Page 1

USER MANUAL

ARMASIGHT by FLIR

SPARK

®

Night Vision Monocular

Page 2

2

ARMASIGHT by FLIR

SPARK

USER MANUAL

© 2018 FLIR Systems, Inc. All rights reserved worldwide. No parts of this manual, in whole or in part,

may be copied, photocopied, translated, or transmitted by any electronic medium or in machine-readable

form without the prior written permission of FLIR Systems, Inc.

Names and marks appearing on the products herein are either registered trademarks or trademarks of

FLIR Outdoor & Tactical Systems and/or its subsidiaries. All other trademarks, trade names, or company

names referenced herein are used for identification only and are the property of their respective owners.

This product is protected by patents, design patents, patents pending, or design patents pending.

If you have questions that are not covered in this manual, or need service, contact FLIR OTS customer

support for additional information prior to returning a product.

Phone:1-888-959-2259

E-mail: OTS-Support@flir.com

This documentation is subject to change without notice.

FLIR OUTDOOR & TACTICAL SYSTEMS

815 Dubuque Avenue, South San Francisco, CA 94080

Phone: 1-888-959-2259 or (650) 492-7755

Fax: 1-888-959-2260

International Phone/Fax: (650) 492-7755

E-mail: OTS-Support@flir.com

www.flir.com

EXPORT INFORMATION

Equipment described herein may require US Government authorization for export purposes. Diversion

contrary to US law is prohibited.

©2018 FLIR Systems, Inc.

Specifications are subject to change without notice, check our website: www.flir.com

Page 3

3

ARMASIGHT by FLIR

SPARK

USER MANUAL

PROPER DISPOSAL OF ELECTRICAL AND ELECTRONIC EQUIPMENT (EEE)

The European Union (EU) has enacted Waste Electrical and Electronic Equipment Directive 2002/96/EC

(WEEE), which aims to prevent EEE waste from arising; to encourage reuse, recycling, and recovery of

EEE waste; and to promote environmental responsibility.

In accordance with these regulations, all EEE products labeled with the “crossed out wheeled bin” either

on the product itself or in the product literature must not be disposed of in regular rubbish bins, mixed

with regular household or other commercial waste, or by other regular municipal waste collection means.

Instead, and in order to prevent possible harm to the environment or human health, all EEE products

(including any cables that came with the product) should be responsibly discarded or recycled.

To identify a responsible disposal method where you live, please contact your local waste collection

or recycling service, your original place of purchase or product supplier, or the responsible government

authority in your area.

Business users should contact their supplier or refer to their purchase contract.

IMPORTANT INSTRUCTIONS AND NOTICES TO THE USER:

Modification of this device without the express authorization of FLIR Commercial Systems, Inc. may void

the user’s authority under FCC rules to operate this device.

Note 1: This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection against

harmful interference in a residential installation.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications. However,

there is no guarantee that the interference will not occur in a particular installation. If this equipment

does cause harmful interference to radio or television reception, which can be determined by turning

the equipment off and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

• Reorient or relocate the receiving antenna

• Increase the separation between the equipment and receiver

• Connect the equipment into an outlet on a circuit different from

that of the receiver

• Consult the dealer or an experienced radio/television technician for help.

INDUSTRY CANADA NOTICE:

This Class B digital apparatus complies with Canadian ICES-003.

AVIS D’INDUSTRIE CANADA:

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

Page 4

4

ARMASIGHT by FLIR

SPARK

USER MANUAL

LIST OF CONTENTS

TITLE PAGE

Safety Summary 5

1. INTRODUCTION 7

1.1 Purpose of Equipment 7

1.2 Warranty Information and Registration 7

2. DESCRIPTION AND DATA 8

2.1 System Description 8

2.2 Specifications 9

2.3 Standard Components 11

2.4 Optional Equipment 12

2.5 Key Features 14

3. OPERATING INSTRUCTIONS 15

3.1 Installation and Mounting 15

3.2 Controls 21

3.3 Operating Procedures 22

3.4 Storage 23

4. PREVENTIVE MAINTENANCE AND TROUBLESHOOTING 24

4.1 Preventive Maintenance Checks and Services 24

4.2 Troubleshooting 26

4.3 Identification of Operational Defects 26

4.4 Maintenance 28

APPENDIX 30

A. Spark List of Spare Parts 30

Page 5

5

ARMASIGHT by FLIR

SPARK

USER MANUAL

SAFETY SUMMARY

• Read and follow all instructions

• Read all warnings

• Only use the attachments/accessories specified by the manufacturer

• All service must be provided by the manufacturer

WARNING:

This product contains natural rubber latex which may cause allergic reactions! The FDA

has reported an increase in the number of deaths that are associated with an apparent sensitivity to

natural latex proteins. If you are allergic to latex, it is a good idea to learn which products contain it

and strictly avoid exposure to those products.

WARNING:

• Always make sure your firearm is unloaded before you place the equipment on the firearm.

Reconfirm that the chamber is empty if you stop the procedure then resume later. Safe handling

rules should be followed at all times.

• The light from the unit infrared (IR) illuminator is invisible to the unaided eye when used in total

darkness. However, the light can be detected by other Night Vision Devices (NVD).

• To reduce the risk of detection by another NVD, avoid prolonged activation of the IR illuminator.

• The IR light is more detectable by an NVD when used in smoke, fog and rain. Avoid prolonged

activation of the unit IR illuminator in these conditions.

• This product contains natural rubber latex, which may cause allergic reactions.

• The intensifier’s phosphor screen contains toxic materials. Please note the following:

– If the intensifier tube breaks, be extremely careful to avoid inhaling the phosphor screen

material. DO NOT allow the material to come in contact with your mouth, eyes, or any open

wounds on the skin.

– If the phosphor screen material comes in contact with your skin, wash it off immediately with

soap and water.

– If you inhale or swallow any phosphor screen material, drink a lot of water, induce vomiting,

and seek medical attention as soon as possible.

Page 6

6

ARMASIGHT by FLIR

SPARK

USER MANUAL

CAUTION:

• The Spark is a precision electron-optical instrument, and must be handled carefully at all times to

prevent damage to the device and danger to the user.

• To protect the intensifier tube, do not remove the lens cap of the Spark when the monocular is

being operated in daylight conditions, or when the device is not in use.

• Use of the Spark in brightly lit conditions may damage the unit’s intensifier tube.

