Fisher & Paykel 635 Active Smart, 680 Active Smart, 790 Active Smart, R600a, 900 Active Smart Service Manual

...Page 1

Service Manual

635 / 680 / 790 / 900 Active Smart®

Refrigerator/Freezer

R134a & R600a Systems

321144

Page 2

321144

2

Page 3

321144 - JULY 2012 REPRINT - AUGUST 2012

The specifications and servicing procedures outlined in this manual are subject to change without notice.

The latest version is indicated by the reprint date and replaces any earlier editions.

Fisher & Paykel Appliances Ltd

78 Springs Road,

East Tamaki

Auckland 2013

PO Box 58-732, Botany,

Auckland 2163,

New Zealand

Fisher & Paykel Australia Pty Ltd

A.C.N. 003 335 171

19 Enterprise Street

P O Box 798

Cleveland, Queensland 4163

Telephone: 07 3826 9100

Facsimile: 07 3826 9164

Telephone: 09 273 0600

Facsimile: 09 273 0656

Fisher & Paykel Appliances

5800 Skylab Road

Huntington Beach

CA 92647

Telephone: 888 936 7872

Fisher & Paykel Appliances Ltd U.K

Maidstone Road,

Kingston, Milton Keynes

Buckinghamshire, MK10 0BD

England

Telephone: 0845 066 2200

Facsimile: 0845 331 2360

COPYRIGHT © FISHER & PAYKEL LTD 2012 - ALL RIGHTS RESERVED

3

Fisher & Paykel Singapore Pte Ltd

150 Ubi Avenue 4

Sunlight Building #02-00

Singapore 408825

Telephone: 65 65470100

Facsimile: 65 65470123

Page 4

321144

CONTENTS

SPECIFICATIONS ...................................................................................................................................8

1

1.1 Cabinet Specifications – 230 - 240 Volt....................................................................................8

1.2 Cabinet Specifications – 110 - 115 Volt..................................................................................10

1.3 Compressor Specifications – R134a – 220 - 240 Volt............................................................11

1.4 Compressor Specifications – R600a – 220 - 240 Volt............................................................12

1.5 Compressor Specifications – R134a – 110 - 115 Volt............................................................13

1.6 Model Number Identification – 635 / 680 / 790 .......................................................................14

1.7 Model Number Identification – 900 .........................................................................................15

2 SERVICING REQUIREMENTS..............................................................................................................16

2.1 Specialised Service Tools.......................................................................................................16

2.1.1 Static Strap .........................................................................................................................16

2.1.2 Interface Light Pen Mk 2 ....................................................................................................16

2.2 Health & Safety .......................................................................................................................16

2.2.1 Good Work Practices.........................................................................................................16

2.2.2 Environmental Health And Safety ......................................................................................16

2.2.3 Good Practice And Safety..................................................................................................16

3 INSTALLATION INSTRUCTIONS .........................................................................................................17

3.1 Levelling ..................................................................................................................................17

3.2 Door Hinging (Tasman Models Only) .....................................................................................18

3.3 Air Space Requirements .........................................................................................................18

3.4 Temperature Adjustment ........................................................................................................18

4 THEORY OF OPERATION ....................................................................................................................19

4.1 Terms ......................................................................................................................................19

4.2 Internal Air Flow ......................................................................................................................20

4.2.1 Ice & Water Models............................................................................................................20

4.2.2 Non Ice & Water Models ....................................................................................................21

4.3 Defrost Cycle...........................................................................................................................22

4.3.1 R134a System....................................................................................................................22

4.3.2 R600a System....................................................................................................................23

4.4 The Refrigeration Circuit .........................................................................................................24

4.5 Evaporator...............................................................................................................................24

4.6 Condensate Disposal..............................................................................................................25

4.7 Filter Drier ...............................................................................................................................25

4.8 Internal Condenser .................................................................................................................26

4.8.1 Condenser Lay Out 635 / 680 / 790 "T" Models ................................................................27

4.8.2 Condenser Lay Out 635 / 680 / 790 / 900 "B" Models .......................................................28

4.9 Compressor Compartment Layout..........................................................................................29

4.10 Cross Rail................................................................................................................................29

4.11 Door and Door Hinge ..............................................................................................................29

4.12 Compressor.............................................................................................................................29

4.13 Thermal Fuse ..........................................................................................................................29

4.14 Drain Heater Wire ...................................................................................................................29

4.15 Divider Partition.......................................................................................................................30

4.16 LCD Display Panel ..................................................................................................................31

4.17 Door Switches .........................................................................................................................31

4.18 Defrost Heater.........................................................................................................................31

4.19 Low Ambient Heater................................................................................................................32

4.20 PC / FC Fans ..........................................................................................................................32

4.20.1 “B” Model Fan.....................................................................................................................32

4.20.2 “T” Model PC Fan...............................................................................................................33

4.21 Interior Light ............................................................................................................................34

4.22 Thermistor Temperature Sensors ...........................................................................................35

4.23 Basic Operation.......................................................................................................................36

4.23.1 Temperature Adjustment – Ice & Water Models ................................................................36

4.23.2 Temperature Adjustment – Non-Ice & Water Models ........................................................36

5 ELECTRONICS SECTION.....................................................................................................................37

5.1 Diagrammatic Overview Function Description........................................................................37

5.2 Control and Peripheral Functions ...........................................................................................38

5.3 Power/Control Module ............................................................................................................38

4

Page 5

321144

Display Module .......................................................................................................................39

5.4

6 VARIABLE CAPACITY COMPRESSOR ..............................................................................................40

6.1 Variable Capacity Compressor Control Overview .................................................................. 40

6.2 Built-in Electronic Protections (Within the Module/Inverter) ...................................................40

6.2.1 Compressor Start-up..........................................................................................................40

6.2.2 Overload Detection and Protection....................................................................................40

6.2.3 Power Limitation (Temperature Protection) ....................................................................... 41

6.2.4 Short Circuit Protection ......................................................................................................41

6.3 VCC Module/Inverter Identification.........................................................................................41

6.4 Fault Finding ...........................................................................................................................41

6.4.1 High Voltage Power Supply Circuit....................................................................................41

6.5 VCC-3 Inverter With Diagnostic Function...............................................................................42

6.5.1 Diagnostic Procedures.......................................................................................................42

6.5.2 Testing The VCC3 Inverter (With Diagnostic Function).....................................................44

7 DISPLAY INTERFACE – ICE & WATER MODELS .............................................................................48

7.1 Display Functional Schematic ................................................................................................48

7.2 Display Interface Features...................................................................................................... 49

7.3 Features..................................................................................................................................49

7.3.1 Icemaker On/Off.................................................................................................................49

7.3.2 Freezer Chill Mode.............................................................................................................49

7.3.3 Bottle Chill Mode ................................................................................................................49

7.3.4 Water Dispensing...............................................................................................................49

7.3.5 Sabbath Mode....................................................................................................................50

7.3.6 Key Silent Mode ................................................................................................................. 50

7.3.7 Dispenser Lock ..................................................................................................................50

7.3.8 Key Lock ............................................................................................................................50

7.3.9 Filter Replacement Alert ....................................................................................................50

7.4 Key Presses............................................................................................................................51

7.5 Temperature Settings .............................................................................................................51

8 ICEMAKER ............................................................................................................................................52

8.1 Ice Production.........................................................................................................................52

8.2 Information About The Icemaker ............................................................................................52

8.3 Ice Bin Full Sequence............................................................................................................. 52

8.4 Safety First..............................................................................................................................53

8.5 Icemaker Fill Tube Heater ......................................................................................................53

8.6 Pressure Limiting Valve ..........................................................................................................53

8.7 Water Inlet Valves...................................................................................................................53

8.8 Noises .....................................................................................................................................54

8.9 Ice & Water Common Complaints ..........................................................................................54

9 WATER DISPENSER ............................................................................................................................55

9.1 Installation Precautions / Warning ..........................................................................................55

9.2 Pressure Dispensing Pad .......................................................................................................55

9.3 Initial Use ................................................................................................................................55

9.4 Water Filter and Cartridge ......................................................................................................55

9.5 Changing The Water Filter......................................................................................................56

9.6 To Reset The Filter Icon .........................................................................................................56

9.7 To Disable The Filter Alarm ....................................................................................................56

10 DIAGNOSTICS ......................................................................................................................................57

10.1 Ice & Water Models................................................................................................................57

10.1.1 Fault Codes........................................................................................................................57

10.1.2 Testing Icemaker Sensor ...................................................................................................61

10.1.3 Testing Icemaker Motor .....................................................................................................61

10.1.4 Testing Water Valve...........................................................................................................62

10.1.5 Diagnostic Modes ..............................................................................................................63

10.1.6 Input / Output Status ..........................................................................................................65

10.1.7 Fault History ....................................................................................................................... 65

10.1.8 To Manually Force A Defrost .............................................................................................65

10.1.9 LCD Display .......................................................................................................................65

10.1.10 To Manually Force The Icemaker......................................................................................66

10.1.11 Data Download ..................................................................................................................66

10.2 Non-Ice & Water Models.........................................................................................................67

10.2.1 Fault Codes........................................................................................................................67

5

Page 6

321144

Diagnostic Mode For Service .............................................................................................70

10.2.2

10.2.3 Sensor Temperature Conversion .......................................................................................70

10.2.4 Input / Output Status ..........................................................................................................71

10.2.5 Data Download...................................................................................................................72

10.2.6 To Manually Force A Defrost .............................................................................................72

10.2.7 Show Room Mode..............................................................................................................72

10.2.8 Special Option Mode (Israel)..............................................................................................73

10.3 Problem Solving Checklist ......................................................................................................74

11 ICEMAKER & WATER DISPENSER SERVICE PROCEDURES .........................................................75

11.1 Component Replacement .......................................................................................................75

11.1.1 Icemaker PCB Replacement ..............................................................................................75

11.1.2 Icemaker Unit Removal ......................................................................................................75

11.1.3 Refitting Icemaker ..............................................................................................................75

11.1.4 Icemaker Temperature Sensor Replacement ....................................................................75

11.1.5 Water Valve Replacement .................................................................................................75

11.1.6 Display Module Replacement ............................................................................................76

11.1.7 Water Dispenser Pad Replacement...................................................................................77

11.1.8 Removing Water Tank........................................................................................................77

11.1.9 Refitting Water Tank...........................................................................................................78

11.1.10 Replacing Icemaker Fill Tube Heater ................................................................................78

11.1.11 Replacing PC Door On Ice & Water Models......................................................................81

11.1.11.1 Designer Doors.........................................................................................................81

11.1.11.2 Classic Doors............................................................................................................84

12 SERVICING PROCEDURES.................................................................................................................88

12.1 Safety Considerations .............................................................................................................88

12.2 Electrical Safety Test ..............................................................................................................88

12.3 Doors and Door Gaskets ........................................................................................................89

12.4 Removal Of Power/Control Module ........................................................................................89

12.4.1 Initialisation Of The Power/Control Module After Installation – Non-Ice & Water Models .90

12.5 Freezer Bin, Runner and Air Deflector Removal - E402B and E372B Models.......................90

12.6 FC Bin Removal - 900 Models ................................................................................................90

12.7 FC Drawer Removal - 900 Models .........................................................................................91

12.7.1 Refitting Of The FC Drawer................................................................................................91

12.8 PC Fan Motor - “T” Models .....................................................................................................92

12.9 PC Fan Motor - “B” Models .....................................................................................................92

12.10 Defrost Element Replacement ................................................................................................92

12.11 Thermal Fuse ..........................................................................................................................92

12.12 Cross / Base Rail Door Switches ............................................................................................93

12.13 Removal Of Display Module – Non-Ice & Water Models........................................................93

12.14 PC Sensor Replacement ........................................................................................................93

12.15 FC Sensor Replacement- “T” and “B” Models........................................................................93

12.16 FC Sensor Replacement - 900 Models...................................................................................93

12.17 Icemaker Temperature Sensor Replacement.........................................................................93

12.18 Replacement Of Low Ambient Heater - “T” Model..................................................................94

12.19 Replacement Of Low Ambient Heater - “B” Models ...............................................................94

12.20 Replacement Of Low Ambient Heater - “B” Model (In Return Grill) .......................................94

12.21 Interior LED Light Replacement..............................................................................................94

12.22 Flapper Element Replacement ...............................................................................................95

12.23 Block/Edge Connectors ..........................................................................................................97

12.24 Fan Cover Removal Tool (T Models Only) .............................................................................99

12.25 Active Smart® PC/FC Fan Motor Tester .................................................................................99

13 WORKING ON THE SEALED SYSTEM............................................................................................. 101

13.1 Safe Work Practices ............................................................................................................ 101

13.2 Leak Detection ..................................................................................................................... 101

13.3 R600a Operating Pressures ................................................................................................ 101

13.4 Reclaiming ........................................................................................................................... 101

13.5 Brazing Off The System....................................................................................................... 102

13.6 Pressure Testing Of The Refrigeration System ................................................................... 102

13.7 Transporting Of Refrigerators .............................................................................................. 104

13.8 Evaporator Replacement ..................................................................................................... 105

13.9 Refilling A Void In Foam Insulation After System Service Or Adjustment ........................... 105

13.9.1 Polyurethane Foam ......................................................................................................... 106

13.9.2 Safe Practices ................................................................................................................. 106

6

Page 7

321144

Removing Back Panel For Access To Water Lines And Joints............................................ 107

13.10

13.11 Embraco Compressor Fitted With External Overload ..........................................................108

13.12 Matsushita “D” Series Compressor Fitted With External Overload And Run Capacitor ......109

13.13 Compressor Replacement ....................................................................................................110

13.14 Compressor Fault Diagnosis ................................................................................................111

13.14.1 Compressor Won't Start - Dead (PTC Relay Fitted) ....................................................111

13.14.2 Compressor Won't Start - Hums......................................................................................112

13.14.3 Compressor Starts, Runs And Then Stops .....................................................................112

14 WIRING DIAGRAMS...........................................................................................................................113

14.1 Non Ice & Water Models Power Module Wiring Connections ..............................................113

14.2 Non-Ice & Water Models Wiring Diagram.............................................................................114

14.3 Ice & Water Models Power Module Wiring Connections...................................................... 115

14.4 Ice & Water Models Wiring Diagram ....................................................................................116

14.5 900 Models Power Module Wiring Connections - Reciprocating Compressor ....................117

14.6 900 Models Wiring Diagram - Reciprocating Compressor ...................................................118

14.7 900 Models Power Module Wiring Connections – VC Compressor..................................... 119

14.8 900 Models Wiring Diagram - VC Compressor....................................................................120

14.9 “B” Model Wiring Route ........................................................................................................121

14.10 “T” Model Wiring Route.........................................................................................................122

15 SERVICE REFERENCE ......................................................................................................................123

15.1 Service Reference ‘B’ Models ..............................................................................................123

15.2 Service Reference ‘T’ Models...............................................................................................127

16 FAULT FINDING FLOW CHART - SERVICING .................................................................................130

16.1 Refrigerator Not Operating ...................................................................................................131

16.2 No Power To Power/Control Module And/Or Display Module.............................................. 132

16.3 PC/FC Warm.........................................................................................................................133

16.4 FC Too Cold – PC Too Warm...............................................................................................134

16.5 PC Too Cold .........................................................................................................................135

16.6 Ice/Condensation Forming....................................................................................................136

16.7 No Light.................................................................................................................................137

16.8 Door Switch Not Operating ...................................................................................................138

16.9 Defrost Heater Faults............................................................................................................139

16.10 Compressor Faults ...............................................................................................................140

16.11 Compressor Runs Continuously...........................................................................................140

16.12 Compressor Will Not Run And Is Hot To Touch...................................................................141

16.13 Compressor Electrical Tests.................................................................................................141

16.14 Refrigeration System Faults .................................................................................................142

16.15 Not Dispensing Water...........................................................................................................143

16.16 Not Producing Ice .................................................................................................................144

