Page 1

INTEGRATED COLUMN

REFRIGERATOR FREEZER

RS2484WR, RS2484WL,

RS3084WR & RS3084WL

models

INSTALLATION GUIDE

US CA

86026B0.20

Page 2

Page 3

CONTENTS

Safety and warnings 4

Integrated columns — refrigerator–freezer 5

Check your appliance 6

Moving your appliance 7

Before installation 8

Supplied parts 9

Required parts 11

toe kick panel 11

Door panel set 12

Door and drawer handle kits 12

Hinge change kit 13

Product dimensions — RS24 model 14

Cavity dimensions — RS24 model 15

Door panel dimensions — RS24 model 16

Custom door panel install dimensions — rs24 model 17

Door clearance — RS24 model 18

Drawer clearance — RS24 model 19

Toe kick dimensions — RS24 model 20

Toe kick install options 21

Product dimensions — RS30 model 22

Cavity dimensions — RS30 model 23

Door panel dimensions — RS30 model 24

Custom door panel install dimensions — RS30 model 25

Door clearance — RS30 model 26

Drawer clearance — RS30 model 27

Toe kick dimensions — RS30 model 28

Dual install options 29

Cavity dimensions — RS24 + RS24 dual install 30

Cavity dimensions — RS24 + RS30 dual install 31

Cavity dimensions — RS30 + RS30 dual install 32

Toe kick panel dimensions — dual install 33

Power supply dimensions 34

Electrical specification 35

Plumbing specification 35

Install anti-tip bracket 36

Connect water and power supply 38

Position and alignment in cabinetry 40

Secure appliance to cabinetry 45

Remove hanging brackets 46

Install door and drawer panels 47

Install locking bracket 51

Install adjustment brackets 51

Install toe kick panel 52

Install toe kick grilles 53

Install top trim 53

Install water filter 54

Install air flow divider 55

Install cabinet side trims 56

Install door and drawer side trims 57

Dual installation 58

Change the door hinges (optional) 64

Final checklist 70

SAVE THESE INSTRUCTIONS

The models shown in this installation guide may not be available in all markets and are subject to change at any time. For current details about model and specification availability in your country, go to our

website fisherpaykel.com or contact your local Fisher & Paykel dealer.

3

Page 4

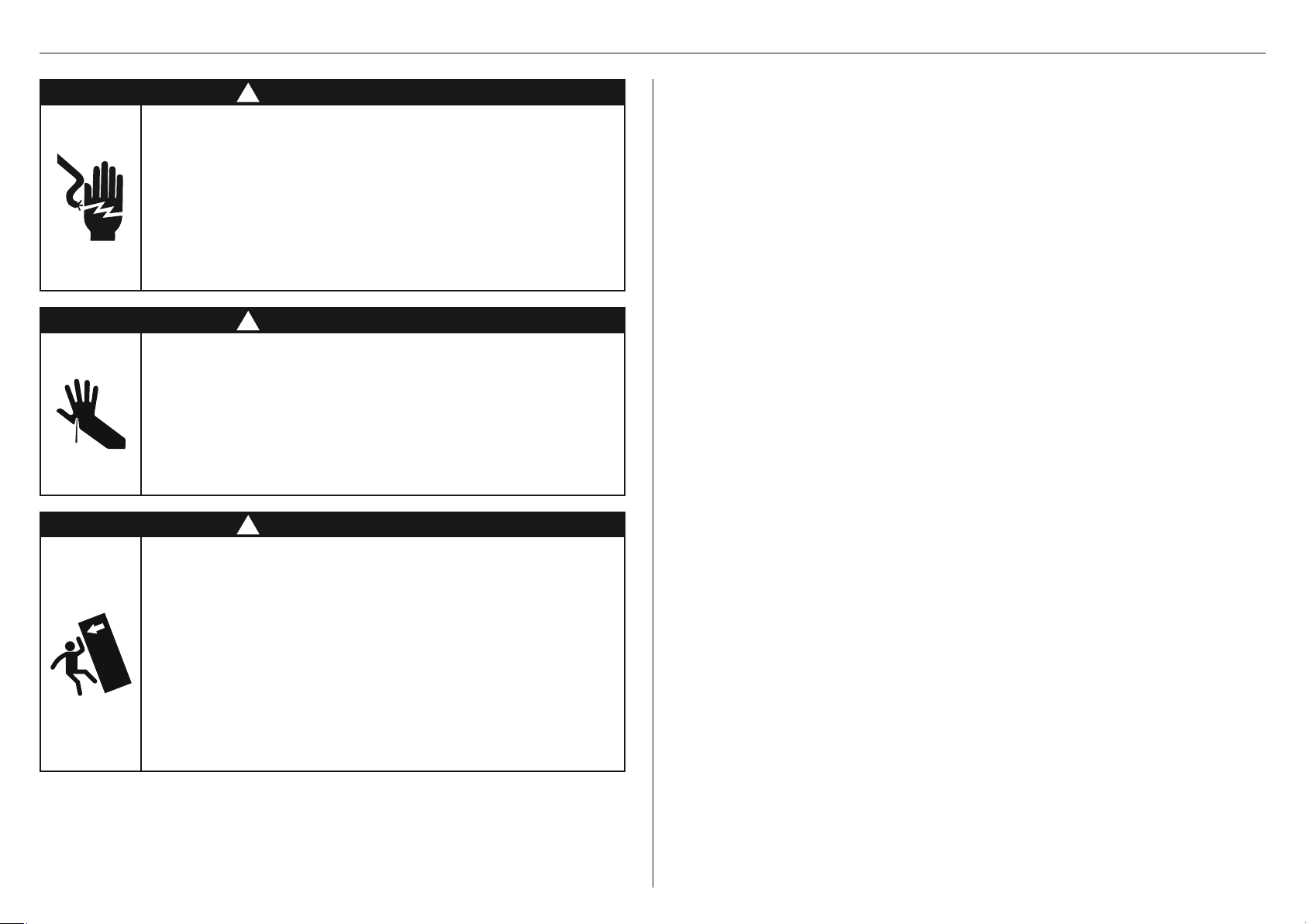

SAFETY AND WARNINGS

!

WARNING!

Electric Shock Hazard

Read and follow the safety and warnings

outlined in this installation guide before

operating this appliance.

Failure to do so can result in death, electric

shock, fire or injury topersons.

!

WARNING!

Cut Hazard

Take care—panel edges are sharp.

Failure to use caution could result in injury

or cuts.

!

WARNING!

This appliance is top-heavy and must

be secured to prevent the possibility of

tippingforward.

To ensure that the appliance is stable under

all loading conditions, theanti-tip bracket

and fittings supplied must be installed

according tothe following installation steps

by a professional installer.

WARNING!

To avoid hazard, follow these instructions carefully before installing or using thisappliance.

z

Please make this information available to the person installing the appliance.

z

Assume all electrical parts are live.

z

Disconnect power supply before servicing and installation.

BEFORE INSTALLATION

z

The appliance has front and rear rollers for moving the appliance forward and backward.

Do not move the appliance sideways to avoid damaging the rollers or the floor

covering/surface.

z

Ensure your appliance is not exposed to any heat generating appliance eg cooktop, oven

or dishwasher.

z

The appliance must be installed by a qualified installer, or Fisher & Paykel trained and

supported service technician to avoid faulty electrical and plumbing connections.

z

All connections for electrical power and earthing must comply with local codes and

ordinances and be made by licensed personnel when required.

z

Avoid installation of the appliance/s near a ground fault circuit interrupter (GFCI).

z

Ensure the appliance is installed properly. Improper installation that results in appliance

failure is not covered under the appliance warranty.

UNPACKING

z

The appliance is heavy and requires at least twopersons to move and install.

z

Remove the installation kit (internal box) and trims kit (external box) while the product is

still on the pallet.

z

Avoid scratching the surface of your appliance when moving or installing.

z

Keep the appliance stable and door closed to prevent tipping over when moving to the

installation location.

z

Ensure the feet of the appliance are retracted before moving to the installation location.

z

If the appliance is damaged, contact your Fisher & Paykel dealer.

z

Ensure all components and accessories are complete. Refer to 'Before installation' page.

z

Record the default Wifi password, and the model and registration numbers for future

servicing or repair of your appliance.

ELECTRICAL/PLUMBING

z

Electrical and water supply connections for these appliances must be located in an

adjacent area or unit (cabinet or cupboard) that are easily accessible in case of repair or

disconnection.

z

Ensure an isolating switch is available if electrical connection is not accessible.

INSTALLATION

Cavity preparation

z

The anti-tip bracket and fittings supplied must be fitted tothe wall of the finished

enclosure to withstand a 225lb/100kg load.

z

Ensure that the anti-tip bracket is installed correctly to prevent the possibility of the

appliance tipping forward when the door is open.

4

Page 5

SAFETY AND WARNINGS

Positioning inside the cabinetry

z

Ensure the door of the appliance is closed when rolling into thecabinetry.

z

Ensure the power cord is not run over or damaged when rolling the product into

the cabinetry.

Aligning inside the cabinetry

z

For flush installation, ensure the door panels are installed flush with cabinetry front surface.

Ensure the appliance is properly is centred.

z

All four corners of the appliance must be supported firmly on the floor to eliminate any

movement. Installing the appliance on a soft, uneven, or not level floor may cause twisting

and poor door sealing.

Fixing inside the cabinetry

z

Use low speed, low torque setting when using a powered driver for the screws when fixing

or aligning the product.

z

Make sure to remove the depth alignment brackets before fixing theappliance inside the

cabinetry.

z

Open the appliance door to remove the alignment brackets from both sides of the

appliance, and then re-tighten the screws.

Installing the door panel

Stainless steel panel

z

Protect the finish of the Fisher & Paykel Stainless Steel door panels from any scratch

or damage.

z

Remove the blue tape attached to inner edges of the door panels after the handles are

installed.

z

We recommend to load the shelves in the appliance door with weights to ensure an

accurate door panel gap width.

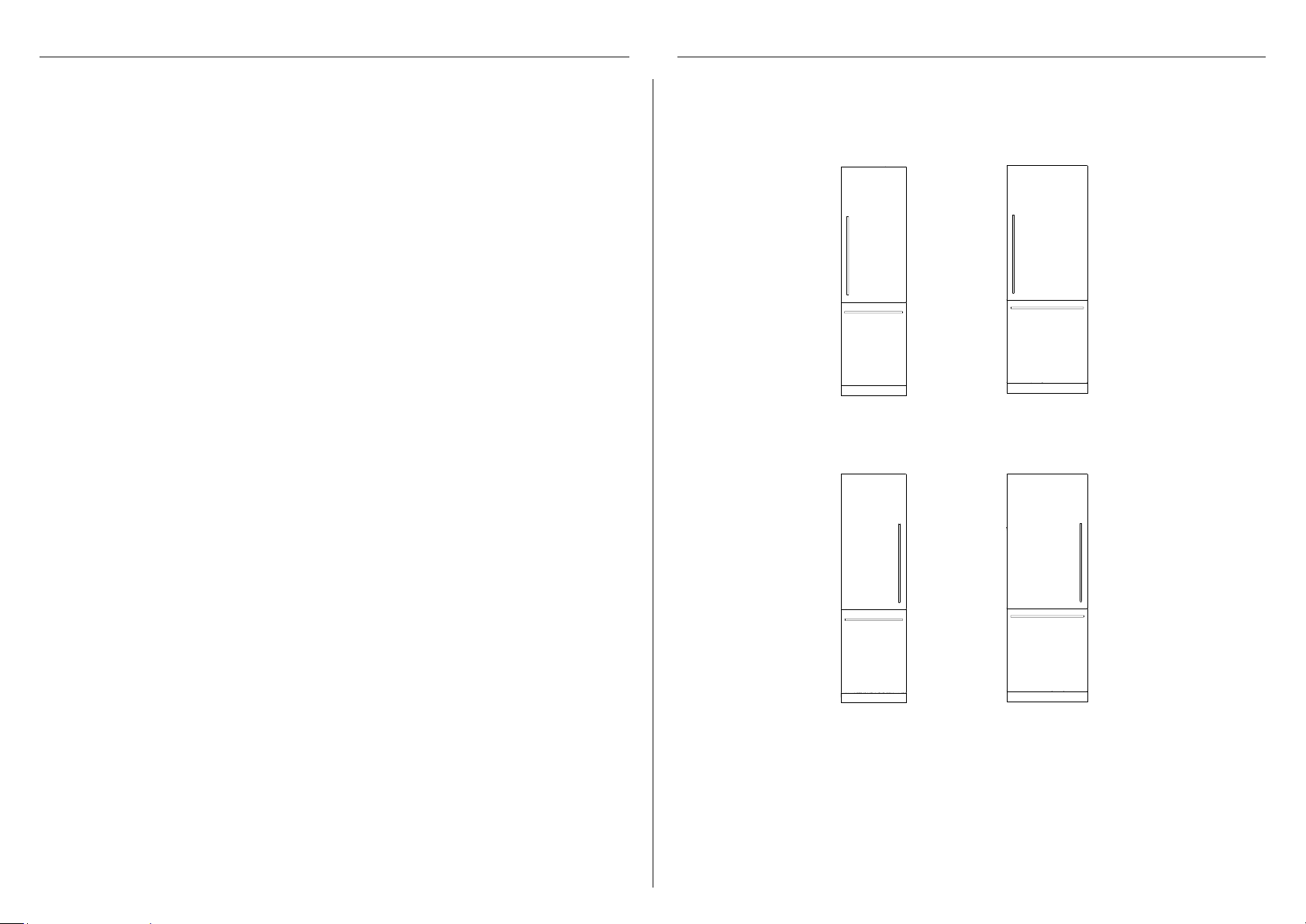

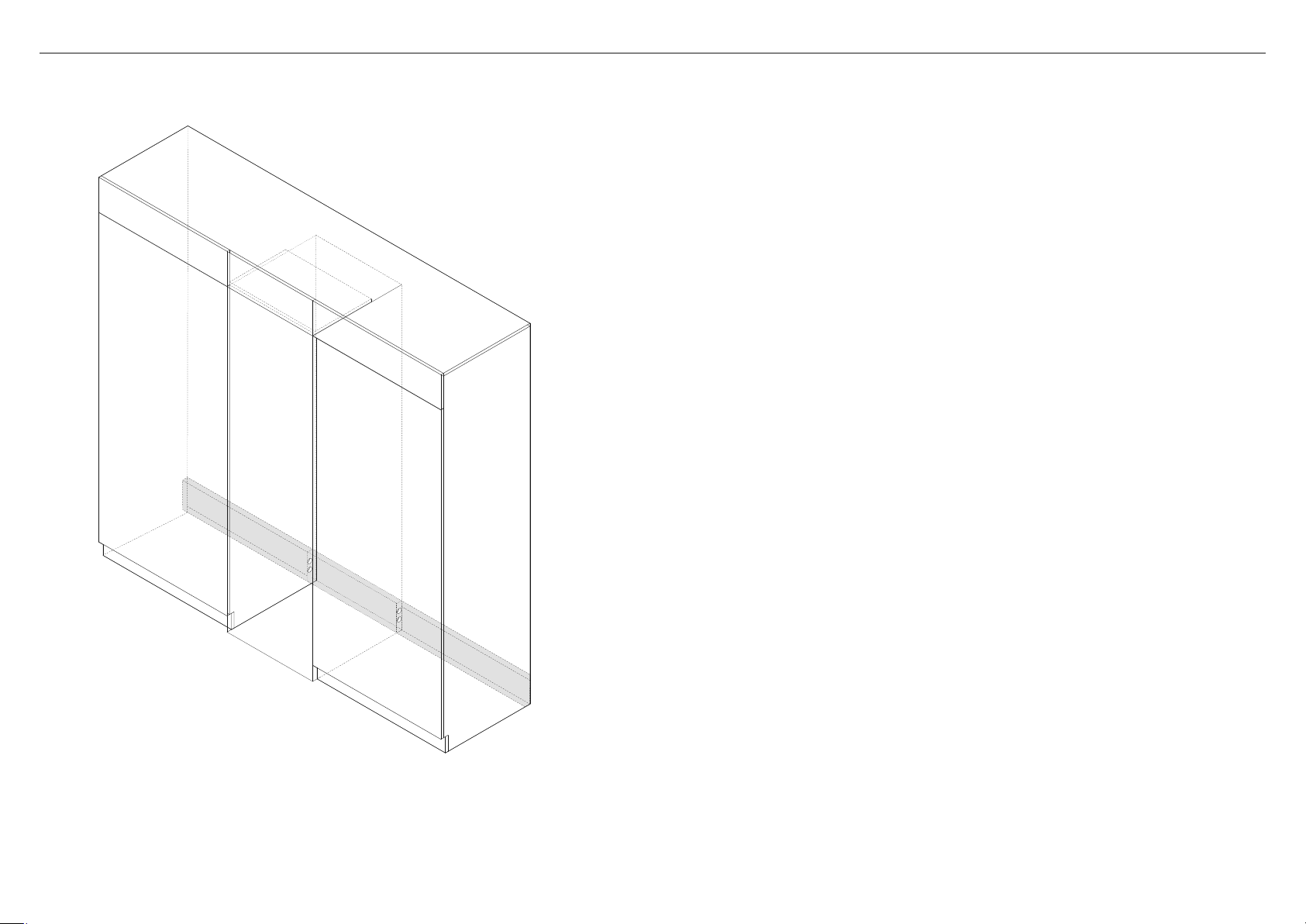

INTEGRATED COLUMNS — REFRIGERATOR–FREEZER

24” (610mm) 30” (762mm)

RS2484WR

RS3084WR

Custom panel

z

If using Custom door panels, ensure they are prepared as per 'Custom door panel install

dimensions' section.

z

The thickness of the custom door panel can vary as long as the screws do not penetrate

beyond the full depth of the door panel, and as long as the overall weight of the panel

does not exceed 55lb/25kg.

z

Do not place the handle holes in marked areas to avoid clashing with panel

attachment brackets.

z

Minimum panel thickness where screw hole is drilled must be 16mm.

Switching the door hinge (optional)

z

Door hinges are interchangeable for each model. A hinge change kit is available and can be

purchased separately if you prefer to change from ‘right hand hinge’ to ‘left hand hinge’ or

vice versa.

RS2484WL

RS3084WL

5

Page 6

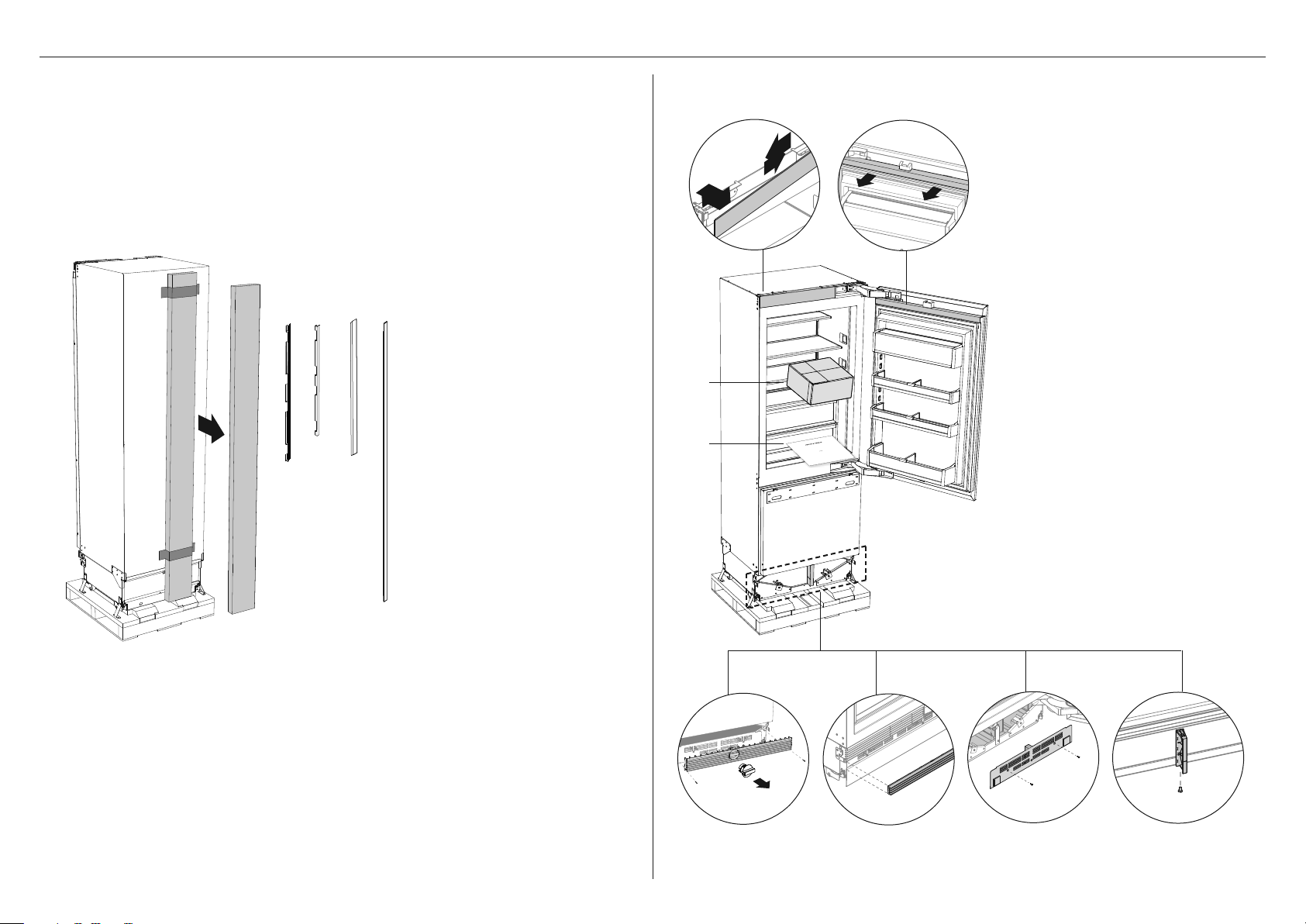

CHECK YOUR APPLIANCE

z

Ensure you follow the unpacking steps printed on the packaging box of your appliance.

z

Check that your appliance is the correct model as per your order.

z

Check that the components and install kits are complete.

A

B

1

2

34

Remove external box (trims kit)

from the back of the appliance.

The box contains:

1 Top door panel side extrusion

2 Bottom drawer panel

side extrusion

3 Bottom drawer top trim

4 Cabinet side trim

C

D

Remove installation kit, miscellaneous

items pack and pre-installed parts.

Keep all components to use later.

A Top trim

B Top door extrusion

C Installation kit

D Miscellaneous items pack and

water filter kit

E Top grille and water filter tool

F Bottom grille

INTEGRATED

CO

LUMNS

RS46

2

1F

,

RS6121F

R

S

612

,

R

1S & RS7

S76

2

1F

,

621S mod

els

INS

T

A

LL

A

TI

O

N

GUIDE

N

Z

AU

G

B

E

U

8

4

9

1

6

4

B

10

.

18

G Toe kick mounting plate

H Air flow divider

e hg

f

6

Page 7

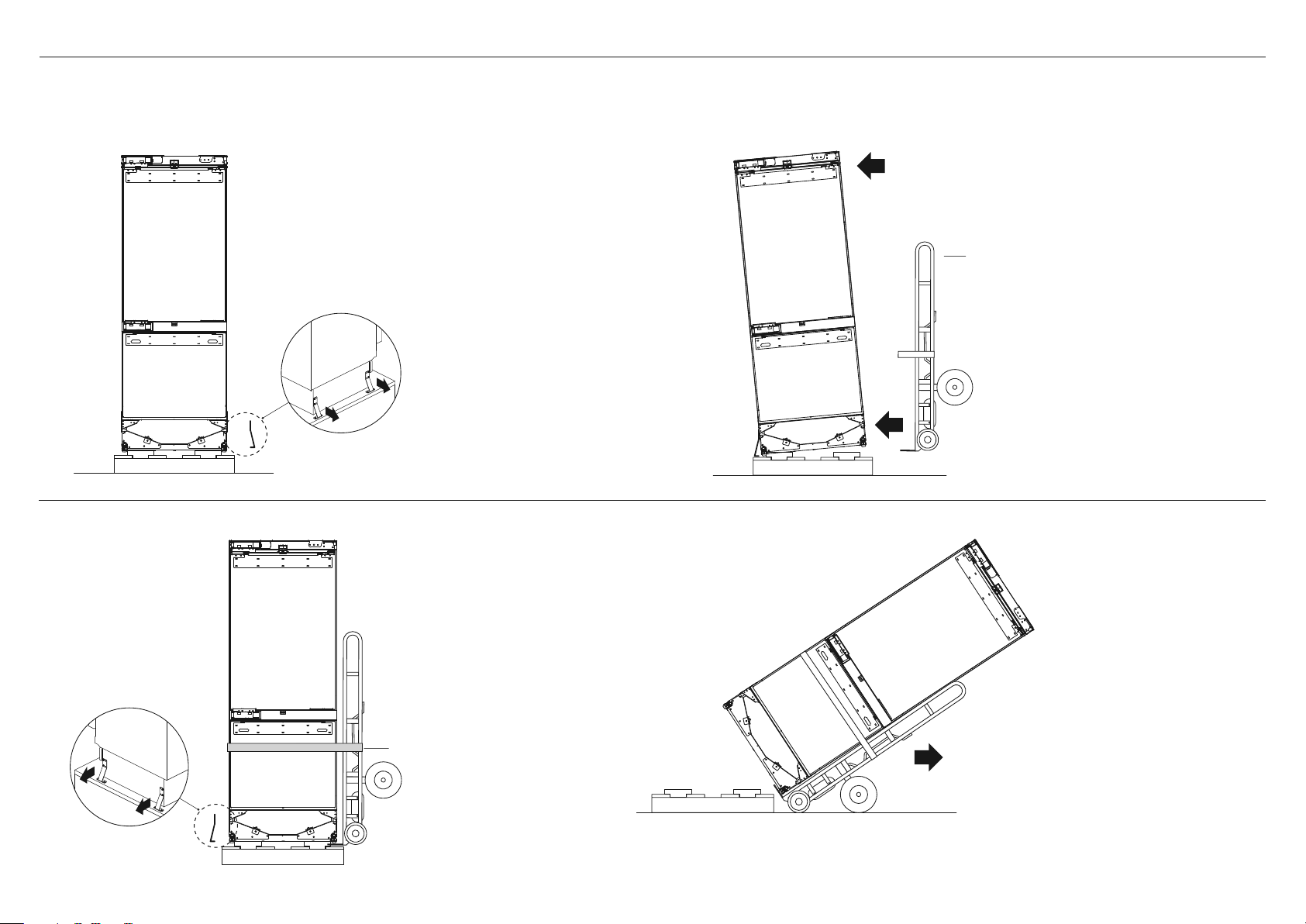

z

Follow the steps below to move your appliance to the install location.

z

Be careful when tilting the appliance forward/backward.

z

Tape the door shut to prevent opening while moving the appliance.

