Fisher & Paykel RX256DT4X1 FP, RX256DT7X1 FP, RX256ET2B1 EL, RX256ET2W1 EL Service Manual

321023

Service Manual

Side-by-Side Refrigerator

Fisher & Paykel

Models:

RX256DT4X1 FP

RX256DT7X1 FP

Elba

Models:

RX256ET2B1 EL

RX256ET2W1 EL

321023 - MAY 2009

Fisher & Paykel Appliances Inc

5800 Skylab Rd,

Huntington Beach

California, CA92647

USA

Telephone: 888 936 7872

E-mail: customer.care@fisherpaykel.com

Fisher & Paykel Appliances Canada Inc

2900 – 595 Burrard Street

Vancouver

BC, V7X 1J5

Canada

Telephone: 888 936 7872

E-mail: customer.care@fisherpaykel.com

COPYRIGHT © FISHER & PAYKEL LTD 2008 - ALL RIGHTS RESERVED

2

PRODUCT

Brand: Fisher & Paykel

Models: RX256DT4X1 FP, RX256DT7X1 FP

Brand: Elba by Fisher & Paykel

Models: RX256ET2B1 EL, RX256ET2W1 EL

321023

CONTENTS

1 COMPONENT SPECIFICATIONS ..................................................................................................8

2 PRODUCT DESIGN ........................................................................................................................9

2.1 Refrigeration System................................................................................................................9

2.2 Fully Electronic Defrost System ...............................................................................................9

2.3 Refrigerant Flow .....................................................................................................................11

2.4 Cabinet Air Flow .....................................................................................................................12

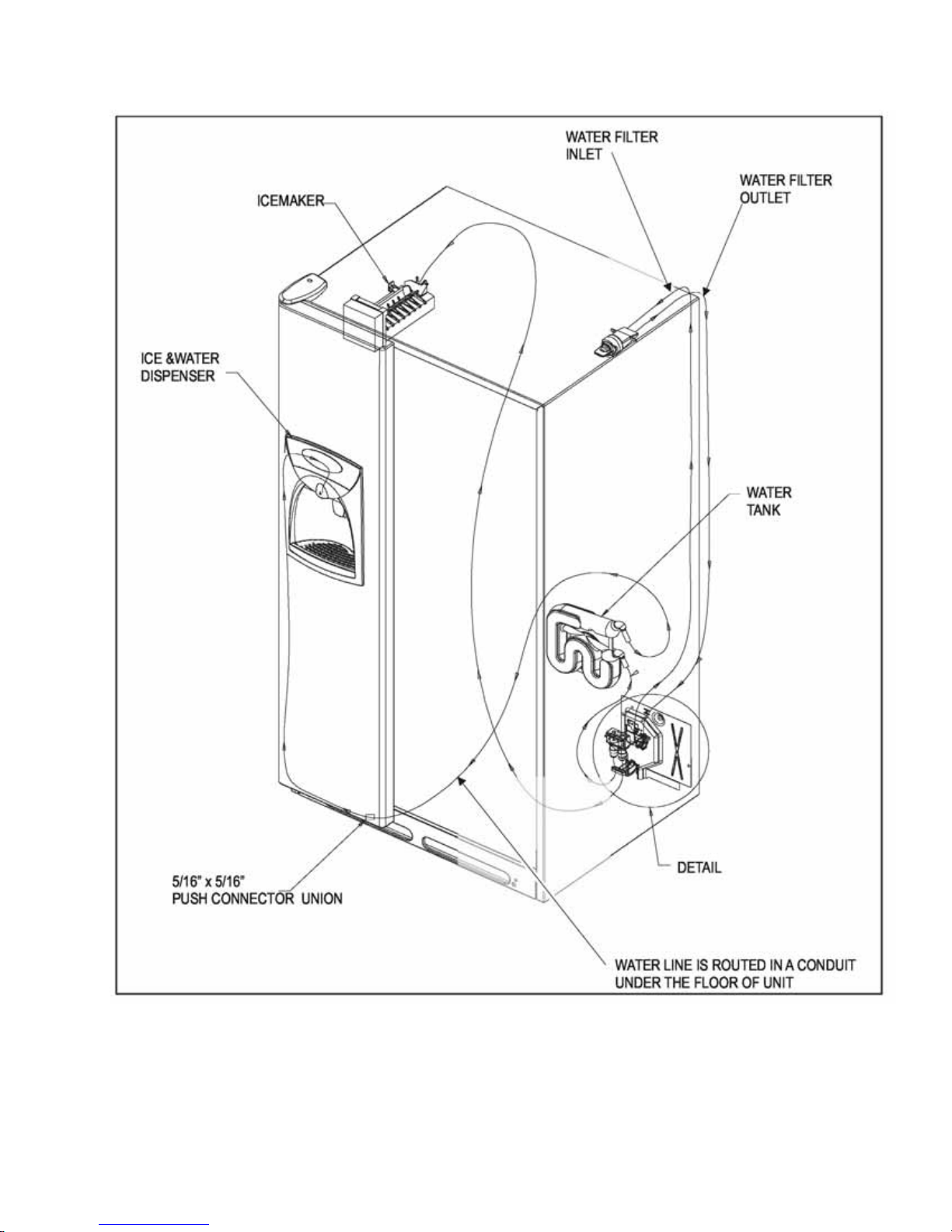

2.5 Ice And Water Dispenser Diagram.........................................................................................13

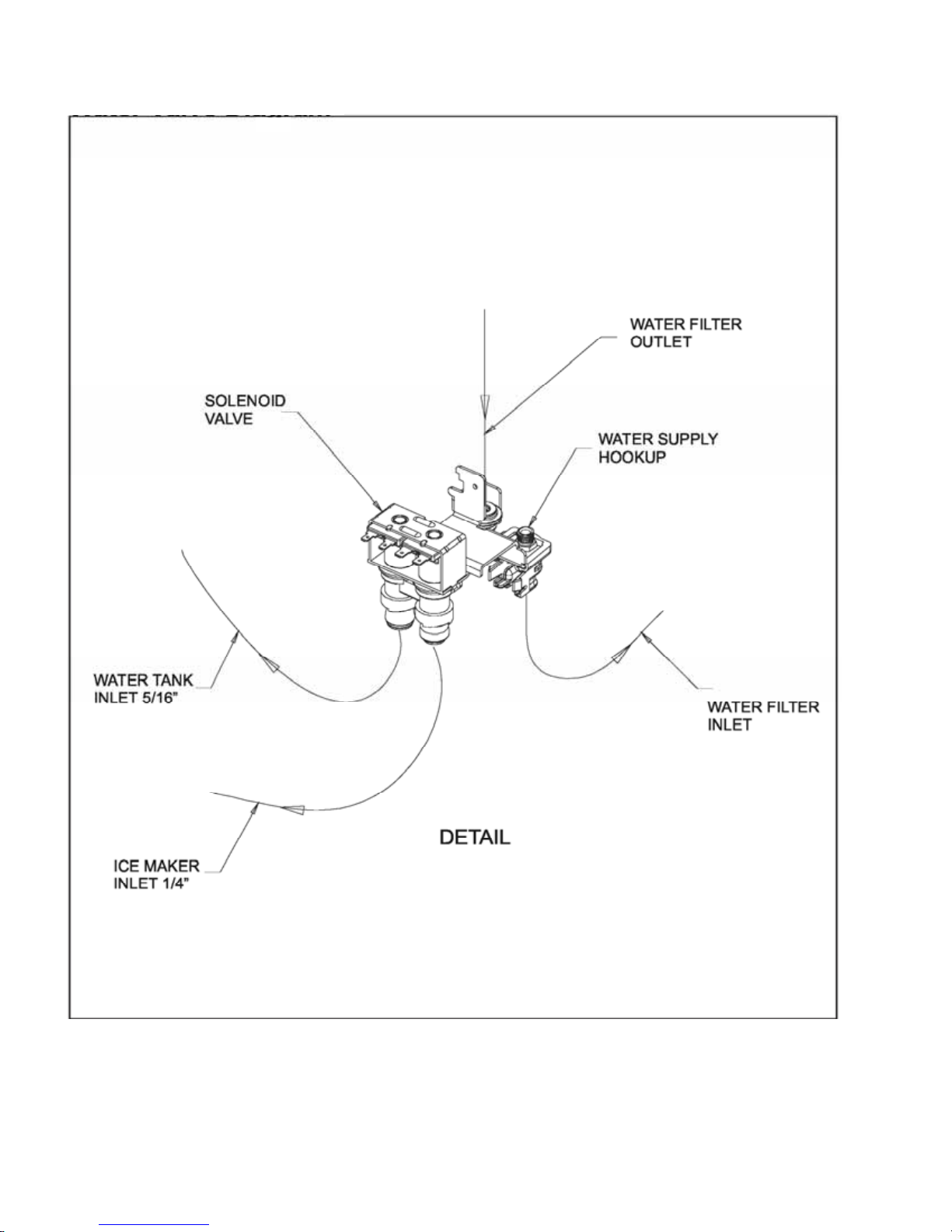

2.6 Water Valve Diagram .............................................................................................................14

