8 LoZ Voltage Measurements ........ .. ............. .. ............... 11

5.9 Low Pass Filter (VFD) Voltage Measurements..... ............ 12

5.10 Milli-Volt Measurements ................ .. ............... ............ 12

5.11 Current Measurements (Clamp)......... ............... ........... 13

5.12 Resistance Measurements .... ............... .. ............... ..... 15

5.13 Continuity Measurements........... .. ............. .. ............... 16

5.14 Diode Measurements ............. .. ............. .. ................. . 17

5.15 Type-K Thermocouple Measurements........... .. .............. 18

5.16 External Clamp Adaptor Current Measurements .. ............ 20

#NAS100017; r. AB/59644/59644; en-US

v

Page 6

Table of contents

6 Bluetooth® Communication and FLIR Tools™ ............... ....... 21

6.1 FCC Compliance .. ............... ................. ............... ..... 21

7 Function Icons .... ................. ............... .. ............... ............. 23

8 Programming Menu ........ ................. ............... ................. .. 26

9 Data Logging . ............... ............... .. ............... ............... .. ... 28

9.1 Data Logging Basics .... ................. ............... ............. 28

9.2 Start/Stop a Data logging session........ ............... .. ........ 28

9.3 Deleting Data Log Files............... ............... ................ 28

9.4 Transmitting Data Log Files to a Mobile Device.... ............ 28

9.5 Transferring Data Log Files to a PC.......... ............... .. .... 28

9.6 Viewing Data Log File Contents on the CM65

Display......... ................. ............... .. ............... ......... 28

10 USB Connectivity ..... .. ............. .. ............... .. ............. .. ........ 29

10.1 Field Firmware Updates ................ .. ............... ............ 29

10.2 Transferring Data Log Files to PC ............ .. ............. .. .... 29

11 Maintenance............. .. ............. .. ............... .. ............. .. ....... 30

11.1 Cleaning........... .. ............... ............... .. ............... ..... 30

11.2 Battery Replacement....... .. ............. .. ............... .. ........ 30

11.3 Meter Storage... ................. ............... ................. .. .... 30

12 Specifications..... ................. ............... ................. ............. 31

12.1 General Specifications..... .. ............. .. ............... .. ........ 31

12.2 DC Voltage Specifications ........... .. ............... .. ............ 32

12.3 DC mV Specifications........... ............... .. ............... ..... 32

12.4 AC Voltage Specifications................ ............... ............ 32

12.5 AC mV Specifications ........ .. ............... ................. ...... 32

12.6 VFD AC Voltage Specifications .............. ................. ..... 32

12.7 LoZ Voltage AC and DC Specifications ............... .. ......... 33

12.8 Frequency Specifications ............. ............... .. ............. 33

12.9 DC Current Specifications (Clamp) ........ ............... .. ...... 33

12.10 AC Current Specifications (Clamp) ..... ............. .. ........... 33

12.11 Resistance Specifications.. ............... ................. ......... 34

12.12 Continuity Specifications . ................. ............... ........... 34

12.13 Diode Specifications ........... ................. .. ............. .. .... 34

12.14 External (Flex) Clamp Adaptor — AC Current

Specifications ................ ............... ................. .......... 34

12.15 Temperature Specifications...... ............... ................. ... 35

#NAS100017; r. AB/59644/59644; en-US vi

Page 7

Table of contents

12.16 Input Specifications... ................. ............... ................ 35

12.17 Safety Specifications .. ............... .. ............. .. ............... 35

13 Three-Year Warranty ....... .. ............... ............... .. ............... .. 37

14 Customer Support....... .. ............... ................. ............... ..... 38

14.1 Corporate Headquarters .............. .. ............... ............. 38

#NAS100017; r. AB/59644/59644; en-US vii

Page 8

Page 9

1

Advisories

1.1 Copyright

©2019, FLIR Systems, Inc. All rights reserved worldwide. No parts of the

software including source code may be reproduced, transmitted, transcribed

or translated into any language or computer language in any form or by any

means, electronic, magnetic, optical, manual or otherwise, without the prior

written permission of FLIR Systems.

The documentation must not, in whole or part, be copied, photocopied, reproduced, translated or transmitted to any electronic medium or machine-readable form without prior consent, in writing, from FLIR Systems. Names and

marks appearing on the products herein are either registered trademarks or

trademarks of FLIR Systems and/or its subsidiaries. All other trademarks,

trade names or company names referenced herein are used for identification

only and are the property of their respective owners.

1.2 Quality Assurance

The Quality Management System under which these products are developed

and manufactured has been certified in accordance with the ISO 9001

standard.

FLIR Systems is committed to a policy of continuous development; therefore,

we reserve the right to make changes and improvements on any of the products without prior notice.

1.3 Documentation

To access the latest manuals and notifications, go to the Download tab at:

https://support.flir.com. It only takes a few minutes to register online. In the

download area you will also find the latest releases of manuals for our other

products, as well as manuals for our historical and obsolete products.

1.4 Disposal of Electronic Waste

As with most electronic products, this equipment must be disposed

of in an environmentally friendly way, and in accordance with existing

regulations for electronic waste. Please contact your FLIR Systems

representative for more details.

#NAS100017; r. AB/59644/59644; en-US

1

Page 10

2

Introduction

The CM65 is a 600 A True RMS Clamp Meter designed to meet the challenges of the solar, alternative/renewable energies, and utilities industries.

The supplied MC4 test leads help you troubleshoot photovoltaic systems and

keep them running efficiently. The CM65 accurately measures voltage, current

and other electrical parameters to ensure proper installation of PV systems.

FLIR’s exclusive METERLiNK® technology wirelessly connects to FLIR

Tools® Mobile so you can view readings and receive data log files from the

CM65 on your mobile device. The CM65 is the perfect tool for the installation

and maintenance of photovoltaic systems and includes features and accessories optimized for residential and light commercial electricians, and RV

technicians.

Visit https://www.support.flir.com/prodreg to register your CM65 and to read

the three-year warranty text.

Features

• 6000 count digital backlit display

• 1000 V AC/DC test lead measurements

• 600 A AC/DC clamp measurements

• Frequency reading for AC Current/Voltage measurements

• Resistance measurements to 60 k ohms

• Continuity and Diode measurements

• Type-K thermocouple temperature measurements

• External clamp adaptor measurements

• Display Hold

• DC zero adjust

• Minimum/Maximum/Average recording memory

• Integrated VFD mode (low-pass filter) on AC V and Hz measurements

• LoZ (low impedance) mode eliminates ‘ghost’ voltage problems

• Bluetooth® connectivity for remote measurement monitoring and data log

file transmit

• USB port in battery compartment for field firmware updates and data log

file transfer

• Adjustable Auto power OFF (APO) timer

• Safety Category Rating: CAT III 1000 V & CAT IV 600 V AC & DC

#NAS100017; r. AB/59644/59644; en-US

2

Page 11

3

Safety

3.1 General Safety Information

This user manual contains information and warnings that must be followed for

operating the instrument safely and maintaining the instrument in a safe operating condition. If the instrument is used in a manner not specified by the manufacturer, the protection provided by the instrument may be impaired.

The meter protection rating, against the users, is double insulation per UL/

IEC/EN61010-1 Ed. 3.0, IEC/EN61010-2-033 Ed. 1.0, CAN/CSA C22.2 No.

