Page 1

ELECTRONIC WASHING MACHINE

PHASE 6 Series 11 120v 60 Hz

Supplementary manual to be used

in conjunction with

GWL03 Service Manual – 426348

(including a complete new set of

DETAILED FAULT CODES)

517766

Page 2

517766 March 2003

Page 3

517766 March 2003

FISHER & PAYKEL

ELECTRONIC WASHING MACHINE

MODELS

GWL11

plus fault codes for GWL03, GWL08, GWL10

November 2002: Repaginated (simplified page numbers) and alterations to sections

12 and 13.7.

January 2003: Changes to pages 16 & 17 (Sections 16.2 & 16.3).

March 2003: Added new fault code (66), user warnings and diagnostics table

(16.2).

Fisher & Paykel Appliances

78 Springs Road, East Tamaki,

Auckland, New Zealand

PO Box 58-732, Greenmount,

Auckland, New Zealand

Phone 00 64 9 273 0640,

Fax 00 64 9 273 0649

Fisher & Paykel Appliances Inc.

27 Hubble,Irvine

California 92618

USA

Phone 1-888-9FNP-USA or

(1-888-936-7872),

Fax 949-790-8911

Page 4

517766 March 2003

C O N T E N T S

12. WHAT PHASE, SIZE & MODEL IS YOUR SMARTDRIVE ? .......................................5

13. SPECIFICATIONS........................................................................................................6

13.1 Finish.....................................................................................................................6

13.2 Dimensions............................................................................................................6

13.3 Maximum Capacity (Full Load) (AS 2040).............................................................6

13.4 Water consumption per fill with clothes load using the Bern Clothes Washer

Study 6

13.5 Water fill temperature (Approximate Factory Settings)..........................................7

13.6 Wash Motor ...........................................................................................................7

13.7 Pump Motor 120V AC 60Hz (SELNI) ....................................................................7

13.8 Water Valves .........................................................................................................7

13.9 Thermistor .............................................................................................................7

13.10 Basket Speed ........................................................................................................7

13.11 Water Conservation Rating ...................................................................................7

13.12 Fabric Softener Dispenser.....................................................................................8

13.13 Electric Supply.......................................................................................................8

13.14 Use and Care Compact Disc .................................................................................8

13.15 Diverter Valve ........................................................................................................8

13.16 Lid Lock .................................................................................................................8

14. INTRODUCTION ..........................................................................................................9

14.1 Electronics.............................................................................................................9

14.2 Stand by mode ......................................................................................................9

14.3 Water Temperature Sensing ...............................................................................10

14.4 Water Valves .......................................................................................................10

14.5 Stator...................................................................................................................10

14.4 Pump ...................................................................................................................11

14.7 Lid-Lock...............................................................................................................12

15. SIZE SETTING MODE FOR SERIES 11....................................................................12

15.1 GW Size setting...................................................................................................12

16. DIAGNOSTIC MODE .................................................................................................14

16.1 GW (Ecosmart)....................................................................................................14

16.2 Smartdrive Diagnostic Table ...............................................................................15

16.3 USER WARNINGS.............................................................................................15

16.4 Drain Pump Test .................................................................................................19

16.5 Water Valve Test.................................................................................................19

16.6 Restart Feature ...................................................................................................19

16.7 Recycle Feature ..................................................................................................20

16.8 Hot Tub Flag........................................................................................................20

17. WIRING DIAGRAM ....................................................................................................21

18. READINGS FROM MODULE .....................................................................................22

Pump/Motor....................................................................................................................22

RPS................................................................................................................................22

Display ...........................................................................................................................22

Therm.............................................................................................................................22

Lid Lock / OOB...............................................................................................................22

Diverter Valve.................................................................................................................22

19. DETAILED FAULT CODES........................................................................................23

FAULT DESCRIPTIONS................................................................................................24

Page 5

517766 March 2003

- 5 -

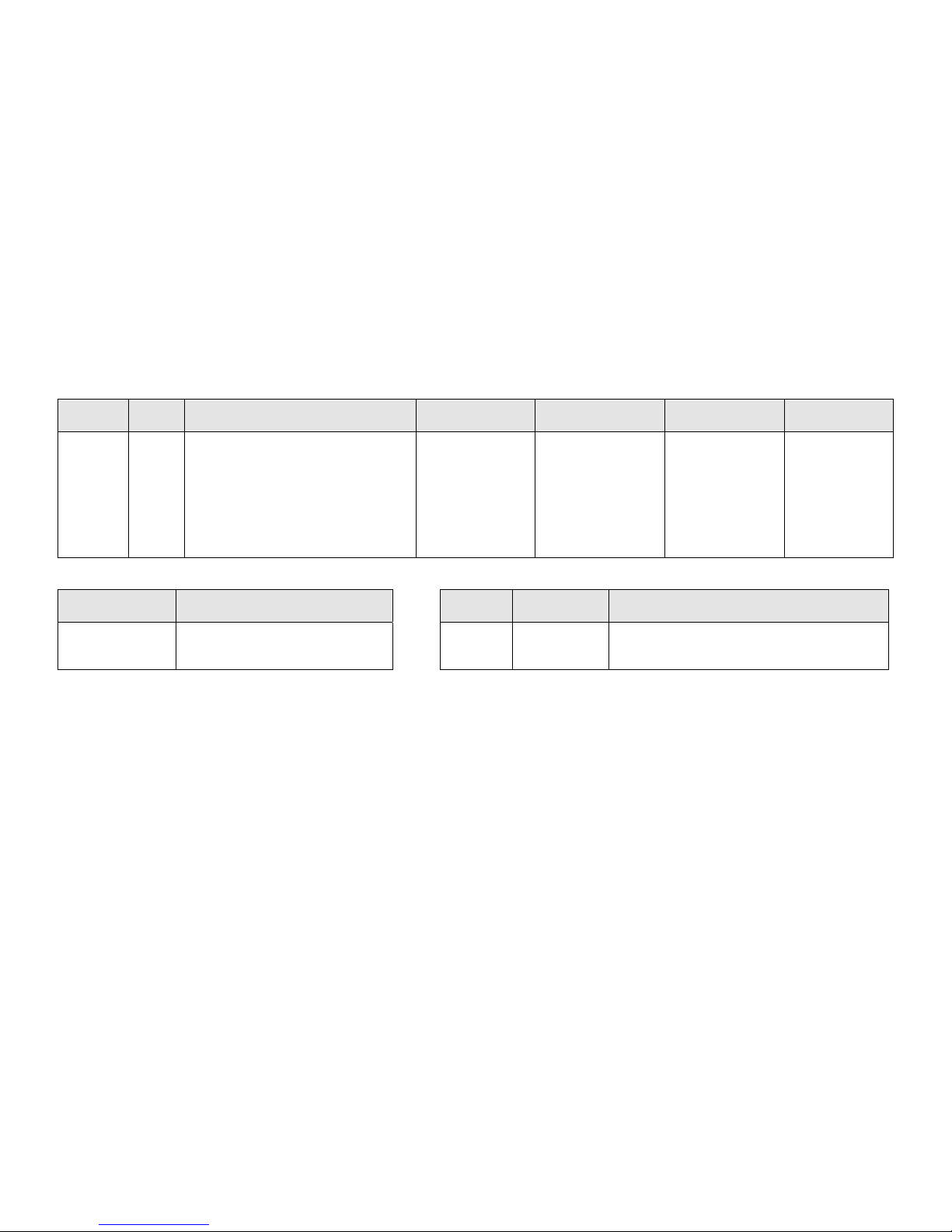

12. WHAT PHASE, SIZE & MODEL IS YOUR SMARTDRIVE ?

PHASE YEAR FRONT PANEL COLOURS MODEL

NUMBERS

MOTOR

CONTROLLER

COMPONENTS MODEL

TYPES

PHASE 6

Series 11

2002 Blue / green panel, blue buttons GWL11 Brown, aircooled

GW has a

thermistor in the

mixing chamber.

Inlet valves 24v

64 ohms.

Stator 16 ohms

per winding.

Lid lock 73 ohms

Selni pump 7

ohms. (all @

20°C) 68 °F

ecosmart

(recirc)

DISPLAY TYPE IDENTIFIER SIZE CAPACITY DIMENSIONS

US 120V Green background

favourite, permanent press

wool washables, softener rinse

Large (8 kg) 17.6lb 650 x 650 x (1020 – 1050 h)

25 ½ in. x 25 ½ in x (40 in – 41.3 in h)

Note: Phase 6 machines are a maximum of 1.5 inches (lid to floor) higher than phases 4 and 5.

