Page 1

SZ16-ZN/EN-A05

Adventurer 3

User Guide

This guide is only applicable to FLASHFORGE Adventurer3 3D printer

Page 2

Page 3

Preface

Notice

Terms

Content

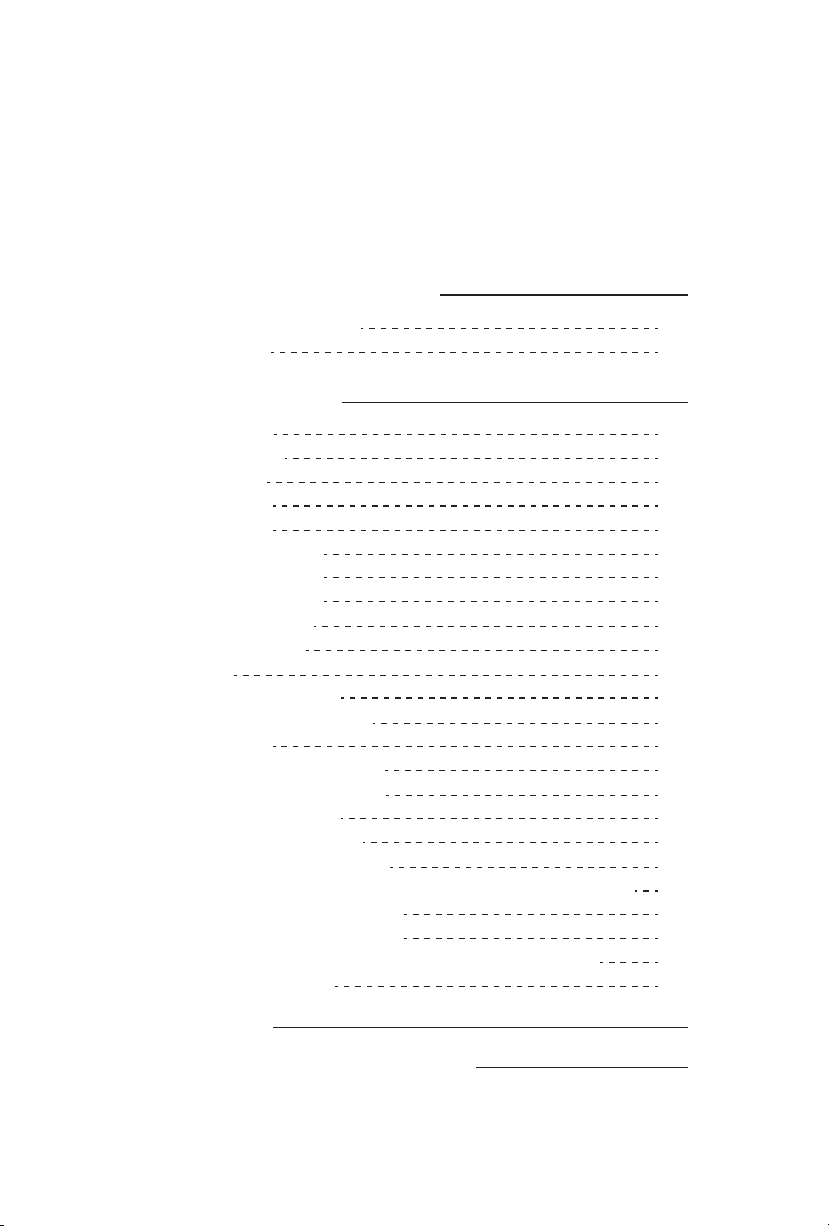

Chapter 1: About Adventurer 3

1.1 - Components Introduce

1.2 - Reference

Chapter 2: Operating

2.1 - Unpacking

2.2 - Accessories

2.3 - Interface

2.3.1 - Build

2.3.2 - Tools

2.3.2.1 - NetWork

2.3.2.2 - Preheat

2.3.2.3 - Setting

2.3.2.4 - About

2.3.3 - Filament

2.4 - Print

2.4.1 - Load Filament

2.4.2 - Model File Transfer

2.4.3 - Print

2.4.3.1 - FlashCloud Print

2.4.3.2 - PolarCloud Print

2.4.4 - Model Remove

2.4.5 - Replace Filament

2.5 - The Guide of Using Camera

2.5.1 - The Switching Can Be Controlled by the Lower Computer

2.5.2 - FlashCloud Camera Use

2.5.3 - PolarCloud Camera Use

2.5.4 - The Switching Can Be Controlled Through the Cloud

2.5.5 - Error Handling

06

06

07

08

08

10

11

11

13

13

16

19

20

21

22

22

24

29

29

31

35

36

37

37

38

40

42

44

Chapter 3: Q&A

Chapter 4: Supports and Service

01

37

40

Page 4

Preface

Note: Each device must be tested before leaving factory. If there are some residues in

extruder or some tiny scratches on the build tape, it is normal and won’t affect

the printing quality.

On the completion of this User Guide, thanks all FlashForge engineers and the FlashForge

3D printer users for their unremitting efforts and sincere assistance.

The FlashForge Adventurer 3 User Guide is designed for the Adventurer 3 users to start their

printing journey with FlashForge Adventurer 3. Even if you are familiar with earlier FlashForge

machines or 3D printing technology, we still recommend that please read this guide, as there

is lots of important information about the Adventurer 3 for you to get a better 3D experience.

For a better and more successful printing experience, you can refer to the following materials:

Quick Start Guide:

Users will find the Quick Start Guide together with the printer accessories. The Quick Start Guide

will help you start your print journey as soon as possible.

Official FlashForge Website: www.flashforge.com

The official FlashForge website contains the up-to-date information concerning FlashForge

software, firmware, device maintenance and so on. Users are also able to get the contact

information from there.

02

Page 5

Notice

Safety Notice: PLEASE READ AND STRICTLY FOLLOW ALL THE

SAFETY WARNINGS AND NOTICE BELOW.

Work Environment Safety

Keep your work place tidy.

Do not operate Adventurer 3 in the presence of flammable liquids, gases or dust.

Keep Adventurer 3 out of children and untrained people’s reach.

Electrical Safety

Always use the Adventurer 3 with a properly grounded outlet. Do not refit Adventurer 3 plug.

Do not use Adventurer 3 in damp or wet locations. Do not expose Adventurer 3 to burning sun.

In case of device damage, please use the power supply provided by FlashForge.

Avoid using the device during an thunderstorm.

In case of uncertain accident, please unplug the device if you do not use it for long.

Personal Safety

Do not touch the nozzle and build plate during printing.

Do not touch the nozzle after finishing printing.

Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and gloves

away from moving parts.

Do not operate the device while you are tired or under the influence of drugs, alcohol or

medication.

Cautions

Do not leave the device unattended for long.

Do not make any modifications to the device.

To lower the build plate before loading/unloading filament.

(The distance between the nozzle and build plate should be kept for at least 50mm)

Operate the device in a well-ventilated environment.

Never use the device for illegal activities.

Never use the device to make any food storage vessels.

Never use the device to make any electrical appliance.

Never put the model into your mouth.

Do not remove the models with force.

Wireless Communcations

Wi-Fi frequency: 2.4G

CPU (MT7688) frequency: 580MHZ

Frequency band(s) in which the radio equipment operates: 2.4-2.4835GHZ

The maximum radiated transmitter power: 14-18 DBM

Wi-Fi is for transfer printing model file and connect with FLASHPRINT software or print cloud.

03

Page 6

The computer connects to the device via WIFI to download the printed model. Connect

to the cloud platform through wifi, you can check the printing status, transfer the printing

documents and control the printer.

Environment Requirements

Temperature: RT 15-30℃; Moisture: 20%-70%

Place Requirements

The device must be placed in a dry and ventilated environment.

The distances of the left, right and back side space should be at least 20cm, and

the distance of the front side space should be at least 35cm. Device storage

temperature: RT 0-40℃

Filament Requirements

Do not abuse the filament. Please make sure you use the FlashForge filament or

the filament from the brands accepted by FlashForge.

Nozzle clogging and damage may be caused by non-FlashForge filament due to

inappropriate material properties.

Filament Storage

All polymers degrade with time. Do not unpack filament until necessary. Filament

should be stored at clean and dry conditions.

Legal Notice

All the information in this document is subject to any amendment or change

without the official authorization from FlashForge.

FLASHFORGE CORPORATION MAKES NO WARRANTY OF ANY KIND WITH REGARD TO THIS

DOCUMENT, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRATIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE.

FCC Notice

This device complies with part 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) This device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired

operation.

FlashForge shall not be liable for errors contained herein for incidental consequential

damages in connection with furnishing, performance or use of this material.

This document contains proprietary information protected by copyright.

Copyright © 2017 FlashForge Corp. All Rights Reserved.

04

Page 7

Terms

Build Plate

Build Tape

Build Volume

Extruder

Nozzle

Cooling Fan

Filament Cartridge

The surface on which the Adventurer 3 builds an object.

The black tape that covers Adventurer 3’s build plate so that

the object can stick to the build plate well.

The three dimensional amount of space that an object

will use once it is completed. The largest build volume

is 150*150*150mm.

The integral extruder device installed on X-Axis. Extruder

draws the filament from the spool, melts it and pushes it

through a nozzle into the build plate.

Also called “print head”, which located at the bottom

of the extruder where heated filament is squeezed out.

To cool the outer assembly of the extruder and gear motor.

A specific box for placing FlashForge filament, which is

located on the right of printer.

Filament Guide Tube

Filament Intake

Solid Glue Stick

A white plastic tube that guides the filament from the

filament box to the filament intake.

An opening located at the top of the extruder.

A solid adhesive used for making the model stick to the

build plate firmly.