1 Remove the brackets from the

non-hinge side of the pallet.

MOVING YOUR APPLIANCE

Hand truck

2 Tilt the appliance slightly

forward and insert the

hand truck between

pallet and appliance.

3 Restrain the appliance

with strap and remove the

remaining brackets.

Strap

4 Tilt backward to load appliance

onto hand truck and push to

install location

7

Page 8

BEFORE INSTALLATION

Check the cabinetry

z

Check the dimensions of the cabinetry: height, width, depth, floor level, finished

alcove returns. Refer to 'Cavity Dimensions' for the correct measurements.

Check the power supply and water connections

z

Ensure that there is a separate power socket for each appliance.

z

Avoid sharing the power point with other appliances to prevent accidental switching off of

the appliance.

z

For power requirements, refer to the information on the serial plate.

z

Ensure your appliance is properly grounded (earthed).

z

Connect your appliance to an electrical supply with the fitted plug and lead.

z

If power connection is located behind the appliance, we recommend to install an isolating

switch to a location that is easily accessible to the user for repair or disconnection.

z

If water connection is behind the appliance, we recommend to connect the hose to exit at an

angle if there is not enough clearance between the cabinet wall and back of appliance.

z

Follow local codes and ordinances when installing the appliance.

8

Page 9

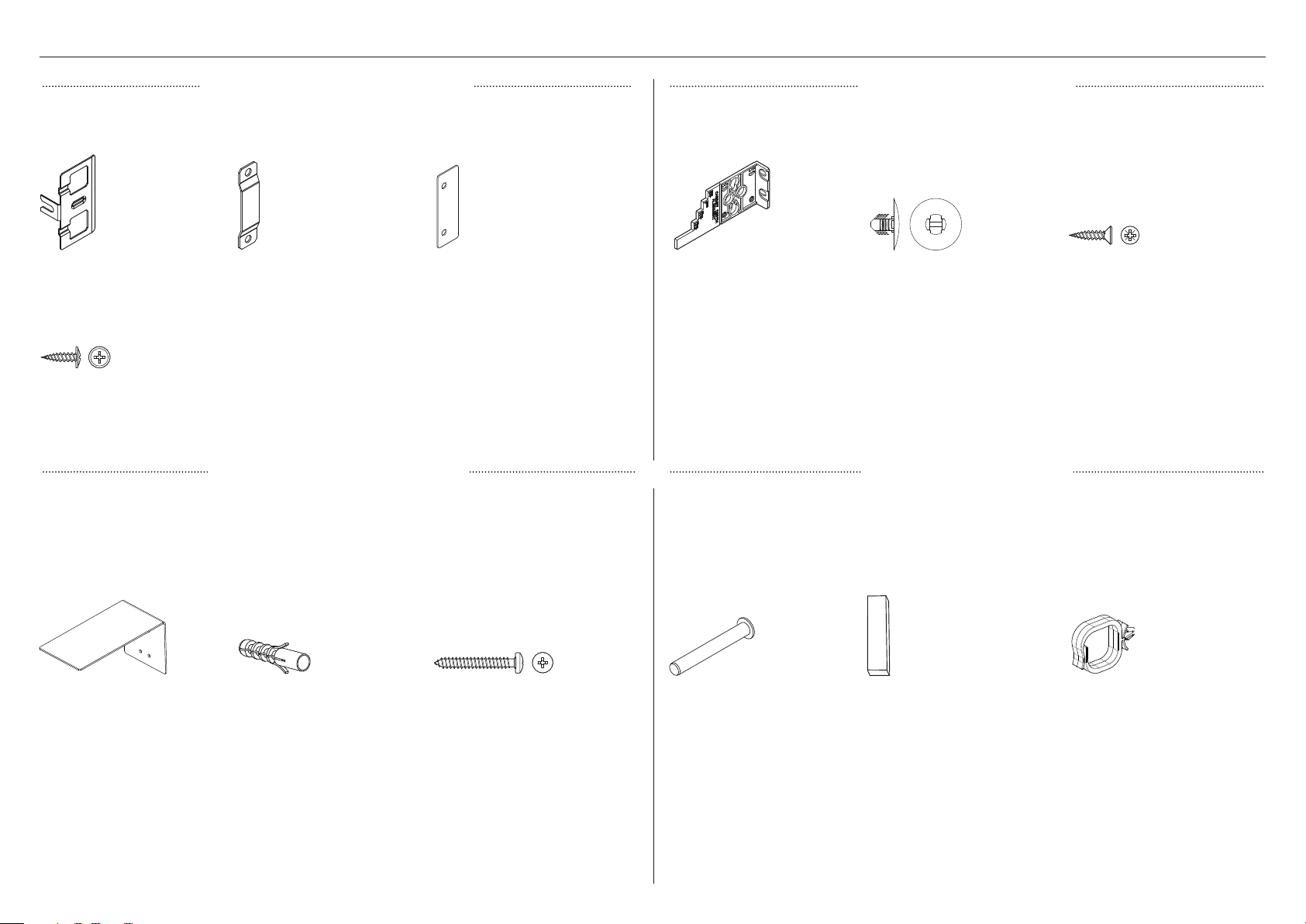

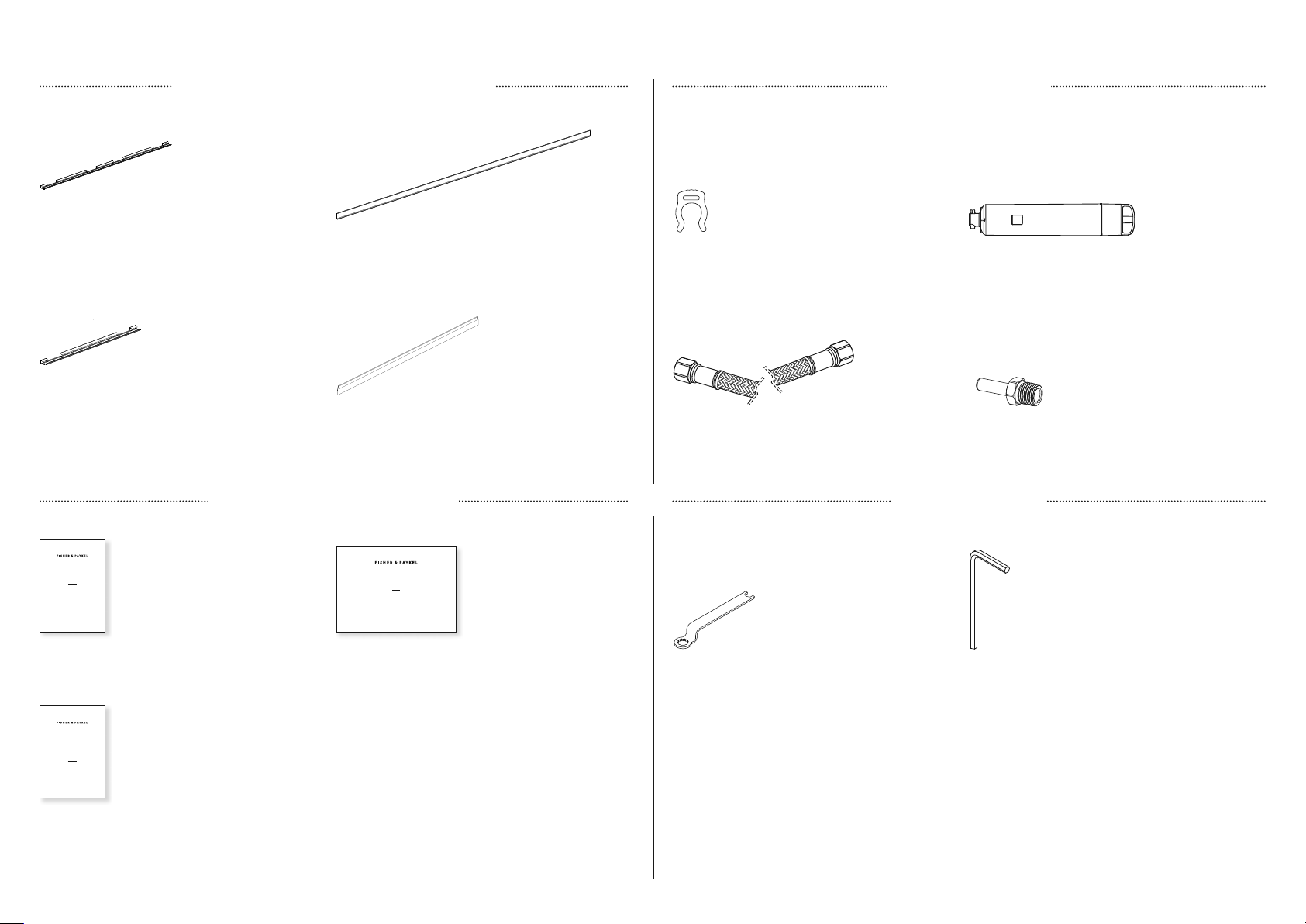

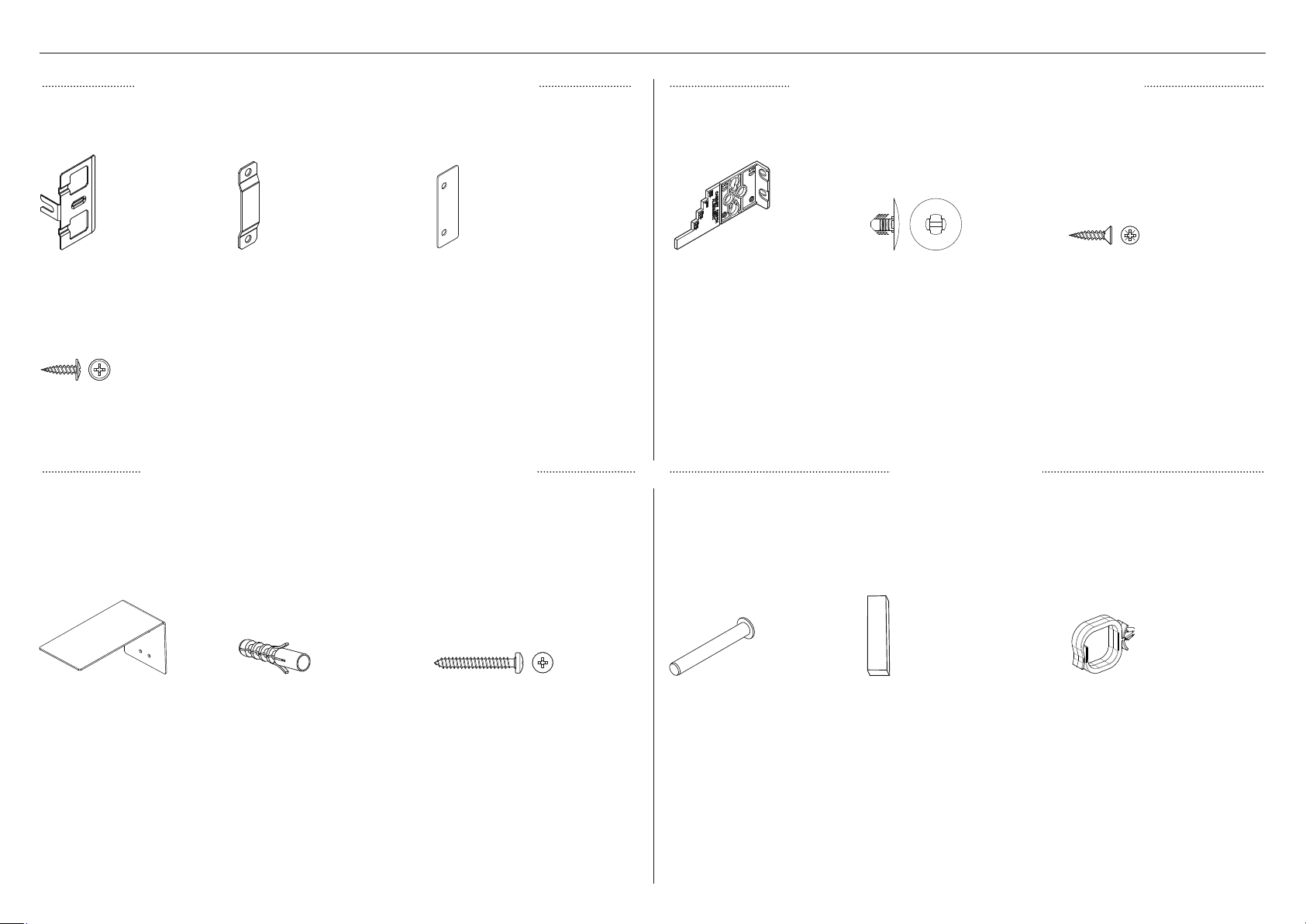

SUPPLIED PARTS

DOOR PANEL ATTACHMENT KIT INSTALL FASTENERS KIT

Side bracket

(6)

For Custom door panels:

M5x12 Cross-head screw (32)

Anti-tip bracket

(1)

Bracket slider

(6)

Side spacer bracket

(6)

ANTI-TIP BRACKET ASSEMBLY

Masonry plug

(4)

10-12x35mm crosshead screw

(5)

Depth alignment gauge

(4)

Supplied in separate bags

Hinge limiting pin

(3)

Barbed plug

(2)

MISCELLANEOUS PARTS

Air toe kick seal

(1)

8Gx16 Countersunk screw

(7)

Locking clip

(2)

9

Page 10

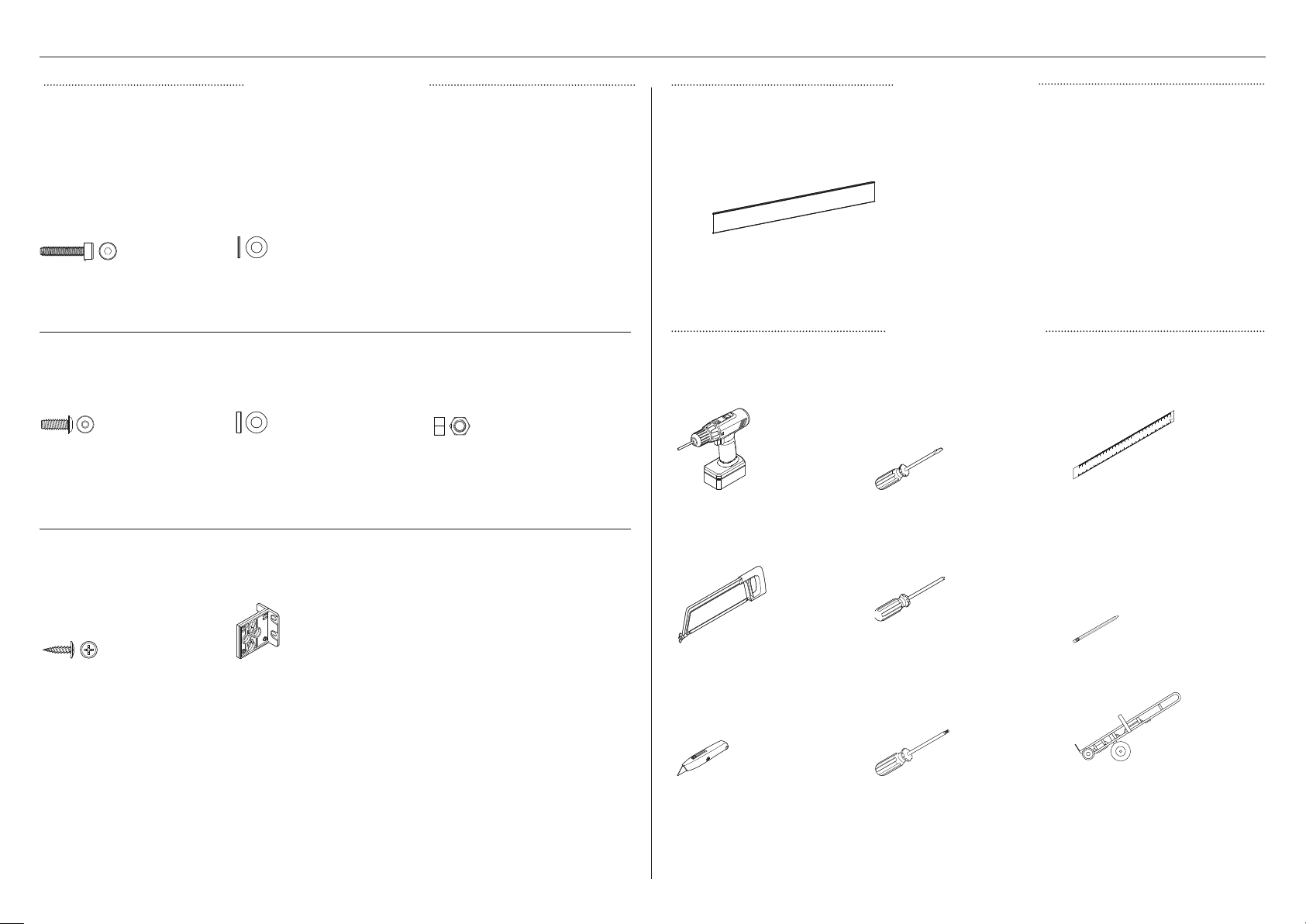

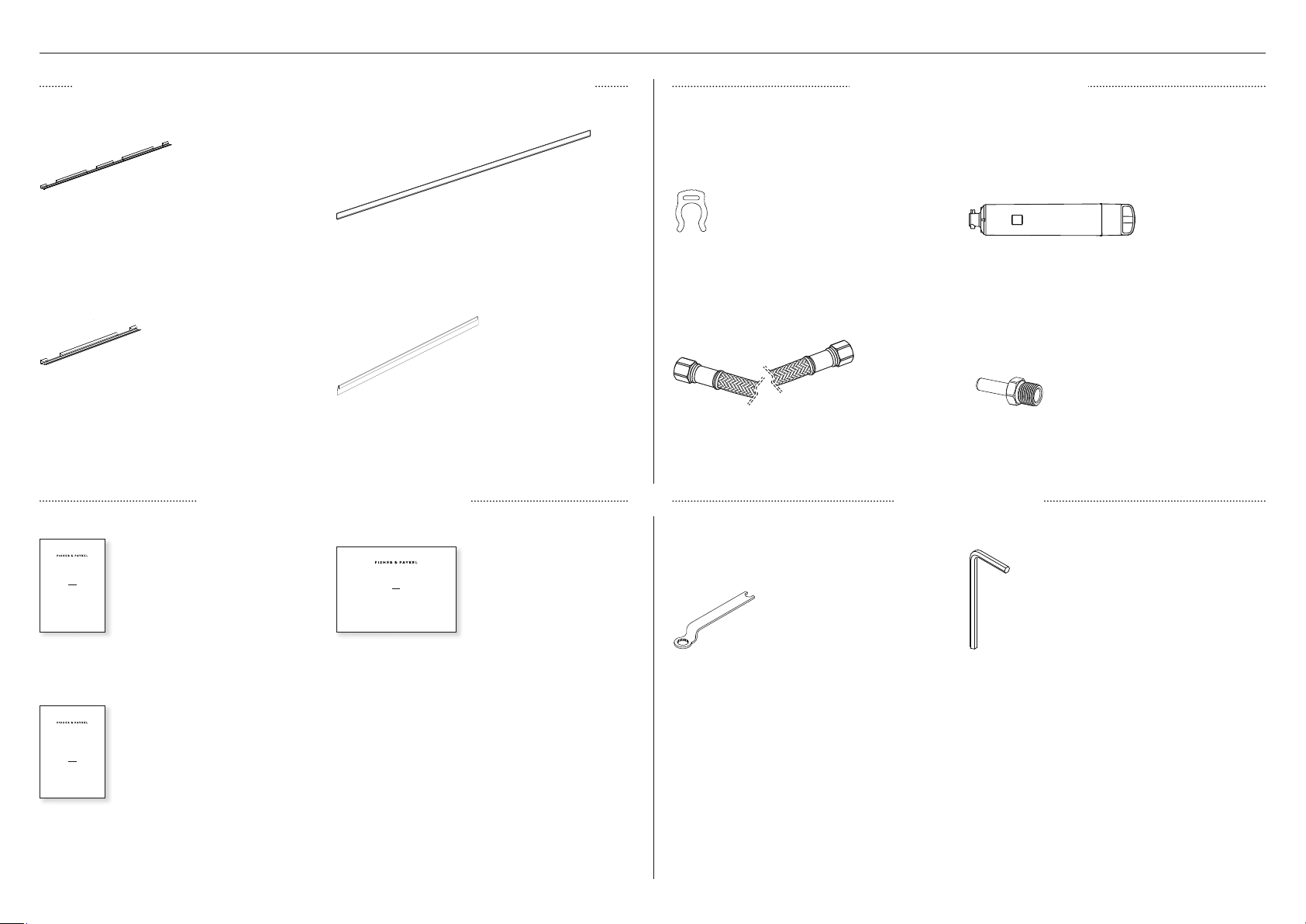

SUPPLIED PARTS

TRIMS INSTALL KIT (EXTERNAL BOX)

Top door panel side extrusion

(2)

Bottom drawer panel side

extrusion (2)

Cabinet side trim

(2)

Bottom drawer top trim

(1)

MISCELLANEOUS ITEM PACK

WATER FILTER KIT

Collet locking clip

(1)

7/16" (11mm) UNS Stainless steel braided hose

(1)

SUPPLIED TOOLS

Water filter

(1)

1/4” (6.35mm) Adaptor

(2)

INTEGRATED COLUMN

WINE CABINET

RS2484VL2K1, RS2484VR2K1,

RS6121VL2K1, RS6121VR2K1

models

USER GUIDE

US CA NZ AU GB IE SG HK

8602A09.19

User guide

(6)

SERVICE & WARRANTY

SERVICE ET GARANTIE

ΣΈΡΒΙΣ ΚΑΙ ΕΓΓΎΗΣΗ

SERVIZIO E GARANZIA

SERVICE & GARANTIE

HUOLTO JA TAKUU

SERVICE OG GARANTI

保修和维修

݉ଡ଼ڸߴঔ

Service & Warranty

(1)

10

INTEGRATED COLUMNS

WINE CABINET

RS2484VL2K1, RS2484VR2K1,

RS6121VL2K1, RS6121VR2K1

models

INSTALLATION GUIDE

US CA NZ AU GB IE SG HK

86020A09.19

Installation guide

(1)

Door spanner

(1)

M4 Hex key

(1)

Page 11

REQUIRED PARTS

INSTALL JOINER KIT TOE KICK PANEL

Used for dual or multiple installation of appliances. Can be purchased separately through an

authorised Fisher & Paykel dealer. Visitfisherpaykel.com for more information.

Top joiner fastener kit

M5x20 Cap screw

(1)

Bottom joiner fastener kit

M6x16 Washer screw

(1)

M5x16x1 Plain washer

(1)

M6x12x3.2 Plastic washer

(1)

M6 Hex nut

(1)

TOE KICK PANEL

Not supplied and can be purchased separately through an authorised Fisher & Paykel dealer.

Visitfisherpaykel.com for more information.

z

Standard toe kick height is 102mm forstandard

stainless steel door panel.

z

For Custom door panel installation, atoe kick

2"–6" (50-152mm) must be fitted andadjusted

accordingly.

z

An extra bottom grille is required for 2" (50mm)

Toe kick panel (1)

toe kick installation. You can purchase the extra

bottom grille (Part No. 847542P) online at

fisherpaykel.com.

REQUIRED TOOLS

Not supplied and must be provided by the installer.

Powered driver Flathead screwdriver Ruler

Top joiner bracket kit

8Gx16 Mush washer screw

(2)

Central spacer

(1)

Hacksaw Cross-head screwdriver Pencil

Cutter T20 star-head screwdriver Hand truck

11

Page 12

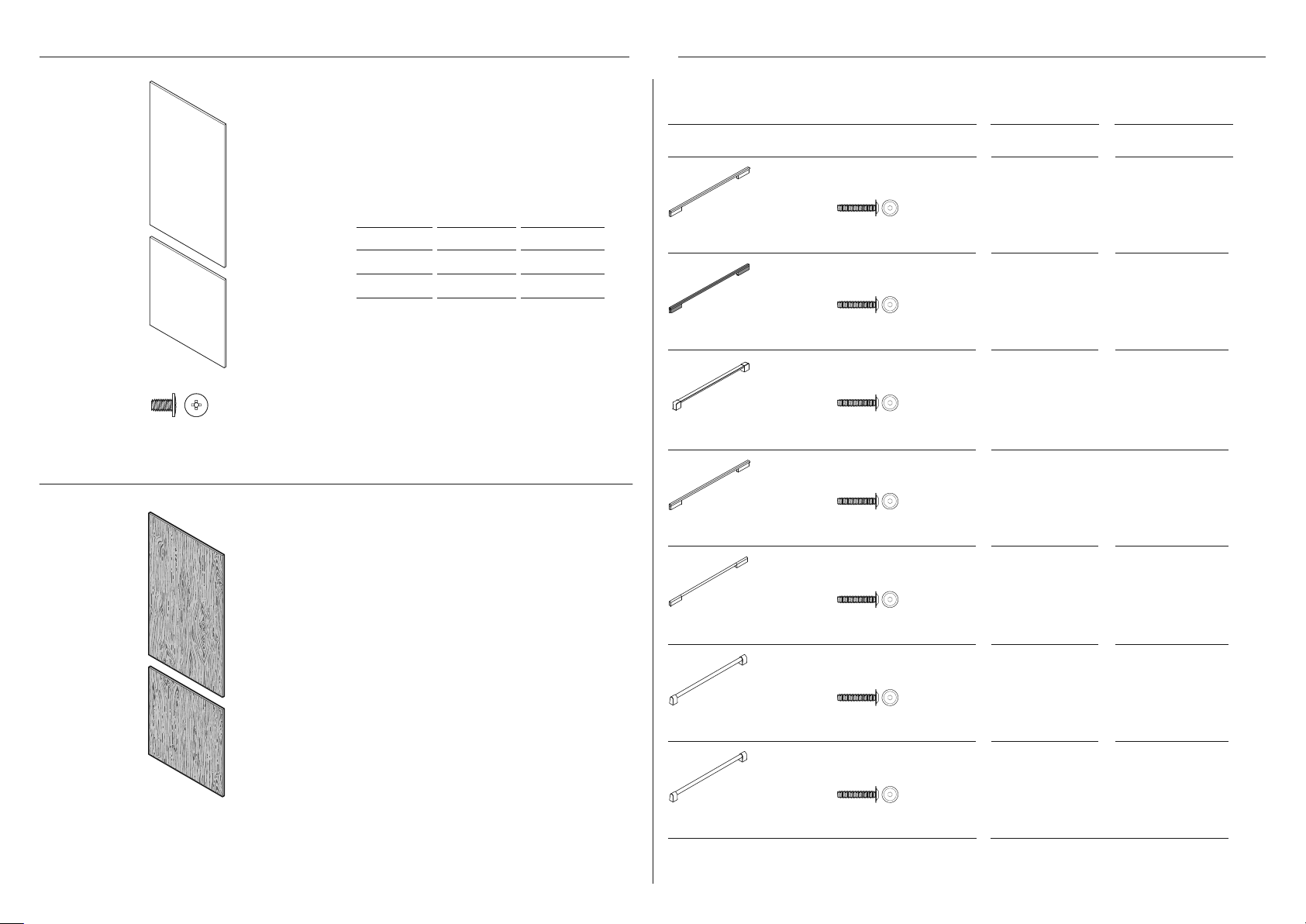

DOOR AND DRAWER HANDLE KITSDOOR PANEL SET

Not supplied and must be purchased separately through an authorised Fisher & Paykel dealer.