Page 6

517766 March 2003

- 6 -

13. SPECIFICATIONS

13.1 Finish

Cabinet Pre-paint (Polyester)

Touch-Up Paint: White #503086

Lid ABS Co-injected, one piece

Console ABS with ABS insert for display control

Inner bowl stainless steel grade 430T

Outer bowl Polypropylene

Agitator Polypropylene

Top Deck Polypropylene

13.2 Dimensions

GWL11

Height to lid

Open (1410 mm – 1440 mm) 55.5 in – 56.6 in

Closed (950 mm – 980 mm) 37.4 in – 38.5 in

Height to console (1010 mm – 1050 mm) 39.7 in – 41.3 in

Width (650 mm) 25.5 in

Depth (650 mm) 25.5 in

Note: Exact height of the Smart Drive is dependent on how far the feet are inserted into

the base of the machine.

“L” models

Inlet hose length (1200 mm) 47.2 in

Weight:

Packed

Unpacked

(57.5 kg) 126.5 lb

(51.0 kg) 112 lb

13.3 Maximum Capacity (Full Load) (AS 2040)

Dry Weight (8kg) 17.6 lb

13.4 Water consumption per fill with clothes load using the Bern

Clothes Washer Study

Load Size lb

Total H2O gal

19.4

3 18.9

5 24.5

7 24.6

9 29.2

11 34.9

13 34.6

15 34.3

Page 7

517766 March 2003

- 7 -

13.5 Water fill temperature (Approximate Factory Settings)

GW

Hot

(60oC) 140° F

Hot / Warm

(50oC) 122° F

Warm

(40oC) 104° F

Warm / Cold

(35oC) 95° F

Cold Plus

(20oC) 68° F

Cold Supply temperature

Recommended hot water inlet temperature 65°C (Max) 149°F

13.6 Wash Motor

Electronically commutated direct drive 3 Phase brushless DC Motor

Motor Resistance per Phase 16 ohms @ (20°C) 68°F

13.7 Pump Motor 120V AC 60Hz (SELNI)

Thermal cut-out fitted

Flow Rate (24 litres per minute) 6.3 gal / min

Pump motor resistance 7 ohms @ (20°C) 68°F

13.8 Water Valves

24 Volts DC

Digital Valve Resistance 64 ohms @ (20°C) 68

°F

Flow Rate (10 litres per min) 2.6 gal/min

Proportional Valve Resistance 64 ohms @ (20°C) 68°F

Flow Rate (16 litres per min) 4.2 gal/min

Operating pressures Maximum 1034 kPa (150 PSI) 1034 kPa

Minimum 20 kPa (3 PSI) 20 kPa

Low flow can affect the digital valve (Hot) and create seating problems with the seal.

13.9 Thermistor

NTC-type temperature sensor Resistance 10,000 ohms @ (25°C) 77°F

13.10 Basket Speed

Fast Spin 1,000 RPM

Medium Spin 700 RPM

Slow 300 RPM

Stir Speed 25 RPM

13.11 Water Conservation Rating

AAA

Page 8

517766 March 2003

- 8 -

13.12 Fabric Softener Dispenser

Dosage 75cc

13.13 Electric Supply

Operating Voltage 110/120V AC 60Hz

Maximum Current 7.0 amps

13.14 Use and Care Compact Disc

PN 420082

USA Replaces video on GWL 10

13.15 Diverter Valve

Resistances 0.7KW to 2.5KW

13.16 Lid Lock

Resistances 73 ohms +/- 5 ohms

Page 9

517766 March 2003

- 9 -

14. INTRODUCTION

MODEL: GWL11 Ecosmart

This Service Supplement contains information on the Product Specifications, Diagnostic

Mode and the Detailed Fault Codes for Phases 4, 5 and 6, being Series 8, 10 and Series

11 machines respectively.

14.1 Electronics

The electronics for Series 11 are air-cooled in the same way as the Phase 5 (series 10)

machine. This has changed from being water cooled as in earlier models. This has been

made possible by changes to the stator winding which allows a lower current through the

electronics and the use of the latest low loss, semi-conductor-switching device.

Electronic modules are not inter-changeable between models. The different modules for

the different models can be identified by their colour. L03 (green), L08 phase 4 modules

(yellow) and L10, phase 5 GW modules are grey. The new L11, phase 6 modules, GW

are coloured brown.

GW p/n 420094,

It is important not to mix the different coloured modules as they are not compatible

and the washing machine will not work.

The latest module is similar to the series 10 module. The difference is that the terminals

are pushed on sideways at the top of the module.

The Series 11 module now has a 7 position connection for the display and a 4 position

connection for the Lid Lock / OOB.

14.2 Stand by mode

If a Series 11 machine has not received any instructions for 10 to 15 minutes after being

switched on at the power point or after completing the cycle, it will automatically go into a

low power Stand By mode, same as the Series 10 Smart Drive. Before entering the

Diagnostic or Option Adjustment modes, the machine must be taken out of the Stand By

mode. To do this, the power button will have to be pressed on and off or the machine

turned off and on at the power point.

Page 10

517766 March 2003

- 10 -

14.3 Water Temperature Sensing

The thermistor for sensing water temperature in the ecosmart is located in the inlet

chamber and is available as a separate spare part under part number 479164P. See

specifications for the temperature / resistance readings.

14.4 Water Valves

The Series 11 machines use different water valves to the Series 8 and 10 machines. The

valves are essentially the same (24 volts) but now have US standard threads which are

not interchangeable with previous models of Smart Drive washing machines, especially

the early LO3’s which are 12V with posilock connectors.

It is suggested when replacing a valve to use the same part number or superseded

number, leaking may occur if unlike threads are attached to inlet hoses.

The terminals are the “RAST 2.5” system. Extra care must be taken to ensure these

connections are plugged in squarely to avoid damage to the terminals.

There are two types of coil orientations possible on these valves, however the fittings are

identical. When removing the harness plug from the valve, a small retaining clip must be

released. The series 8 and 10 machines have these valves with the retaining clip located

on the solenoid behind the plug. Harness removal is a blind action.

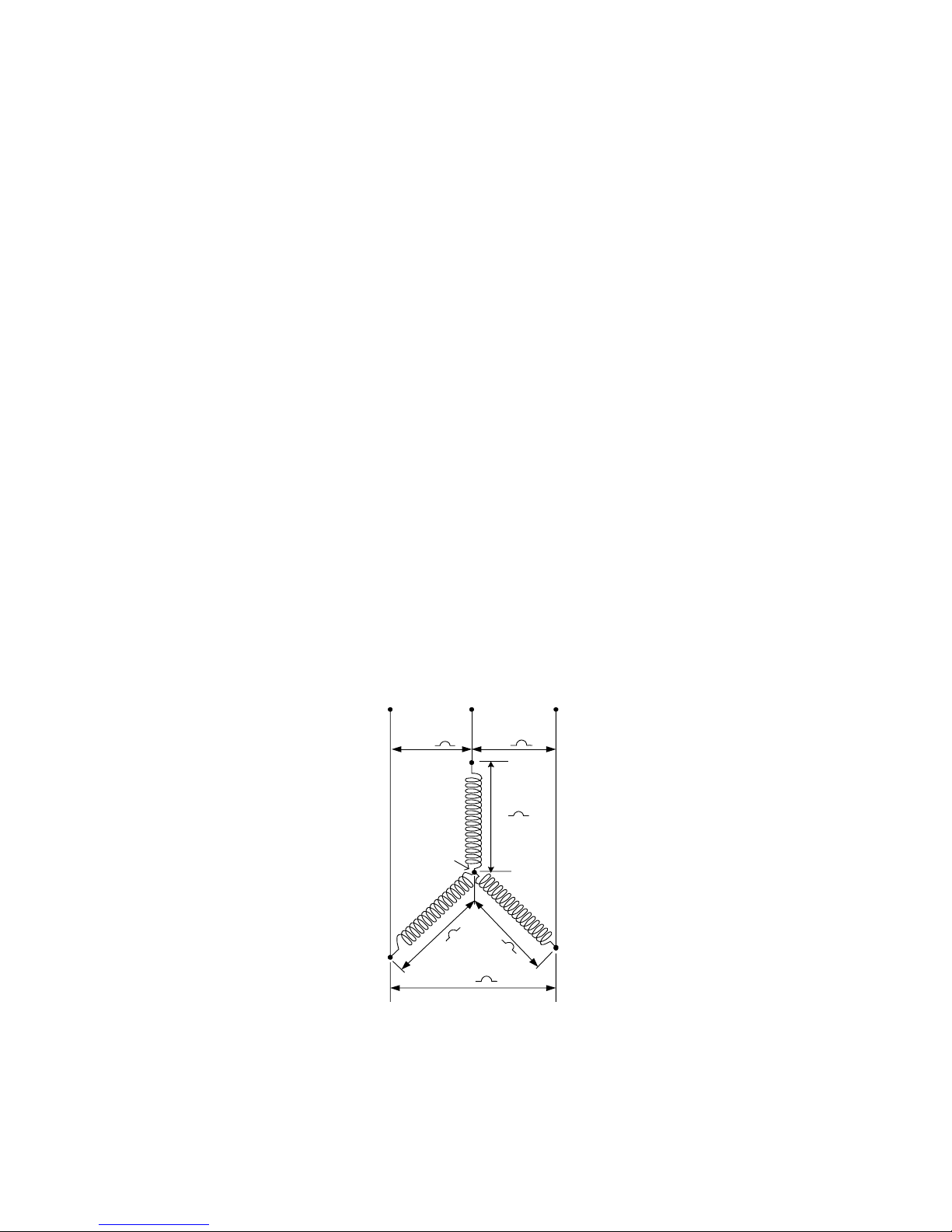

14.5 Stator

The stator resistance of the Phase 6 is 16 ohms per phase, same as the previous

phase 5, which changed to allow for a lower current through the electronics. This stator is