61010-1 Ed. 3.0, IEC/EN61010-2-032 Ed. 3.0 & IEC/EN61010-031 Ed. 1.1:

Measurement Category III 1000V & Category IV 600V AC & DC.

3.2 Safety Terms Used In This Manual

WARNING: Identifies conditions and actions that could result in serious injury

or even death to the user.

CAUTION: Identifies conditions and actions that could cause damage or malfunction in the instrument.

3.3 Warning and Caution Statements

WARNING

To reduce the risk of fire or electric shock, do not expose this product to rain or moisture.

The meter is intended only for indoor use.

WARNING

To avoid electrical shock hazard, observe the proper safety precautions when working with

voltages above 60 V DC or 30 V AC rms. These voltage levels pose a potential shock hazard to the user. Before and after hazardous voltage measurements, test the voltage function on a known source such as line voltage to determine proper meter functioning.

WARNING

Keep hands/fingers behind the hand/finger barriers (of the meter and the test leads) during

measurement. Inspect test leads, connectors, and probes for damaged insulation or exposed metal before using the instrument. If any defects are found, replace them immediately. Use only the test leads provided with the equipment (or UL Listed probe assemblies

rated CAT III 1000 V or better).

#NAS100017; r. AB/59644/59644; en-US

3

Page 12

3

Safety

WARNING

The accompanied test probe assembly meets UL/IEC/EN61010-031 Ed. 1.1 to 10A maximum at 140℉ (60℃). IEC 61010-031 requires exposed conductive test probe tips to be ≤

4 mm for CAT III & CAT IV ratings. Refer to the category markings on your probe assemblies as well as on the add-on accessories (detachable Caps or Alligator Clips, etc.), if any,

for applicable rating changes.

WARNING

This Clamp meter is designed for clamping around or removing from non-insulated, hazardous live conductors. Nonetheless, individual protective equipment must be used when

hazardous live parts in the installation, where the measurement is to be made, could be

accessible.

WARNING

Remove test leads from the meter before taking clamp measurements.

CAUTION

The maximum current rating for the supplied MC4 test leads is 10 A at 140℉ (60℃)

maximum.

CAUTION

Disconnect the test leads from the test points before changing meter functions.

CAUTION

Do not use the device for a procedure that it is not intended for. This can cause damage to

the protection built into the instrument.

3.4 UL Listing Note

UL listing is not an indication or a verification of the accuracy of the meter

3.5 International Electrical Symbols

Caution! Refer to the explanation in the user manual.

Caution! Risk of electrical shock.

Earth ground.

#NAS100017; r. AB/59644/59644; en-US

4

Page 13

3

Safety

Double/reinforced insulation.

Fuse.

AC (alternating current).

DC (direct current).

Application around, and removal from, hazardous live conductors is

permitted.

3.6 CENELEC Directives

This instrument conforms to CENELEC Low-voltage directive 2014/35/EC,

Electromagnetic compatibility directive 2014/30/EU and RoHS directive 2011/

65/EU.