7

Page 8

321144

1 SPECIFICATIONS

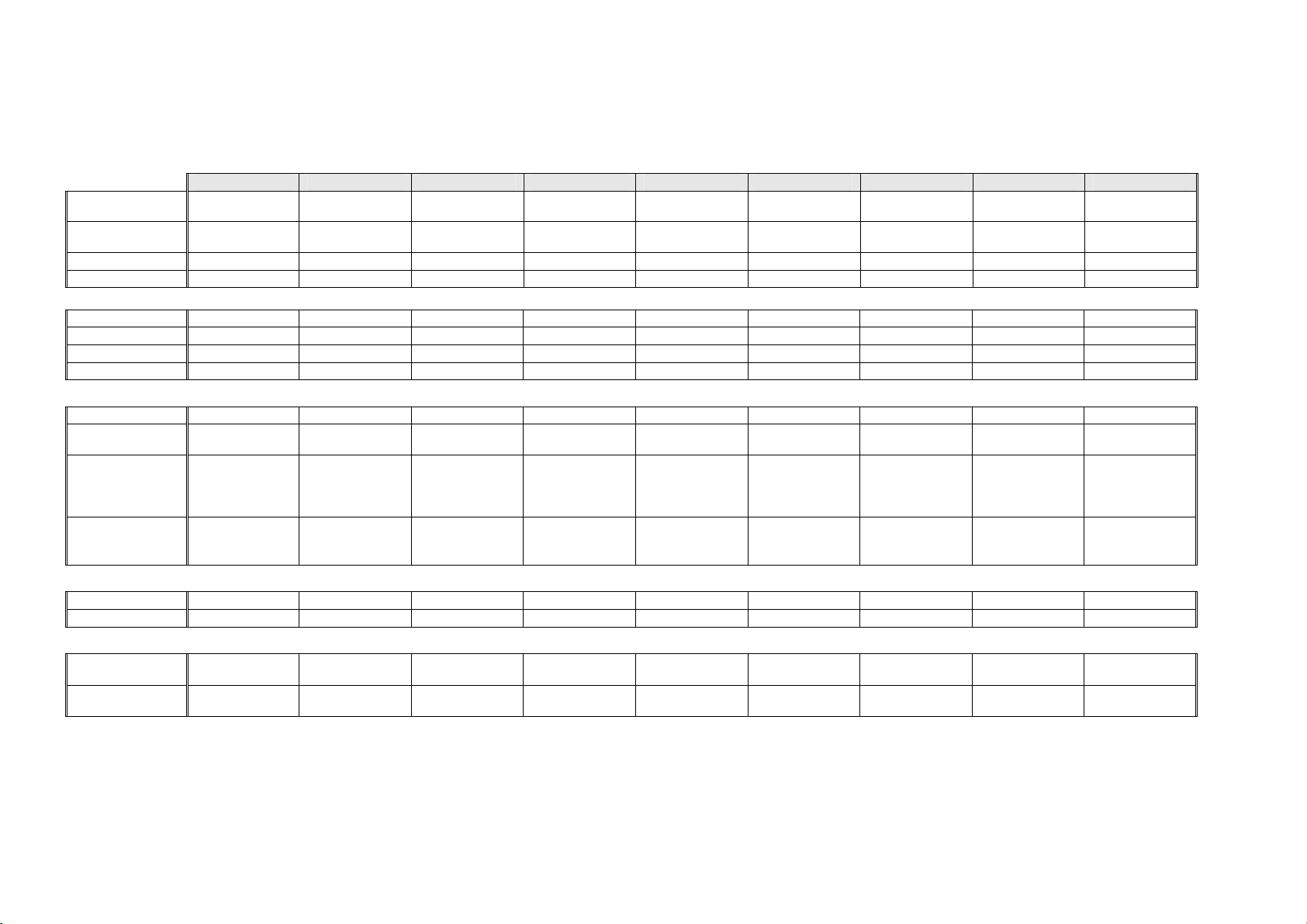

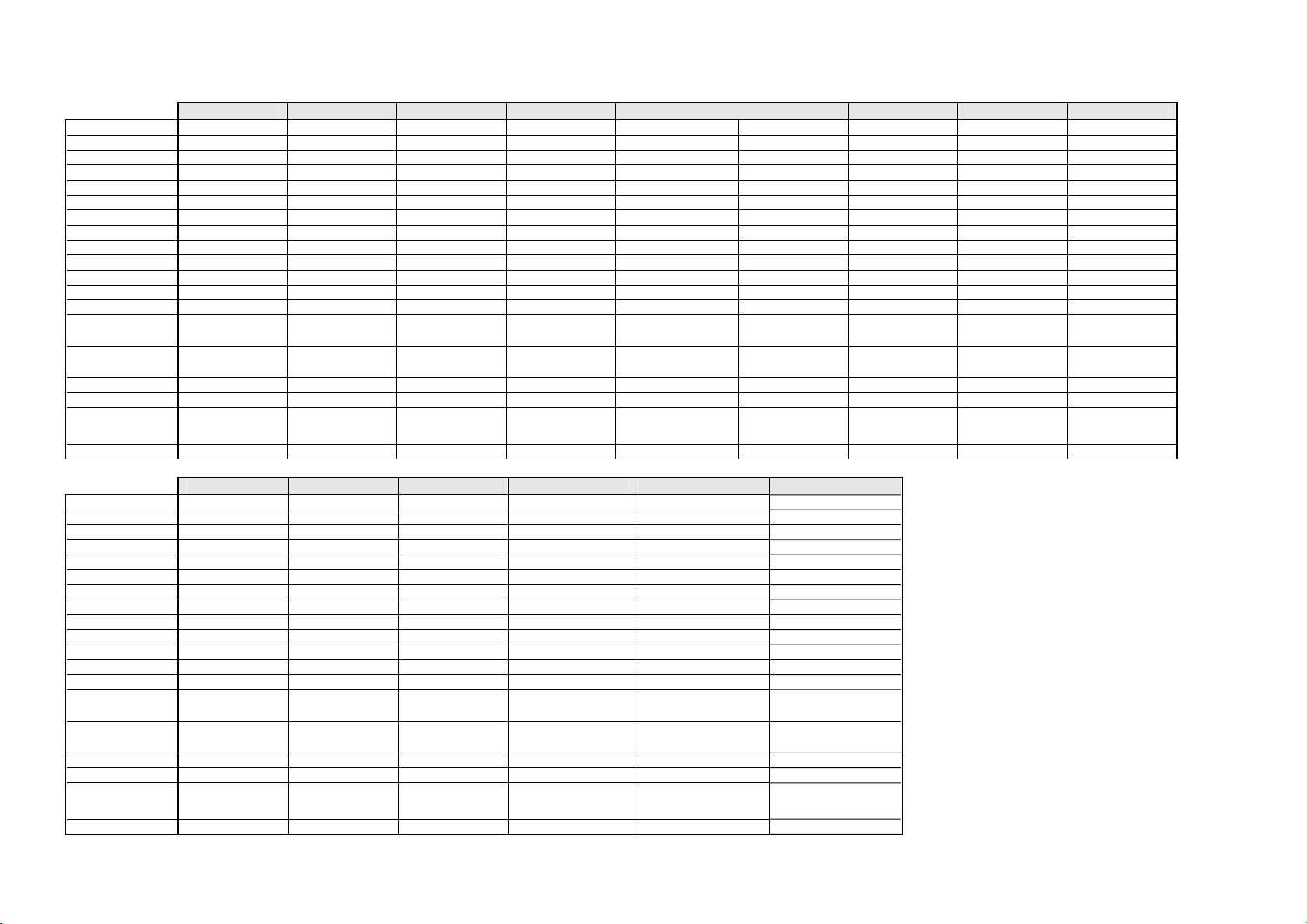

1.1 Cabinet Specifications – 230 - 240 Volt

DIMENSIONS

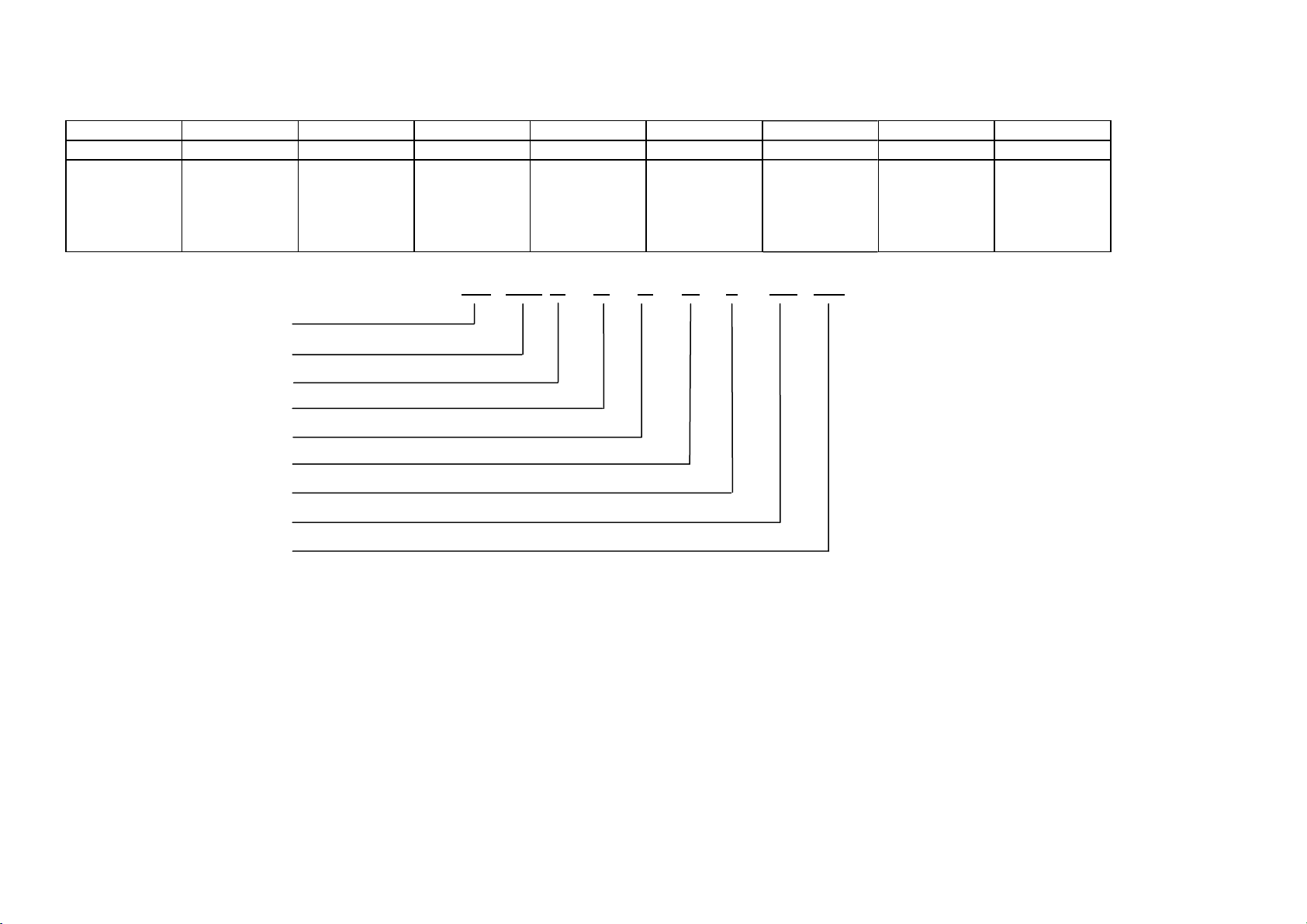

E331T E372B E381T E402B E406B E411T E413T E415H E440T

Height with

Standard Door

Height with

Designer Door

Depth 700 mm 700 mm 700 mm 700 mm 700 mm 700 mm 700 mm 700 mm 700 mm

Width 635 mm 635 mm 635 mm 635 mm 680 mm 635 mm 680 mm 635 mm 680 mm

CAPACITY GROSS VOLUME IN LITRES (AS 1430)

Refrigerator PC 232 litres 250 litres 283 litres 280 litres 271 litres 314 litres 314 litres 229 litres 342 litres

Freezer FC 97 litres 123 litres 97 litres 123 litres 133 litres 97 litres 97 litres 97 litres 99 litres

Humidity Dr N/A N/A N/A N/A N/A N/A N/A 85 litres N/A

TOTAL

ELECTRONICS – 230 – 240V (FOR SPARE PARTS)

Display Module P/No. 881218P P/No. 881218P P/No. 881218P P/No. 881218P P/No. 881218P P/No. 881218P P/No. 881218P P/No. 881218P P/No. 881218P

Display Module -

Ice & Water

Power/Control

Module - Non

RoHS

(AUS/NZ/ROW)

Power/Control

Module - RoHS

(UK/IRE/EU)

1425 mm 1595 mm 1595 mm 1700 mm 1700 mm 1700 mm 1595 mm 1700 mm 1700 mm

N/A N/A N/A 1710 mm N/A N/A N/A N/A N/A

329 litres 373 litres 380 litres 403 litres 404 litres 411 litres 411 litres 411 litres 441 litres

N/A N/A N/A P/No. 821074P N/A N/A N/A N/A N/A

P/No. 820817P P/No. 820817P P/No. 820817P P/No. 820817P P/No. 820817P P/No. 820817P P/No. 820817P P/No. 820817P P/No. 820817P

P/No. 820818P P/No. 820818P P/No. 820818P P/No. 820818P P/No. 820818P P/No. 820818P P/No. 820818P P/No. 820818P P/No. 820818P

SUCTION LINE ASSY (FOR SPARE PARTS)

R134a Models P/No. 813374 P/No. 817862 P/No. 813374 P/No. 817862 P/No. 817865 P/No. 817863 P/No. 817866 P/No. 817863 P/No. 817866

R600a Models N/A P/No. 821189 N/A P/No. 821149 P/No. 821149 N/A P/No. 821151 N/A P/No. 821150

DEFROST ELEMENT – 230 - 240V (FOR SPARE PARTS)

R134a Models

Wattage

R600a Models

Wattage

P/No. 820673

295W

N/A

P/No. 820673

295W

P/No. 821875

178W

P/No. 820673

295W

N/A

P/No. 820673

295W

P/No. 821875

178W

P/No. 820675

322W

P/No. 821876

196W

P/No. 820673

295W

N/A

P/No. 820675

322W

P/No. 821876

196W

P/No. 820673

295W

N/A

P/No. 820675

322W

P/No. 821876

196W

8

Page 9

DIMENSIONS

E442B E521T E522B RF540A/RF610A

Height with

Standard Door

Height with

Designer Door

Depth 700 mm 700 mm 700 mm (27.6”) 730 mm (28.7”)

Width 680 mm 790 mm 790 mm (31.1”) 900 mm (35.4”)

1700 mm 1700 mm 1700 mm (67”) 1780 mm (70.1”)

1710 mm N/A 1710 mm (67.3”) 1790 mm (70.5”)

CAPACITY GROSS VOLUME IN LITRES (AS 1430)

Refrigerator PC 307 litres 400 litres 360 litres (12.7 c/ft) 433 litres (15.3 c/ft)

Freezer FC 135 litres 117 litres 159 litres (5.6 c/ft) 181 litres (6.4 c/ft)

Humidity Dr N/A N/A N/A N/A

TOTAL

442 litres 517 litres 519 litres (18.3 c/ft) 614 litres (21.7 c/ft)

ELECTRONICS – 230 - 240V (FOR SPARE PARTS)

Display Module P/No. 814321P P/No. 814321P P/No. 814321P N/A

Display Module Ice & Water

Power/Control

Module - Non

RoHS

(AUS/NZ/ROW)

Power/Control

Module –RoHS

(UK/IRE/EU)

P/No. 821074P N/A P/No. 821074P P/No. 821074P

P/No. 820817P P/No. 820817P P/No. 820817P

P/No. 820818P P/No. 820818P P/No. 820818P

(RF610A)

P/No. 821024P

(RF540A)

P/No. 821025P

SUCTION LINE ASSY (FOR SPARE PARTS)

R134a Models P/No. 817865 P/No. 817866 P/No. 817864 P/No. 817864

R600a Models P/No. 821149 P/No. 821150 P/No. 821148 P/No. 821148

321144

DEFROST ELEMENT – 230 - 240V (FOR SPARE PARTS)