not interchangeable with the previous models and can be identified by smaller terminal

connections. The rotor has not changed and can be used for all models of Smart Drive.

32 32

32

16

1

6

1

6

RED BLUE YELLOW

STAR POINT

SERIES 11 STATOR RESISTANCE

Page 11

517766 March 2003

- 11 -

14.4 Pump

The pump now uses a vortex impellor, which reduces the operating sound levels at the

end of the drain cycle. The new pump is a dedicated 110V 60Hz Selni pump. The way the

pump is controlled has changed. During the drain cycle the pump is stopped and started

quickly every 10 / 15 seconds.

The pulsing on and off of the drain pump only occurs when the basket is afloated.

Changing the factory setting.

Pulsing can be turned off if a higher head height is required (7 feet max), however the

possibility of pump blockage and Suds lock increases, which inturn affects the required

head height.

Enter “SIZE SETTING” mode (TEMP UP and POWER) this should be familiar when

changing modules and or displays.

The REGULAR cycle button toggles between having this feature disabled or enabled.

The REG LED shows the current status, when the LED is on in this mode the pulsing is

disabled. No other settings will be affected by this change and the setting will be saved in

eeprom. Power off in the same manner as with size setting to retain the setting.

If dual pumps were to be fitted, this feature should be used where the intermediate head

height is above 5 feet. The pulsing function is most effective in standard head height

situations (up to 6 feet).

Note:

If the pump has blocked/jammed and the thermal overload has gone open circuit, just

remove the blockage from the pump. The module and the pump should still be okay. If

the pump windings are water damaged, the pump will quickly overheat and cut off again.

The pump must be replaced in this case. (If the pump shorted to earth, it is possible that

the module could short out on series 10 machines). Series 11 should not have this

problem. The pump is not powered through the motor controller as with the phase 5

products. Series 11 phase 6 machines do not utilise the pump to dump energy. This

change also reduces the potential for failure.

It is important to check the pump windings thoroughly for water damage. It is possible for

the resistance of a water-damaged pump to be normal, however the inductance of the

pump can change causing it to overheat and cut out. There are new fault codes in the

system that now relate to the pump circuit and it’s extended function.

Page 12

517766 March 2003

- 12 -

14.7 Lid-Lock

On the Series 11 Smartdrive there is now a lid lock.

During the spin and drain out part of the cycle prior to

spray rinsing, the lid will lock down until the completion

of the spin. Once the spin has completed, the lock will

release and the lid can be opened. The Lid Lock LED

will illuminate when locked.

If the lid lock fails in the closed position the removal process is as follows:

The locked lid can be lifted on the sides enough to allow the lid buffers to be removed.

This will allow the screws holding down the top deck to be unscrewed. The top deck can

then be lifted up, removing the lid lock screw will allow the lid lock housing to be replaced.

Replacement part number is 420036P. Un-clip the clear cap from the housing and

disconnect the Rast connection. Clip the new housing in and re-assemble.

If the harness is damaged, replacing it requires the following method.

Remove the lid from the top deck assembly. The Console will then need to be removed to

access the wiring connection to the motor controller if the wiring loom is replaced. This

harness is also part of the harness to the OOB switch and the motor controller will need to

be lifted to remove and replace it. Remember to secure the wire into the retainers under

the top deck, or damage may occur during operation.

Note:

If the power supply is cut during the spin cycle, the machine will keep the lid locked until

the rotor has ceased to turn (3 to 15 secs). Only then will it release the lock, the motor is

acting like a generator and allows the lock to stay energised under the baskets inertia via

the motor controller. In a brown out situation the machine will restart at the start of

whatever cycle it was doing and continue the wash. The lid lock would then be reactivated

if it happened to be on a spin cycle.

15. SIZE SETTING MODE FOR SERIES 11

15.1 GW Size setting

The difference between Series 11 and previous machines is the position of the Power

button. The sequence for sizing the modules is the same.

It is important to set the size switch setting into the Motor Controller’s memory whenever a

replacement Motor Controller and or IW Display Module is fitted to Smartdrive. Failure to

do this will result in Smartdrive faulting with fault code 9.

Accessing size setting mode is the best way to check the size for GW. The size setting of

Smartdrive may be checked in Diagnostic mode for all phases.

To set the size switch turn the power on at the power point and off at the console. Press

and hold the TEMPERATURE UP button then press the POWER button. Smartdrive will

give 4 short beeps and the pattern of LEDs will change.

Page 13

517766 March 2003

- 13 -

· Press SPIN SPEED UP button, the SPIN HOLD LED is on for (8.0kg) 17.6lb (650mm

wide). 25.5 in

· Press POWER to exit this mode.

If the size setting is wrong Smart drive will have the following settings incorrect: -

· The Auto Water Levels chosen by Smartdrive may be wrong.

· The High Water Level may be wrong by as much as 1.5 in.

· The flow rate for inlet water, normally (3 litres or 0.8 gal per minute), may be set

incorrectly.

· The wash profile controls the strength of the agitator. This could result in poor wash

performance or splash over.

· Water saver settings.

Page 14

517766 March 2003

- 14 -

16. DIAGNOSTIC MODE

16.1 GW (Ecosmart)

Turn the power on at the power point but off at the machine. Press and hold the WASH

TEMP DOWN button and then the POWER button until the machine gives 2 short beeps

and lights up. Release buttons when the beeps indicate diagnostic mode has been

entered.

Note: The power button is relocated to the left of the panel but central to the console, not

on the right hand side as with all previous GW Smart Drive machines.

Last fault can be found by pressing the SPIN SPEED UP button three times. The HOLD

and SLOW lights should be illuminated. Binary can then be read from the wash progress

lights. Fault code 49 is shown above, 32+ 16+ 1 = 49 which is a cold water valve fault.

Binary code is read from the Wash Progress lights.

1286432168421

o o o ooooo

Page 15

517766 March 2003

- 15 -

16.2 Smartdrive Diagnostic Table

To use this table, firstly enter Diagnostic Mode. The different levels of information can be

extracted by using the Spin Speed up and down buttons.

Diagnostic

Mode

Spin Speed LEDs

Fast Med Slow Hold

Diagnostic Info Displayed

0 OFF OFF OFF OFF Last User Warning Number

1 OFF OFF OFF ON Last User Warning Cycle Position

2 OFF OFF ON OFF HVDC setting (used by auto WL sense agitate)

3 OFF OFF ON ON Fault Code at last fault (if within the last 8

cycles)

4 OFF ON OFF OFF OOB status

5 OFF ON OFF ON Cycle count at last fault (low byte)

6 OFF ON ON OFF Cycle count at last fault (high byte)

7 OFF ON ON ON Cycle position at last fault

8 ON OFF OFF OFF Water Temp (deg C)

9 ON OFF OFF ON Cycle count (low byte)

10 ON OFF ON OFF Cycle count (high byte)

11 ON OFF ON ON Motor speed (rpm/10)

12 ON ON OFF OFF Water Level

13 ON ON OFF ON EEPROM version number

14 ON ON ON OFF Software Version number

15 ON ON ON ON (F&P development use only)

16.3 USER WARNINGS

There are a number of warnings which are generally caused by the user or poor

installation. These warnings should be corrected by the user. Smartdrive signals user

warnings by flashing LEDs and a rippling set of 5 beeps repeated every 6 seconds. This is

the same tone that is heard when Smartdrive is first plugged into the mains power. Some

warnings are indicated by the wash progress LEDs flashing and no user warning tone,

(Restart or Recycle mode). Most of this information is available to the user in the ‘Use and

Care Manual’

Page 16

517766 March 2003

- 16 -

16.3.1 Insufficient Hot Water (Hot Water LED flashing)

This warning is indicated by the hot water LED flashing. Smartdrive will also

be making a rippling set of 5 beeps repeated every 6 seconds. The hot water

is not connected or the water temperature is too low. NB. This warning mode

does not cause the product to PAUSE.