• Bright light sources such as firelight, headlights, searchlights, etc. can damage the Spark. Avoid

exposing the unit to these types of light sources.

• DO NOT attempt to force the controls past their stopping points, as this may cause damage to the

mechanisms.

• Before replacing the intensifier tube, confirm that it is no longer covered by warranty.

• Do not store the equipment with the battery still inserted.

• Clean and dry each component of the Spark thoroughly before placing them in the storage case.

NOTES:

• The equipment requires some ambient light (moonlight, starlight, etc.) to operate.

• Performance of the device in nighttime conditions depends on the level of ambient light in the

environment. Please remember the following:

– The level of ambient light is reduced by the presence of clouds, shade, or objects that block

natural light (trees, buildings, etc.).

– The equipment is less effective when operated in shadows and other darkened areas.

– The equipment is less effective when operated in rain, fog, sleet, snow, dust or smoke.

– The equipment will not “see” through dense smoke.

• The IR illuminator is intended for increased illumination, as needed, when viewing at a close

distance of up to 3m.

• The Spark is not a weapon sight. However, it can be used in conjunction with a collimator dot sight

or laser aiming device.

• For the purpose of returning defective components, retain all packaging materials.

Page 7

7

ARMASIGHT by FLIR

SPARK

USER MANUAL

SECTION 1

INTRODUCTION

1.1 PURPOSE OF EQUIPMENT

To provide the operator with the ability to observe at night under moonlight and starlight

conditions.

The Spark can be used as a handheld, head-mounted, helmet-mounted or weapon-mounted device

to allow walking, weapon firing, short-range surveillance, map reading, vehicle maintenance, and

administering of first aid.

The Spark allows for horizontal and vertical adjustments when mounted to the user’s head or helmet, and

is equipped with an infrared light-emitting source (IR illuminator).

1.2 WARRANTY INFORMATION AND REGISTRATION

1.2.1 WARRANTY INFORMATION

For warranty information and customer support visit www.armasight.com/customer-support

1.2.2 PRODUCT REGISTRATION

In order to validate the warranty on your product, the Customer must complete and submit FLIR Outdoor

& Tactical Systems’ PRODUCT REGISTRATION FORM on our website (www.armasight.com/customersupport).

1.2.3 OBTAINING WARRANTY SERVICE

For service, repair or replacement, please contact:

FLIR OUTDOOR & TACTICAL SYSTEMS

815 Dubuque Avenue, South San Francisco, CA 94080

Phone: (888) 959-2259

Fax: (888) 959-2260

Int’l Phone/Fax: (650) 492-7755

OTS-Support@flir.com

Page 8

8

ARMASIGHT by FLIR

SPARK

USER MANUAL

SECTION 2

DESCRIPTION AND DATA

2.1 SYSTEM DESCRIPTION

The Spark is a hand-held, head-mounted, helmet-mounted, or weapon-mounted night vision system

that allows the user to operate it while walking, firing weapons, conducting short-range surveillance,

reading maps, conducting vehicle maintenance, or administering first aid in both moonlight and starlight

conditions.

The Spark utilizes the principle of intensification of the residual light that is reflected from the

surrounding objects. The optical system of the unit consists of an objective lens, an intensifier tube (IT),

and an eyepiece.

Exclusive CORE (Ceramic Optical Ruggedized Engine) technology image intensifier tubes are used in the

Spark monoculars. While CORE does not contain a micro channel plate (and so by definition lands in the

Gen 1 category) that is where the parallels end. Instead of glass, CORE tubes use a specially formulated

ceramic compound fused with metal alloys similar to those used in production of Gen 2 and Gen 3 image

intensifier tubes. Further advances in CORE have almost removed edge distortion, dramatically increased

photo-sensitivity and most importantly, almost doubled resolution up to 70 lp/mm.

A built-in IR illuminator makes it possible to use the unit in low light or total darkness.

The Spark allows for vertical and fore-and-aft adjustment when mounted to the user’s head or helmet,

when focusing the lens, and when focusing the eyepiece.

NOTE:

The equipment requires some light (moonlight, starlight, etc.) to operate. Performance of the device

depends upon the level of ambient light in the environment. Please remember the following:

– The level of ambient light in the environment is reduced by the presence of clouds, shade, or

objects that block natural light (trees, buildings, etc.

– The equipment is less effective when operated in shadows and other darkened areas.

– The equipment is less effective when operated in rain, fog, sleet, snow, or smoke.

– Under starlight conditions, particularly in low-contrast environments such as snow-covered

territory, sandy deserts, large bodies of water or grassy hills, the visibility may degrade,

thereby disguising or masking changes in terrain.

– The equipment will not “see” through dense smoke.