#NAS100017; r. AB/59644/59644; en-US

5

Page 14

4

Descriptions

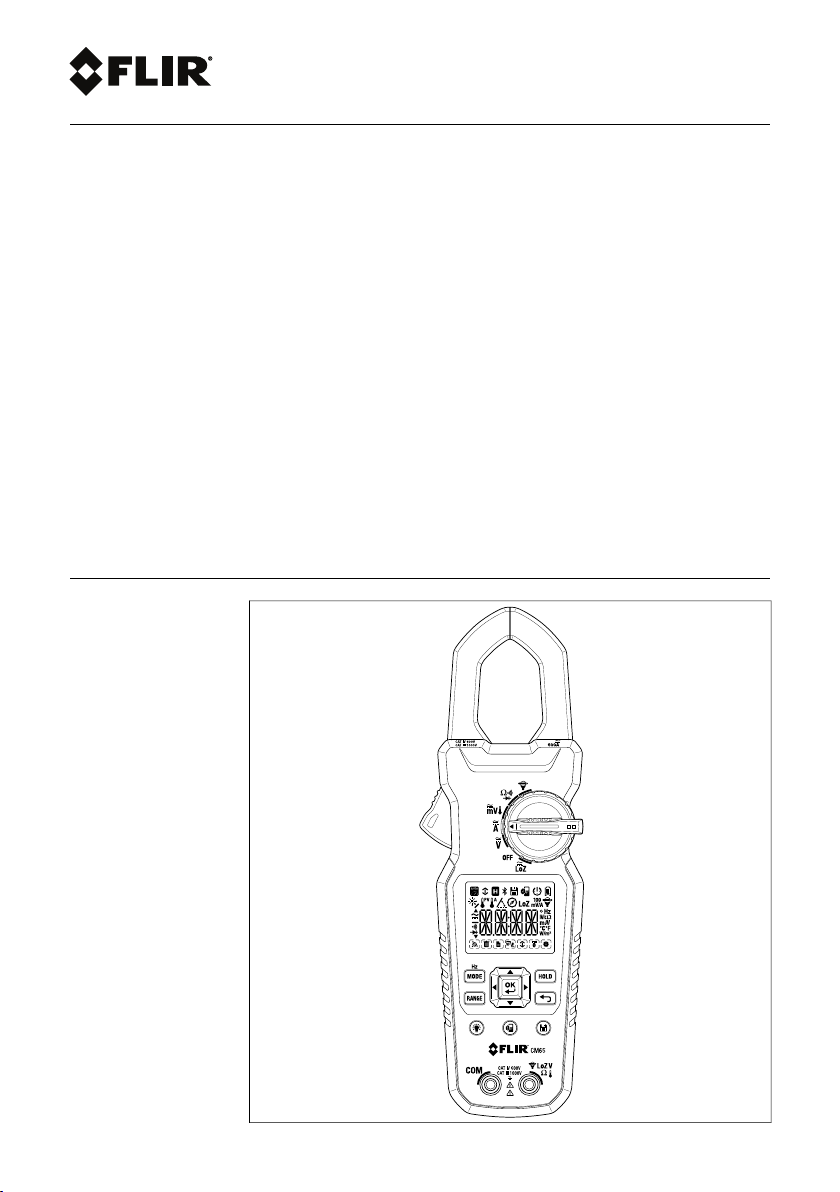

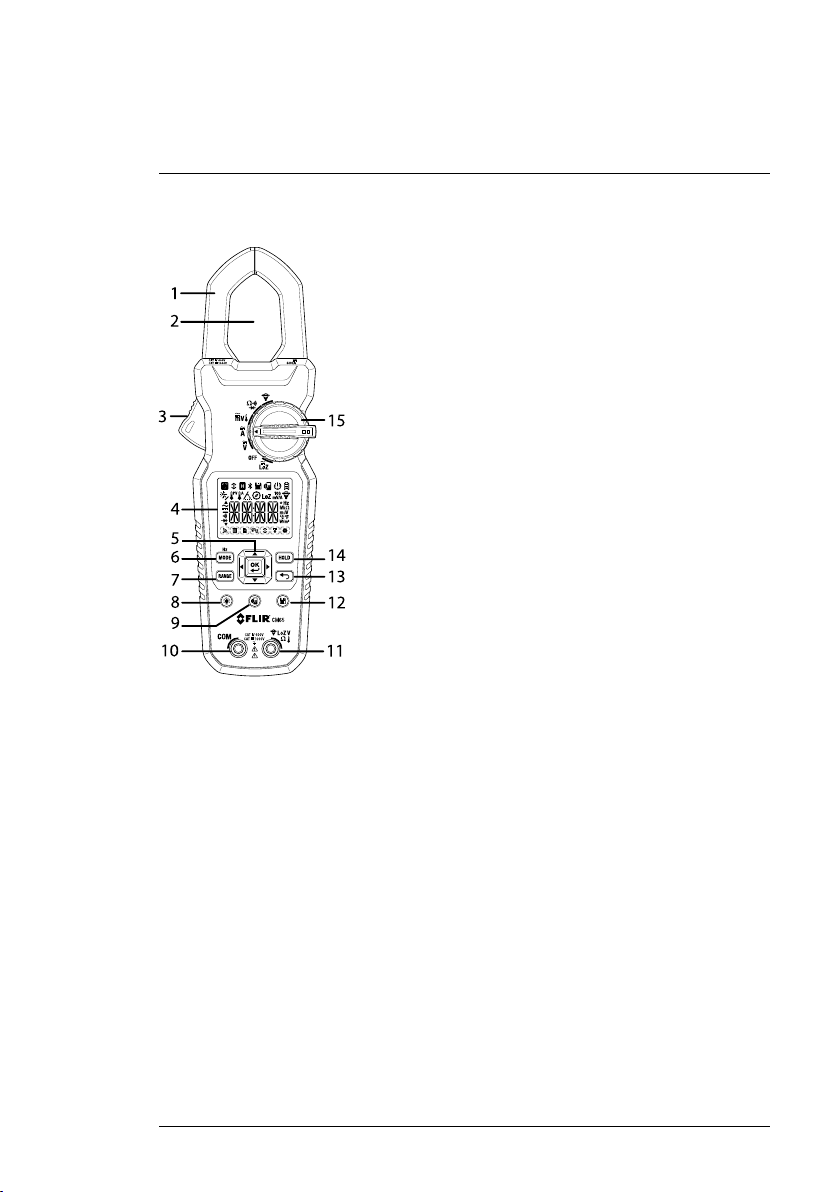

4.1 Product Description

Figure 4.1 Product Description

1. Clamp jaws

2. Clamp measurement area

3. Jaw opening trigger

4. Display area

5. OK menu button (center) and navigation arrows

6. MODE/Hz button

7. RANGE button

8. Display backlight button

9. Bluetooth® ON/OFF button

10. COM (-) test lead terminal

11. Positive (+) test lead terminal

12. Data log button

13. Return button (back up and exit menu)

14. HOLD button

15. Rotary function selector

#NAS100017; r. AB/59644/59644; en-US

6

Page 15

4

Descriptions

Note: Battery compartment on rear, not pictured. USB port located inside battery compartment.

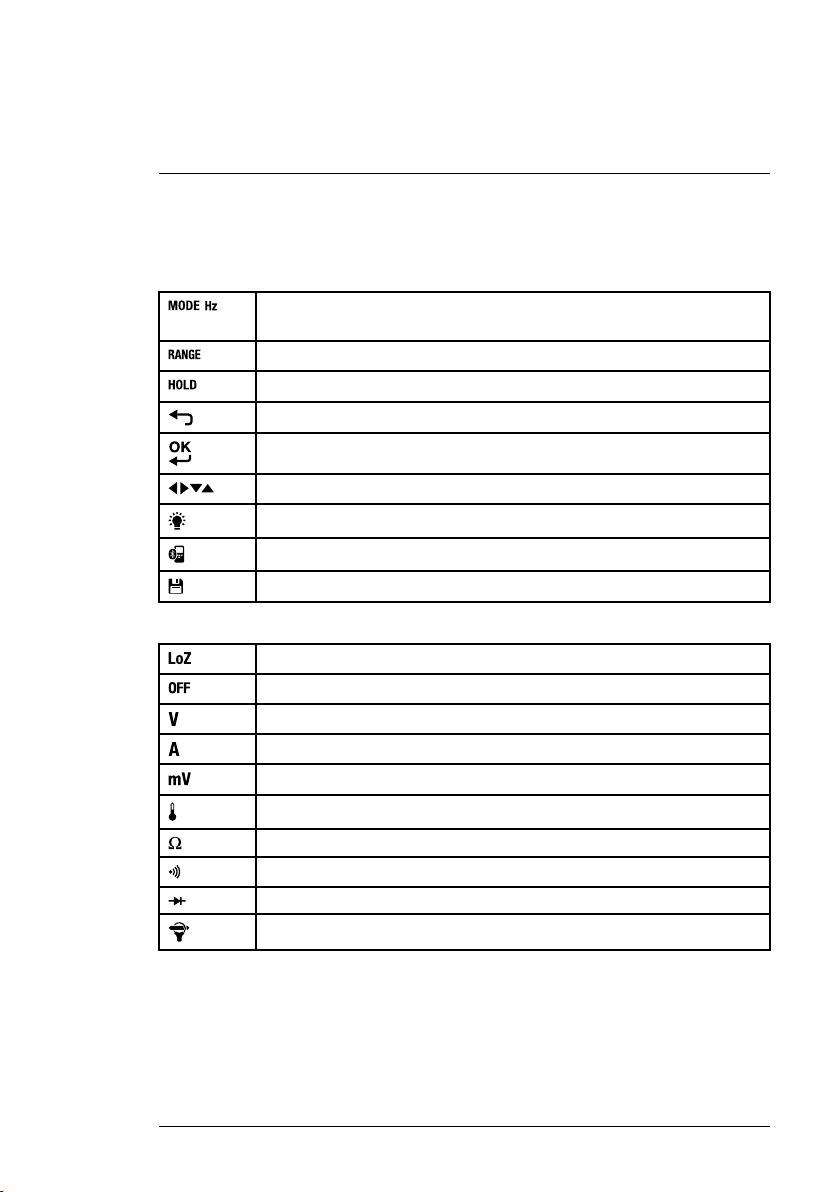

4.2 Control Button Descriptions

Toggle AC/DC (short presses), select frequency (Hz) mode (long press),

select an option at a multi-option rotary switch position.

Short press for Manual range mode, long press to return to Auto.

Short press to freeze/unfreeze displayed readings.

Return button, short press to back up or exit the menu system.

Short press to open a menu and to confirm selections.

Navigation buttons (short presses).

Short press to toggle display backlight ON/OFF.

Short press to toggle Bluetooth® ON/OFF.

Short press to start/stop the data logger.

4.3 Rotary Switch Positions

Low Impedance mode.

Meter power is switched OFF.

Voltage mode (AC/DC).

Current mode (AC/DC).

Millivolt mode (AC/DC).

Thermocouple measurement mode.

Resistance mode.

Continuity mode.

Diode mode.

External clamp meter adaptor mode.

#NAS100017; r. AB/59644/59644; en-US

7

Page 16

4

Descriptions

4.4 Display Description

Figure 4.2 Display Icon Descriptions

1. Auto Range

2. MAX/MIN/AVG memory

3. Data Hold

4. Bluetooth®

5. Data logger

6. Prompt to use up/down arrow buttons

7. Auto Power OFF (APO)

8. Battery status

9. AC measurements

10. DC measurements

11. Continuity function

12. Diode function

13. Resistance function (ohms)

14. Low Impedance mode

15. External clamp adaptor range

16. External clamp adaptor mode

17. Data Log File transmit function icon

18. Data Log File delete function icon

19. Data Log File open function icon

20. Low pass filter function icon

21. MAX/MIN/AVG function icon

22. DC Zero function icon

23. Settings function icon (opens Programming Menu)

NOTE

Not all icons are represented in Figure 4–2. Other available icons are explained in their respective sections of this user manual.