R134a Models

Wattage

R600a Models

Wattage

P/No. 820675

322W

P/No. 821876

196W

P/No. 860686

355W

P/No. 821877

240W

P/No. 860686

355W

P/No. 821877

240W

P/No. 860686

355W

P/No. 821877

240W

9

Page 10

321144

1.2 Cabinet Specifications – 110 - 115 Volt

DIMENSIONS

E402B E415H

Height with

Standard Door

Height with

Designer Door

Depth 694 mm 694 mm

Width 635 mm 635 mm

CAPACITY GROSS VOLUME IN LITRES (AS 1430)

Refrigerator PC 280 litres 226 litres

Freezer FC 123 litres 97 litres

Humidity Dr N/A 88 litres

TOTAL

ELECTRONICS – 100 - 110V (FOR SPARE PARTS)

Display Module P/No. 881218P P/No. 881218P

Display Module -

Ice & Water

Power/Control

Module

SUCTION LINE ASSY (FOR SPARE PARTS)

R134a Models P/No. 817862 P/No. 817863

DEFROST ELEMENT –100 - 110V 321W (FOR SPARE PARTS)

R134a Models

100V

110V

1700 mm 1700 mm

1710 mm N/A

403 litres 411 litres

P/No. 820174P N/A

P/No. 820819P P/No. 820819P

P/No. 820821P

P/No. 820699P

P/No. 820821P

P/No. 820699P

10

Page 11

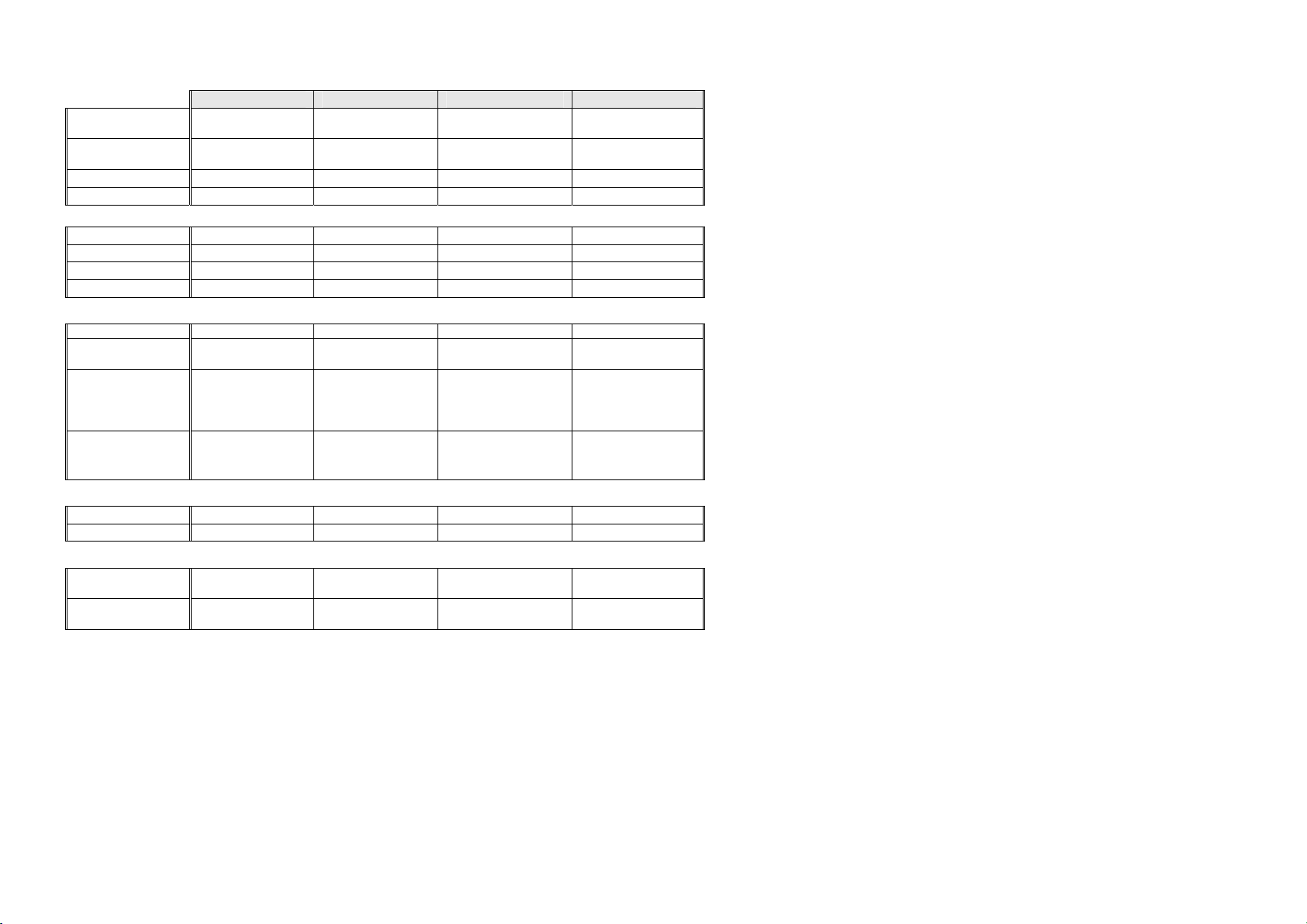

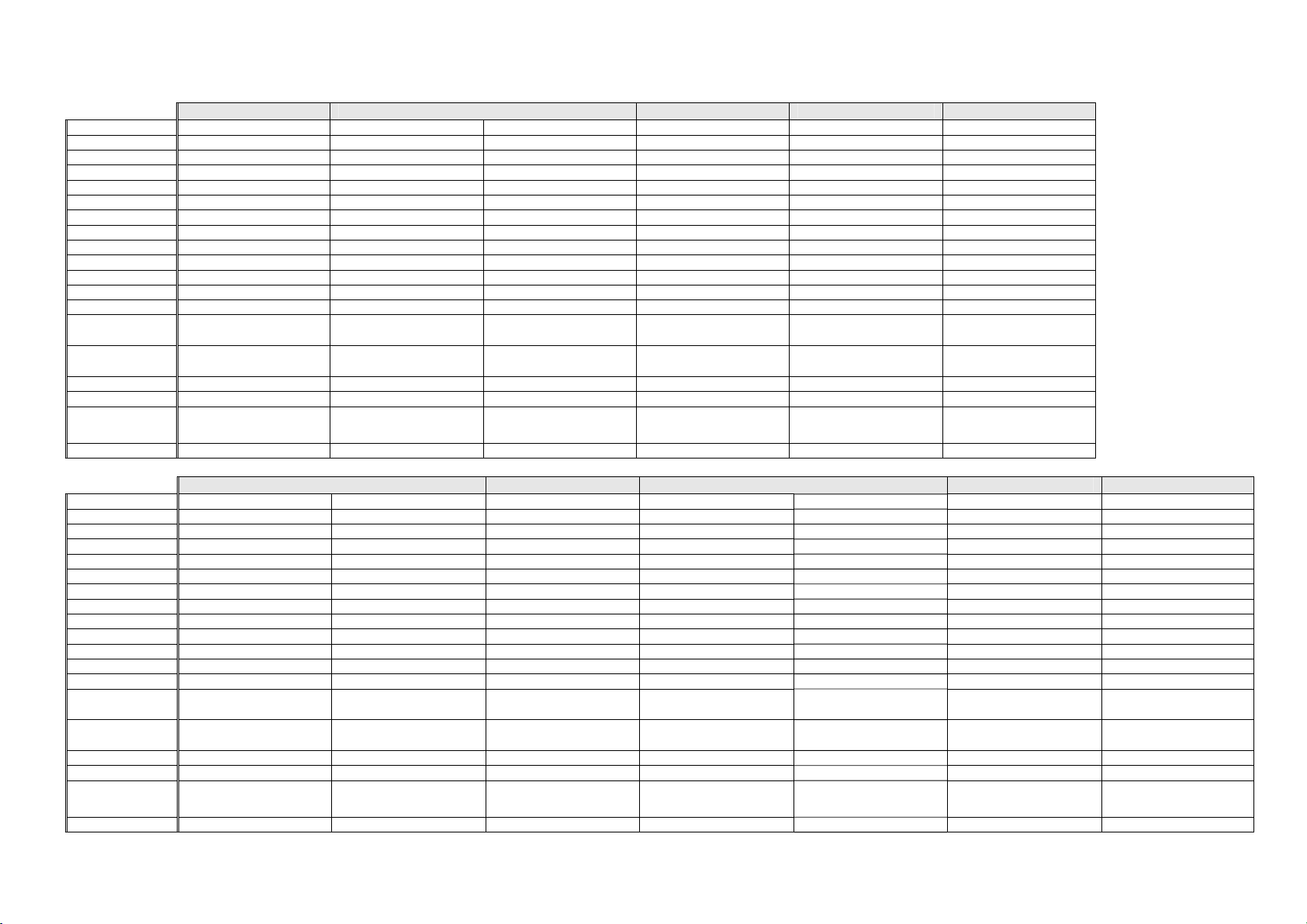

1.3 Compressor Specifications – R134a – 220 - 240 Volt

E331T E372B E381T E402B E406B E411T E413T E415H

Make Matsushita Matsushita Matsushita Matsushita Embraco Matsushita Matsushita Matsushita Matsushita

Model DHS73C10RAW DHS73C10RAW DHS66C88RAW DHS73C10RAW EGZS90HLC DB77C14RAY DB77C14RAY DHS73C10RAW DHS66C88RAW

Part number 207216P 207216P 207215P 207216P 207188P 209492P 209492P 207216P 207215P

Volts 220 - 240 220 - 240 220 - 240 220 - 240 230 230 - 240 230 - 240 220 - 240 220 - 240

Hertz 50 50 50 50 50 - 60 50 50 50 50

Input Watts 123 123 113 123 129 / 153 147 147 123 113

Output Watts 210 210 190 210 226 / 278 213 213 210 190

Nominal BTU 717 717 649 717 770 / 950 742 742 717 649

Run current 0.57 amps 0.57 amps 0.53 amps 0.57 amps 0.71 amps 1.2 amps 1.2 amps 0.57 amps 0.53 amps

Refrigerant type R134a R134a R134a R134a R134a R134a R134a R134a R134a

Start Resistance 18.5 ohms 18.5 ohms 23.3 ohms 18.5 ohms 21.7 ohms 16.43 ohms 16.43 ohms 18.5 ohms 23.3 ohms

Run Resistance 18.4 ohms 18.4 ohms 19.7 ohms 18.4 ohms 10.4 ohms 11.62 ohms 11.62 ohms 18.4 ohms 19.7 ohms

Oil charge (cm3) 280 (Ester) 280 (Ester) 280 (Ester) 280 (Ester) 280 (Ester) 310 (Ester) 310 (Ester) 280 (Ester) 280 (Ester)

Relay PTC

Overload

Gas charge 120 Grams 130 Grams 120 Grams 140 Grams 150 Grams 150 Grams 130 Grams 140 Grams 130 Grams

Start Capacitor N/A N/A N/A N/A N/A N/A N/A N/A N/A

Run Capacitor

Inverter N/A N/A N/A N/A N/A N/A N/A N/A N/A

PTHTM330MD3

207276

5TM22NFBYY

207224

4µF

814809P

E440T E442B E521T E522B RF540A/RF610A RF540A/RF610A

Make Matsushita Matsushita Matsushita Matsushita Embraco Embraco

Model DB77C14RAY DB77C14RAY DHS77C13RAW DHS77C13RAW EGZS100HCL VEGY6H

Part number 209492P 209492P 207217P 207217P 207253P 819639P

Volts 230 - 240 230 - 240 220 - 240 220 - 240 220 - 240 220 - 240

Hertz 50 50 50 50 50 / 60 53 - 150

Input Watts 147 147 133 133 143 / 171 55.7 - 177

Output Watts 213 213 222 222 251 / 308 97 - 283

Nominal BTU 742 742 758 758 855 / 1050 330 - 965

Run current 1.2 amps 1.2 amps 0.64 amps 0.64 amps 0.8 amps 0.8 - 2.23 amps

Refrigerant type R134a R134a R134a R134a R134a R134a

Start Resistance 16.43 ohms 16.43 ohms 18.2 ohms 18.2 ohms 25.8 ohms 6.4 ohms

Run Resistance 11.62 ohms 11.62 ohms 15.2 ohms 15.2 ohms 9.84 ohms 6.4 ohms

Oil charge (cm3) 310 (Ester) 310 (Ester) 280 (Ester) 280 (Ester) 280 (Ester) 430 (Ester)

Relay PTC

Overload

Gas charge 140 Grams 150 Grams 155 Grams 150 Grams (5.3 oz) 180 Grams 180 Grams

Start Capacitor N/A N/A N/A N/A N/A N/A

Run Capacitor

Inverter N/A N/A N/A N/A N/A 207213

MM8-5DDT33M

209988

MM3-18GCF

209083

4µF

814809P

PTHTM330MD3

207276

5TM22NFBYY

207224

4µF

814809P

MM8-5DDT33M

209988

MM3-18GCF

209083

4µF

814809P

PTHTM330MD3

207276

5TM205NFBYY

207222

4µF

814809P

PTHTM330MP3

207276

5TM232NFBYY

207226

4µF

814809P

PTHTM330MD3

207276

5TM22NFBYY

207224

4µF

814809P

PTHTM330MP3

207276

5TM232NFBYY

207226

4µF

814809P

PTH7M220MD3

207080

4TM283NFBYY-53

207289

4µF

814809P

207080

7M220MD3

4TM302KFBYY

207259

4µF

814809P

MM8-5DDT33M

209988

MM3-18GCF

209083

4µF

814809P

N/A

N/A

N/A

MM8-5DDT33M

209988

MM3-18GCF

209083

4µF

814809P

PTHTM330MD3

207276

5TM22NFBYY

207224

4µF

814809P

PTHTM330MD3

207276

5TM205NFBYY

207222

4µF

814809P

321144

11

Page 12

321144

1.4 Compressor Specifications – R600a – 220 - 240 Volt

E372B E402B E406B E413T E440T

Make Embraco Embraco Embraco Embraco Embraco Embraco

Model EMB55CLC EMB66CLC VEMC9C EMB66CLC EMB66CLC EMB66CLC

Part number 207314P 207278P 207308P 207278P 207278P 207278P

Volts 220 - 240 220 - 240 220 - 240 220 - 240 220 - 240 220 - 240

Hertz 50 50 53 - 150 50 50 50

Input Watts 86 102 33 - 117 102 102 102

Output Watts 162 190 62 -210 190 190 190

Nominal BTU 553 648 213 - 715 648 648 648

Run current 0.4 amps 0.5 amps 0.28 - 0.86 amps 0.5 amps 0.5 amps 0.5 amps

Refrigerant type R600a R600a R600a R600a R600a R600a

Start Resistance 11.6 ohms 12.7 ohms 8.1 ohms 12.7 ohms 12.7 ohms 12.7 ohms

Run Resistance 21 ohms 15.9 ohms 8.1 ohms 15.9 ohms 15.9 ohms 15.9 ohms

Oil charge (cm3) 150 (Alquib/ISO5) 150 (Alquib/ISO5) 210 (Alquib/ISO5) 150 (Alquib/ISO5) 150 (Alquib/ISO5) 150 (Alquib/ISO5)