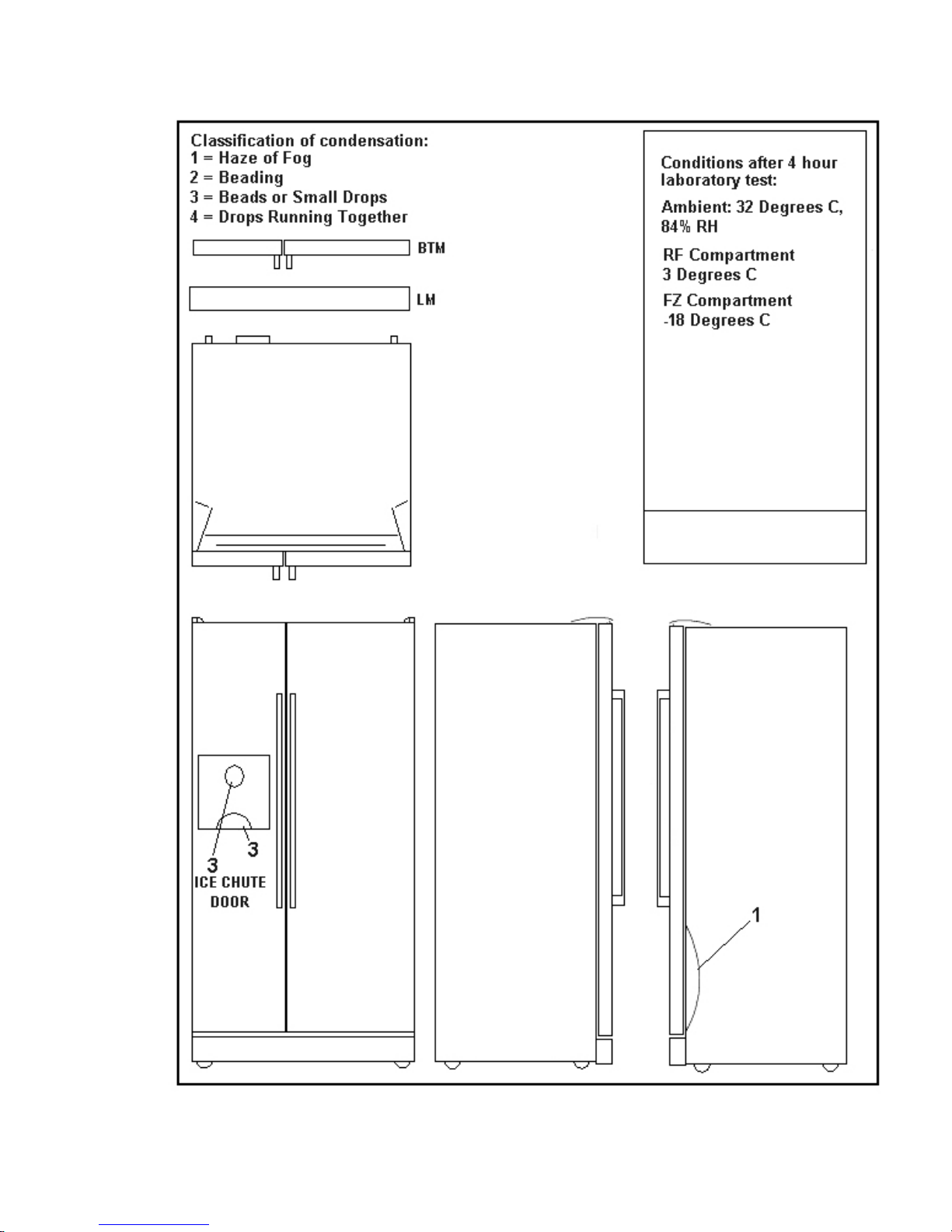

2.7 Typical External Sweat Pattern ..............................................................................................15

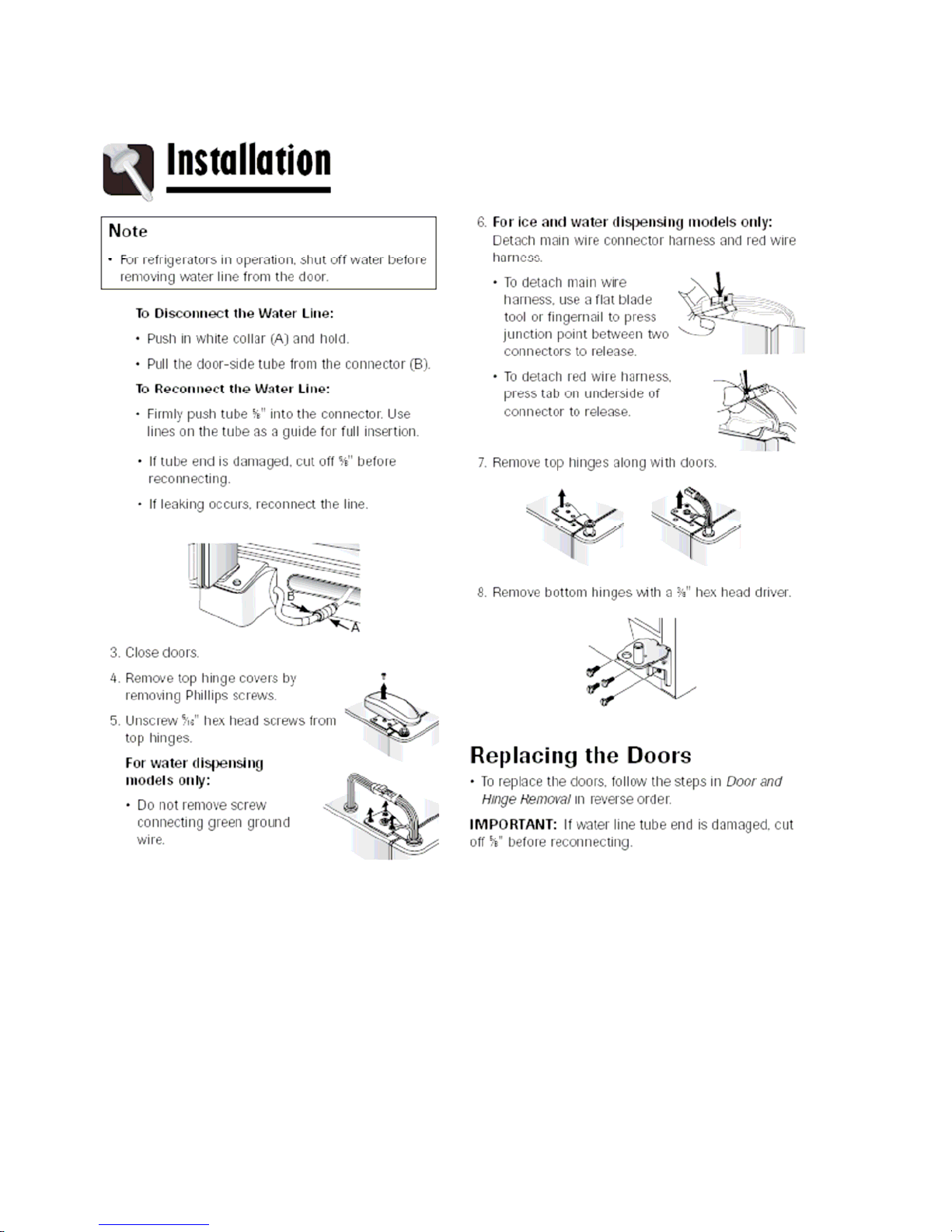

3 INSTALLATION ............................................................................................................................16

4 WATER FILTER REMOVAL AND INSTALLATION (SELECTED MODELS)..............................19

4.1 Initial Installation.....................................................................................................................19

4.2 Replacing Water Filter............................................................................................................19

5 TEMPERATURE CONTROLS & USER OPTIONS.......................................................................20

5.1 Warm Cabinet Temperatures .................................................................................................20

5.2 Adjusting The Controls ...........................................................................................................20

5.2.1 Touch Temperature Controls (Selected Models - Style Varies by Model).......................20

5.2.1.1 Initial Control Settings...............................................................................................20

5.3 Speed Ice ...............................................................................................................................20

5.4 Reset Filter (Selected Models) ...............................................................................................21

5.5 Vacation Mode .......................................................................................................................21

5.6 Temp Alarm............................................................................................................................21

5.7 Door Alarm ............................................................................................................................. 21

5.8 Max Cool ................................................................................................................................ 21

5.9 User Preferences ...................................................................................................................22

5.9.1 Super Cool (CC) (Selected Models) ................................................................................22

5.9.2 Temperature Display (F_C) ............................................................................................. 22

5.9.3 Alarm (AL) .......................................................................................................................22

5.9.4 Auto Light Level (LL) (Selected Models) .........................................................................22

5.9.5 Sabbath Mode (SAB).......................................................................................................22

6 ICE AND WATER..........................................................................................................................23

6.1 Dispenser Features (Selected Models) ..................................................................................23

6.1.1 Dispensing Light (Selected Models)................................................................................24

6.1.2 Dispenser Pad.................................................................................................................24

6.1.3 Removable Tray ..............................................................................................................24

6.2 Dispenser Control (Selected Models)..................................................................................... 24

6.2.1 Ice Dispenser Operation.................................................................................................. 25

6.2.2 Dispenser Lock (Selected Models).................................................................................. 25

6.2.3 Water Filter Status Indicator Light (Selected Models) .....................................................25

6.2.4 Auto Light (Selected Models) ..........................................................................................25

6.2.5 Light (Selected Models)...................................................................................................25

6.2.6 Sabbath Mode (Selected Models) ...................................................................................26

6.2.7 Front Fill (Selected Models).............................................................................................26

7 COMPONENT TESTING...............................................................................................................27

3

321023

8 ELECTRONIC CONTROL BOARD...............................................................................................33

8.1 Full Electronic Specification Control Board (RX256DT7X1) ...................................................34

8.1.1 Programming Mode .........................................................................................................34

8.1.2 Forced Defrost Mode .......................................................................................................35

8.1.3 Service Test Mode...........................................................................................................35

8.1.4 Service Test Mode - Navigation.......................................................................................36

8.1.4.1 Service Test 001 - Power-Up Test Results...............................................................36

8.1.4.2 Service Test 101 - Defrost Heater. ...........................................................................37

8.1.4.3 Service Test 102 - Compressor/Condenser System. ...............................................38

8.1.4.4 Service Test 112 - Freezer Fan Operation. ..............................................................38

8.1.4.5 Service Test 121 - Damper Operation. .....................................................................39

8.1.4.6 Service Test 141 - Refrigerator Thermistor (See Thermistor Chart in Section 8.1.13).

..................................................................................................................................

39

8.1.4.7 Service Test 142 - Freezer Thermistor Test. (See Thermistor Chart in Section

8.1.13).......................................................................................................................

40

8.1.4.8 Service Test 143 - Ambient Thermistor Test. (See Thermistor Chart in Section

8.1.13).......................................................................................................................