05

Page 8

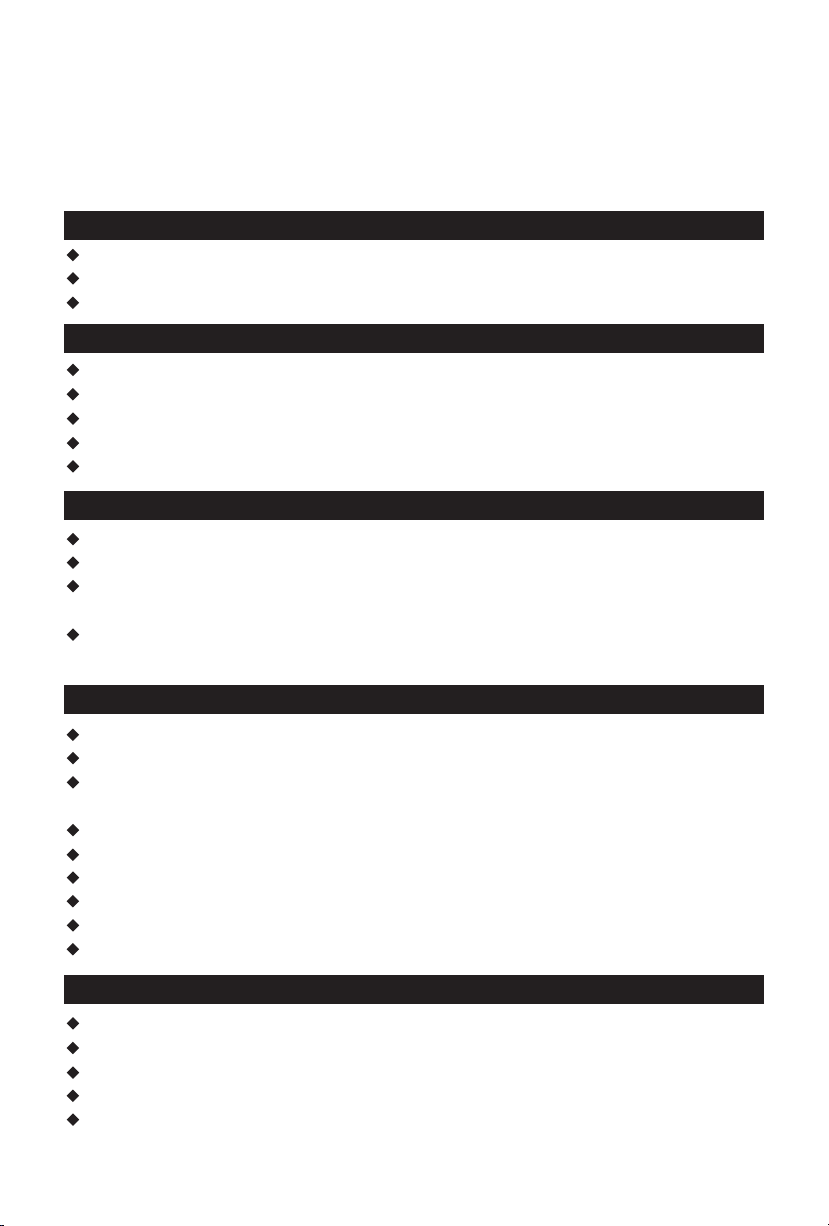

Chapter 1: About Adventurer 3

1

2

3

4

5

10

11

12

13

14

6

7

8

9

21

20

19

18

17

16

15

25

23

22

24

26

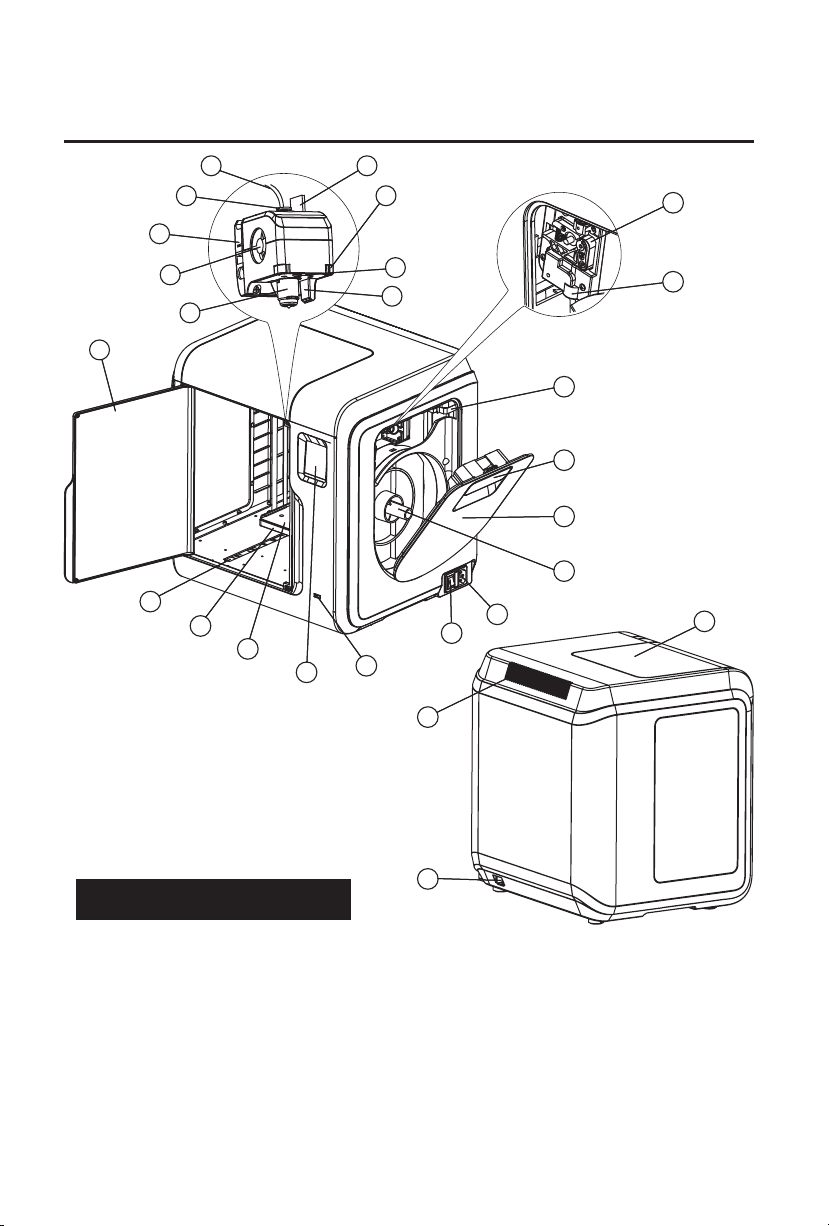

1.1 Components Introduce

1. Filament guide tube 2. Filament guide tube joint 3. Extruder base 4.Cooling Fan

5. Removable nozzle 6. Extruder cables 7. Clip 8. Led light

9. Air guide 10. Front door 11.Y-Axis sliding slot 12.Platform base

13. Removable build plate 14.Touch-screen 15.USB stick input 16.Power switch

17. Power input 18. Spool holder 19.Filament cover 20. Filament cover handle

21. Moto 22. Filament intake 23.Filament feeding wheel 24. Top cover

25. Air outlet 26. Ethernet input

06

Page 9

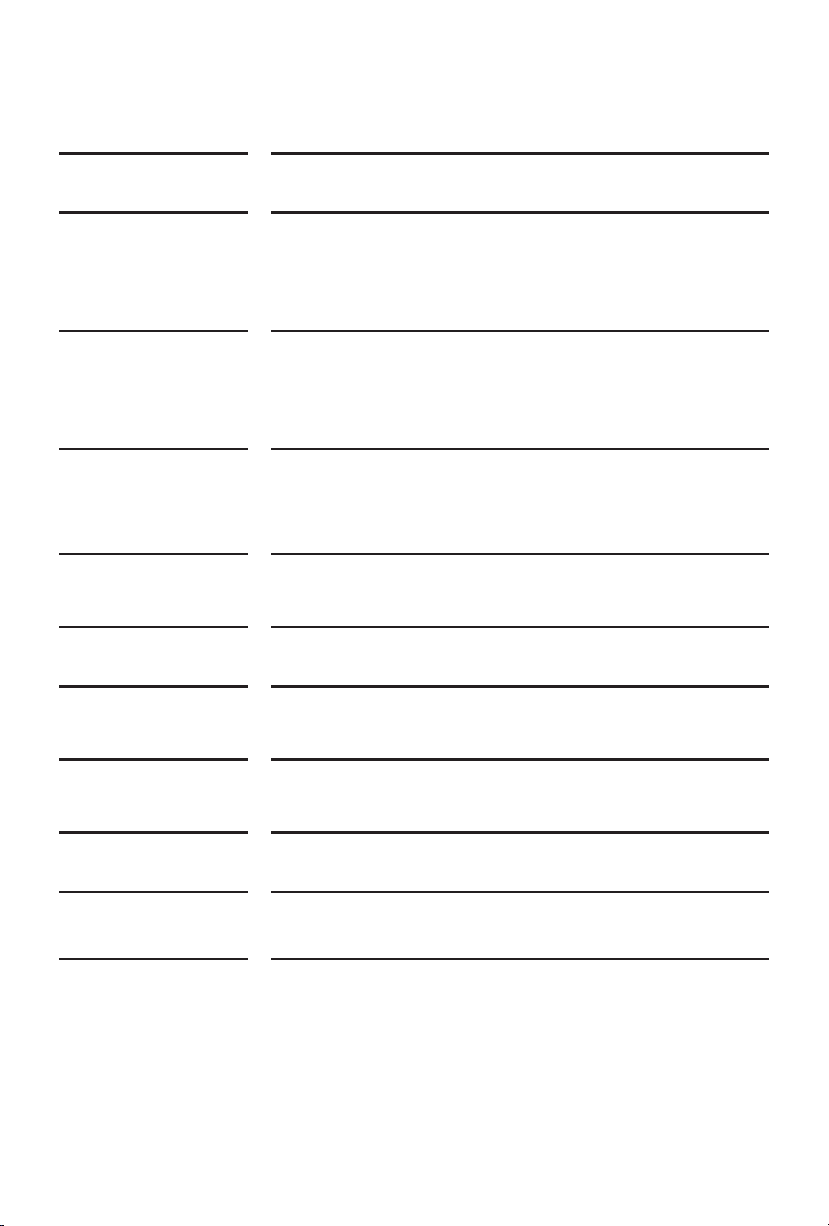

1.2 Reference

Name

Number of Extruder

Print Technology

Screen Size

Build Volume

Layer Resolution

Build Accuracy

Positioning Accuracy

Filament Diameter

Nozzle Diameter

Build Speed

Software

Support Formats

Adventurer 3

1, Removable

Fused Filament Fabrication (FFF)

