Fishman Acoustic Matrix Installation Guide

This article is intended to illuminate the finer points of fitting an under-the-saddle

piezo pickup.The positioning of a piezo element on or within an instrument is a challenging installation problem. Necessarily, the pickup is extremely sensitive, and accordingly, its environment must fall within a small envelope to achieve full performance.

Problems are not always what they first appear to be, but the mysteries WILL BE

REVEALED to the perceptive. I have always been able to resolve balance problems by

checking and truing the surfaces that touch the pickup. Only rarely should any corrective saddle "sculpting" (see “Drop-In Installations”) be required if the parts around the

pickup are correctly shaped.

The Fishman AG-125 and Martin 332 contain 6 piezo elements. For best performance, each element must be located directly under each string - or in the 12-string,

under the center of each pair of strings. Yes, it MAY work if slightly misaligned or differently spaced, but there's nothing like getting them right underneath! Our recommendation is no more than .050" total difference between the outside string to string measurement at the saddle and the spacing of the crystal elements within the pickup.

The Fishman Acoustic Matrix Pickup contains a multi-layer configuration of continuous strips of sensing material. This continuous design allows the Acoustic Matrix to

sense the motion of the entire saddle, rather than small sections. The job of aligning

the strings with the piezo sensing material is eliminated with the Acoustic Matrix

pickup.

Please remember that custom length, string spacing or string number pickups are

available from Fishman Transducers. Do not hesitate to order a custom pickup if necessary.

Also please note that the methods and techniques described in this article are

intended only for

held responsible for any damages to your pickup or instrument that may result from

improper installation procedures.

professional

repairmen and luthiers. Fishman Transducers cannot be

The Finer

Points

of

Undersaddle

Pickup

Installation

Adapted from an article by

Ken Parker; first published in the

12th issue of Guitarmaker -

Stock Pickups Available

without Special Ordering

STRING OVERALL

FORMAT WIDTH SPACING WHL LENGTH

THINLINE 332 3/32” 2.125” .234” 2.625”

2.3125” .183” 2.725”

2.375” .234” 2.825”

4-STRING 2.125 .234” 2.625”

BACKPACKER 2.190” .100” 2.500”

BACKPACKER

CLASSICAL 2.4375” .150” 2.825”

AG-125 1/8” 2.125” .234” 2.625”

2.155” .234” 2.625”

2.00” .234” 2.500”

AGX-125 2.3125” .234” 2.725”

B-30 4-STRING 2.0625” .234” 2.500”

CUATRO 55mm .234” 2.725”

4-STRING 2.1875” .234” 2.625”

12-STRING 2.260” .234” 2.725”

2.200” .234” 2.625”

The Official Newsletter and

Publication of A.S.I.A.

(Association of Stringed

Instrument Artisans)

THINLINE GOLD + 3/32” 2.00” - 2.50” .100” 2.725”

ACOUSTIC MATRIX 1/8” & 3/32” 2.00” - 2.50” .100” 2.650”

LOWDEN SPLIT 2.00” - 2.50” .100” 1.750” + .875”

Fishman Transducers, Inc.

340-D Fordham Road, Wilmington, MA 01887 USA

Phone 978-988-9199 • Fax 978-988-0770

www.fishman.com

UNDER SADDLE PICKUP INSTALLATION ... Continued

WIRE HOLE LOCATION

The wire hole must be in the correct place, as per the

pickup instructions, drilled 3/32" (,093"), and perpendicular to

the bottom of the slot. The wire hole must also be centered in

the slot width.

Failure to precisely locate the wire hole may cause balance

problems and in worse cases, electrical failure due to a pickup

deformed or pinched by saddle pressure.

PICKUP INSTALLATION

OBJECTIVES:

1. Position the pickup under the strings so that it is uniformly

loaded in compression between the saddle and the bottom

of the saddle slot.

2. Interfere as little as possible with or improve the unampli-

fied sound of the guitar.

METHODS:

(in ascending order of precision, control and complexity)

I - DROP IN INSTALLATIONS

Some guitars will accept a pickup "as is". The pickup wire

hole is located and drilled, the pickup installed, the signal and

shield wires temporarily "twisted" up to a cord, and the saddle

reduced in height as specified in the installation instructions.

Re-string and test for balanced output. To avoid unnecessary

resoldering and heartbreak, always verify correct operation of

the pickup by temporarily hooking up to a test cord.

String balance problems with a drop in installations can

often be corrected by "sculpting" the underside of the saddle,

equalizing the pressure on the pickup. By sculpting, I mean

the adjustment of the saddle bottom to form under string tension, a surface parallel to the slot bottom. This is done to even

out the pressure on the piezo elements. See the trouble

shooting section for detailed instructions.