#NAS100017; r. AB/59644/59644; en-US

8

Page 17

5

Meter Operation

CAUTION

Before operating the device, you must read, understand, and follow all instructions, dangers, warnings, cautions, and notes.

NOTE

When the meter is not in use, the function switch should be set to the OFF position.

CAUTION

When connecting the probe leads to the device under test, connect the negative lead before connecting the positive lead. When removing the probe leads, remove the positive

lead before removing the negative lead.

CAUTION

Before and after hazardous voltage measurements, test the voltage function on a known

source (such as line voltage) to determine proper meter functionality.

5.1 Powering the Meter

Set the function switch to any position to power the meter ON.

If the low battery voltage warning is displayed, or if the meter does not power

ON, replace the batteries. See Section 11, Maintenance, for battery replacement details.

5.2 Auto Power OFF (APO)

The APO feature switches the meter OFF after approximately 10 minutes (default) of inactivity. The APO timer can be set from 1 to 99 minutes (see the

Programming Menu section). The meter will beep to alert you when it is about

to power OFF, press any button to extend the APO time before it powers OFF.

5.3 Automatic and Manual Ranges

The meter uses automatic ranging by default. To manually select a measurement range, short press the RANGE button to exit the Auto mode. Subsequent, short presses will step through the available ranges. Long press the

RANGE button to return to the Auto Range mode. When the Auto Range

mode is active, the Auto Range symbol is displayed. In the manual mode, the

meter may display an up arrow, suggesting that a higher range should be selected for best accuracy and resolution.

#NAS100017; r. AB/59644/59644; en-US

9

Page 18

5

Meter Operation

Figure 5.1 Auto Range Display Icon

5.4 Out-of-Range Alert

If the input is out-of-range, OL is displayed. Please do not attempt to make

measurements beyond the specified ranges of the meter.

5.5 Display Hold Function

After taking a measurement, short press the HOLD button to freeze a reading.

Press the HOLD button again to return to normal operation. The H icon will

appear when the display hold function is engaged.

5.6 Display Backlight

Short press the backlight button

to turn ON the display backlighting. Press

again to switch the backlight OFF.

5.7 Voltage Measurements

CAUTION

Use caution when the measured voltage is greater than 30V DC or AC rms.

#NAS100017; r. AB/59644/59644; en-US

10

Page 19

5

Meter Operation

Figure 5.2 Basic Voltage Measurement Setup

1. Set the function switch to the Voltage position .

2. Short press the MODE button to select AC or DC voltage mode.

3. Insert the black test lead into the negative (COM) terminal and the red test

lead into the positive terminal.

4. Place the probe ends of the test leads in parallel to the part under test.

5. Read the Auto Range voltage measurement on the display.

6. To switch to Manual Range mode, short press the RANGE button. Subse-

quent short presses of the RANGE button will step through the available

ranges. Long press the RANGE button to return to Auto Range mode.

7. Long press the MODE button to read the frequency (Hz) of an AC signal.

8. The available Function Icons in Voltage mode are Settings, MIN/MAX/AVG,

and VFD (AC only). See Section 7, Function Icons, for complete details.

5.8 LoZ Voltage Measurements

CAUTION

Use caution when the measured voltage is greater than 30V DC or AC rms.

#NAS100017; r. AB/59644/59644; en-US

11

Page 20

5

Meter Operation

LoZ Voltage measurements eliminate the affects of ‘ghost’ voltages. The procedure for taking LoZ Voltage measurements is virtually the same as for taking standard Voltage measurements, the only difference is that for LoZ

Voltage measurements you select the LoZ rotary switch position. Note that

frequency (Hz) measurements are not available in Loz Voltage mode. Refer to

Section 5.7, Voltage Measurements, for other voltage measurement details.

5.9 Low Pass Filter (VFD) Voltage Measurements

CAUTION

Use caution when the measured voltage is greater than 30V DC or AC rms.

The VFD feature in the CM65 eliminates high frequency noise in AC voltage

measurements by means of a low pass filter. The VFD mode is designed for

variable frequency drive measurements. When taking AC Voltage measurements, the VFD function icon will appear on the bottom of the display. Scroll to

the icon with the arrow buttons and press the OK button to engage the VFD

mode. Press the Return button to disengage the mode (see Section 7, Func-

tion Icons, for complete details). The procedure for taking VFD Voltage measurements is identical to the procedure for taking standard Voltage

measurements. Refer to Section 5.7, Voltage Measurements, for additional

voltage measurement details.

5.10 Milli-Volt Measurements

CAUTION

Use caution when the measured voltage is greater than 30V DC or AC rms.

#NAS100017; r. AB/59644/59644; en-US

12

Page 21

5

Meter Operation

Figure 5.3 Millivolt Measurements

1. Set the function switch to the millivolt position .

2. Short press the MODE button to select AC or DC voltage mode.

3. Insert the black test lead into the negative (COM) terminal and the red test

lead into the positive terminal.

4. Place the probe ends of the test leads in parallel to the part under test.

5. Read the Auto Range voltage measurement on the display.

6. To switch to Manual Range mode, short press the RANGE button. Subse-

quent short presses of the RANGE button will step through the available

ranges. Long press the RANGE button to return to Auto Range mode.

7. Long press the MODE button to read the frequency (Hz) of an AC signal.

8. The available Function Icons in the millivolt mode are Settings and MIN/

MAX/AVG. See Section 7, Function Icons, for complete details.

5.11 Current Measurements (Clamp)

WARNING

Do not measure current on a circuit if the voltage increases to more than 1000 V. This can

cause damage to the instrument and can cause injury to persons.

#NAS100017; r. AB/59644/59644; en-US

13

Page 22

5

Meter Operation

WARNING

Do not use the meter to measure current above the rated frequency. This may cause the

magnetic circuits in the jaws to reach hazardous temperatures.

WARNING

Disconnect the test leads from the meter before taking Clamp measurements.

Clamp Measurement Considerations

• Press the jaw trigger to open the jaws and then clamp around the conductor(s) of only one pole of a circuit.

• Ensure that the jaws are completely closed. Enclosing conductor(s) of

more than one pole of a circuit may result in differential current

measurements.

• Align the conductor(s) to the jaws center indicators as closely as possible.

• Adjacent current-carrying devices such as transformers, motors and conductor wires may affect measurement accuracy.

Figure 5.4 Basic Current Clamp Measurement

Taking Current Clamp Measurements

1. Set the function switch to the Ampere position

#NAS100017; r. AB/59644/59644; en-US

.

14

Page 23

5

Meter Operation

2. Short press the MODE button to select AC or DC current mode.

3. For DC current mode, with no conductor in the clamp, use the DC Zero

menu icon to zero the display (see the Function Icons section for complete

details).

4. Press the trigger to open the clamp jaws and clamp around the conductor

under test.

5. Read the Auto Range current measurement on the display.

6. To switch to Manual Range mode, short press the RANGE button. Subse-

quent short presses of the RANGE button will step through the available

ranges. Long press the RANGE button to return to Auto Range mode.