2.8" color IPS Touch Screen

150×150×150mm

0.1-0.4mm

±0.2mm

Z axis 0.0025mm; XY axis 0.011mm

1.75mm (±0.07mm)

0.4mm

10~100 mm/s

FlashPrint

Input: 3mf/stl/obj/fpp/bmp/png/jpg/jpeg File

Output: gx/g File

Memory Size

OS

Device Power

Connectivity

Device Size

Net Weight

8G

Win xp/Vista/7/8/10, Mac OS, Linux

<120W

USB stick, WiFi, Ethernet

388×340×405mm

9 kg

07

Page 10

Chapter 2: Operating

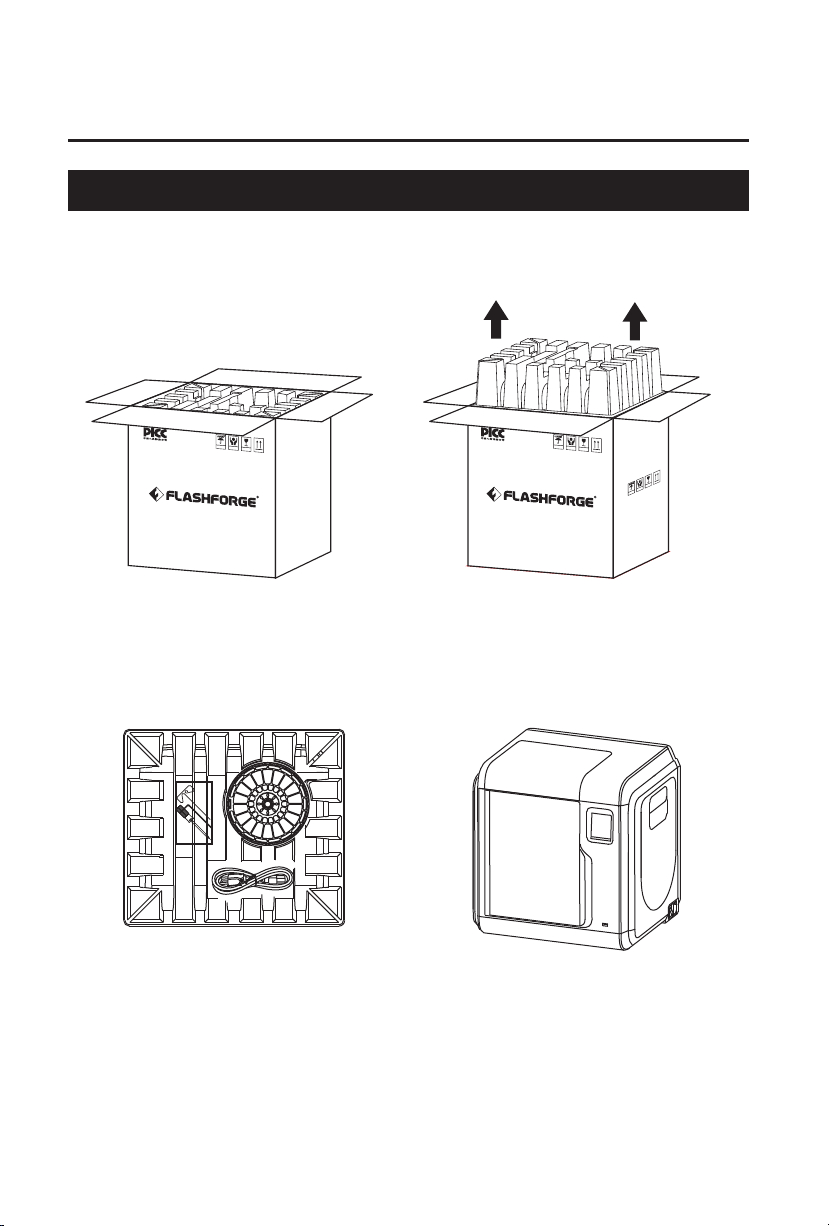

2.1 Unpacking

The People's Insurance Company of China

KEEP DRY

HANDLE

WITH CARE

FRAGILE

1. Open the box.

3

. Be careful! Filament, build tape, solid

glue, scraper and power cable are all

placed inside the wrapping paper box.

The People's Insurance Company of China

KEEP DRY

HANDLE

WITH CARE

FRAGILE

FRAGILE

HANDLE

WITH CARE

KEEP DRY

2. Take out the wrapping paper box

on the top.

4

. Take out the printer from the box.

08

Page 11

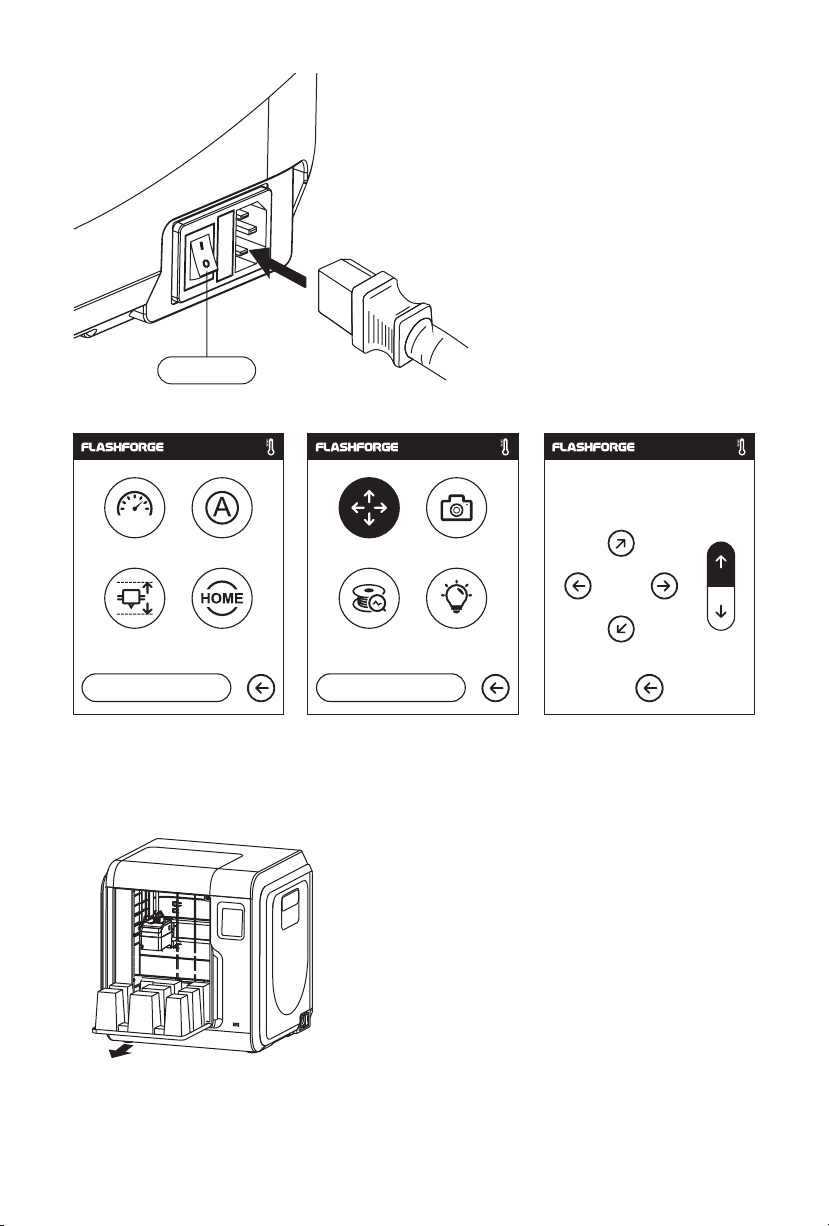

Power Switch

5. Plug the power cable into the input on the

back and turn on the power switch, the touch

screen is turned on.

X: 20.00 Y: 45.00 Z: 36.00

Y

1/3

Language

<<

Status

Calibration Home

<

6. Click [tools]-[setting] in turn to enter page like this, turn to page two, click [move].

Click the upper arrow in the moving page to make the extruder raises for removing the

paper box on the bottom easier.

Move Camera

FilamentCheck Led

2/3

<

7. Open the front door, take out the paper box inside

the printer, printer unpacking completed.