Page 9

9

ARMASIGHT by FLIR

SPARK

USER MANUAL

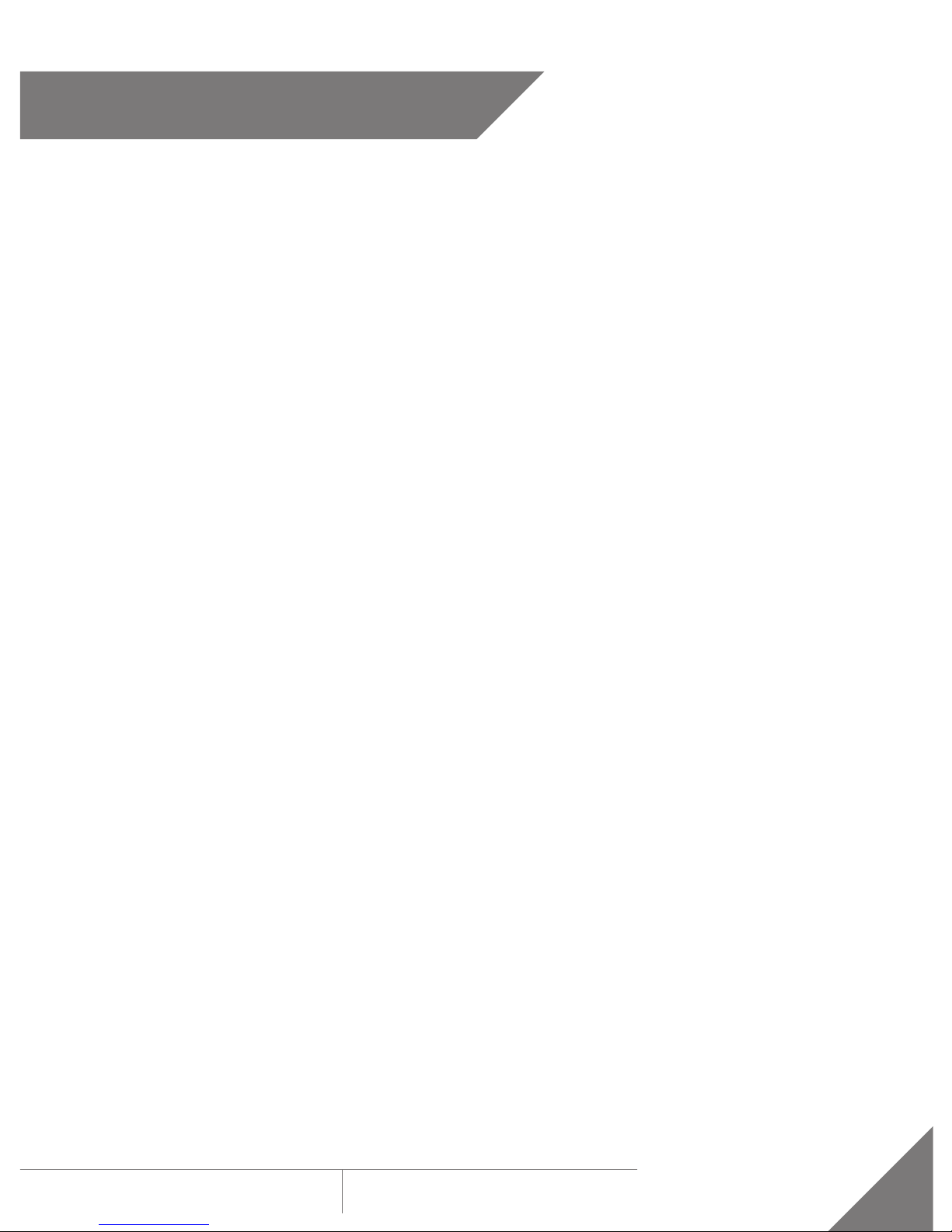

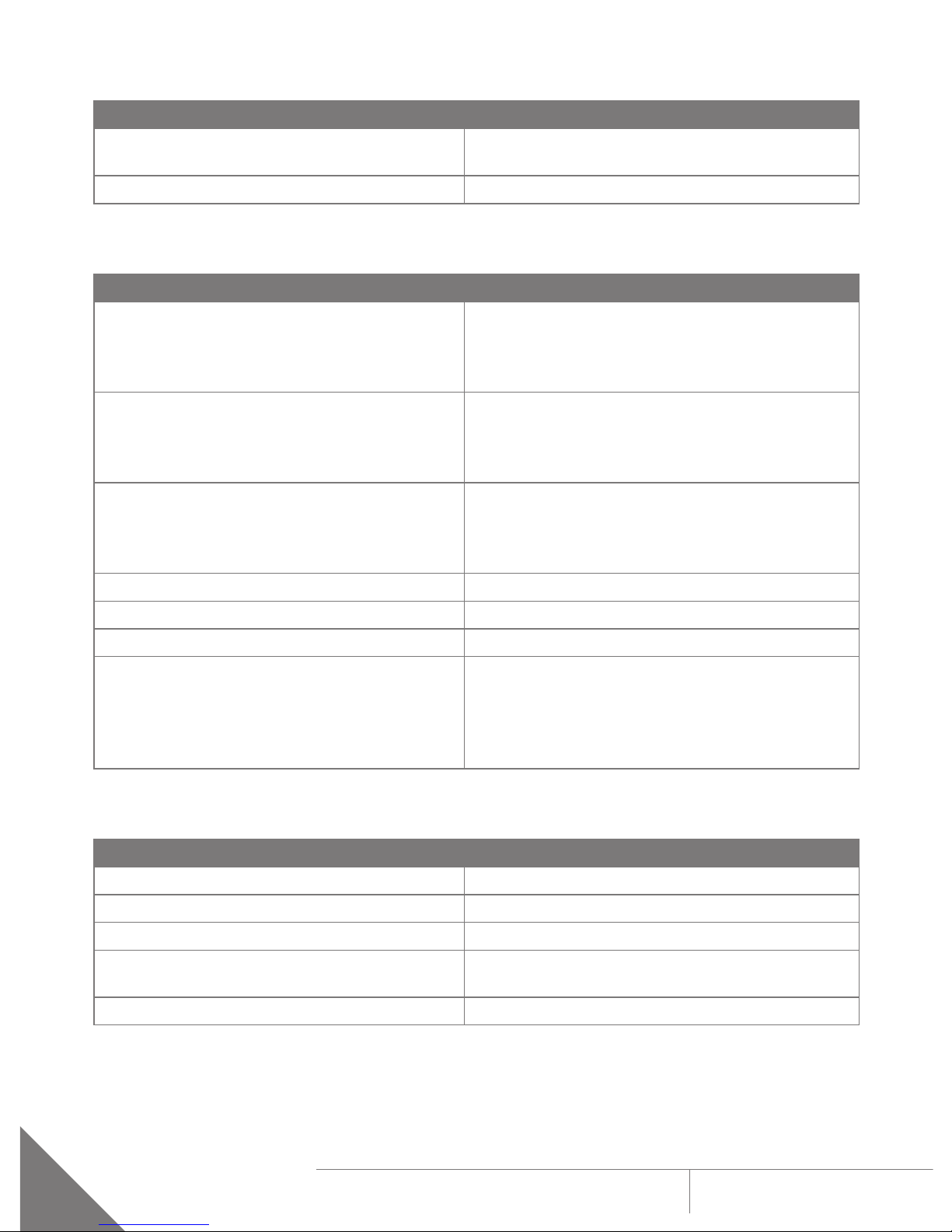

TABLE 2-1. SPARK SYSTEM DESCRIPTION

ITEM DESCRIPTION ITEM DESCRIPTION

1 Body 7 Battery Compartment

2 Rail 8 IR Illuminator

3 Eyepiece Ring 9 Battery Cap

4 Eyepiece 10 Focus Ring

5 Eyecup 11 Lens

6 Function Switch 12 Lens Cap

2.2 SPECIFICATIONS

TABLE 2-2. MECHANICAL DATA

EQUIPMENT ITEM DIMENSIONS, MM WEIGH T, G

Spark Night Vision Monocular

181 x 49 x 82

(145 x 49 x 82 w/o eyecup and lens cap)

