Fishman PREFIX INSTALLATION

WARNING

INSTALLATION BY A QUALIFIED PROFESSIONAL REPAIRMAN IS STRONGLY RECOMMENDED.

FISHMAN TRANSDUCERS WILL NOT BE RESPONSIBLE FOR INSTRUMENTS DAMAGED DUE TO

IMPROPER INSTALLATION.

PARTS

•

(4) 7/16" self-tapping screws

•

Two (2) plastic backing plates

•

Endpin jack with hardware (may be pre-soldered) • Preamp cutout template

•

Prefix preamp

•

Acoustic Matrix Pickup (may be pre-tinned)

•

Adhesive-backed wire guide clips

TOOLS

•

Detail sander with attached 2.5" (63.mm) diameter saw blade, or flex shaft tool with 1" (25.4 mm) diam-

eter cutting wheel, or router with 3/16" (4.76 mm) cutter

•

#45 (.082", 2.08mm) drill

•

Soldering iron (30 watt max)

•

Rosin core solder

•

Wire strippers

•

#1 Phillips screwdriver

•

1/2" open end wrench

•

3/32" or 2 mm Allen wrench

•

2.4mm (3/32") slot head screwdriver

•

15/32" (11.9 mm) reamer or:

Variable speed drill Center punch 1/8" (3.2 mm) twist drill

15/32" (11.9 mm) spade bit drill X-Acto miniature saw

PREPARE THE INSTRUMENT

I - Widen The Endpin Hole to Accept The Endpin Jack

There are two methods to widen the endpin hole:

A) Slow and Safe

If you have the time, this is the preferred method.

Remove the endpin and widen the hole to size with a 15/32" (11.9mm) reamer (available in

the US & Canada through Stewart Macdonald, 800-848-2273 part #4323).

OR

B) Quick and Clean

The objective of this method is to quickly drill out the endpin jack hole, with the endpin or

other suitable plug in place. If the endpin is loose, remove and refasten it in the endblock

with cyanoacrylate glue before starting the procedure.

NOTE: We do not recommend this method for instruments with brittle ornamental veneers (for

example: Abalone) around the endpin hole.

1. Apply masking tape around the endblock area to protect the instrument.

2. Locate an X-Acto saw 1/16" (1.6 mm) away from the body and saw off the endpin,

nearly flush to the instrument.

3. Centerpunch a guide hole in the trimmed endpin.

4. Drill a 1/8" (3.2 mm) pilot hole through the endpin and endblock.

5. Line up 15/32" (11.9 mm) Spade bit in the pilot hole and begin drilling. Maintain a perpen-

dicular plunge in relation to the instrument. Use steady (but not heavy) pressure, especially as the drill exits inside the guitar.

6. To avoid damage to the instrument, let the drill come to a complete stop before removing

it from the hole.