X

Z

09

Page 12

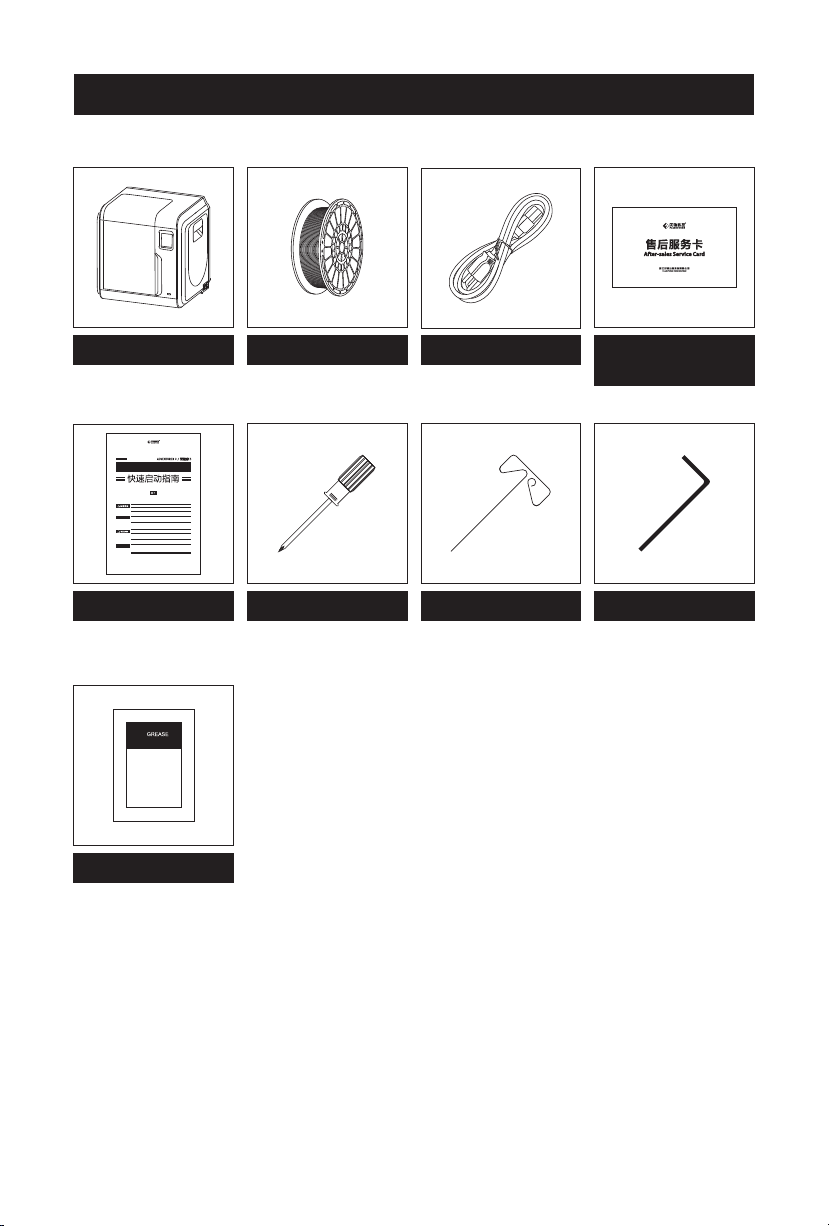

2.2 Accessories

3D Printer

SZ16-ZN/EN-A01

Quick Start Guide

9

1. 高温危险!打印机喷嘴和打印平台在工作时会被加热,请避免接触!

2. 可动部件可能造成卷入挤压和切割伤害。操作机器时请不要佩戴手套或缠绕物。

资料下载

前往闪铸科技官方网站 www.sz3dp.com ,可以在[ 技术支持 ] 页面下载用户使

用手册、切片软件等资料,或查看相关操作视频。

1. Hot! Avoid touching the heating nozzle and heating build plate in operation.

2. Moving parts in printer may cause injury. Do not wear gloves or other

sources of entanglement in operation.

Download

Please refer to FlashForge official website www.flashforge.com to download

the newest User's Guide, Software and Instruction Videos.

(Support-Support Center-Select a Product)

本手册仅适用于闪铸科技 Adventurer3 3D打印机

This guide is only applicable to FLASHFORGE Adventurer3 3D printer

User Guide

Grease

Filament

Power Cable

After-sales

service card

Allen WrenchScrewdriver Unclogging Pin Tool

10

Page 13

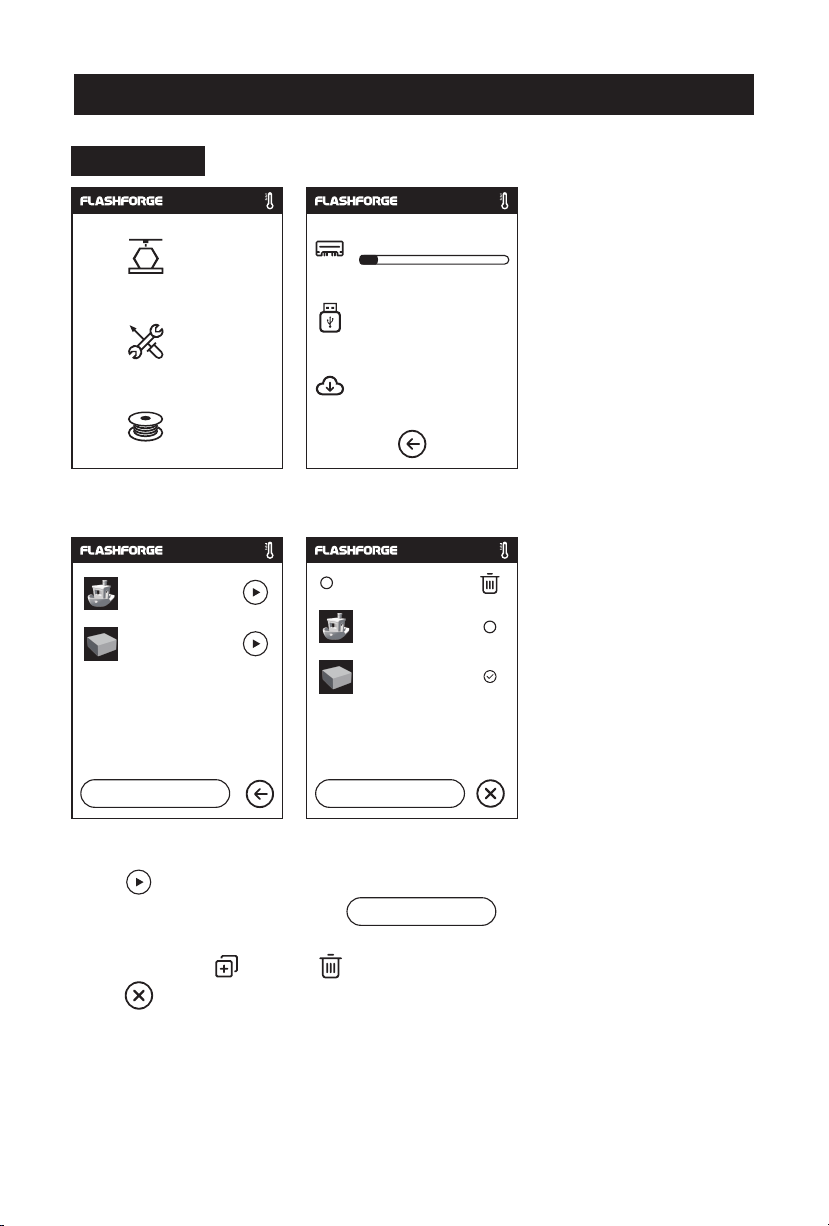

2.3.1 Build

2.3 Interface Menus Intrduction

Build

Tools

Filament

1. Tap [Print]. 2. Choose the read path of the print file File list.

Ship-PLA.gx

20mm_BoxPLA.gx

1/1

<

<

6.62GB

Not Available

No job

Select all

<

Ship-PLA.gx

20mm_BoxPLA.gx

1/1

<

Read the print file from:

The local memory card

The USB stick

The Cloud

Back: Back to upper interface

3. File list

Tap to begin printing; tap the picture of the selected file to enter file details.

Page-flip: Tap the left/right arrow.

Long press the file picture or file name, quit out multi-selected interface, you can

select all, copy ,delete .

Tap to quit out multi-selected interface.