40

8.1.4.9 Service Test 152 - Freezer Door State. ....................................................................41

8.1.4.10 Service Test 161 - Cube Dispense Test. ..................................................................41

8.1.4.11 Service Test 162 - Crush Dispense Test. .................................................................42

8.1.4.12 Service Test 163 - Water Dispense Test. .................................................................42

8.1.4.13 Service Test 164 - Ice Chute Test. ...........................................................................42

8.1.4.14 Service Test 165 - Dispenser Light Test...................................................................43

8.1.4.15 Service Test 171 - Actuator Pad Test.......................................................................43

8.1.4.16 Service Test 172 - Sports Fill Test............................................................................43

8.1.4.17 Service Test 173 - Ambient Light Test......................................................................44

8.1.4.18 Service Test 174 - Dispenser Water Actuator (Bottom Mount units only).................44

8.1.4.19 Service Test 175 - Dispenser Line Test....................................................................44

8.1.4.20 Service Test 181 - Keypad Operation Test...............................................................45

8.1.4.21 Service Test 182 - Indicator Operation Test. ............................................................46

8.1.4.22 Service Test 191 - Valve State Test. ........................................................................46

8.1.4.23 Service Test 241 - Main Control Software. ...............................................................46

8.1.4.24 Service Test 242 - Main Display Software................................................................46

8.1.4.25 Service Test 243 - Main Fountain Software..............................................................46

8.1.4.26 Thermistor Reference Chart .....................................................................................47

8.1.5 Show Room Mode ...........................................................................................................47

8.1.6 Sabbath Mode .................................................................................................................47

8.1.7 Fahrenheit or Celsius Mode.............................................................................................48

8.1.8 Cooling Fan Mode ...........................................................................................................48

8.1.9 Alarm Enable Mode .........................................................................................................48

8.1.10 Light Level Mode .............................................................................................................48

8.1.11 Filter Status Light.............................................................................................................48

8.1.12 Filter Status Light Reset ..................................................................................................49

8.1.13 Thermistor Resistance Chart ...........................................................................................49

8.2 Troubleshooting Flow Chart (RX256DT7X1)..........................................................................50

8.2.1 Compressor Does Not Turn On .......................................................................................50

8.2.2 Evaporator Fan Does Not Turn On..................................................................................51

8.2.3 Damper Does Not Move ..................................................................................................52

8.2.4 Damper Opens and Never Closes...................................................................................53

8.2.5 Flashing Display at Power Up..........................................................................................54

8.2.6 Blank Display ...................................................................................................................55

8.3 Mid Electronic Specification Control Board (RX256DT4X1, RX256ET2B1, RX256ET2W1) ..56

8.3.1 Programming Mode .........................................................................................................56

8.3.2 Forced Defrost Mode .......................................................................................................57

4

321023

8.3.3 Service Test Mode...........................................................................................................58

8.3.4 Service Test Mode – Navigation......................................................................................58

8.3.4.1 Service Test 1 – Defrost Thermostat & Defrost Circuit Test.....................................59

8.3.4.2 Service Test 2 - Compressor/Condenser Fan Test. .................................................59

8.3.4.3 Service Test 3 - Evaporator/Freezer Fan Test. ........................................................59

8.3.4.4 Service Test 4 - Refrigerator Thermistor Test. .........................................................60

8.3.4.5 Service Test 5 - Freezer Thermistor Test.................................................................60

8.3.4.6 Service Test 6 - Open Damper Test.........................................................................61

8.3.4.7 Service Test 7 - Refrigerator Performance Adjustment............................................61

8.3.4.8 Service Test 8 - Freezer Performance Adjustment. .................................................62

8.3.5 Show Room Mode ........................................................................................................... 62

8.4 Troubleshooting Flow Chart (RX256DT4X1, RX256ET2B1, RX256ET2W1)......................... 63

8.4.1 Compressor Does Not Turn On.......................................................................................63

8.4.2 Evaporator Fan Does Not Turn On..................................................................................64

8.4.3 Damper Does Not Move ..................................................................................................65

8.4.4 Damper Opens and Never Closes...................................................................................66

8.4.5 Flashing Display at Power Up .........................................................................................67

8.4.6 Blank Display................................................................................................................... 68

8.5 Defrost Cycle..........................................................................................................................69

9 ELECTRONIC TROUBLESHOOTING..........................................................................................70

9.1 Models RX256DTX1, RX256ET2B1, RX256ET2W1.............................................................. 70

10 GENERAL TROUBLESHOOTING ..........................................................................73

11 DISASSEMBLY PROCEDURES.............................................................................75

11.1 Fresh Food Compartment ......................................................................................................75

11.1.1 Light Switch .....................................................................................................................75

11.1.2 Electronic Control (Full Electronic Specification Model (RX256DT7X1)) ........................75

11.1.3 Ice And Water Dispenser Board...................................................................................... 75

11.1.4 Main Control Board (Full Electronic Specification Model (RX256DT7X1))......................77

11.1.5 Electronic Control (Mid Electronic Specification Models (RX256DT4X1, RX256ET2B1,

RX256ET2W1)) ...............................................................................................................

77

11.1.6 Electronically Controlled Damper ....................................................................................79

11.1.7 Fresh Food Thermistor.................................................................................................... 79

11.1.8 Water Filter Assembly .....................................................................................................79

11.1.9 Water Tank Assembly .....................................................................................................79

11.1.10 Crisper Light Cover and Socket.......................................................................................80

11.2 Freezer Compartment ............................................................................................................80

11.2.1 Freezer Light Socket .......................................................................................................80

11.2.2 Auger Motor Assembly ....................................................................................................80

11.2.3 Auger Motor..................................................................................................................... 80

11.2.4 Auger Motor Capacitor ....................................................................................................80

11.2.5 Evaporator Fan Motor Assembly ..................................................................................... 80

11.2.6 Evaporator Fan Motor and Fan Blade .............................................................................81

11.2.7 Freezer Thermistor.......................................................................................................... 81

11.2.8 Evaporator Removal........................................................................................................81

11.2.9 Defrost Terminator (Thermostat) .....................................................................................81

11.2.10 Defrost Heater .................................................................................................................83

11.2.11 Ice Maker Removal..........................................................................................................83

11.3 Machine Compartment ...........................................................................................................83

11.3.1 Water Valve.....................................................................................................................83

11.3.2 Condenser Fan Motor and Blade ....................................................................................84

11.3.3 Compressor.....................................................................................................................84

11.3.4 Condensate Drain Tube ..................................................................................................84

11.3.5 Condensate Drain Pan ....................................................................................................84

5

321023

11.3.6 Overload/Relay ................................................................................................................84

11.3.7 Condenser Removal ........................................................................................................85

11.4 Bottom of Cabinet...................................................................................................................85

11.4.1 Front Levelling Rollers .....................................................................................................85

11.4.2 Rear Levelling Rollers......................................................................................................85

11.5 Cabinet Doors.........................................................................................................................85

11.5.1 Door Gaskets...................................................................................................................85

11.5.2 Dispenser Façade............................................................................................................85

11.5.3 Dispenser Ice Chute Door ...............................................................................................86

11.5.4 Dispenser Light Socket....................................................................................................86

11.5.5 Dispenser D/C Solenoid ..................................................................................................86

11.5.6 Dispenser Water Tube.....................................................................................................86

12 SEALED SYSTEM DIAGNOSIS ..............................................................................87

12.1 Symptoms of an Overcharge ..................................................................................................87

12.2 Symptoms of Refrigeration Shortage......................................................................................87

12.3 Symptoms of a Restriction......................................................................................................88

12.4 Symptoms of Air in System.....................................................................................................90

12.5 Symptoms of Low or High Ambient Temperature Installation.................................................90

13 SEALED SYSTEM SERVICE PROCEDURES ........................................................92

13.1 Service Equipment..................................................................................................................92

13.2 Drier Replacement..................................................................................................................92

13.3 Refrigerant Precautions..........................................................................................................94

13.4 Line Piercing Valves ...............................................................................................................94

13.5 Open Lines .............................................................................................................................94

13.6 Compressor Operational Test.................................................................................................94

13.7 Dehydrating Sealed Refrigeration System..............................................................................95

13.8 Leak Testing ...........................................................................................................................95

13.8.1 Testing Systems Containing a Refrigerant Charge .........................................................95

13.8.2 Testing Systems Containing No Refrigerant Charge.......................................................95

13.9 Restrictions.............................................................................................................................97

13.9.1 Symptoms........................................................................................................................97

13.9.2 Testing for Restrictions ....................................................................................................97

13.10 Evacuation and Charging .......................................................................................................98

13.10.1 Evacuation .......................................................................................................................98

13.10.2 Charging ........................................................................................................................100

13.10.3 Refrigerant Charge ........................................................................................................100

13.10.4 HFC134a Service Information .......................................................................................100

13.10.5 Health, Safety, and Handling .........................................................................................101

13.11 Replacement Service Compressor .......................................................................................103

13.11.1 Compressor Testing Procedures ...................................................................................103

13.12 Brazing 103

14 WIRING DIAGRAMS..............................................................................................104

14.1 Wiring Schematic (RX256DT7X1) ........................................................................................104

14.2 Wiring Diagram (RX256DT7X1) ...........................................................................................105

14.3 Wiring Schematic (RX256DT4X1, RX256ET2B1, RX256ET2W1)........................................106

14.4 Wiring Diagram (RX256DT4X1, RX256ET2B1, RX256ET2W1) ..........................................107

6

321023

IMPORTANT INFORMATION

Important Notices for Service Technicians and Consumers

Fisher & Paykel Appliances will not be responsible for personal injury or property damage from

improper service procedures. Pride and workmanship go into every product to provide our customers

with quality products. It is possible, however, that during its lifetime a product may require service.

Products should be serviced only by a qualified service technician who is familiar with the safety

procedures required in the repair and who is equipped with the proper tools, parts, testing instruments

and the appropriate service information. IT IS THE TECHNICIAN’S RESPONSIBILITY TO REVIEW

ALL APPROPRIATE SERVICE INFORMATION BEFORE BEGINNING REPAIRS.

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit

before working on/servicing the appliance.

To locate an Authorised Service Centre, please consult the dealer from whom you purchased this

product. For further assistance, please contact:

Fisher & Paykel Customer Care

E-mail

New Zealand

Australia customer.care@fp.com.au

USA/Canada customer.care@fisherpaykel.com

United Kingdom customer.care@fisherpaykel.co.uk

Recognize Safety Symbols, Words, and Labels

customer.care@fp.co.nz 0800 372 273

Telephone

1300 650 590

1 888 936 7872

0845 066 2200

DANGER

DANGER - Immediate hazards that WILL result in severe personal injury or death.

WARNING

WARNING - Hazards or unsafe practices that COULD result in severe personal injury or death.

CAUTION

CAUTION - Hazards or unsafe practices that COULD result in minor personal injury, product or

property damage.