Relay PTC

Overload

Gas charge 50 Grams 50 Grams 50 Grams 55 Grams 52 Grams 52 Grams

Start Capacitor N/A N/A N/A N/A N/A N/A

Run Capacitor

Inverter N/A N/A 207309 N/A N/A N/A

EMB66QP2 20A

207292

4TM232KFBYY-53

207243

4µF

814809P

EMB66QP2 20A

207292

4TM232KFBYY-53

207243

4µF

814809P

E442B E521T E522B RF540A RF610A

Make Embraco Embraco Embraco Embraco Embraco Embraco Embraco

Model EGX80CLC VEMC9C EGX80CLC EGX90CLC VEMB11C VEMB11C EGX100CLC

Part number 207279P 207308P 207279P 207280P 207306P 207306P 207281P

Volts 220 - 240 220 - 240 220 - 240 220 - 240 220 - 240 220 - 240 220 - 240

Hertz 50 53 - 150 50 50 53.3 – 143.3 53.3 – 143.3 50

Input Watts 107 33 - 177 107 117 58 - 161 58 - 161 133

Output Watts 199 62 - 210 199 216 108 - 283 108 - 283 248

Nominal BTU 679 213 - 715 679 737 510 - 965 510 - 965 846

Run current 0.49 amps 0.28 - 0.86 amps 0.49 amps 0.85 amps 0.43 - 1.16 amps 0.43 - 1.16 amps 0.61 amps

Refrigerant type R600a R600a R600a R600a R600a R600a R600a

Start Resistance 22.45 ohms 8.1 ohms 22.45 ohms 22.45 ohms 8.1 ohms 8.1 ohms 17.6 ohms

Run Resistance 18.35 ohms 8.1 ohms 18.35 ohms 18.35 ohms 8.1 ohms 8.1 ohms 17.3 ohms

Oil charge (cm3) 280 (Alquib/ISO5) 210 (Alquib/ISO5) 280 (Alquib/ISO5) 280 (Alquib/ISO5) 210 (Alquib/ISO5) 210 (Alquib/ISO5) 280 (Alquib/ISO5)

Relay PTC

Overload

Gas charge 55 Grams 50 Grams 60 Grams 60 Grams 55 Grams 62 Grams 70 Grams

Start Capacitor N/A N/A N/A N/A N/A N/A N/A

Run Capacitor

Inverter N/A 207309 N/A N/A 207307 207307 N/A

PTH7M220MD3

207080

4TM189NFBYY-53

209890

4µF

814809P

N/A

N/A

N/A

N/A

N/A

N/A

PTH7M220MD3

207080

4TM189NFBYY-53

209890

4µF

814809P

EMB66QP2 20A

207292

4TM232KFBYY-53

207243

4µF

814809P

PTH7M220MD3

207080

4TM189NFBYY-53

209890

5µF

814812P

EMB66QP2 20A

207292

4TM232KFBYY-53

207243

4µF

814809P

N/A

N/A

N/A

N/A

N/A N/A

EMB66QP2 20A

207292

4TM232KFBYY-53

207243

4µF

814809P

PTH7M220MD3

207080

4TM283KFBYY-53

207154

5µF

814812P

12

Page 13

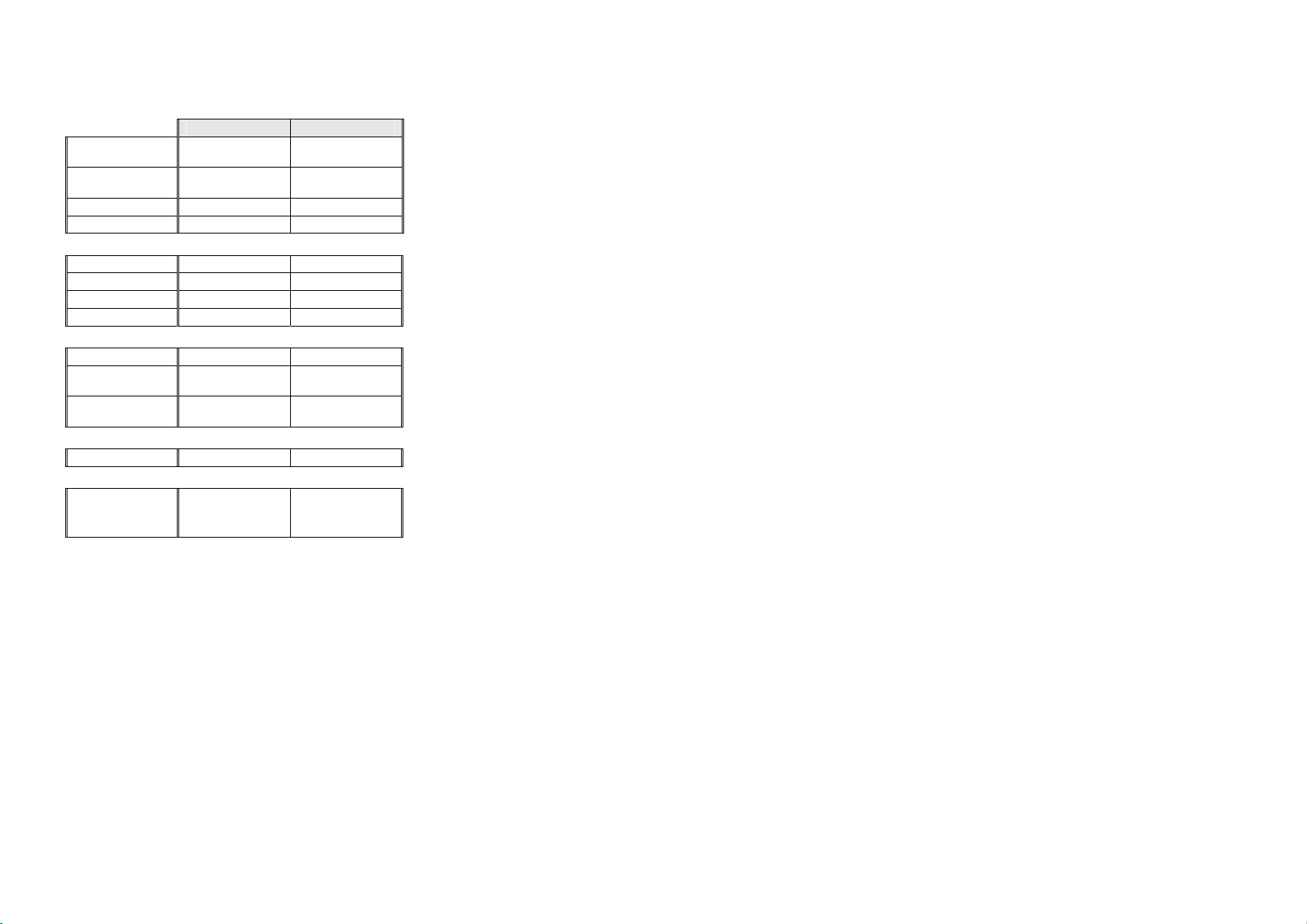

1.5 Compressor Specifications – R134a – 110 - 115 Volt

Make Embraco Embraco Embraco

Model EGZS70HLP EGZS70HLP VEGY6H

Part number 207206P 207206P 819652P

Volts 115 115 115

Hertz 60 60 53.3 - 150

Input Watts 116 116 55.7 - 177

Output Watts 204 204 97 - 283

Nominal BTU 695 695 330 - 965

Run current 1.04 amps 1.04 amps 0.8 - 2.23 amps

Refrigerant type R134a R134a R134a

Start Resistance 6.94 ohms 6.94 ohms 6.4 ohms

Run Resistance 4.88 ohms 4.88 ohms 6.4 ohms

Oil charge (cm3) 280 (Ester) 280 (Ester) 430 (14.54 oz) (Ester)

Relay PTC

Overload

Gas charge 140 Grams (4.9 oz) 120 Grams (4.2 oz) 180 Grams (6.3 oz)

Start Capacitor N/A N/A N/A

Run Capacitor N/A N/A N/A

Inverter N/A N/A 207214

E402B E415H RF540A/RF610A

7M4RMD3

207068

4TM319NFBYY

207205

7M4RMD3

207068

4TM319NFBYY

207205

N/A

N/A

321144

13

Page 14

321144

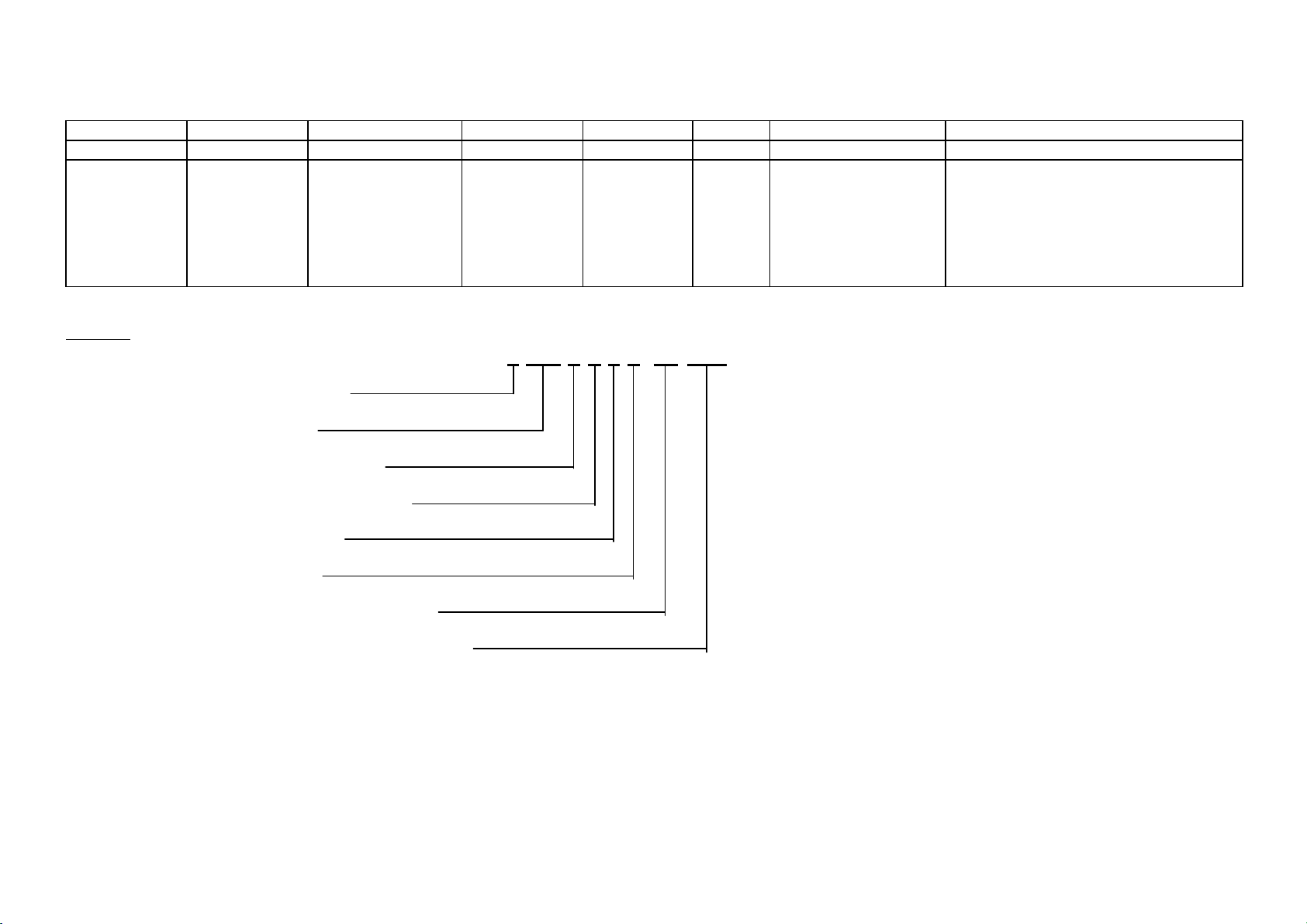

1.6 Model Number Identification – 635 / 680 / 790

1 2 3 4 5 6 7 8

E 402 B R E C FP WW

Type of

refrigeration

system

E = Electronic

Example:

E Electronic

402 Litres

B Bottom freezer

R Right hand hinged

E Elegance

C Series

FP Fisher & Paykel brand

WW White cabinet, white doors

Approximate

capacity of

cabinet in

litres

402 = 402 litres

Freezer location

T = Top freezer

B = Bottom freezer

H = Humidity drawer

Door hinging

R = Right hand

L = Left hand

Style

D = Designer

E = Elegance

I = Inox

M = Iridium

T = Tasman

E402BREC FP WW

Series Brand

FP = Fisher & Paykel

Colour of the cabinet and doors

WW = White cabinet / white doors

SA = Sandstone cabinet / sandstone

doors

SM = Silver cabinet / matt stainless doors

SX = Silver cabinet / brushed stainless

doors

14

Page 15

1.7 Model Number Identification – 900

1 2 3 4 5 6 7 8 9

RF 610 A D U M 2 FP SG

Product Type Capacity of

cabinet in

Litres

610 = 610

litres

RF Refrigerator

610 Litres/Cubic feet

A French Door

D Designer Handle

U Ice & Water

M Iridium

2 Iteration

FP Fisher & Paykel

SG Singapore

French

Doors

Designer

Ice & Water Colour

Handles

RF 610 A D U M 2 FP SG

321144

Iteration Brand Market

M = Iridium

X = S/S

Ezkleen

15

Page 16

321144

2 SERVICING REQUIREMENTS

2.1 Specialised Service Tools

For the servicing of this product, specialised tools are needed.

2.1.1 Static Strap

To be used as ESD protection when replacing any of the electronic boards.

2.1.2 Interface Light Pen Mk 2

Used in conjunction with a diagnostic programme on a laptop computer to retrieve and download data from

the electronic power/control module.

2.2 Health & Safety

2.2.1 Good Work Practices

1. Take care while removing all plastic components, especially when cold.

2. Leave the product clean and tidy when service work is completed.

3. Extreme heat in cabinets will cause plastic deterioration or distortion and thermal fuses in the

evaporator to go open circuit (be careful with heat guns).

2.2.2 Environmental Health And Safety

When servicing products, consider health and safety issues and requirements that must be adhered to at all

times. Specific safety issues are:

1. Electrical safety.

2. Electrostatic discharge.

3. Mixing of foam insulation.

4. Vapours while brazing.

5. Reclaiming of refrigerant.

2.2.3 Good Practice And Safety

1. Take care when removing or servicing all electrical components to avoid electrical shock or short

circuit conditions.

2. Take care when removing plastic components at low temperatures as breakages can occur with these

components.

3. Extreme heating of plastic components can cause distortion of those parts being heated.

4. Avoid overheating temperature sensitive devices such as the element thermal fuses and cabinet

sensors.

5. Avoid using solvents and citrus-based cleaners on all plastic parts. We advise only warm soapy water

be used.

CAUTION – R600a REFRIGERANT (ISOBUTANE)

Some models of refrigerators contain R600a refrigerant within the sealed in system. This refrigerant is

flammable. All care must be taken when servicing these products. Vent well before brazing. Avoid any

open flames or ignition source.