<

1/3

11

<

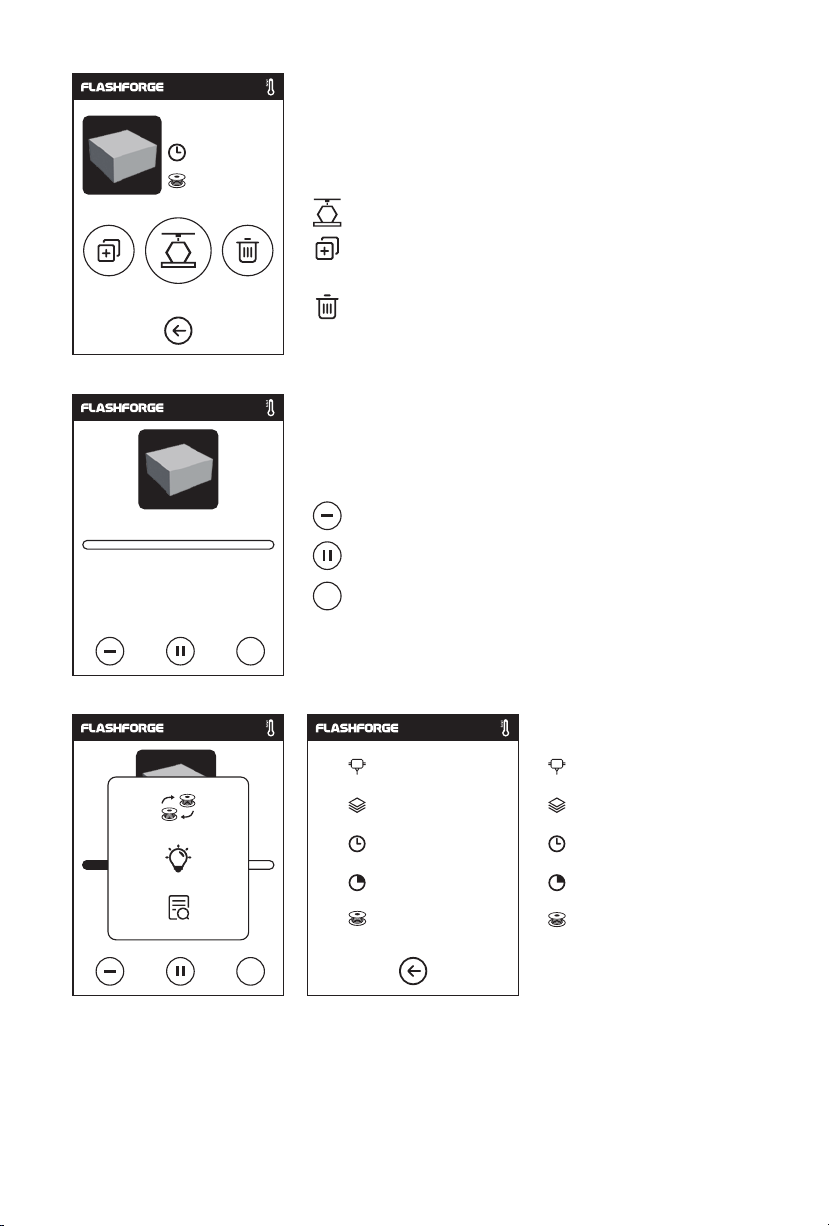

Page 14

20mm_Box-P...

0 10

h min

m

0.7

File details: Including file picture, time needed,

filament needed.

Build: To begin printing the file.

Copy: To copy the files to the local memory

card from the USB stick.

Delete: To delete the print file.

Print interface

20mm_Box-PLA.gx

0h10

Time Remaining

min

Cancel: To cancel the print job.

Pause/Resume: To suspend or resume the print job.

...

More: To check more settings and details information

during printing.

...

235

℃/235℃

100

℃/100℃

warrior.gx

2h18

min

剩余

0 1

h min

8

%

0.7

M

...

More

Replace: To change filament during printing progress.

Led Light: To turn on or turn off the led light.

Detail: To check more detail information.

Details

Extruder temperature

Build plate temperature

Used time

Printing progress

Whole filament needed

12

Page 15

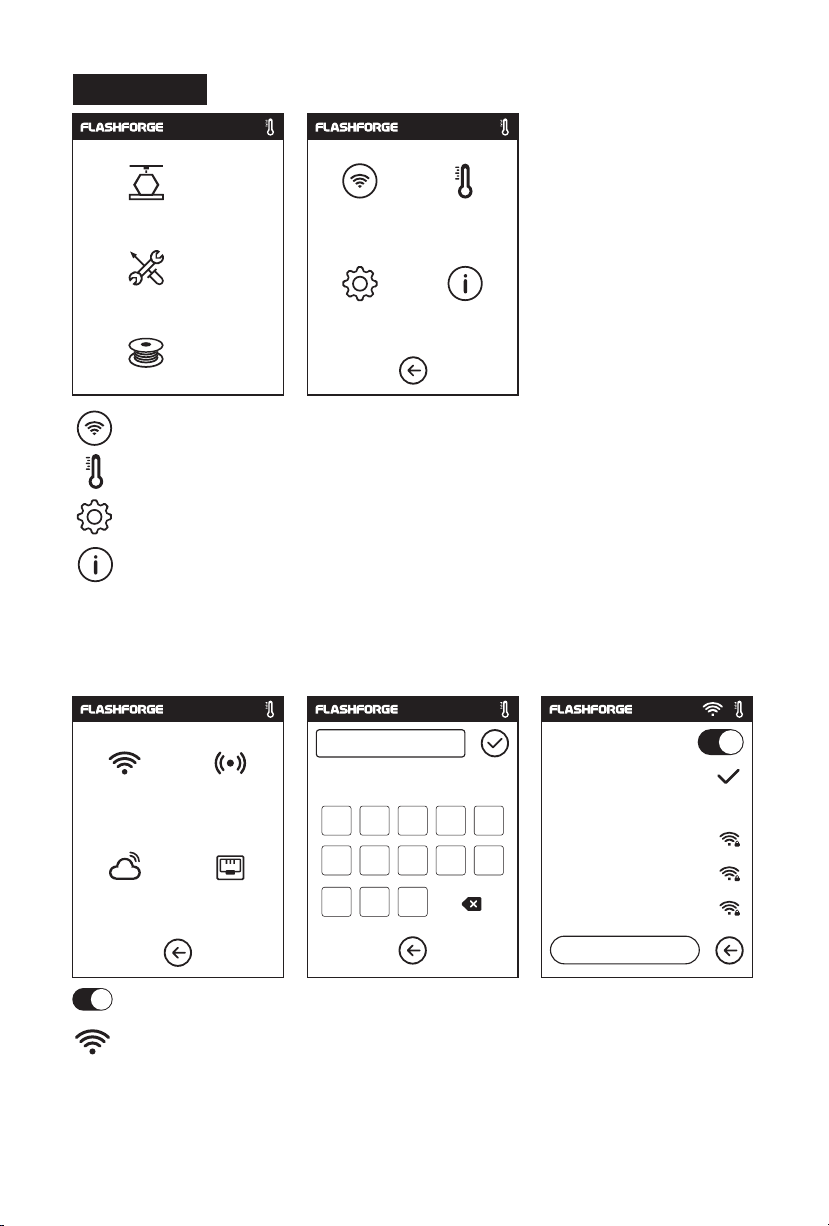

2.3.2 Tools

Build

Tools

Network

Preheat

Setting

Filament

Network: To connect printer to your PC or internet.

Preheat: To preheat the extruder and build plate.

Setting: To implement relevant function setups.

About: Information about the printer.

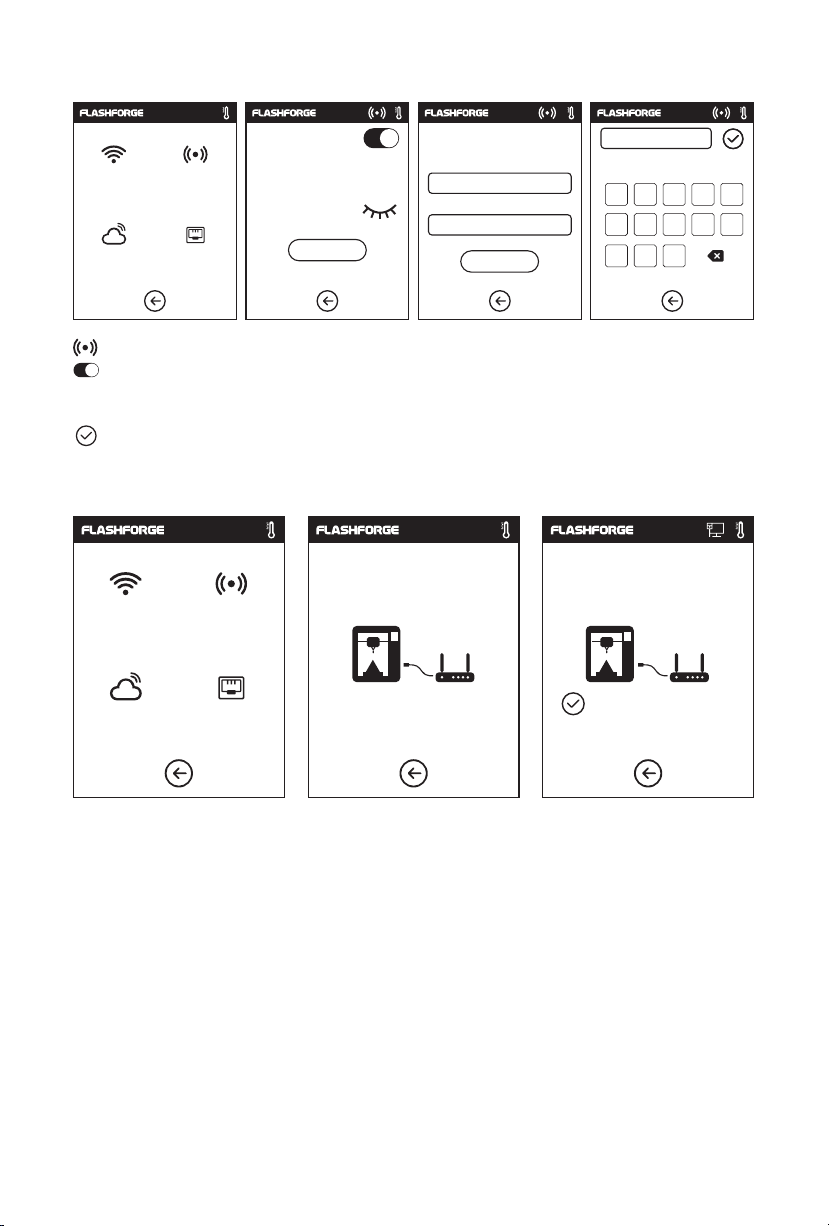

2.3.2.1 Network

WiFi

WiFi

Cloud

Hotspot

Ethernet

123

1 2 3 4 5

6 7 8 9

,

.

abc

About

WiFi

%#

0

_

Flashforge

Choose a network

ChinaNet-AnCr

TP-LINK_EDC2

QS_1234

1/3

<

ON/OFF: To turn on/off the WIFI connection.

WiFi connection: To connect your printer with your PC via a stable WIFI signal.

13

<

Page 16

Hotspot

Setup WLan hotspot

SSID:

Password:

Save

123

1

6 7 8 9 0

,

WiFi

Cloud

Hotspot

Ethernet

WLan hotspot

SSID:

Password:

Setup hotspot

To set your printer as a WLAN hotspot.

