Page 1

Quick Start Guide

GUIDER II

SZ11-EN-A02

WARNING

USERGUIDE

1. Hot! Avoid touching the heating nozzle in operation.

2. Moving parts in printer may cause injury. Do not wear gloves

or other sources of entanglement in operation.

The User Guide is in the USB stick.

This guide is only applicable to FLASHFORGE Guider II 3D printer

Page 2

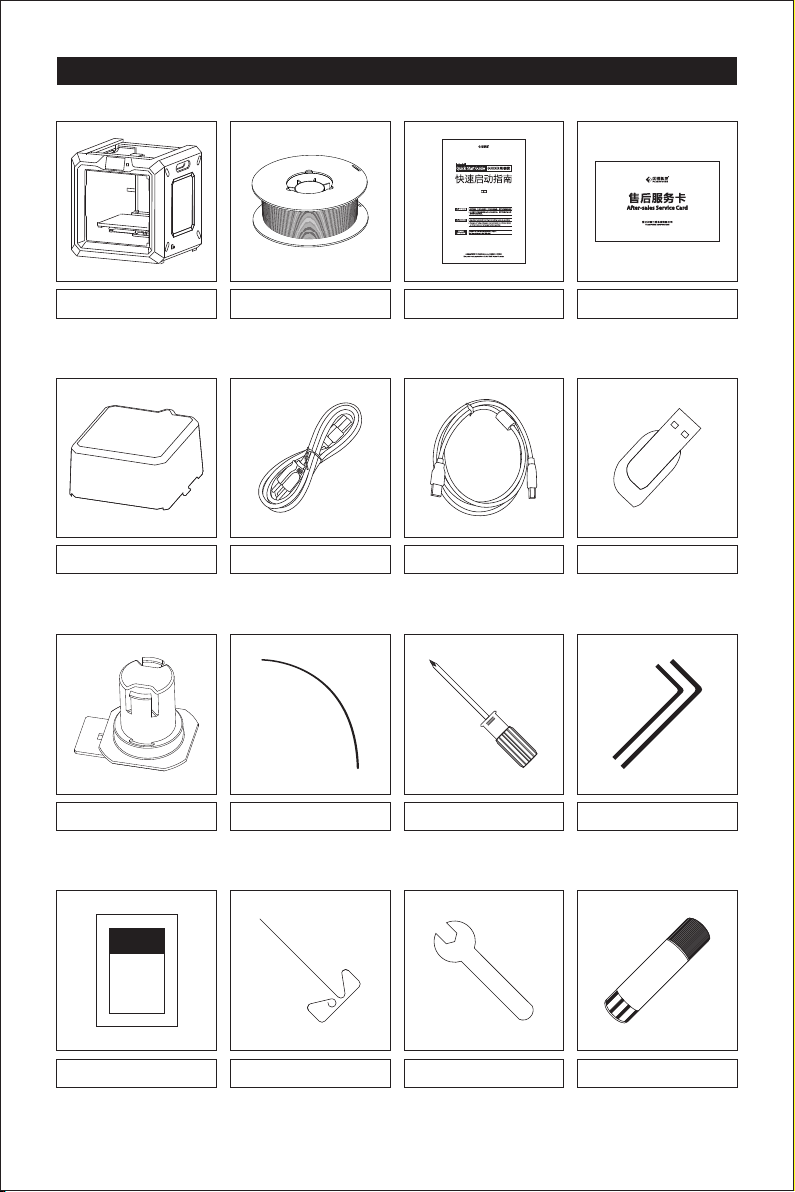

Kit Contents

3D Printer

Lid

Spool Holder

Filament Spool

Quick Start Guide

Power Cable USB Cable

Filament Guide Tube

Screwdriver

After-sales Service Card

USB Stick

Allen Wrench

GREASE

Grease

Unclogging Pin Tool

Wrench

01

Solid Glue

Page 3

Getting to Know Your Guider II

9

11

12

3

4

5

8

2

1

6

7

13

14

15

10

16

17

18

1. Z-Axis Guide Rod

5. Touch Screen

9. Servo

13. Network Interface

17. Power Switch

2. Filament Inlet

6. Touch Screen Button

10. Turbo Fan

14. USB Stick Input

18. Power Input

02

3. Y-Axis Guide Rod

7. Build Plate

11. Nozzle

15. USB Cable Input

4. X-Axis Guide Rod

8. Leveling Knob

12. Turbo Fan Baffle

16. Spool Holder Slot

Page 4

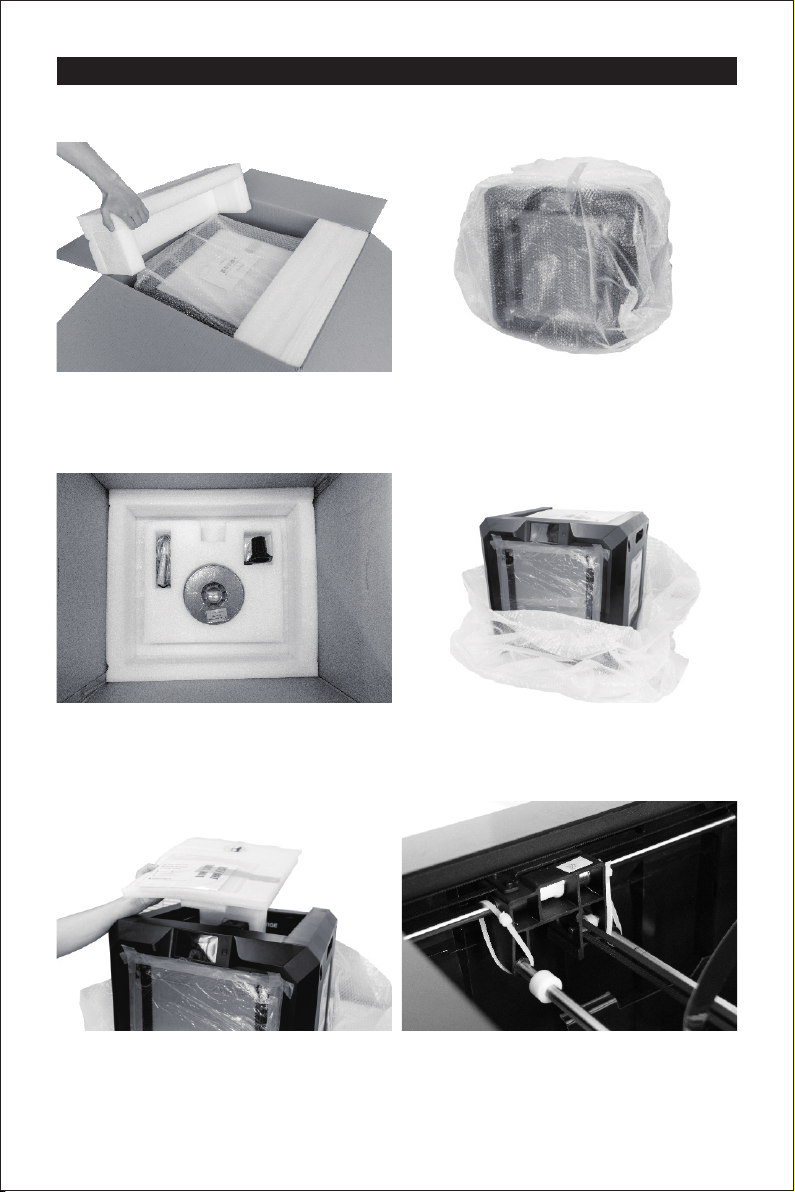

Unpacking

1. Open the box and remove both top foam

sheets.

3. The bottom PE foam should contain: filament,

spool holder, solid glue, USB cable, grease

and accessories bag.

2. Take your Guider II out of the box and remove

the bubble wrap.

4. Remove bubble wrap.

5. Remove the top PE foam piece,which

contains a power cable, a Quick start guide

and a After-sales service card.

6. Use scissors to cut the buckles that hold the

rods in the place.

03

Page 5

HOME

Filament Level Home Manual

Setting Status About

X: 87.00

Y: 70.50

Z: 140.00

X+X-

Y+

Y-

Z-

Z+

7. Open the door and take out the lid. 8. Take out power cable and plug the power

cable into the input on the back and turn

on the power switch.

Print Preheat Tool

9. Press the touch screen button and tap [Tools] .

11. Tap [Z-] to partially elevate the build plate.

10. Tap [Manual].

12. Remove both bottom foam pieces.

Congratulations! You've unpacked

your Guider II.

04

Page 6

Hardware Assembly

1. Locate the spool holders.Install the spool

holders in the two quadrangular openings on

the back.To install a spool holder, level it and

insert the end into one of the openings.

3. Squeeze the spool holder top and mount the

filament spool to the holder.

