Page 1

Installation Guide

Installation Guide

AG-Series

Passive Acoustic Guitar Pickup

Includes Installation Instructions for Models

AG-125

.125” (3.2 mm) Width • 2.125” String Spacing

AGX-125

.125” (3.2 mm) Width • 2.3125” String Spacing

AG-094

.094” (2.3 mm) Width • 2.125” String Spacing

AGX-094

.094” (2.3 mm) Width • 2.3125” String Spacing

Page 2

AG Series -

AG Series -

Passive Guitar Pickup

Passive Guitar Pickup

Thank you for choosing the classic AG Series undersaddle pickup. Please read these instructions carefully. For technical assistance, contact Fishman Customer Support at

oorr tteecchh@@ffiisshh mmaann..ccoomm

The AG-Series is our original string-sensitive, piezo-ceramic undersaddle pickup. It provides

natural acoustic reproduction of your guitar with an explosive attack well-suited for percussive

playing styles. The pickup senses individual string vibrations with six fully shielded piezo elements. Installation is straight forward and you can plug the AG-Series pickup directly into an

instrument amplifier with great results. For improved performance we recommend one of our

dedicated outboard preamps.

Included with each AG pickup is our versatile Switchjack stereo endpin jack, which enables you

to wire up the AG pickup with another pickup or a microphone for outboard stereo blending

applications.

997788--998888--99666655

CHOOSING THE RIGHT MODEL TRANSDUCER

Before installation, be sure to select the right pickup for your instrument.

AG-125

E to E string spacing = 2.125" (54.0 mm)

Wire hole location = .234" (5.9mm) from closest outside string

The AG-125 is suitable for most instruments

with string spacings from 2.075" (52.7 mm) to

2.175" (55.3 mm)

AGX-125

E to E string spacing = 2.3125" (58.7 mm)

Wire hole location is .234" (5.9mm) from closest outside string

The AGX-125 is suitable for most 6 and 12string instruments with E to E string spacings

from 2.262" (57.4 mm) to 2.362" (59.9 mm)

NOTE: Custom string spacings are available

upon request.

WIDTH: .125" (3.2 mm)

HEIGHT: .048" (1.22 mm)

LENGTH: AG-125: 2.625" (66.67 mm)

AGX-125: 2.725" (69.22 mm)

AG-094

E to E string spacing = 2.125" (54.0 mm)

Wire hole location = .234" (5.9mm) from closest outside string

The AG-094 is suitable for most instruments

with string spacings from 2.075" (52.7 mm) to

2.175" (55.3 mm)

AGX-094

E to E string spacing = 2.3125" (58.7 mm)

Wire hole location is .234" (5.9mm) from closest outside string

The AGX-094 is suitable for most 6 and 12string instruments with E to E string spacings

from 2.262" (57.4 mm) to 2.362" (59.9 mm)

NOTE: Custom string spacings are available

upon request.

WIDTH: .094" (2.3 mm)

HEIGHT: .048" (1.22 mm)

LENGTH: AG-094: 2.625" (66.67 mm) /

2

2

AGX-094: 2.725" (69.22 mm)

Page 3

Installation Guide

Installation Guide

Installation of the AG Series Acoustic Guitar Pickup requires fine woodworking & soldering

skills and should be performed only by a qualified repairman. Fishman Transducers will not be

responsible for any damages that may result from improper installation.

Please read these instructions carefully. For technical assistance, contact Fishman

Customer Support at 978-988-9665 or tech@fishman.com.

If you are new to under saddle piezo installations, a comprehensive guide, The Finer Points of

Piezo Installation by Ken Parker, is available at www.fishman.com.

Handle the pickup carefully! Mishandling may result in ground hum or intermittent signal.

Fishman Transducers will not be responsible for any damages to the pickup that may occur

due to misuse or poor installation.

II MMPPOO RR TT AA NN TT

PREPARATION

Tools

• Caliper • Router with 1/8" (3mm) Straight Bit (single flute)

• 400 Grit Sandpaper or Scraper • Soldering Iron (30 watt max)

