Flex-a-Lite 130-Pusher, 230-Pusher, 140-Pusher, 240-Pusher Installation Instructions Manual

Page 1

130&140 230&240

Pusher Fans

Installation Instructions

Model 130 - Single fan w/ thermo-

Pusher

Model 140 - Single fan w/o ther-

Pusher

static control &

A/C relay

mostatic control &

A/C relay

Model 230 - Dual fan w/ thermo-

Pusher

Model 240 - Dual fan w/o ther-

Pusher

Through Core Mounting Instructions

(SEE DIAGRAM “A”)

1.Position the electric fan against the front of the

radiator , and mark location of the holes on radiator .(Some

applications may have A/C condensers and/or tranny

coolers on the front of the radiator. Additional adjustments or modifications may be necessary for installation)

2. Holding fan in position, rotate fan blades to make sure

they are free of obstructions.

3. With a small Phillips screwdriver pass through the

marked holes, carefully spread the fins to allow easy passage for the nylon bolts (4 for the single fan unit, 6 for the

double fan unit). Pass the bolts through the shroud holes

then twist the bolts through the radiator . Note: Be sure to

pass through the motor lead connectors when inserting the

bolt through the top middle hole of the double unit. See

expanded view on diagram B.

4. Slide the rubber washer , then the steel washer onto the nylon bolt and

finger tighten wing nuts until snug.