7

321023

1 COMPONENT SPECIFICATIONS

WARNING

To avoid risk of electrical shock that can cause death or severe personal injury, disconnect unit from

power before servicing unless tests require power. Discharge capacitors through a 10,000 ohm

resistor before handling. Wires removed during disassembly must be replaced on correct terminals

to ensure proper grounding and polarization.

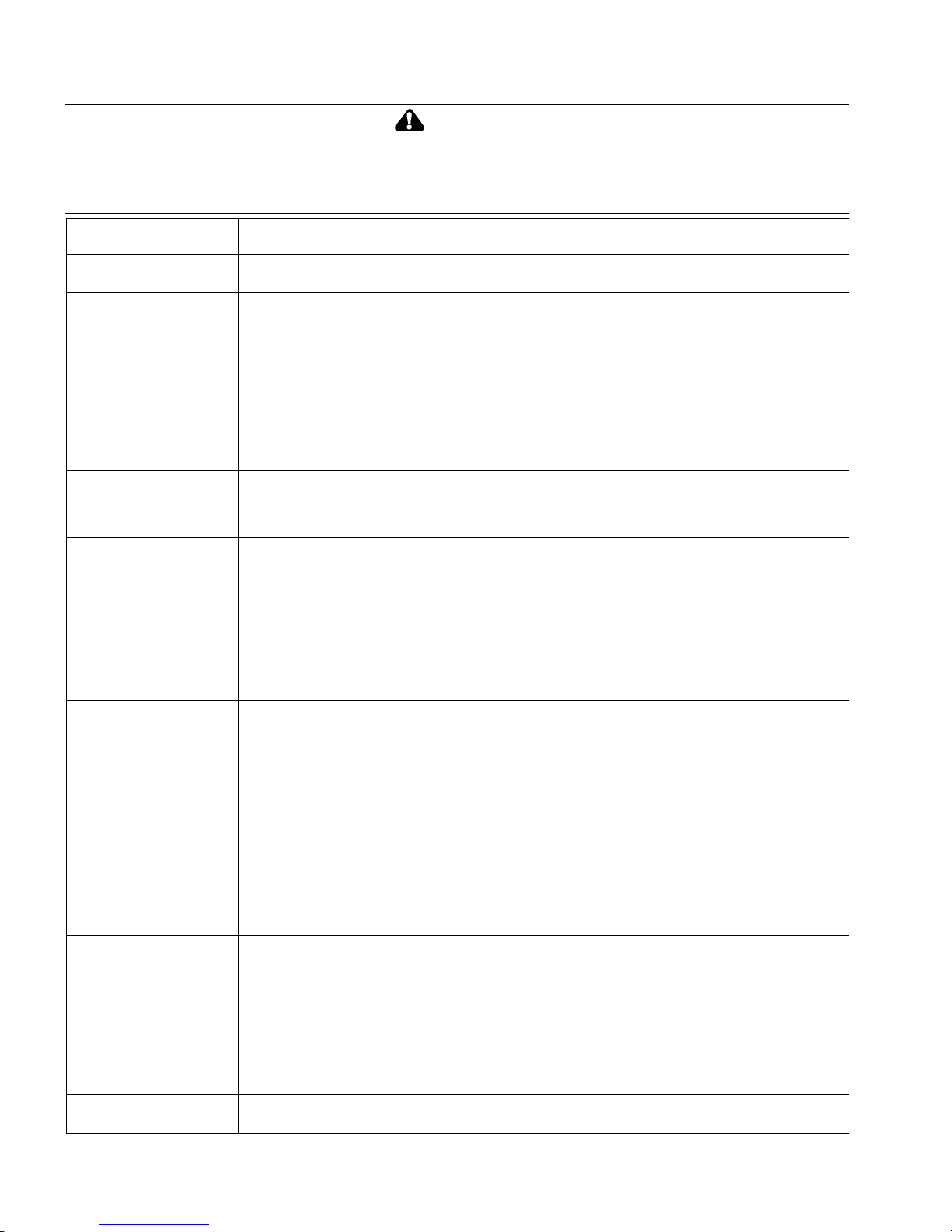

Component Specifications all parts 115VAC/60HZ unless noted

Compressor Run Capacitor Volts............................................................................................................... 220 VAC

Compressor BTUH ............................................................................................................. 905 BTUH

Electric Damper Control Maximum closing time (RX256DT7X1) ............................................................ 8 seconds

Thermistor Temperature................................................................................................ Resistance

Condenser Motor Rotation (facing end opposite shaft) .............................................................. Clockwise

Evaporator Fan Motor Rotation (facing end opposite shaft) .............................................................. Clockwise

Overload/Relay Ult. trip amps @ 158°F (70°C) ......................................................................... 2.40 amps ± 15%

Thermostat (Defrost) Volts............................................................................................................ 120/240 VAC

Evaporator Heater

26 cu. ft.

Control Board Volts............................................................................................................... 120 VAC, 60 HZ

Auger Motor Rotation (facing end opposite shaft) Power to blue and white is clockwise. Power to orange

Water Valve Watts.............................................................................................................. Brown side 35W

Capacitance...................................................................................................... 15µfd ± 10%

Watts................................................................................................................. 60 Hz / 153 watts

Current Lock rotor............................................................................................. 19.0 amps ± 15%

Current Full load ............................................................................................... 1.26 amps ± 15%

Resistance Run windings................................................................................. 3.33 ohms ± 15%

Resistance Start windings................................................................................ 4.28 ohms ± 15%

Maximum closing time (RX256DT4X1, RX256ET2B1, RX256ET2W1) .......... 36 seconds

Temperature Rating ......................................................................................... 20°F - 110°F

RPM (RX256DT7X1) ....................................................................................................... 5

RPM (RX 256DT4X1, RX256ET2B1, RX 256ET2W1).............................................. 1

77°F...................................................................................................................................... 10,000 ohms ± 1.8%

36°F...................................................................................................................................... 29,500 ohms ± 1.0%

0°F........................................................................................................................................ 86,300 ohms ± 1.8%

RPM ..................................................................................................................................... 1120 RPM

Watts................................................................................................................. 3.4 watts ± 15% @ 115 VAC

Current.............................................................................................................. 0.085 amps ± 15% @ 115

VAC

RPM ..................................................................................................................................... 2800 RPM

Watts................................................................................................................. 6.0 watts ± 15% @ 115 VAC

Note: Fan blade must be fully seated

on shaft to achieve proper airflow.

Close temperature ............................................................................................ 140° ± 10°

Open temperature (RX256DT7X1) .................................................................. 230° ± 5°

Open temperature (RX256DT4X1, RX256ET2B1, RX256ET2W1)................. 284° ± 9°

Short time trip (seconds) (RX256DT7X1) ...................................................... 17 seconds ± 5

Short time trip (seconds) (RX256DT4X1, RX256ET2B1, RX256ET2W1) ...... 10 seconds ± 5

Short time trip (amps @ 77°F (25°C) .......................................................... 12 amps ± 2 amps

Watts (RX256DT7X1) ............................................................................................ 475 watts

Watts (RX256DT4X1,

Current (RX256DT7X1) ......................................................................................... 10/5 amps

Current (RX256DT4X1,

Resistance across terminals:

Above 42°F ± 5° ............................................................................................... Open

Below 12°F +7° .................................................................................................... Closed

Volts............................................................................................................... 115 VAC

Wattage.......................................................................................................... 450 ± 5% watts @ 115 VAC

Resistance ..................................................................................................... 29 ± 5% ohms

....................................................................................................................... See Control board

troubleshooting section.

RPM ............................................................................................................... 17 ± 3 RPM

Yellow side 20W

RX256ET2B1, RX256ET2W1) ........................................ 495 watts

RX256ET2B1, RX256ET2W1) ..................................... 5.8/2.9 amps

and white is counterclockwise.

8

321023

Light Switch (RX256DT4X1,

RX256ET2B1,

RX256ET2W1)

Light Switch / Interlock Type ............................................................................................................... SPDT NO/NC

Solenoid (Ice Chute) Resistance across leads ................................................................................ 101 ohms ± 10%

Ice Maker Harvest 4 lbs of ice per 24 hours.

Type ............................................................................................................... SPST NC

Volts ............................................................................................................... 125/250 VAC

Current ........................................................................................................... 8/4 amps

Volts ............................................................................................................... 125/250 VAC

Current ........................................................................................................... 8/4 amps