Visitfisherpaykel.com for more information. Select among the handle kit options below:

For SS door panels:

8Gx16 Mush washer screw (32)

Stainless steel door panel set

Not supplied and must be purchased

separately through an authorised Fisher

& Paykel dealer. Visitfisherpaykel.com for

more information..

MODEL RH LH

RS24 CA 25715 CA 25716

RS30 CA 25713 CA 25714

Custom door panel set

Supplied by customers to match their

cabinetry.

HANDLE KIT RS24 RS30

Square fine aluminum

handle (1)

Square fine black

handle (1)

Professional square

handle (1)

Square aluminum

handle (1)

Round aluminum

handle (1)

M5x25 Hex screw (4)

M5x25 Hex screw (4)

M5x25 Hex screw (4)

M5x25 Hex screw (4)

M5x25 Hex screw (4)

CA 25865 CA 25864

CA 25911 CA 25910

CA 25732 CA 25724

CA 25729 CA 25721

CA 25731 CA 25723

12

Professional round

handle (1)

Professional round

flush handle (1)

M5x25 Hex screw (4)

M5x25 Hex screw (4)

CA 25730 CA 25722

CA 25923 CA 25922

Page 13

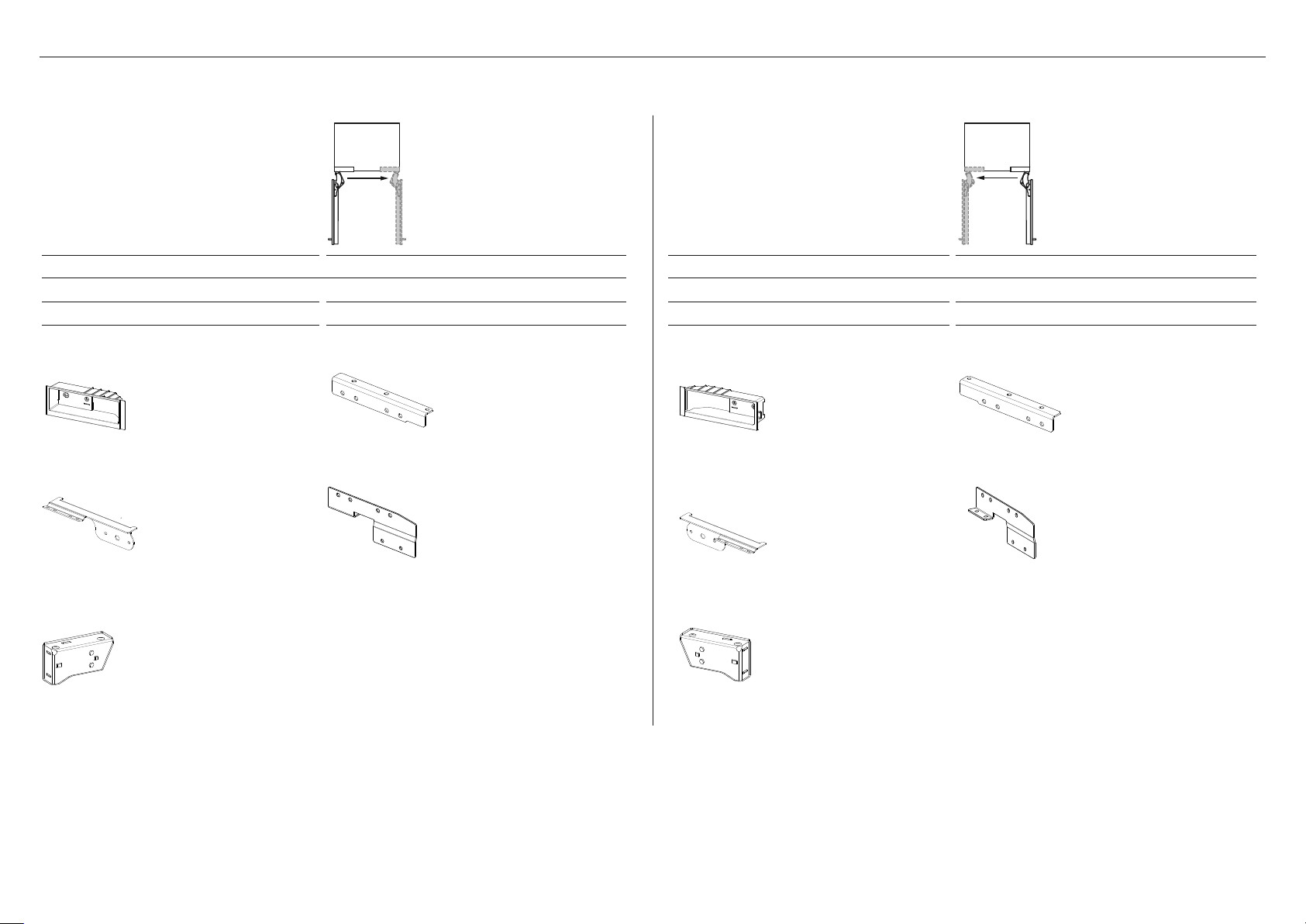

Not supplied and must be purchased separately. Available online at fisherpaykel.com.

HINGE CHANGE KIT

MODEL LEFT HINGE TO RIGHT HINGE KIT

RS24 CA 848184P

RS30 CA 848184P

Top hinge pocket RH

(2)

K05 bottom adaptor bracket RH

(1)

Top alcove bracket RH

(1)

Bottom hinge bracket RH

(1)

K05 top adaptor bracket RH

(1)

MODEL RIGHT HINGE TO LEFT HINGE KIT

RS24 CA 848183P

RS30 CA 848183P

Top hinge pocket LH

(2)

Top alcove bracket LH

(1)

Bottom hinge bracket LH

(1)

K05 bottom adaptor bracket LH

(1)

K05 top adaptor bracket LH

(1)

13

Page 14

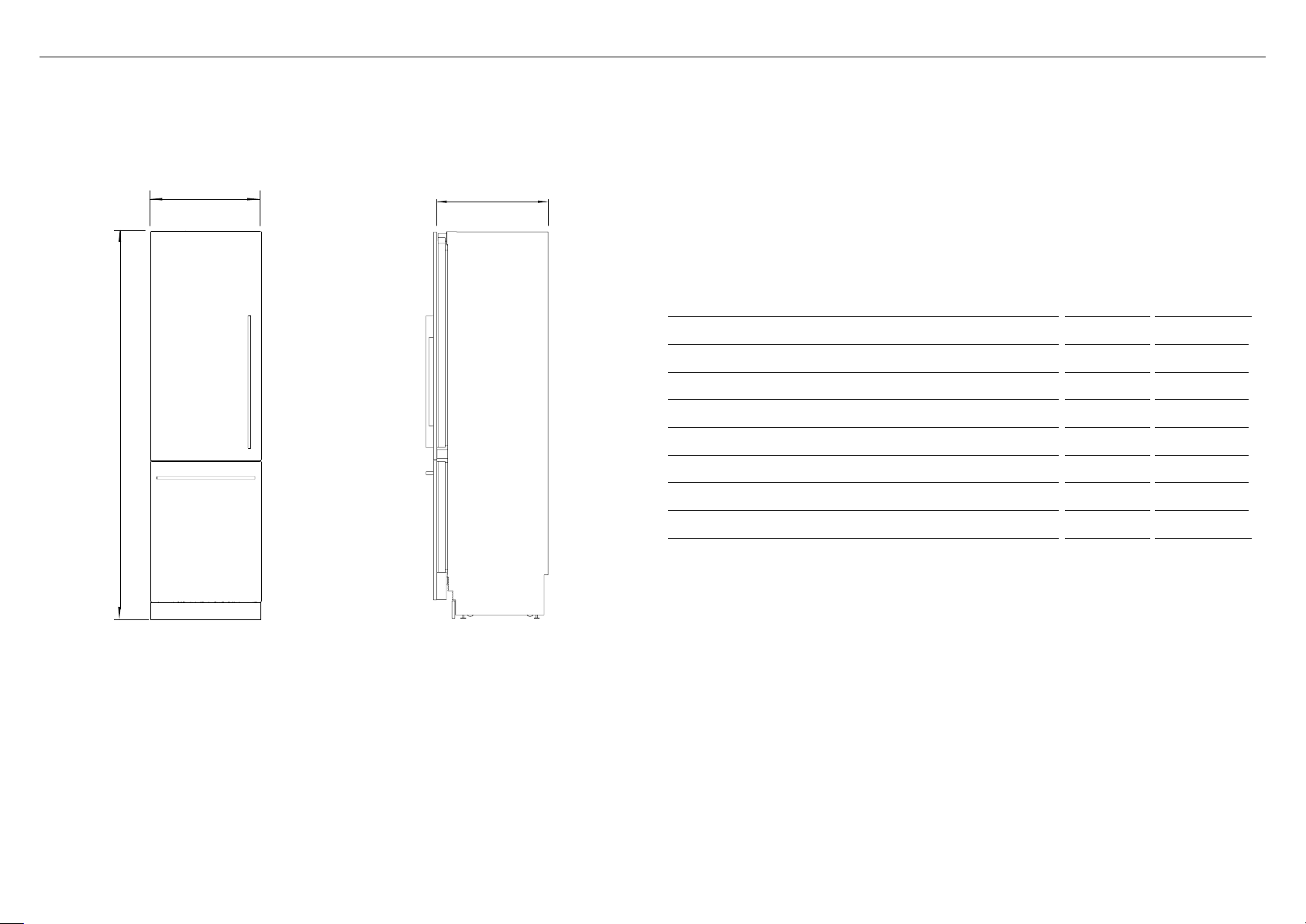

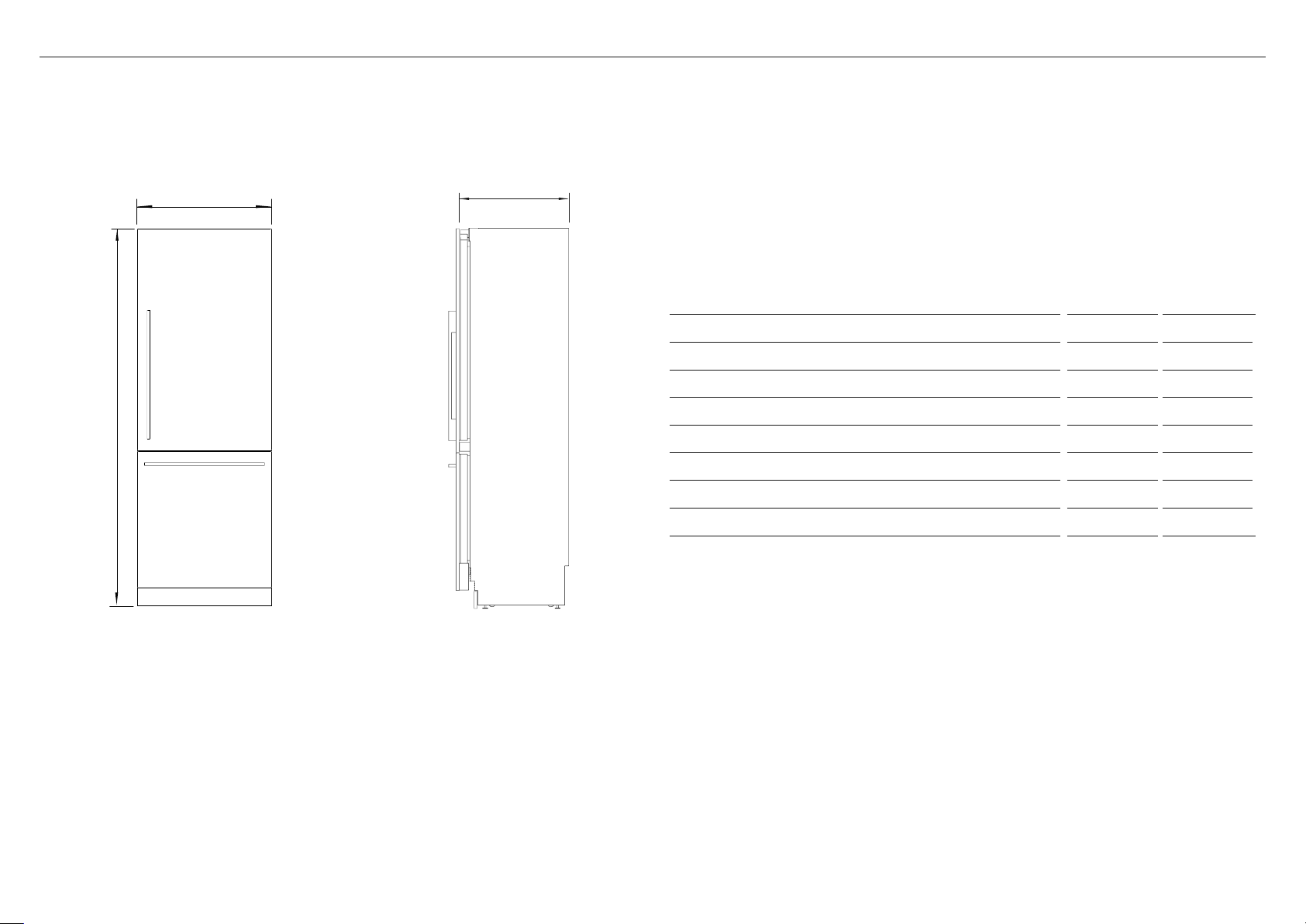

PRODUCT DIMENSIONS — RS24 MODEL

A

B

C

PRODUCT DIMENSIONS IN MM

A Overall height of product 84 2134

B Overall width of product 23 3/4 603

C Overall depth of product (excluding front door panel) 24 610

PRODUCT WEIGHT LBS KG

Weight (with packaging) 357 162

Weight (without packaging) 313 142

14

FRONT VIEW

PROFILE VIEW

Page 15

CAVITY DIMENSIONS — RS24 MODEL

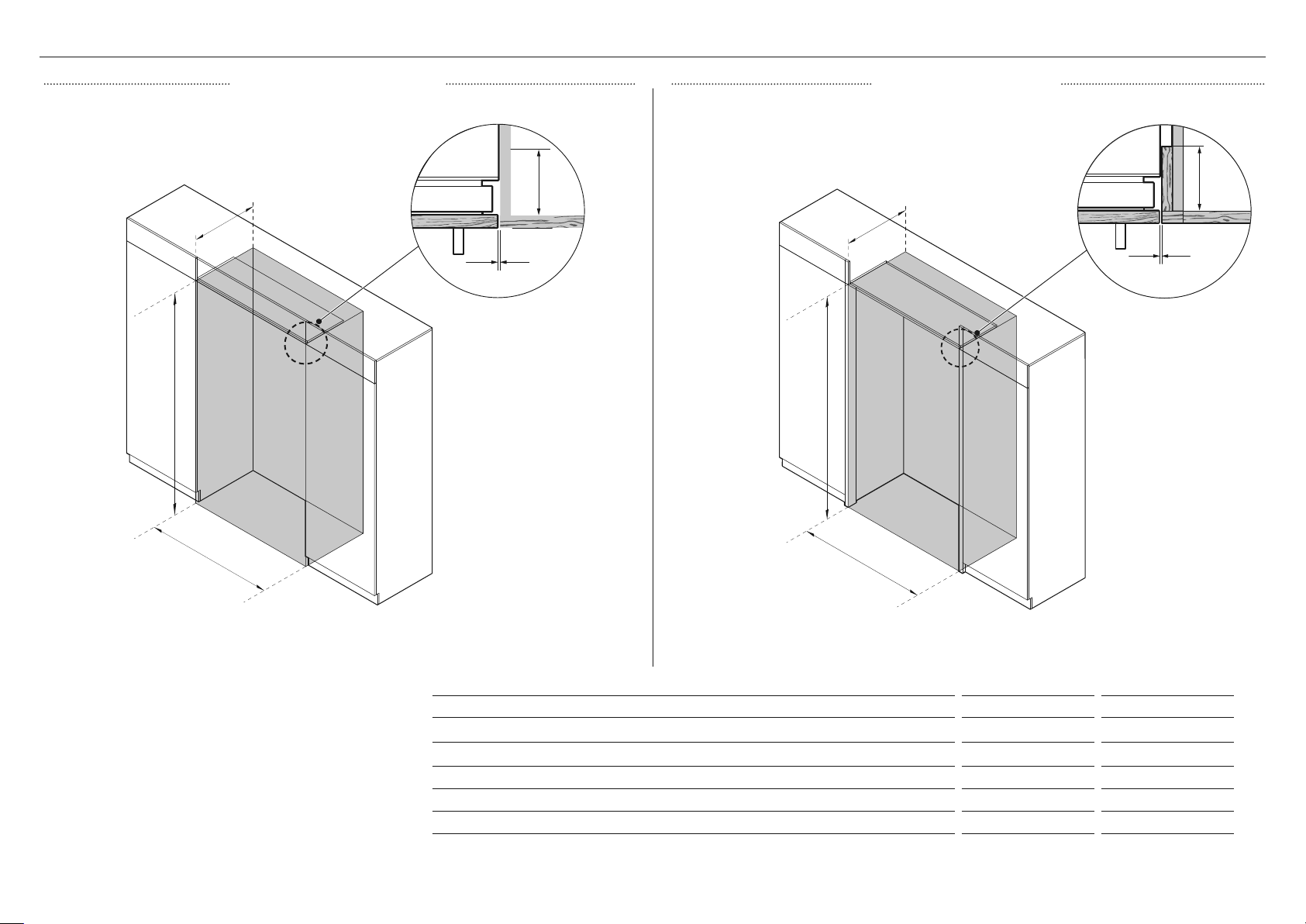

FRAMELESS CABINETRY FRAMED CABINETRY

Aligns appliance flush with the cabinetry.

C

A

D

B

A

E

Aligns appliance flush with the frame of cabinetry.

E

C

D

A

B

B

DIMENSIONS IN MM

A Overall height of cavity

B Overall width of cavity

C Minimum overall depth of cavity* 25 635

D Minimum cabinetry gap clearance from edge of door panels 1/8” 3

E Minimum required finished return 4” 102

* Assumes a door panel thickness of 3/4” (19mm).

84 2134

24 610

15

Page 16

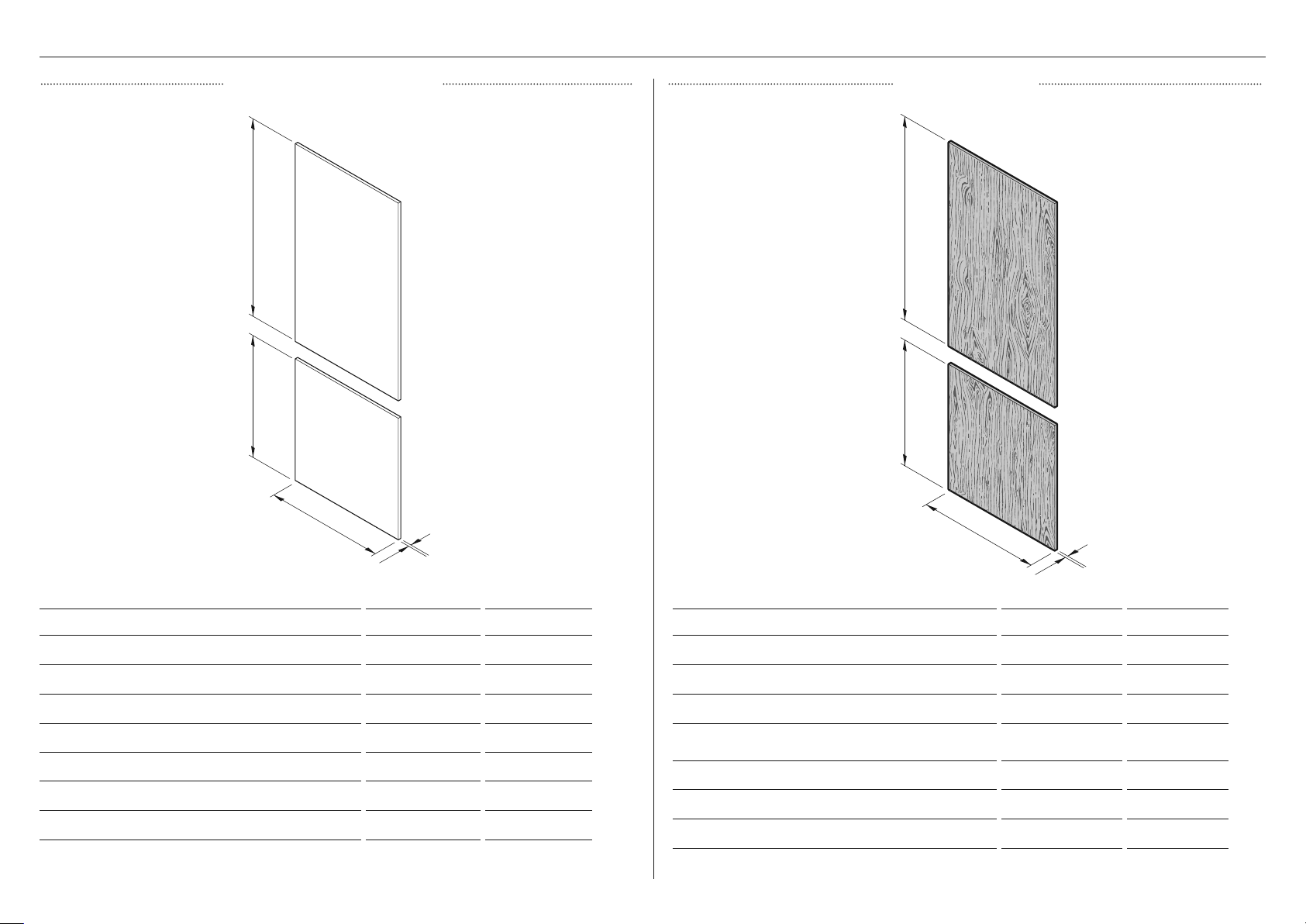

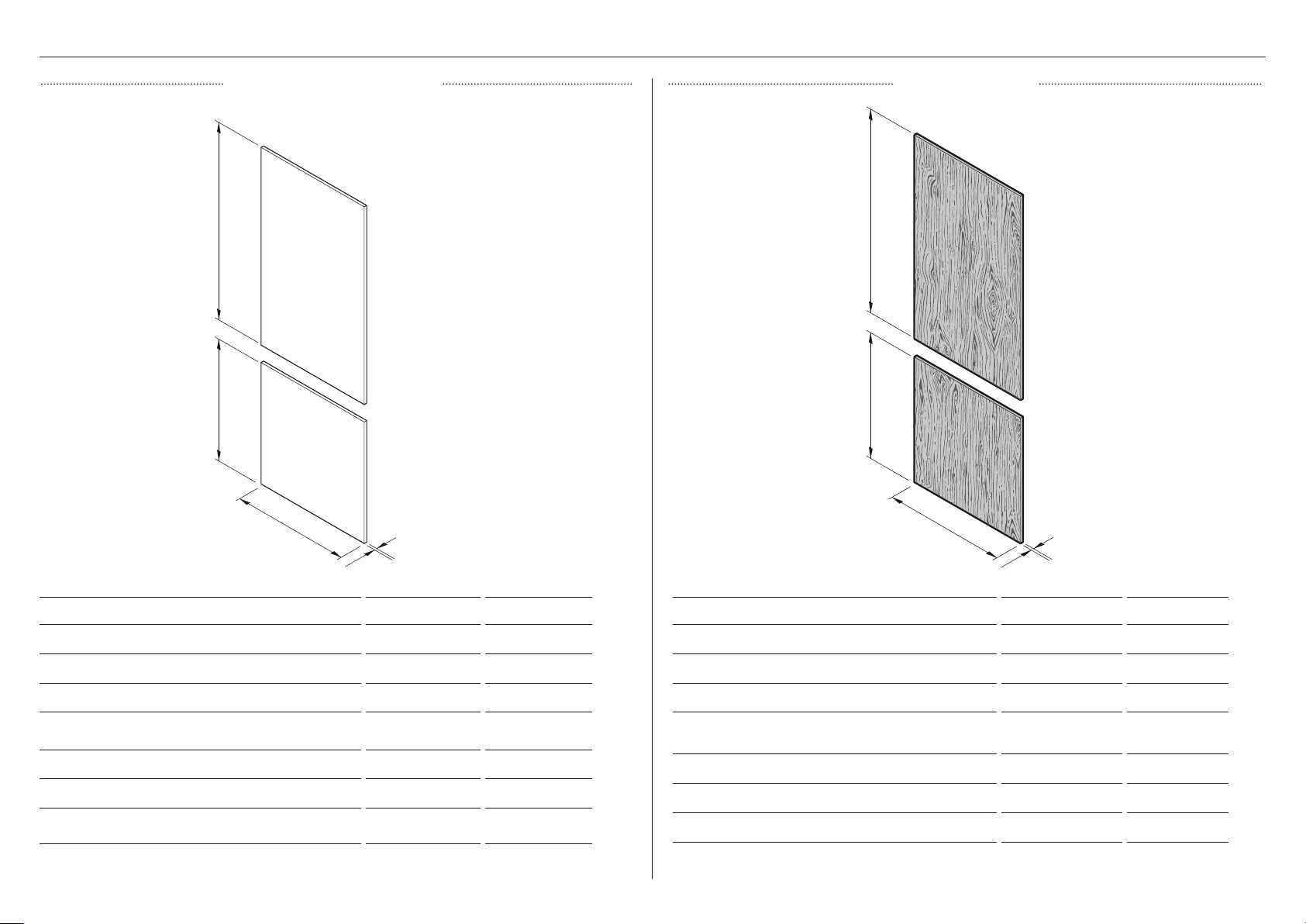

DOOR PANEL DIMENSIONS — RS24 MODEL

STAINLESS STEEL PANEL CUSTOM PANEL

A

B

C

DIMENSIONS IN MM

A Height of top door panel 49 3/8 1254

A

B

C

DIMENSIONS IN MM

A Height of top door panel 49 3/8 1254

B Height of bottom drawer panel 30 3/8 772

C Width of door/drawer panel 23 3/4 603

D Depth of door panel (excluding door handle) 3/4 19

DOOR PANEL WEIGHT LBS KG

Weight of top door panel* 20 9

Weight of bottom drawer panel* 13 6

16

B Height of bottom drawer panel 30 3/8 772

C Width of door/drawer panel 23 3/4 603

D Depth of door panel (excluding door handle)