5. Once again, rotate fan blades to insure that they are free of obstruction.

Wing Nut

Steel Washer

static control & A/C

relay

mostatic control &

A/C relay

Diagram A

Rubber Disk Spacer

Nylon Bolt

OR

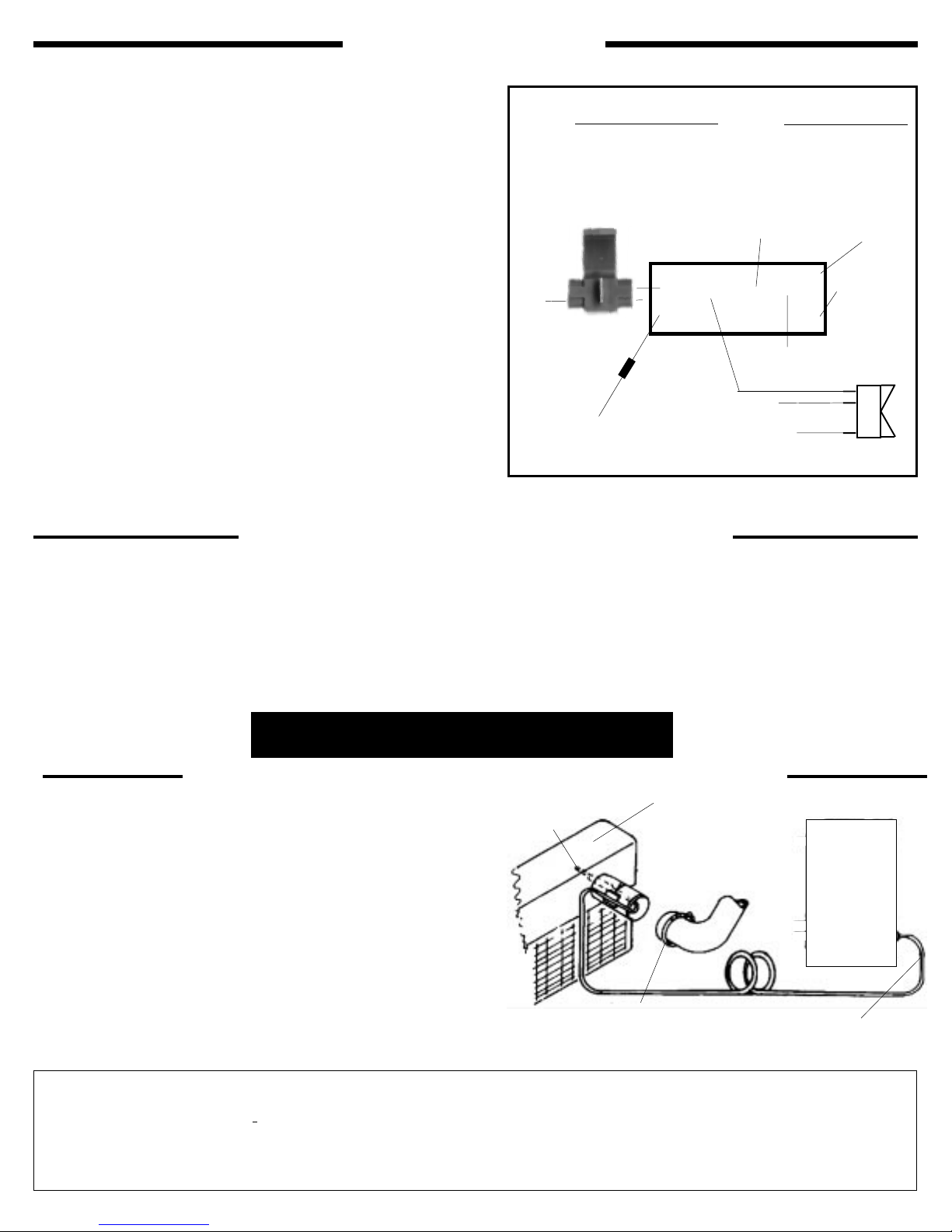

Radiator Support Channel Or Frame Installation

(SEE DIAGRAM “B”)

1. Attach frame mounting brackets to fan using

nylon bolts, cut them to 1", using wing nuts to

secure. Note: Be sure to pass through the motor lead

connectors when inserting the bolt through the top

middle hole of the double unit. See expanded view

on diagram B.

2. Position fan to desired location, mark holes on

radiator channels or frame.

3. Rotate fan blades to insure that they are free of

obstruction.

4. On the marked hole locations drill 13/64" holes.

5. Secure the fan to radiator using the provided

1/4" x 1" self tapping screws.

6. Once again, rotate fan blades to insure that they

are free of obstruction.

(See circled areas for location of

installed clamp. Wire holders

shown in inset.)

Page 1 of 6

Black Nylon

Clamps

Motor Leads

Radiator

Channel Frame

Self T apping

Screw

Diagram B

Frame

Mounting

Brackets

Nylon Bolt

(cut to 1")

Page 2

Wiring Instructions

Note: Each connection shown in this section is mandatory for operation.

1. Disconnect battery .

2. Attach black motor wire(s) to M+.

3. Attach white motor wire(s) to M-.

4. Connect the “+” terminal to a 12 volt positive (+)

power source, e.g. fuse box. Use the wire provided in

the kit.Note: To stop the fan unit from operating when

the vehicle is shut off, attach this wire to an ignition

switched 12 volt power source.

5. Connect the “B” terminal to a 12 volt positive (+)

power source, e.g. Positive side of battery , or alternator . Use the wire and inline fuse provided in the

kit.

6. If you have air conditioning: Connect the “C”

terminal to the positive(+) side of the air conditioning

compressor . Splice into the A/C clutch positive wire

using the 3-way connector and wire provided in the

kit. Air Conditioning Relay (Activates fan(s) when A/C

is turned on)

7. Connect the “G” terminal to ground, i.e. chassis,

negative (-) side of the battery . Use the wire

provided in the kit.

Control Box Terminals

Mandatory Connections

M+ Black motor wire(s)

M- White motor wire(s)

+ 12 volt positive source

G Ground

B 12 volt positive source

C Air conditioning relay

Control Box

C

M

3-way

connector

A/C positive (+)

wire from clutch

12 Volt Positive Source

B

Fuse

12 Volt Source

Optional Connection

M Manual switch

Ground

G

Black Motor(s)

wire(s)

M+

+

White motor(s)

wire(s)

M-

12 Volt Source

1 2 3

Ground

(Illuminate switch connection

for Flex-a-lite Part #31 148)

Wiring Instructions For Accessories

Note: Connection shown in this section is optional and is not crucial for standard operation

Manual Switch (Allows manual activation of the fan(s)

1. Connect the “M” terminal to terminal 1 of the switch. Attach separate wire to terminal 2, attach other

end of the same wire to a 12 volt positive source. T o illuminate switch, connect a ground to

terminal 3.

Note: (Instructions based on Flex-a-lite manual switch, part number 31148. Manual switch not included)

*WARNING: If not using Flex-a-lite’ s illuminated switch

(PN #31148) you must disconnect the switch ground.

T emperature Control Sensor Bulb Installation

1. Loosen upper radiator hose at the radiator , pull the

hose off the radiator inlet pipe.

T emp.

Sensing Bulb

2. Insert sensor bulb, bend the sensor bulb tube

around the end of the radiator inlet pipe.

(The tube is hollow , do not kink. Use wide bends.)

3. Place the sensor gasket (rubber piece with the slit)

between the sensor bulb tube and radiator inlet

pipe. Be sure the tube lays in the slit of the rubber

gasket.