2. Turn down the spool holder to make the holder

bottom cleave to the printer back.

4. Secure the filament guide tube with R-shaped

buckles and thread the filament through the

tube. The filament spool must be oriented

correctly (see above), and should feed

filament from bottom to top.

05

Page 7

Leveling Build Platform

How to change language

Filament Level Home Manual

HOME

Print Preheat Tools

Language

Resume Print

WiFi

WLan hotspot

English

Setting Status About

简体中文

English

日本語

繁體中文

How to use the leveling knobs

Rotate the knob clockwise

Raise the build plate to reduce the distance between the nozzle and build plate.

Rotate the knob Anticlockwise

Lower the build plate to increase the distance between the nozzle and build plate.

06

Page 8

Please wait while the extruder and platform

finish initial movement...

Screw three knobs under the platform

anticlockwise until you can’t tighten them any

more, then tap [OK] button.

OK

1. Tap [Tools]-[Level] on your Guider II's touch screen. Please wait while the extruder and platform

complete initial movements. Then, rotate all three knobs under the platform anticlockwise

until you can't tighten them anymore. Then tap [Ok].

Confirm

Are you sure you can’t finger

tighten these three knobs any

more?

Yes No

Verifying the distance between nozzle

and plate...

Wait

2. Tap [Yes] if you can't tighten all the nuts any more, or tap [No] to continue tightening. After

selecting [Yes], the extruder will move towards the first point and the plate will move up and

down to verify the distance between nozzle and plate.

Distance Too Big

Unscrew corresponding knob under

platform clockwise until hearing

a steady beep.

Distance Too Small

Screw corresponding knob under

platform anticlockwise until hearing

a steady beep.

3. If the distance between the nozzle and plate is too large, rotate the knob underneath the

platform clockwise until you hear a steady beep. If the distance is too small, rotate the knob

anticlockwise until you hear a steady beep.

Wait

Please tap [Verify] button to

check whether the distance

is appropriate now.

Verify

Congrats

Tap [OK] button

to next point leveling.

OK

4. Then tap the [Verify] button to check whether the distance is appropriate this time.

If the distance is appropriate now, tap [OK] to second leveling point. If still not, please follow

the prompts to adjust again till you see [OK] button.

Repeat steps 3 and 4 to level the second and third points. Then tap [Finish] to exit.

07

Page 9

Loading / Changing Filament

HOME

Filament Level Home Manual

Build Preheat Tools

Setting Status About

1. Tap [Tools] and then tap [Filament] and [Load] to load filament.

I’m heating up...

100%

Load Unload

Extruder

Cancel

2. The extruder will automatically heat up. Once heated, filament will be drawn through the

extruder. Continue extruding until the extruder provides a steady flow of filament.

220℃ / 220℃

Changing Filament

Build Preheat Tools

Do not pull out the filament with force as it will damage the gears. If the melted

filament has cooled down in the extruder, please repeat the steps above.

Extruder

Platform

Start

220℃

100℃

1. Tap [Preheat]--[Start] to the heat up the extruder.

2. Once preheated, hold down the spring presser and pull out the filament.

3. Tap the return button, insert the new filament into the filament intake, tap [Tools]-[Filament] [Load]. The filament will be drawn through the extruder once heated. Wait for the extruder to

provide a steady flow of filament.

08

Page 10

First Print

Build Preheat Tools

1. Please insert the USB stick into Finder. In the print interface, tap [Print]-[USB Stick].

flashprint切片软件

System Volume Information

40mm_Box-ABS.gx

40mm_Box-PLA.gx

2. Select one file to print according to the

Build

Delete

3. Tap [Build].

40mm_Box-ABS.gx

Total: 0 hr 54 min

Copy

filament type used, tap [Build].

40mm_Box-ABS.gx

Extruder 50℃/220℃

Platform 50℃/105℃

Time left 0 hr 54 min

25%

4. Once heated, the printer will start printing.

Suggestions

Ensure that the build plate has been leveled before printing.

Ensure that the filament has been loaded in an appropriate approach.

Load the filament for a while to extrude all the melted filament you printed last time out of the extruder.

Do not leave the Guider II unattended during operation.

09

Page 11

Scan QR to Get More

After-Sales Support

After-Sales Service: support@ff3dp.com

Tel: +8 6 579 822 73989 Web: ww w.flash forge.com Add : 2/F, No. 518, Xi anyua n Road, Ji nhua, Z hejia ng, Chi na

Loading...

Loading...