Flame Gard 750606 Installation Manual

®

Flat Access Door

Ultimate Protection Against Grease

®

Installation Instructions

Installation is simplified through step-by-step instructions.

The estimated time required for installation is 15 minutes per door.

The only tools required for installation are:

1) Drill

2) 5/8” or 3/4” hole saw (or drill bit)

3) 5/16” drill bit for drill (Cobalt bits recommended)

4) Metal cutting saw and blades (or power shears)

5a) (2)-1/2” or 3/4” long self-drilling, self tapping screws (#10 recommended)

5b) (1)-power driver bit for self-drilling screws (This allows front panel to

act as a template and a guide. Keeps bit from wandering.)

The contents of this package are:

1) Access door cover (Front Panel)

2) Access door frame (Back Frame)

3) 1/4” Wing nuts for each stud

4) “E”-Clips for each stud

HOOD AND DUCT

ACCESSORY

65X3

NFPA #96

FILE No. MH16475

1. Select best location on the exhaust duct or the blower housing you need to access.

2. For grease ducts or blower housings with reduced clearance wraps, the outer insulation must be trimmed back to expose a

seamless wall of the duct or housing slightly larger than the access door itself.

3. Remove the cover plate from the grease duct access door frame and affix it to the location you selected in step one by using

two 5/16” self-drilling, self-tapping screws (not included) at two of the four corner holes on the panel cover.

4. Using the cover plate as a template, drill out the mounting holes for the panel studs using a 5/16” drill bit. Remove the two self tapping screws when complete and, where those screws were, drill two holes with your 5/16” drill bit.

5. From the outside of the duct, take the back frame of the access door and place the bolts inside the holes.

6. With a marker, trace the inside of the frame onto the duct, then remove back frame from duct. Using a hole saw, make two 5/8”

pilot holes at opposite corners of the lines you just traced on the duct for easier saw access.

7. Using a reciprocating saw make two straight cuts from each of the hole saw holes. Cut just outside of the trace marks, to other

traced corner. Extract the plate from the interior of the duct or blower housing. (Cutting to the outside allows the cut edge to be

behind the finished back frame and prevents cuts when using panel.)

8. Place the back frame diagonally INTO the duct, align the studs with the bolt holes and pull the frame outward towards you so

the frame is flush against the inside of the duct and the mounting studs protrude through the pre-drilled holes in the side of the

duct. Be sure to have a good grip on the frame so it doesn’t fall into the duct.

9. Take the ”E”-clips and slide onto the base of all studs to hold the back frame in place. Be sure to use an “E”-clip on all of

the studs.

10. Put the front panel on, gasket side toward the duct, and tighten with the supplied wing nuts in a criss-cross pattern.

11. If prior to installation, you removed reduced clearance wrap from the surface, you’ll need to cover the access panel. To do

this, employ two layers of the same material used for the reduced clearance insulation and follow the directions provided for

insulating access cover plate. You will need additional hardware to attach the insulation blankets during this step. (not provided)

750001 9/2011

1890 Swarthmore Avenue, PO Box 2020, Lakewood, NJ 08701 • Tel. 800-526-3694 • 732-363-4700 • Fax 732-364-8110

Component Hardware Group, Inc.