1. Check that the hot water is connected and that the tap is turned on. If

your product is set for 'controlled cold' hot water may still be required for a

cold wash.

2. Check that the water temperature is not too low. The water temperature

may need to be 60oC for a hot wash.

3. Check that the hot water inlet is not connected to the cold water supply.

4. Check that the filter on the hot inlet hose is not blocked.

5. Motor Controller.(Phase 1 to 4). Thermistor (Phase 5). The temperature sensor has

failed. Replace motor controller.(Phase 1 to 4) Check the resistance of the thermistor.

Resistance is 12.5k ohms at 20oC. Replace if faulty. (Phase 5).

6. Check the size is set correctly.

NB. It is possible to get this warning when washing with cold water if the cold wash

temperature is set at 20oC or more. Wash temperatures may be adjusted, see section

7.1.

16.3.2 Insufficient Cold Water (Cold Water LED flashing)

This warning is indicated by the cold water LED flashing. Smartdrive will also

be making a rippling set of 5 beeps repeated every 6 seconds and the product

will be paused. The cold water is not connected or the flow rate is too low.

1. Check that the cold water is connected and that the tap is turned on.

2. Check that the flow rate is not too low. The product requires a minimum

flow rate of 3 litres per minute. Check that the filter on the cold inlet hose is

not blocked. If the installation has a flow rate below 5 litres per minute the

flow may be improved by using large bore inlet hoses p.n. 426123.

3. Taps may be connected the wrong way round.

4. Cold water temperature exceeds 35oC. NB. Phase 2-4. If cold water

temperature exceeds 40oC high purge motor controllers are available.

Contact your ASC’s.

5. Phase 1-4. Motor Controller. The temperature sensor has failed. Replace motor

controller.

6. Phase 5. Thermistor. Check the resistance of the thermistor. Resistance is 12.5k ohms

at 20oC. Replace if faulty.

7. Check the size is set correctly.

Page 17

517766 March 2003

- 17 -

16.3.3 No Water (Both Hot and Cold Water LEDs flashing)

This warning is indicated by the cold and hot water LEDs flashing. Smartdrive

will also be making a rippling set of 5 beeps repeated every 6 seconds and

the product will be paused.

1. Check that the taps are turned on.

2. Check that the inlet hoses are connected.

3. Check that the flow rate is not too low. The product requires a minimum

flow rate of 3 litres per minute. Check that the filters on the inlet hose are

not blocked. If the flow rate is always low then fit large bore inlet hoses.

4. Check that the hot water is connected and that the tap is turned on. If

your product is set for 'controlled cold' hot water may still be required for a

cold wash.

5. Siphoning. Check the drain hose is not installed too low and is siphoning.

6. Check the size is set correctly.

16.3.4 Overloaded Product (High Water LED flashing)

This warning is indicated by the high water LED flashing. Smartdrive will

also be making a rippling set of 5 beeps repeated every 6 seconds and

the product will be paused. The product is overloaded.

1. Check that the product is not overloaded. This is more likely on a

smaller size product. Also it may be that the user has selected the

wrong water level this is more likely to be a LW or MW which only

has 3 water levels.

2. Check that the rotating bowl assembly is not jammed to the agitator

with any foreign object that may be caught under the agitator skirt.

3. Check that the clutch teeth are not locked together with dirt,

detergent or lint. Check that the teeth are not broken.

16.3.5 Out of Balance (First Rinse or Final Spin and Current Spin Speed LED is

flashing)

This warning is indicated by a rinse or spin LED and the current spin speed LED flashing.

Smartdrive will also be making a rippling set of 5 beeps repeated every 6 seconds and the

product will be paused.

1. Generally this can be caused by a large load. Smartdrive will normally manage to

redistribute the load and spin. Under exceptional circumstances the user may need to

redistribute the wash load manually once the bowl is stationary.

2. Check that Smartdrive is correctly installed, is level and does not wobble.

3. Check the bias spring is fitted between the wrapper and the outer bowl.

4. Check the OOB lever, switch and bracket.

5. Check the switch operates correctly with a multimeter. Resistance should be less than

2 ohms.

6. Check the suspension is not catching or bouncy.

7. Check both balance rings on the inner bowl contain water.

8. The Motor Controller, (Display for Phase 1) should only be replaced if fault code 43.

Page 18

517766 March 2003

- 18 -

16.3.6 Suds (First Rinse LED is flashing or Final Spin LED is flashing)

This warning is indicated by a rinse or spin LED flashing. Smartdrive will also be making a

'rippling sound of 5 beeps repeating every 6 seconds' and the product will be paused. Too

much Detergent has been used and Smartdrive has a suds build up.

1. This is generally caused by too much detergent. Wait for suds to dissolve then rinse

clothes using a deep rinse.

2. Check that the pump is not partially blocked, or that the drain hose is not kinked.

16.3.7 Restart and Recycle (Wash Progress LEDs flashing)

During normal operation restart is on and recycle is off. If either of these are in the wrong

state the wash progress lights will flash when the power button is off, (but not in standby).

It may indicate that the user has inadvertently set the product into the wrong mode. In this

mode there are no beeping sounds.

If restart is OFF the 5 leftmost wash progress LEDs are flashing. There should be no

noticeable effect of this on Smartdrive, except that it is more likely to fault. Set Restart

back to ON.

If recycle is ON the 3 rightmost wash progress LEDs are flashing. In this mode

Smartdrive will be continuously doing cycles! Set recycle to OFF.

This can normally be resolved by powering off Smartdrive.

If this does not resolve the problem, RESTART or RECYCLE are set in the EEPROM

memory. To reset, a similar keypress sequence similar to Diagnostic mode is required as

follows: -

Phase 4 & 5

· Enter Diagnostic Mode. Turn the power on at the power point and off at the console.

Press and hold the WASH TEMPERATURE DOWN button then press the POWER

button. Smartdrive will give 2 short beeps.

· From Diagnostic mode use the WATER LEVEL DOWN button to turn RESTART on.

The LOW WATER LEVEL LED on indicates RESTART ON. Use the WATER LEVEL

UP button to turn RECYCLE off. The MEDIUM WATER LEVEL LED off indicates

RECYCLE OFF. To set these modes in EEPROM the Advance button must be

held while selecting Restart or Recycle. Power off Smartdrive.

Phase 1 to 3

· Turn the power on at the power point. Press the Power button to power up Smartdrive.

Press and hold the REGULAR button then press the ADVANCE button.

· Use the WATER LEVEL DOWN button to turn RESTART on. The LOW WATER

LEVEL LED on indicates RESTART ON. Use the WATER LEVEL UP button to turn

RECYCLE off. The MEDIUM WATER LEVEL LED off indicates RECYCLE OFF.

Power off Smartdrive.

16.3.8 Demonstration Mode (All LEDs flashing in patterns)

This feature is designed for in store demonstration purposes. Smartdrive can draw

attention to itself with a selection of flashing LEDs. In this mode Smartdrive cannot be

Page 19

517766 March 2003

- 19 -

started. To Select DEMONSTRATION MODE press and hold the ADVANCE button, then

press the POWER button.

During the DEMONSTRATION display the LEDs will alternate between all on, LEDs

flashing, and all LEDs off. To return Smartdrive to normal operation, the mains supply

must be switched off. Some Phase 1-3 displays may inadvertently go into this mode if

affected by condensation.

16.4 Drain Pump Test

GW pump testing is activated by the regular button when in diagnostic mode. Enter

Diagnostics using the same sequence as previous phases. The Power button is in the

middle of the console, not on the right hand side as with series 8 and 10 machines!

For testing the pump, the Regular button (ecosmart) will activate the regular light, which in

turn activates the pump. Pressing the button activates the pump. Pressing the button

again de-activates the pump.

This feature can be helpful if the bowl is still full of water.

16.5 Water Valve Test

Valves are activated in diagnostic mode by pushing the Temp up button for Hot valve

(digital) and Temp down button for Cold valve (proportional) as with previous models.

Pressing each button once will activate the valve. To de-activate the valve, press the

same button again. Caution: Do not leave the machine unattended when either or

both valves are operating. This is also good to use when installing machines. It takes

the shock out of the fittings and seals and allows checks for leaks on the inlet hoses both

machine end and tap end.