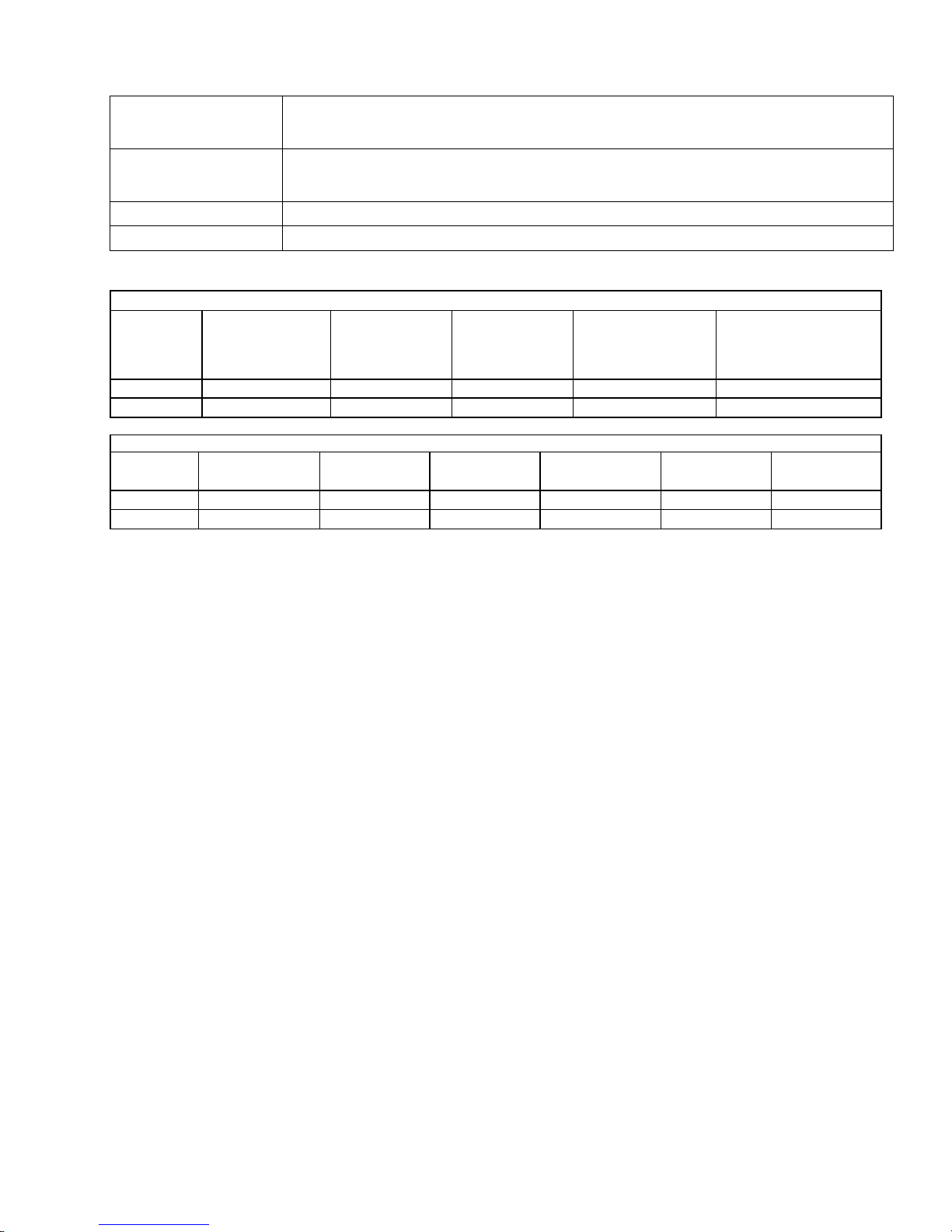

No-Load Performance, Controls in Normal Position

Percent Run Time

Kw/24 hr ±0.4

Ambient °F 70° 90° 110° 70° 90° 110° 70° 90° 110° 70° 90° 110° 70° 90° 110°

26cuft 1.2 1.85 2.6 35 55 75 24 24 19 37 39 42 0 0 -2

Evaporator Outlet

Ambient °F 70° 90° 70° 90° 70° 90° 70° 90° 70° 90° 70° 90°

26cuft -15 -15 -16 -16 72 98 132 138 6"(Vac.) 0 87 137

±3°F

Evaporator Inlet

±10%

Temperature Relationship Test Chart

±3°F

Cycles/24 hr

±25%

Suction Line

±7°F

Provision Center

Compartment

Average Food

Temperature ±3°F

Average Total

Wattage ±10%

Freezer Compartment

Average Food

Temperature ±3°F

Suction Pressure

±2 PSIG

Head Pressure

± 5 PSIG

2 PRODUCT DESIGN

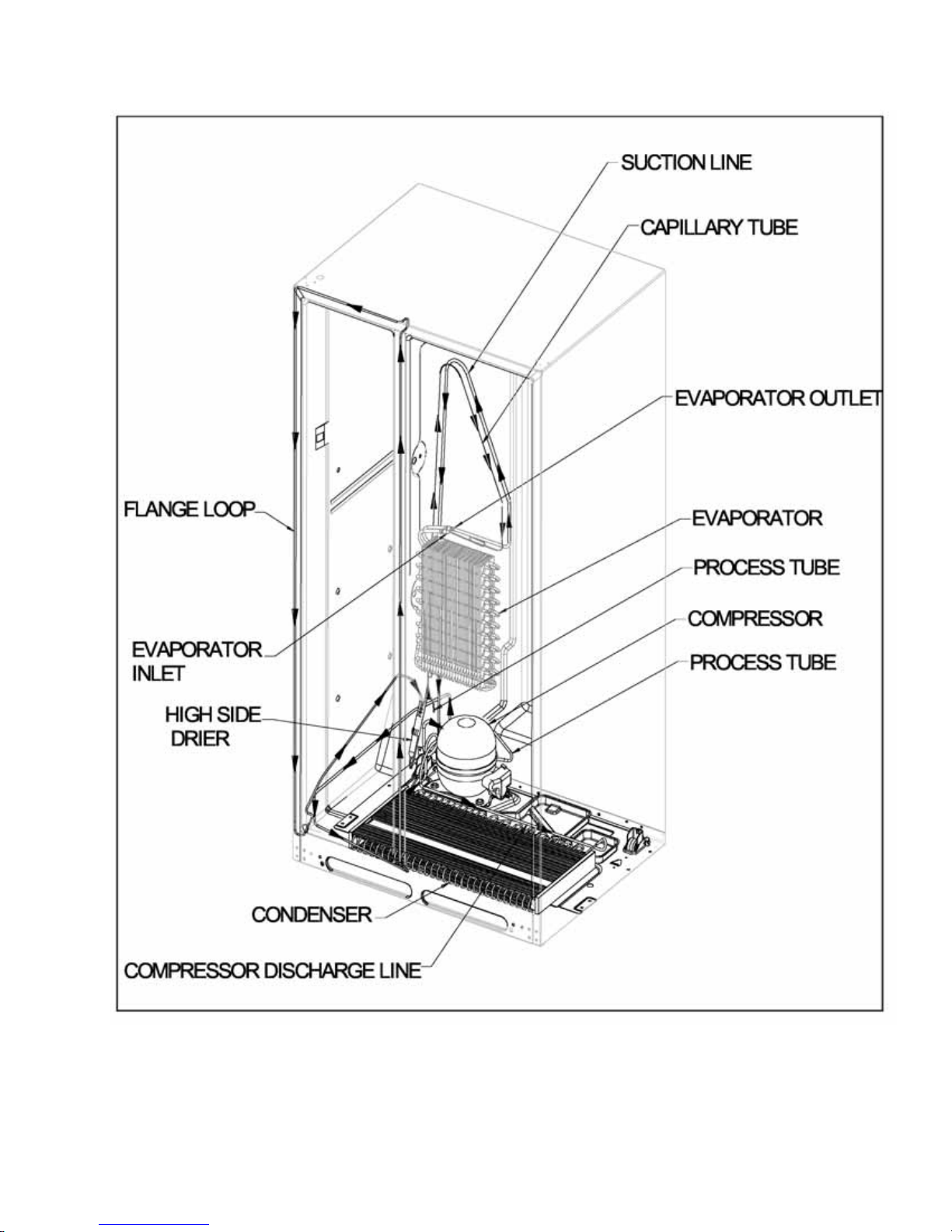

2.1 Refrigeration System

The compressor forces high temperature vapor into the fan cooled tube and wire condenser, where

vapor is cooled and condensed into high pressure liquid by circulation of air across the condenser

coil (refer to Section

High-pressure liquid passes into a post-condenser loop, which helps to prevent condensation

around the freezer compartment opening, and through the molecular sieve drier and into the

capillary tube. The small inside diameter of the capillary offers resistance, decreasing pressure and

temperature of the liquid discharged into the evaporator. The capillary diameter and length is

carefully sized for each system.

The capillary enters the evaporator at the top front. Combined liquid and saturated gas flows

through the front to the bottom of the coil and into the suction line. The aluminium tube evaporator

coil is located in the freezer compartment where the circulating evaporator fan moves air through the

coil and into the fresh food compartment.

The large surface of the evaporator allows heat to be absorbed from both the fresh food and freezer

compartments, by airflow over the evaporator coil causing some of the liquid to evaporate. The

temperature of the evaporator tubing near the end of the running cycle may vary from –13

O

25

F (-25OC to –31OC).

Saturated gas is drawn off through the suction line, where superheated gas enters the compressor.

To raise the temperature of the gas, the suction line is placed in heat exchange with the capillary.

2.3).

O

F to –

2.2 Fully Electronic Defrost System

The Control Board adapts the compressor run time between defrosts to achieve optimum defrost

intervals by monitoring the length of time the defrost heater is on.

9

321023

After initial power up, the defrost interval is 4 hours compressor run time. Defrost occurs

immediately after the 4 hours.

Note: Once the unit is ready to defrost, there is a 4 minute wait time prior to the beginning of the

defrost

cycle.