370

Flip-up Helmet Mount* 140 x 70 x 90 280

Goggle Kit* 280 x 180 x 80 295

IR850-XLR* 150 x 46 x 46 210

Quick Release Picatinny Mount Adapter #26* 120 x 76 x 13 70

Dual Bridge* 110 x 39 x 19 69

Dovetail to Weaver Transfer Piece* 38 x 21 x 7.5 8

Swing Arm #37* 49 x 46 x 64 50

3x Afocal Lens* Dia 61 x 73 180

5x Afocal Lens* Dia 78 x 90 344

* Optional

6

7

10

FIGURE 2-1. SPARK NIGHT VISION MONOCULAR

4

12

5

9

2

11

3

1

8

Page 10

10

ARMASIGHT by FLIR

SPARK

USER MANUAL

TABLE 2-3. ELECTRICAL DATA

ITEM DATA

Battery One CR123A Lithium 3V or CR123 type

rechargeable batteries with voltage 3.2V

Continuous Operation* Up to 40 hr at 20°C (68°F)

* With IR illuminator off.

TABLE 2-4. OPTICAL DATA

ITEM DATA

Magnification:

- with 1x Lens

- with 3x Afocal Lens*

- with 5x Afocal Lens*

1x

3x

5x

1X Lens:

- Focal Length

- Lens F/number

- Focus Range

35 mm

1:1.7

0.25 m to infinity

FOV:

- with 1x Lens

- with 3x Afocal Lens*

- with 5x Afocal Lens*

35°

11°30’

7°30’

Exit Pupil Diameter 8 mm

Eye Relief 20 mm

Eyepiece Diopter Adjustment -5 to +5 diopters

Built-in IR Illuminator

- Power

- Illumination Range

- Focus Distance

- Illumination Wavelength

50 mW

20 m

3 m

810 nm

* Optional.

TABLE 2-5. ENVIRONMENTAL DATA

ITEM DATA

Operating Temperature -40 to +50°C

Storage Temperature -50 to +70°C

Humidity 95%, 25°C to 40°C for 48 hr

Illumination Required Natural night illumination

(overcast starlight to moonlight)

Environmental Rating Water and fog-resistant

Page 11

11

ARMASIGHT by FLIR

SPARK

USER MANUAL

2.3 STANDARD COMPONENTS

The standard components of the Spark are shown in Figure 2-2 and listed in Table 2-6.

The ITEM NO. column indicates the number used to identify items in Figure 2-2.

TABLE 2-6. SPARK STANDARD COMPONENTS

ITEM NO. DESCRIPTION QUANTITY

1 Night Vision Monocular 1

2 Lens Cap 1

3 Eye-cup 1

4 CR123A Lithium Battery 1

5 Operation and Maintenance Manual 1

6 Carrying Case 1

FIGURE 2-2. SPARK STANDARD COMPONENTS

1

2

3

4

5

6

Page 12

12

ARMASIGHT by FLIR

SPARK

USER MANUAL

2.4 OPTIONAL EQUIPMENT

Optional items are shown and listed in Table 2-7.

The PART NO. column indicates the primary number used by the manufacturer to identify an item.

TABLE 2-7. SPARK OPTIONAL EQUIPMENT

IMAGE DESCRIPTION PART NO.

3x A-Focal Lens Kit Lens #22 with Adapter #23

ANAF3X0023

5x A-Focal Lens with Adapter #23

ANAF5X0023

ARFS3

ANAMRF0003

ARFS5

ANAMRF0005

Goggle Kit #1

ANHG000001

Helmet Mount #3

ANHM000002

Helmet Mount #170 (Shroud)

ANHM000170

Dual Bridge #197

ANHM000197

Swing Arm #37

ANHG000002

Swing Arm #172

ANHM000172

Quick Release Picatinny Mount Adapter #26/ #142

ANAM000004

IR850-XLR Detachable Long-Range Infrared Illuminator

w/Dovetail to Weaver Transfer Piece #21, Rechargeable

Battery, and Charger

ANKIXLR017

Page 13

13

ARMASIGHT by FLIR

SPARK

USER MANUAL

IMAGE DESCRIPTION PART NO.

IR850-XLR Doubler

ANAF18XLRM

Extended Rail Adapter #85

ANAM000045

Universal Camera Adapter #45

ANAM000006

Hard Shipping/Storage Case #101

ANHC000001

TABLE 2-7. CONTINUED

Page 14

14

ARMASIGHT by FLIR

SPARK

USER MANUAL

2.5 KEY FEATURES

• CORE (Ceramic Optical Ruggedized Engine) technology intensifier tube

• Built-in IR illuminator

• Left or right eye use

• Lightweight

• Compact and robust design

• Easy to operate

• Serviceability under severe conditions

• High-performance

• Highly reliable

• Powered by single CR123 battery

• Head or helmet-mountable for hands-free usage

• Weapon-mountable

• Adaptable for use with cameras

• Compatibility with most weapons, IR laser aiming/ illuminating devices, reflex sights, and scopes

• Water and fog-resistant

• Limited two-year warranty

Page 15

15

ARMASIGHT by FLIR

SPARK

USER MANUAL

SECTION 3

OPERATING INSTRUCTIONS

3.1 INSTALLATION AND MOUNTING

CAUTION:

To protect the intensifier tube when the sight is not in use or when it is being operated in daylight,

keep the protective lens cap securely fitted over the lens.

3.1.1 BATTERY INSTALLATION

The Spark operates on a single CR123A battery.

Install the CR123A battery as follows:

1. Unscrew the battery cap (A) and insert the CR123A battery (B), observing the polarity markings on

the body of the device.

2. Screw the battery cap (A) back on securely.

3.1.2 MOUNTING THE SPARK TO A GOGGLE KIT

Mount the Spark to the optional goggle kit as follows (refer to Figure 3-2):

1. Put on the goggle kit. Adjust the goggle kit strap pads until the goggles fit securely around your

head. Remove the goggle kit.

2. Loosen the screw (A). While pushing down on the button (B), insert the Spark rail into the guide (C)

of the goggle kit bracket. Tighten the screw (A).

FIGURE 3-1. BATTERY INSTALLATION

A

B

Page 16

16

ARMASIGHT by FLIR

SPARK

USER MANUAL

3. Put on the goggle kit, now mounted with the Spark.

4. To adjust the equipment for greater comfort, loosen the screw (A) and move the unit along the guide

(C).