16.6 Restart Feature

For GW Restart setting, enter Diagnostics Mode with the power off at the machine but on

at the wall outlet. Press and hold the Wash Temp down button and then press the Power

button. 2 beeps will be heard when this mode has been entered successfully.

An illuminated LED on low water level will indicate the Restart feature is activated.

Using the low water level button this feature can be disabled for servicing and quick fault

diagnosis, or enabled when returning to the customer.

To make sure the phase 6 module retains the restart feature (when it has been disabled

for service reasons), press and hold the Advance button down at the same time when

pressing the Water level down button. A long beep will acknowledge the setting has been

retained in EE prom. Power off to retain selection as with size switching.

When the machine is first turned on:

1. If none of the 5 left most green wash progress LED’s are on, the restart feature

is on.

2. If all 5 of the left most green wash progress LED’s flash, the restart feature is

off and smart drive will not restart automatically if a minor fault occurs during

normal usage.

With the RESTART feature on:

Page 20

517766 March 2003

- 20 -

1. If a fault occurs in the machine, the diagnostic system will detect it. However,

instead of displaying a fault code immediately, the machine will try to RESTART.

2. If the fault was only of a temporary nature, the machine will restart and finish the

cycle.

3. If there is a continuous fault the machine will try to RESTART a number of times.

This process could take up to 8 minutes depending on the type of fault. After this, if

the machine still cannot restart, the fault code is displayed and the machine will

beep continuously.

NOTE - This feature is designed as a service aid only and should be left ON in the

customer’s home. To return to normal operation, and to reset the RESTART feature to

the factory setting, switch the machine off at the wall or disconnect from the mains supply.

16.7 Recycle Feature

At the end of servicing, the machine may require an extended test where the machine can

be left to complete a number of wash cycles. By turning on the RECYCLE feature the

machine will continuously repeat the wash cycle until the RECYCLE feature is turned off.

Whether or not the RECYCLE feature is on is indicated during normal use of the machine

as follows:

When the machine is first turned on:

1. If none of the 3 right most wash progress LED’s are on, the recycle feature is

off.

2. If all 3 of the right most wash progress LED’s flash, the recycle feature is on and

smart drive will continuously recycle.

NOTE - This feature is designed as a service aid only and should be OFF in the

customer’s home. To return to normal operation, and to return the recycle feature to the

factory setting, switch the machine off at the wall or disconnect from the mains supply.

16.8 Hot Tub Flag

If the machine has been filled with the hot water valve utilised (ie. warm or hot fill) and has

not had a cold rinse, the electronics will not allow the machine to spin up to its full speed

of 1000 RPM. It will only allow the spin speed to reach 700 RPM.

To allow the machine to spin up to 1000 rpm, restart the machine at cold rinse and this will

reset the Tub flag detecting.

The Softener Rinse LED will be on when the Diagnostic Mode is selected if the spin

speed is restricted to 700 rpm. To clear this flag press the Wash Option button below the

Softener Rinse LED.

NOTE: The drain pump test, water valve test, restart, recycle and hot tub flag features

can be accessed from any level in the diagnostic mode.

Page 21

517766 March 2003

- 21 -

17. WIRING DIAGRAM

Page 22

517766 March 2003

- 22 -

18. READINGS FROM MODULE

Expected Readings on 120V Motor Controller

Pump/Motor

Winding resistance check,

phase to phase

(already in service manual) 32 ohms

120 VAC

RPS

C B A 15v ÆV

Should always be 15V DC

Individual phases should be either 15V or ÆV, will

change when the motor turns

Display

CLK DAT STR ÆV COMS 5v SM Sleep Mode 2.5V:

On: 0.1V

Therm

Resistance check with power off.

12.5k ohms at (20°C) 68° F

ÆV ÆV Therm

Lid lock drive

Lid Lock / OOB

Pulses up to 30V when locking,

when lid locked, sits at approx 10V DC

ÆV OOB

Diverter Valve

Approx 100 V AC when on, across the terminals, not strictly AC, rectified mains

Fluke meters read approx 100 V AC or 220 V DC (rms) depending on meter.

Page 23

517766 March 2003

- 23 -

19. DETAILED FAULT CODES

DETAILED FAULT CODES

FOR

MODELS

Phase 1 GW500 GW600 GW700 GW050 GW060 GW070 GW650

Phase 2 GW701 GW601 GW501 MW051 W015 MW061 MW071

Phase 3 GW703 GW603 GW503 MW053 LW035

Phase 4 GW708 GW608 W508 MW058 LW085 AW085 GWC08

GWM08 GWL08 THM08 THL08

Phase 5 GW709 GW609 GW509 MW059 LW095 AW095 GWC09 GWM09 GWL09

Phase 5 IW IW709 IW609 IW509 IWL10 IWM10 IWC09 IW710 IW810 IWM09 IWL09

Phase 6 GW711 GW611 GW511 MW511 GWL11 GWM11 GWC11

Phase 6 IW IW811 IW711 IW511 IWL11 IWM11 MWC11

INTRODUCTION

The format for fault description in this booklet follows the Primary, Secondary, Tertiary and

Quaternary fault source system. These sources have mostly been arranged in order of

most likely source of fault, but in some cases the sequence has been modified to aid the

servicing procedure.

It should be noted that the fault source Pump System includes the pump and drain hose

assembly.

Fault code shows the last recorded fault. Always confirm fault.

Page 24

517766 March 2003

- 24 -

FAULT DESCRIPTIONS

1. (00000001) Phase 1 - Display Module Fault

Phase 2 to 6 - Motor Controller Module Fault

The Motor Controller Module (Display for phase 1) has encountered an error when

writing to an Eeprom address.

Primary Source: Motor Controller module. (Display Module for Phase 1)

Action: Replace Motor Controller module. (Display Module for Phase 1)

2. (00000010) Phase 1 - Display Module Fault

Phase 2 to 4 - Motor Controller Module Fault

An error has been encountered when trying to read the pressure sensor.

Primary Source: Motor Controller module. (Display Module for Phase 1)

Action: Replace Motor Controller module. (Display Module for Phase 1)

3. (00000011) Phase 1 to 6 Motor Controller Module Fault

The Motor Controller Module has found a memory error.

Primary Source: Motor Controller module.

Action: Replace Motor Controller module.

4. (00000100) Phase 1 - Communications Fault

The Motor Controller has had difficulty communicating with the Display Module

Primary Source: Motor Controller module.

Action: 1. Turn off at the wall and on again after 5 seconds and try again.

2. If still faulty, replace the Motor Controller

3. Replace Display Module. If the new Display Module corrects the

fault, then refit the original Motor Controller.

5. (00000101) Phase 1 - Communications Fault

The Display Module has had difficulty communicating with the Motor Controller.

Primary Source: Display Module.

Action: Turn off at the wall and on again after 5 seconds and try again.

1. Check connections of the 12 way harness for bad contacts,

corrosion etc.

2. Check for moisture in the console area. Dry out if necessary

2. If still faulty, replace the Display Module

3. If still faulty, replace the Motor Controller. If the new Motor

Controller corrects the fault, then refit the original Motor Controller.

6. (00000110) Phase 1 – Display Module Fault

Phase 2 – 4 Motor Controller Module Fault

The Motor Controller module (Display Module for Phase 1) has received an

incorrect signal from the pressure sensor.

Primary Source: Motor Controller module. (Display Module for Phase 1)

Action: Replace Motor Controller module. (Display Module for Phase 1)

Page 25

517766 March 2003

- 25 -

7. (00000111) Phase 1 to 6 - Display Module Fault

The Display module has found a memory fault.

Primary Source: Display Module.

Action: Replace Display module.

8. (00001000) Phase 1 - Display Module Fault

The Display micro has not been able to start up correctly.

Primary Source: Display Module.

Action: Turn off at the wall and on again after 5 seconds and try again.If still

faulty replace the Display Module.

9. (00001001) Phase 1 to 6 Size Switch Error

The Display size switch setting does not match that stored in the memory.

Primary Source: Display Module Phase 1,2 & 3.

Action:

If the Display module for Phase 1, 2 or 3 has just been inserted into a console

housing, then check that the two size switch plungers accurately locate onto the

console housing. If this fault has appeared during normal operation of the

machine, check for condensation damage, check the size switch or replace the

Display module.

Secondary Source: Motor Controller module.

Action Phase 1, 2 &3:

If the Motor Controller module has been changed from one size machine to

another, then the size switch settings in the memory will have to be reset. This can

be done by entering and exiting the Option Adjustment mode. Push and hold

START/PAUSE then push POWER button.