DOOR PANEL WEIGHT LBS KG

Weight of top door panel max 34 max 15 1/2

Weight of bottom drawer panel max 21 max 9 1/2

* Maximum panel weight must not be exceeded.

min 5/8

max 1

min 16

max 25

Page 17

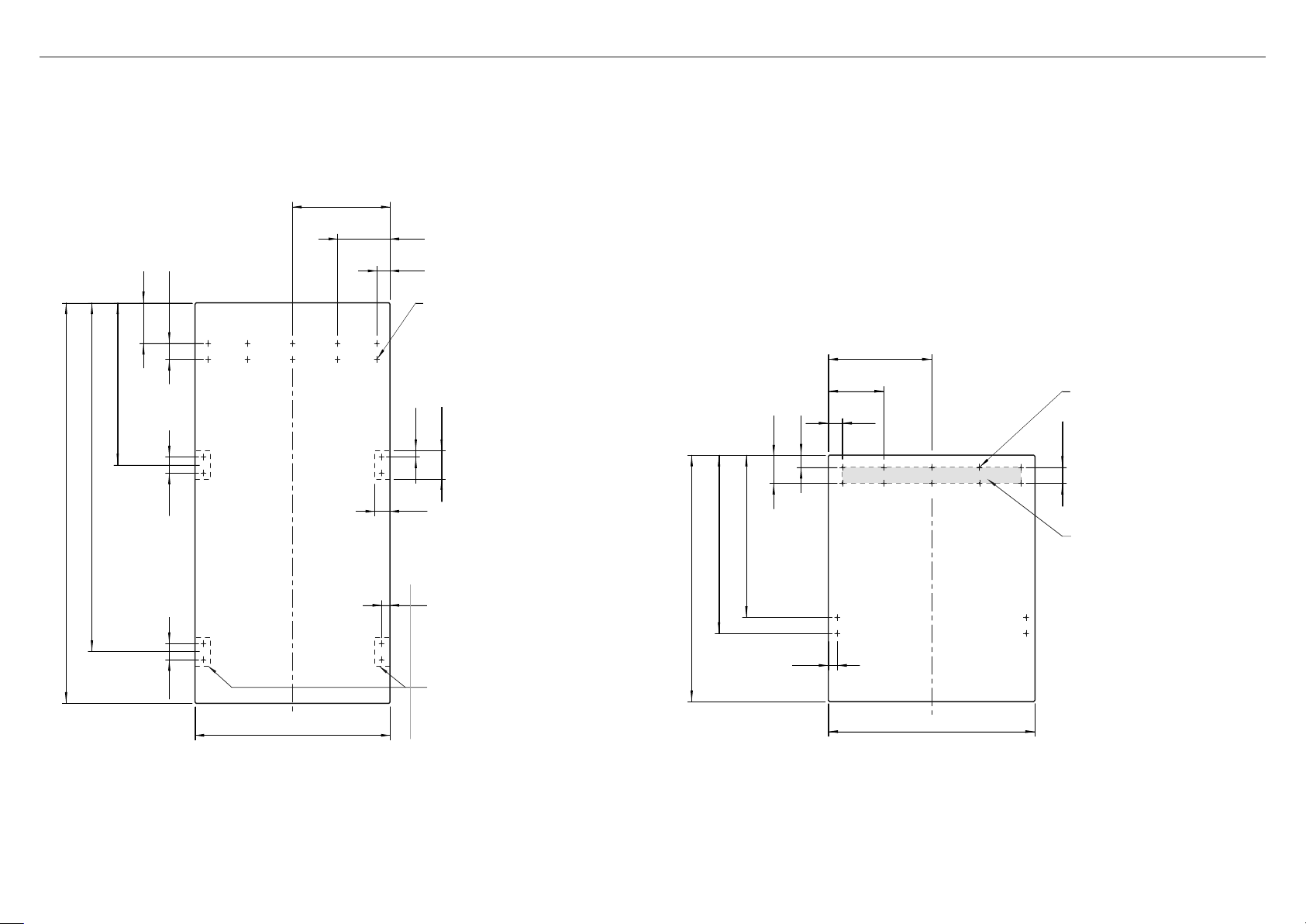

CUSTOM DOOR PANEL INSTALL DIMENSIONS — RS24 MODEL

Dimensions apply for the preparation and installation of Custom door panels. For Dwg and Dxf files of the below panel preparation download the folder on thekitchentools.fisherpaykel.com.

z

The thickness of the custom door panel can vary provided that the screws do not penetrate beyond the full depth of the door panel.

z

Measurements of screw hole locations can vary depending on the height of toe kick 50–152mm.

11 7/8" (301.6mm)

8" (203.2mm)

2" (50.8mm)

1/2" (38.m)

15" (127mm)

20" (507.8mm)

2" (50mm)2" (50mm)

Ø2mm REF

10x Pilot holes recommended

for bracket attachment.

(Do not penetrate front surface).

2" (50mm)

1 1/2" (38.1m)

3 1/2" (88mm)

11 7/8" (301.6mm)

8" (203.2mm)

2" (50.8mm)

Ø2mm REF

10x Pilot holes recommended

for bracket attachment.

(Do not penetrate front surface).

2" (50mm)

43" (1092mm)

49 3/8" (1254mm)

23 3/4" (603.2mm)

TOP PANEL—REAR VIEW

Ensure handle is mounted

2 9/16" (65mm) from edge

to center of panel — this will

avoid interference with bracket.

1 1/4" (32.6mm)

30 3/8" (771.5mm)

20" (508.4mm)

23 3/16" (588.4mm)

1 1/4" (32.6mm)

Cutouts in the hanging bracket

are applicable for Fisher &

Paykel handles only.

Iflocating a custom handle in

the shaded area shown above,

ensure handle screw headsare

countersunk into the back of the

door panel to avoid interference

with the hanging bracket.

29 3/4" (755.6mm)

BOTTOM PANEL—REAR VIEW

17

Page 18

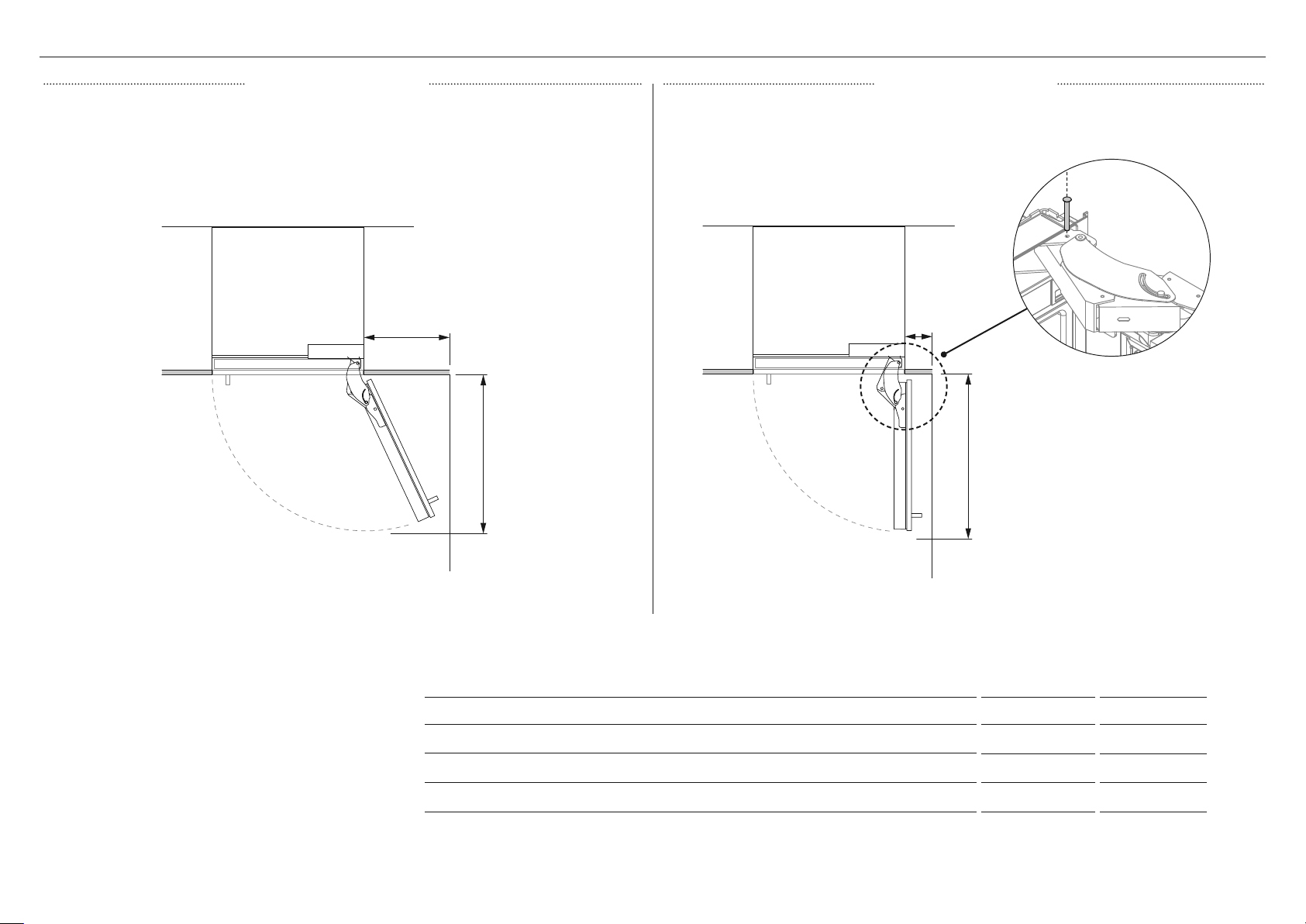

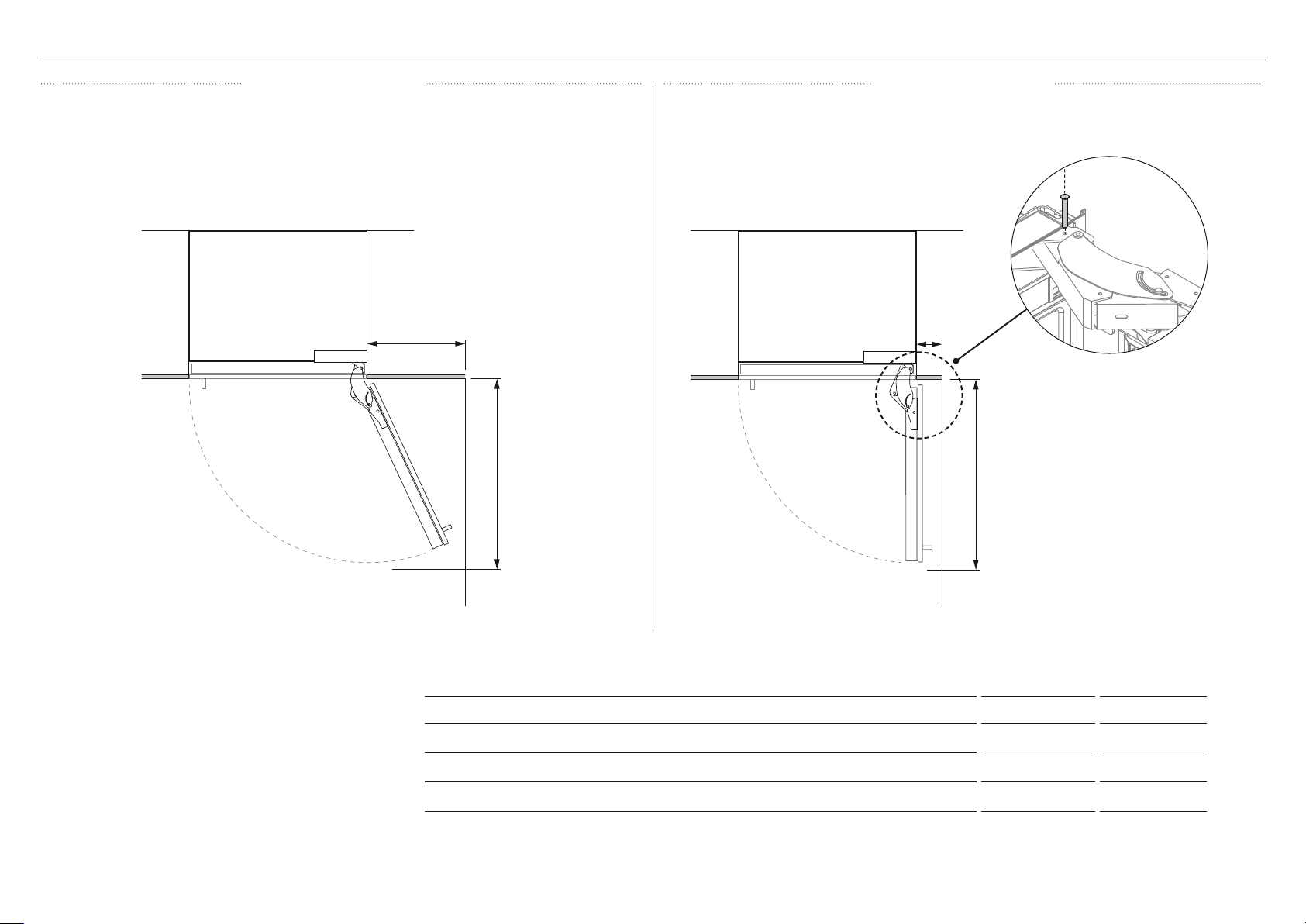

DOOR CLEARANCE — RS24 MODEL

115° DOOR OPENING 90° DOOR OPENING

FULL INTERNAL ACCESS

B

C

Insert hinge limiting pin

Before pushing the appliance into

the cabinetry, insert the supplied

A

A

hinge limiting pin into the borehole

of the top hinge. The hinge limiting

pin limits the door swing to

WALL

LIMITED INTERNAL ACCESS

WALL

DIMENSIONS IN MM

A Width of door (90° open) measured from front of door 26 660

B Minimum door clearance* to adjacent wall** (115°—full internal access) 14 356

90°.

18

C Minimum door clearance* to adjacent wall** (90°—reduced internal access) 4 5/16 110