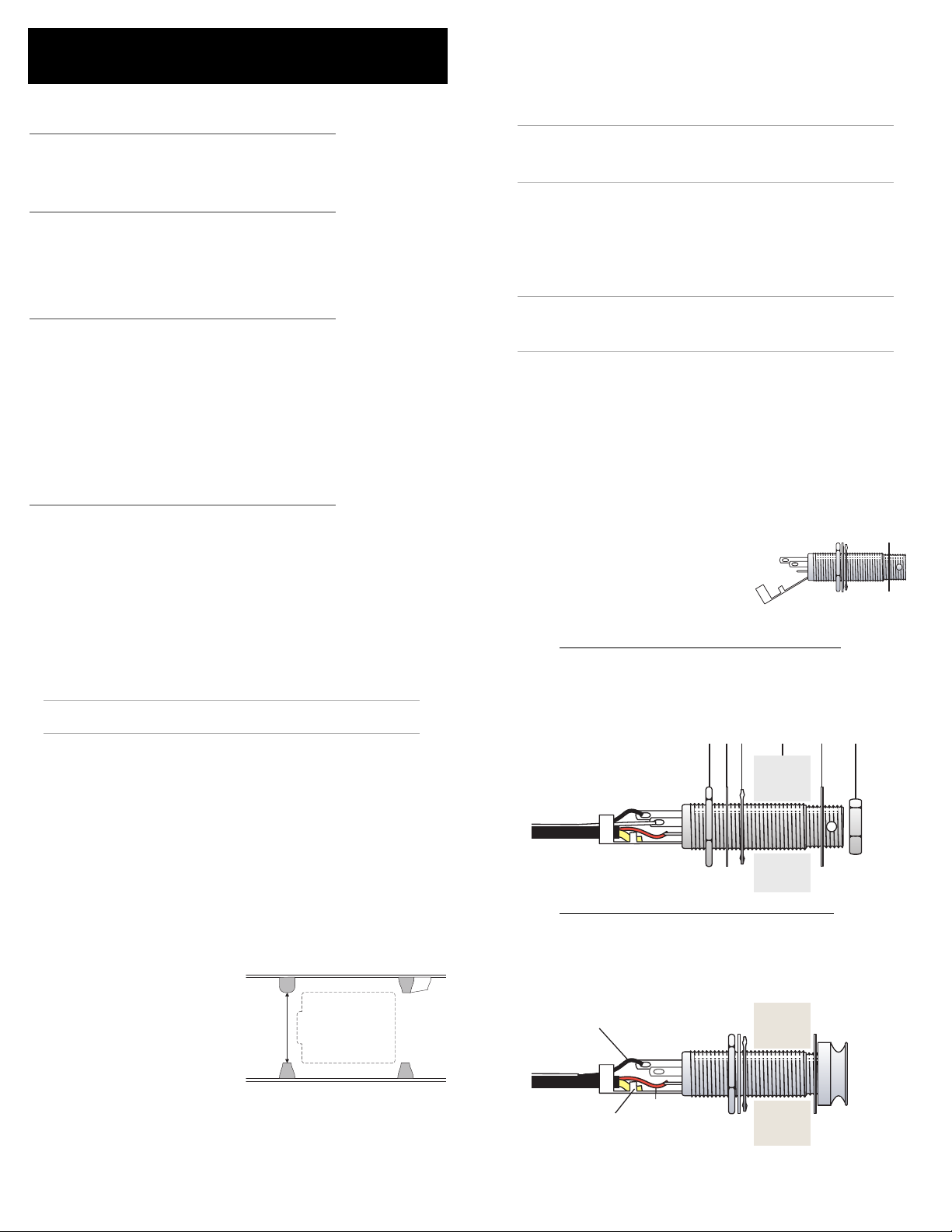

II - Cut Out the Preamp Cavity

Preliminary Warning:

The Prefix preamp will only

fit in guitars with a clearance of at least 2 1/4"

(57.15 mm) between the

top and back braces, at

the point where the preamp chassis swings inside

the instrument.

PLEASE NOTE: For instruments with solid wood sides (especially maple), we strongly recommend that you glue 2.5"(63.5mm) x .5"(12.7mm) plywood patches in the areas inside the guitar

where the screw holes will be drilled. Doing so will prevent the area around the mounting holes

from cracking or splintering and will strengthen the side of the instrument at the cutout.

1. Choose the flattest possible location for the preamp on the side of the instrument. The

flattest and most comfortable location for the player is often at the upper bout, just above

the instrument's waist and well below the shoulder. Note that the bezel has a limited ability to bend just enough to conform to the curved sides of most standard sized instruments.

CAUTION! When mounting the Prefix on solid wood instruments with highly curved sides (such

as small bodied acoustic-electrics), exercise extreme caution when choosing the preamp location. A highly curved mounting surface may cause the preamp to bind against the mounting

bezel or in worst cases, may cause the wood to crack around the preamp mounting holes.

2. Attach the enclosed cutout template at the desired location. and cut out the cavity for the

preamp. We have found that a Fein Pneumatic Detailing Sander (part# MOx6-25), with a

2 ½" diameter saw blade (part# 6-35-02-096-02-3) to be an excellent choice for cutting

out the preamp cavity.

3. Drill the preamp mounting holes with a #45 drill (.082"/2.08mm)

III - Output Cable/Endpin Jack Wiring

IMPORTANT NOTE: To ensure full pivot action for the preamp, remember to leave an extra 3"

(76.2mm) of slack when you decide the output cable's final length.

Solder the Wire Connections

1. Determine the proper length for the cable, then if

necessary, strip and tin the output wires.