Turn on/off the WLAN hotspot.

Hotspot setting: To set the hotspot name and password. Input hotspot name with

numbers, characters and symbols.

Tap to save the name and password.

Ethernet Connection

WiFi

Cloud

Hotspot

Ethernet

Please connect the cable Connected successful

%#

abc

5

3 4

2

_

.

To connect your printer with your PC via Ethernet cable.

14

Page 17

Cloud Connection

Network Preheat

Setting

FlashCloud

Printer Name:

Flashforge

Registration Code:

ABCDEF

About

WiFi

Cloud

PolarCloud

Account:

PIN:

Hotspot

Ethernet

Save

FlashCloud

PolarCloud

1. Turn on the WiFi or Ethernet connection, connect the printer to internet successfully.

2. Tap[Tools]-Tap[Network]-Tap[Cloud] on the printer;

3. Turn on the Cloud Connection function;

4. Register your cloud account and set your settings on https://cloud.sz3dp.com with the

registration code on printer's touch screen, or register your cloud account on

https://polar3d.com to get your polar3d account and pin code.

15

Page 18

2.3.2.2 Preheat setting

Extruder

Network Preheat

Platform

Setting

ON/OFF: Turn ON/OFF the extruder or platform preheat;

Tap symbol, you could set preheat temperature;

Long press symbol, set preheat temperature rapidly;

Extruder/Platform preheat interface

Extruder

About

235

/235℃

Extruder

Platform

220℃

50℃

Start

235

75

/235℃

/100℃

Abort

It contains actual temperature, target temperature and heating progress.

Extruder highest preheat temperature: 240℃

Platform highest preheat temperature: 100℃

Tap : Abort the preheat job.

Abort

Abort

16

Page 19

2.3.2.3 Setting

Network

Setting

<

Status

Buzzer

Update

3/3

Preheat

About

FactoryReset

<

Status

Calibration

<

Setting interface

Status

Home

FilamentCheck

FactoryReset

Language

1/3

Move

Home

<<

FilamentCheck

<

Language

Move

Led

Update

2/3

Camera

Led

Calibration

Camera

Buzzer

20℃

20℃

Load

17

1/3

Language

X: 20.00 Y: 45.00 Z: 36.00

<

Status

Calibration Home

<

It displays the real-time coordinates of X-axis, Y-axis, Z-axis and the real-time

temperature of extruder and platform.

Page 20

Language

En

1/3

1/3

Language

<

Language

<

De

Fr

1/2

<

Click the arrow to adjust the

nozzle so that it just touches

the platform

Z axis

Extruder

Es

<<

0.00

OK

Status

Calibration Home

<

Choose the target language.

Status

Calibration Home

<

Up arrow: Extruder will elevate, away from the platform;

Down arrow: Extruder will descend, move close to the platform;

Ar

2/2

<

Calibration

To calibrate the initial distance

between extruderand platform.

After homing completed,slide

the piece of paper continuously

back and forth between the

nozzle and the build plate. And

simultaneously manually tap

up and down arrow to adjust the

distance until the paper causes

a slight friction. Tap [OK] to

complete calibration.

Home

Homing, please wait... Homing completed

1/3

Language

<

18

Status

Calibration Home

<

To make the X, Y and Z axes back to the mechanical zero point.

YesYes

Page 21

Move Camera

FilamentCheck Led

2/3

<

<

X: 20.00 Y: 45.00 Z: 36.00

Y

Y

X

X

Z

Z

Manual:

To manually adjust the

positions of extruder and

build plate.

Extruder moves to the right;

Extruder moves to the left;

Build plate moves to the front;

Build plate moves to the back;

Extruder moves upward;

Extruder moves downward;

Auto Mode

Idling Printing

Move Camera

FilamentCheck Led

2/3

<

Note: when using cloud print and using camera function on cloud, camera will be on manual mode, USB

stick will be off; turn on the auto mode on printer if you want to turn off the manual mode.

More details about Camera, please check Chapter 2.5.

Move Camera

FilamentCheck Led

<

Manual Mode

Move Camera

FilamentCheck Led

Camera:

Turn on or turn off the camera.

Auto Mode:

Printing: Camera is on; USB stick is off

Idling: Camera is off; USB stick is on

Manual Mode:

Users choose camera is on or USB stick

is on, when one of them is on, the other

is off.

Filament check:

To turn on/off the filament

check, notice will pop out

when filament is used up

or suspended when the

check is turned on.

Led: To turn on/off the light.

<

2/3

<

<

2/3

<

19

Page 22

Buzzer

Update

FactoryReset

Factory Setting

Delete all data

in internal memory

Completed!

Restored to factory setting

<

3/3

<

Start

ok

Factory Setting: Delete all data in internal memory, return the printer to factory setting.

Buzzer: To turn on/off the buzzer.

Update: To upgrade the newest firmware.

2.3.2.4 About:

Machine Type:

Adventurer 3

Serial No:

123456

RegisterCode:

XXXXXX

Polar Serial No:

XXXXXX

1/3

<

Firmware Version:

v1.03-1.1

Build Volume:

150 x 150 x 150

Usage counter:

12 hours

IP Address:

10.90.243.184: 8899

2/3

<

<

WiFi MAC:

02:00:00:00:11:66

3/3

<

< <

Shows the basic information about the printer.

Notice: When contacting after-sales support, please give your Serial No to after-sales

engineer, which is showed in the [About] interface.

20

Page 23

2.3.3 Filament

Load

Change

200

Heating extruder...

Cancel

/235℃

Preheat completed.

Begin loading.

235

ok

/235℃

/235℃

235

Press ok when new color appears

ok

Load

• The extruder is heated up to 220℃.

• After heat completed, insert the filament into the extruder at an upright angle until

some resistance is sensed(as the filament is pushed through the feeding wheel).

• Load will complete when you see filament come out of extruder.

Load

Change

/235℃

235

Unloading the filament,

please wait...

Pull out old filament,

feed new filament, press [ok].

235

ok

/235℃

/235℃

235

Press ok when new color appears

ok

Change

• The extruder is heated up to 235℃, after heat completed, filament will be unloaded

from the extruder.

• Pull out the filament according to the instruction.

• Insert new filament into the filament intake, tap [OK] ;

• New filament will be pushed into the extruder, replace will complete when you see

new filament come out of extruder.

21

Page 24

2.4 Print

Plug the power cable into the input on the right

side and turn on the power switch, the touch

screen is turned on.

Power Switch

2.4.1 Load Filament

1. Open the filament cover, insert the filament into the

filament intake, push filament into the feeding wheel

until some resistance is sensed.

Note: Please make sure filament has been pushed into

the feeding wheel!

22

Page 25

Build

Load

200

/235℃

Tools

Change

Filament

2. Tap [Filament]--Tap [Load]--After Load completed--Tap [OK]

/235℃

235

Preheat completed,

Begin loading...

ok

3. Load completed when you see filament come out of extruder, Tap [OK].

Put the spool of filament on the spool holder, close the filament cover.

Press ok when new color appears

ok

235

/235℃

Heating extruder...

Cancel

Mind the loading direction of filament, make sure

to be clockwise as the picture showed.

23

Page 26

2.4.2 Model File Transfer

After generating the Gcode file, you can transfer it to your Adventurer 3 with different

network methods. If use USB stick to print, please insert your USB stick with target .g/.gx file

to your Adventurer 3, there will be no need to set new network.

Method 1 :

WiFi Connection

Network

Setting

Preheat

About

WiFi

Cloud

1. Tap [Tools]--Tap [Network]--Tap [WIFI] ;

WiFi

Choose a network

Flashforge

ChinaNet-AnCr

TP-LINK_EDC2

QS_1234

1/3

<

<<

123

1 2 3 4 5

6 7 8 9

,

.

2. Choose a network and input the password.

abc

_

Hotspot

Ethernet

%#

WiFi

Flashforge

Choose a network

ChinaNet-AnCr

0

TP-LINK_EDC2

QS_1234

1/3

<

3. Open the FlashPrint software, click [Print], then click [machine type], select [Flashforge

Adventurer III]. Then click [connect to the machine].

24

Page 27

4. In the pop up dialog box, the connection mode selects Wi-Fi, and fill in the IP port column

with the IP address of the printer. Query IP address clicking [tools] - [about], turn to next

page, you can see the IP address. Input completion and click connect.

5. When the connection is succeed, the machine status bar will appear in the lower right

corner of the software interface, and the printer icon will be displayed as a connected

state. After processing the model in FlashPrint software, click the top print icon. Click

[OK]. Select the appropriate location to save the slice processed files.

Notices

When the user wants to use the browser to view the images, the printer and PC must be in an

intranet (that is, the printer and PC connect to the same router).

25

Page 28

5. After the software slicing is completed, click [Print]. Then the printer starts preparatory

work such as preheating, and automatically starts printing after it is ready.

26

Page 29

Method 2: Cloud Connection

Network Preheat

Setting

FlashCloud

Printer Name:

Flashforge

Registration Code:

ABCDEF

About

WiFi

Cloud

PolarCloud

Account:

PIN:

Hotspot

Ethernet

Save

Use the cloud connection to process printing operation.

FlashCloud

PolarCloud

* The use of FlashForge cloud is in 2.4.3.1 section.

27

Page 30

2.4.3 Print

Build

Tools

Filament

6.62GB

Not Available

No job

1. Tap [Build], choose the file path: Printer internal memory, USB stick, Cloud.

Ship-PLA.gx

20mm_BoxPLA.gx

1/1

<

<

2. Choose the model file, tap on its right to start printing; or tap model picture or model

name to enterdetail page, tap to start printing.

20mm_Box-P...