Dropping in a pickup is generally successful only on newer

instruments where:

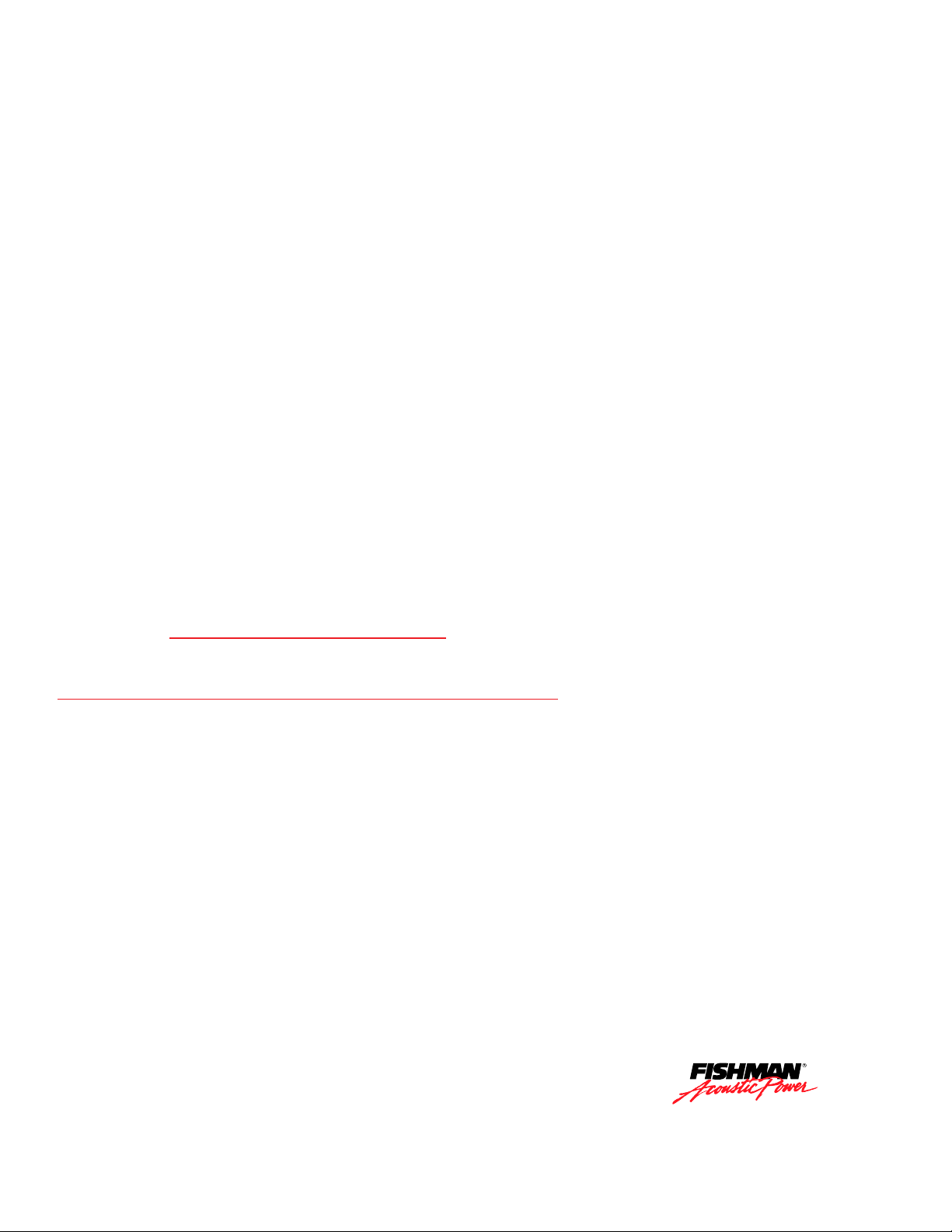

1. The saddle slot is not distor ted into a long "D" shape (Fig.

1) by an overly tall or loose saddle.

2. The slot has enough depth to safely reduce the saddle

height and maintain proper and desirable relationships

between the bridge and saddle (see Mechanical Factors

Affecting Pickup Performance).

3. The slot has not been deepened by hand or otherwise

chewed up -the bottom of the slot must present a smooth

and flat or nearly flat surface.

4. The bridge and top around the br idge are essentially the

same shape as when manufactured. Guitars with big "bellyup" will probably need more "sculpting" of the saddle than

is easily done.

If all is well, untwist the test wire and solder up as usual.

Sometimes the saddle bottom will need to reshaped or

"sculpted" one or more times before it successfully squeezes

the pickup evenly. This method does not always produce good

results, but if the guitar fulfills criteria 1-4, the chances are

very good that it can.

The advantage of this is, of course, speed. No major

machining is done, and fitting the saddle for good response is

within the abilities of any "set-up-capable" repairman.

The disadvantages can be great, also.

1. To lower action from the bottom of a sculpted saddle, the

surface needs to be re-shaped. Ugh.