16

Page 17

321144

3 INSTALLATION INSTRUCTIONS

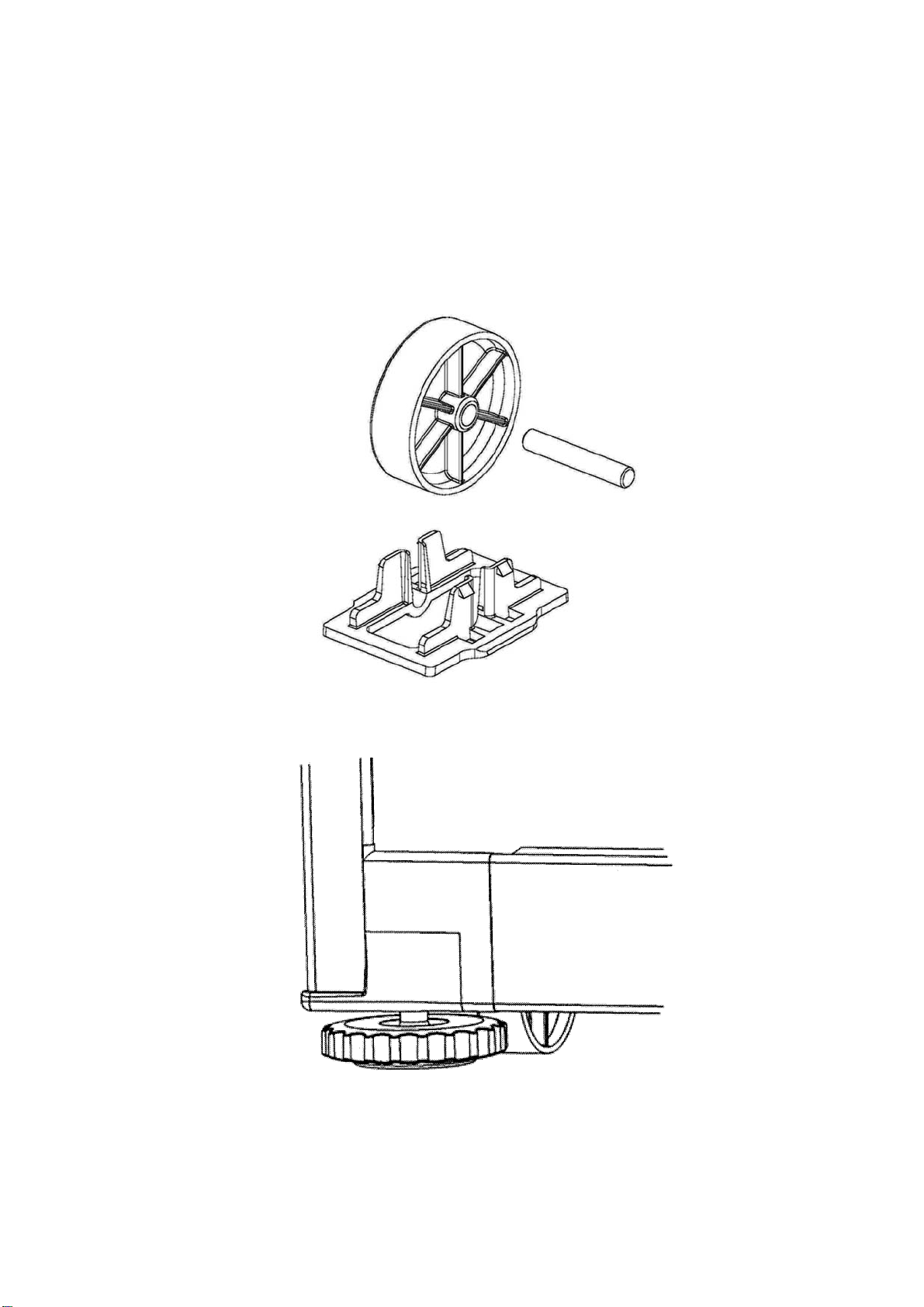

3.1 Levelling

The word 'level' is somewhat of a misnomer, as a 'spirit level' need not be used to set the appliance level. It

is preferable to have the appliance level in appearance where both doors will close with the aid of the door

closing cams. It is also important that the appliance sits solidly on the floor.

• Front and rear rollers are fitted ex factory. These are not adjustable.

• Cabinet levelling can be done by adjustment of the front levelling feet fitted ex factory. Refer to

Diagram

• Weight should be lifted off cabinet for ease of adjustment.

3.1B).

Diagram

Rear Roller

Diagram

Front Roller and Levelling Wheel

3.1A

3.1B

17

Page 18

321144

3.2 Door Hinging (Tasman Models Only)

The product leaves the factory hinged right hand or left hand. The door hinging can be changed by

obtaining a door hinge conversion kit appropriate for the cabinet being converted. There are a number of

kits changing the door hinging from RH to LH or from LH to RH. They also include two door B & T models,

single door models and “H” models in the 635, 680 and 790 cabinet widths, along with handle colours of

white and silver. Inox and Elegance models will require a complete door change.

3.3 Air Space Requirements

On all refrigerators and freezers it is important that an air gap is left around the product:

50mm (2 inches) clearance at the top.

20mm (¾ inch) clearance on each side.

3.4 Temperature Adjustment

Refer BASIC OPERATIONS in Section 4.23.

18

Page 19

321144

4 THEORY OF OPERATION

4.1 Terms

CABINET WRAPPER

Pre-painted steel.

LINER

A one-piece vacuum formed ABS liner with a plug-in divider

DIVIDER PARTITION

Injected moulding of HIPS, with two outer injected moulded housings, and an insulated ducted moulded

polystyrene inner core.

FAN MOTORS

DC 12 volt brushless variable speed fan motors for air circulation in both the FC and PC compartments.

EVAPORATOR

Aluminium fin on tube type mounted vertically on the back wall of the FC.

SUCTION and CAPILLARY LINE

Foamed into the back of the cabinet with all joints of the evaporator having been joined by induction brazing

in the FC.

POWER/CONTROL MODULE

Contains the microprocessor that controls all functions of the refrigerator and gathers data from the sensors.

This module also contains support circuitry to switch the various outputs.

DISPLAY MODULE

Using signals from the power/control module, this module generates the LCD or LED display.

REED SENSORS

A reed switch encapsulated within a plastic housing, mounted on the cross and base rails behind a plastic

cover. A magnet housed just under the lower end cap of each door activates this sensor when the door is

closed.

TERMS

Within this manual the following terms are used:

PC = Provision compartment

FC = Freezer compartment

LOW AMBIENT HEATER

Two types are used. A PCB type used in the air duct of “T” models. A blanket wire type used in the divider

of “B” models.

19

Page 20

321144

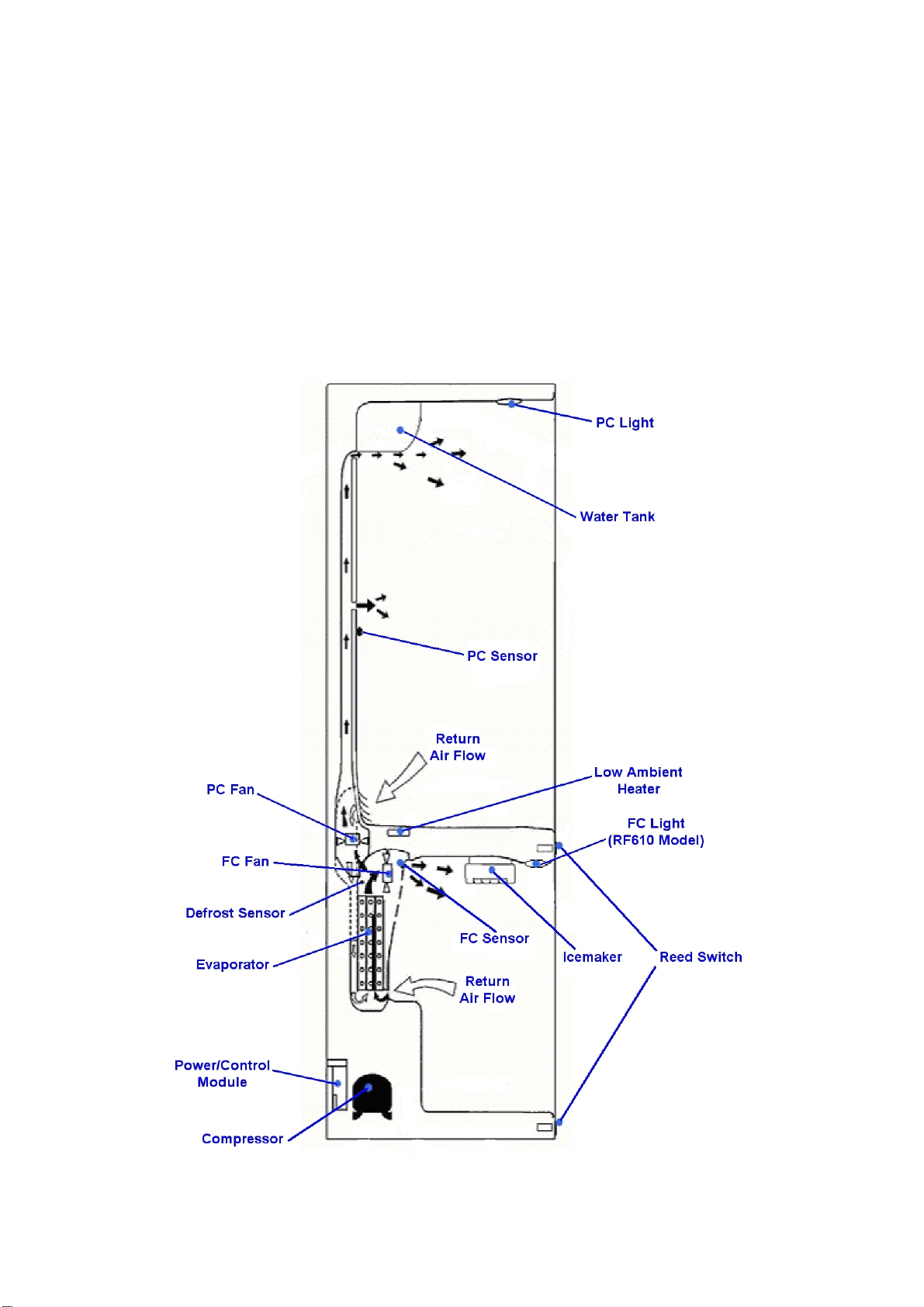

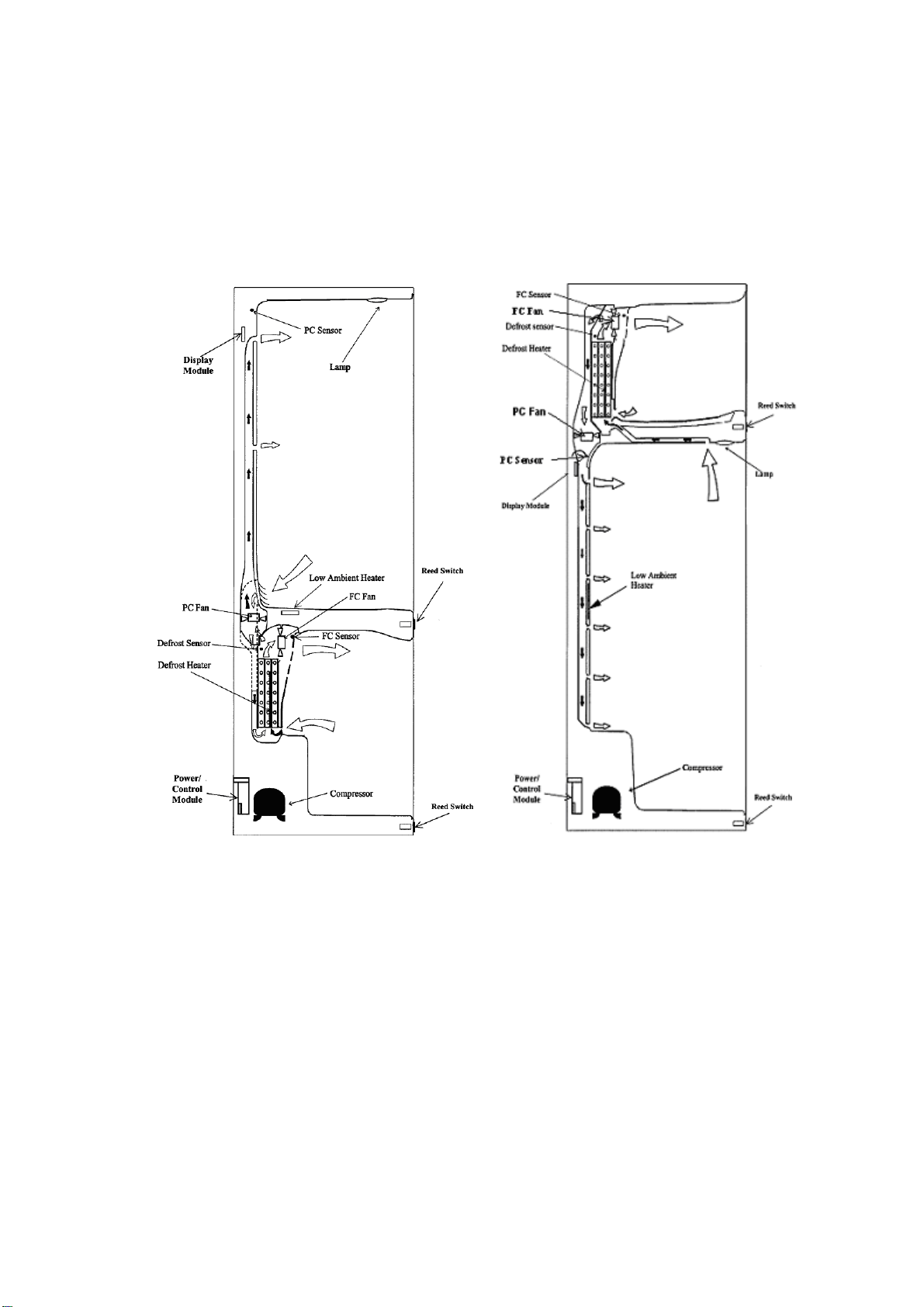

4.2 Internal Air Flow

4.2.1 Ice & Water Models

The freezer fan draws air through the evaporator and into a duct in the rear wall of the freezer compartment.

This air exits through the fan grill at the top of the freezer compartment. The air behind the freezer coil cover

is also diverted through the divider partition to another fan, which supplies the cold air into the PC

compartment. The amount of air is controlled electronically by two sensors, which in turn regulate, through

the power/control module, the speed of both PC and FC fans to maintain selected temperatures in each

compartment.

Air from the PC returns to the FC evaporator by way of the return air duct, which is built into the divider

partition. This air is drawn across the evaporator by the FC fan motor to be recirculated again throughout

the PC/FC compartments.

Diagram

4.2

20

Page 21

321144

4.2.2 Non Ice & Water Models

The freezer fan draws air through the evaporator and into a duct in the rear wall of the freezer compartment.

This air exits through the fan grill at the top of the freezer compartment. The air behind the freezer coil cover

is also diverted through the divider partition to another fan, which supplies the cold air into the PC

compartment. The amount of air is controlled electronically by two sensors, which in turn regulate the speed

of both PC and FC fans to maintain selected temperatures in each compartment.

Air from the PC returns to the FC evaporator by way of the return air duct, which is built into the divider

partition. This air is drawn across the evaporator by the evaporator FC fan motor to be recirculated again

throughout the PC / FC compartments.

Diagram

“B” Model Active Smart

4.2.2A Diagram 4.2.2B

®

“T” Model Active Smart®

21

Page 22

321144

4.3 Defrost Cycle

4.3.1 R134a System

The following table outlines the defrost cycle of an R134a refrigerant system Active Smart® refrigerator.

COMPRESSOR DEFROST ELEMENT DEFROST ELEMENT COMPRESSOR BOTH PC AND FC

TURNS OFF TURNS ON TURNS OFF TURNS ON FANS TURN ON

DEFROST TIME:

TARGET IS 18 MINUTES OR

SENSOR REACHES 8

2 MINUTES MAXIMUM IS 40 MINUTES 4 MINUTES 30 SECONDS

NORMAL RUN WARM UP DEFROST DRIP TIME DELAY BACK TO NORMAL RUN

If 40 minutes has elapsed, defrost

would be aborted if defrost sensor

has not reached 8

defrosts are aborted, Fault Code 2

is displayed.

O

C (46OF). If 2

O

C.

Diagram

4.3.1

22

Page 23

321144

play

4.3.2 R600a System

The following table outlines the defrost cycle of an R600a refrigerant system Active Smart refrigerator.

COMPRESSOR

TURNS OFF

DEFROST ELEMENT DEFROST ELEMENT COMPRESSOR

TURNS ON TURNS OFF TURNS ON

PC FAN PC FAN PC FAN FC FAN

TURNS ON TURNS OFF TURNS ON TURNS ON

DEFROST TIME:

TARGET IS 25 MINUTES OR

SENSOR REACHES 8

MAXIMUM IS 65 MINUTES 4 MINUTES 5 MINUTES 12.8 MINUTES

NORMAL RUN DEFROST DRIP TIME BACK TO NORMAL RUN

NOTE: The FC fan runs at a

If 65 minutes has elapsed,

defrost would be aborted if

defrost sensor has not

reached 8

are aborted, Fault Code 2 is

dis

O

C. If 2 defrosts

ed.

O

C.

lower speed than the

PC fan during these

12.8 minutes.