5. The goggle kit has a flip-up mechanism. Push the button (D) of the goggle kit bracket and lift the unit

up until it reaches its top position.

6. Push the same button (D) to lower the unit into the correct viewing position.

Figure 3-2 shows the Spark in the correct position for the right eye. To readjust the unit for the other

eye, remove the unit from the goggle kit bracket. Turn the unit around (180º) and mount it on the bracket

through the rail on the second side. With the button (E) pushed, move the unit along the slide-rail (F) until

the desired, most comfortable position is reached.

To remove the Spark from the goggle kit, loosen the screw (A), push the button (B), and slide the unit out

of the bracket guide (C).

3.1.3 MOUNTING THE SPARK TO A HELMET

An optional flip-up helmet mount can be used to attach the Spark to a helmet. The helmet mount fits the

Spark securely onto helmet via a rugged strapping device and grooved hooks. With the helmet mount, the

Spark can be positioned directly in front of the user’s eyes, or flipped backwards, out of the field of view.

Mount the Spark to a helmet as follows (refer to Figure 3-3):

1. Attach the mount to the helmet.

2. Adjust and tighten the straps (A).

3. Loosen the screw (B). With the button (C) pushed down, insert the Spark rail into the guide (D) of the

helmet mount bracket. Tighten the screw (B).

4. Put on the helmet with the Spark attached.

5. Push the button (F) and move the unit along the slide-rail (G) until the most comfortable position is

reached.

C

D

E

F

B

A

FIGURE 3-2. MOUNTING SPARK TO A GOGGLE KIT

Page 17

17

ARMASIGHT by FLIR

SPARK

USER MANUAL

6. Adjust the mount for comfortable using. Loosen the screw (B) and move the unit along the guide (D)

for eye relief adjustment. Turn the lever (H) and move the unit along vertical slide-rail until the most

comfortable vertical position is reached.

7. The helmet mount has a flip-up mechanism. Push the button (E) of the mount bracket and lift the unit

up until it reaches its top position.

8. Push the same button (E) to lower the Spark into the proper viewing position.

The Spark can be mounted in position for the right or left eye. To readjust the Spark for other eye,

reverse its positioning and reinstall it on the helmet mount bracket. Use the second unit rail located on

the opposite side of the unit. Push the button (F) and move the unit along the slide-rail (G) until the most

comfortable position is reached.

To remove the Spark from the helmet mount, loosen the screw (B), push down on the button (C), and slide

the unit out of the guide (D). To remove the flip-up mechanism from the helmet mount, loosen the lever

(H), pull the knob out (I), and slide the flip-up mechanism out of the vertical rail.

3.1.4 MOUNTING THE SPARK TO A WEAPON WITH A QUICK-RELEASE WEAPON

MOUNT

NOTE:

The Spark is not a weapon sight. However, it can be used in conjunction with a collimator dot sight

or laser aiming device.

To mount the Spark to a weapon using an optional quick-release weapon mount (QRM), perform the

following (refer to Figure 3-4):

1. While pushing down on the lever holder (C), turn the lever (B) backwards to loosen the QRM

clamping device (A).

2. Install the QRM on the weapon rail by inserting the stop (not shown in Figure 3-4) into one of

transverse slots of the weapon rail.

C

D

E

G

B

A

F

H

I

FIGURE 3-3. MOUNTING THE SPARK TO A HELMET

Page 18

18

ARMASIGHT by FLIR

SPARK

USER MANUAL

3. To secure the QRM onto the weapon rail, turn the lever (B) forward. Secure the clamping device (A)

tightly to the weapon rail. To adjust the force of the lever clamp, loosen or tighten the nut (D) as

necessary:

– When the clamping device (A) unlocked, push the lever holder (C) so that the nut (D) gets out of its

hollow.

– To tighten/loosen clamping device, turn the nut (D) CW/CCW, respectively, by one-two increments

(the eight-sided nuts of the AIM clamping devices fit their hollows only if turned in one of the

discrete positions), when the holder (C) pushed. Just as the holder (C) released, backmoving

springs makes the nut (D) get back into its hollow.

– Check to ensure the clamping device holds weapon/NVM rail firmly.

4. While pushing down on the lever holder (F), turn the lever (E) forward.

5. Install the Spark on the QRM rail by inserting the stop (G) into the transverse slot of the unit rail.

6. Attach the Spark to the QRM rail by turning the lever (E) backwards. Secure the QRM clamping

device (H tightly to the Spark rail. To adjust the force of the lever clamp, loosen or tighten the nut (I)

as necessary.

3.1.5 MOUNTING AN IR ILLUMINATOR TO THE SPARK

To mount an IR illuminator to the Spark, use the optional Dovetail to Weaver Transfer Piece. Perform the

following steps (refer to Figure 3-5):

FIGURE 3-4. MOUNTING THE SPARK TO A WEAPON WITH A QUICK-RELEASE WEAPON MOUNT

A

B

F

D

B

A

E

C

D

G

I

H

E

FIGURE 3-5. MOUNTING AN IR ILLUMINATOR TO THE SPARK

B

C

A

Page 19

19

ARMASIGHT by FLIR

SPARK

USER MANUAL

1. Install the transfer piece (A) onto one of the Spark rails.

2. Tighten the fixing screw (B) on the transfer piece.

3. Loosen the IR illuminator fixing screw (C).

4. Mount the IR illuminator on the Weaver rail of transfer piece and tighten the fixing screw (C).

3.1.6 MOUNTING THE SPARK TO A STANDARD US MIL HELMET/ HEADGEAR

ASSEMBLY

To mount the Spark to a Standard US Mil helmet or headgear assembly, use an optional transfer adapter.

Perform the following steps (refer to Figure 3-6):

1. Push down on the lever (C). Mount the adapter (A) to the Spark rail (B).

2. Align the adapter prism (D) with the helmet/ headgear assembly mount (E). Slide the Spark

backwards until its alignment boss is in line with the alignment groove on the helmet/ headgear

assembly mount. Push down until the Spark locks into the helmet/ headgear assembly mount.

To dismount the Spark from the helmet/ headgear assembly, push down on the lever (F) and remove the

unit.

Push down on the lever (C) and remove the adapter from the Spark rail.

The transfer adapter can be adjusted for either the right or left eye. In Figure 3-6, the Spark is shown in

the proper position for the left eye. Readjust the adapter for the right eye as follows:

1. Push down on the lever (C). Remove the adapter from the Spark rail.

2. Loosen the nut (G), and turn the adapter around between the two fixing devices. Retighten the nut

(G).