Action Phase 4 Series 8, Phase 5 Series 9 / 10 & Phase 6 Series 11:

Reselect the size of the machine by using the SIZE SETTING MODE. Push and

hold the WATER TEMP UP button then press the POWER button. To select the

size of the machine. Push the temperature up button until the cold LED is on for

5kg machines, push the water level up button until the low water level LED is on for

the 6kg machines, push the SPIN SPEED UP button until the hold LED is on for

7kg machines.

10. (00001010) Phase 1 to 6 Temperature Sensor (Thermistor) Error

The temperature sensor may be open circuit or the ambient temperature is below

minus (10oC) 50° F. This fault is only applicable in the Intuitive Washer and the

GW models.

Primary Source: Thermistor.

Action: Replace Thermistor.

11. (00001011) Phase 1 to 6 - Pressure Sensor Fault

While measuring the water level, the Motor Controller micro has detected a

negative pressure. Reconnecting the pressure tube to the pressure sensor while

the bowl has been partly filled with water may have caused this.

Primary Source: Pressure Tube.

Action:

Page 26

517766 March 2003

- 26 -

1) Check bowl is fully pumped out. Remove pressure tube from pressure

sensor, clear pressure tube of any water and reconnect tube.

2) If fault is still present, replace the Motor Controller module.(Display Module

Phase 1)

12. (00001100) Phase 1 to 6 - Flood Protection Error

The Motor Controller module has found the water level to be above the flood level

and tried to pump the excess water out. (Under extremely high flow rate conditions

the machine may overfill during the “top-up” routine in agitate.) After pumping for

30 seconds, it has been unable to lower the water level below the flood level.

Either the water valves have stuck on and are letting water in at a flow rate that is

higher than the pump can handle, or the pump is blocked and can’t remove the

excess water.

Primary Source: Water Valves.

Action:

If the water valves are on continuously, check that the water valves turn off

mechanically (remove power from machine).

Secondary Source: .Pump system

Action:

Check pump for blockage and drain hose for correct height and kinking

Tertiary Source: Motor Controller module. (Display Module Phase 1)

Action:

If water valves are being driven on electrically, replace Motor Controller

module. (Display Module Phase 1)

13. (00001101) Phase 1 – Pump Fault

The Display module has detected that the pump is on when it should be off.

Action:

1. The pump is fitted with a thermal cut out device. Check if this device has

been activated. If it has wait until the pump cools down before restarting.

Check for any pump blockage and condition of pump before attempting to

restart. i.e. pump seizure.

2. Check for open circuit pump windings. Check the resistance of the pump.

3. Check the pump harness or the connectors for an open circuit.

4. Replace the Display Module.

14. (00001110) Phase 1 – Pump Connection Fault

The Display Module has detected that the pump is not on when it should be.

Primary Source – Pump

Action:

1. The pump is fitted with a thermal cut out device. Check if this device has

been activated. If it has wait until the pump cools down before restarting.

Check for any pump blockage and condition of pump before attempting to

restart. i.e. pump seizure.

2. Check for open circuit pump windings. Check the resistance of the pump.

3. Check the pump harness or the connectors for an open circuit.

4. Replace the Display Module.

15. (00001111) Phase 1 – Display Module Fault

The Display Module has read an incorrect voltage on the pump circuit

Primary Source: Display Module

Action:

Page 27

517766 March 2003

- 27 -

Replace the Display Module.

Note: If Smartdrive is running at well below its rated supply voltage and the pump

has operated for more than 4 seconds at the voltage this fault will also appear.

17 – 20. (00010xxx) Phase 1 – Display / Motor Controller out of Sequence

22 – 23. (000101xx) Phase 1 – Display / Motor Controller out of Sequence

Primary Source: The Display Module and Motor Controller are running out of

sequence.

Action:

Turn the Smartdrive off at the wall and then back on again in 5 seconds. Restart.

If the fault persists, disable auto restart feature and retest. A new fault code will

appear, carry out actions necessary to fix this new fault.

25. (00011001) Phase 5 IW – LCD Initialisation Error

The Intuitive Display has detected a problem with the LCD. Liquid Crystal Display

Primary Source: IW Display Module

Action: Replace IW Display Module

28 – 30. (000111xx) Phase 1 – Display / Motor Controller out of Sequence

Refer to fault code 17

32. (00100000) Phase 1 – Pump Circuit Error

The Display Module has detected that the pump is on when it is off.

Primary Source: Display Module

Action:

1. Check for moisture in the console area.

2. Replace the Display Module.

Page 28

517766 March 2003

- 28 -

33. (00100001) Phase 1 – Water Valve Fault

The Module has detected a water valve fault.

Primary Source: Water Valve connection

Action: Check that both valves are connected up properly.

Secondary Source: Water Valve coil faulty

Action:

1. Check the valve coils are not open circuit.

2. Replace Display Module if the valve coils are not faulty.

34. (00100010) Phase 1 – Brake Resistor Fault

The circuit that controls the braking of the motor is faulty.

Primary Source: Motor Controller

Action: Replace Motor Controller

Secondary Source: Display Module

Action: Replace the Display Module

If the Display Module corrects the fault, then refit the original Motor Controller.

35. (00100011) Phase 1 – MC Reset Error

The Display Module has sent a false signal to the Motor Controller.

Primary Source: 12 way Harness Connection.

Action: Check the 12 way harness connection between the display Module

and the Motor Controller.

Secondary Source: Display Module

Action: Replace the Display Module.

36. (00100100) Phase 1 to 6 - Water Leak Fault

The Motor Controller module has needed to top up the water level more than 4

times during agitate. This is excessive, as normally only one or two top ups are

required to replace the air that has escaped from a full load during agitate. The

most likely cause is that the machine is siphoning. The other alternative is that the

machine has developed a leak.

Primary Source: Pump System.

Action

1) Check the height of the drain hose outlet. Minimum 33.4 in (850mm),

Maximum 47 in (1200mm).

2) Check that the hose guide is fitted and check that the hose does not

protrude more than (20mm) ¾ in beyond the guide.

Secondary Source: Mechanical.

Action:

1) Check the pressure tube connections on the Tub and Motor Controller

module.

2) Check that the drive shaft seal and the pump housing seal have not

developed a leak.

Tertiary Source: Motor Controller module.(Display Module Phase1)

Action: Replace Motor Controller module.(Display Module Phase 1)

Page 29

517766 March 2003

- 29 -

37. (00100101) Phase 1 to 6 - Pump Blocked Error ( No change in the water

level)

While draining, the water level reading from the pressure sensor has not changed

for over 3 minutes. There are three likely reasons for this fault. One is that the

drain hose or the pressure switch hose has been squashed or kinked and the pump

out rate has been dramatically reduced. The second possibility is that the pump is

partially or fully blocked. The third is that the pump is not operating due to Motor

Controller module, wiring or pump failure. This fault could also appear if the

machine is pumping to an unusually high head of drain hose or into an extended

length of drain hose. The Fourth possibility is a diverter valve fault or blockage,

water level is not altering as the diverter is stuck in the recirculation mode, giving

the module the appearance the pump is not lowering the water level.

Primary Source: Pump System.

Action:

1) Check that the drain hose has not been kinked.

2) Check the length of the drain hose and try to reduce the length if excessively

long. A 39 inch (1 metre) extension hose of the same diameter fitted to the

existing drain hose is the maximum allowable length.

3) Check for open circuit windings in the pump. (Note: Pumps are fitted with a

thermal cut-out which will reset on cooling.)

4) If the Tub is empty of water, remove the pump from the pump housing and

check that it is not blocked. Also check the drain hose is not blocked.

5) If the Tub contains water, then service the pump from the top of the machine

by removing the top deck and Basket. Bail out the water, remove the pump

cap and hood and clear the restriction.

Secondary Source: Wiring.

Action:

1) Check the pump harness is connected correctly to the pump.

2) Check continuity of the pump harness.

Tertiary Source: Motor Controller module.

Action:

Activate the pump by operating the machine in spin mode. Check the pump

is rotating. If it is not operating, and Primary and Secondary checks have

been performed, then replace the Motor Controller module.

Note: Consider fitting Pump Hood Kit (WM013). If (5kg) 11lb Smartdrive fit splash

guard to pump.

Quaternary Source: Diverter Valve failure (Phase 5 and 6 Eco’s )

Action:

Check the diverter valve, see fault code 51

38. (00100110) Phase 1 to 6 - Pressure Sensor Fault

The Motor Controller module has recorded a water level of empty while it is

agitating. The water level must have been greater than empty for the machine to

enter the agitate mode initially. The most likely cause of this fault is that the

pressure sensor hose has been severed or fallen off during agitate. Alternatively

the pressure sensor may be faulty.

Primary Source: Mechanical.