Page 19

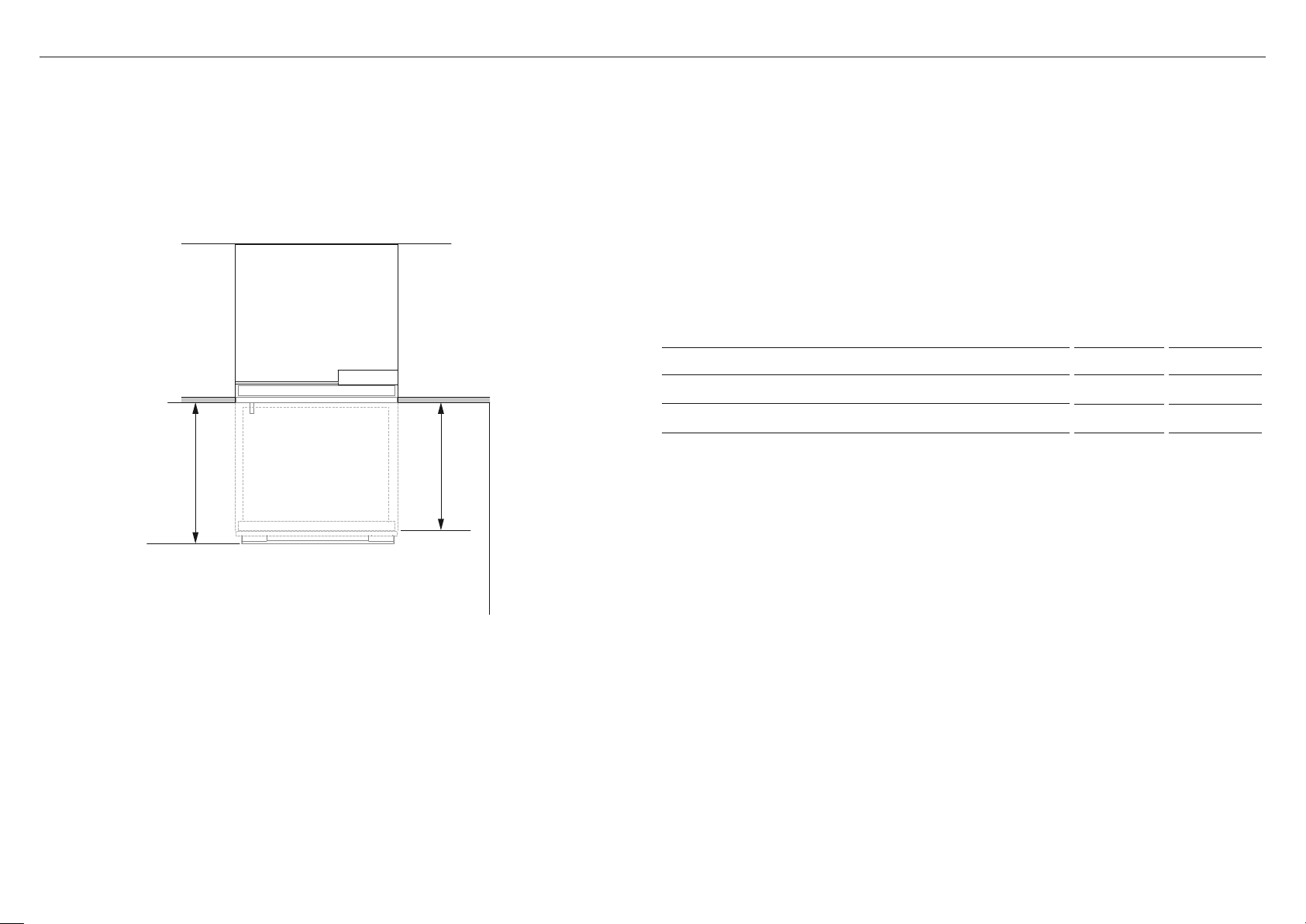

DRAWER CLEARANCE — RS24 MODEL

DIMENSIONS IN MM

A Maximum drawer extension when open (excluding handle) 15 3/4 400

B Maximum drawer extension when open (including handle) 18 1/8 461

B

A

19

Page 20

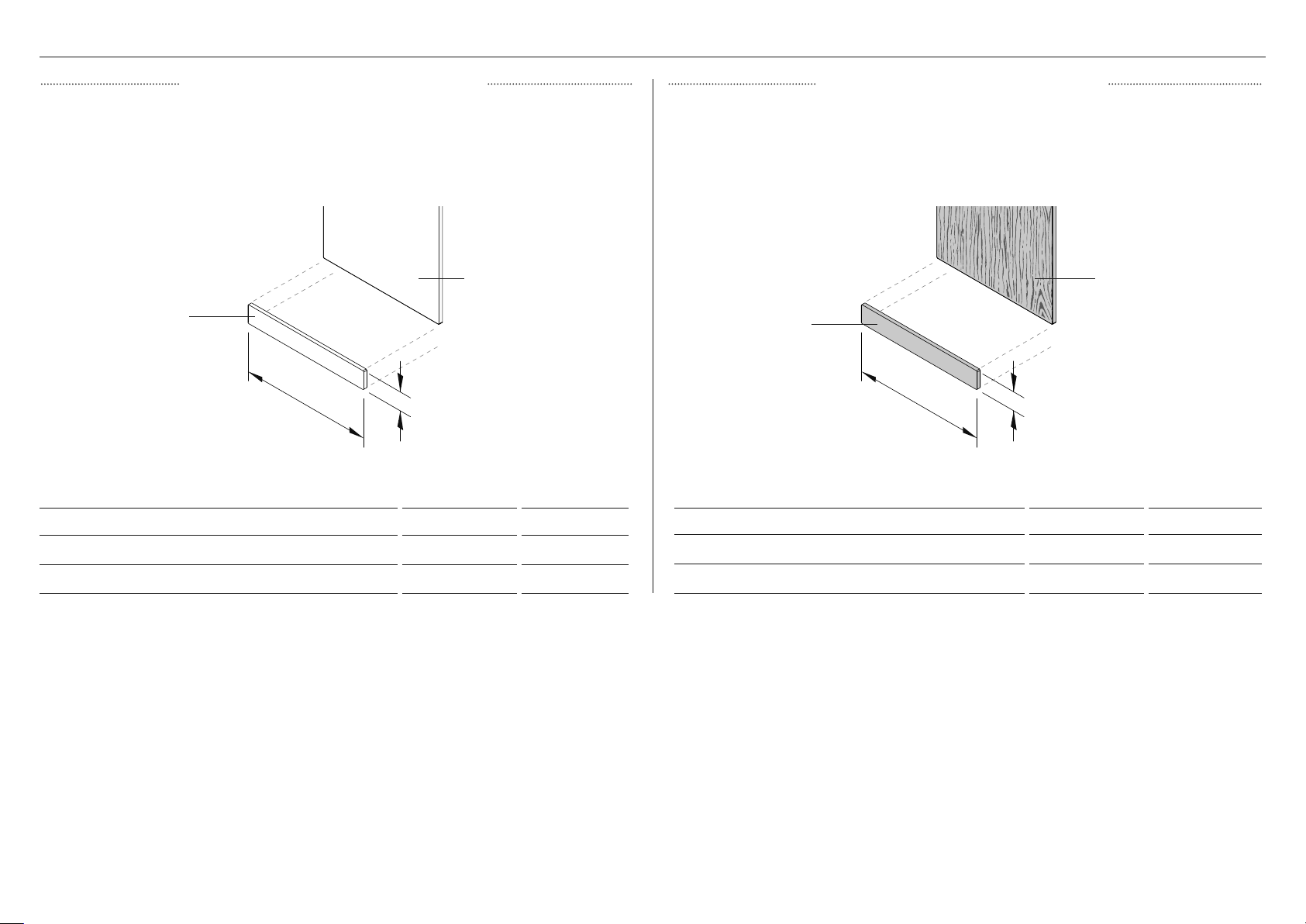

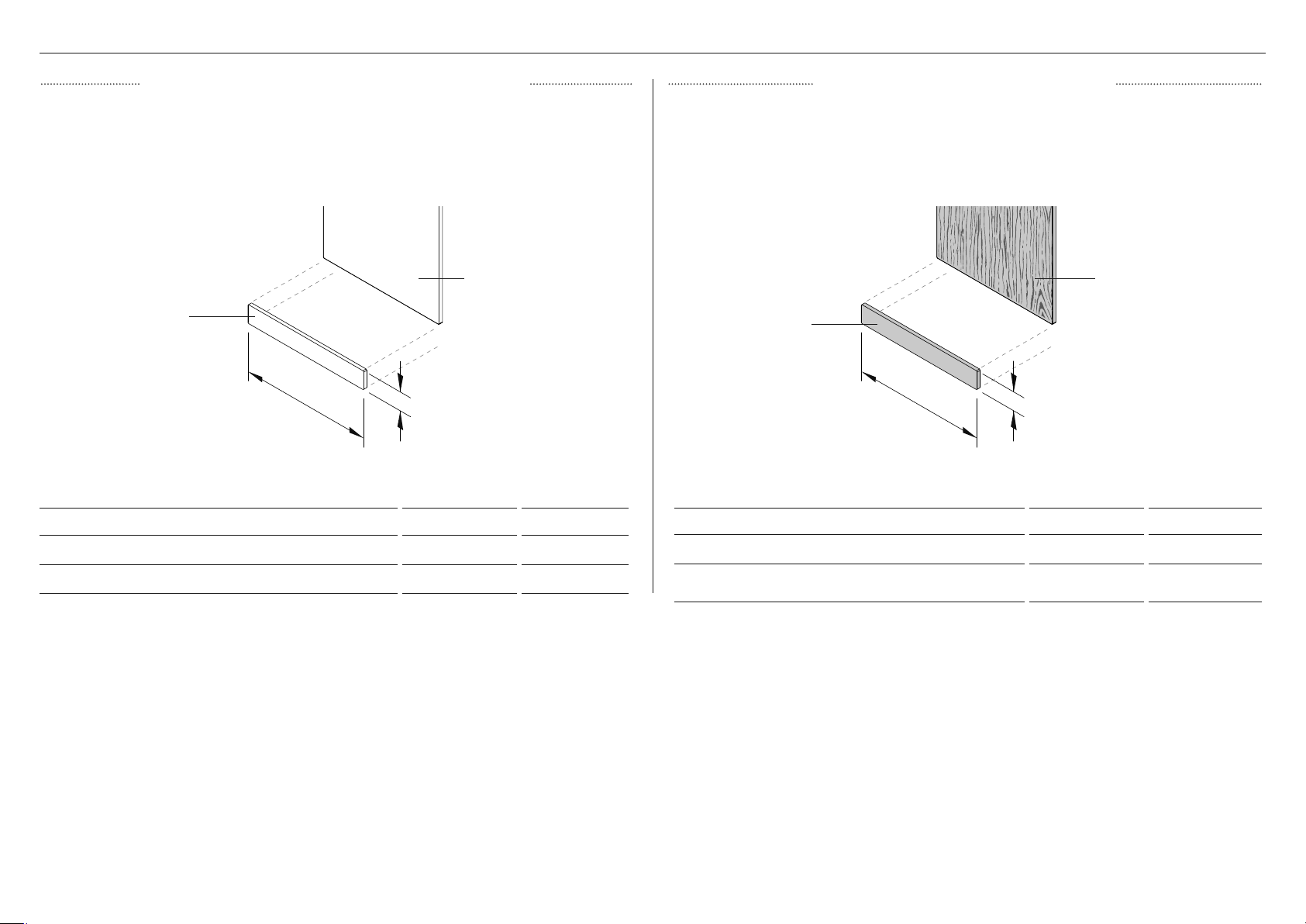

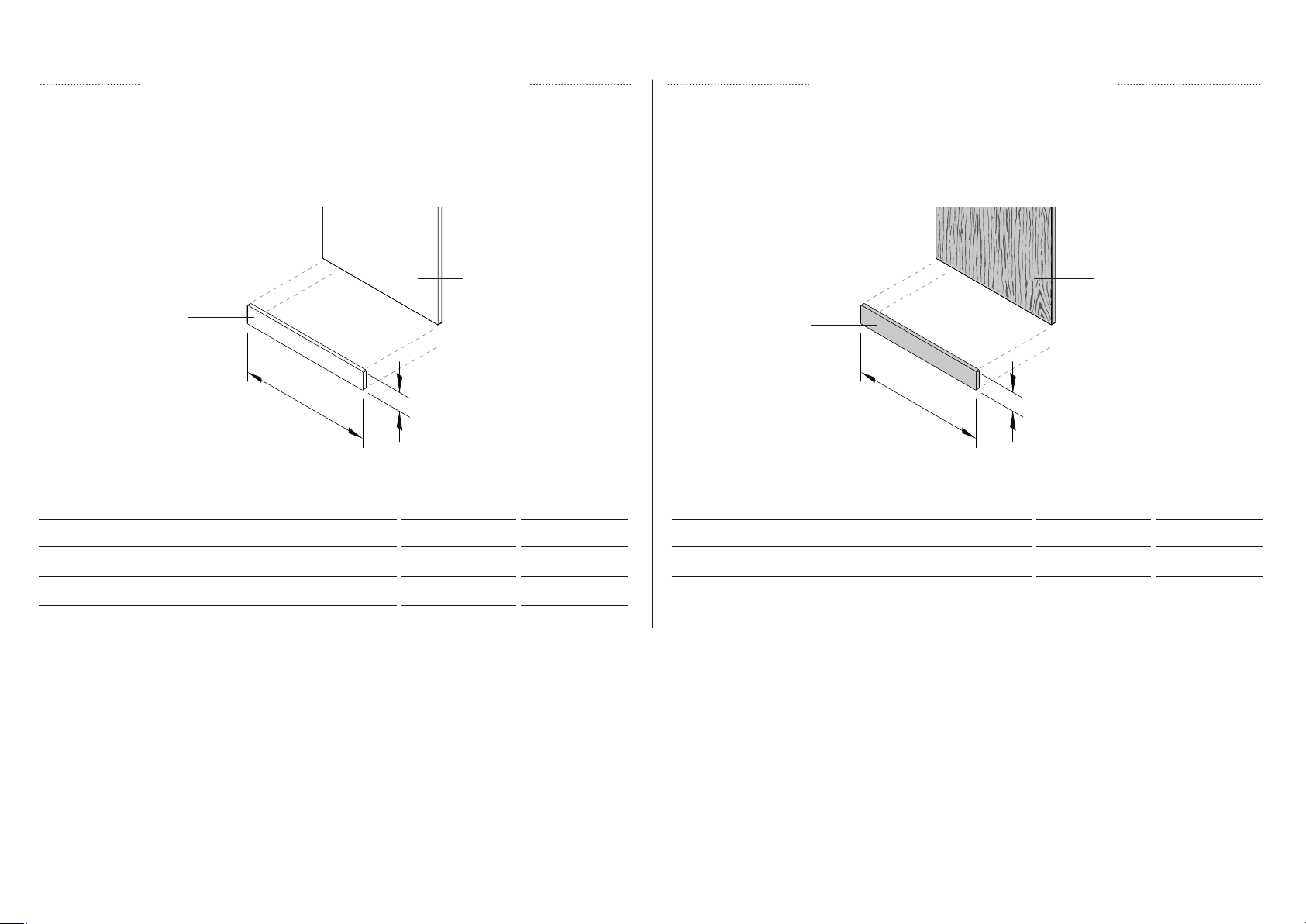

TOE KICK DIMENSIONS — RS24 MODEL

STAINLESS STEEL TOE KICK PANEL CUSTOM PANEL TOE KICK PANEL

Can be purchased separately through an authorised Fisher & Paykel dealer. Visit fisherpaykel.

com for more information.

door panel

toe kick panel

A

TOE KICK PANEL (CA 25390)

DIMENSIONS IN MM

A Width of toe kick 23 7/8 606

B

For Custom door panel installation, a custom toe kick 2” –6” (50 – 152mm) can be

manufactured and fitted by cabinetmaker. The Custom door panel height needs to be adjusted

accordingly. Extra lower grilles are required for a 2” (50mm) toe kick installation.

door panel

toe kick panel

A

DIMENSIONS IN MM

A Width of toe kick 23 7/8 606

B

B Height of toe kick 4 102

20

B Height of toe kick* min 2 - max 6 min 51 - max 152

Page 21

TOE KICK INSTALL OPTIONS

Standard toe kick height is

4" (102mm) with Stainless steel

door panel.

For custom toe kick

with 2" (50mm) height

(extra lower grille attached).

For custom toe kick with 6"

(152mm) height.

Min 27/8" (73mm) – max

4" (102mm) toe kick depth

measured from rearof door

panel

toe kick panel

21

Page 22

PRODUCT DIMENSIONS — RS30 MODEL

A

B

C

PRODUCT DIMENSIONS IN MM

A Overall height of product 84 2134

B Overall width of product 29 3/4 756

C Overall depth of product (excluding front door panel) 24 610

PRODUCT WEIGHT LBS KG

Weight (with packaging) 406 184

Weight (without packaging) 357 162

22

FRONT VIEW

PROFILE VIEW

Page 23

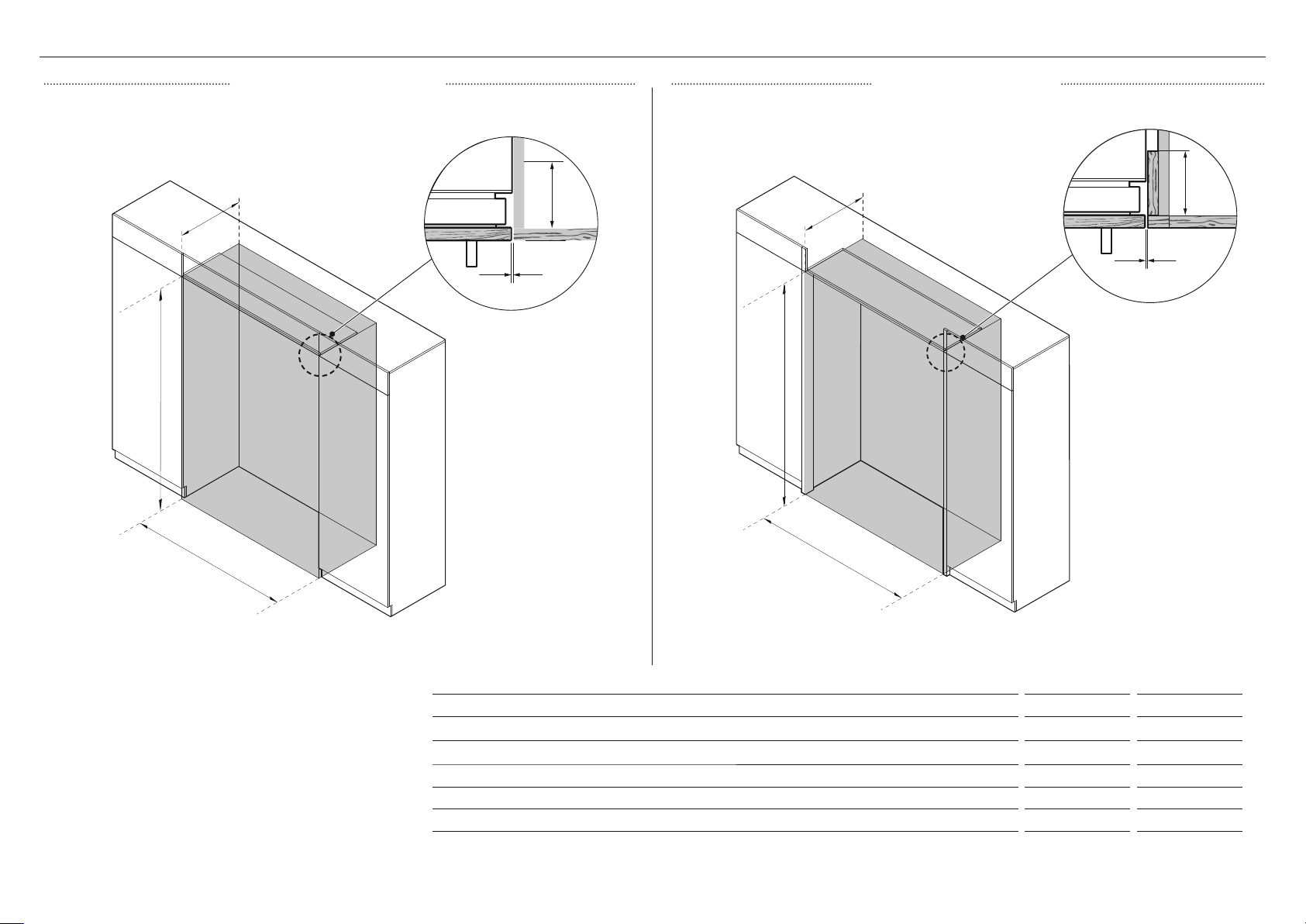

CAVITY DIMENSIONS — RS30 MODEL

FRAMELESS CABINETRY FRAMED CABINETRY

Aligns appliance flush with the cabinetry.

C

A

B

D

A

E

Aligns appliance flush with the frame of cabinetry.

E

C

D

A

B

B

DIMENSIONS IN MM

1 Overall height of cavity

2 Overall width of cavity

3 Minimum overall depth of cavity* 25 635

4 Minimum cabinetry gap clearance from edge of door panels 1/8” 3

5 Minimum required finished return 4” 102

* Assumes a door panel thickness of 3/4” (19mm).

84 2134

30 762

23

Page 24

DOOR PANEL DIMENSIONS — RS30 MODEL

STAINLESS STEEL PANEL CUSTOM PANEL

A

A

B

B

C

DIMENSIONS IN MM

A Height of top door panel 49 3/8 1254

B Height of drawer door panel 30 3/8 772

C Width of door panel 29 3/4 756

D Depth of door panel

(excluding door handle)

DOOR PANEL WEIGHT LBS KG

Weight of top door 22 10

Weight of bottom drawer door 15 7

3/4 19

24

C

DIMENSIONS IN MM

A Height of top door panel 49 3/8 1254

B Height of drawer door panel 30 3/8 772

C Width of door panel 29 3/4 756

D Depth of door panel

(excluding door handle)

DOOR PANEL WEIGHT LBS KG

Weight of top door max 41 max 18 1/2

Weight of bottom drawer door max 25 max 11 1/2

min 5/8

max 1

min 16

max 25

Page 25

CUSTOM DOOR PANEL INSTALL DIMENSIONS — RS30 MODEL

Dimensions apply for the preparation and installation of Custom door panels. For Dwg and Dxf files of the below panel preparation download the folder on thekitchentools.fisherpaykel.com.

z

The thickness of the custom door panel can vary provided that the screws do not penetrate beyond the full depth of the door panel.

z

Measurements of screw hole locations can vary depending on the height of toe kick 50–152mm.

14 7/8" (377.8mm)

8" (203.2mm)

2" (50.8mm)

2" (50mm)

15" (127mm)

20" (507.8mm)

Ø2mm REF

10x Pilot holes recommended

for bracket attachment.

(Do not penetrate front surface).

1 1/2" (38.1m)

3 1/2" (88mm)

14 7/8" (377.8mm)

8" (203.2mm)

2" (50.8mm)

Ø2mm REF

10x Pilot holes recommended

for bracket attachment.

(Do not penetrate front surface).

2" (50mm)

43" (1092mm)

49 3/8" (1254mm)

2" (50mm)

2" (50mm)

29 3/4" (755.6mm)

TOP PANEL—REAR VIEW

Ensure handle is mounted

65mm from edge of panel

to the center—this will avoid

interference with bracket.

1 1/4" (32.6mm)

30 3/8" (771.5mm)

20" (508.4mm)

23 3/16" (588.4mm)

1 1/4" (32.6mm)

Cutouts in the hanging bracket

are applicable for Fisher &

Paykel handles only.

Iflocating a custom handle in

the shaded area shown above,

ensure handle screw headsare

countersunk into the back of the

door panel to avoid interference

with the hanging bracket.

29 3/4" (755.6mm)

BOTTOM PANEL—REAR VIEW

25

Page 26

DOOR CLEARANCE — RS30 MODEL

115° DOOR OPENING 90° DOOR OPENING

FULL INTERNAL ACCESS

B

C

Insert hinge limiting pin

Before pushing the appliance into

the cabinetry, insert the supplied

hinge limiting pin into the borehole

of the top hinge. The hinge limiting

pin limits the door swing to

WALL

A

A

WALL

LIMITED INTERNAL ACCESS

DIMENSIONS IN MM

A Width of door (90° open) measured from front of door 32 813

B Minimum door clearance* to adjacent wall** (115°—full internal access) 16 1/2 419

90°.

26

C Minimum door clearance* to adjacent wall** (90°—reduced internal access) 4 5/16 110

Page 27

DRAWER CLEARANCE — RS30 MODEL

DIMENSIONS IN MM

A Maximum drawer extension when open (excluding handle) 15 3/4 400

B Maximum drawer extension when open (including handle) 18 1/8 461

B

A

27

Page 28

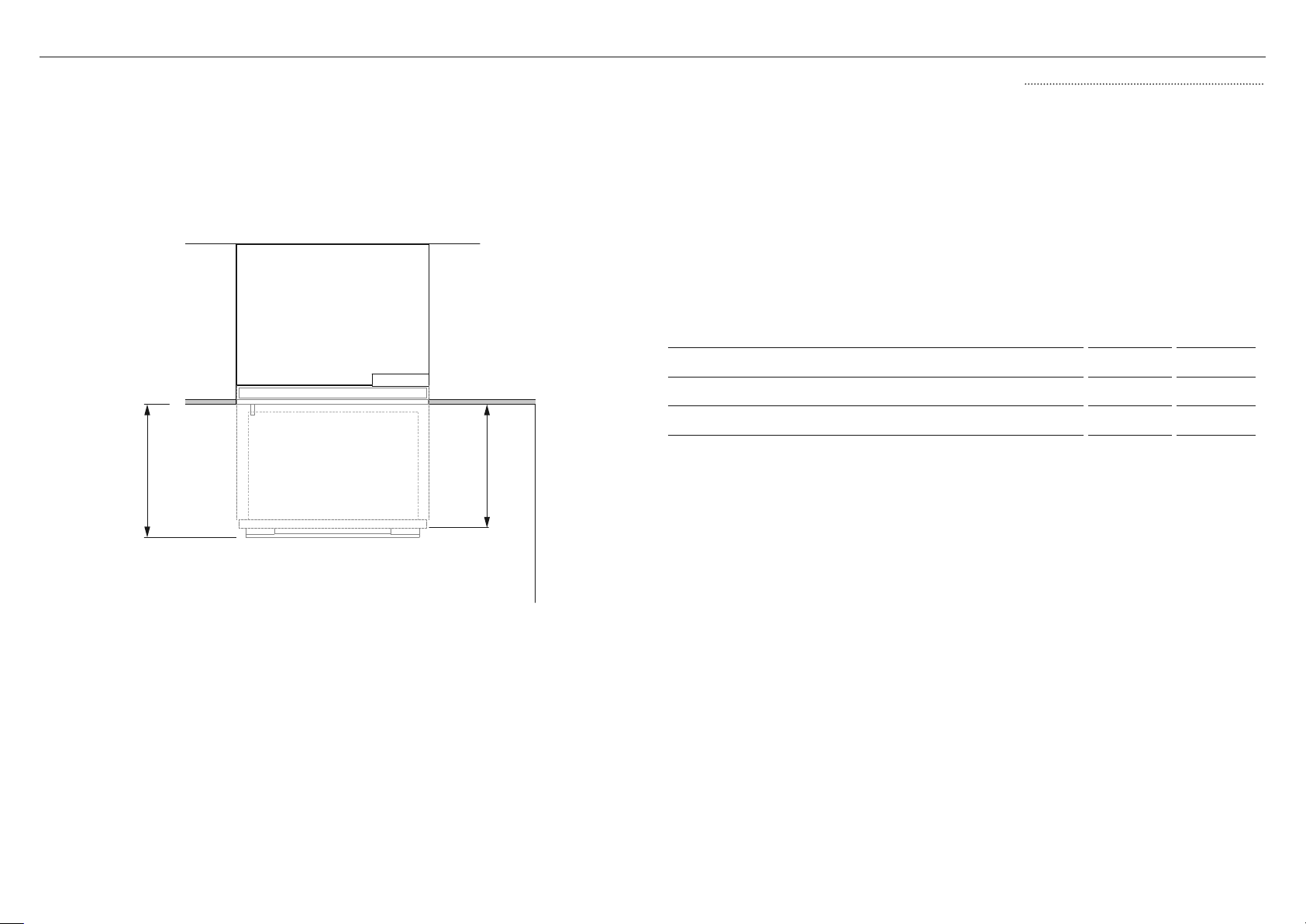

TOE KICK DIMENSIONS — RS30 MODEL

STAINLESS STEEL TOE KICK PANEL CUSTOM PANEL TOE KICK PANEL

Can be purchased separately through an authorised Fisher & Paykel dealer. Visit fisherpaykel.

com for more information.

door panel

toe kick panel

A

TOE KICK PANEL (CA 25392)

DIMENSIONS IN MM

A Width of toe kick 297/8 759

B

For Custom door panel installation, a custom toe kick 2” –6” (50 – 152mm) can be

manufactured and fitted by cabinetmaker. The Custom door panel height needs to be adjusted

accordingly. Extra lower grilles are required for a 2” (50mm) toe kick installation.