3. Mount the adapter to the other Spark rail located on the opposite side of the unit.

FIGURE 3-6. MOUNTING THE SPARK TO A STANDARD US MIL HELMET/HEADGEAR ASSEMBLY

A

C

B

G

D

F

F

C

E

D

D

Page 20

20

ARMASIGHT by FLIR

SPARK

USER MANUAL

3.1.7 MOUNTING ACCESSORY LENSES TO THE SPARK

To mount the 3x or 5x afocal lens (A) with adapter (B) to the device, screw it into the threading of the

standard 1x objective lens (C) of the Spark.

3.1.8 UNIVERSAL CAMERA ADAPTER APPLICATION

To mount the Spark (affixed with a camera or video recorder) to a tripod, you will need a universal camera

adapter. Mount the connected devices to a tripod as follows:

1. Screw the adapter onto the tripod.

2. Remove the eyecup from the Spark eyepiece.

3. Install the Spark on the adapter rail (A) and tighten the fixing screw (B).

4. Install the camera on the adapter rail (C) and insert the fixing screw (D) into the tripod socket of the

camera. Tighten the fixing screw.

5. Loosen the screws one by one. Align the optical axis of the Spark with the camera objective. Tighten

the screws (E and F).

6. To focus the image, loosen the screw (G) and adjust the distance between the monocular and the

camera’s eyepiece. Tighten the screw (G).

FIGURE 3-7. MOUNTING ACCESSORY LENS TO SPARK

A

C

B

FIGURE 3-8. UNIVERSAL CAMERA ADAPTER APPLICATION

F

E

D

B

C

G

A

Page 21

21

ARMASIGHT by FLIR

SPARK

USER MANUAL

3.2 CONTROLS

3.2.1 CONTROLS

The Spark controls are defined in Table 3-1.

The Spark controls are shown in Figure 3-9.

TABLE 3-1. SPARK CONTROLS

CONTROL/ INDICATOR FUNCTION

Function Switch

(Figure 3-9, A)

OFF position — the unit is off.

ON position — the unit is on (IT powered).

Turn the unit on by turning the switch CCW from OFF to ON.

IR position — the unit is on, and the IR illuminator is activated.

Activate the IR illuminator by turning the switch CW from ON to the IR

position.

Eyepiece Ring

(Figure 3-9, B)

Adjusts the unit diopter. The total dioptric range is covered in a 1/2 ring

revolution.

Focusing Ring

(Figure 3-9, C)

Focuses the lens. Adjusts for sharpest view of the scene. The total focus

range is covered in a 1/3 ring revolution.

Bi-color LED Indicator

(Figure 3-9, D)

A GREEN glow indicates that the unit is turned on and ready for operation.

A RED glow indicates that the IR illuminator is operating.

CAUTION:

DO NOT over-adjust the controls by forcing them past their stopping points.

FIGURE 3-9. SPARK CONTROLS

C

B

A

D

Page 22

22

ARMASIGHT by FLIR

SPARK

USER MANUAL

3.3 OPERATING PROCEDURES

3.3.1 OPERATING PROCEDURES

These procedures should be performed under nighttime conditions only.

CAUTION:

Use of the Spark brightly lit conditions may damage the unit’s intensifier tube.

1. Verify that the battery is installed as indicated on the monocular body.

2. Make a visual estimation of the illumination level in the viewing area. The required level of

illumination is less than 1 lx (late twilight sky conditions).

3. Remove the lens cap and place it over the housing of the lens.

4. Turn the function switch ON. The green indicator light (Fig. 3-9, D) indicates that the unit is ready for

operation. After a slight delay, a green glow will appear in the eyepiece of the monocular.

5. Adjust the unit diopter by rotating the ring of the eyepiece.

6. Observe the scene. Rotate the focus ring until the image is clear and sharp.

CAUTION:

Bright sources such as firelight, headlights, searchlights, etc. can damage the Spark. Avoid exposing

the unit to these types of light sources.

3.3.2 IR ILLUMINATOR OPERATIONS

CAUTION:

When operating the device in extremely dark conditions, the light from the unit’s IR illuminator will

be invisible to the unaided eye. However, the light can be detected by other NVDs.

NOTE:

The IR illuminator is designed to provide additional illumination (when needed) while viewing scenes

or targets from a short distance (up to 3m).

Page 23

23

ARMASIGHT by FLIR

SPARK

USER MANUAL

To activate the IR illuminator, turn the monocular on. Flip the function switch (Fig. 3-10, A) CW from ON to

the IR position. A red indicator (Fig. 3-10, B) lights when the IR illuminator is turned on.

3.3.3 SPARK SHUT-DOWN

1. Turn the function switch to OFF. The green glow of the viewing area will fade to black.

2. Secure the lens cap over the objective lens.

3. If necessary, remove the unit from the rail (from the scope lens). Remove the unit by following the

mounting instructions in reverse.

4. Unscrew the battery cap and take out the battery. Replace the battery cap. Do not store the unit

with the battery still in it.

5. Store the unit and all accessories in the case.

3.4 STORAGE

3.4.1 PREPARATIONS FOR STORAGE

Prepare the Spark for storage as follows:

1. Verify that the Spark and all accessories are clean and dry before returning them to the storage

case.

2. Secure the cap over the objective lens.

3. Remove the battery.

4. Place the Spark and accessories in the appropriate locations in the case, and close the cover.

FIGURE 3-10. IR ILLUMINATOR OPERATIONS

A

B

Page 24

24

ARMASIGHT by FLIR

SPARK

USER MANUAL

SECTION 4

MAINTENANCE AND TROUBLESHOOTING

4.1 PREVENTIVE MAINTENANCE CHECKS AND SERVICES

4.1.1 PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS)

Table 4-1: Preventive Maintenance Checks and Services has been provided so that you can keep your

equipment operable and in good condition.

Perform all functional tests in the order listed in Table 4-1.

Operating Procedures are detailed in Chapter 3.

A. Cautions

Always observe any CAUTIONS that appear in the table.

B. Explanation of Table Entries

SEQ NO. column. Sequence numbers are for reference and appear in the order required to perform

checks and services.

LOCATION ITEM TO CHECK/ SERVICE column. Indicates the location and the item to be checked or

serviced.

PROCEDURE column. Details the checking/ servicing procedure.

NOT FULLY MISSION CAPABLE IF... column. Indicates what faults will prevent your equipment from

operating successfully.