7. Long press the MODE button to read the frequency (Hz) of an AC signal.

8. The available Function Icons in the Current mode are Settings, MIN/MAX/

AVG, and DC Zero (DC only). See Section 7, Function Icons, for complete

details.

5.12 Resistance Measurements

WARNING

Do not take resistance measurements before removing power to the resistor or circuit

under test. Injury to persons can occur.

Figure 5.5 Resistance Measurements

1. Set the function switch to the Resistance position .

#NAS100017; r. AB/59644/59644; en-US

15

Page 24

5

Meter Operation

2. If necessary, short press the MODE button to select the Resistance func-

tion k

.

3. Insert the black test lead into the negative (COM) terminal and the red test

lead into the positive terminal.

4. Place the probe ends of the test leads in parallel to the part under test.

5. Read the resistance value on the display.

6. To switch to Manual Range mode, short press the RANGE button. Subse-

quent short presses of the RANGE button will step through the available

ranges. Long press the RANGE button to return to Auto Range mode.

7. The available Function Icons in the Resistance mode are Settings and

MIN/MAX/AVG. See Section 7, Function Icons, for complete details.

5.13 Continuity Measurements

WARNING

Do not perform continuity tests before removing power to the device under test. Injury to

persons can occur.

Figure 5.6 Continuity Measurements (note the OPEN and the SHORTED wire examples)

1. Set the function switch to the Continuity position .

2. If necessary, short press the MODE button to select the Continuity

function.

#NAS100017; r. AB/59644/59644; en-US

16

Page 25

5

Meter Operation

3. Insert the black test lead into the negative (COM) terminal and the red test

lead into the positive terminal.

4. Place the probe ends of the test leads in parallel to the part under test.

5. If the measurement is <30 Ω, the meter will beep. If the measurement is >

480Ω, the meter will not beep. Between 30 Ω and 480Ω, the meter will

stop beeping at an unspecified point.

6. The available Function Icons in the Continuity mode are Settings and MIN/

MAX/AVG. See Section 7, Function Icons, for complete details.

5.14 Diode Measurements

WARNING

Do not perform diode tests before removing power to the diode under test. Injury to persons can occur.

Figure 5.7 Basic Diode Test Setup (Note Test 1 and Test 2 examples)

1. Set the function switch to the Diode position .

2. If necessary, short press the MODE button to select the Diode function.

3. Insert the black test lead into the negative (COM) terminal and the red test

lead into the positive terminal.

#NAS100017; r. AB/59644/59644; en-US

17

Page 26

5

Meter Operation

4. Take two diode measurements, one in forward bias and one in reverse

bias. This can be accomplished by, first, placing the probe ends of the test

leads in parallel to the part under test in one direction and then taking a

second measurement in the reverse polarity orientation.

5. If the reading is between 0.40 V and 0.90 V in one direction and OL (over-

load) in the opposite direction, the component is good. If the measurement

is 0V in both directions (shorted) or OL in both directions (open), the component is bad.

6. The available Function Icons in the Diode mode are Settings and MIN/

MAX/AVG. See Section 7, Function Icons, for complete details.

5.15 Type-K Thermocouple Measurements

CAUTION

The supplied thermocouple is rated for -4~482℉ (-20~250℃) only, it is not rated for the

entire specified temperature range of the meter.

#NAS100017; r. AB/59644/59644; en-US

18

Page 27

5

Meter Operation

Figure 5.8 Thermocouple Temperature Measurements

1. Set the function switch to the Temperature position .

2. Use the MODE button to select the Temperature mode.

3. Insert the banana plug Type-K temperature probe into the meter’s input

terminals observing correct polarity. A plug adapter with banana plug to

Type-K socket (to adapt to other Type-K standard mini plug temperature

probes) can be obtained optionally.

4. Touch the thermocouple probe tip to the surface of an object under test or

hold the probe in air.

5. Read the temperature measurement on the display.

6. To select ℃ or ℉ as the default unit of measure, see Section 8, Program-

ming Menu.

7. The available Function Icons in Temperature mode are Settings and MIN/

MAX/AVG. See Section 7, Function Icons, for complete details.

#NAS100017; r. AB/59644/59644; en-US

19

Page 28

5

Meter Operation

5.16 External Clamp Adaptor Current Measurements

Note: This section applies only to measurements taken with an external clamp

adaptor that connects to the CM65 input terminal jacks. For clamp measurements using the CM65’s built-in clamp jaws, please see Section 5.11, Current

Measurements (Clamp).

Figure 5.9 External Clamp Adaptor Test Setup

1. Set the CM65 function switch to the external clamp adaptor position .

2. Connect the external clamp adaptor to the CM65 by inserting the signal

leads from the external clamp to the input terminals on the CM65, observing correct polarity.

3. Press the trigger to open the clamp jaws on the external clamp adaptor

and clamp around the conductor under test.

4. Read the measurement on the CM65 display. See Section 12.15, External

Clamp Adaptor (AC Current), to help interpret the reading based on the

range of the measurement . As an example, in some ranges, for each

100mV sent to the CM65 by the external clamp adaptor, the CM65 displays 1 ampere (100mV/A).

5. The available Function Icons in this mode are Settings and MIN/MAX/AVG.

See Section 7, Function Icons, for complete details.

#NAS100017; r. AB/59644/59644; en-US

20

Page 29

6

Bluetooth® Communication and FLIR Tools™

To connect the CM65 to a mobile device running the FLIR Tools™ Mobile App,

turn on the mobile device and start the FLIR Tools™ Mobile App (download

the mobile App from the Google Play™ store, the Apple App store, or here:

https://www.flir.com/products/flir-tools-app/).

Select INSTRUMENTS from the drop-down menu in the App and search for

the CM65 (the CM65 must be ON and the Bluetooth® button must be

pressed so that the Bluetooth® icon is displayed on the CM65). Tap in the

App to connect to the CM65.

When connected to a device running the App, the CM65 (using the METERLiNK® protocol) continually sends readings for live display on the remote device. The CM65 can also transmit bulk data log files to a mobile device (see

Section 9, Data logging, and Section 7, Function Icons, to learn about these

features).

6.1 FCC Compliance

This device complies with part 15 of the FCC Rules. Operation is subject to

the following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference

that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following

measures:

1. Reorient or relocate the receiving antenna.

2. Increase the separation between the equipment and receiver.

#NAS100017; r. AB/59644/59644; en-US

21

Page 30

6

Bluetooth® Communication and FLIR Tools™

3. Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected.

4. Consult the dealer or an experienced radio/TV technician for help.

WARNING

Changes or modifications not expressly approved by the party responsible for compliance

could void the user’s authority to operate the equipment.

#NAS100017; r. AB/59644/59644; en-US

22

Page 31

7

Function Icons

Figure 7.1 The Seven Function Icons (bottom of display)

The CM65 has seven Function Icons that appear along the bottom row of the

display in a variety of combinations depending on the selected function. The

seven icons are shown in the display description section of this manual and

are explained below. To enable a Function Icon, scroll to it with the left/right arrow buttons. When you’ve reached it, it will begin blinking. Press the OK button to enable it, a box will appear around the icon indicating that it has been

enabled. To disable it, press the Return button, the box will disappear.

• Data Log File Transmit

1. Once a data log file is created (see Section 9, Data Logging, to create

a file), open the Programming Menu (press OK) and scroll to the FILE

parameter. See Section 8, Programming Menu, for more details.