2. To gain better access to the terminals on the

endpin jack, gently bend back the Strain

Relief/Sleeve tab, before you begin to solder.

Jack connections for the Prefix Stereo Blender model

•

Red wire to Tip (short terminal)

•

White wire to Ring (middle terminal)

•

Black wire to Switch (longest terminal)

•

Shield wire to Sleeve (strain relief)

Jack Connections for Prefix and Prefix Plus models:

•

Red wire to Tip (short terminal)

•

Black wire to Switch (longest terminal)

•

Shield wire to Sleeve (strain relief)

•

Ring is not connected (middle terminal)

FISHMAN PREFIX™ SERIES

PREAMP INSTALLATION

Shield to

Sleeve

Red Wire

to Tip

Black Wire

to Switch

Soundboard

Minimum 2.250"

(57.15 mm)

Clearance between

Top and

Back Braces

Back

23 4 5 61

IV - Install the Endpin Jack

Follow this sequence when installing the endpin jack:

1. Large hex nut

2. Large dress washer

3. Star washer

4. Guitar end block

5. Small dress washer

6. Small dress nut

7. Strap button

Fit the jack so that the larger diameter threads will sit slightly below the surface, on the outside of the endblock. After fitting the small dress washer and the dress nut over the end of

the jack, insert a 3/32" (or 2 mm) Allen wrench (or suitably sized screwdriver or rod) through

the cross drilled hole on the end of the jack. Tighten the dress nut with a 1/2" open end

wrench while holding the jack in place with the allen wrench. Thread and hand tighten the

strap button.

NOTE: With the strap button in place, the end of the jack should protrude

slightly, so that when a plug is inserted, it can snap securely in place.