TABLE 4-1. PREVENTIVE MAINTENANCE CHECKS AND SERVICES

SEQ

NO.

LOCATION IT EM TO

CHECK/ SERVICE

PROCEDURE

NOT FULLY MISSION

CAPABLE IF...

PRE-OPERATIONAL CHECKS

1 Completeness Open the carrying case and inventory items by means

of comparing with the data specified in this manual.

Items are missing.

2 Soft Carrying

Case

Shake out loose dirt or foreign material. Inspect for

tears, cuts, excess wear or damage to the mounting

clips.

3 External

Surfaces

Inspect for cracks or damage.

Scratches and gouges are OK if operation is not

affected.

Cracked or damaged.

4 Lens Cap Inspect for cracked, torn, or missing lens caps. Cap is torn or cut.

Cup is not secured to the

housing of the lens.

Page 25

25

ARMASIGHT by FLIR

SPARK

USER MANUAL

SEQ

NO.

LOCATION IT EM TO

CHECK/ SERVICE

PROCEDURE

NOT FULLY MISSION

CAPABLE IF...

5 Eyecup Inspect for dirt, dust. Inspect for cracked or torn,

bent, broken or improperly fitting eyecup.

If necessary, clean as per Para 4.4.2.

Cup torn or cut.

6 Battery

Compartment/

Cap

Verify that the battery cap is present. Inspect for

corrosion, moisture, corroded or defective contacts.

Verify that the o-ring is present.

Cap is missing, contacts

damaged or corroded, or

o-ring is missing.

7 Function Switch Check the switch for operation (without a battery). Switch has no definite

stopping points. Switch knob

is broken or missing.

8 Lenses Inspect optical surfaces for dirt, fingerprint residue,

scratches, chips, or cracks.

Scratches or chips hinder

vision with Spark turned on.

Cracks are present.

9 Focusing Ring Rotate the focusing ring to ensure free movement

(range is approximately 1/3 turn).

Ring gets stuck or adversely

affects the user’s ability to

properly focus the unit.

10 Eyepiece Ring Rotate the eyepiece ring to make sure the eyepiece

is not too tight or too loose. Range is approximately

½ turn.

Ring gets stuck, is too loose,

or adversely affects the

user’s ability to properly

adjust the diopter.

11 Optional

Equipment

Inspect optional items for dirt, or corrosion, damage,

and missing parts. Check for proper operation.

If necessary, clean as detailed in Part 4.4.2.

Equipment is damaged or

parts are missing.

OPERATIONAL CHECKS

CAUTION:

Do not activate the Spark in daylight unless the lens cap is on, or you are operating under dark conditions.

NOTE:

Daylight checks are described below.

12 Function Switch Install the battery. Turn the switch from OFF to ON.

Look for the green glow in eyepiece (it should appear

after a slight delay), and wait about 10 s for image to

disappear.

Image is present.

13 Viewed Image Inspect for any operational defects (refer to Part

4.3.1: Identification of Operational Defects).

Shading, edge glow, flashing,

flickering, and intermittent

operation, or excessive

cosmetic defects are found.

POST-CHECKS PROCEDURES

14 Turn the unit OFF. Verify that the green glow fades

from the eyepieces.

Remove the battery.

Return the unit and all accessories to the soft

carrying case.

TABLE 4 -1. CONT INUED

Page 26

26

ARMASIGHT by FLIR

SPARK

USER MANUAL

4.2 TROUBLESHOOTING

4.2.1 OPERATOR TROUBLESHOOTING

The purpose of troubleshooting is to identify the most frequently occurring equipment malfunctions, their

probable causes, and the corrective actions required to fix them.

Table 4-2 lists common malfunctions that may occur during the operation or maintenance of the Spark.

Perform the tests, inspections, and corrective actions in the order listed in the table.

This table does not list all of the malfunctions that may occur with your device, or all of the

tests and corrective actions that may be necessary. If you experience an equipment malfunction

that is not listed, or is not fixed by the corrective actions listed in the table, please contact Customer

Service center.

TABLE 4-2. OPERATOR TROUBLESHOOTING

MALFUNCTION PROBABLE CAUSE/ TEST/INSPECTION CORRECTIVE ACTION

Monocular fails to

activate

Battery is dead, missing or improperly

installed.

Replace the battery or install it correctly.

Battery contact surfaces or contact

springs are dirty or corroded.

Clean the contact surfaces with a pencil

eraser and/ or alcohol and cotton swabs.

Defective image intensifier. Please contact Customer Support.

IR illuminator fails to

activate

Turn the IR illuminator on in a dark

area. Visually estimate whether or not

the observed scene is illuminated.

If the IR illuminator fails to activate,

please contact Customer Support.

Poor image quality Check objective lens or eyepiece

focus.

Refocus the lens.

Check for fogging or dirt on the lens. Clean the lens as detailed in Part 4.4.2. If

image quality is still poor, please contact

Customer Support.

Damaged optical components. Please contact Customer Support

Light is visible around

the eyecup

Check the exit pupil distance value. Readjust for proper eye-relief distance.

Check the eyecup resilience. If the eyecup is defective, please contact

Customer Support.

Focusing ring cannot be

moved

Check to see if the focusing ring is

bent or broken.

If damaged, please contact Customer

Support.

Eyepiece ring cannot be

moved

Check to see if the eyepiece ring is

bent or broken.

If damaged, please contact Customer

Support.

4.3 IDENTIFICATION OF OPERATIONAL DEFECTS

4.3.1 OPERATIONAL DEFECTS

Operational defects relate to the reliability of the intensifier, and are an indication of instability. If

identified, the user will need to return the Spark immediately. Operational defects include shading, edge

glow, flashing, flickering, and intermittent operation.

Page 27

27

ARMASIGHT by FLIR

SPARK

USER MANUAL

A. Shading

If shading is persistent, you will not be able to see a fully circular image (Figure 4-1). Shading is a very

dark, high-contrast area with a distinct line of demarcation present, and you cannot see an image through

it. Shading always begins on the edge, and will eventually migrate inward until it spans across the entire

image area. If you notice shading with your device, please contact Customer Support.

NOTE:

Verify that any shading is not the result of improper eye-relief adjustment.

B. Edge Glow

Edge glow is a bright area (it sometimes appears to be sparkling) in the outer portion of the viewing area

(see Figure 4-2). To check for edge glow, block out all light from the device by cupping a hand over the

lens. If the image tube is displaying edge glow, the bright area will still show up; if edge glow occurs,

please contact Customer Support.