door panel

toe kick panel

A

DIMENSIONS IN MM

A Width of toe kick 297/8 759

B

B Height of toe kick 4 102

28

B Height of toe kick* 2-6 51 - 152

Page 29

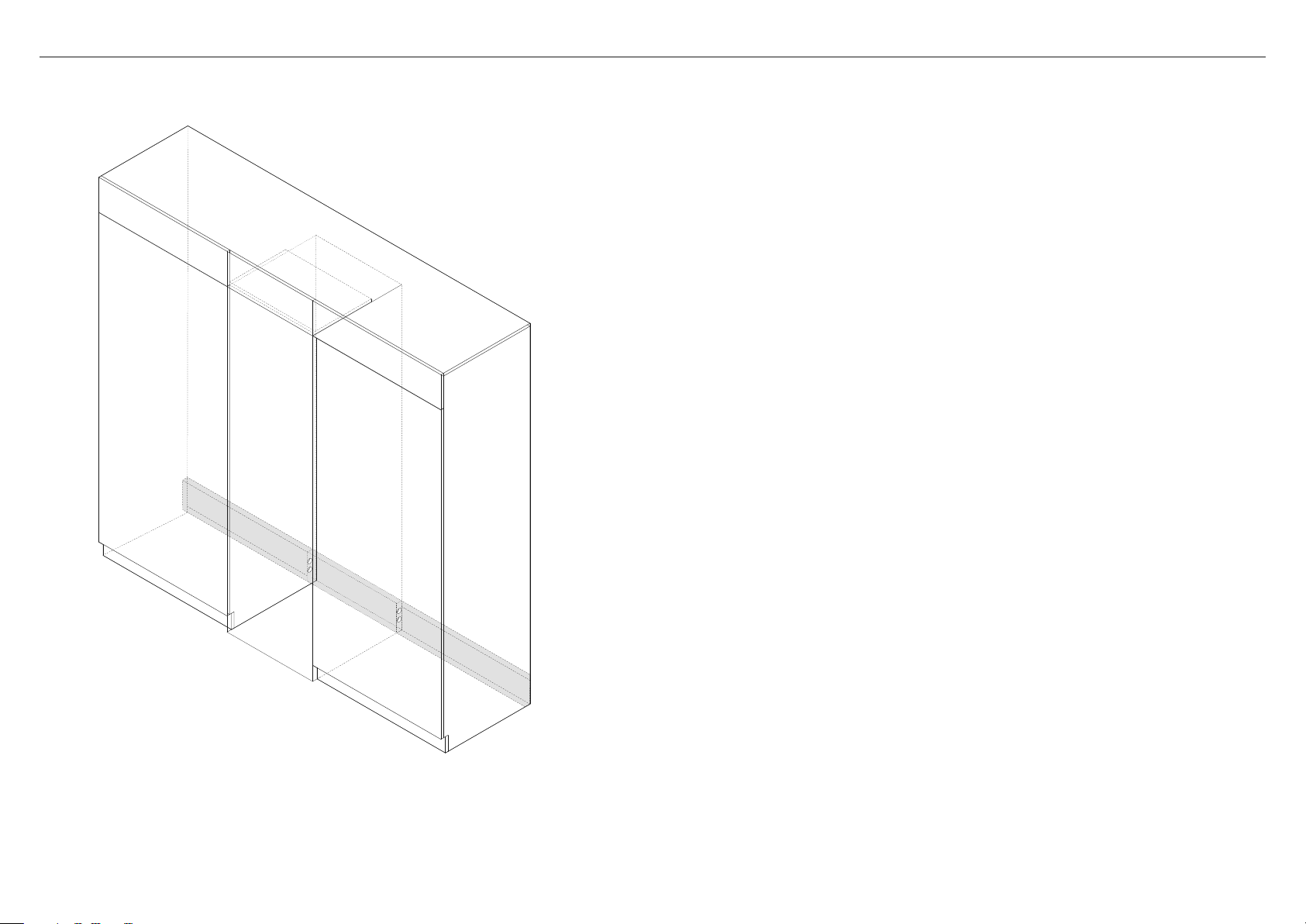

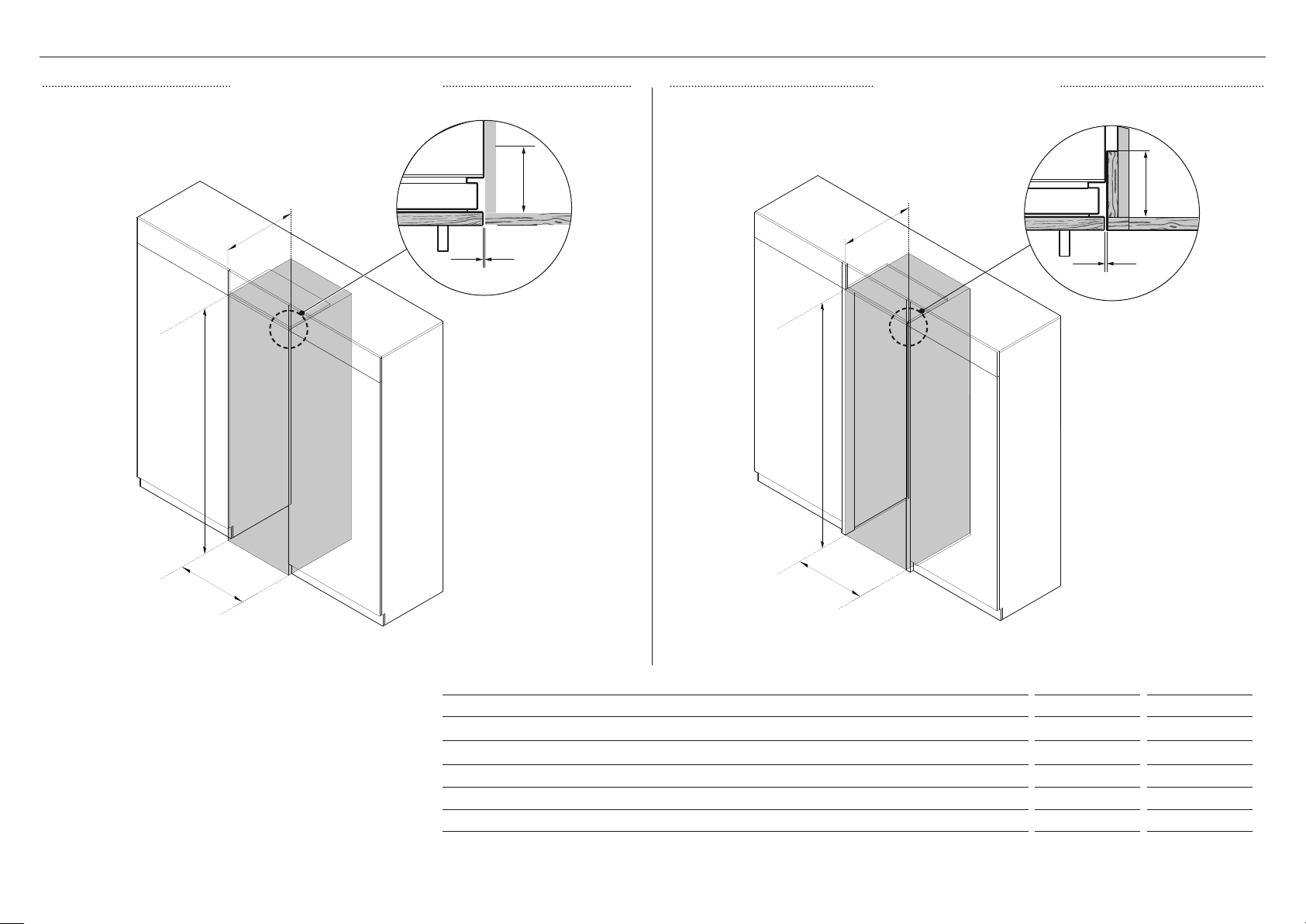

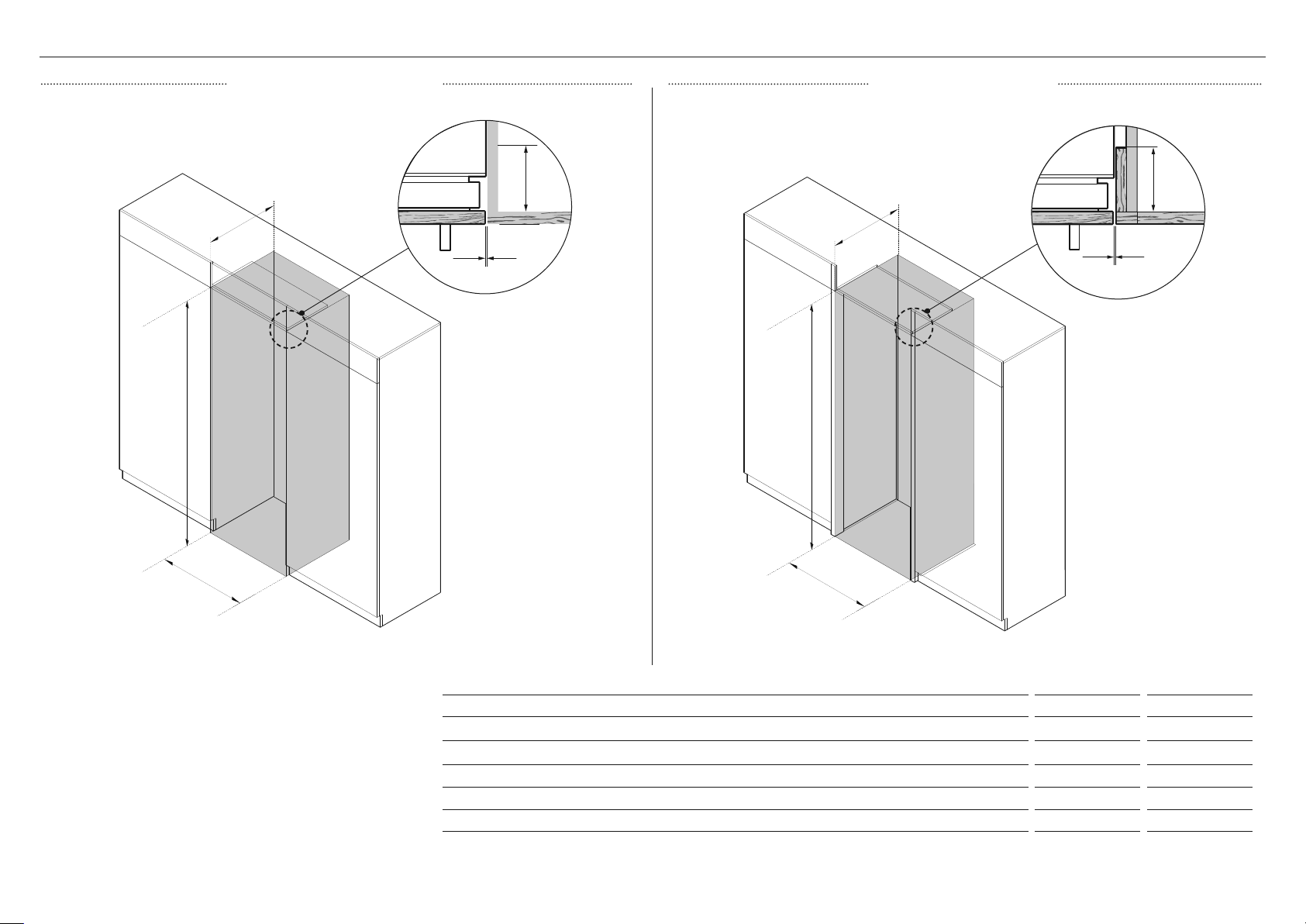

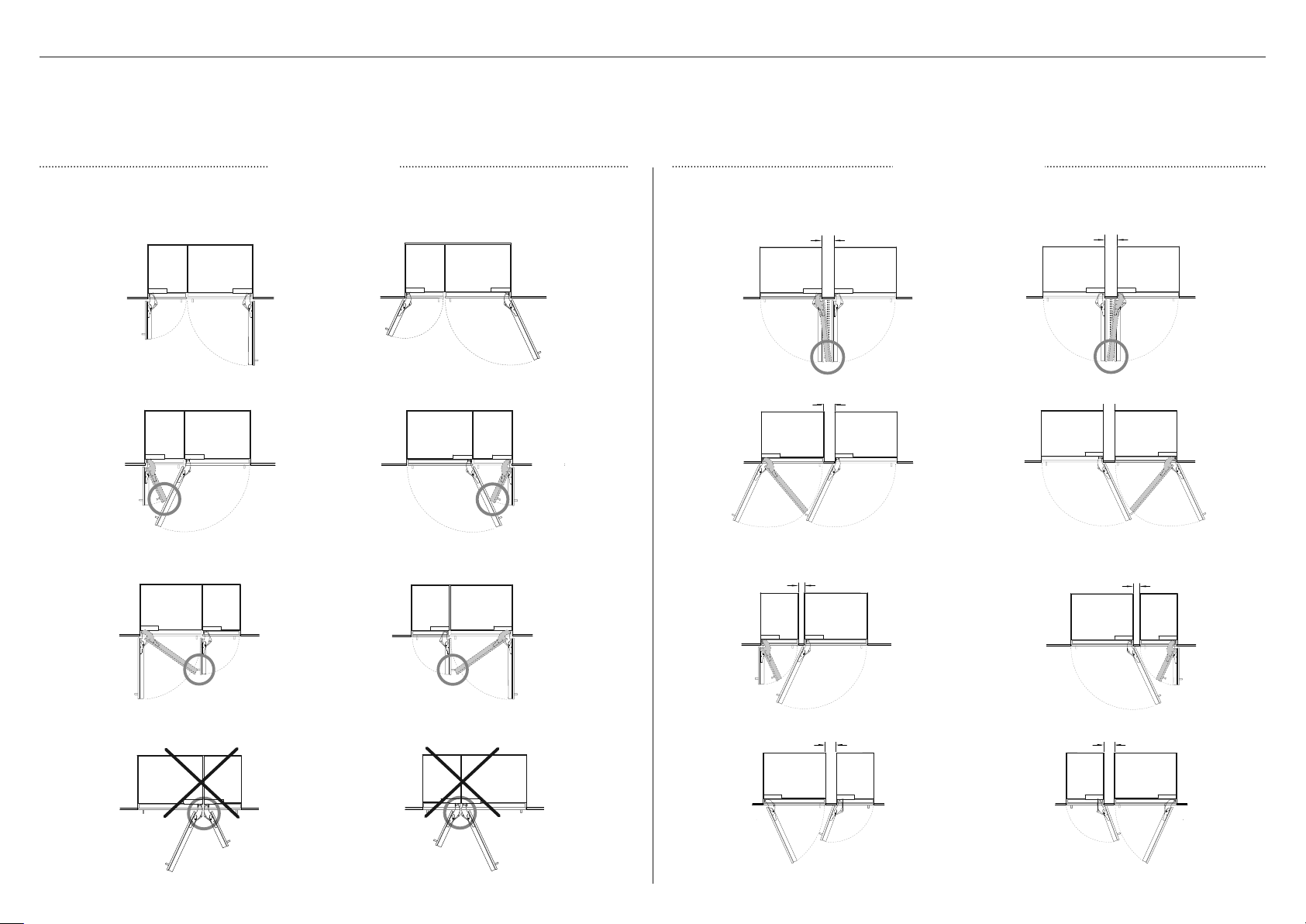

DUAL INSTALL OPTIONS

The following are options for dual/multiple installation with reference to the door opening range and partition (optional) between two appliance combinations.

z

Beware of clashing (circled) when opening the doors. Use a hinge limiting pin to restrict door opening rotation to 90°. Refer to ‘Door Clearance’ for more information.

z

If installing a partition between two appliances, it must have enough clearance to ensure the doors/handles do not interfere with one another when opening or closing.

NO PARTITION WITH PARTITION

min 100mm

min 100mm

min 60mm

min 100mm

min 100mm

min 60mm

min 100mm

min 100mm

29

Page 30

CAVITY DIMENSIONS — RS24 + RS24 DUAL INSTALL

FRAMELESS CABINETRY FRAMED CABINETRY

Aligns appliance flush with the cabinetry.

C

A

B

D

E

Aligns appliance flush with the frame of cabinetry.

E

C

D

A

B

30

DIMENSIONS IN MM

A Overall height of cavity

B Overall width of cavity

C Minimum overall depth of cavity* 25 635

D Minimum cabinetry gap clearance from edge of door panels 1/8” 3

E Minimum required finished return 4” 102

* Assumes a door panel thickness of 3/4” (19mm).

84 2134

48 1219

Page 31

CAVITY DIMENSIONS — RS24 + RS30 DUAL INSTALL

FRAMELESS CABINETRY FRAMED CABINETRY

Aligns appliance flush with the cabinetry.

C

A

B

D

E

Aligns appliance flush with the frame of cabinetry.

E

C

D

A

B

DIMENSIONS IN MM

A Overall height of cavity

B Overall width of cavity

C Minimum overall depth of cavity* 25 635

D Minimum cabinetry gap clearance from edge of door panels 1/8” 3

E Minimum required finished return 4” 102

* Assumes a door panel thickness of 3/4” (19mm).

84 2134

54 1372

31

Page 32

CAVITY DIMENSIONS — RS30 + RS30 DUAL INSTALL

FRAMELESS CABINETRY FRAMED CABINETRY

Aligns appliance flush with the cabinetry.

C

A

B

D

E

Aligns appliance flush with the frame of cabinetry.

E

C

D

A

B

32

DIMENSIONS IN MM

A Overall height of cavity

B Overall width of cavity

C Minimum overall depth of cavity* 25 635

D Minimum cabinetry gap clearance from edge of door panels 1/8” 3

E Minimum required finished return 4” 102

* Assumes a door panel thickness of 3/4” (19mm).

84 2134

60 1524

Page 33

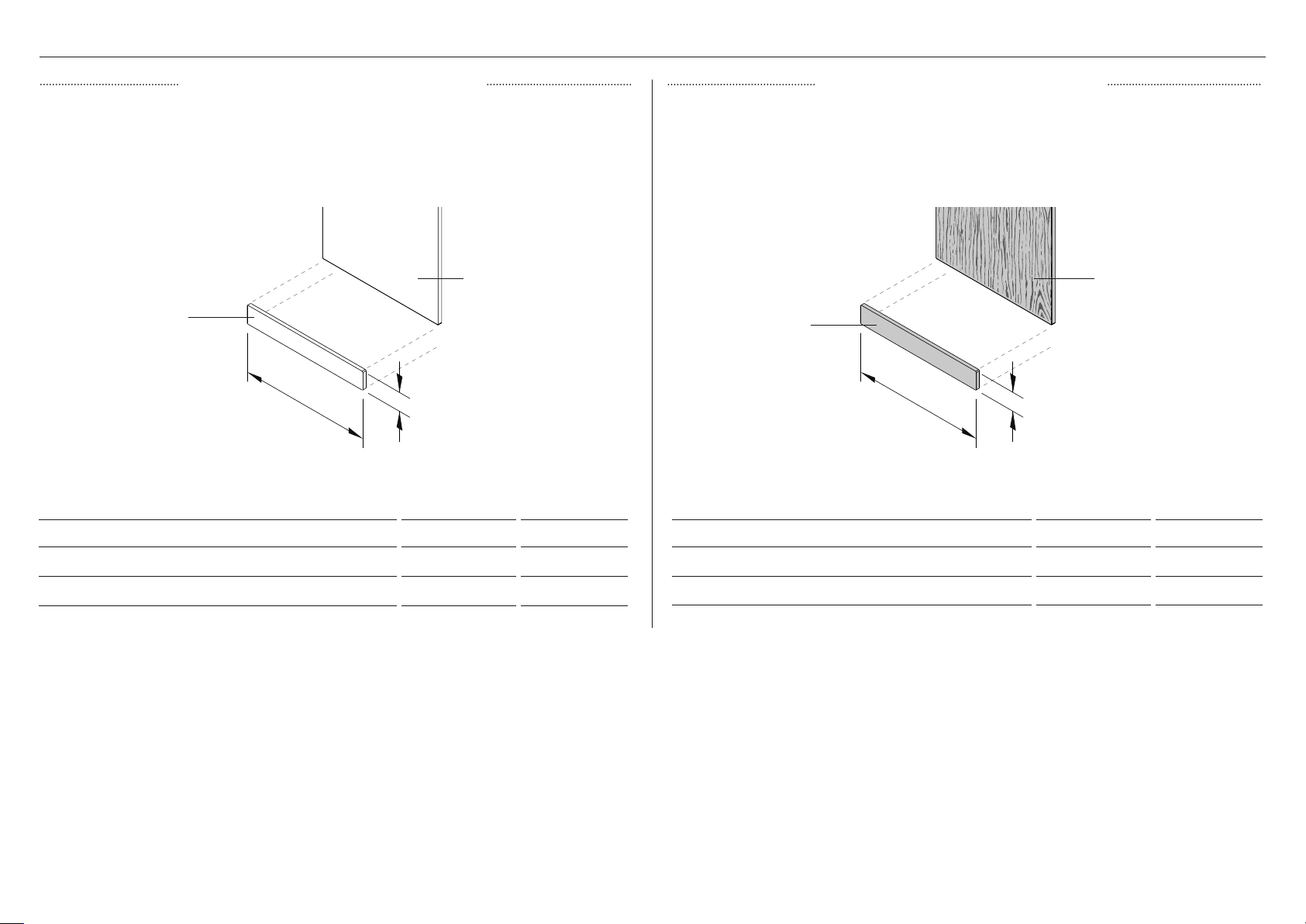

TOE KICK PANEL DIMENSIONS — DUAL INSTALL

STAINLESS STEEL PANEL CUSTOM PANEL

toe kick panel

C

A

B

TOE KICK PANEL (CA 25396) RS24 + RS24 MODELS

DIMENSIONS IN MM

A Width of toe kick 477/8 1216

B Height of toe kick 4 102

TOE KICK PANEL (CA 25398) RS24 + RS30 MODELS

DIMENSIONS IN MM

A Width of toe kick 53 7/8 1368

B Height of toe kick 4 102

door panels

toe kick panel

A

DIMENSIONS IN MM

A Width of toe kick 477/8 1216

B Height of toe kick* min 2 - max 6 min 51 - max 152

DIMENSIONS IN MM

A Width of toe kick 53 7/8 1368

B Height of toe kick* min 2 - max 6 min 51 - max 152

C

door panels

B

RS24 + RS24 MODELS

RS24 + RS30 MODELS

TOE KICK PANEL (CA 25400) RS30 + RS30 MODELS

DIMENSIONS IN MM

A Width of toe kick 59 7/8 1521

B Height of toe kick 4 102

RS30 + RS30 MODELS

DIMENSIONS IN MM

A Width of toe kick 59 7/8 1521

B Height of toe kick* min 2 - max 6 min 51 - max 152

33

Page 34

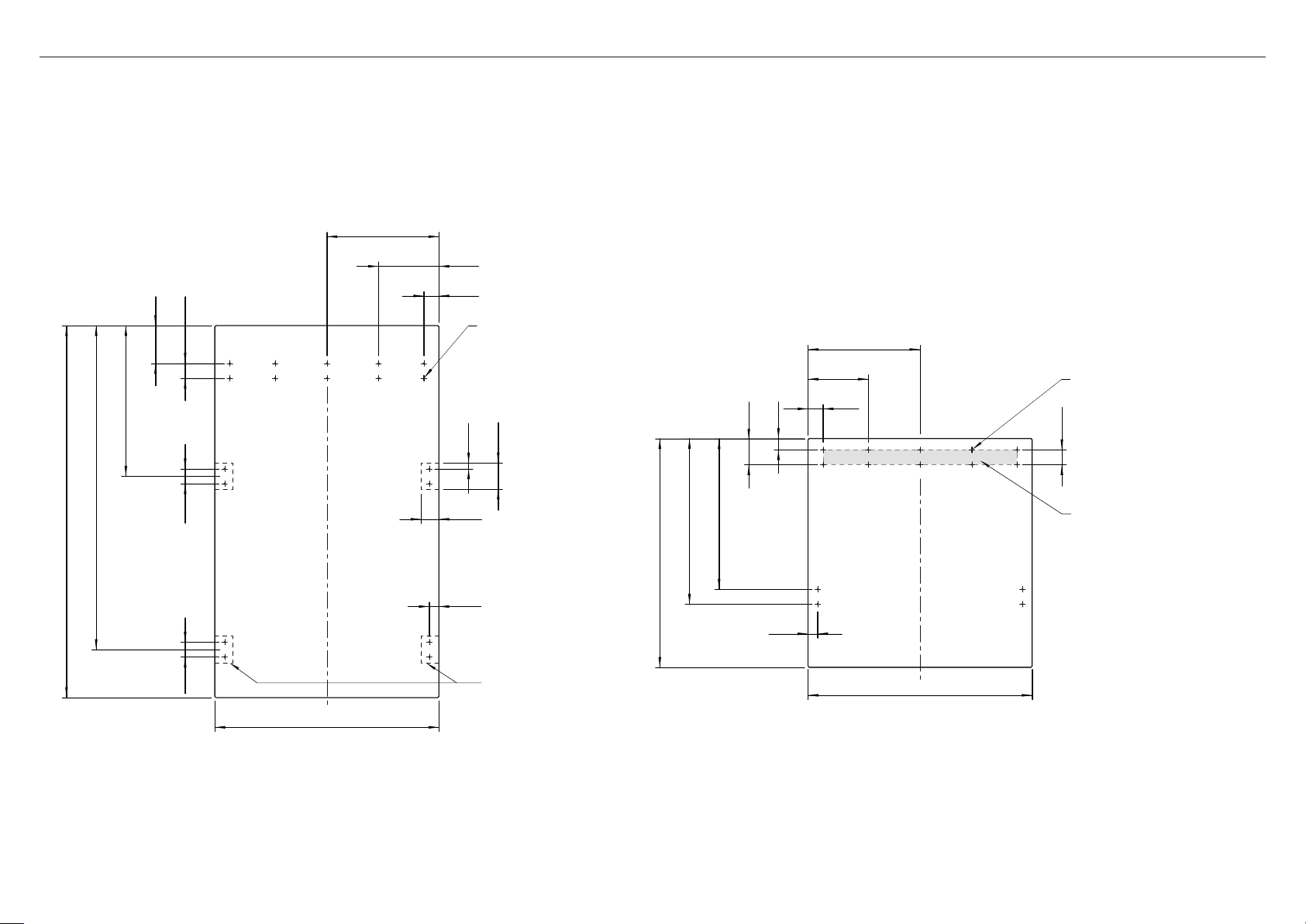

POWER SUPPLY DIMENSIONS

SINGLE INSTALLATION DUAL INSTALLATION

A

1

2

1

Electrical connection must be within this

space if located behind the appliance and

must not protrude from the back wall.

C

1

2

1

ELECTRICAL AND PLUMBING CONNECTIONS

1 Recommended location for connections in adjacent area or unit

2 Alternative location for connections at rear of cavity

ELECTRICAL DIMENSIONS IN MM

A Overall height of supply area 9 229

B Overall depth of supply area 1" 25

C Width of notch in supply area

(both sides) 1/2 13

34

D

B

D Height of sides of supply area

(both sides) 5127

Page 35

PLUMBING SPECIFICATIONELECTRICAL SPECIFICATION

A

Power cord

b

Power cord

Supply 115 VAC, 60 Hz

Service 10 amp circuit

Socket 3-prong grounding-type

Power cord (total length) 78 3/4" (2000mm)

RS24 RS30

MAXIMUM DISTANCE OF POWER CORD in mm in mm

A Power cord length from left side edge of appliance

(excluding plug)

B Power cord length from right side edge of appliance

(excluding plug)

71 1/4 1809 68 1/4 1733

72 1/4 1835 69 1/4 1759

a

Water hose

b

Water hose

Supply 1/2” (12.7mm) BSP Stainless steel braided hose

withadaptor

Pressure psi (kPa) min 150psi (22) /max 827psi (120kPa) @ 68°F

(20°C)

Water inlet hose (total length) 118 1/8 (3000mm)

RS24 RS30

MAXIMUM DISTANCE OF SUPPLIED WATER HOSE in mm in mm

A Water inlet hose length from left side edge of

appliance

B Water inlet hose length from right side edge of

appliance

86 7/16 2196 83 7/16 2120

73 15/16 1878 70 15/16 1802

35

Page 36

Anti-tip bracket

assembly kit

overhead

cabinetry

INSTALL ANTI-TIP BRACKET

Anti-tip bracket

(1)

Masonry plug

(4)

#10x40 cross-head screw

(4)

Tools

Cross-head screwdriver

Powered drill

Floor

A

back wall

min 7 3/4" (197mm)

bracket

stud

B

Locating the attachment position of anti-tip bracket

1 Measure the height (A) of the attachment location from

the floor to the alcove return at the back wall, and mark a

horizontal line (B).

z

The height (A) must not exceed 84 3/16" (2138mm) to

ensure the appliance does not tip over during installation.

z

Ensure there is a stud behind the wall.

2 Place the bracket to the backwall. Align the undersurface of

the bracket along the marked line.

Pencil

36

PROFILE VIEW

3 Mark screw hole locations, and drill screw holes with

powered drill.

z

For solid wall installation, drill holes suitable to the size of

the masonry plugs.

Page 37

Anti-tip bracket

assembly kit

INSTALL ANTI-TIP BRACKET

Anti-tip bracket

(1)

Masonry plug

(4)

#10x40 cross-head screw

(4)

Tools

Cross-head screwdriver

Powered drill

screws

masonry plugs

For plaster board wall

Fix the anti-tip bracket to the

wall with #10x40mm cross head

screws, and screw tightly with a

screwdriver.

For solid wall installation

Hammer 10x30mm masonry plugs

into wall until flush. Fix bracket to

wall with #10x40mm cross head

screws, and screw tightly.

min 7 1/16" (180mm)

Bracket

Appliance Wall

PROFILE VIEW

min 7 1/16" (180mm)

Bracket

Appliance

Spacer

Wall

Roll the appliance slowly into

the cabinetry until the anti-tip

bracket overlaps the back edge

of the appliance.

z

Ensure the bracket overlaps

the appliance by a minimum

7 1/16" (180mm) for a secure

hold.

If minimum 7 1/16" (180mm)

overlap cannot be achieved,

install a solid spacer to the wall

stud behind the bracket.

z

Be careful not to run over

the power cord when rolling

in the appliance.

Pencil

PROFILE VIEW

37

Page 38

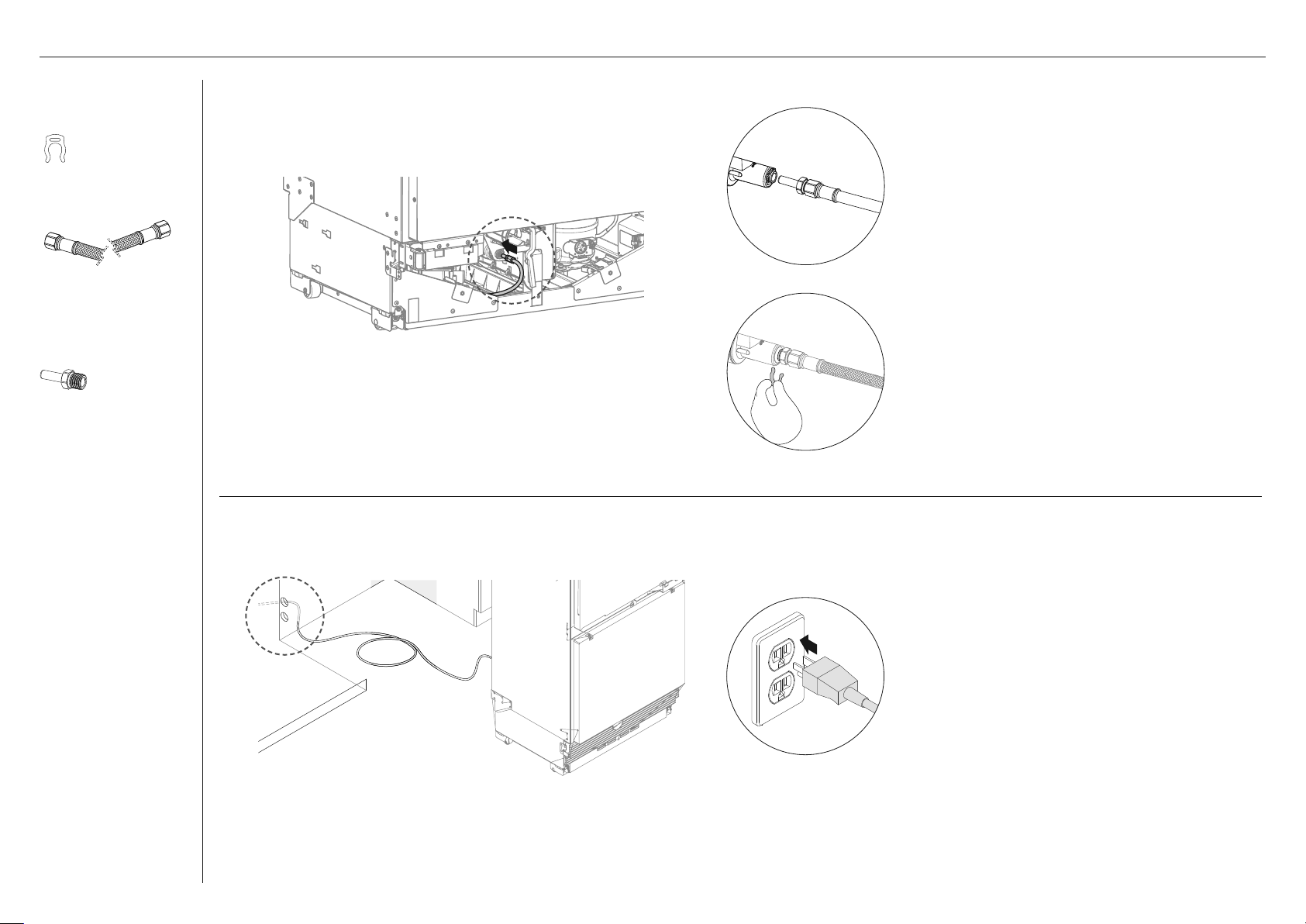

Water fittings kit

Collet locking clip

(1)

7/16" (11mm) BSP

Stainless steel braided

hose with adaptor

(1)

1/4” (6.35mm) Adaptor

(2)

A

Rear side

CONNECT WATER AND POWER SUPPLY

Connecting to water supply

1 Roll the appliance to the front of the cabinetry close enough to

allow access at the back for power and water connection.

