Page 1

PREFIX PRO SERIES PREAMP

INSTALLATION GUIDE

www.fishman.com

Read Me First!

Installation of this product is a simple procedure,

but we recommend this job only if you are an

experienced repair technician.

Requirements

Saddle slot

Minimum saddle slot length: 2.775” (70.4mm)

Maximum E to E spacing at saddle: 2.5” (63.5mm)

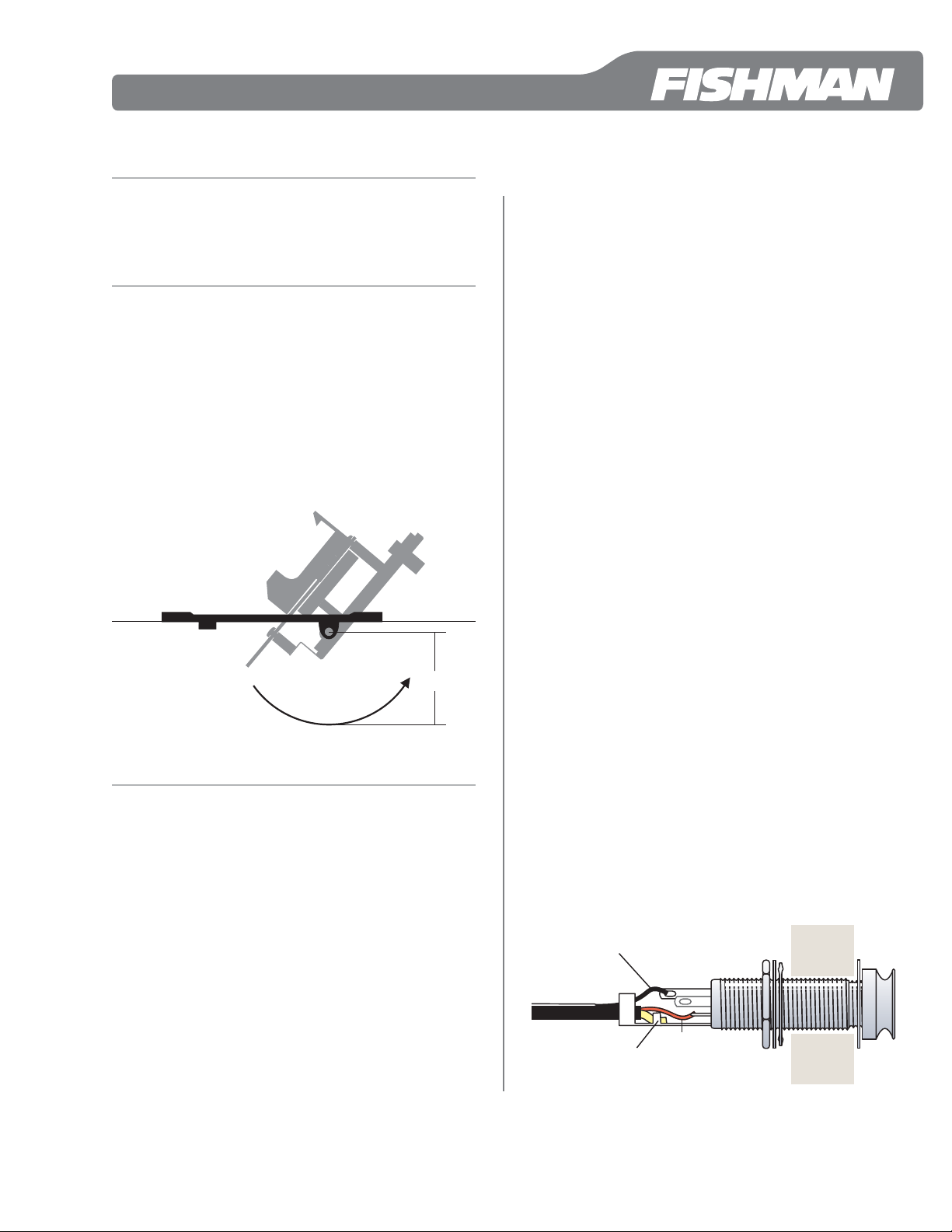

The Prefi x Pro Series preamp will only fi t in guitars

with a clearance of at least 1 11⁄16” (42.86mm) between the top and back braces, at the point where

the preamp chassis swings inside the instrument.