4. W rap vinyl tape around the inlet pipe and sensor

tube at least twice.

5. Replace radiator hose, tighten clamp. (Do not overtighten) Note: You must use a screw-type hose

clamp, some original equipment clamps will leak.

The Flex-a-lite Limited Warranty

Flex-a-lite Corporation, 7213-45th Street Court East, Fife, Washington 98424, Telephone No. 253/922-2700, warrants to the original purchaser

user, all Flex-a-lite products to be free of defects in material and workmanship for a period of 365 days (1 year) from date of purchase. Flex-alite products failing within 365 days (1 year) from date of purchase, may be returned to the factory through the point of purchase, transportation charges prepaid. If, on inspection, cause of failure is determined to be defective material or workmanship and not by misuse, accident, or

improper installation, Flex-a-lite will replace the fan free of charge, transportation prepaid. Flex-a-lite will not be liable for incidental,

progressive, or consequential damages. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you. This warranty gives you specific legal rights and you may also have other rights, which vary

from state to state.

Page 2 of 6

Radiator Top T ank

Bend capillary tube as shown.

Lay cap tube into sensor

gasket groove & wrap with

vinyl tape.

Hose clamp over sensor gasketDo Not Position Clamp Screw

Over Gasket.

Control

Capillary Tube

Do not bend less than

1/4" radius.

Box

Page 3

Instructions ’installation

Modèle propulsif 130-Ventilateur

unique avec contrôle à thermostat

et relais de climatisation

Modèle propulsif 140-Ventilateur

unique avec contrôle à thermostat

et relais de climatisation

Modèle propulsif 230-Double

ventilateur avec contrôle à

thermostat et relais de

climatisation

Modèle propulsif 240-Double

ventilateur avec contrôle à

thermostat et relais de

climatisation

Instructions d’installation à travers le corps

(VOIR LE DIAGRAMME «A»)

1. Placez le ventilateur électrique contre l’avant du

radiateur et marquez les trous de montage. (Dans

certaines applications, il peut y avoir des condensateurs de

climatisation et/ou des refroidisseurs devant le radiateur .

Ecrou à oreilles

Rondelle en acier

Diagramme A

Entretoise en caoutchouc

en forme de disque

Boulon en

nylon

Des réglages ou des modifications supplémentaires

pourront être nécessaires afin de procéder à l’installation).

2. Tournez les pales du ventilateur pour vous assurer de

l’absence d’obstructions.

3. A l’aide d’un petit tournevis à tête étoilée, passez à travers les

trous marqués et écartez avec soin les ailettes pour faciliter le passage des boulons en nylon (4 pour l’unité à ventilateur unique, 6 pour l’unité

à double ventilateur). Faites passer les boulons dans les trous du capot de

refoulement, puis tordez-les à l’intérieur du radiateur . Remarque : Veillez à passer à

travers les connecteurs des fils du moteur quand vous insérez les boulons dans le trou supérieur

central de l’unité à double ventilateur . Voir la vue éclatée, au diagramme B.

4. Faites glisser la rondelle en caoutchouc, puis la rondelle en acier , sur le boulon en nylon, puis serrez

les écrous à oreille à la main jusqu’à ce qu’ils soient bien assujettis.

5. Une fois de plus, tournez les pales du ventilateur pour vous assurer de l’absence d’obstructions.

OU

Installation par les rainures de support ou le châssis du radiateur

(VOIR LE SCHEMA «B»)

1. A l’aide des boulons en nylon, fixez les supports de montage du châssis au ventilateur , puis coupez-les à 254 mm

(1 po), et assujettissez-les à l’aide des écrous à oreilles.

2. Placez le ventilateur à l’endroit désiré, et marquez les

trous dans les rainures ou le châssis du radiateur .

3. Tournez les pales du ventilateur pour vous assurer de

l’absence d’obstructions.

4. Forez des trous de 5,15 mm (13/64 po) à l’emplacement des

marques.

5. Fixez le ventilateur au radiateur à l’aide des vis

autotaraudeuses de 6,53 mm x 254 mm (1/4 po x 1 po).

6. Vérifiez la rotation du ventilateur .

Page 3 of 6

Pinces noires

en nylon

Fils du moteur

(Voir les zones

encerclées pour

l’emplacement de la

pince installée. Les

porte-fils sont illustrés

dans l’encadré)

Vis autotaraudeuse

Châssis à rainures

du radiateur

Diagramme B

Supports de

montage du

châssis

Boulon en nylon

(coupé à 2,54 cm (1 po))

Page 4

Instructions de câblage

Remarque : Chaque connexion illustrée dans cette section est exigée pour permettre le fonctionnement.