• Rosin Core Solder • Wire Strippers

• Masking Tape • X-Acto Saw

• Variable Speed Drill • Center Punch

• 1/8" Twist Drill • 15/32" Spade Bit Drill

• 1/2" Open End Wrench • 3/32" Allen Wrench

MECHANICAL FACTORS AFFECTING PICKUP PERFORMANCE

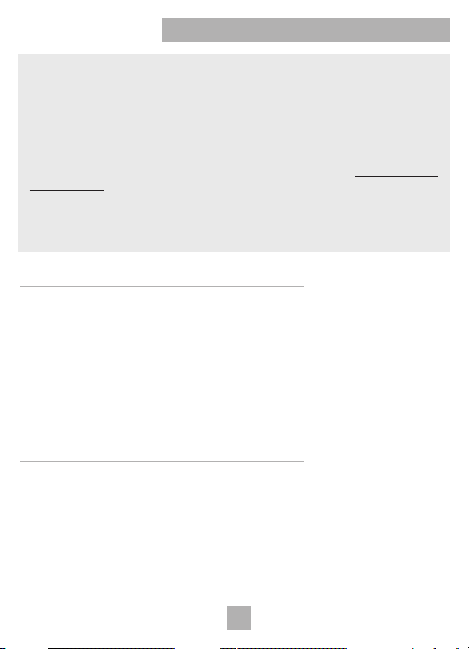

Break Angle

For the pickup to perform optimally, there should be a 20° (minimum) string break

angle across the back of the saddle. An adequate break angle can be realized by

"ramping" the string slots. In extreme cases, where the break angle is less than

20°and the saddle is so low that it is nearly flush with the top of the bridge, the

instrument probably requires a neck re-set. In these cases, re-setting the neck to a

higher angle will restore the saddle height and the string break angle required for

good pickup performance.

3

3

Page 4

AG Series -

NO MORE THAN 50%

R

AM

P

AG Series -

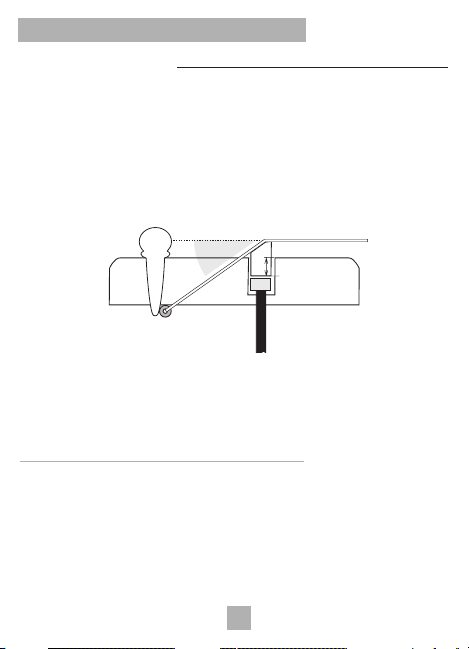

The 50/50 Rule

We have found that there is a critical relationship between the overall saddle height

and the bridge slot depth. For adequate mechanical coupling and pickup balance,

we recommend that the saddle slot depth (with pickup installed) measures no more

than 50% of the total height of the saddle. If the slot measures more than 50% of

the total height of the saddle, balance and/or output level may suffer. In these

cases, add a hardwood shim under the pickup. To determine the shim's thickness,

subtract ½ the total saddle height from the slot depth, then remove an equal amount

of material from the bottom of the saddle.

Exception to the 50/50 Rule: Pickups in bridges (especially Martin style 3/32" width) with

exceptionally steep string break angle will generally perform well, even if the saddle slot depth

measures more than 50% of the total saddle height.

Passive Guitar Pickup

Passive Guitar Pickup

Mechanical Factors Affecting Pickup Performance - Continued

PREPARATION

I • Prepare the Saddle Slot

A large percentage of string balance problems with undersaddle pickups can be

traced to an unevenly cut or warped saddle slot. Irregularities on the bottom or

sides of the slot can often prevent the saddle from uniformly pressurizing the pickup.

For this reason, we strongly recommend that before you install any undersaddle

pickup, re-mill an existing slot with a plunge router, jigged up in an appropriate slot

cutting fixture.

4

4

Page 5

Installation Guide

.234"

(5.9 mm)

.234"

(5.9 mm)

Installation Guide

1. Rout a .125" (3.2 mm) or .094 (2.3 mm)

wide saddle slot.

2. Be certain that the bottom of the slot is

FLAT. Deepen an existing slot just

enough to obtain a clean, flat surface.

II • Locate the Wire Hole

The location of the wire hole is critical to the performance to the AG-125 / AG-094

as it determines the correct position of the piezo elements relative the strings.

1. Locate the center of the wire hole .234" (5.9 mm) from the closest outside string.

(Or center of the closest pair of outside strings for 12-string models.)