This path is defi ned as a 1 5⁄8“ radius, with the hinge

point on the bezel being the center of the circle.

PREAMP

GUITAR BODY

15/8”

Installation

Preliminary

1. Widen the endpin hole to 15⁄32” (11.9mm) to

accommodate the endpin jack.

2. Drill a 3⁄32” hole (2.4mm) in the saddle slot for the

pickup wire, no less than .100” (2.5mm) from the

nearest string. Install the pickup per Acoustic Matrix

installation instructions.

Cut out the preamp cavity

Please note: For instruments with solid wood sides

(especially maple), we strongly recommend that you

glue 2.5” (63.5mm) x .5” (12.7mm) plywood patches

in the areas inside the guitar where the screw holes

will be drilled. Doing so will prevent the area around

the mounting holes from cracking or splintering

and will strengthen the side of the instrument at

the cutout.

1. Choose the fl attest possible location for the preamp on the side of the instrument. The fl attest and

most comfortable location for the player is often at

the upper bout, just above the instrument’s waist

and well below the shoulder. Note that the bezel has

a limited ability to bend just enough to conform to

the curved sides of most standard sized instruments.

Caution! When mounting the Prefi x Pro Series

preamp on solid wood instruments with highly

curved sides (such as small bodied acousticelectrics), exercise extreme caution when choosing

the preamp location.

A highly curved mounting surface may cause the

preamp to bind against the mounting bezel or in

worst cases may cause the wood to crack around the

preamp mounting holes.

2. Attach the enclosed cutout template at the desired location and cut out the cavity for the preamp.

3. Drill the preamp mounting holes with a #45 drill

(.082” / 2.08mm).

Output cable / endpin jack wiring

Important note: To ensure full pivot action for the

preamp, remember to leave an extra 3” (76.2mm)

of slack when you decide the output cable’s

fi nal length.

Solder the wire connections

1. Determine the proper length for the cable, then, if

necessary, strip and tin the output wires.

2. To gain better access to the terminals on the

endpin jack, gently bend back the Strain Relief/

Sleeve tab before you begin to solder.

Jack connections

• Red wire to Tip (short terminal)

• Black wire to Switch (longest terminal)

• Shield wire to Sleeve (strain relief)

• Ring is not connected (middle terminal)

Black Wire

to Switch

Shield to

Sleeve

Red Wire

to Tip

1

Page 2

Endpin jack

Y

Install the endpin jack per Switchjack Installation

Guide.