Action:

Check that the pressure tube is intact and has not been cut.

Secondary Source: Motor Controller module. (Display Module Phase 1)

Page 30

517766 March 2003

- 30 -

Action:

Replace the Motor Controller module if the pressure tube shows no sign of being

faulty. ( Display Module Phase 1)

39. (00100111) Phase 1 to 6 - Pressure Tube Fault

The probable cause of this fault is that the pressure tube has become blocked or

kinked or has fallen off completely. Alternatively the pressure sensor may be faulty.

Primary Source: Mechanical.

Action:

Check that the pressure tube is intact and not blocked with water or dirt and is not

kinked.

Secondary Source: Motor Controller module.(Display Module Phase 1)

Action:

Replace the Motor Controller module.(Display Module Phase 1)

40. (00101000) Phase 1 to 6 - Bowl Dis-engage Fault

While carrying out a Basket check, the Motor Controller module has found that the

basket is not engaged even though the pressure sensor indicates that the Tub is

empty. The Motor Controller module continues to check for 2 minutes, after which

time it displays this fault. The first two areas to check are the clutch and the

pressure tube. If these two appear correct, then the fault could be in the pressure

sensor in the Motor Controller module.

Primary Source: Mechanical.

Action:

1) Check that there are no clothes or other foreign objects preventing the clutch

from re-engaging. Excessive suds can stop the basket rotating.

2) If the machine is empty of water, carry out a clutch disassembly procedure

and check the spline drive.

3) Next check that the pressure tube has not come off and that it is not kinked.

Secondary Source: Motor Controller module.(Display Module Phase 1)

Action:

Replace Motor Controller module.(Display Module Phase 1)

41. (00101001) Phase 1 to 6 - Temperature Sensor Fault (Thermistor)

The temperature sensor is measuring temperatures above 110oC. The fault is

probably due to a short circuit in the sensor line. (Only in the Intuitive Washer and

the GW Models.)

Primary Source: Thermistor (Phase 5 and 6) Motor Controller (Phase 1 to 4)

Action: Phase 1

1. Check connections of the 12 way harness

2. Check for moisture in the console area

3. Replace Motor Controller.

4. Replace Display Module, if the new display fixes the fault then refit the

original Motor Controller.

Phase 2 to 4

Change Motor Controller module.

Phase 5 and 6

Action:

1. Check the connection from the thermistor the Motor Controller

2. Check the resistance of the thermistor, should read 12.5k ohms at (20

degrees C) 68° F. Replace if faulty.

Page 31

517766 March 2003

- 31 -

3. Replace the Motor Controller module.

42. (00101010) Phase 1 – Rotor Fault

Primary Source: The Motor Controller has had some confusing information

feedback.

Action: Turn off Smartdrive at the wall and back on again after 5 seconds.

Restart.

43. (00101011) Phase 1 to 6 - OOB Switch Fault

The Motor Controller module has found that the signal returning from the out of

balance switch indicates that the switch is permanently on or the harness to it is

disconnected.

Primary Source: Mechanical.

Action:

1) Check that the out of balance switch is free to move.

2) Check that no harnesses are blocking switch movement.

3) Check that the switch operates correctly when activated. Replace the switch

if suspect.

4) If the out of balance micro switch shows signs of corrosion, replace the

switch and switch harness, and fit a condensation kit to the console area if

not incorporated in the top deck.

5) Check the level of the machine and also the bias spring.

Secondary Source: Wiring.

Action:

Check the harness to the switch is connected correctly. The terminals should be

connected to the normally closed position. If the harness terminals show signs of

corrosion, then fit a new harness.

Tertiary Source: Motor Controller module.(Display Module Phase1 )

Action:

Replace Motor Controller module.(Display Module Phase 1)

44. (00101100) Phase 2 to 6 - Water in Tub during Spin

The Motor Controller has sensed a water level in the Tub during spin. This may be

caused by a slow pump out rate due to a partial blockage in the pump hose or

pump.

Primary Source: Pump System.

Action:

1) Check that the drain hose is not squashed or kinked.

2) Check the length of the drain hose and try to reduce the length if excessively

long. A 39 inch (1 metre) extension hose of the same diameter fitted to the

existing drain hose is the maximum allowable length.

3) If the Tub is empty of water, remove the pump from the pump housing and

check that it is not blocked. Also check that the drain hose is not blocked.

4) If the Tub contains water, then service the pump from the top of the machine

by removing the top deck and basket. Bail out the water, remove the pump

cap and hood and clear the pump of any obstruction.

5) Check that water is not siphoning back into the machine when the pump turns off

when the spin speed reaches 700 rpm

Secondary Source: Motor Controller module.

Action:

Replace Motor Controller module.

Page 32

517766 March 2003

- 32 -

45. (00101101) Phase 5 Display Memory Check Fault

On power up, the display has checked its memory against a known reference and

found differences.

Primary Source: Display Module.

Action: Replace Display Module.

46. (00101110) Phase 5 IW – Display EEPROM Check

The Intuitive Display has detected a problem with its internal EEPROM.

Primary Source: IW Display Module

Action: Replace IW Display Module

47. (00101111) Phase 2 and 3 - Basket Dis-engage Fault

While carrying out a Basket check, the Motor Controller module has found that the

basket is not engaged even though the pressure sensor indicates that the Tub is

empty. The Motor Controller module continues to check for 2 minutes. During this

time the module has not been able to determine a valid tub status and so displays

this fault. This fault differs from fault code 40 in that a valid tub status could not be

determined. The first two areas to check are the clutch and the pressure tube. If

these two appear correct, then the fault could be with the pressure sensor in the

Motor Controller module.

Primary Source: Mechanical.

Action:

1) Check that there are no clothes or other foreign objects preventing the clutch

from re-engaging.

2) Next check that the pressure tube has not come off and that it is not kinked.

Secondary Source:Motor Controller module.

Action:

Replace Motor Controller module, if the above checks out without fault.

48. (00110000) Phase 2 to 6 - Hot and Cold Valve Faulty

The Motor Controller module has measured voltages from the valve diagnostic

circuit that indicate both the hot and cold valves are faulty. The most likely cause is

that the valve harnesses have not been connected correctly or the valve is open

circuit.

Primary Source: Wiring.

Action:

Check the valve harnesses are correctly fastened to the valves or the pins are not

bent backwards.

Secondary Source: Water Valves.

Action:

Check the valve coils are not faulty (open circuit).

Tertiary Source: Motor Controller module.

Action:

Replace the Motor Controller module.

49. (00110001) Phase 2 to 6 - Cold Valve Faulty (proportional)

The Motor Controller module has measured a voltage from the valve diagnostic

circuit that indicates the cold valve is faulty. The most likely cause is that the valve

harness has not been connected correctly or the valve is open circuit. See fault

code 48 for service procedure.

Page 33

517766 March 2003

- 33 -

50. (00110010) Phase 2 to 6 - Hot Valve Faulty (digital)

The Motor Controller module has measured a voltage from the valve diagnostic

circuit that indicates the hot valve is faulty. The most likely cause is that the valve

harness has not been connected correctly or the valve is open circuit. See fault

code 48 for service procedure.

Note: Phase 5 can give a fault code 50 when the smart drive powers off while

spinning. There will actually be no fault if this has happened.

51. (00110011) Phase 5 and 6 Eco - Diverter Valve Fault

Primary: The motor controller has registered a drop in water level in the

recirculation phase of the wash cycle, water is being drained instead of recirculated.

Or water has been sprayed onto the valve from an external source and caused the

solenoid to blow.

Action:

Turn the power off at the machine but leave the power on at the wall, then measure

the voltage across the terminals of the wax actuator, if a reading of 120V is

achieved the motor controller has failed due to the valve and both will need to be

replaced.

Secondary: Check for blockage in the valve itself or a broken hinge mechanism.

52. (00110100) Phase 5 and 6 Eco - Diverter Top-up Fault

More than 6 attempts to top-up the water level in the tub, this then signifies the

valve has not closed and is diverting to drain, or the top-up was not increasing quick

enough suggesting the valve has a blockage and is also draining.

Primary Source: Diverter valve

Action: Remove the diverter valve and check for blockages or broken hinge

mechanism.

Secondary Source: Wax Solenoid

Action:

Check the resistance of the wax solenoid, also look for corrosion on the terminals

(greenie deposit) resistance range will be between 0.7kW and 2.5kW. Values are

dependant on ambient temp and when the valve was last actuated. Anything

outside of these values should be automatically replaced.

53. (00110011) Phase 2 to 6 - Rotor Position Sensor Step Fail

The motor controller has attempted a motor step test and has found that the motor

has not stepped in the correct direction. It has detected that the motor is connected

and that the motor drive is operational. The rotor position sensing system is at fault

here.