www.flamegardusa.com

Installation Instructions

HOOD AND DUCT

ACCESSORY

65X3

NFPA #96

FILE No. MH16475

Flat Access Door

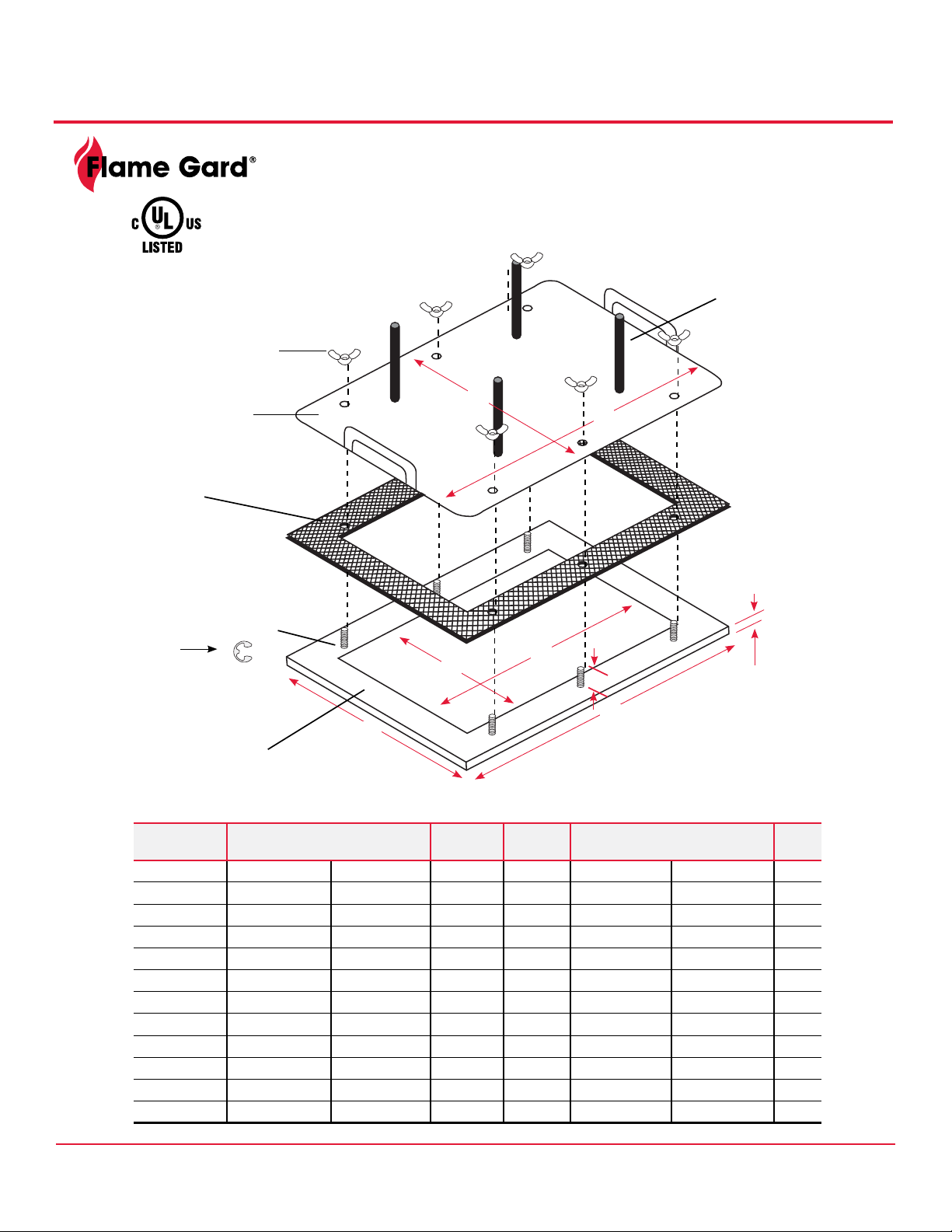

Optional 4”(102 mm) studs

for zero clearance duct

wrap-order with sufx (-4)

Wing Nuts

Door

Gasket

NOTE: Gasket is

High Temp bonded

to front panel

E-Clip holds back frame

to duct for each stud

E-Clip

F

E

A

Back

Frame

MODEL NO. PANEL OUTSIDE DIMENSION

A B C D E F

750710 7” (178mm) 10” (254mm) FLAT 1” (25mm) 5.5” (140mm) 8.5” (216mm) 6

750715 7” (178mm) 15” (381mm) FLAT 1” (25mm) 5.5” (140mm) 13.5” (343mm) 6

750723 7” (178mm) 23” (584mm) FLAT 1” (25mm) 5.5” (140mm) 21.5” (546mm) 10

750606 8” (203mm) 8” (203mm) FLAT 1” (25mm) 6” (152mm) 6” (152mm) 4

750707 10” (254mm) 10” (254mm) .5” (13mm) 1” (25mm) 7” (178mm) 7” (178mm) 4

750712 10” (254mm) 15” (381mm) .5” (13mm) 1” (25mm) 7” (178mm) 12” (305mm) 6

750720 10” (254mm) 23” (584mm) .5” (13mm) 1” (25mm) 7” (178mm) 20” (508mm) 10

751212 15” (381mm) 15” (381mm) .5” (13mm) 1” (25mm) 12” (305mm) 12” (305mm) 8

751220 15” (381mm) 23” (584mm) .5” (13mm) 1” (25mm) 12” (305mm) 20” (508mm) 14

751620 19” (483mm) 23” (584mm) .5” (13mm) 1” (25mm) 16” (406mm) 20” (508mm) 16

752020 23” (584mm) 23” (584mm) .5” (13mm) 1” (25mm) 20” (508mm) 20” (508mm) 16

PANEL

HEIGHT

STUD

HEIGHT

B

D

B

HOLE SIZE

Inches (mm)

**Access Panels over

7” x 7” (178mm x 178mm)

have a 1/2” 13mm) turndown to

add rigidity to the panel. Smaller

sizes do not have a turndown.

A

C

MTG

STUDS

1890 Swarthmore Avenue, PO Box 2020, Lakewood, NJ 08701 • Tel. 800-334-3072 • 732-363-4700 • Fax 732-364-8110

Component Hardware Group, Inc.

www.amegardusa.com

Loading...

Loading...