Diagram

4.3.2

23

Page 24

321144

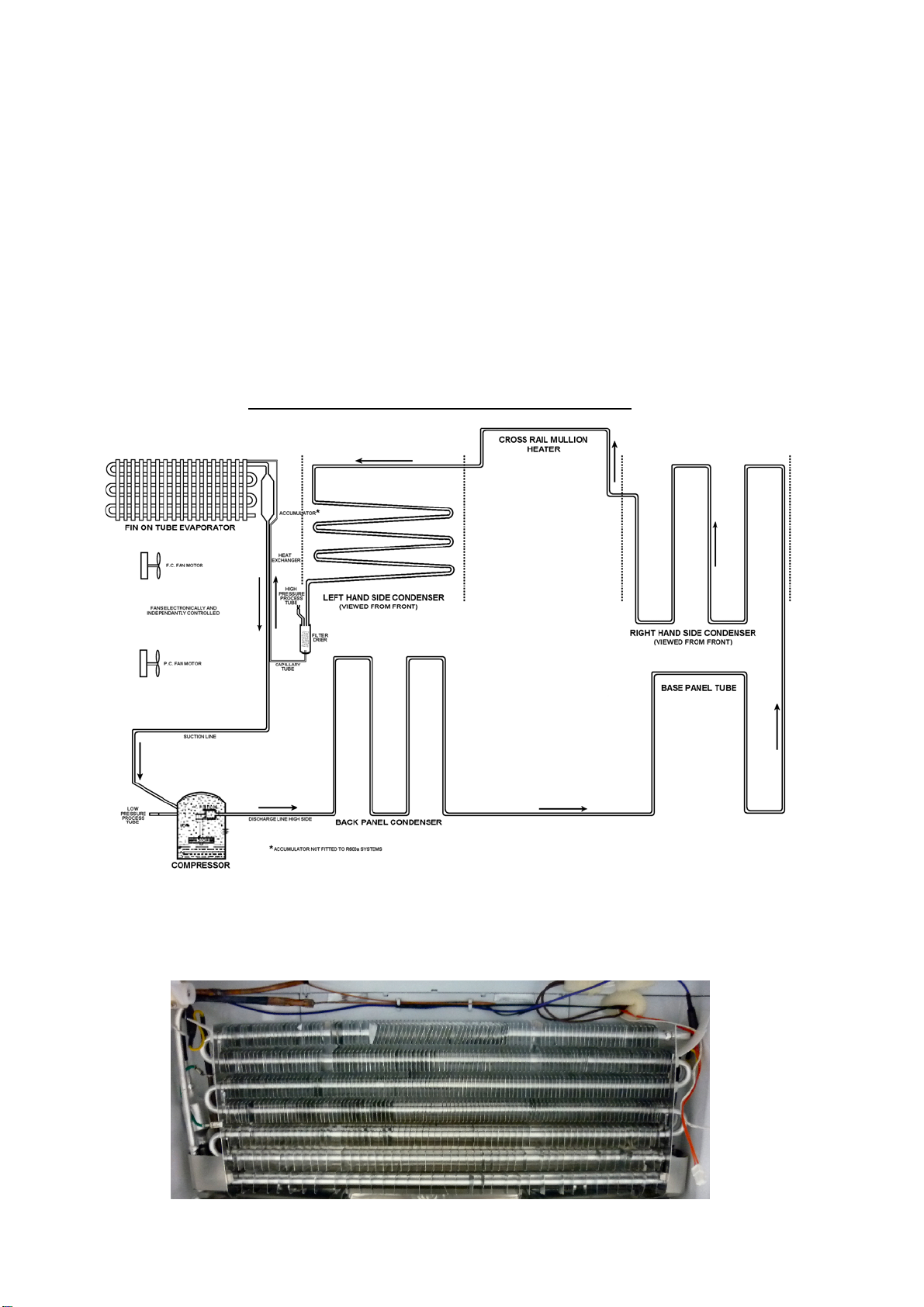

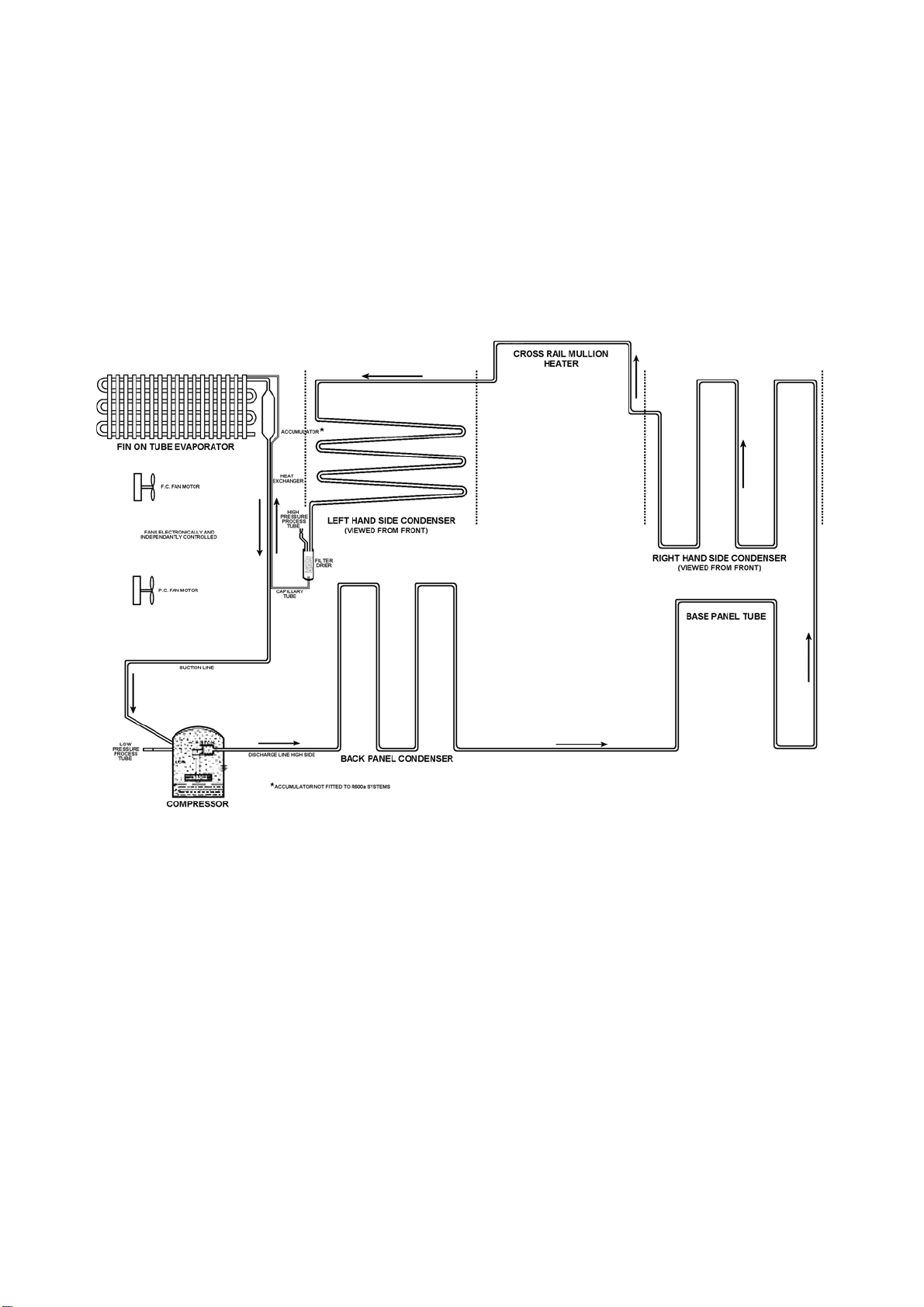

4.4 The Refrigeration Circuit

The compressor discharges high pressure, high temperature gas into the back panel condenser circuit first,

returning via the oil cooler in the compressor and entering the side condenser in the cabinet by way of the

base tube. This tube runs from the compressor compartment forward to the front bottom edge of the

cabinet, returning down the left hand side to be connected to the left hand side condenser coil.

A loop from this condenser coil forms the cross rail mullion on dual temperature cabinets. The condenser

then continues across the top front edge of the cabinet to form the right hand side condenser entering the

filter drier, which is mounted vertically in the unit compartment.

Now the high-pressure gas has been condensed, the liquid refrigerant flows through the capillary tube

entering the evaporator mounted in the freezer compartment. The liquid refrigerant then boils off due to the

low suction pressure applied to within the evaporator from the compressor. The heat-laden vapour is drawn

back to the compressor by way of the suction line to start the cycle all over again.

The above information relates to the cabinet, not the drawing below.

SINGLE EVAPORATOR TWIN FAN SYSTEM

Diagram

4.4

4.5 Evaporator

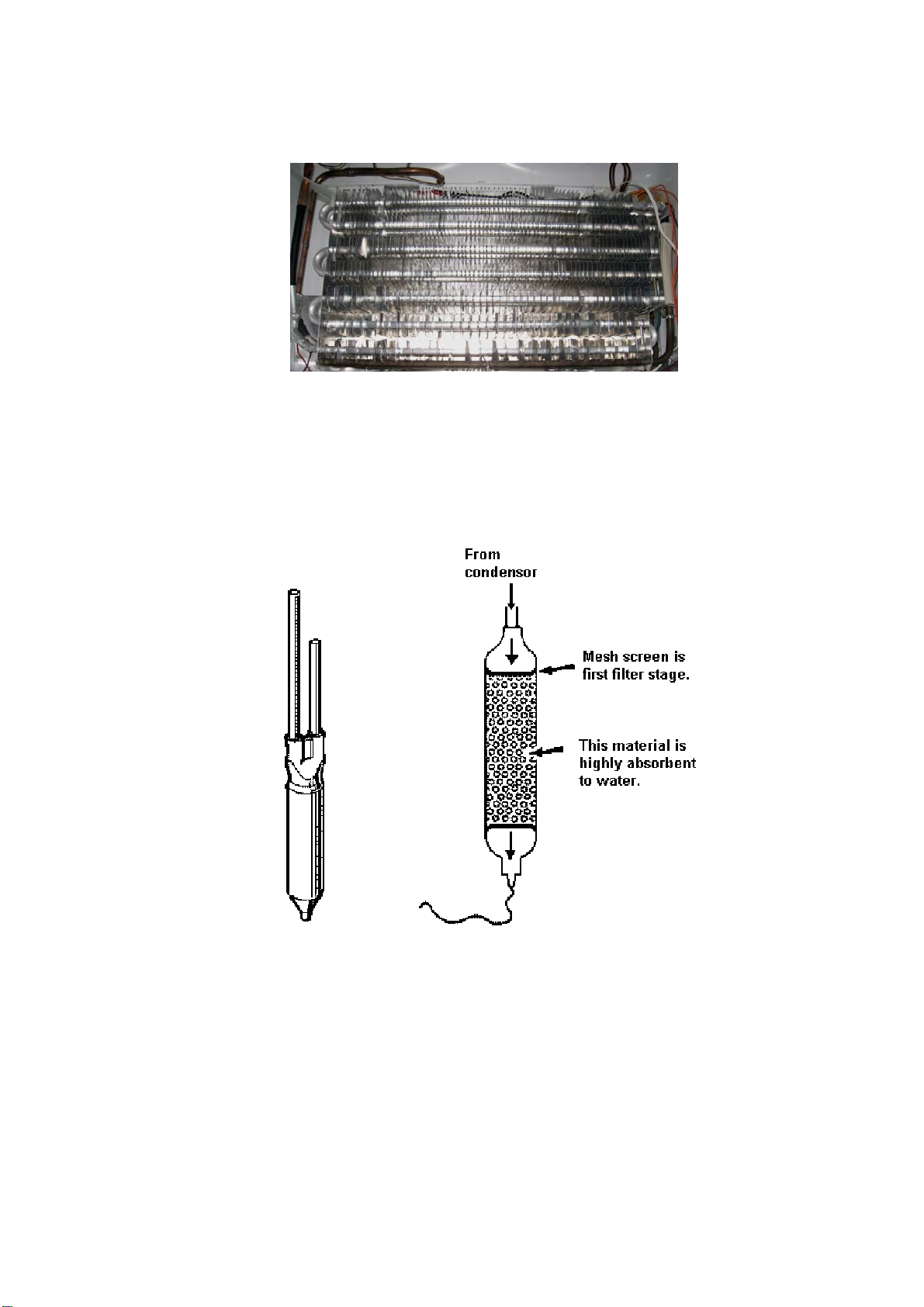

The evaporator on R134a models is of the Fin and Tube type with the expansion and suction inlet/outlet on

the left hand side. The defrost element is fitted to the left and right hand end plates of the evaporator and

clamped into position.

Diagram

24

4.5.1

Page 25

321144

The evaporator on R-600a models is of the Fin and Tube type with the expansion and suction inlet/outlet on

the left hand side. The defrost element is fitted to the right hand end plate of the evaporator and clamped

into position. The R-600a evaporator does not have an accumulator fitted. This is to reduce the risk of oil

slugging with the type of refrigerant used.

Diagram

4.5.2

4.6 Condensate Disposal

During the defrost cycle, which is electronically timed and controlled, live frost is melted off the evaporator by

means of heat from the defrost element. Condensate from the evaporator defrosting drops into a collection

trough, which has an outlet hole in the centre of the liner. A tube then allows the condensate to flow into a

water evaporation tray above the compressor.

4.7 Filter Drier

Diagram 4.7

The filter drier or molecular sieve, as the name suggests, is both a filter and a drier. Whenever a system is

opened it is essential that the filter drier is replaced. ALWAYS ensure that replacement filter driers are kept

well sealed and airtight prior to being fitted to a system.

NOTE: When filter driers are replaced on systems being serviced, it is important that the filter drier is

either cut from the system or the desiccant is removed before heat is applied to the old filter drier.

Failure to do so will drive any moisture held in the desiccant back into the system.

ALWAYS mount vertically or as near to vertical as possible and use the correct desiccant to suit the

refrigerant being used.

XH7 or XH9 suits R-600a.