1. Débranchez la batterie.

2. Reliez le ou les fils noirs du moteur à M+

3. Reliez le ou les fils blancs du moteur à M-.

4. Connectez la borne positive “+” à une boîte à fusibles de

source d’alimentation positive (+) de 12 volts basse

intensité. Utilisez pour ce faire le fil contenu dans le

kit.

Remarque : Connectez à la source d’allumage si vous

ne voulez pas que l’unité continue de fonctionner une

fois que le moteur a été coupé.

5. Connectez la borne “B” à une source d’alimentation

positive (+) de 12 volts haute intensité, par exemple au

côté positif de la batterie ou de l’alternateur. Utilisez

pour ce faire le fil et le fusible en ligne contenus dans le

kit.

6. Connectez la borne “C” au côté positif (+) du

compresseur de climatisation. Raccordez au fil positif

de l’embrayage de climatisation à l’aide du

connecteur à trois broches et du fil contenus dans le

kit. Relais de climatisation (actionne le ou les

ventilateurs lorsque la climatisation est mise en

marche).

7. Connectez la borne “G” au côté terre, c’est à dire au

châssis, côté négatif (-) de la batterie. Utilisez pour ce

faire le fil contenu dans le kit.

Fil positif de la climatisation

s

Source de courant de haute

intensité de 12 volts positifs

Bornes et connexions du coffret de commande

Connexions obligatoires

M+ Fils noirs du moteur

M- Fils blancs du moteur

+ Source de 12 volts basse intensité

G Terre

B Source de courant de haute

intensité de 12 volts

s

C Relais de la climatisation

Connecteur

à 3 voies

Coffret de commande

C

M

B

Disjoncteur

BAT

AUX

Source de

12 volts

Terre

(illumination du commutateur)

Connexions facultatives

M Commutateur manuel

T erre

G

+

Source de courant

de faible intensité

de 12 volts

Instructions de câblage des accessoires

Remarque : La connexion illustrée dans cette section, facultative, n’est pas cruciale au fonctionnement standard.

Commutateur manuel (pour le fonctionnement manuel du ou des ventilateurs)

1. Connectez la borne «M» à la borne 1 du commutateur. Fixez le fil séparé à la borne 2, puis fixez l’autre

extrémité de ce fil à une source d’alimentation positive de 12 volts. Pour illuminer le commutateur,

connectez une terre à la borne 3.

Remarque : (Ces instructions supposent l’emploi d’un commutateur manuel Flex-a-lite, n° de pièce 31148.

Commutateur manuel non inclus)

Installation de la poire de détection pour le contrôle de température

1. Desserrez le tuyau supérieur du radiateur, puis

retirez-le de la conduite d’admission du radiateur.

Poire de détection

de température

2. Insérez la poire de détection, puis courbez le tube de

la poire de détection autour de l’extrémité de la

conduite d’admission du radiateur. (Le tube est creux,

ne le tordez pas. Courbez-le légèrement).

3. Placez le joint du détecteur (pièce en caoutchouc

comportant une fente) entre le tube de la poire de

détection et la conduite d’admission du radiateur.

Veillez à ce que le tube soit calé dans la fente du joint

en caoutchouc.

4. Faites passer la bande en vinyle au moins deux fois

autour de la conduite d’admission et du tube du

Collier de serrage du tuyau par dessus

le joint du détecteur. Ne placez pas la

vis de serrage sur le joint.

détecteur.

5. Remettez le tuyau du radiateur en place, puis serrez

la pince. (Ne serrez pas à l’excès).

Garantie limitée de Flex-a-lite

Flex-a-lite Corporation, 7213-45th Street Court East, Fife, Washington 98424, numéro de téléphone 253/922-2700, garantit à l’ac heteur d’origine que tous les produits Flex-a-lite sont

exempts de défauts de matériaux et de fabrication. Cette garantie est valable pendant 365 jours (1 an) suivant la date d’achat. Si, dans les 365 jours (1 an) suivant la date d’achat, des

produits Flex-a-lite se révèlent défectueux, vous pouvez les réexpédier à l’usine, frais d’expédition prépayés. Si l’inspection détermine que la cause de la panne est due à un défaut de

matériau ou de fabrication, et non à un usage abusif, à un accident ou à une installation incorrecte, Flex-a-lite remplacera gratuitement le produit, frais d’expédition prépayés. Flex-a-lite

décline toute responsabilité en cas de dommages fortuits, progressifs ou connexes. Certains états n’autorisant pas l’exclusion ou la limite des dommages fortuits, il est possible

que la limite ou l’exclusion ci-dessus ne s’applique pas à votre cas. Cette garantie vous donne des droits légaux spécifiques, et vous pouvez également avoir d’autres droits,

varient d’un état à un autre.