2. When you press OK at the FILE parameter in the Programming Menu,

a data log list will be available. Scroll through the list and press OK at

the desired log to select it.

3. With the CM65 paired with a mobile device (see Section 6, Bluetooth®

Communications and FLIR Tools™), press the Data Log File Transmit

icon (see icon at beginning of this section) to transmit the log file to the

mobile device.

• Data Log File Delete

1. To create a data log file, see Section 9, Data Logging.

2. Once a data log file is created, press OK to open the Programming

Menu and scroll to the FILE parameter. Press OK at the FILE parameter

to open it. See Section 8, Programming Menu, for more information.

3. When you open the FILE parameter in the Programming Menu a data

log list will be available. Scroll to the desired log and press OK.

4. Scroll to the Data Log File Delete icon (bottom of display) and press

OK, this will erase the selected file (see icon at the beginning of this

section).

• Data Log File Open

To view the logged readings of a file directly on the CM65 display, see the

steps below:

#NAS100017; r. AB/59644/59644; en-US

23

Page 32

7

Function Icons

1. Press OK to open the Programming Menu

2. Scroll to the FILE parameter in the menu

3. Scroll to the desired data log file (they are serially numbered)

4. With the desired data log file number displayed, press OK.

5. Scroll to the Data Log File Open function icon at the bottom of the dis-

play

and press OK. See Section 8, Programming Menu, for addi-

tional details.

6. The data log file is now open, you can scroll through the data using the

arrow buttons. The display will prompt you with arrow symbols indicating which arrow buttons are available for use. Note that the file provides

date and time along with the measurement readings.

7. Press the Return button to return to the Programming. Press the Return

button again to exit the menu.

• Low Pass Filter

1. This icon appears when you’ve selected the AC Voltage mode of opera-

tion. See Section 5.9, Low Pass Filter, for additional information.

2. With the AC Voltage mode selected, you’ll see the VFD icon at the bot-

tom of the display, scroll to it with the left/right arrow buttons. When the

icon is blinking, press the OK button to activate the VFD mode (a box

will appear around the icon). To disengage the VFD mode, press the

Return button (the box will disappear).

• Max/Min/Avg

1. This icon is available in most measurement modes. When selected, the

CM65 records the maximum, minimum, and average readings.

2. When this icon is available, scroll to it with the left/right arrow buttons

until the icon is blinking.

3. Press OK at the blinking icon to engage the Max/Min/Avg mode.

4. Use the up/down arrow buttons to scroll through the Max (up arrow

symbol), Min (down arrow symbol), Average (up and down arrow symbol) and real time reading (no arrow symbols).

5. To exit this mode (and to reset the Max/Min/Avg memories), press the

Return button.

• DC Zero

1. This icon is available in the DC current mode. When selected, the

CM65 display zeros so you can take an accurate DC clamp meter

measurement.

#NAS100017; r. AB/59644/59644; en-US

24

Page 33

7

Function Icons

2. When this icon is available, scroll to it with the left/right arrow buttons

until the icon is blinking.

3. Press OK at the blinking icon to engage the mode and the display will

zero.

4. To exit this mode, press the Return button.

• Settings (to access Programming Menu)

1. The Settings function icon takes you to the Programming Menu. See

Section 8, Programming Menu, for complete details.

#NAS100017; r. AB/59644/59644; en-US

25

Page 34

8

Programming Menu

To access the CM65 Programming Menu, short press the OK button with the

meter ON (or select the Settings function icon as explained in Section 7,

Function Icons). Use the up/down arrow buttons to scroll the Programming

Menu list and press OK at a parameter to open it. See the details below:

• APO: Auto Power OFF utility.

1. Press OK at the APO parameter to open it.

2. Use the up/down arrow buttons to change the value of the flashing digit.

3. Use the left/right arrows to select a digit for editing and use the up/down

arrows to change it. The APO setting range is OFF (no APO function)

and 1 to 99 minutes.

4. Press OK to confirm the new APO time.

5. Use the up/down arrows to select a new parameter to edit, or press the

Return button to exit to the normal operating mode.

• FILE: Data Log file list.

1. Press OK at the FILE parameter to open it. If Data Log records are

saved, the list will appear here.

2. Use the up/down arrows to scroll through the data log list.

3. Press OK at a list to open it.

4. When a list is open, the Function Icons for file delete

, and file open will appear on the bottom of the display. Note

that the file transmit icon will only appear if Bluetooth® is enabled in

this Programming Menu (BLE), the Bluetooth® button is pressed so

that the Bluetooth® icon is shown on the CM65 display, and the CM65

is paired with a mobile device. For details, see Section 6 for Bluetooth®

and Section 7 for Function Icons.

5. Press the Return button to return to the main menu list. Press again to

return to the normal operating mode or use the arrows to select another

menu parameter.

• TIME: Set the date and time.

1. Press OK at the TIME parameter to open it.

2. Use the up/down arrows to set the year.

3. Press OK to confirm.

4. Use the up/down arrows to set the month.

5. Use the right arrow to move to the date digits, use the up/down arrows

to set the date.

, file transmit

#NAS100017; r. AB/59644/59644; en-US

26

Page 35

8

Programming Menu

6. Press OK to confirm the month and date.

7. Use the up/down arrows to set the hours.

8. Use the right arrow to select the minutes digits and use the up/down ar-

rows to set the minutes.

9. Press OK to confirm the hours and minutes.

10. Use the up/down arrows to select a new parameter to edit, or press Re-

turn to exit to the normal operating mode.

• BLE: Bluetooth® enable/disable.

1. Press OK at the BLE parameter.

2. Use the up/down arrows to select ON or OFF.

3. Press OK to confirm setting.

4. Use the up/down arrows to select a new parameter to edit, or press Re-

turn to exit to the normal operating mode.

• TEMP: Select the temperature units of measure.

1. Press OK at the TEMP parameter.

2. Use the up or down arrow button to select ℃ or ℉.

3. Press OK to confirm.

4. Use the up/down arrows to select a new parameter to edit, or press Re-

turn to exit to the normal operating mode.

• RST: Factory Default Reset.

1. Press OK at the RST parameter.

2. Use the up or down arrow to select YES or NO.

3. Press OK to confirm.

4. Use the up/down arrows to select a new parameter to edit, or press Re-

turn to exit to the normal operating mode.

#NAS100017; r. AB/59644/59644; en-US

27

Page 36

9

Data Logging

9.1 Data Logging Basics

The CM65 data logging utility allows you to automatically log readings to an

internal file every 10 seconds. Each file can contain up to 9999 readings and

the maximum number of files that can be created is 999. Files are automatically serially numbered. Each time a data log session is opened and closed, a

new file is created.

9.2 Start/Stop a Data logging session

Short press the Data log button to start a data logging session. Readings will

be stored every 10 seconds. The data log icon will appear at the top of the

CM65 display while the meter is logging. To stop the session, press the data

log button again (the data log icon will disappear).

Figure 9.1 Data Log Start/Stop button and display icon.

9.3 Deleting Data Log Files

To delete a Data log file, use the Data Log Delete function icon

see Section 7, Function Icons, for complete details.

9.4 Transmitting Data Log Files to a Mobile Device

The CM65 can transmit Data Log files to a paired mobile device using the Da-

ta Log File Transmit function icon

File Transmit in Section 7, Function Icons, for complete details. See also Section 6, Bluetooth®, and Section 8, Programming Menu, for more information.