10

2.3 Refrigerant Flow

321023

11

321023

2.4 Cabinet Air Flow

12

2.5 Ice And Water Dispenser Diagram

321023

13

321023

2.6 Water Valve Diagram

14

2.7 Typical External Sweat Pattern

321023

15

321023

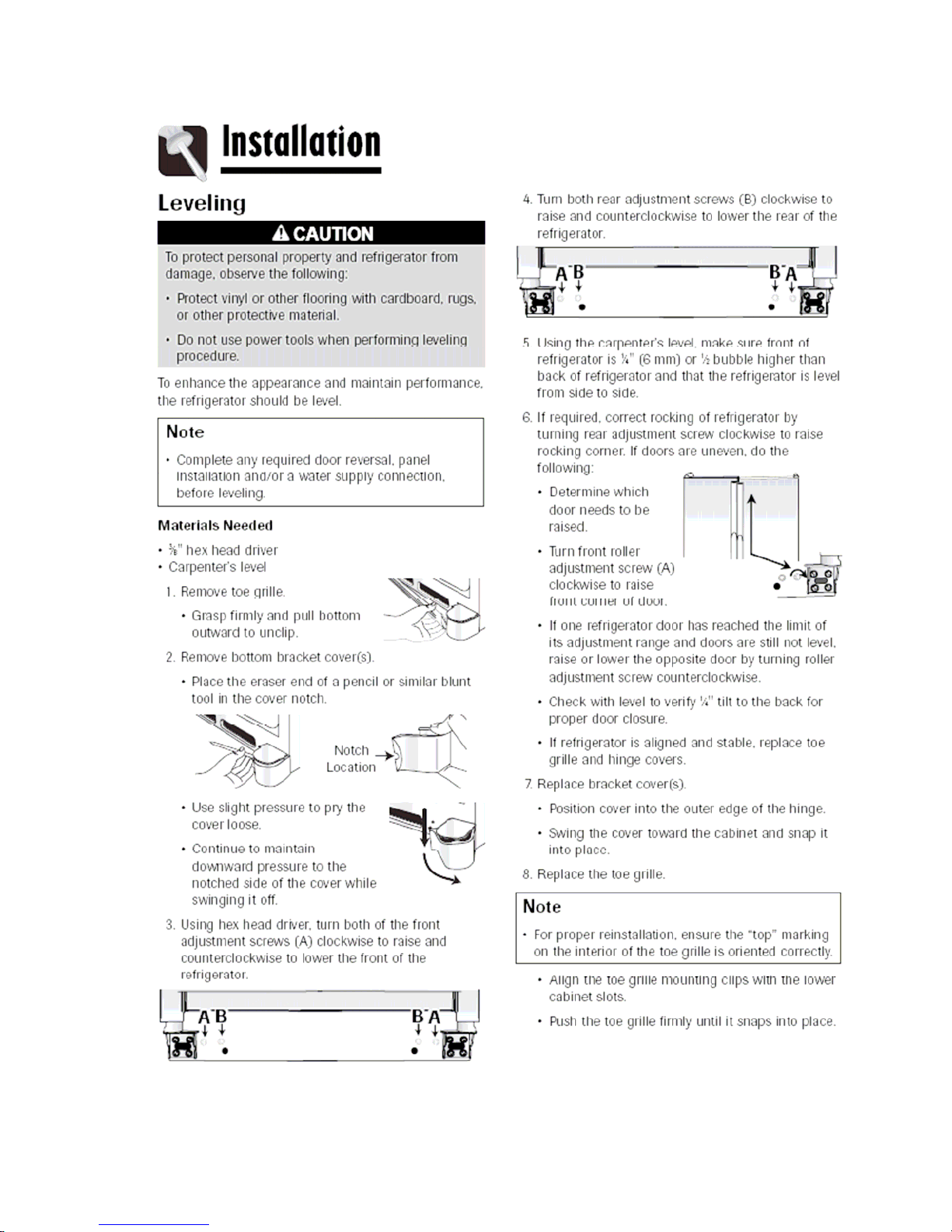

3 INSTALLATION

16

321023

17

321023

18

321023

4 WATER FILTER REMOVAL AND INSTALLATION

(SELECTED MODELS)

WARNING

To avoid serious illness or death, do not use the refrigerated water where the water is unsafe or of

unknown quality without adequate disinfection before or after filtration.

CAUTION

After installing a new water filter, always dispense water for two minutes before removing the filter

for any reason. Air trapped in the system may cause water and the cartridge to eject. Use caution

when removing.

The bypass cap does not filter water. Be sure to have a replacement cartridge available when a

filter change is required.

If the water filtration system has been allowed to freeze, replace the filter cartridge.

If the system has not been used for several months, or water has an unpleasant taste or odor,

flush the system by dispensing water for two or three minutes. If the unpleasant taste or odor

persists, change the filter cartridge.

4.1 Initial Installation

The water filter is located in the upper right-hand corner of the fresh food

compartment.

Remove the blue bypass cap and retain for future use.

Remove the sealing label from the end of the filter and insert the filter into

the filter head.

Rotate gently clockwise until the filter stops. Snap the filter cover closed.

Reduce water spurts by flushing air from the system. Run water continuously for two minutes

through the dispenser until the water runs steadily. During initial use, allow

about a one to two minute delay in water dispersal to allow the internal

water tank to fill.

Additional flushing may be required in some households where water is of

poor quality.

4.2 Replacing Water Filter

IMPORTANT: Air trapped in the system may cause water and the

cartridge to eject. Use caution when removing.

Turn the filter counterclockwise until it releases from the filter head.

Drain the water from the filter into a sink and dispose of the filter in normal household trash.

Wipe excess water from the filter cover and install the new filter as described in Initial Installation

above.

The filter should be changed at least every 12 months.

IMPORTANT: The condition of the water and the amount used determines the life span of the water

filter cartridge. If the water use is high, or if the water is of poor quality, replacement may need to take

place more often.

The dispenser feature may be used without a water filter cartridge. If this option is chosen, replace the

filter with the blue bypass cap.

19

321023

5 TEMPERATURE CONTROLS & USER OPTIONS

5.1 Warm Cabinet Temperatures

At times, the front of the refrigerator cabinet may be warm to touch. This is a normal occurrence that

helps prevent moisture from condensing on the cabinet. This condition will be more noticeable when

the refrigerator is first started, during hot weather and after excessive or lengthy door openings.

5.2 Adjusting The Controls

24 hours after adding food, the customer may decide that one or both compartments should be

colder or warmer, so they can adjust the control(s) as indicated in the temperature control guide

table below.

Except when starting the refrigerator, do not change either control more than one number at a time.

Allow 24 hours for temperatures to stabilize.

Changing either control will have some effect on the temperature of the other compartment.

5.2.1 Touch Temperature Controls (Selected Models - Style Varies by Model)

The controls are located at the top front of the fresh food compartment compartment.

5.2.1.1 Initial Control Settings

Pressing the TEMPERATURE UP or TEMPERATURE DOWN keypads, adjust the controls to the

desired setting.

Set the freezer control to 4.

Set the fresh food compartment control to 4.

Let the refrigerator run for at least 8 to 12 hours before adding food.

Fresh food compartment too

warm.

Set the fresh food compartment control to the next higher

number by pressing the FRESH FOOD

COMPARTMENT TEMPERATURE UP keypad.

Fresh food compartment too

cold.

Freezer too warm. Set the FREEZER control to the next higher number by

Freezer too cold. Set the freezer control to the next lower number by

Turn refrigerator OFF. Press the freezer or fresh food compartment

Set the fresh food compartment control to the next lower

number by pressing the FRESH FOOD

COMPARTMENT TEMPERATURE DOWN keypad.

pressing the FREEZER TEMPERATURE UP keypad.

pressing the FREEZER TEMPERATURE DOWN

keypad.

TEMPERATURE DOWN keypad until a dash “-“ appears

in the display.

5.3 Speed Ice

When activated, Speed Ice reduces the freezer temperature to the optimum setting for 24 hours in

order to produce more ice.

NOTE: When the Speed Ice feature is in operation, the FREEZER TEMPERATURE UP and

FREEZER TEMPERATURE DOWN keypads will not operate.

20

321023

5.4 Reset Filter (Selected Models)

When a water filter has been installed in the refrigerator, the yellow ORDER light will illuminate when

90 percent of the volume of water for which the filter is rated has passed through the filter OR 11

months have elepsed since the filter has been installed.

The red REPLACE light will illuminate when the rated volume of water has passed through the filter

OR 12 months have elepsed since the filter was installed. A new filter should be installed immediately

when the REPLACE light is illuminated.

After replacing the filter, press the RESET FILTER keypad for three seconds. The ORDER and

REPLACE lights will go out on the display.

5.5 Vacation Mode

The Vacation Mode feature causes the freezer to defrost less frequently, conserving energy. The

VACATION MODE indicator light will illuminate when the feature is activated. To deactivate, press

the VACATION MODE keypad again OR open either door. The indicator light will go out.

NOTE: Door openings will not deactivate the Vacation Mode for approximately one hour after

activation.

5.6 Temp Alarm

The Temp Alarm will alert the customer if the freezer or fresh food compartment temperatures exceed

normal operating temperatures due to a power outage or other event. When activated, the TEMP

ALARM light will illuminate.

If the freezer or fresh food temperatures have exceeded these limits, the display will alternately show

the current compartment temperatures and the highest compartment temperature reached when the

power was out. An audible alarm will sound repeatedly.

Press the TEMP ALARM keypad once to stop the audible alarm. The TEMP ALARM light will

continue to flash and the temperature display will alternate until the temperatures have stabilized.

To turn off Temp Alarm, press and hold the TEMP ALARM keypad for three seconds. The indicator

light will go out.

5.7 Door Alarm

The Door Alarm will alert the customer when one of the doors has been left open for five minutes

continuously. When this happens, an audible alarm will sound every few seconds until the door is

closed OR the DOOR ALARM keypad is pressed to deactivate the feature.

5.8 Max Cool

When activated, Max Cool causes the fresh food and freezer compartmentment temperatures to drop

to the minimum settings on the control. This cools down the fresh food and freezer compartments

after extended door openings or when loading the compartments with warm food.

NOTE: When the Max Cool feature is activated, the temperature setting kaypads will not operate.

To activate, press the MAX COOL keypad. Max Cool will deactivate automatically after 12 hours, OR

press the MAX COOL keypad to deactivate the feature.

21

321023

5.9 User Preferences

Access the User Preferences menu to:

Activate or deactivate Super Cool (selected models).

Change the temperature display from

Enable or diable audible alarms.

Adjust the light level at which the Dispenser Auto Light will illuminate (when this feature is activated

on the ice and water dispenser) (selected models).

Activate the Sabbath Mode.

To access the User Preferences menu, press and hold the DOOR ALARM keypad for three seconds.

When in the User Preferences mode, a short title for the feature will appear in the freezer temperature

display. And the feature status will appear in the fresh food display.

Use the FREEZER TEMPERATURE UP and FREEZER TEMPERATURE DOWN keypads to scroll

through the features.

When the desired feature is displayed, use the FRESH FOOD COMPARTMENT TEMPERATURE

UP and FRESH FOOD COMPARTMENT TEMPERATURE DOWN keypads to change the status.

When changes are complete, press the DOOR ALARM keypad for three seconds OR close the

fresh food compartment door and any change will be saved.

5.9.1 Super Cool (CC) (Selected Models)

When Super Cool is ON, an air-mixing fan in the fresh food compartment is activated to improve air

flow and temperature control. To save energy, this feature may be deactivated by choosing OFF.

O

F to OC.

5.9.2 Temperature Display (F_C)

Change the temperature display to show in degrees Fahrenheit or degrees Celsius.

5.9.3 Alarm (AL)

When the Alarm mode is OFF, all audible alarms will be disabled until the feature is turned on.

5.9.4 Auto Light Level (LL) (Selected Models)

This setting adjusts the light level at which the dispenser light will illuminate when the sensor detects

that the light levels in the room are low. Setting 1 is the darkest light level setting, setting 9 is the

lightest light level setting.

NOTE: The Auto Light mode must be activated on the ice and water dispenser control to take

advantage of this option.

5.9.5 Sabbath Mode (SAB)

When the Sabbath Mode is ON, all control lights and the night light will be disabled until the feature is

turned OFF. This feature does not disable the interior lights. Press any keypad to restore the control

lights.