Page 4 of 6

Réservoir supérieur

du radiateur

Courbez le tube capillaire

comme illustré. Placez-le

dans la rainure du joint du

détecteur et enveloppez-le

d’une bande en vinyle.

Boîtier de

contrôle

Tube capillaire. Ne le

courbez pas à moins

d’un rayon de 254

mm (1/4 po).

qui

Page 5

Instrucciones de instalación

Modelo 130 de empuje -

Ventilador simple con control

termostático y relé de aire

acondicionado.

Modelo 140 de empuje-

Ventilador simple sin control

termostático y relé de aire

acondicionado.

Instrucciones de montaje a través del núcleo

(VEA EL DIAGRAMA «A»)

1. Coloque el ventilador eléctrico contra el frente del

radiador y marque los orificios de montaje (Algunas

aplicaciones pueden tener condensadores de aire

acondicionado y o enfriadores en la parte frontal del

radiador. Pueden necesitarse modificaciones o ajustes

adicionales para la instalación).

2. Haga girar las aspas del ventilador para asegurarse de

que no tengan obstrucciones.

3. Con un pequeño destornillador Phillips, pase por los

orificios marcados, separe con cuidado las aletas para

permitir que pasen libremente los tornillos de nilón (4

para la unidad de ventilador simple y 6 para la de

doble). Haga pasar los tornillos por los orificios de la

gualdera y, luego, tuérzalos para que atraviesen el

radiador. Nota: Asegúrese de pasar por los conectores de

conductores del motor al insertar el tornillo a través del

orificio mediano superior de la unidad doble. V ea la

vista ampliada en el diagrama B.

4. Deslice la arandela de caucho y, luego, la de acero sobre

el tornillo de nilón y apriete con los dedos las tuercas de

mariposa hasta que queden sin holgura.

5. Una vez más, haga girar las aspas del ventilador para

asegurarse de que no tengan obstrucciones.

Tuerca de mariposa

Arandela de acero

Modelo 230 de empuje -

Ventilador doble con control

termostático y relé de aire

acondicionado.

Modelo 240 de empuje -

Ventilador doble sin control

termostático y relé de aire

acondicionado.

Diagrama A

Espaciador de disco de caucho

Tornillo de nilón

O BIEN,

Canal de soporte del radiador o instalación de armazón

(VEA EL DIAGRAMA “B”)

1. Sujete las ménsulas de montaje del armazón al

ventilador , utilizando tornillos de nilón y, luego,

córtelas a 2.54 cm (1 pulgada), utilizando tuercas de

mariposa para sujetarlas.

2. Coloque el ventilador en la ubicación deseada y marque

los orificios en los canales del radiador o el armazón.

3. Haga girar las aspas del ventilador para asegurarse de

que no tengan obstrucciones.

4. En los sitios marcados para los orificios, haga

perforaciones de 5.15 mm (13/64").

5. Fije el ventilador al radiador , utilizando los tornillos

autorroscantes de 6.35 mm x 25.4 mm (1/4" x 1").

6. Verifique la rotación del ventilador

(Vea las zonas encerradas

en círculos para encontrar

la abrazadera instalada. Los

portaalambres se muestran

en la inserción).

Page 5 of 6

Conductores del

Abrazaderas

negras de nilón

motor

Tornillo autorroscante

Diagrama B

Armazón de canales

del radiador

Ménsulas de

montaje del

armazón

Tornillo de nilón

(cortado a 2.54 cm (1"))

Page 6

Instrucciones de cableado

Nota: Todas y cada una de las conexiones que se muestran en esta sección son obligatorias para el

funcionamiento.

1. Desconecte la batería

2. Acople el o los conductores negros del motor a M+.

3. Acople el o los conductores blancos del motor a M-.

4. Conecte la terminal positiva “+” a una caja de fusibles

de fuente de alimentación positiva (+) de 12 voltios.

Use el conductor que se proporciona en el estuche.

Nota: Conecte a la fuente de encendido si no desea que

la unidad funcione después de que se detenga el motor.