2 Insert the adaptor end of the braided

hose through a hole at the rear of the

plinth (A) and push all the way to the front of the appliance.

38

B

3 Connect one end of the braided water hose to the water tap (B).

z

Flush water through the hose prior to connection to the appliance

to remove any debris in the hose.

4 Pull the hose from the front of the appliance and connect

an adaptor (C).

C

Page 39

Water fittings kit

CONNECT WATER AND POWER SUPPLY

Collet locking clip

(1)

7/16" (11mm) BSP

Stainless steel braided

hose with adaptor

(1)

1/4” (6mm) Adaptor

(2x)

C

D

5 Insert the tube end of the adaptor fully into the

PLV (C) at the bottom front of the appliance.

6 Secure the connection with a locking clip

between the PLV and hose end of adaptor (D).

z

Check the connection and open the water

supply to testfor leaks.

E

Connecting to power supply

1 At the back of your appliance, connect the power

cable to the power supply (115VAC, 60Hz) (E).

z

You will hear a chime sound when the

appliance is powered on.

z

Refer to your ‘User guide’ for more details on

activating the appliance.

39

Page 40

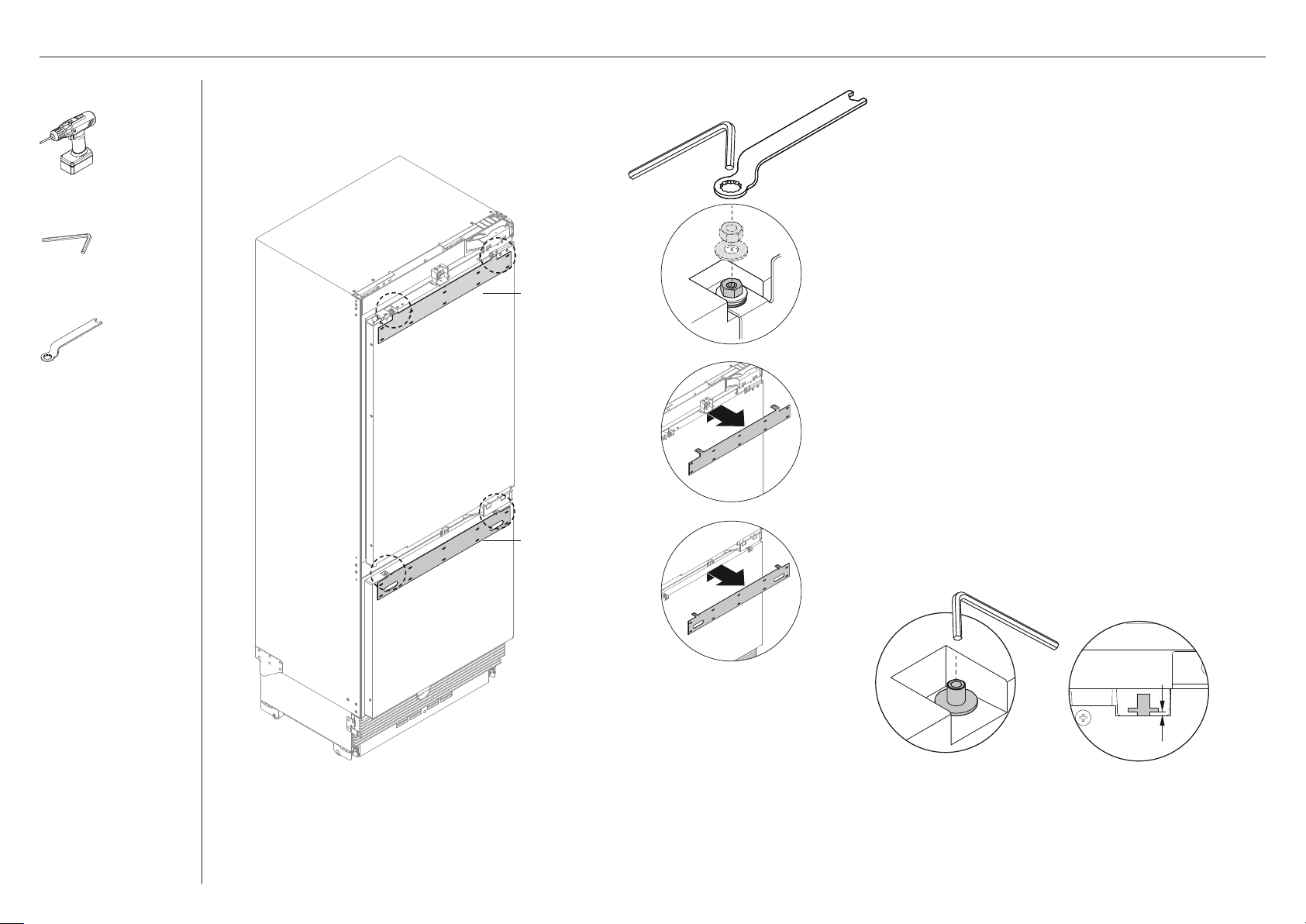

Install fasteners kit

POSITION AND ALIGNMENT IN CABINETRY

Barbed plugs

(2)

Barbed plug

A

B

Attaching the barbed plugs

1 Before rolling into the cavity, insert a barbed

plug into a large hole at the top left side (A)

of the appliance.

z

The plugs protect the inside surface of

cabinetry from being damaged by screws

when pushing in the appliance.

Repeat steps

1 — 2 to the right side (B) of the

appliance.

40

Page 41

Install fasteners kit

Cabinet depth

alignment gauge

(4)

Tools

Cross-head screwdriver

POSITION AND ALIGNMENT IN CABINETRY

Attaching the depth alignment gauges

1 Loosen the right and left screws at the top and bottom

sides of the door. (A)

2 Locate the alignment gauges at correct orientation to the

right and left screws.

A

C

B

Left

3 Position the alignment gauge by inserting the screw head

through the keyhole of the gauge. (B)

4 Push the alignment gauge down to lock the screw position

in the keyhole. (C)

5 Tighten the screw just enough to firmly hold the gauge.

The alignment gauges are only temporary and must be

removed after installation.

Right

41

Page 42

POSITION AND ALIGNMENT IN CABINETRY

min 7 1/16" (180mm)

Bracket

PROFILE VIEW

Positioning into the cabinetry

1 Roll the appliance slowly into the cabinetry until the

anti-tip bracket overlaps the back edge of the appliance.

Ensure the bracket overlaps the appliance by a minimum

7 1/16" (180mm) for a secure hold.

Be careful not to run over the water hose and power cord when

rolling in the appliance.

42

Page 43

Tools

Cross-head screwdriver

Ruler

POSITION AND ALIGNMENT IN CABINETRY

Aligning with the depth gauges

1 Mark the step of the depth gauges (A, B) on both sides of

the door based on the thickness of door panel.

z

Example illustrations showing 1" (25.4mm) door panel

thickness marked on the gauges.

Pencil

A

Left

C

B

Right

2 Check if the gaps between appliance and cabinetry side walls are

even on left and right sides (C, D).

D

C

C

D

D

Left

Right

43

Page 44

Tools

Cross-head screwdriver

Powered driver

(optional)

POSITION AND ALIGNMENT IN CABINETRY

Adjusting the alignment in the cabinetry

z

Clockwise turn of the front and rear adjustment screws

Front foot

A

A

adjustment

screw

Rear foot

adjustment

screw

Foot

(A) raise the height of the appliance.

z

Counter-clockwise turn of the adjustment screws lower

the height of the appliance.

1 Turn the front and rear adjustment screws clockwise

to extend the front feet (B) and rear feet (C) until

they engage the floor and the top bracket reaches the

cabinetry ceiling.

44

b

Front side view Rear side view

D

c

2 Check the depth gauges (D) while adjusting the

screws to maintain alignment of the appliance.

Page 45

Install fasteners kit

8Gx16 Countersunk

screw (6)

Tools

SECURE APPLIANCE TO CABINETRY

Securing the top brackets

Fix the top brackets to the ceiling surface of the

cabinetry with 8Gx16 countersunk screws. (A)

Cross-head screwdriver

Powered driver

(optional)

AA

Securing the side brackets

bb

Fix the side brackets (2x) to the lower right and left sides

of the cabinetry with 8Gx16 countersunk screws. (B)

Once the appliance is secured to the cabinetry, remove

the alignment gauges and re-tighten the side screws.

45

Page 46

Tools

Powered driver

M8 hex key

(1)

REMOVE HANGING BRACKETS

a

b

top hanging bracket

1 Remove the M8 nut (A) and M8 washer (B) from the

M8 screw at the top of the refrigerator door using the

supplied hex key and spanner.

z

Repeat for the top of the drawer door.

13mm spanner (1)

2 Remove the top and bottom hanging brackets (D, E) and

set aside to use later.

d

bottom hanging bracket

3 Loosen the M8 screw (C) by 1/8" (3mm).

e

c

46

Page 47

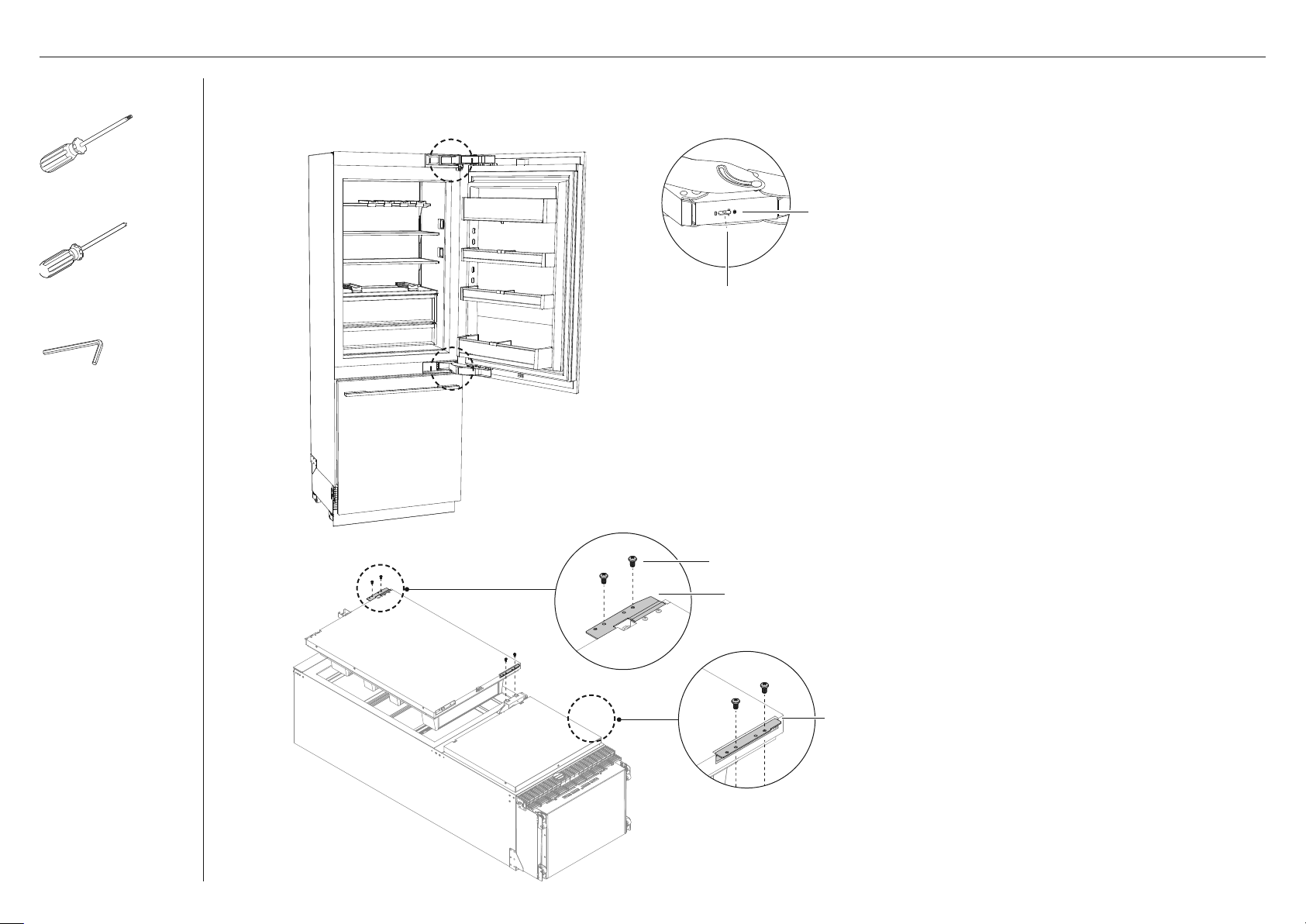

INSTALL DOOR AND DRAWER PANELS

Door handle kit

M5x25 Hex screw

(4x)

Tools

Powered driver

M8 hex key

(1)

13mm spanner (1)

STAINLESS STEEL PANELS CUSTOM PANELS

Remove the protective film around the handle attachment area of the

stainless steel panel before installing the handle.

Attaching refrigerator door handle

1 Secure the door handle to the handle

holes of the refrigerator door with

M5x25 pan head socket screws. (A)

A

blue tape

A

Attaching refrigerator door handle

1 Refer to 'Custom door panel

dimensions' page to locate the screw

holes on the door panel.

2 Secure the top door handle to the

handle holes of the refrigerator door

with #8x16 mush washer screw. (A)

B

Attaching freezer drawer handle

2 Secure the door handle to the

handle holes of the freezer door with

M5x25 pan head socket screws. (B)

blue tape

Remove the blue tape attached to inner edges of the door panels after the

handles are installed.

B

Attaching freezer drawer handle

3 Secure the bottom door handle to the

handle holes of the freezer door with

#8x16 mush washer screw. (B)

Ensure the door and drawer handles do not interfere when attaching the

side attachment brackets. Refer to 'Custom door panel install dimensions'

(page 17, page 25).

47

Page 48

INSTALL DOOR AND DRAWER PANELS

Door panel

attachment kit

Side bracket

(6)

Bracket slider

(6)

Bracket spacer

(6)

8Gx16 Mush washer

screw (30) — For

Stainless steel panels

M5x12 Cross-head screw

(30) — For Custom

panels

Tools

Powered driver

c

c

c

STAINLESS STEEL PANELS

Attaching top hanging

bracket

1 Secure the top hanging

Attaching side brackets

2 Secure the bracket

Attaching bottom hanging

bracket

3 Secure the bottom

B

B

B

A

A

B

c

d

d

bracket (A) to the screw

holes of the refrigerator

door panel with 8Gx16

Mush washer screws.

spacer, side bracket

and bracket slider (in

order as per drawing)

to the screw holes on

both sides of the door

and drawer panels

with 8Gx16 mush

washer screws. (B)

hanging bracket (D)

to the screw holes

of the freezer door

panels with 8Gx16 Mush

washer screws.

D

D

D

custom door panel

A

CUSTOM PANELS

B

C

C

C

A

C

D

hanging bracket

Attaching top hanging

bracket

1 Mark a line across

the center of the

custom door panel.

2 Align the top of the

centerline to the ‘V’

notch in the bracket. (A)

3 Secure the top hanging

B

bracket (B) to the screw

holes of the refrigerator

custom door panel with

M5x12 cross-head screws

Attaching side brackets

4 Secure the bracket

spacer, side bracket

and bracket slider (in

order as per drawing)

to the screw holes on

both sides of the door

and drawer panels

with M5x12 crosshead screw. (C).

48

Attaching bottom hanging

bracket

5 Secure the bottom

D

hanging bracket to

the screw holes of the

freezer door panels

with M5x12 Crosshead screws. (C)

Page 49

Tools

Powered driver

(with 2.5mm drill bit)

INSTALL DOOR AND DRAWER PANELS

A

b

Hanging the refrigerator door panel

1 Hold the door panel at an angle towards the top of

the refrigerator door (A).

Cross-head screwdriver

M4 hex key

(1)

1/2" (13mm) spanner

(1)

A

c

adjustment

screw

c

c

b

c

Left isometric view

hanging

bracket

D

2 Lower the screw holes of the hanging bracket

onto the adjustment screws at the top of the

refrigerator door. (B)

3 Screw the M8 washer and nut to the adjustment

screw and loosely tighten.

4 Slide-in the side brackets (C) to the side screws

of the door, and align the door panel straight

with the refrigerator door.

5 Tighten the side screws (D) loosely to

temporarily secure the door panel.

door panel

c

Repeat steps 1 - 4 for the freezer drawer panel.

49

Page 50

INSTALL DOOR AND DRAWER PANELS

Tools

Cross-head

screwdriver

M4 hex key

(1)

13mm spanner

(1)

Ensure the side brackets are loosely screwed when adjusting the height of the

door panel. Do not adjust the door panel height when the side brackets are

screwed tight. This can generate friction which causes the hanging brackets to

bend.

Adjusting height of door panel

1 Turn the adjustment screw to raise

or lower the height of the door panel

relative to the door.

2 Continue adjustment until gap with

Lower

Raise

cabinetry is more than 1/8 (3mm).

Do not adjust the adjustment screw

higher than 1/4" (6.5mm) from its fully

down position.

To adjust door panel further, remove the

door panel then loosen the fixing screws

of the hanging bracket and move the

bracket sideways to suit.

50

Adjusting depth of door panel

3 Loosen side screws on the side

brackets, and slide door panel

forward/backward.

4 Re-tighten once satisfied.

To adjust door panel further, remove the

door panel then loosen the fixing screws

of the hanging bracket and move the

bracket sideways to suit.

z

Once satisfied with door panel position,

fully tighten M8 washer and nut to

adjustment screw.

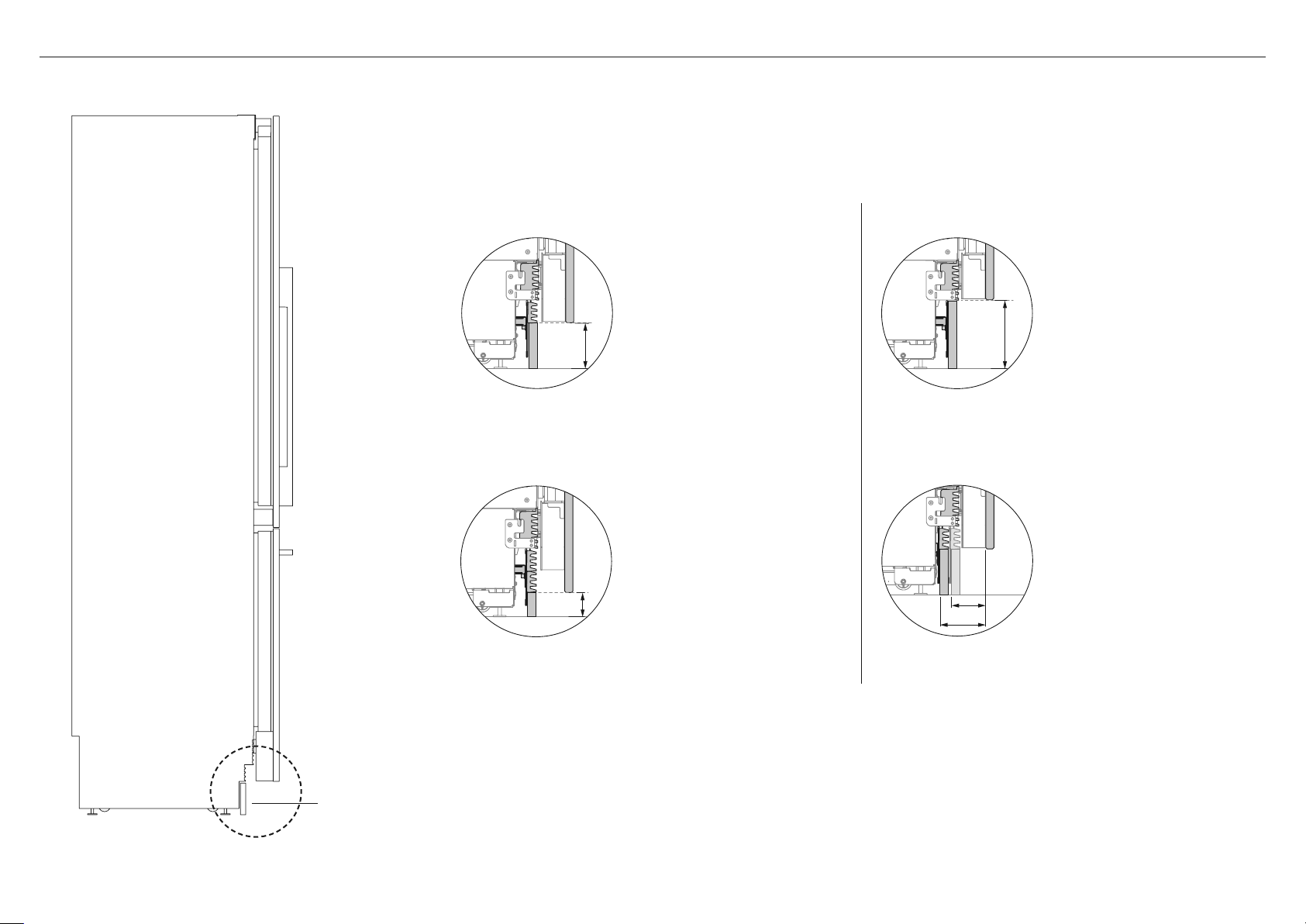

Page 51

Tools

Cross-head

screwdriver

Cutter

M4 hex key

(1)

INSTALL LOCKING BRACKET

INSTALL ADJUSTMENT BRACKETS

13mm spanner

(1)

B

A

1 Loosen the screw at the bottom

of the refrigerator door, and slide

thelocking bracket (A) out until it

touches the panel.

2 Fix the locking bracket

to the door panel with

8Gx16 countersunk screw (B).

3 Re-tighten the screw at the

bottom of the door.

C

D

1 Loosen the cap screws (C) of the

adjustment brackets (D) on both

sides of the plinth with a hex key.

2 Adjust the brackets to the

desired depth by moving it

forward/backward.

3 Re-tighten the cap screws

once satisfied.

51

Page 52

Miscellaneous

components

INSTALL TOE KICK PANEL

Air toe kick seal

(1)

Toe kick install kit

Toe kick panel

(1)

Tools

Cross-head screwdriver

M4 hex key

(1)

C

a

b

C

b

b

C

a

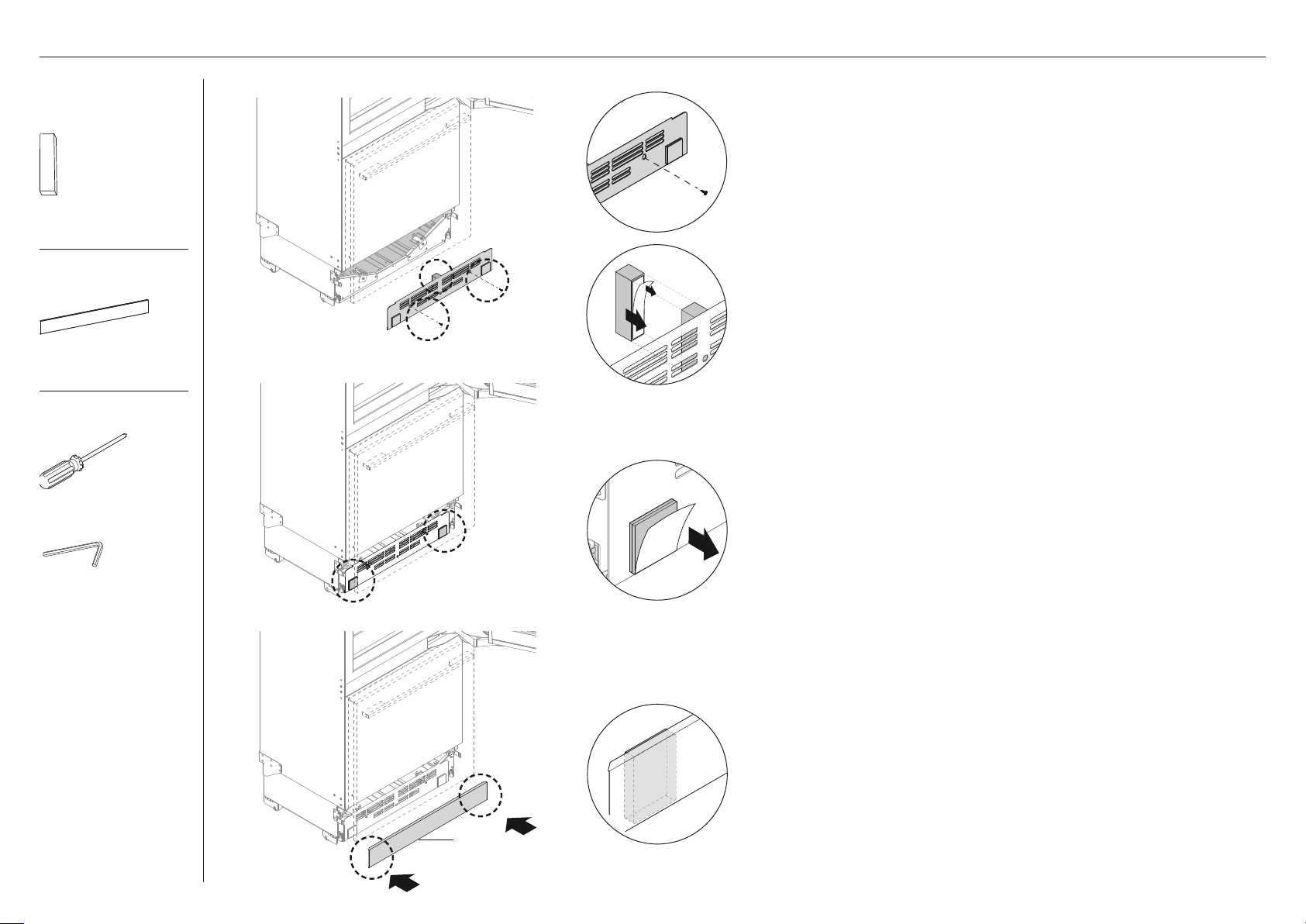

Attaching the mounting plate

1 Re-attach the toe kick mounting plate (A) to the plinth using same

screws that were set aside previously.

2 If toe kick depth is less than 3 5/8" (92mm), attach an air toe kick

seal (B) to the mounting plate.

z

Peel off the adhesive tape of air toe kick seal and attach to the

middle of the back side of the mounting plate.

3 Peel off the adhesive tape backing of the magnets (C) attached to

the mounting plate.

52

D

toe kick

D

D

Attaching the toe kick panel

1 Position the toe kick in front of the mounting plate.

z

The spacers (D) on the toe kick must be aligned with the

magnets of the mounting plate.