2. We all know that no instrument fulfills criteria 1-4 except

the Holy (herringbone) Grail and the box you just built.

3. No chance to correct intonation or saddle tilt. So for many

guitars we move to Methods II and III.

II - MACHINING A SLOT

General points to remember:

1. Do not deepen the slot more than necessar y - the pickup

will sound better the closer it is to the strings, and the

bridge will retain its strength in the area of the slot.

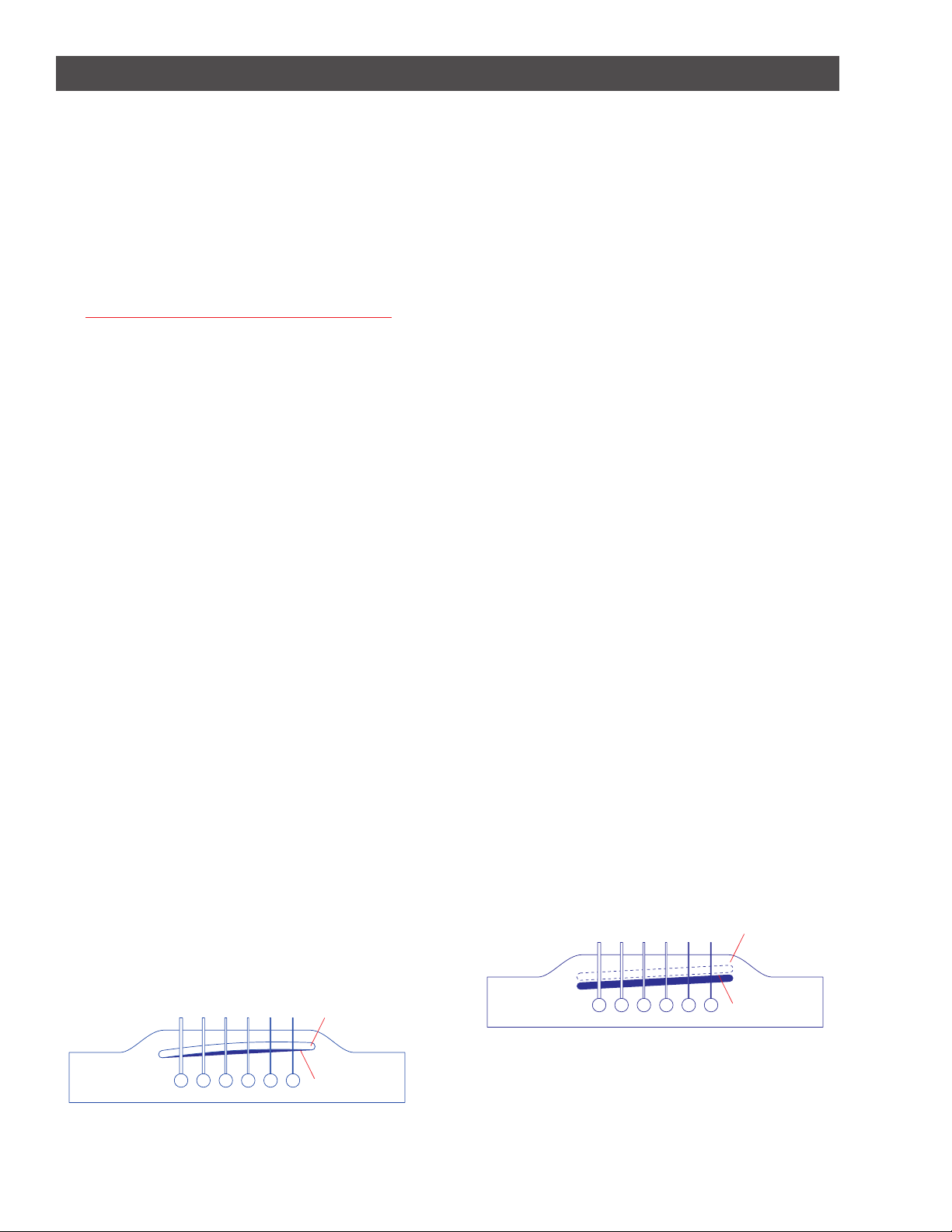

2. Check for intonation before routing. Ideally, set the action

and restring first to determine if the slot needs to be

moved. If so, patch the slot, smooth off the bridge top and

lay a piece of some hard material on the top of the now

slotless bridge. String up and tap the test saddle around to

locate the proper saddle placement. (Fig. 2)

Patched Slot

Saddle

Gap behind center of saddle

Figure 1 - LONG D-SHAPED SLOT

Sliding saddle atop bridge

Figure 2 - FINDING INTONATION

The test saddle can be moved around while strung up at

correct action height to empirically locate exact spot for new

saddle.

Loading...

Loading...