22

6 ICE AND WATER

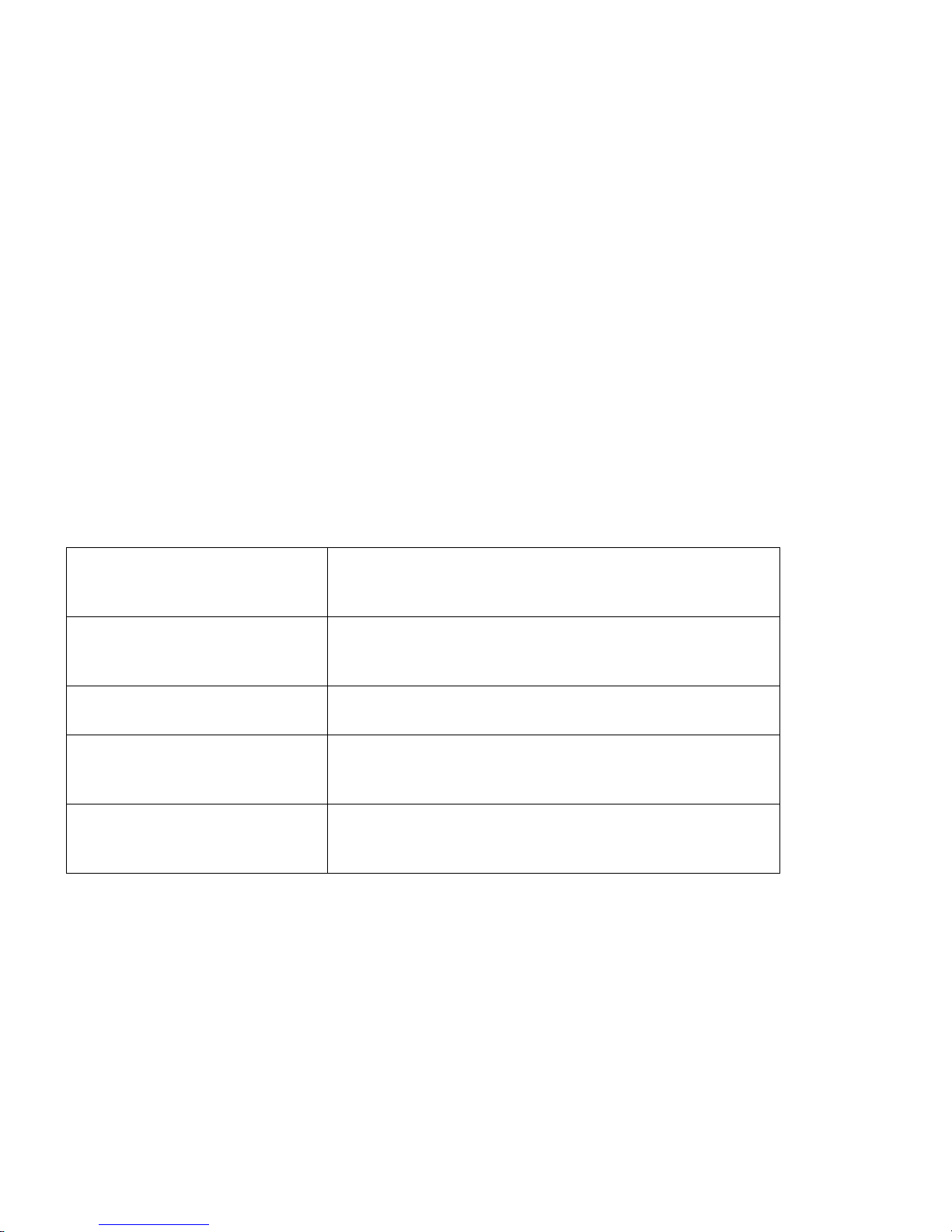

6.1 Dispenser Features (Selected Models)

Full Electronic Specification Dispenser Panel

Mid Electronic Specification Dispenser Panel

321023

Elba Dispenser Panel

23

321023

6.1.1 Dispensing Light (Selected Models)

A light activates within the dispenser area at full power when dispensing ice or water with the main

dispenser pad.

6.1.2 Dispenser Pad

The dispenser pad is located on the back wall of the dispensing area. When the dispenser pad is

pressed, the selection chosen on the dispenser control panel will dispense.

6.1.3 Removable Tray

The removable tray at the bottom of the dispenser area is designed to collect small spills and may be

easily removed for emptying and cleaning purposes.

IMPORTANT: The removable tray does not drain. Do not allow the tray to overflow. If it does,

remove the tray and wipe up the overflow.

6.2 Dispenser Control (Selected Models)

Control features may vary by model.

Water Dispenser Operation:

CAUTION

To aviod personal injury or property damage, observe the following:

Do not put fingers, hands or any foreign object into the dispenser opening.

Do not use sharp objects to break ice.

Do not dispense ice directly into thin glass, fine china or delicate crystal.

NOTE: During initial use of the water dispenser, there will be a one to two minute delay while the

water tank fills before water dispenses. Discard the first 10 to 14 glasses of water after initially

connecting the refrigerator to the household water supply and after extended periods of non-use.

To Use Dispenser Pad:

Select water mode by pressing the WATER keypad on the dispenser control panel. A green light

above the keypad indicates the mode selected.

Press a sturdy, wide-mouthed container against the dispenser pad.

Release pressure on the dispenser pad to stop the water dispensing. A small amount of water may

continue to dispense and collect in the dispenser tray. Large spills should be wiped away.

24

321023

6.2.1 Ice Dispenser Operation

To Dispense Ice:

Select Crush or Cube mode by pressing the appropriate keypad on the dispenser control panel. A

green light above the keypad indicates the mode selected.

Press a container against the dispenser pad. When dispensing crushed ice, hold the container as

close as possible to the chute to reduce spraying.

NOTE:

The mode cannot be changed while the ice dispenser is in operation.

On selected models, if the dispenser is active for more than five minutes, an automatic lock-out

sensor will shut down power to the dispenser area. Refer to Dispenser Lock below for unlocking

information.

6.2.2 Dispenser Lock (Selected Models)

The Dispenser Lock prevents ice or water from being dispensed.

To Lock Dispenser:

Press and hold the LOCK keypad for three seconds. The green indicator light above the keypad

will illuminate when the dispenser is locked.

To Unlock Dispenser:

Press and hold the LOCK keypad for three seconds. The green indicator light above the keypad

will go out.

6.2.3 Water Filter Status Indicator Light (Selected Models)

The Water Status Indicator Light serves as a reminder to replace the water filter. A green light

indicates that the filter is in good condition. A red light indicates that the filter should be changed.

Once the light turns red, it will remain red until the function is reset.

To Reset Indicator:

Press and hold the LOCK and WATER keypads simultaneously for four seconds. The green filter

status indicator light will flash three times when the function has successfully reset.

6.2.4 Auto Light (Selected Models)

The Auto Light function activates the dispenser light at half power when the light sensor detects that

the light levels in the room are low.

To Activate Auto Light:

Press the AUTO LIGHT keypad. A green indicator light above the keypad illuminates when the

sensor is active.

To Deactivate Auto Light:

Press the AUTO LIGHT keypad. The green indicator light will go out.

NOTE: The dispenser light will operate whether Auto Light is ON or OFF.

6.2.5 Light (Selected Models)

To Activate Light:

Press the LIGHT keypad to turn the dispenser light on continuously. The green indicator light

above the keypad will illuminate.

To Deactivate Light:

Press the LIGHT keypad to turn the dispenser light off.

25

321023

6.2.6 Sabbath Mode (Selected Models)

When activated, the Sabbath Mode deactivates the control lights while leaving the controls

operational.

To Activate Sabbath Mode:

Press and hold both the LOCK and AUTO LIGHT keypads simultaneously for three to four

seconds, or until the control lights turn off.

To Deactivate Sabbath Mode:

Press and hold both the LOCK and AUTO LIGHT keypads simultaneously for three to four

seconds, or until the control lights turn on.

NOTE:

The dispenser light will not activate during dispensing while in this mode.

If the power fails, the control remains in Sabbath Mode when the power is restored.

6.2.7 Front Fill (Selected Models)

The Front Fill keypad works independently of the dispenser controls, providing an up-front alternative

to the dispenser pad for dispensing water. This feature is convenient for filling large items that will not

fit into the dispenser area (i.e. sports bottles, pitchers, large pans, coffee pots).

This feature allows the added convenience of dispensing ice and water simultaneously. To do so,

choose the preferred ice mode. Press the container against the dispenser pad to dispense the ice

while pressing the Front Fill keypad to dispense the water.