9.5 Transferring Data Log Files to a PC

The CM65 includes a USB port in the battery compartment for connecting

with a PC. See Section 10, USB connectivity, for details.

9.6 Viewing Data Log File Contents on the CM65 Display

For complete instructions on viewing data log file data directly on the CM65

display, please see Section 7, Function icons and read the Data Log File

Open paragraph.

#NAS100017; r. AB/59644/59644; en-US

. Please read the paragraph Data Log

. Please

28

Page 37

10

USB Connectivity

10.1 Field Firmware Updates

The USB port in the battery compartment allows for field firmware updates,

follow the steps below.

1. Connect the CM65 to a PC using a USB cable. The CM65 USB port is lo-

cated in the battery compartment.

2. Turn the CM65 rotary switch to any position, the CM65 will display ‘USB’.

3. Download the update file (CM65_V0.0x.hex) from the FLIR support site

(https:\\support.flir.com) and transfer it to the CM65 internal memory root

directory.

4. IMPORTANT: Disconnect the CM65 from the PC. Do not proceed unless

the USB cable that connects the CM65 to the PC is disconnected.

5. Turn the CM65 rotary switch to the OFF position.

6. Turn the CM65 rotary switch to any ON position.

7. The CM65 will begin the update process. This will take approximately 30

seconds during which there will be a blank screen.

8. When the update is complete, the CM65 will emit an alert beep and will

reboot.

9. This completes the update process, if errors occur please contact FLIR

customer support.

10.2 Transferring Data Log Files to PC

The USB port in the battery compartment allows for Data Log File transfer.

Connect the CM65 to a PC USB port and use the CM65 as you would any external storage device. For information on data logging, see Section 9, Data

Logging.

#NAS100017; r. AB/59644/59644; en-US

29

Page 38

11

Maintenance

11.1 Cleaning

With the CM65 OFF, wipe the meter housing with a damp cloth as needed.

Do not use abrasives or solvents. Dry completely before use.

11.2 Battery Replacement

The battery compartment is located on the back of the CM65. Use a small

screwdriver to turn the battery compartment lock so that the arrow printed on

the battery compartment cover is pointing toward the ‘open lock’ icon. Open

the compartment and replace the three ‘AA’ batteries observing correct polarity. Please secure the battery compartment before using the meter.

Figure 11.1 Battery Compartment Lock.

11.3 Meter Storage

If the meter is to be stored for an extended period, please remove the batteries for safety.

#NAS100017; r. AB/59644/59644; en-US

30

Page 39

12

Specifications

12.1 General Specifications

Display 6000 count backlit LCD

Polarity Automatic

Update rate 5 readings per second, nominal

Operating temperature 32 ~ 140℉ (0 ~ 60℃)

Relative humidity Maximum relative humidity 80% for temper-

ature up to 88℉ (31℃) decreasing linearly

to 50% relative humidity at 122℉ (50℃)

Pollution Degree 2

Storage temperature –4 ~ 140℉ (-20 ~ 60℃) < 80% RH (with

battery removed)

Operating altitude 7000 ft. (2000 m) maximum

Temperature coefficient Nominal 0.15 x (specified accuracy)/ ℃ @

32 ~ 64.4℉ [0 ~ 18℃] or 82.4 ~ 122℉ [28

~ 50℃]), or as otherwise specified

Sensing True RMS

Transient protection 6.0 kV (1.2/50μs surge)

Power supply 1.5 V ‘AA’ battery x 3

Power consumption 90 mA for all DMM functions with backlight

OFF

APO timer 10 minutes (default). Adjustable from 1 to

99 minutes

Dimensions (LxWxH): 9.9 x 3.4 x 1.6 in. (251 x 86 x 41

mm)

Weight 10.6 oz. (300 g)

Jaw opening/Conductor diameter 1.2 in. (30 mm) maximum

Electrical specification accuracy ± (% reading + number of digits) or as oth-

erwise specified, at 73.4℉ (23℃) ± 9℉

(5℃)

#NAS100017; r. AB/59644/59644; en-US

31

Page 40

12

Specifications

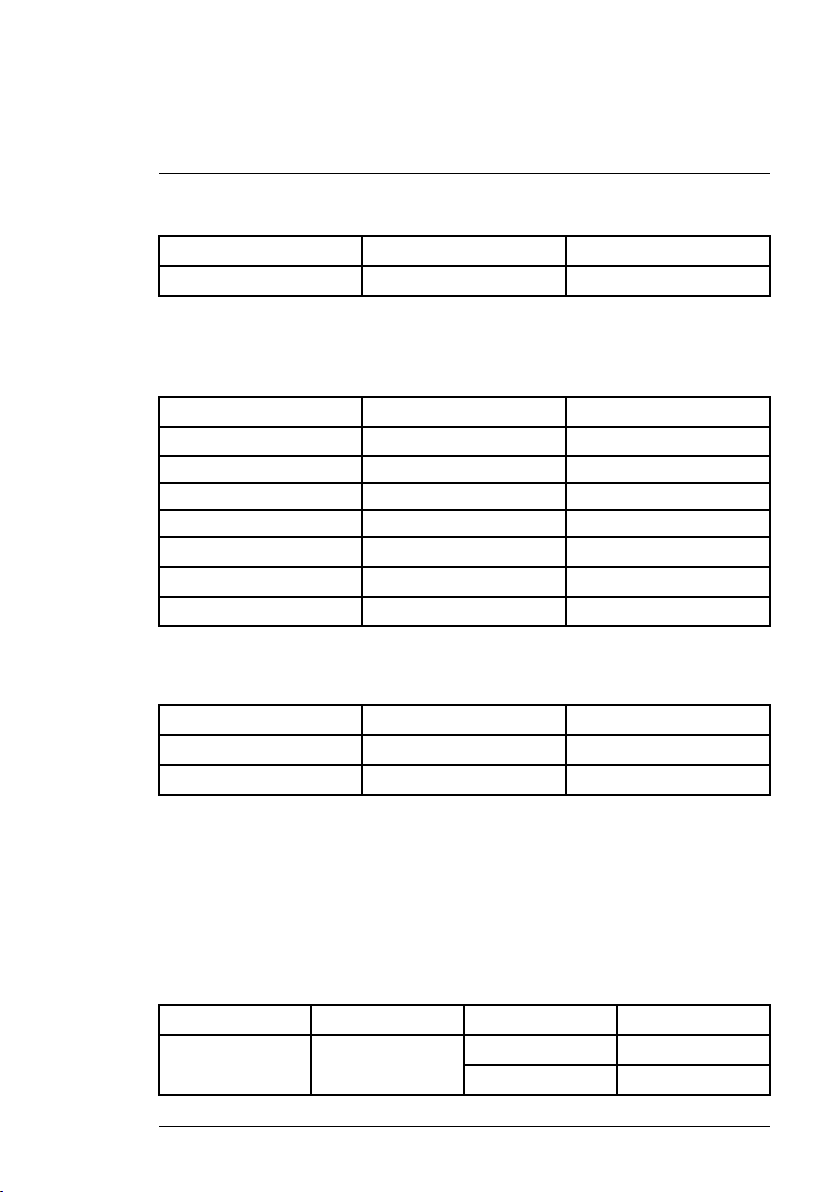

12.2 DC Voltage Specifications

Range and Resolution Accuracy

60.00 V

600.0 V

1000 V

± (1% + 2 digits)