2. Mark the location where the wire will enter the saddle slot. Center the mark

between the walls (width) of the slot. Drill a .09375"(2.4mm) hole.

3. Clear wood chips and foreign materials from the saddle slot

4. Carefully insert the pickup. The wire must slip easily into the wire hole. The pick-

up must fit into the slot without friction or binding.

5

5

Page 6

AG Series -

AG Series -

III • Prepare the Saddle

We highly recommend the Fishman Cleartone™ saddle for enhancing the performance of the AG-Series pickup. We also suggest synthetic materials such as

Micarta or Corian as adequate substitutes. Organic materials such as bone or ivory

can not be recommended since these are not structurally as consistent as synthetics and can produce poor string to string balance through the pickup.

1. Prepare a .125" or .094" wide saddle. Make sure the bottom of the saddle is

FLAT.

2. Remove only enough material from the width of the saddle to provide a sliding fit

in the slot. To test the fit, the saddle should slide easily in the slot, but should not

fall out when overturned. To maintain your current action, the new saddle must

be .048" shorter in height than your current saddle.

IV • Prepare the Endblock

There are two ways to widen the endpin hole to accept the endpin jack:

Slow and Safe

If you have the time, this is the preferred way to enlarge the endpin hole. Remove

the endpin and widen the hole to size with a 15/32'" (11.9mm) reamer, available in

the US & Canada through Stewart Macdonald, 800-848-2273, part #4323.

Quick & Clean

The objective here is to drill out the hole with the endpin or other suitable plug in

place. You may remove a loose endpin and refasten it in the endblock with cyanoacrylate glue before starting the procedure.

Note: We do not recommend this method for instruments with brittle ornamental veneers (ex: abalone) around the endblock.

Passive Guitar Pickup

Passive Guitar Pickup

OR

6

6

Page 7

Installation Guide

Installation Guide

1. Apply masking tape around the endblock area to protect the instrument.

2. Locate an X-Acto saw blade 1/16" (1.6mm) away from the body and saw off the

endpin.

3. Centerpunch a guide hole in the center of the trimmed endpin.

4. Drill a 1/8" (3.2mm) pilot hole through the endblock.

5. Line up a 15/32" (11.9mm) Spade bit in the pilot hole and begin drilling. Maintain

a perpendicular plunge in relation to the instrument. Use steady (but not heavy)

pressure, especially as the drill exits inside the guitar.

6. To avoid damage to the instrument, let the drill come to a complete stop before

removing it from the hole.

V - Install the Pickup

1. Insert the pickup in the slot and then strip and tin the wire ends.

2. Unscrew the shielding cap on the jack to expose the solder terminals. Thread

the pickup wire through the shielding cap.

Gently bend back the strain relief/sleeve tab to gain better access to the Tip ter-

minal.

3. Solder the pickup "hot" wire to the Tip terminal, which is the shortest of the three

tabs.

Solder the pickup shield to the ground tab on the jack. Gently tighten the strain

relief.

4. Refasten the shielding cap to the jack.

7

7

Page 8

AG Series -

Shield

Tip

(Short Terminal)

Ring

TipGuitar Sleeve

1/4" Stereo Plug

Switch

(Long Terminal)

Ring

(Medium Terminal)

AG Series -

Passive Guitar Pickup

Passive Guitar Pickup

Wiring Options with the Fishman Switchjack

The Switchjack T-R-S-S (Tip/Ring/Sleeve/Switch) stereo switching endpin jack

allows simultaneous stereo operation and battery switching for active pickups. This

new configuration simplifies stereo wiring with many pickup combinations that were

once incompatible.

To gain better access to the Tip, Ring and Switch terminals, gently bend back the

Strain Relief/Sleeve tab, before you begin to solder.

Pages 9 & 10 illustrate the various wiring options made possible by the Switchjack.