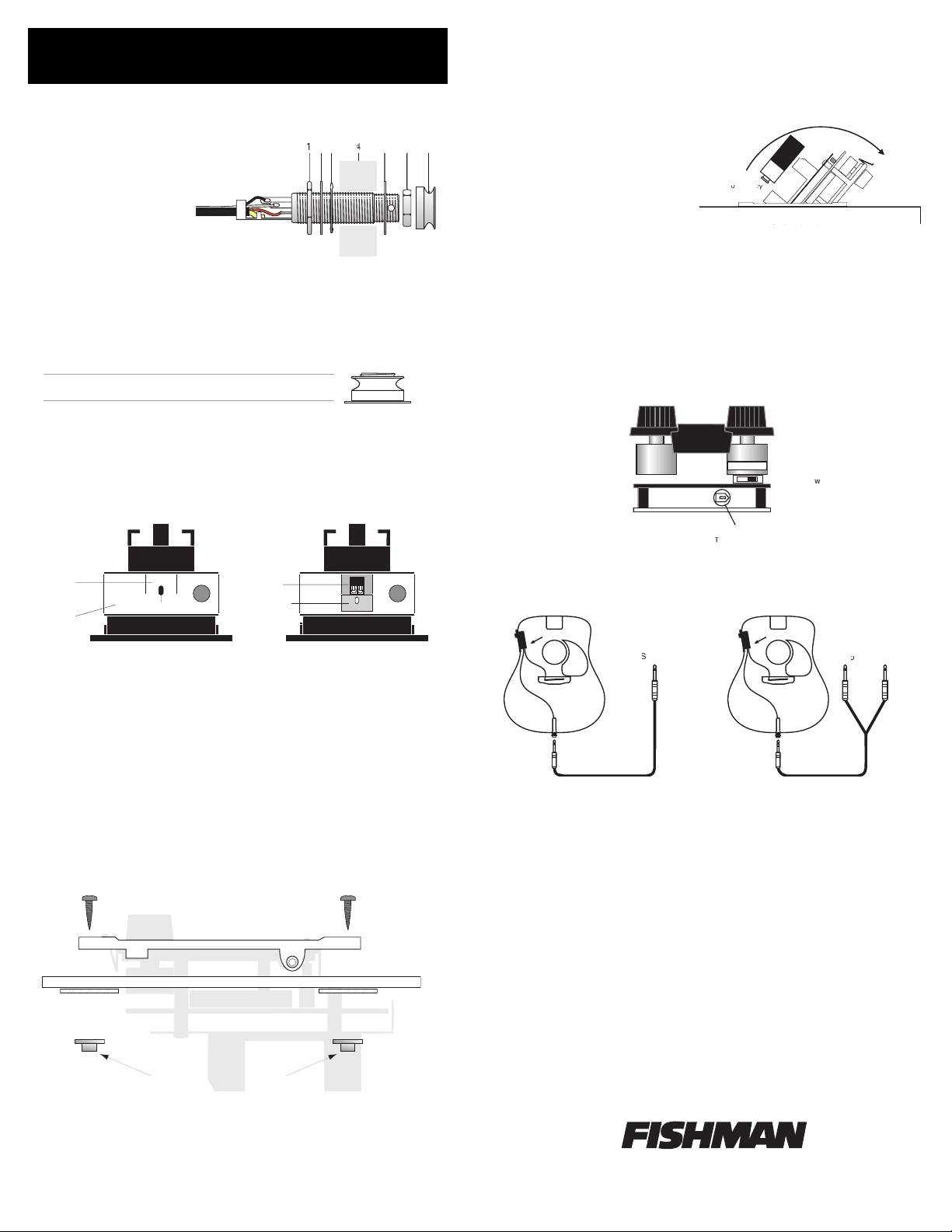

V - Mount the Preamp

1. Insert the pickup in the saddle slot (follow specific installation instructions as out-

lined for the Acoustic Matrix pickup).

2. Carefully pull back the foil "trap door" on the preamp (located next to the output

cable) to expose the terminal block.

3. Punch through the perforated slot in the trap door with the pickup wire and thread it

through the foil.

4. Insert the hot pickup wire (inner conductor) in the left side of the terminal block,

marked "IN".

5. Insert the pickup ground wire (shield) in the right side of the terminal block, marked

"GND".

6. Tighten down the screws on the top of the terminal block with a 2.4mm (3/32") slot

head screwdriver.

7. Replace the foil trap door by gently tucking it back into the preamp, just below the

battery clip.

8. Angle the preamp 90° from the bezel and insert it in the cut-out.

9. Fasten the preamp bezel using the four self-tapping screws and the two plastic

backing plates.

To keep the wires inside the guitar from rattling, secure them with the included adhesive

backed clips. Attach the wire guide clips to the sides or the kerfed lining of the instrument.

Battery Compartment

Pull the small tab at the top of the Prefix

toward you. The body of the preamp will

swing out, revealing the battery compartment. Observe the polarity marks on

the battery clip and install a fresh 9V

alkaline battery accordingly.

Microphone Trim Control

A small circular potentiometer is located on the underside of the preamp just below the battery compartment. This is a "set it and forget it" control. Use it to initially calibrate the microphone balance in relation to the pickup. Set the Blend slider to the center position and with a

small slotted screwdriver, adjust the Trim Control until both the microphone and pickup levels

are balanced to your taste.

Mono/Stereo Switch

A small slide switch, located on the underside of the preamp (across from the Notch control

pot), lets you choose between mono and stereo operation. Leave the switch in the Mono position when you use a standard instrument cable.

If you wish to split the pickup and microphone signals for separate external processing (such

as with a Fishman Blender ™ system), move the switch to the Stereo position and use a

stereo cable or a stereo "Y" cable to carry the two signals to separate destinations. In the

stereo mode, the pickup goes to the tip output and the microphone sits on the ring output.

FISHMAN PREFIX™ SERIES

PREAMP INSTALLATION - CONTINUED

23 4 5 6 71

Plastic Backing Brackets

Soundboard

Self-Tapping Screws

9 Volt Battery

STEREO / MONO

Stereo / Mono

Switch

Microphone

Trim Control

MONO CABLE

Microphone & Pickup

Signals

MIC

STEREO "Y" CABLE

Tip

Pickup

Ring

Microphone

MIC

MONO STEREO

FISHMAN TRANSDUCERS

340-D Fordham Road Wilmington MA 01887 USA

Phone 978-988-9199 • Fax 978-988-0770 www.fishman.com

009-087-007 • Rev 4 • 11-1 9-0 7

Preamp

Tr ap

Door

Foil Sheilding

Battery Case

Slot

Preamp

Control Panel

Terminal

Block

Trap Door

Pulled Back

Preamp

Control Panel

®

Loading...

Loading...