Input Impedance: 10MΩ, 100 pF nominal

Safety Category Rating: CAT III 1000 V & CAT IV 600 V DC

12.3 DC mV Specifications

Range and Resolution Accuracy

60.00 mV

600.0 mV

± (1% + 2 digits)

12.4 AC Voltage Specifications

Range and Resolution Frequency Accuracy

60.00 V /600.0 V /1000 V

50Hz ~ 60 Hz ± (0.7% + 3 digits)

45Hz ~ 440 Hz ± (2.0% + 3 digits)

Input Impedance: 10MΩ, 100 pF nominal

Safety Category Rating: CAT III 1000 V & CAT IV 600 V AC

12.5 AC mV Specifications

Range and Resolution Frequency Accuracy

60.00 mV / 600.0 mV

50Hz ~ 60 Hz ± (1.0% + 3 digits)

10Hz ~ 500 Hz ± (2.0% + 3 digits)

12.6 VFD AC Voltage Specifications

Range and Resolution Frequency Accuracy

60.00 V /600.0 V /1000 V

#NAS100017; r. AB/59644/59644; en-US

10Hz ~ 100 Hz ± (1.0% + 3 digits)

100Hz ~ 440 Hz ± (10.0% + 3 digits)

32

Page 41

12

Specifications

12.7 LoZ Voltage AC and DC Specifications

Range and Resolution Frequency Accuracy

60.00 V /600.0 V /1000 V

45Hz ~ 440Hz ± (2.0% + 3 digits)

For inputs < 50 V, the impedance is 2.3 kΩ. For inputs > 50 V, the initial impedance is 2.3 kΩ increasing to 1 MΩ at 1000V.

12.8 Frequency Specifications

Ranges

60 mV, 600 mV 50 mV 10 Hz ~ 50 kHz

60 V 10 V 10 Hz ~ 50 kHz

600 V 50 V 10 Hz ~ 1 kHz

1000 V 500 V 10 Hz ~ 1 kHz

600 V (VFD) 50 V 10 Hz ~ 400 Hz

1000 V (VFD) 500 V 10 Hz ~ 400 Hz

60 A, 600 A 50 A 50 Hz ~ 400 Hz

Sensitivity

Frequency

Accuracy: ± (0.03% + 2 digits)

12.9 DC Current Specifications (Clamp)

Range Resolution Accuracy

60.00 A 0.01 A ± (1.5% + 5 digits)

600.0 A 0.1 A ± (2.0% + 5 digits)

Safety Category Rating: CAT III 1000 V & CAT IV 600 V DC

Induced error from adjacent current-carrying conductors: <0.01A/A

Accuracy specified with DC Zero mode applied to offset non-zero residual

readings

Add 10 digits to the specified accuracy @ < 9 A

12.10 AC Current Specifications (Clamp)

Range Resolution Frequency Accuracy

60.00 A 0.01 A

#NAS100017; r. AB/59644/59644; en-US

50 ~ 100 Hz ± (1.5% + 5 digits)

100 ~ 400 Hz ± (2.0% + 5 digits)

33

Page 42

12

Specifications

600.0 A 0.1 A

50 ~ 100 Hz ± (1.5% + 5 digits)

100 ~ 400 Hz ± (2.0% + 5 digits)

Induced error from adjacent current-carrying conductors: < 0.1A/A

Safety Category Rating: CAT III 1000 V & CAT IV 600 V AC

12.11 Resistance Specifications

Range Resolution Accuracy

600.0 Ω 0.1 Ω

6.000 kΩ 0.001 kΩ

± (1.0% + 3 digits)

Typical Constant Test Current: 0.1 uA

Open Circuit Voltage: 1.6 VDC

12.12 Continuity Specifications

Built-in beeper activates when measured resistance is < 30Ω and is silent

when measured resistance is > 480Ω. Between 30 and 480Ω the beeper can

be on or off.

Beeper response time: < 15 ms

12.13 Diode Specifications

Range Accuracy

3.000 V ± (0.9 + 2 digits)

Test Current: 0.3 mA typical

Open Circuit Voltage: < 3.0 VDC typical

12.14 External (Flex) Clamp Adaptor — AC Current Specifications

Range Frequency Accuracy

30.00 A (100mV/A)

50 ~ 60 Hz (sine wave) ± (0.7% + 3 digits)*300.0 A (10mV/A)

3000A (1mV/A)

#NAS100017; r. AB/59644/59644; en-US

34

Page 43

12

Specifications

30.00 A (100mV/A)

45~ 440 Hz (sine wave) ± (2.0% + 3 digits)*300.0 A (10mV/A)

3000A (1mV/A)

*Does not include error introduced by the external clamp adaptor.

12.15 Temperature Specifications

Range Accuracy

-40.0 ~ 752℉ ± (1.0% + 2℉)

-40.0 ~ 400℃ ± (1.0% + 1℃)

1. Assumes meter interior and ambient temperature have reached stable isothermal stage for cor-

rect junction voltage compensation. Does not include error introduced by thermocouple probe.

1

*Assumes meter interior and ambient temperature have reached stable isothermal stage for correct junction voltage compensation. Does not include error introduced by thermocouple probe.

Supplied thermocouple is rated for -4 ~ 482℉ (-20 ~ 250℃) only, and therefore not rated for the entire specified temperature range of the meter.

12.16 Input Specifications

Function

Voltage, Current 1100V DC/AC RMS

Resistance, Temperature, Diode, Ext.

Clamp adaptor, LoZ

Overload Protection

1000V DC/AC RMS

12.17 Safety Specifications

General Safety CE/EN/UL/RCM 61010

Safety Category ratings CAT III 1000 V & CAT IV 600 V AC & DC

IP40 rated Protected from tools and small wires greater than

Environmental Safety REACH Regulation EC 1907/2006

#NAS100017; r. AB/59644/59644; en-US

1 millimeter

RoHS2 Directive 2011/65/EC

WEEE Directive 2012/19/EC

35

Page 44

12

Specifications

Drop-proof Designed to 3.3 ft. (1 m)

EMC

EN 61000-6-3

EN 61000-6-2

FCC 47 CFR Part 15 Class B

#NAS100017; r. AB/59644/59644; en-US

36

Page 45

13

Three-Year Warranty

Please register your product within 60 days of purchase. Register your product at https://support.flir.com/prodreg or use the QR Code. Read the warranty

text at the links provided.

Figure 13.1 Product Registration QR Code

#NAS100017; r. AB/59644/59644; en-US

37

Page 46

14

Customer Support

Repair, Calibration, and Technical Support: https://support.flir.com.

14.1 Corporate Headquarters

FLIR Systems, Inc.

27700 SW Parkway Avenue

Wilsonville, OR 97070, USA

#NAS100017; r. AB/59644/59644; en-US

38

Page 47

Page 48

Website

last page

http://www.flir.com

Customer support

http://support.flir.com

Copyright

© 2019, FLIR Systems, Inc. All rights reserved worldwide.

Disclaimer

Specifications subject to change without further notice. Models and accessories subject to regional market

considerations. License procedures may apply. Products described herein may be subject to US Export

Regulations. Please refer to exportquestions@flir.com with any questions.

Publ. No.: NAS100017

Release: AB

Commit:

Head: 59644

Language: en-US

Modified: 2019-09-16

Formatted: 2019-09-16

59644

Loading...

Loading...