8

8

Page 9

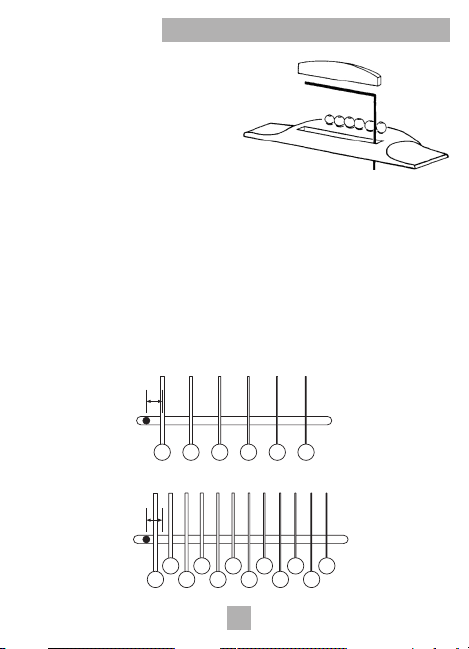

Pickup Signal

to Tip

Shield to

Sleeve

Installation Guide

Installation Guide

Mono Wiring an AG Series Pickup

Mono Wiring an AG Series Pickup

Stereo Wiring a Second Pickup to an AG Series Pickup

Stereo Wiring a Second Pickup to an AG Series Pickup

2nd Pickup

to Ring

Pickup Signal

Common

Ground

to Tip

9

9

Page 10

AG Series -

Negative Battery Wire

to Switch

Pickup Signal

to Tip

2nd Pickup

to Ring

Common

Ground

Common

Ground

Pickup Signal

to Tip

Microphone to Ring

Zener Diode

between Ring & Sleeve

AG Series -

Adding a Microphone to an AG Series Pickup

Adding a Microphone to an AG Series Pickup

Stereo Wiring with an Active Pickup

Stereo Wiring with an Active Pickup

Passive Guitar Pickup

Passive Guitar Pickup

10

10

Page 11

Installation Guide

34 5 6 7 82

1

Installation Guide

VI - Fasten the Jack in the Endpin Hole

Follow this sequence when installing the endpin jack:

1 - Shielding Cap

2 - First Large Hex Nut

3 - Large Dress Washer

4 - Star Washer

5 - Guitar Endblock

6 - Small Dress Washer

7 - Small Dress Nut

8 - Strap Button

The jack should protrude at least 5/16" and no more than 11/32" outside of the guitar body for proper fit.

After fitting the small dress washer and nut over the end of the jack, insert the 3/32"

allen wrench through the small hole on the end of the jack. Tighten the nut with the

1/2" open end wrench while holding the jack in place with the allen wrench. Thread

and hand tighten the the strap button.

Note: With the strap button in place, the end of the jack

should protrude slightly to allow proper plug fit.

PLUGGING IN

Due to the nature of passive pickups, the type of cable you use and the input you

plug into will affect the quality of your sound.

Instrument Cable

Cable lengths over 10 feet (before preamp) will cause audible high frequency loss.

Use a high quality, low capacitance shielded cable. This will ensure minimal tone

coloration and hum. Using fully shielded metal plugs will also help eliminate hum.

11

11

Page 12

AG Series -

AG Series -

Kinds of Audio Inputs

Because of the lack of standardization for high impedance audio inputs, special

attention should be paid to what you are plugging into:

The AG-125 / AG-094 will sound best when plugged directly into an input with a 10

MOhm impedance; the full frequency response of the instrument is reproduced.

The AG-125 / AG-094 can also be plugged into inputs as low as 1 MOhm with

adequate results; the bass frequencies will be slightly rolled off.

Preamps

We strongly recommend using a 10 MOhm, impedance matching, buffered preamp

in conjunction with the pickup.

A matching preamp will:

1. Realize the full frequency response potential of the pickup.

2. Permit long cable runs (after the preamp) without signal deterioration.

3. Allow precise volume and tone shaping with dedicated EQ.

4. Ensure compatibility with virtually any instrument level audio input available.

Fishman Transducers manufactures a complete line of compatible

preamps, all with 10 MOhm inputs:

POWERJACK - Miniature Endpin Preamp

MODEL GII & BII - Outboard Acoustic Instrument Preamp

AGP-2 - Onboard Instrument Preamp

PRO-EQ II - 4 Band Acoustic Instrument Preamp

PRO-EQ PLATINUM - Outboard Acoustic Instrument Preamp / EQ / D.I.

DUAL PARAMETRIC D.I. - Fully Parametric Two Band Preamp / D.I.

ACOUSTIC / BASS BLENDER - 2 Channel Pickup / Mic Preamp

POCKET BLENDER - 2 Channel Pickup/Mic Preamp

Passive Guitar Pickup

Passive Guitar Pickup

12

12

Page 13

Installation Guide

Installation Guide

Musical Instrument Amplifiers

Most musical instrument amplifiers (at least 1 M

useable results. Acoustic instrument amplifiers have a 10 M

matching the pickup.

Direct Boxes

You can plug the AG-125 / AG-094 into an "active" direct box (1 - 10 M

very good results. Using a passive direct box will sound weak and thin.