2 Press the toe kick onto the mounting plate to fix the position.

z

For custom toe kick, spacers are not needed.

z

For correct dimensions of toe kick, refer to 'Toe kick panel

dimensions' for more information.

Page 53

Tools

INSTALL TOP TRIMINSTALL TOE KICK GRILLES

Cutter

Cross-head screwdriver

A

b

Installing the top grille

1 Reattach the top grille (A)

using the same screws set

aside previously.

Installing the bottom grille

1 Reattach the bottom grille

(B) to the mounting plate .

z

For toe kick heights

4 1/2" - 5" (114–127mm),

shorten the bottom grille by

cutting along the vertical ribs.

a

Reinstalling the top trim

1 Slide one end of the top trim

(A) into the hinge pocket

of the appliance.

2 Press the other end to engage the

dual lock strips on the non-hinge

side of the appliance.

Toe kick, top and bottom

grilles complete installation

53

Page 54

Supplied tools

INSTALL WATER FILTER

Water filter

(1)

filter removal tool

top grille

Inserting the water filter

1 Remove the packaging from

the water filter.

2 Align the filter head with the

slot of the filter removal tool

and push until it clips in place.

3 Using the water removal tool,

hold the water filter with the

handle positioned vertically

and insert into the filter casing

through a hole in the top grille.

Removing and replacing the filter

1 To remove the water filter,

turn the filter removal tool

counterclockwise and pull

out the filter.

2 Unclip the tool from the

filter head and discard the

used water filter.

Refer to 'Inserting the water filter'

when replacing the filter.

54

4 Push firmly until the water filter

is all the way into the casing.

5 Turn the filter removal tool

clockwise to lock the water

filter in place.

Page 55

INSTALL AIR FLOW DIVIDER

Miscellaneous

components

Flow divider cap

(1)

Tools

Hacksaw

The air flow divider blocks the air flow from bypassing the front of the bottom grille.

B

B

a

1 Remove the adhesive layer (A) off the air flow divider.

2 Reinstall the air flow divider (B) to the bottom of the

freezer drawer with screw.

z

Ensure the adhesive layer side of the divider

contacts the door panel.

3 Press the flow divider firmly against the door panel.

C

4 Attach a flow divider cap (C) to the flow divider.

C

55

Page 56

INSTALL CABINET SIDE TRIMS

Install parts

Cabinet side trim

(2)

Tools

Cross-head screwdriver

Cutter

Dual adhesive strips are pre-attached at four locations along the side trim.

1 Peel off the liners from the

dual adhesive strips (A).

A

2 Position the trim (B) at an

angle on the throat of the

door hinge (C).

b

c

F

e

d

3 Hold the same angle and

slide the side trim bottom

end behind the lower

hinge down to the bottom

drawer side. (D)

4

Slide the side trim top end

behind the top hinge.

e

5 Slot the side trim behind

the top hinge pocket. (E)

6 Press the adhesive strip to

the cavity to ensure the

trim is also tight against the

inner face of the appliance.

7 On the non-hinge side,

slide in the side trim behind

the top trim. (F)

56

F

Page 57

Trims install kit

INSTALL DOOR AND DRAWER SIDE TRIMS

Top door panel side

extrusion (2)

Bottom drawer panel

side extrusion (2)

Bottom drawer top trim

(1)

A

front of door

c

e

b

D

Install door top extrusion

1 Align the top extrusion (A)

to the top of the door, and

match the notch (B) with the

magnet housing (C).

2 Clip the trim caps (D) at both

ends of top extrusion to both

ends of the top of the door.

3 Press the top extrusion down

to the door top surface. (E)

H

G

H

side trim

Install drawer top and side trims

1 Remove the adhesive

backing of adhesive strips

pre-attached to the underside

of the top trim (G).

2 Press down the top trim firmly

to engage the back surface of

the drawer panel.

z

Ensure the trim is fully seated

against the drawer top

surface.

3 Install the side trims (H) by

inserting into the panel gaps

on each side of the door.

z

Ensure the cabinet is

centered to prevent the

side trims from interfering

withthecabinet.

Cabinet side trim

(2)

f

Install door side extrusions

1 Press the side trims (F) to fit

into the panel gaps on the right

and left sides of the door.

2 Align the top of the side trims

to fit with the right and left

ends of the top extrusion.

side view

Your columns Installation is now complete!

57

Page 58

DUAL INSTALLATION

Install fasteners kit

Cabinet depth alignment

gauges (4)

Top joiner

bracket kit

Central spacer

(1)

8Gx16 Mush washer

screw (2)

Tools

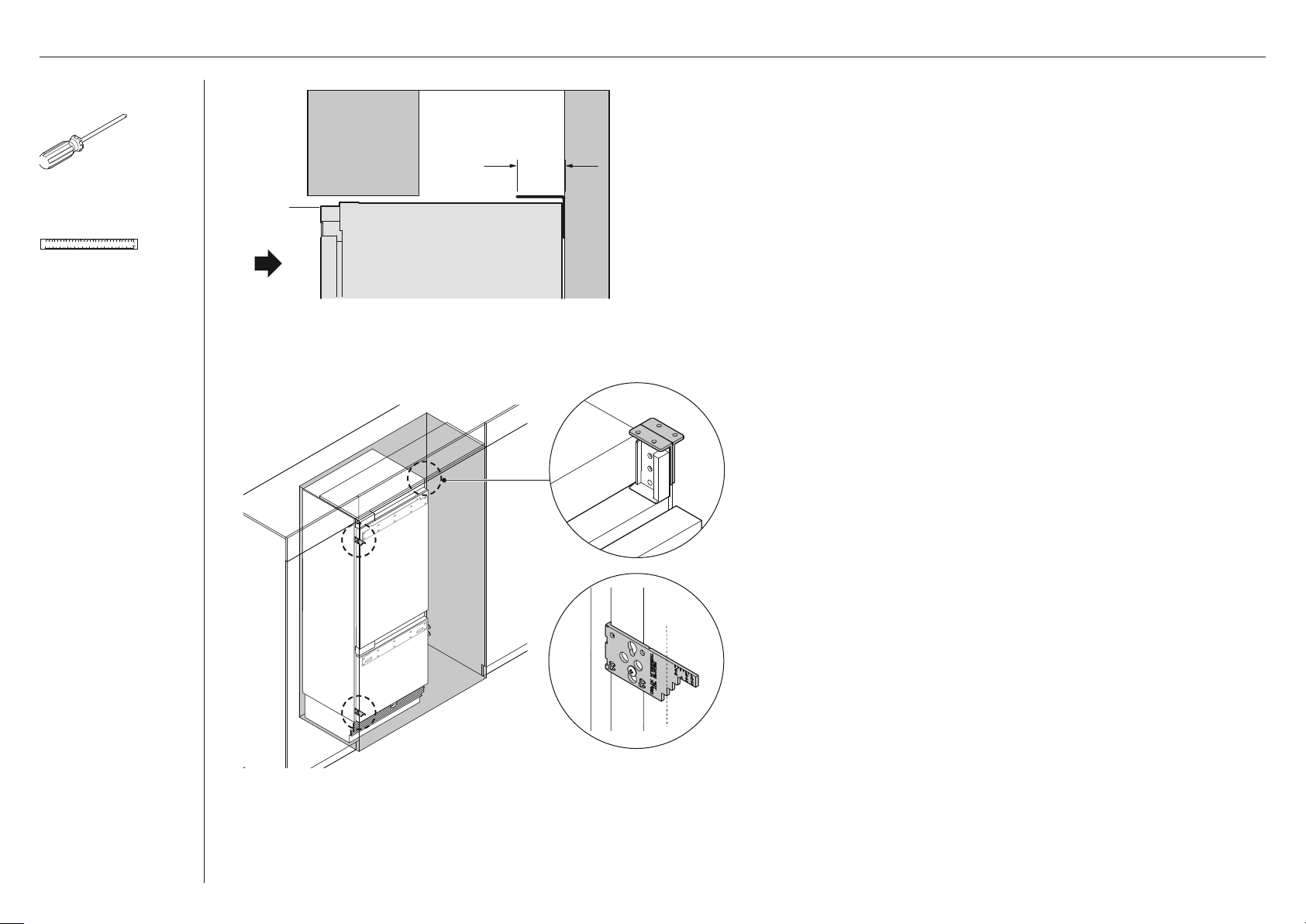

Attach central spacer to cabinetry

A

b

1 Measure the widths from the left (A) and right (B) cabinetry

sides towards thecentre to determine the spacer location.

Refer to "Cavity dimensions' page for correct width of the

appliance.

2 Mark the attachment location of the central spacer on the

cabinetry ceiling using the depth alignment gauge (C).

z

The depth position of spacer depends on the door panel

thickness.

Cross-head screwdriver

Powered driver (optional)

58

C

3 Fix a central spacer (C) to the alcove ceiling with

two 8Gx16 countersunk screws.

4 Tightenthescrews with a screwdriver or powered driver.

Page 59

Install fasteners kit

Cabinet depth alignment

gauges (4)

Barbed plugs

(2)

DUAL INSTALLATION

A

Attaching the depth alignment gauges

1 Loosen the screws (A) at the cabinetry sides of the door

and drawer of each appliance.

2 Locate the alignment gauges (B) at correct orientation to

the right and left side screws.

Tools

Cross-head screwdriver

Powered driver (optional)

C

b

Left

3 Position the alignment gauge by inserting the screw head

through the keyhole of the gauge.

4 Push the alignment gauge down to lock the screw position

in the keyhole.

5 Tighten the screw just enough to firmly hold the gauge.

The alignment gauges are only temporary and must be

removed after installation.

Attaching the barbed plugs

1 Before rolling into the cavity, insert barbed plugs

(C) into large holes on the top right and left sides of

both appliances.

Right

2 The plugs protect the inside surface of cabinetry from

being damaged by screws when pushing in the appliance.

59

Page 60

Tools

Cross-head screwdriver

Ruler

A

min 7 1/16" (180mm)

PROFILE VIEW

b

DUAL INSTALLATION

D

Aligning the first appliance into the cabinetry

1 Roll the first appliance (A) slowly into one side of the cabinetry

until the anti-tip bracket (B) overlaps the back edge of

the appliance.

z

Ensure the bracket overlaps the appliance by a

minimum 7 1/16" (180mm) for a secure hold. Refer to

'Install anti-tip bracket' for more information.

60

e

e

C

e

2 Align the top cap (C) of the first appliance flush with the front

of the spacer (D).

F

3 Mark the step of the depth gauges (E) on the cabinetry side of

the door based on the thickness of door panel.

4 Align the marked line (F) flush with the front surface of the

adjacent cabinetry.

Page 61

Install fasteners

kit

8Gx16 Countersunk

screw (6)

Tools

Cross-head

screwdriver

Powered driver

(optional)

Front foot

adjustment

screw

Rear foot

Rear foot

adjustment

screw

Foot

DUAL INSTALLATION

Adjusting the height of first

appliance in cabinetry

1 Turn the front and rear

adjustment screws clockwise

to raise height of the appliance

and counter-clockwise to

lower the height.

2 Turn the front and rear

adjustment screws clockwise to

extend the feet until it engages

the floor, and the top bracket

reaches ceiling of the alcove.

bA

bA

Securing first appliance in

cabinetry

1 Fix the left and right top

brackets (A, B) to the ceiling

surface of the cabinetry with

8Gx16 countersunk screws.

c

D

2 Fix the left and right lower

side brackets (C, D) to the

cabinetry side surface with

8Gx16 countersunk screws.

Ruler

ruler

Front foot

cd

3 Check the alignment gauges

while adjusting the screws

to maintain the alignment

of the appliance.

4 Using a ruler, check if the

gaps between appliance and

cabinetry side wall are even.

61

Page 62

Tools

Cross-head screwdriver

Ruler

A

PROFILE VIEW

min 180mm

b

DUAL INSTALLATION

D

C

E

Aligning the second appliance into the cabinetry

1 Push the second appliance (A) to roll slowly into

the other side of the cabinetry side by side with the

first appliance.

z

Ensure the bracket (B) overlaps the appliance

by a minimum 180mm for a secure hold. Refer to

'Install anti-tip bracket' for more information.

2 Align the top cap (C) of the second appliance flush

with the central spacer (D) and top cap (E) of the

first appliance.

62

H

G

F

adjacent cabinetry

3 Mark the step of depth gauge (F) on the

cabinetry side of the door based on the thickness

of door panel.

4 Align the marked line (G) flush with the front

surface of the adjacent cabinetry.

5 Adjust the height of the second appliance.

Refer to 'Adjusting the height of first appliance in

cabinetry' (page 59).

6 Using a ruler (H), check if the gaps between

appliances and cabinetry side walls are even.

Page 63

Top joiner fastener kit

DUAL INSTALLATION

M5x20 Cap

screw (1)

M5x16x1 Plain washer

(1)

Bottom joiner

fastener kit

M6x16 Washer screw

(1)

M6x12x3.2 Plastic washer

(1)

M6 Hex nut

(1)

D

BA

Securing the top brackets

1 Secure the top caps of both appliances to the central

spacer with M5x20 cap screw (A) and washer (B).

2 Secure the top brackets to the ceiling surface of the

cabinetry with 8Gx16 countersunk screws. (C)

c

Securing the bottom brackets

3 Secure the bottom joiner brackets of both

appliances together with the bottom joiner

fastener kit (D).

8Gx16 Countersunk screw

(5)

Tools

M4 Hex key

Cross-head screwdriver

D

E F

E

F

4 Secure the left and right bottom side brackets (E, F)

of the second appliance to the cabinetry with 8Gx16

countersunk screw.

Refer to the following pages to complete your

installation (pages 44-55):

z

Remove hanging brackets

z

Install door and drawer panels

z

Install locking bracket

z

Install adjustment brackets

z

Install toe kick panel

z

Install toe kick grilles

z

Install top trim

z

Install water filter

z

Install air flow divider

z

Install cabinet side trims

z

Install door and drawer side trims

63

Page 64

CHANGE THE DOOR HINGES (OPTIONAL)

Tools

T2 star-head screwdriver

Cross-head screwdriver

Hex key

You have the option to switch the door hinge side of your appliance from right hand hinge to left hand hinge or vice versa. A hinge change kit is required for this

installation, and must be purchased separately.

‘0’

T20 screw

Ensure that you remove all the shelves, covers

and trims from the appliance before changing the

hinges. Take care not to damage the door.

1 Release the hinge spring by turning the T20

screw in the hinge to the ‘0’ position.

2 Do this to both top and middle hinges.

64

M6x10 hex screws

Top hinge

Bottom hinge

3 Close the door and place the appliance on its

back on the pallet.

4 Detach the door from the appliance by

unscrewing the door hinge M6x10 hex screws at

the top and middle hinges.

Page 65

Tools

CHANGE THE DOOR HINGES (OPTIONAL)

A

T2 star-head screwdriver

Flat-head screwdriver

Removing the top door hinge

b

C

1 Rotate the top hinge (A) outwards and remove the top

hinge pocket cover (B) using the flat head screwdriver in

the slot of the cover.

E

D

f

2 Unscrew M6x16 countersunk screws (C) to remove top

hinge, and set aside to use later.

3 Unscrew M6x16 countersunk screws (D) from hinge pocket

to remove hinge pocket and top alcove bracket.

4 Unscrew M5x12 countersunk screws (E) to remove top hinge

bracket and spacer.

5 For the non-hinge side, remove the top alcove bracket by

unscrewing the M6x16 countersunk screws (F).

G

Removing the middle door hinge

1 Rotate the middle hinge (G) and unscrew M6x16

H

countersunk screws (H) to remove middle hinge, and set

aside to use later.

2 Unscrew M5x12 countersunk screws (I) to remove top hinge

I

bracket and spacer.

65

Page 66

CHANGE THE DOOR HINGES (OPTIONAL)

Tools

T20 star-head

screwdriver

Flat-head

screwdriver

Moving the sensor housing

1 Unclip the hall sensor

from the housing.

2 Unhook the

interceptor board

harness from

sensor housing so

harness is loose.

4 Move the sensor

housing to align the

opposite hall sensor

clip with the centre

of the cabinet.

5 Reinstall the sensor

housing using #8x16

screws (2x) into the

pre-drilled holes in

the cabinet top panel.

6 Clip the hall sensor

into the sensor housing

in the pocket closest

F

to the centreline

of the cabinet.

66

3 Remove the #8x16

screws (2x) from the

sensor housing.

7 Press the harness from

the interceptor board

into the forks on the

sensor housing.

Page 67

Hinge change

assembly

Hinge (right or left) top

pocket (1)

Lower (right or left)

hinge bracket (1)

K05 top adapter bracket

(1)

Top grille assembly

CHANGE THE DOOR HINGES (OPTIONAL)

D

Reinstalling the top hinge

c

A

e

b

f

1 Reinstall the hinge top bracket and bracket spacer

with M5x12 countersunk screws (A) onthe new hinge

side at the other side of theappliance.

2 Install the new hinge pocket and alcove top bracket

on the new hinge side using two (2x) M6x16

countersunk screws (B).

z

The new hinge pocket and top alcove bracket are

supplied with the hinge kit.

3 Install the new hinge in the new hinge pocket by

screwing M6x16 countersunk screws (2x) (C).

4 Open the hinge (D) and reinstall the top hinge pocket

cover (E) to the top hinge pocket..

5 Install a new top alcove bracket on the new

non-hinge side (F).

Top (fixed) grille

(1)

H

I

Reinstalling the middle door hinge

1 Reinstall the middle hinge bracket and spacer with M5x12

countersunk screws (G).

G

2 Open the middle hinge (H) and reinstall the hinge with

M6x16 countersunk screws (I).

67

Page 68

Hinge change

assembly

K05 top adaptor

bracket R/L (1)

K05 bottom adaptor

bracket R/L (1)

Tools

T2 star-head screwdriver

CHANGE THE DOOR HINGES (OPTIONAL)

A

use new top

adaptor bracket

b

Changing the top door bracket

1 Unscrew the M5x10 screws (4x) to remove the top

adapter bracket from the top of the door (A).

2 Install the new top adapter bracket into the

other side of thetop of the door with M5x10

screws (4x) (B).

Flat-head screwdriver

68

c

d

use new bottom adaptor

bracket and spacer

e

f

use existing locking bracket

Changing the bottom door bracket

1 Remove the door panel locking bracket and

washer from thebottom of the door by

unscrewing M6x25 screw (1x) (C).

2 Remove the bottom adapter bracket and spacer

from the bottom of the door by unscrewing M6x25

screws (2x) andM5x30 screw (1x) (D).

3 Install the new bottom adapter bracket and

existing spacer to the other side of the door with

M6x25 screws (2x) and M5x30 screw (1x) (E).

4 Install the existing door panel locking bracket and

washer tothe other side of the door with M6x25

screw (1x) (F).

Page 69

Tools

T2 star-head screwdriver

Flat-head screwdriver

Hex key

CHANGE THE DOOR HINGES (OPTIONAL)

A

Reinstalling the door

1 Secure the door to the top and middle hinges of

the appliance using M6x10 hex screws (4x). (A)

A

2 Activate the hinge spring by turning the star T20

screws to the I position. (B)

B

3 Return the appliance to the upright position, and

reinstall all covers and trims.

69

Page 70

TO BE COMPLETED BY THE INSTALLER

All models

F Check all parts are installed.

F Ensure the appliance is level.

F Ensure the appliance is securely fastened to the cabinetry with the

supplied anti-tip bracket and fittings.

F Ensure the door can open and close freely with no resistance from

surroundingcabinetry.

F Ensure hinge limiting pin is fitted for 90° door swing.

F Ensure all internal and external packaging is removed from the appliance

before use.

F Ensure that you write down and keep the wifi password, serial and model

numbers of your appliance.

FINAL CHECKLIST

Complete and keep for safe reference:

Model _____________________________________________________________

Serial No. _____________________________________________________________

Purchase Date _____________________________________________________________

Purchaser _____________________________________________________________

Dealer Address _____________________________________________________________

Installer’s Name _____________________________________________________________

Installer’s Signature _____________________________________________________________

Installation Company _____________________________________________________________

Installation Date _____________________________________________________________

70

Page 71

Page 72

FISHERPAYKEL.COM

© Fisher & Paykel Appliances 2020. All rights reserved.

The appliance specifications in this document apply to the specific

appliances and models described at the date of issue. Under our policy

of continuous appliance improvement, these specifications may change

at any time. You should therefore check with your Dealer to ensure this

document correctly describes the appliance currently available.

US CA

86026B0.20

Page 73

COLONNE ENCASTRABLE

RÉFRIGÉRATEUR CONGÉLATEUR

Modèles RS2484WR, RS2484WL, RS3084WR

et RS3084WL

GUIDE D’INSTALLATION

US CA

86026B0.20

Page 74

Page 75

TABLE DES MATIÈRES

Consignes de sécurité et mises en garde 4

Colonnes encastrables — réfrigérateur–congélateur 5

Vérification de votre appareil 6

Déplacement de votre appareil 7

Avant l’installation 8

Pièces fournies 9

Pièces requises 11

panneau de plinthe 11

Ensemble de panneau de porte 12

Ensembles de poignée de porte et tiroir 12

Ensemble de changement de côté des charnières 13

Dimensions du produit— MODÈLE RS24 14

Dimensions de la cavité — Modèle RS24 15

Dimensions de panneau de porte— MODÈLE RS24 16

Dimensions d’installation de panneau de porte sur mesure— MODÈLE RS24 17

Dégagement de la porte — modèle RS24 18

Dégagement du tiroir — modèle RS24 19

Dimensions de la plinthe — modèle RS24 20

Options d’installation de la plinthe 21

Dimensions du produit— modèle RS30 22

Dimensions de la cavité — Modèle RS30 23

Dimensions de panneau de porte— modèle RS30 24

Dimensions d’installation de panneau de porte sur mesure— modèle RS30 25

Dégagement de la porte — modèle RS30 26

Dégagement du tiroir — modèle RS30 27

Dimensions de la plinthe — modèle RS30 28

Options d’installation double 29

Dimensions de la cavité — installation double RS24 + RS24 30

Dimensions de la cavité — installation double RS24 + RS30 31

Dimensions de la cavité — installation double RS30 + RS30 32

Dimensions de panneau de plinthe — installation double 33

Dimensions pour l’alimentation électrique 34

Spécifications électriques 35

Spécifications de plomberie 35

Installation du support antibasculement 36

Raccordement de l’alimentation en eau et de l’alimentation électrique 38

Positionnement et alignement dans les armoires 40

Fixation de l’appareil aux armoires 45

Retrait des supports d’accrochage 46

Installation des panneaux de porte et tiroir 47

Installation du support de blocage 51

Installation des supports d’ajustement 51

Installation du panneau de plinthe 52

Installation des grilles de plinthe 53

Installation de la garniture supérieure 53

Installation du filtre à eau 54

Installation du diviseur de débit d’air 55

Installation des garnitures latérales de bâti 56

Installation des garnitures latérales de porte et tiroir 57

Installation double 58

Changement de côté des charnières de porte (étape optionnelle) 64

Liste de vérification finale 70

CONSERVEZ CES INSTRUCTIONS

Les modèles illustrés dans ce guide d’installation peuvent ne pas être disponibles dans tous les pays et sont sujets à modifications sans préavis. Pour les plus récentes informations sur la disponibilité des

modèles et des caractéristiques dans votre pays, visitez notre site Web fisherpaykel.com ou contactez votre détaillant Fisher&Paykel local.

75

Page 76

CONSIGNES DE SÉCURITÉ ET MISES EN GARDE

!

MISE EN GARDE!

Risque de choc électrique

Lisez et observez les consignes de sécurité

et mises en garde contenues dans ce guide

d’installation avant d’utiliser cet appareil.

Le fait de ne pas respecter ces consignes

peut causer la mort, un choc électrique, un

incendie ou des blessures.

!

MISE EN GARDE!

Risque de coupure

Attention — les bords du panneau sont

tranchants.

Des blessures ou des coupures peuvent

survenir si vous ne faites pas preuve de

prudence.

!

MISE EN GARDE!

Comme cet appareil est lourd du haut, vous

devez le fixer pour éviter qu’il ne bascule

vers l’avant.

Pour assurer la stabilité de l’appareil

dans toutes les conditions d’utilisation, le

support antibasculement et les raccords

fournis doivent être installés par un

installateur professionnel, conformément

aux étapes d’installation suivantes.

MISE EN GARDE!

Pour réduire les risques de danger, suivez attentivement ces instructions avant d’installer ou

utiliser cet appareil.

z

Veuillez remettre ces informations à la personne qui installera l’appareil.

z

Présumez que toutes les pièces électriques sont sous tension.

z

Déconnectez l’alimentation électrique avant de procéder à l’entretien et à l’installation.

AVANT L’INSTALLATION

z

L’appareil est muni de roulettes avant et arrière qui facilitent le déplacement vers l’avant

et l’arrière. Pour éviter d’endommager les roulettes ou le revêtement/la surface du

plancher, ne déplacez pas l’appareil latéralement.

z

Veillez à ce que votre appareil ne soit exposé à aucun appareil générant de la chaleur

comme une surface de cuisson, un four ou un lave-vaisselle.

z

Pour éviter des raccordements d’alimentation électrique et de plomberie incorrects,

faites installer l’appareil par un installateur qualifié ou un technicien de service formé et

supporté par Fisher&Paykel.

z

Tous les raccordements d’alimentation électrique et de mise à la terre doivent être

conformes aux codes et règlements locaux et être effectués par un technicien autorisé,

lorsque nécessaire.

z

Évitez d’installer les appareils à proximité d’un disjoncteur différentiel de fuite à la terre

(DDFT).

z

Assurez-vous que l’appareil est installé correctement. Les défaillances de l’appareil

résultant d’une installation incorrecte ne sont pas couvertes par la garantie de l’appareil.

DÉBALLAGE

z

L’appareil est lourd; le déplacement et l’installation nécessitent au moins deuxpersonnes.

z

Retirez l’ensemble d’installation (boîte interne) et l’ensemble de garnitures (boîte externe)

pendant que le produit est toujours sur la palette.

z

Évitez d’égratigner la surface de votre appareil lors du déplacement ou de l’installation.

z

Gardez l’appareil stable et la porte fermée pour éviter tout basculement lors du

déplacement jusqu’à l’emplacement d’installation.

z

Assurez-vous que les pattes de l’appareil sont rétractées avant le déplacement jusqu’à

l’emplacement d’installation.

z