0 h 10 min

0.70M

20mm_Box-PLA.gx

0h10

Time Remaining

min

...

Ship-PLA.gx

20mm_Box-

PLA.gx

Build completed!

1/1

<

ok

3. Extruder will heat up automatically, when heating finishes, the printer will start

to build the model. After printing completed, printer will sound a beep and pop

out a notice on the touch screen.

28

<

Page 31

Type State

En

2.4.3.1 FlashCloud Print

Login

E-mail

Password

FlashCloud:Cloud.sz3dp.com

Remember Password

1. Register your account on Flashforge cloud:

After activate your account through your email box,

login in Flashforge cloud with your account.

FlashCloud

Home

My Printer

My Model

My Job

Model Library

My Printer

Name Register Code Type State

Add printer

+

The current printer is empty. Please add a printer

Forgot password Rigister

2. After login in cloud with your own account, click [My Printer] - click [Add Printer].

FlashCloud

Home

My Printer

My Model

My Job

Model Library

Add printer

My Printer

Name Register Code

+

The current printer is empty. Please add a printer

Add Printer

All fields must be filled in

Name

Registration Code

OK Cancel

Login

En

FlashCloud

Printer Name:

Registration Code:

ABCDEF

3. Input your printer’s name and Flashcloud registration code in [Add printer] interface. These information are

showed in your printer’s FlashCloud interface.

29

Page 32

FlashCloud

Home

My Printer

My Model

My Job

Model Library

My Printer

Name

4. Add printer completed.

+

Flashforge

Add printer

En

The current printer is empty. Please add a printer

Register Code Type State

ABCDEF Adventorer 3 Idle

FlashCloud

Home

My Printer

My Model

My Job

Model Library

User

2018.3.2

3D Model

Model Detail

Print

5. Choose a model from cloud model library or upload your own model (stl file), click [Print], enter the edit model

interface to edit model.

FlashCloud

Home

My Printer

My Model

My Job

Model Library

Flashforge

Edit model

Move Rotate Scale

-150

X:

-150

Y:

Print para

150

150

0

0

En

En

-150

Z:

150

0

Print

6. In the drop down menu of the printer's name, you can choose the printer which runs this mission. (the printer must

be added into 'my printer')

30

Page 33

FlashCloud

首页

我的打印机

我的模型

我的任务

模型库

Flashforge

2.4.3.2 Polar云打印

1. Register Polar cloud account.

Log i n https://polar3D.com to register the account.

2. Query Polar cloud PIN code.

En

Time Remaining

h

min

0

0

0%

21℃ / 0 ℃ 21℃ / 0℃ Closed Normal

Start Cancel

(1). After completing the Polar cloud registration and log in the Polar cloud website, click the icon on the top right

corner and click [Settings].

31

Page 34

Location

Biography

Website URL

http://www.example.com/profile

Email

+ADD Email

PIN Code

XXXX

(2). Find the PIN Code column below the page, and the shown number is PIN code.

3. Connect the Adventurer 3 to the internet.

Choose the appropriate network connection mode in the communication interface to connect the

network (see the 2.3.2.1 section of the connection method).

4. Connect the Adventurer 3 to the Polar cloud.

PolarCloud

Polar cloud switch

Account:

Enter the cloud connection interface (click tools >

PIN:

Save

5. After the connection is completed, you can see the printer's information on the front page of Polar cloud

website. (if you turn on the camera function, you can see the real time picture on the page).

communication > cloud connection), turn on the Polar cloud

switch (After the Polar cloud is turned on the switch will change

into green). Fill in the below account and PIN code columns

with the account before the registration of Polar cloud and the

PIN code queried before, click save.

32

Page 35

7. Click [MY OBJECTS], then click [UPLOAD] to upload the model.

8. Drag and drop the model files that need to be uploaded to the box area or click the box area to select the upload

model, then click [UPLOAD] to upload.

33

Page 36

9. Click [PRINT].

10. Click [START], the printer starts the cloud task downloading, and starts printing when the download is finished.

34

Page 37

2.4.4 Model Remove

1. Take out the removable build plate.

When printing completed, extruder and build

plate may still be hot, please start operating after

cooling down!

Notices

2

. Bend the build plate, the plate will produce certain deformation, seperating the

plate away from the bottom of model (Please use a scraper to assist removing

when model is too small or big).

35

Page 38

2.4.5 Replace Filament

/235℃

200

Load

Heating extruder...

Change

Cancel

1. Tap [Filament]--Tap [Change], extruder will start preheating.

. Pull out the filament as the picture

2

showed above.

/235℃

235

Unloading the filament,

please wait...

. When new filament come out of extruder steadily, replace is completed, Tap [OK].

4

feed new filament, press [OK].

3. Insert new filament into the filament intake

and push the filament into the feeding wheel

until resistance is sensed.

/235℃

235

Pull out filament,

OK

36

Press ok when new color appears.

OK

235

/235℃

Page 39

2.5 The Guide of Using Camera

Camera User Manual

Camera and USB Disk use the same interface, so the use of Adventurer 3's camera is different

from that of other models. The use of Adventurer 3's camera and the use of Adventurer 3's USB

Disk are incompatible (that is, only one (camera or USB Disk) can be used in the same time).

The switching between camera and USB Disk can be realized through the Cloud or the lower

computer. The use of Adventurer 3's camera is introduced as follows.

2.5.1. The switching can be controlled by the lower computer

In respect of the use of Adventurer 3's camera, there are two modes, that is automatic mode

(default mode) and manual mode. The route is (Tools->Settings (on the second page) ->

Camera), the user can click the “Camera” button to enter the relevant page.

Auto Mode

Idling Printing

Manual Mode

Automatic Mode: When the printer is working (such as

the printer is printing the files), the camera is turned on

and USB Disk is turned off. When the printer is not working,

the camera is turned off and USB Disk is turned on.

Build

Tools

Build

Tools

Auto Mode

Manual Mode

Manual Mode: The switching

between camera and USB Disk

can be controlled by the user

at will.

Filament

Filament

After the camera is turned on successfully, the icon of camera

will appear in Status Bar. After the camera is turned off, the icon

of USB Disk will appear in Status Bar in case of successful insertion

of USB Disk.

37

Page 40

2.5.1. The use of FlashForge cloud camera

类型

En

Login

E-mail\phone

1. Login FlashForge cloud website and

register an account. After the mailbox

activation, you can login and use the

FlashForge cloud.

FlashForge cloud website:

https://cloud.sz3dp.com

FlashCloud

Home

My Printer

My Model

My Job

Model Library

My Printer The current printer is empty. Please add a printer.

Name Register Code Type

Add printer

+

2. After login, click [My Printer] - [Add Printer].

FlashCloud

Home

My Printer

My Model

My Job

Model Library

My Printer The current printer is empty. Please add a printer.

Name Register

Add printer

+

Add printer

All fields must be filled in

Name

Register Code

OK Cancel

Password

Remember password

Login

Forgot password Register

中

FlashCloud

Printer Name:

XXXXXX

Registration Code:

XXXXXX

3. Fill in the printer page with the printer name and registration number. This information is

displayed on the FlashForge cloud’s interface of the printer. Please make sure that the printer

has been properly connected to the network (see section 2.3.2.1), the FlashForge cloud

function is in the turned on state and the printer is in the camera function (see section 2.5.1).

38

Page 41

FlashCloud

Home

My Printer

My Model

My Job

Model Library

My Printer

Flashforge

Add printer

+

The current printer is empty. Please add a printer.

Register Code Type

4. Add succeed.

5. Click the camera icon pointed by the arrow.

中

State

XXXXXX Adventorer 3 offline

6. Camera begins to work.

39

Page 42

2.5.3. PolarCloud camera use

1. Register Polar cloud account

Enter www.polar3D.com website to register account.

2. Find Polar cloud pin code

(1). After registering polar cloud and log in polar cloud webiste, click the upper

right arrow, click [Settings]

Location

Biography

Website URL

http://www.example.com/profile

Email

+ADD Email

PIN Code

XXXX

(2). Find PIN Code on the bottom of the page, the display numbers is PIN code.

40

Page 43

3. Connect Adventurer 3 to the internet. Choose the proper connecting way in the Network

interface (the connecting way consults pagexx ).

4. Connect Adventurer 3 to the Polar cloud.

PolarCloud

Account:

PIN:

Save

PolarCloud Switch

Enter the cloud connection interface (click Tools-NetworkCloud), turn on the Polar cloud switch (After the Polar cloud

is turned on, the switch will change in to green).

Fill in the bottom account and pin code column Polar account

and Pin code showed before respectively, click Save.

After the connection is completed, you can see the camera image in Polar cloud website.

Notices

1. Make sure the printer is connected to the internet.

2. When using the camera please make sure the camera

is in the camera status instead of USB status.

(there should be a camera icon in the status bar).

41

Page 44

2.5.4. The switching can be controlled through the Cloud

1. Connect to Polar Cloud

The user can turn on or turn off the camera through Polar Cloud. Click Tools->

Communication -> Cloud Connect -> Polar Cloud, enter the settings page of Polar Cloud,

click the input boxes of account number and PIN, enter the account number and PIN, click

the “Start” button to connect to Polar Cloud. The account number is the mailbox used for

sign-up with Polar Cloud; for the acquisition of PIN.

PolarCloud

Account:

PIN:

Save

The guide of getting a Polar could account.

The Polar cloud account is the register email account.

Polar cloud website: www.polar3D.com

The way of getting PIN code

(1). After registering polar cloud and log in polar cloud webiste, click the upper

right arrow, click [Settings]

42

Page 45

Location

Biography

Website URL

http://www.example.com/profile

Email

+ADD Email

PIN Code

XXXX

(2). Find PIN Code on the bottom of the page, the display numbers is PIN code.