25

Page 26

321144

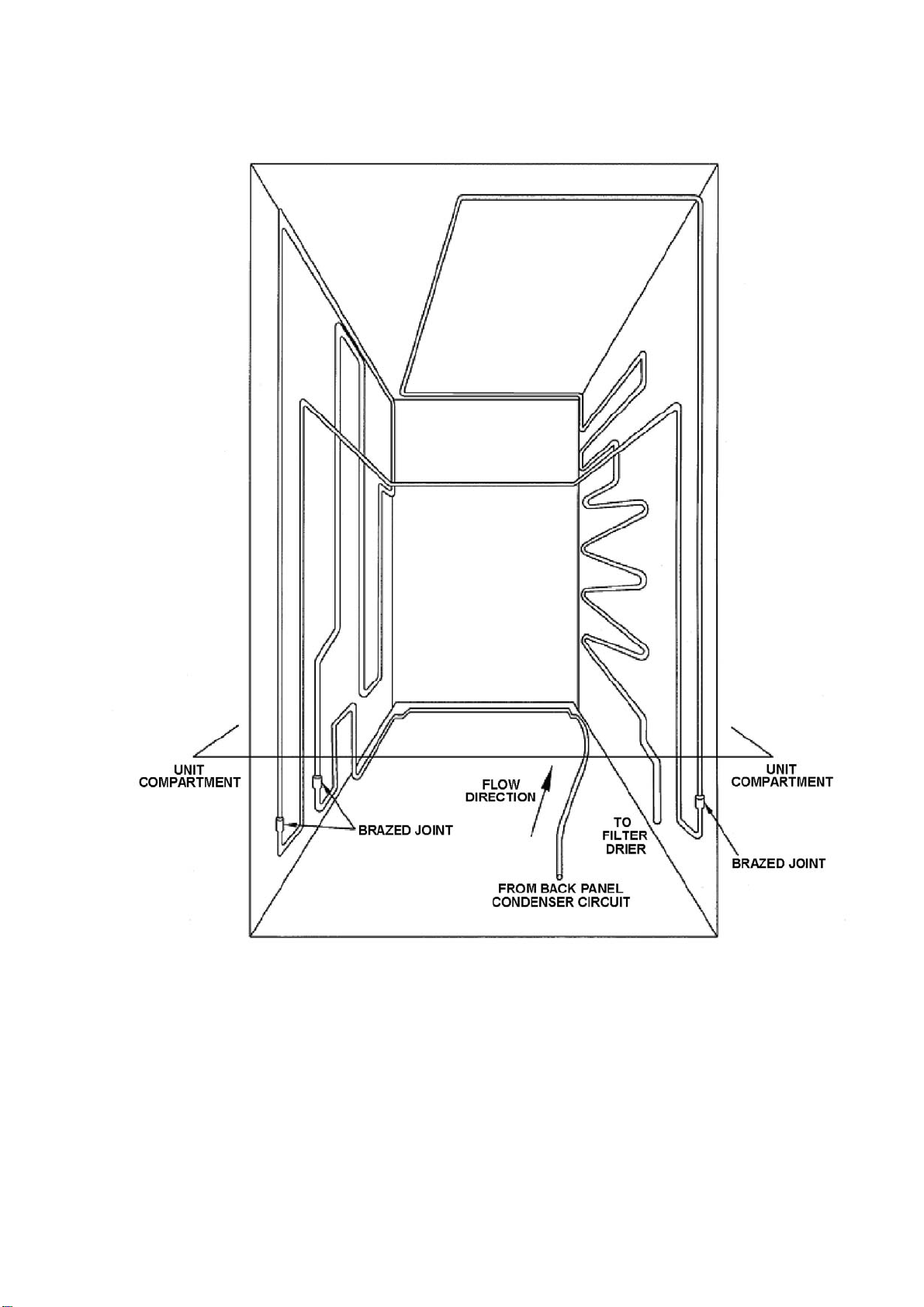

4.8 Internal Condenser

The internal condenser is made in three sections (refer circuit diagram below). One third of the condenser is

attached to the inside if the back panel, and the other parts are attached to the inside of the right and left

sides of the cabinet wrapper (as viewed from the back) all being foamed into place. It is very important, if

pressure testing the high side circuit, to split the condenser into its three sections to locate which section is

at fault. Always ease the back panel away from the cabinet slightly before pressure testing the internal pipe

work. This will prevent a pressure build-up within the cabinet should any leak be found internally in the foam

insulation. Such a leak could pressurise and damage the cabinet liner.

The back panel condenser comes as part of the back panel and should always be replaced as a complete

assembly if the back panel is ever removed. On fitting a new back panel assembly always replace the

mastic vapour-sealing compound before fitting the back panel into the triple fold of the cabinet.

Diagram 4.8

26

Page 27

4.8.1 Condenser Lay Out 635 / 680 / 790 "T" Models

CONDENSER WITH TUBE CROSS RAIL

321144

BACK PANEL CIRCUIT REMOVED FOR CLARITY

ALL BRAZED CONDENSER JOINTS ARE EXTERNAL IN UNIT COMPARTMENT

Diagram

4.8.1

27

Page 28

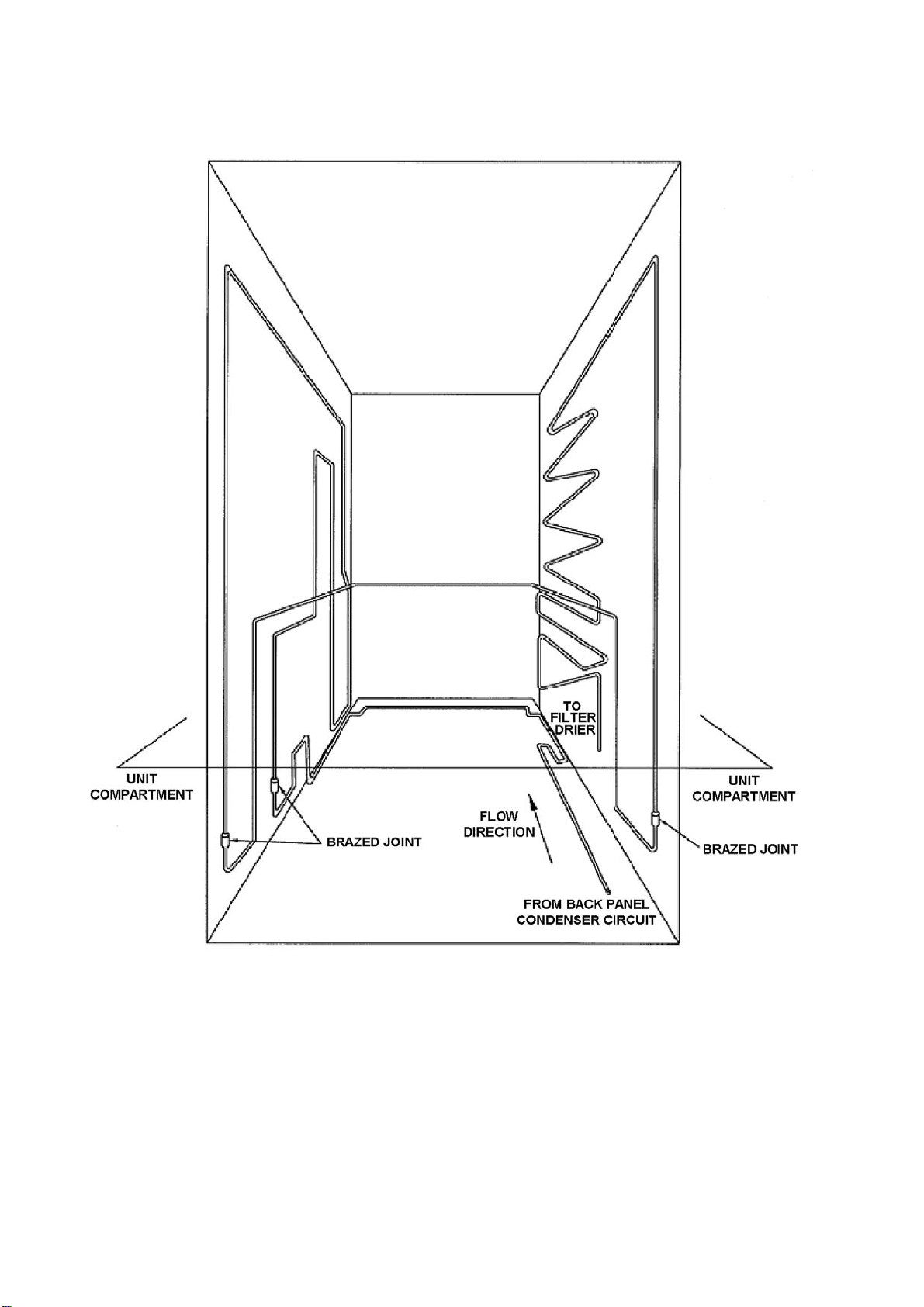

321144

4.8.2 Condenser Lay Out 635 / 680 / 790 / 900 "B" Models

CONDENSER WITH TUBE CROSS RAIL

BACK PANEL CIRCUIT REMOVED FOR CLARITY

ALL BRAZED CONDENSER JOINTS ARE EXTERNAL IN UNIT COMPARTMENT

Diagram

4.8.2

28

Page 29

321144

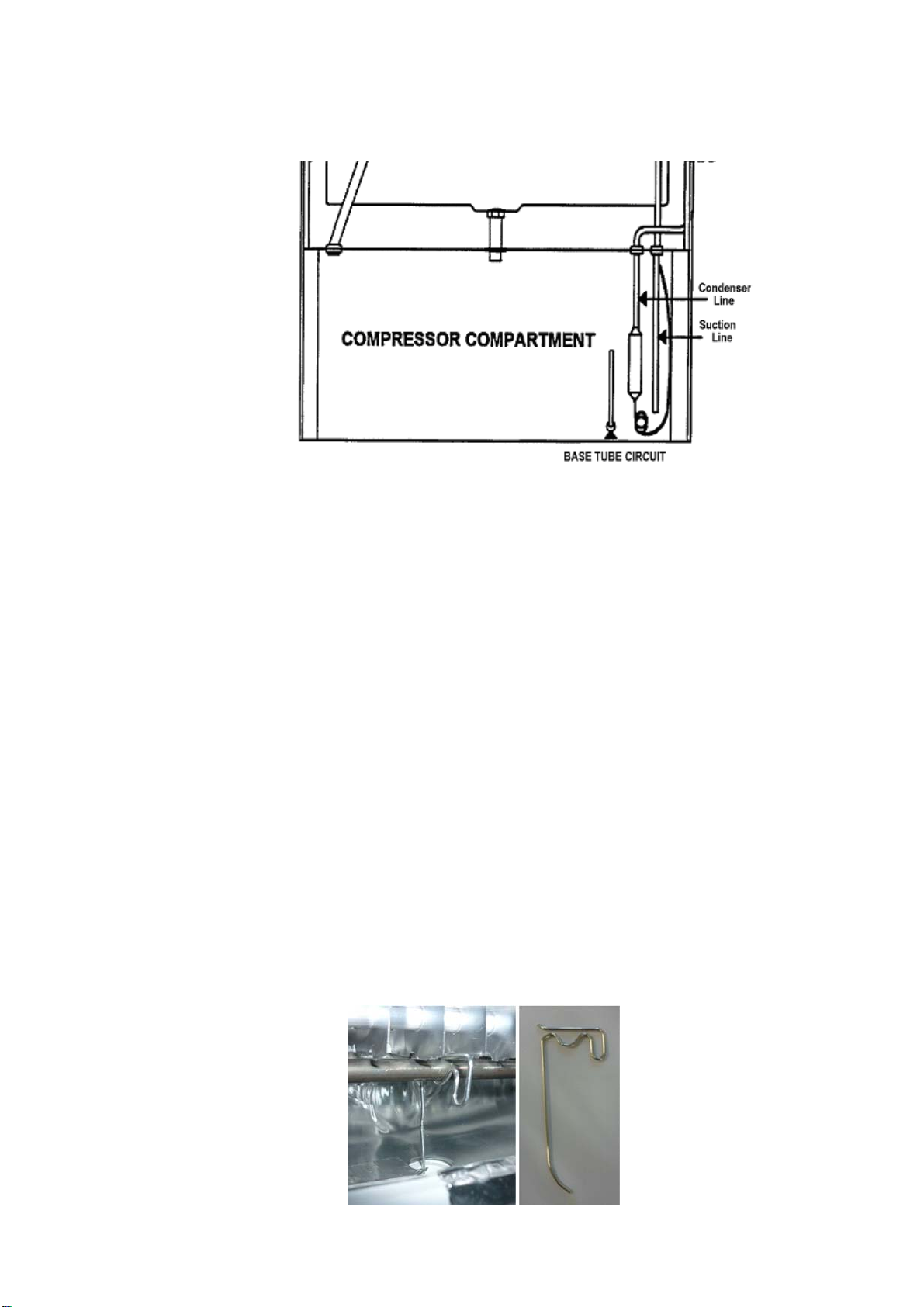

4.9 Compressor Compartment Layout

The diagrams below will assist in identifying the various pipes within the compressor compartment. They

should be read in conjunction with the full system diagram (refer to Diagram

4.4).

Diagram 4.9

4.10 Cross Rail

The cross rail contains part of the condenser copper tubing (mullion heater) providing heat to the gasket

area between the PC and FC compartments, preventing sweating of the gasket. Also mounted on the cross

rail is the Reed Sensor, under the plastic cover in the centre.

4.11 Door and Door Hinge

On the Designer models, the upper door hinge is concealed and cannot be seen with the door closed. The

upper door height is extended past the top of the cabinet to cover the hinge area.

4.12 Compressor

The compressor is turned on when cooling is required. It is switched by a Triac (solid state switching device)

on the power/control module.

4.13 Thermal Fuse

There are two thermal fuses mounted in the wiring harness of the defrost element, having a tripping

temperature of 72

assembly.

These fuses in both leads of the element protect the refrigerator from any over heating through failure of the

element itself or a triac failure in the power/control module. Both sides are protected in case phase and

neutral are reversed.

NOTE: Care should be taken if manually defrosting the evaporator if using heat guns, that the thermal fuses

are not over heated.

O

C. Once open circuit they cannot be reset. Replacement is part of the element heater

4.14 Drain Heater Wire

A drain heater wire is fitted to all cabinets except R134a B models. This drain heater helps to prevent the

drain tube from blocking with ice. The wire clips onto the double-pass defrost element, with the tail of the

heater wire in the drain tube, thus conducting heat from the defrost element into the drain tube area during

defrost.

Diagram

29

4.14

Page 30

321144

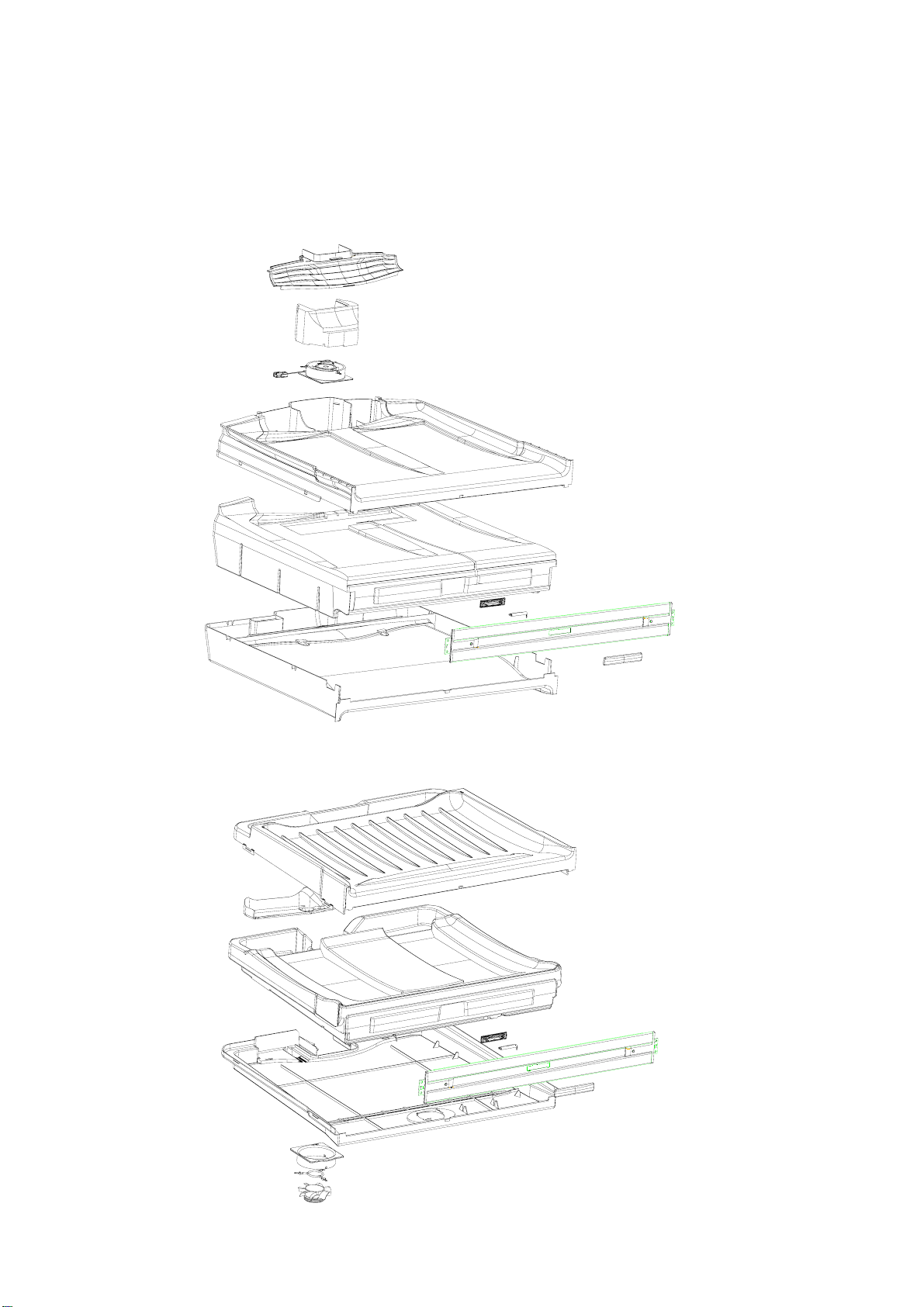

4.15 Divider Partition

This is moulded in two outer pieces and has an inner polystyrene moulded duct assembly that is wax coated.