26

7 COMPONENT TESTING

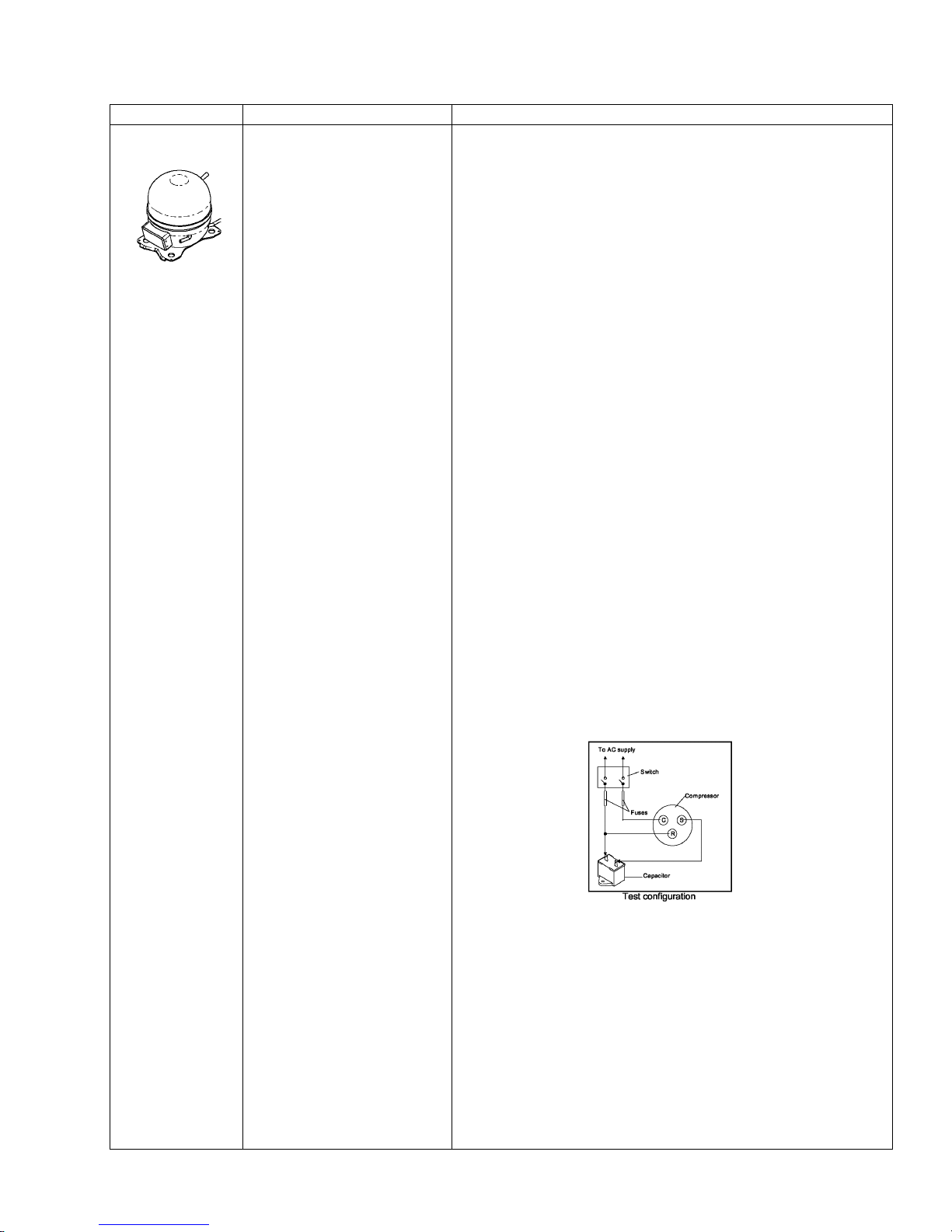

Component Description Test Procedures

Compressor

When compressor electrical

circuit is energized, the start

winding current causes relay

to heat. After an amount of

starting time, the start winding

circuit turns off. The relay will

switch off the start winding

circuit even though

compressor has not started

(for example, when attempting

to restart after momentary

power interruption).

With “open” relay, compressor

will not start because there is

little or no current to start

windings. Overload protection

will open due to high locked

rotor run winding current.

With “shorted” relay or

capacitor, compressor will

start and overload protector

will quickly open due to high

current of combined run and

start windings.

With open or weak capacitor,

compressor will start and run

as normal but will consume

more energy.

Resistance test

1. Disconnect power to unit.

2. Discharge capacitor by shorting across terminals with a resistor

for 1 minute.

NOTE: (Some compressors do not have a run capacitor.)

3. Remove leads from compressor terminals.

4. Set ohmmeter to lowest scale.

5. Check for resistance between:

Terminals “S” and “C”, start winding.

Terminals “R” and “C”, run winding.

If either compressor winding reads open (infinite or very high

resistance) or dead short (0 ohms), replace compressor.

Ground test

1. Disconnect power to refrigerator.

2. Discharge capacitor, if present, by shorting terminals through a

resistor.

3. Remove compressor leads and use an ohmmeter set on highest

scale.

4. Touch one lead to compressor body (clean point of contact) and

other probe to each compressor terminal.

• If reading is obtained, compressor is grounded and must be

replaced.

Operation test

If voltage, capacitor, overload, and motor winding tests do not show

cause for failure, perform the following test:

1. Disconnect power to refrigerator.

2. Discharge capacitor by shorting capacitor terminals through a

resistor.

3. Remove leads from compressor terminals.

4. Wire a test cord to power switch.

5. Place time delayed fuse with UL rating equal to amp rating of

motor in test cord socket. (Refer to Technical Data Sheet.)

6. Remove overload and relay.

7. Connect start, common and run leads of test cord on

appropriate terminals of compressor.

8. Attach capacitor leads of test cord together. If capacitor is

used, attach capacitor lead to a known good capacitor of same

capacity.

321023

9. Plug test cord into multimeter to determine start and run

wattage and to check for low voltage, which can also be a

source of trouble indications.

10. With power to multimeter, press start cord switch and release.

• If compressor motor starts and draws normal wattage,

compressor is okay and trouble is in capacitor,

relay/overload, freezer temperature control, or elsewhere in

system.

• If compressor does not start when direct wired, recover

refrigerant at high side. After refrigerant is recovered, repeat

compressor direct wire test. If compressor runs after

recovery but would not run when direct wired before

recovery, a restriction in sealed system is indicated.

• If compressor does not run when wired direct after recovery,

replace faulty compressor.

27

321023

Component Description Test Procedures

Capacitor

Condenser Condenser is a tube and wire construction

Run capacitor connects to relay terminal 3 and

L side of line.

Some compressors do not require a run

capacitor; refer to the Technical Data Sheet for

the unit being serviced.

located in machine compartment.

Condenser is on high-pressure discharge side

of compressor. Condenser function is to

transfer heat absorbed by refrigerant to

ambient.

Higher pressure gas is routed to condenser

where, as gas temperature is reduced, gas

condenses into a high pressure liquid state.

Heat transfer takes place because discharged

gas is at a higher temperature than air that is

passing over condenser. It is very important

that adequate airflow over condenser is

maintained.

Condenser is air cooled by condenser fan

motor. If efficiency of heat transfer from

condenser to surrounding air is impaired,

condensing temperature becomes higher.

High liquid temperature means liquid will not

remove as much heat during boiling in

evaporator as under normal conditions. This

would be indicated by higher than normal head

pressures, long run time, and high wattage.

Remove any lint or other accumulation that

would restrict normal air movement through

condenser.

From condenser, the refrigerant flows into a

post condenser loop that helps control exterior

condensation on flange, centre mullion, and

around freezer door. Refrigerant then flows

through the drier to evaporator and into

compressor through suction line.

To avoid electrical shock which can cause

severe personal injury or death, discharge

capacitor through a resistor before

handling.

1. Disconnect power to refrigerator.

2. Remove capacitor cover and disconnect

capacitor wires.

3. Discharge capacitor by shorting across

terminals with a resistor for 1 minute.

4. Check resistance across capacitor terminals

with ohmmeter set on “X1 K” scale.

• Good—needle swings to 0 ohms and

slowly moves back to infinity.

• Open—needle does not move. Replace

capacitor.

• Shorted—needle moves to zero and

stays. Replace capacitor.

• High resistance leak—needle jumps

toward 0 and then moves back to constant

high resistance (not infinity).

Leaks in condenser can usually be detected by

using an electronic leak detector or leak

detection fluid. Look for signs of compressor oil

when checking for leaks. A certain amount of

compressor oil is circulated with refrigerant.

Leaks in post condenser loop are rare because

loop is a one-piece copper tube.

For minute leaks:

1. Separate condenser from rest of refrigeration

system and pressurize condenser up to a

maximum of 235 PSI with a refrigerant and

dry nitrogen combination.

2. Recheck for leaks.

To avoid personal injury or death from sudden

eruption of high pressure gases, observe the

following:

Protect against a sudden eruption if high

pressures are required for leak checking.

Do not use high pressure compressed

gases in refrigeration systems without a

reliable pressure regulator and pressure

relief valve in the lines.

WARNING

WARNING

28

Component Description Test Procedures

Overload/Relay

Ice maker

ECM condenser

motor

Evaporator fan

motor

When voltage is connected

and relay is cool, current

passes through relay to start

winding.

After a short time, current

heats the resistor in relay and

resistance will rise blocking

current flow through relay.

Start winding remains in the

circuit through run capacitor.

Solid state relay plugs directly

on compressor start and run

terminals. Relay terminals 2

and 3 are connected within

relay. Run capacitor is

connected to relay terminal 3.

L2 side of 120 VAC power is

connected to relay terminal 2.

See “Ice Maker” section for

service information.

Condenser fan moves cooling

air across condenser coil and

compressor body.

Condenser fan motor is in

parallel circuit with

compressor.

Evaporator fan moves air

across evaporator coil and

throughout refrigerator

cabinet.

1. Disconnect power to the refrigerator.

2. Remove relay cover and disconnect leads.

Check resistance across terminals 2 and 3 with an ohmmeter:

3.

Normal = 3 to 12 ohms

Shorted = 0 ohms

Open = infinite ohms

Check resistance across coil.

1. Disconnect power to unit.

2. Disconnect fan motor leads.

3. Check resistance from ground connection

solder. Trace to motor frame must not exceed .05

ohms.

Fresh food light

switch

Freezer

light/interlock switch

Single pole, single throw

switch completes circuit for

light when door is open.

Single pole, Double throw

switch completes circuit for

light when door is open.

Completes circuit for

dispenser when door is

closed.

4. Check for voltage at connector to motor with unit in

refrigeration mode and compressor operating.

Check resistant across terminals.

Switch arm depressed

“NO” terminals Open

Switch arm up

“NO” terminals Closed

Check resistant across terminals.

Switch arm depressed

“NO” terminals Open

”NC” terminals Closed

Switch arm not depressed

“NC” terminals Open

“NO” terminals Closed

321023

29

321023

Component Description Test Procedures

Drier

Drier is placed at post

condenser loop outlet and

passes liquefied refrigerant to

the capillary.

Desiccant 12grams XH9.

Long tail drier P/no 814843P.

Drier must be changed every time the system is opened for

testing or compressor replacement.

Before opening refrigeration system, recover HFC134a

refrigerant for safe disposal.

1. Cut drier out of system using the following

procedure. Do not unbraze drier.

2. Applying heat to remove drier will drive moisture into the

system.

3. Score capillary tube close to drier and break.

4. Reform inlet tube to drier allowing enough space for large

tube cutter.

5. Cut circumference of drier 32mm below condenser inlet tube

joint to drier.

6. Remove drier.

7. Apply heat trap paste on post condenser tubes to protect

grommets from high heat.

8. Unbraze remaining part of drier. Remove drier from system.

9. Discard drier in safe place. Do not leave drier

with customer. If refrigerator is under warranty, old

drier must accompany warranty claim.

WARNING

To avoid death or severe personal injury, cut drier at correct

location. Cutting drier at incorrect location will allow

desiccant beads to scatter. If spilled, completely clear area

of beads.

Water valve

Controls water flow to the

icemaker.

Controlled by thermostat in

icemaker.

See Ice Maker Section for

further information.

Check resistance across coil windings.

Electric damper

control

Damper control balances the

air delivery between provision

and freezer compartments

providing temperature control

for the fresh food

compartment.

The Electrical voltage

activates damper control and

the door closes, restricting

flow of air from freezer

compartment to fresh food

compartment.

Check resistance across terminals.

If no resistance across terminals replace damper control.

Can be checked in Diagnostic

30

Loading...

Loading...