5. Conecte la terminal “B” a una fuente de alimentación

positiva (+) de 12 voltios, o sea, al lado positivo de la

batería o el alternador. Utilice el cable y el fusible en

línea que se proporcionan en el estuche.

6. Conecte la terminal “C” al lado positivo (+) del

compresor de aire acondicionado. Haga un empalme

en el conductor positivo del embrague de aire

acondicionado, utilizando el conector en tres sentidos

y el conductor proporcionado en el estuche. Relé de

aire acondicionado (activa el o los ventiladores

cuando se enciende la corriente de aire

acondicionado).

7. Conecte la terminal “G” a tierra, o sea, al chasís o el

lado negativo (-) de la batería. Utilice el conductor

proporcionado en el estuche.

del aire acondicionado

Conductor positivo

s

Positivo de bajo

amperaje de 12 volts

Terminales y conexiones de la caja de control

Conexiones obligatorias

M+ Conductor(es) negro(s) del motor

M- Conductor(es) blanco(s) del motor

+ Fuente de bajo amperaje de 12 voltios

G Tierra

B Fuente de alto amperaje

de 12 voltios

s

C Relé de aire acondicionado

Conector en

tres sentidos

Caja de control

C

M

B

Disyuntor

BAT

AUX

Fuente de

alimentación de 12

voltios

Conexiones opcionales

M Interruptor manual

Tierra

G

+

Fuente de bajo

amperaje de 12 voltios

Tierra

(se ilumina el interruptor)

Instrucciones de cableado para accesorios

Nota: Las conexiones que se muestran en esta sección son opcionales y no son cruciales para el

funcionamiento estándar

Interruptor manual (Permite la activación manual del o los ventiladores)

1. Conecte la terminal «M» a la 1 del interruptor. Acople el conductor separado a la terminal 2 y acople el

otro extremo del mismo alambre a una fuente positiva de 12 voltios. Para iluminar el interruptor,

conecte una tierra a la terminal 3.

Nota: (Las instrucciones se basan en un interruptor manual Flex-a-lite, pieza número 31148. No se incluye el

interruptor manual).

Instalación del bulbo sensor de control de temperatura

1. Afloje la manguera superior del radiador y sáquela del

tubo de entrada.

2. Inserte el bulbo sensor, doblando su tubo en torno al

extremo del tubo de entrada del radiador.

(El tubo es hueco, no produzca sesgos. Use vueltas

amplias).

3. Coloque el empaque sensor (la pieza de caucho con la

hendidura) entre el tubo del bulbo sensor y el de

entrada del radiador. Asegúrese de que el tubo repose

en la hendidura del empaque de caucho.

4. Aplique al menos dos vueltas de cinta de vinilo en

torno al tubo de entrada y el del sensor.

5. Vuelva a colocar la manguera del radiador y apriete la

abrazadera (no apriete en exceso).

Garantía limitada de Flex-a-Lite

Flex-a-lite Corporation, 7213-45th Street Court East, Fife, Washington 98424, teléfono número 253-922-2700, le garantiza al usuario comprador original, que todos los productos de Flex-a-lite

estarán libres de toda clase de defectos de materiales y mano de obra durante un periodo de 365 días (1 año) a partir de la fecha de compra. Los productos de Flex-a-lite que fallen dentro de los

365 días siguientes (1 año) a la fecha de compra, podrán regresarse a la fábrica, con los cargos de transporte pagados por adelantado. Si al efectuar una inspección se determina que la causa del

fallo es un defecto de los materiales o la mano de obra y no el mal uso, un accidente o una instalación inadecuada, Flex-a-lite reemplazará el ventilador sin cargo alguno, con el transporte pagado

por adelantado. Flex-a-lite no será responsable de daños incidentales, progresivos ni consecuentes. Algunos estados no permiten la exclusión ni la limitación de daños incidentales o

consecuentes, de modo que es posible que la limitación o exclusión precedente no se le aplique. Esta garantía le concede derechos legales específicos y es posible que tenga también otros,

que varían de un estado a otro.

Bulbo sensor de

temperatura

Abrazadera de manguera sobre el

empaque sensor. No ponga el tornillo de

la abrazadera sobre el empaque.

Page 6 of 6

Depósito superior

del radiador

Doble el tubo capilar como

se indica. Coloque el tubo de

casquete en la ranura del

empaque sensor y

envuélvalo con cinta de

vinilo.

Caja de

control

Tubo capilar . No lo

doble en un radio de

menos de 6 mm (1/4").

99875 7/00

Loading...

Loading...