PA / Recording Consoles

Professional PA and recording consoles have a much lower input impedance than

what is acceptable for the AG-125 / AG-094 ; you will need an impedance matching

preamp. Plugging a passive piezo pickup into a mixer without an impedance

matching preamp will sound harsh and thin.

W

input impedance) will yield

W

Piezo input, ideally

W

input) with

13

13

Page 14

ROUBLESHOOTING

T

T

ROUBLESHOOTING

SYMPTOM CAUSE SOLUTION

WEAK

STRING OR

STRINGS

* See Ken Parker's The Finer Points of Piezo Installation.

Saddle is not

completely seated.

Bottom of saddle is uneven

or out of square with its sides.

Debris in the saddle slot.

Improper saddle fit

(too tight or loose).

Saddle material.

Not enough downbearing

pressure on saddle.

Uneven or belly up

saddle slot.

Wire hole too tight.

Pickup binding in saddle slot.

Push the saddle down

over the weak strings.

Check bottom of saddle for

flatness and squareness.

Remove debris

from the saddle slot.

Make sure that the saddle has

a sliding fit in the slot.

Do not use bone, ivory

or other organic materials

for the saddle material.

We recommend synthetic

materials such as Corian,

Micarta, and Tusc.

Follow the 50/50 rule.

Sculpt the bottom of the saddle

to compensate for depth

differences in the saddle slot

or re-rout the saddle slot.

The wire hole must be

.093" diameter.

The saddle slot must be

.125" wide. Rout the slot

to the correct width.

*

14

14

Page 15

ROUBLESHOOTING

T

T

ROUBLESHOOTING

SYMPTOM CAUSE SOLUTION

HUM

Improper saddle fit (too tight,

resulting in poor s/n ratio).

Torn pickup shield.

Unshielded jack.

Poorly shielded

instrument cable.

Check saddle for

sliding fit in the slot.

Examine the pickup. Replace

pickup if the material is torn.

Fasten the Shielding Cap

to the jack.

Use only fully shielded

instrument cables.

THIN OR

WEAK

SIGNAL

HIGH

FREQUENCY

LOSS

Pickup binding in wire hole (wire

PICKUP

INTERMITTENT

OR DEAD

Weak downbearing pressure

due to low string break angle.

Impedance mismatch

(see PLUGGING IN section).

Instrument cable too long.

hole too small

or misaligned).

Pickup binding in saddle slot.

15

15

Observe the 50/50 rule. Ramp

Match the pickup to the audio

the string slots if necessary.

input with a buffer-preamp.

Use 10' or shorter

instrument cable before

your amplifier

Align or widen

pickup wire hole.

Widen or lengthen pickup

saddle slot to accommodate

the pickup.

Page 16

Limited Warranty

Limited Warranty

The FISHMAN Switchjack™ Equipped AG Series Acoustic Guitar Pickup is

warranted to function for a period of One (1) Year from the date of purchase. If the

unit fails to function properly within the warranty period, free repair and the option

of replacement or refund in the event that FISHMAN is unable to make repair are

FISHMAN’s only obligations. This warranty does not cover any consequential

damages or damage to the unit due to misuse, accident, or neglect. FISHMAN

retains the right to make such determination on the basis of factory inspection.

Products returned to FISHMAN for repair or replacement must be shipped in

accordance with the Return Policy, as follows. This warranty remains valid only if

repairs are performed by FISHMAN. This warranty gives you specific legal rights

and you may also have other rights which may vary from state to state.

Return Policy

To return products to FISHMAN TRANSDUCERS, you must follow these steps...

1. Call FISHMAN TRANSDUCERS at 978-988-9199 for a Return Authorization

Number (“RAN”).

2. Enclose a copy of the original Bill of Sale as evidence of the date of purchase,

with the product in its original packaging and a protective carton or mailer.

3. FISHMAN TRANSDUCERS’ technicians will determine whether the item is

covered by warranty or if it instead has been damaged by improper customer

installation or other causes not related to defects in material or workmanship.

4. Warranty repairs or replacements will be sent automatically free of charge.

5. If FISHMAN TRANSDUCERS determines the item is not covered by warranty, we

will notify you of the repair or replacement cost and wait for your authorization to

proceed.

F

340-D Fordham Road Wilmington MA 01887 USA

Phone 978-988-9199 • Fax 978-988-0770

ISHMAN

T

RANSDUCERS

www.fishman.com

3-0 0 • 009-010-001

Loading...

Loading...