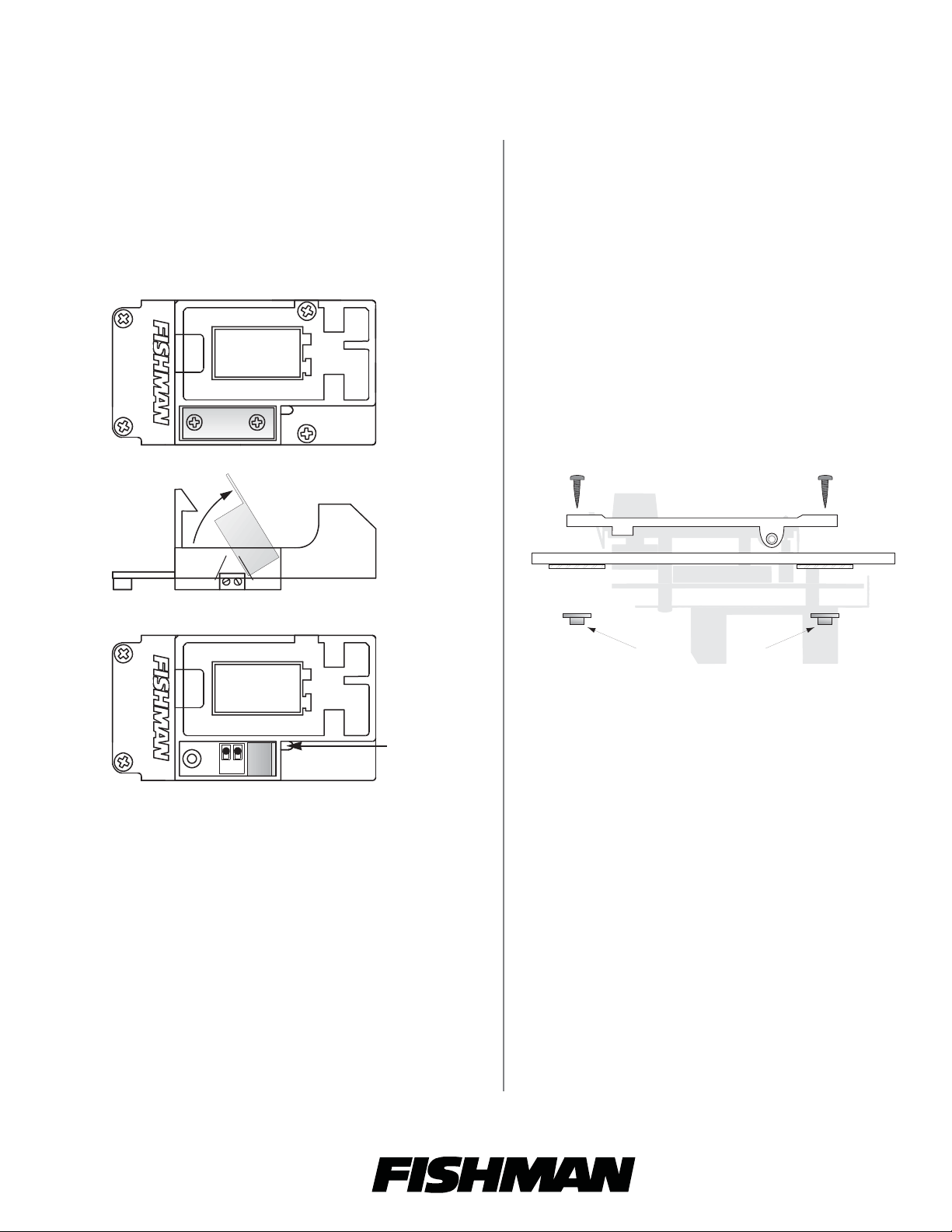

Mount the preamp

1. Insert the pickup in the saddle slot.

2. Carefully pull back the foil shield on the preamp

(located next to the output cable) to expose the

terminal block.

3. Tighten the terminal block screws with a small

slotted screwdriver.

4. Pull the slack on the pickup wire until it lies within

the terminal block compartment, tucked in behind

the screw boss where the wire exits.

5. Check the foil shield sides to make sure that the

shape is intact and the corners are square.

6. Carefully replace the foil enclosure. Note that

when properly installed, the foil enclosure will

cleanly surround both the terminal block and one of

the screw bosses. If the sides of the foil jam up on

the terminal block or screw boss, adjust the fi t so

that the enclosure closes easily.

7. Replace the two screws that hold the foil in place.

Be careful not to cross thread the holes.

8. Angle the preamp 90° from the bezel and

insert it in the cut-out, then fasten the preamp

bezel using the four self-tapping screws and the

two plastic backing plates.

FOIL SHIELD

TERMINAL BLOCK SCREWS

GROUND WIRE SIGNAL WIRE

PICKUP WIRE ENTR

Self-Tapping Screws

Soundboard

Plastic Backing Brackets

Complete the installation

Install a 9V alkaline battery.

To keep the wires inside the guitar from rattling,

secure them with the included adhesive backed

clips. Attach the wire guide clips to the side of the

instrument.

www.fi shman.com

514-300-115 Rev A 5-09

Loading...

Loading...