C. Flashing, Flickering, or Intermittent Operation

The image may appear to flicker or flash. If there is more than a single flicker, check for a loose battery

adapter or a weak battery. If flickering continues, please contact Customer Support.

4.3.2 COSMETIC BLEMISHES

Cosmetic blemishes are usually the result of manufacturing imperfections. They do not affect the

reliability of the image intensifier, and are not normally a cause for returning the Spark. However, some

types of cosmetic blemishes can worsen over time and interfere with the user’s ability to properly

operate the device during missions. If you believe a cosmetic blemish is cause for returning the device,

record the specific nature of the problem on the maintenance forms and use the clock method to identify

the position of the blemish and its approximate distance from the center (e.g., 5:00 toward the outside,

2:30 near the center, or 1:00 midway).

SHADING

FIGURE 4-1. SHADING

EDGE

GLOW

FIGURE 4-2. EDGE GLOW

Page 28

28

ARMASIGHT by FLIR

SPARK

USER MANUAL

The following are examples of cosmetic blemishes:

A. Bright Spots

A bright spot is a small, non-uniform bright area that may flicker or appear constant (Figure 4-3).

Not all bright spots make the Spark rejectable. Cup your hand over the lens to block out all light. If the

bright spot remains please contact Customer Support.

Bright spots usually go away when all light is blocked out. Verify that any bright spots are not simply the

result of bright light in the area you are observing. Bright spots are acceptable if they do not interfere

with the user’s ability to view the scene or perform missions.

B. Emission points

Emission points are steady or fluctuating pinpoints of bright light in the image area that do not go away

when all external light is blocked from the objective lens (Figure 4-3). The position of an emission point

within the image area does not move. Not all emission points are cause to return the Spark. Verify that

emission points are not simply light sources present in the scene you are observing. Emission points are

acceptable if they do not interfere with the user’s ability to perform missions.

BRIGHT

SPOT

EMISSION

POINT

FIGURE 4-3. EMISSION POINTS AND BRIGHT SPOTS

C. Black Spots

Black spots are cosmetic blemishes in the image intensifier or debris between the lenses. Black spots

are acceptable as long as they do not interfere with the user’s ability to observe the scene. No action

is required if this condition is present, unless the spots interfere with the operator’s ability to perform

missions.

4.4 MAINTENANCE

4.4.1 GENERAL

The section regarding Spark operator maintenance consists of operational tests, inspections for the

unit serviceability, cleaning and mounting procedures, troubleshooting, and replacement instructions

for a limited number of parts. Maintenance instructions covered elsewhere in this manual (PMCS,

troubleshooting, etc.) are not repeated in this section.

CAUTION:

The Spark is a precision electron-optical instrument, and must be handled carefully at all times to

prevent damage to the device’s body or mechanisms.

Page 29

29

ARMASIGHT by FLIR

SPARK

USER MANUAL

V12-20171127

4.4.2 CLEANING PROCEDURES

CAUTION:

The coating on the demist shield can be damaged if the shield is cleaned while wet, or if it is

cleaned with wet lens paper. Clean the shield only when it is dry, and only use dry lens paper.

CAUTION:

Thoroughly dry each item before placing them into the storage case.

Clean the Spark as follows:

1. Gently brush off any dirt from the unit’s body using a clean, soft cloth.

2. Moisten the cloth with fresh water and gently wipe external surfaces (except for glass surfaces).

3. Dry any wet surfaces (except for glass surfaces) with another clean, soft, dry cloth.

4. Using a lens brush, carefully remove all loose dirt from the glass surfaces.

5. Slightly dampen a cotton swab with ethanol. Gently and slowly wipe the lenses. Without touching

the lens holders, clean the glass surfaces in circular movements, beginning in the center and moving

out towards the edge. Change the cotton swab after each circular stroke. Repeat until the glass

surfaces are clean.

6. Clean the battery contact surfaces and contact springs with a pencil eraser and/ or alcoholdampened cotton swabs.

Clean optional mounting devices with a soft brush (cloth), soap, and water as required.

Clean optional lenses as detailed in items 4 and 5 above (except for the demist shield).

4.4.3 BATTERY REMOVAL AND REPLACEMENT

Refer to Part 3.1.1 for battery installation procedures. No special tools are required to replace the battery.

Page 30

30

ARMASIGHT by FLIR

SPARK

USER MANUAL

APPENDIX

SPARK LIST OF SPARE PARTS

The parts authorized in this list of spare parts are required for operator maintenance. This list includes

parts that must be removed in order to replace authorized parts.

ITEM NO. Column indicates the number used to identify items in Figure A-1.

PART NO. Column indicates the primary number used by the manufacturer to identify an item; this number

controls the design and characteristics of the item by means of its engineering, specifications, standards,

and inspection requirements.

TABLE A-1. SPARK LIST OF SPARE PARTS

ITEM NO. DESCRIPTION PART NO.

1 Battery Cap ASSPKBC

2 Battery Cap Retainer ASSPKBCR

3 Lens Cap ASSPKLC

4 Objective Lens Assembly ASSPKOLA

5 Eyepiece Assembly ASSPKEPA

6 Eyecup ASSPKECA

7 Function Switch ASSPKFS

8 Rail ASSPKPR

9 Operation and Maintenance Manual ASSPKOMM

10 Soft Carry Case ASSPKSCC

8

6

9

FIGURE A-1. SPARK SPARE PARTS

3

4

5

10

2

1

7

Page 31

31

ARMASIGHT by FLIR

SPARK

USER MANUAL

Page 32

OUTDOOR & TACTICAL SYSTEMS

815 Dubuque Avenue, South San Francisco, CA 94080

Phone: 1-888-959-2259 or (650) 492-7755

Fax: 1-888-959-2260

International Phone/Fax: (650) 492-7755

US Commercial Sales:

OTS-Sales@ir.com

Government Sales:

OTS-Gov@ir.com

International Sales and Export:

OTS-Export@ir.com

Technical Support, Repairs, Returns, Refunds & Warranty:

OTS-Support@ir.com

www.ir.com

www.armasight.com

Equipment described herein is subject to US export

regulations and may require a license prior to export.

Diversion contrary to US law is prohibited. Imagery for

illustration purposes only. Specications are subject

to change without notice. ©2018 FLIR Systems, Inc.

All rights reserved. 05/07/2018

Loading...

Loading...