2.

Open or close the camera through the Cloud.

(1). After switching on the camera funcition, click camera image on the front page to enter

the interface like this, click the COMMANDS button pointed by the arrow.

CUSTOM COMMANDS

open camera

close camera

CANCEL SEND

(2). You can use check mark to open or close the camera in the pop-up window.

43

Page 46

Notices

a. If PolarCloud is in an intranet (that is, the printer and PC connect to the same router), the video

is shown, and the state of printing can be displayed in real time. If PolarCloud is in an extranet,

the pictures are shown (in case of printing, a picture is sent per 20s; in case of not working,

a picture is sent per 60s).

b. When the camera is turned on or off, the lower computer will turn off and reconnect PolarCloud,

so PolarCloud will not respond for a while. The recovery time depends on the state of network.

c. After the camera is operated through the Cloud, the lower computer will set the camera to be in

the manual mode; if the automatic mode is to be recovered, please set manually (Tools->

Settings (on the second page) -> Camera).

2.5.5. Error Handling

Auto Mode

Manual

Camera has not be found

Confirm

PolarCloud

Account:

error

PIN:

Confirm

Save

1. When the camera is damaged or not inserted, the error

is reported in case of turning on the camera. At this point,

the lower computer will automatically set the camera to

be in manual mode and the camera is turned off.

2. If the lower computer does not connect to PolarCloud and

the printer is deleted from the Cloud, the error is reported;

at this point, the factory settings can be restored in order to

solve the problem. After the lower computer connects to the

printer and the printer is deleted from the Cloud, the sign-up

needs to be done again according to the foresaid steps.

44

Page 47

Chapter 3: Q&A

Q1. How to solve if the nozzle is clogged?

Method 1: Tap [Preheat], heat up the extruder to 240℃, after heating completed, press the air

tube joint and pull out the filament guide tube. Check to see whether the filament is

bended or filament tip is not smooth, cut filament tip smooth and flat, install the

guide tube and filament back, Tap [Load] .

Method 2: If method 1 not improving, use an unclogging pin tool to unclog filament.

Method 3: If method 1 and method 2 not improving, please replace the nozzle.

Q2. How to replace the nozzle ?

Notice

Power off before replacing nozzle! Make sure power off operation!

Please make filament tip smooth and flat when cutting off the filament.

1. Press the left and right clips and pull out the nozzle.

2. Push in a length of filament through the filament intake manually, making it long enough to

be cut off.

3. Rotate the filament spool anti-clockwise manually, making filament retreat back a little.

4. Press the left and right clips, install the new nozzle back into the extruder, making the nozzle

slot and bottom of extruder are on the same level.

5. Tap[Filament] -- Tap[Load], nozzle replace completed when you see filament come out of

new nozzle.

Clips

The buckle is not installed in place The buckle is installed in place

Whether the assembly of the sprinkler is in place is judged as follows:

1. When installing, must press the sprinkler hard to the end.

2. Check whether the installation is in place:

( 1 ) Touch the black buckle and white sprinkler's lower shell, make sure

no sunken.

( 2 ) Look at the black buckle and white sprinkler's lower shell, make sure

there is not a large gap in the contact.

45

Page 48

Q3. Do we need to do extruder calibration again after replacing nozzle?

Yes, do extruder calibration again to ensure high print quality as minimal error may be

caused by extruder installation.

Q4. How to solve if displayed temperature is abnormal after replacing nozzle?

Abnormal temperature indicates extruder sensor can not be read, please check the nozzle

whether it is well installed.

Q5. How to solve if no filament come out of extruder after tap [Build] model file and

extruder begins moving normally?

1. Check the filament guide tube, make sure filament has been pushed into the extruder, if not,

please tap [Load]. Restart building model file after you see filament come out of extruder.

2. Check the nozzle whether it is clogged or not, if so, please refer to Q1 for resolution.

Q6: How to replace the filament ?

1. Tap[Filament]--Tap[Replace], after extruder heating up completed, filament will be unloaded,

pull out the filament according to the instruction.

2. Insert new filament into the filament intake and feeding wheel, tap [OK]; New filament will be

pushed into the extruder.

3. Replace will complete when you see new filament come out of extruder.

Q7: How to take down the model ?

1. Take out the removable build plate.

2. Bend the build plate, the plate will produce certain deformation, seperating the plate away

from the bottom of model. (Please use a scraper to assist removing when model is too small

or too big).

3.Take down the model.

Q8: How to solve if the distance between nozzle and platform is too large(far away) or

too small(hit) during printing?

1. Tap[Setting]--Calibration.

2. The extruder homing automatically, moves down some height.

3. Tap up and down arrow to adjust the distance between extruder and platform until extruder

is just about to touch platform.

4. Tap[OK], printer will memorize current calibration position and start homing automatically.

Q9: Can we use other brand filament which is not produced by Flashforge ?

Adventurer 3 support normal ABS and PLA filament but different brand filament has different

ingredients. Adventurer 3 tests out default settings according to the properties of Flashforge

ABS and PLA filament.

Other brand filament is ok but not recommended for using, if that causes extruder clogging

or bad printing quality or other failure, FlashForge will take no responsibility. These problems

are not in the warranty of FlashForge .

Q10. Is Adventurer 3 compatible with all kinds of AC power input ?

Adventurer 3 is equipped with a built-in 24V/6.5A power supplier, suitable for 110V-240V

input voltage.

Q11. Is Adventurer 3 capable to be turned off automatically after printing job is finished ?

No.

46

Page 49

Q12. What kinds of file formats does Adventurer 3 support?

Input: 3mf / stl / obj / fpp / bmp / png / jpg / jpeg files.

Output: gx/g files.

Q13. Does Adventurer 3 support other cloud platform besides the FlashCloud?

Yes, Adventurer 3 interface is open up to all other cloud platforms.

Q14. Is the ABS printing safe?

ABS filament will give off certain poisonous gas when heated up, please put the printer in

well ventilated condition when printing ABS. We suggest printing non-toxic PLA filament

when printer is used in children activity places.

Q15. How to solve if printing result has edge warp?

Method1: Heating up the platform can solve or minimize the problem by increasing

adhesion between platform and model.

Method2: Adding raft to model when slicing in FlashPrint.

Method3: Apply the solid glue to platform before printing.

Q16. Is it a must to add a raft before printing the model?

Not necessarily, much more filament will come out of extruder when printing the raft,

increasing printing success. Heating up the platform also increases printing success by

increasing adhesion between platform and model.

Q17. After replacing nozzle completed, printer status displays extruder temperature

is 300℃, extruder fan is also working, what is the problem and how to slove?

The new nozzle is not properly installed, extruder temperature can not be read and the

displayed extruder temperature is abnormal. Please plug out and install the nozzle again,

push nozzle to the end, make sure the nozzle slot and bottom of extruder are on the same level.

Q18.The extruder makes out chug noise and no filament come out of extruder, what is

the problem and how to slove ?

Filament has not loaded into extruder, making out chug noise,more likely the nozzle is clogged

or filament guide tube is not properly installed. Check the guide tube joint first, if the guide tube

is normal, refer to Q1 for resolution.

Q19.What is the difference between filament load and filament replace ?

Load: Only include loading filament into extruder;

Replace: Include loading and unloading two functions, first unloading and then loading filament.

Q20.Adventurer3 starts printing when the distance between extruder and build plate is

still large,causing filament can not stick to build plate and print fails.

Do the printer Calibration again or do the Homing again, then print again to check result.

Q21. You cannot find printing files when you use USB driver.

USB driver file is not corrected. Adventurer3 only supports FAT32 file system, please format USB

driver into FAT32 file system.

47

Page 50

Daily Maintenance Instruction:

Please apply lubricate grease to printer guide rods if you do not use it for long,or do the same

maintenance once a month.

Chapter 4: Supports and Service

FlashForge team is on standby and ready to help you with any challenges you may have with

your Adventurer 3. If the issues or questions are not covered in this User Guide, you can seek

for solutions on our official website or contact us via telephone.

There are solutions and instructions to common issues that can be found in our knowledge

base. Have a look first as most basic questions are answered there.

www.FlashForge.com

The FlashForge support team can be reached by e-mail or phone between the working hours

of 8:00 a.m. to 5:00 p.m. PST Monday through Saturday. In case you contact us during off-duty

time, your inquiry will be answered the following business day.

Note: Because of changing different filament the extruder maybe blockaded. It’s not owing to

quality issue, and outside the scope of 400 hours life. If users encounter this problem, please

contact our after-sale department and finish clean work according to their instruction.

QQ: 2850862986 2850863000 2853382161

Email: support@ff3dp.com

aftersales@flashforge.com

ADD: No. 518, Xianyuan Road, Jinhua, Zhejiang, China.

When contacting support, please have your serial number ready. The serial number is a bar

code on the back of your Adventurer 3.

S/N: FFAD******

48

Page 51

FCC Statement

Any Changes or modifications not expressly approved by the party responsible for compliance

could void the user’s authority to operate the equipment.

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received,

including interference that may cause undesired operation.

FCC Radiation Exposure Statement:

This equipment complies with FCC radiation exposure limits set forth for an uncontrolled

environment .This equipment should be installed and operated with minimum distance 20cm

between the radiator& your body.

Note: This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference ina residential installation. This equipment generates,

uses and can radiateradio frequency energy and, if not installed and used in accordance with

the instructions, may cause harmful interference to radio communications. However, there is

no guarantee that interference will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the interference by

one or more of the following measures:

—Reorient or relocate the receiving antenna.

—Increase the separation between the equipment and receiver.

—Consult the dealer or an experienced radio/TV technician for help.

—Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

Page 52

Scan QR to Get More After-Sales Support

Twitter

Facebook

Official Website

Loading...

Loading...