This provides a barrier between the FC and PC compartments, also allowing return air from the PC to move

back to the FC evaporator in ‘T’ models. In both models it houses the PC fan motor. In ‘B’ models it houses

also the low ambient heater. The divider is fitted into the cabinet as an assembly and cannot be replaced.

“B” DIVIDER PARTITION

Diagram 4.15A

“T” DIVIDER PARTITION

Diagram 4.15B

30

Page 31

321144

4.16 LCD Display Panel

The ice & water models are fitted with an LCD display on the exterior of the PC door. This is the user

interface. Refer to Section

5 for further details of the display interface.

Diagram

4.16

4.17 Door Switches

“Reed” switches are used to detect the opening and closing of the doors. They are activated by two small

magnets that are built into the PC and FC doors. The reed switches are encapsulated within a plastic

housing, which is clipped under the plastic covers on the base and cross rails.

4.18 Defrost Heater

A heating element is used to defrost the ice accumulated on the evaporator. The defrost heating element

used on the evaporator is of an inconal folded type having both wiring terminations at one end. The defrosts

are adaptive to the usage and environment and are controlled by the power/control module and sensed by

the defrost sensor located on the evaporator chassis registering +8

element. Previous defrost history, the number of door openings, and the compressor run time are used to

determine the interval between defrosting. The typical time interval for defrosts is between 12 hours and 1

day. However it can be as short as 3 hours or as long as 70.8 hours depending on the usage and

environment.

O

C before terminating the defrost heater

R134a Evaporator Defrost Element

R600a Evaporator Defrost Element

Diagram

4.18

31

Page 32

321144

4.19 Low Ambient Heater

In low ambient temperatures, a 12 Volt, 7 Watt low power heater is used to keep the temperature in the

Provision compartment above freezing. The ambient heater is controlled by the power/control module,

which uses pulse width modulation (PWM) to run the heater at 58% to give 4.1 watts of heat. The ambient

heater is situated in the air duct of the “T” models and in the divider partition on “B” models. The element

has the purpose of warming the area if the ambient becomes too low, hence in the “B” models the element is

on when the compressor cycles off as the crispers could freeze. The low ambient heater in “T” models

operates when the percentage of compressor run time for the last four cycles drops below 30%. It switches

off when the percentage run time increases to above 35%. The heater will always be switched off during

defrosting. There may be less than 4 cycles in the calculation if a defrost has occurred or there were long

cycle times.

“T” MODEL

Diagram

4.19

4.20 PC / FC Fans

4.20.1 “B” Model Fan

There are two 12 Volt DC electrically commutated motors (ECMs). They provide the required cooling air

flow to both compartments. The motor speeds are controlled using a pulse width modulating (PWM)

technique. The power/control module controls the on/off of the compressor, and the fans. The speed of the

FC fan is set, and the speed of the PC fan is regulated using pulse width modulation.

The freezer compartment fan will always be set at the maximum FC fan speed, with the PC fan being

adjusted to meet the requirement of that compartment. We alter the speed of the FC fan under certain

loading conditions. Therefore the PC fan speed will be set at the average speed used from the previous

cycles under normal door openings and loading conditions.

When the compressor is turned on, provided the doors are closed both the fans will also be switched on

except immediately following a defrost cycle, where there is a delay of 5 minutes after the compressor has

started before the FC fan starts.

32

Page 33

321144

FC Fan (Viewed from front)

Diagram

“B” Model PC Fan (Viewed from PC side)

4.20.1

4.20.2 “T” Model PC Fan

The PC fan in the “T” model cabinets has an air shroud duct fitted to the base of the fan. This is to deflect

the airflow down the duct and prevent air leaks in the area of the top of the duct.

“T” Model PC Fan Fan in Position

NOTE: The same PC fan assembly is supplied as a spare part for both “B” and “T” models. This part

comes with the air shroud duct for use in “T” models. When the spare part is used in “B” models, the air

shroud duct should be discarded, as it is not used in “B” models.

Diagram

4.20.2

33

Page 34

321144

4.21 Interior Light

The interior light of this cabinet uses a LED mounted on a small PCB board located in the roof of the PC

(and FC in some models). The light fittings can be rectangle or oval.

On opening the door, the light has a soft start feature, increasing in brightness to a preset level. To prevent

overheating of the lens cover, the lamp is turned off after 5 minutes if the door is left open, and the module

will beep continuously indicating that the door has been left open.

“T” models have one LED on the PC board; “B” models have either two or three LEDs on the PC board.

The power/control module controls the light.

“T” Model PCB Board Board in Housing

“B” Model Board, Housing & Cover

Diagram

NOTE: It is important that the polarity to the LED lamp is correct, as it will not operate if transposed.

0

34

Page 35

321144

4.22 Thermistor Temperature Sensors

These sensors are used to monitor temperatures within the refrigerator. They are:

1. A defrost sensor mounted above the evaporator used to measure the temperature when in defrost.

2. An FC sensor mounted on the evaporator coil cover used to measure the temperature in FC.

3. A PC sensor mounted in the PC on the duct cover and used to sense the PC temperature.

4. On ice & water models, an ice tray sensor mounted on the bottom of the ice cube tray used to

measure the temperature of the ice tray.

5. On ice & water models, a water tank sensor mounted at the rear of the water tank used to measure

the temperature of the water tank.

Thermistor sensors are used for temperature measurement. Their electrical resistance changes as the

temperature changes. The table below lists some typical resistance values. The temperature can be read

using Diagnostic Mode as described in the Section

water models).

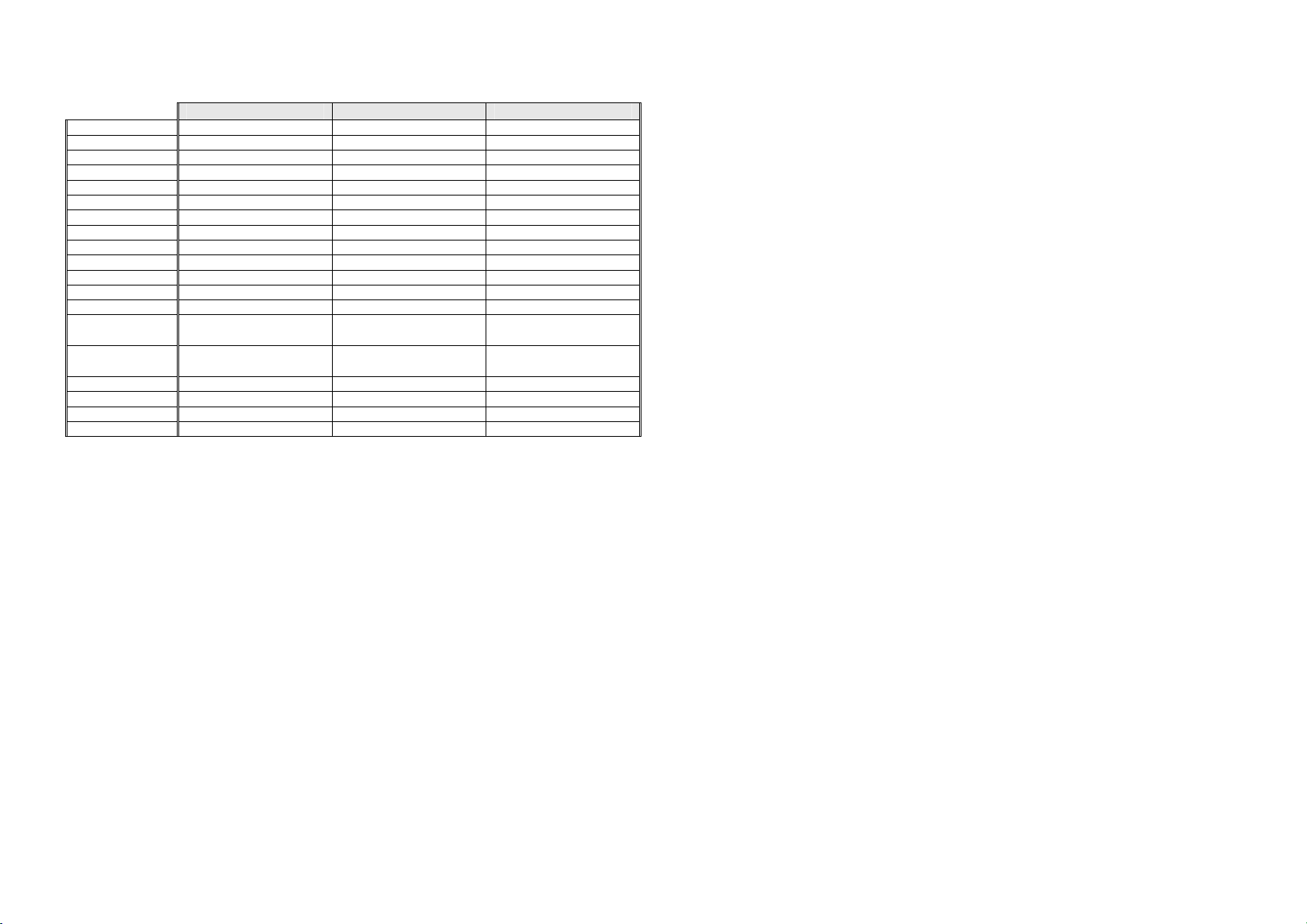

THERMISTOR SENSOR RESISTANCE TABLE

TEMPERATURE (°C)

-30.0 25.17

-25.0 19.43

-20.0 15.13

-15.0 11.88

-10.0 9.392

-5.0 7.481

0.0 6.000

5.0 4.844

10.0 3.935

15.0 3.217

20.0 2.644

25.0 2.186

30.0 1.817

35.0 1.518

40.0 1.274

45.0 1.075

50.0 0.9106

10.1.5 (ice & water models) or Section 10.2.3 (non-ice &

RESISTANCE

(K Ohms ±5%)

Diagram

4.22

35

Page 36

321144

4.23 Basic Operation

4.23.1 Temperature Adjustment – Ice & Water Models

To adjust Compartment Temperatures:

1. Use the MENU button to scroll to the TEMPERATURE screen on the LCD display.

2. Use the MENU button to select the compartment to change.

3. Use the UP or DOWN arrows to adjust the temperature. The temperature setting will be indicated on

the icon below.

Diagram

4.23.1

4.23.2 Temperature Adjustment – Non-Ice & Water Models

To adjust Compartment Temperatures:

1. Press the MODE button.

The provision compartment light on the refrigerator diagram will flash on and off. The temperature

indicator illustrated by a thermometer will show the temperature setting for this compartment.

2. The temperature can be altered by pressing the TEMPERATURE UP or TEMPERATURE DOWN

buttons. Fewer LED lights on the thermometer means a cooler temperature.

3. To adjust the freezer temperature press the MODE button again. The freezer temperature light will

flash on the refrigerator diagram.

4. The freezer temperature can be altered by pressing the appropriate TEMPERATURE UP or

TEMPERATURE DOWN buttons.

Successively pressing the MODE button will automatically select between the compartments. A return to the

provision compartment will be accompanied by a longer beep.

LEDs INDICATE APPROXIMATE TEMPERATURE

PC

FC

+10

+8

+6

+4

+2

0

Diagram

Temperatures shown are average temperatures. One degree C incremental temperature adjustment is

indicated by the “half” lights that illuminate as the temperature up / down button is pressed.

4.23.2

-12.5

-14.0

-15.5

-17.0

-18.5

-20.0

36

Page 37

321144

5 ELECTRONICS SECTION

5.1 Diagrammatic Overview Function Description

The electronic system consists of several parts:

Power/control module, display module, compressor, defrost heater, low ambient heater, door flapper heater,

produce compartment fan, freezer compartment fan, light, temperature sensors, icemaker sensors,

solenoids and door sensors.

The purpose of the power/control module is to turn on the compressor, which cools the evaporator, then to

use the fans to efficiently cool the compartments. Both fans turn on with the compressor. The freezer

compartment (FC) fan is kept at a constant speed while the produce compartment (PC) fan is regulated to

provide the balanced cooling for both compartments. The function of the microprocessor in the

power/control module is to provide independence of both compartments to their set temperatures, although

the environment of one compartment effects the other as they are linked by the ducts as can seen by the

internal air flow of the cabinet. (Refer to diagrams

ELECTRONIC FUNCTIONAL SCHEMATIC

4.2, 4.2.2A and 4.2.2B).

Diagram

5.1

37

Page 38

321144

5.2 Control and Peripheral Functions

The control system consists of the power/control module located in the unit compartment of the refrigerator,

the slave display module located either in the back of the produce compartment or, in the case of ice and

water models, on the outside of the door, and various sensors and actuators controlled by the power/control

module. The function and brief description of each of these units is defined below (refer to Electronic

Functional Schematic – Diagram

5.1).

5.3 Power/Control Module

There are two types of power/control modules used on these Active Smart® cabinets, one for the non-ice &

water cabinets and the other for those cabinets having the ice & water feature.

NOTE: While the two types of modules are not interchangeable, the ice & water module can be used on a

non-ice and water model.

This module is the electronic brain and control centre of the refrigerator. It contains a microprocessor,

support circuitry and switching devices. The power/control module controls the Provision Compartment (PC)

and Freezer Compartment (FC) temperatures by sensing the temperature and door state and operating the

compressor and fans accordingly. This module also houses the alarm beeper.

The speed of the fans is controlled by pulse width modulation (PWM). The power/control module controls

the motor speed by driving them with short pulses. These pulses vary in duration to change the speed of the

motor. The longer the pulses, the faster the motor turns, and vice versa.

The micro controller in the power/control module uses its internal memory for control; its ROM (Read Only

Memory), for program and fixed constant storage including tables, the RAM (Random Access Memory) for

variable storage and access. It uses an external Electrically Erasable Programmable Read Only Memory (E

2 PROM) for storage of variables and history data which is retained even when the power is turned off.

The power/control module contains a special type of memory device call an E 2 PROM. The information on

the fridge operation, faults and diagnostic information is stored in this memory. They include the

temperature setting, the history of FC, PC temperatures (approx 18 hours), defrost history (the last 12

defrosts) and fault history. This will help the service person find and remedy the cause of failure. All this

memory will be retained even when the fridge is disconnected from mains power supply.

Compressor Start Delay

All Active Smart

the compressor is off and compartments warm up above their respective switch (turn on) temperatures, and

the doors are open, the compressor will not switch on until one minute after the doors are closed. However,

the compressor will start after 90 seconds irrespective of whether the doors are open or not. (Primarily

introduced for Orthodox Jewish compliance to ensure there is no link between door opening and compressor

starting.)

The piezo beeper is used to signal prolonged door opening and other fault conditions:

1. The PC door alarm sounds if the door is left open for 90 seconds and the FC door alarm sounds if

door is left open after 60 seconds. Both PC and FC alarm will sound every 30 seconds until the door

is closed.

2. If the doors are left open longer than 5 minutes, the alarm will sound continuously and the PC light will

turn off. The alarm will stop with the closing of the door. The light is only reactivated by closing and

opening the door.

3. On non-ice & water models, all electronic faults, when detected, will sound the alarm and the LED’s on

the display module will flash indicating the fault code. The pressing of any button will cancel the alarm

but the fault code will remain until the cabinet has been serviced.

4. On ice & water models, a spanner symbol and LCD fault code will appear automatically if there is a

fault in the temperature measuring system, defrost system, icemaker, fans or low ambient heater.

When the PC door is opened, an alarm will sound. The number of beeps also indicates the fault code.

Pressing any of the control buttons can deactivate this alarm.

®

products will not start the compressor until one minute after both doors are closed, i.e. if

38

Page 39

®

There are two types of power/control modules used on these Active Smart

water cabinets and the other for those cabinets having the ice & water feature.

cabinets, one for non-ice &

321144