Primary Source: Wiring.

Action:

Check the Rotor Position Harness for continuity and that the connectors are

correctly to the Rotor Position Sensor and the Motor Controller.

Secondary Source: Rotor Position Sensor

Action:

Check the Rotor Position Sensor patterns with a RPS Tester, if faulty fit a

new Rotor Position Sensor.

Tertiary Source: Motor Controller module.

Action:

Replace the Motor Controller module as the sensing circuitry may be faulty.

Page 34

517766 March 2003

- 34 -

54. (00110110) Phase 2 to 6 - Motor/Motor Controller module Step Fail

The Motor Controller module has attempted a motor step test and has found that

the motor has not stepped in the correct position. The Motor Controller module has

detected that there is no current. This indicates that either the motor is not

connected or the Motor Controller module motor drive is faulty.

Primary Source: Wiring.

Action:

Check the continuity of the motor harness and that the connectors are correctly

applied to the motor and Motor Controller module.

Secondary Source: Motor.

Action:

Check continuity of motor phases. Check the bridge terminal on the stator is not

open circuit or burnt. Replace the stator.

Tertiary Source: Motor Controller module.

Action:

Replace Motor Controller module.

55. (00110111) Phase 3 to 6 – System Step Fail

Primary Source: Rotor Position Sensor

Action:

1. Check Motor and Rotor Position Sensor wiring

2. Check Rotor Position Sensor with RPS Tester

56. (00111000) Phase 4 to 6 – Basket Check No Valid Fault

While carrying out a basket check, the machine has not been able to determine a

valid tub status and so the Display flags this fault. This fault differs from fault 40 in

that a valid tub status could not be determined. The first two areas to check are the

clutch and pressure tube. If these two appear correct, then the fault could be with

the pressure transducer in the motor controller.

Primary Source: Mechanical.

Action:

1) Check that there are no clothes or other foreign objects preventing the clutch

from re-engaging.

2) Next check that the pressure tube has not come off and that it is not kinked.

Secondary Source: Motor Controller module. (Phase 4) Rotor Position

Sensor (Phase 5 and 6)

Action:

Replace the Motor Controller module. (Phase 4) Rotor Position Sensor (Phase 5

and 6)

Page 35

517766 March 2003

- 35 -

57. (00111001) Phase 4 to 6 - Brown Out During Display EEPROM Write Fault

The Display has requested the Motor Controller module to perform an EEPROM

write. Prior to writing, the Motor Controller has tested the 15 Volt supply and found

that it is below the safety level for writing EEPROM and has reported this to the

Display. This may be due to transients at the time of writing or due to a faulty Motor

Controller module.

Primary Source: Motor Controller module.

Action:

Replace Motor Controller module.

58. (00111010) Phase 4 to 5 - Pressure Transducer at Maximum Adjustment

Fault

When the pause or delay start is pressed to start the machine, the Display has

checked the memory and found the count greater than expected.

Primary Source: Motor Controller module.

Action:

Replace Motor Controller module.

59. (00111011) Phase 4 to 5 - I D Out of Range Fault

When the pause or delay start is pressed to start the machine, the Display checked

the physical ID and found it was out of range.

Primary Source: Display module.

Action:

Replace Display module.

60. (00111100) Phase 4 to 6 - Motor Control Memory Check Fault

On power up, the Motor Controller module has checked its memory against a

known reference and found differences.

Primary Source: Motor Controller module.

Action:

Replace Motor Controller module.

61. (00111101) Phase 4 - Brown Out During Motor Controller EEPROM Write

Fault

The Motor Controller module has been attempting to perform an internal EEPROM

write. Prior to writing, the Motor Controller has tested the 15 volt supply and found

that it is below the safety level for writing EEPROM and has reported this to the

display.

Primary Source: Motor Controller module.

Action:

Replace Motor Controller module.

62. (00111110) Phase 5 - Pump Over Current

The Motor Controller module has detected an excessive pump current.

Primary Source: Pump.

Action:

Replace Pump.

Secondary Source: Motor Controller module.

Action:

Replace Motor Controller module.

Page 36

517766 March 2003

- 36 -

63. (00111111) Phase 5 - Pump Comms Error

The Motor Controller module has detected an internal communications problem

between its main control system and the pump control system.

Primary Source: Motor Controller module.

Action:

Replace Motor Controller module.

64. (01000000) Phase 5 and 6 - Pressure Transducer (Ptx) error frequency < 66

kHz

The Motor Controller module has received signals from the water level sensor (Ptx)

below normal frequency values.

Primary Source: Motor controller module.

Action: Replace Motor Controller module.

65. (01000001) Phase 5 and 6 - Pressure Transducer (Ptx) error frequency > 90

kHz

The Motor Controller module has received signals from the water level sensor (Ptx)

above normal frequency values.

Primary Source: Motor Controller module.

Action:

Replace Motor Controller module.

66. (01000001) Pressure Transducer Error [Ptx Frequency > 90 kHz]

Note: this supersedes Fault code 65 from V41 Motor controller code onwards.

The Motor Control module has received signals from the water level sensor (Ptx)

above normal frequency values.

Primary Source: Motor Control module

Action: Replace Motor Control module

81. - 95. (0101xxxx) Phase 2 to 3 – Display/ Motor Controller. See fault code 106

104. (01101000) Phase 2 to 6 See fault code 106

105. (01101001) Phase 2 to 6 Comms Error Time out

These faults are reported when the Display module detects an error in the

communications between the Display module and the Motor Controller.

Note: If the product is an IW the wrong Motor Controller may have been fitted.

Replace with a compatible part.

Primary Source: Display Module

Action: Replace Display Module

Secondary Source: Motor Controller

Action: Replace Motor Controller

Tertiary Source: Rotor Position Sensor (Phase 5 and 6)

Action: Replace Rotor Position Sensor, if this corrects the fault refit the

original Display or Motor Controller.

106. (01101010) Phase 2 to 3 - Display to Motor Controller module

Communications Errors (Phase 6 IW also)

These faults are reported when the Display module detects an error in the

communications between the Display module and the Motor Controller module.

Primary Source: Display module.

Page 37

517766 March 2003

- 37 -

Action:

Replace Display module.

Secondary Source: Motor Controller module.

Action:

Replace Motor Controller module. If the new Motor Controller module corrects the

fault, refit the original Display module.

107. (01101011) Phase 2 to 6 - Motor Controller module Reset Error

The Display Module has detected that the Motor Controller module has reset when

it should not have. This can be due to a Motor Controller module supply

disturbance or microprocessor failure.

Primary source: Motor Controller module.

Action: Replace Motor Controller module.

108. (01101100) Coms CRC error Phase 6 IW Display only See fault code 106

127. (01111111) Phase 5 – Machine Set up Error

The display module has been fitted to the wrong model, size and or phase

machine! eg. Phase 5 Display cannot be fitted to a Phase 4 Motor Controller! The

colour of the modules is a good indicator, part numbers are also very important.

130. (10000010) Phase 1 to 6 Single Rotor Position Sensor Error

The Motor Controller has found an error in the pattern received from the Rotor

Position Sensor. Likely causes of this fault are a bad connection on the harness

between the Rotor Position Sensor and the Motor Controller, or a faulty Rotor

Position Sensor.

Primary Source: Wiring.

Action:

1) Check for corrosion on the edge connector of the Rotor Position Sensor and

the Motor Controller module connector.

2) Check the contacts on the rotor positional sensor end of the hall harness to

see if any have been damaged. (Each set of contacts in the socket has two

wipers. If the distance between these wipers varies between different

contacts, replace the rotor positional sensor harness).

Secondary Source: Rotor Position Sensor.

Action:

Check the Rotor Position Sensor with an R.P.S. tester. Replace if faulty.

Tertiary Source: Motor Controller module.

Action:

Replace Motor Controller module.

131. (10000011) Phase 1 to 6 - Repetitive Rotor Position Sensor Error

This fault is similar to fault number 130 above but differs slightly in that it is a

continuous condition. See fault code 130 for service procedure.

132. (10000100) Phase 1 to 4 - Single Current Trip

The Motor Controller has detected excess current in the motor or electronic

switches. This fault has occurred momentarily.

Primary Source: Wiring.

Action: Check the wiring connections from the Motor Controller to the Stator

and the Rotor Position Sensor.

Page 38

517766 March 2003

- 38 -

Secondary Source: Motor.

Action

1) Measure/check the motor harness, connectors and motor for shorts. This

can be done by taking a resistance measurement between phases of the

motor harness at the Motor Control module end. Nominal resistance should

be around 12.2 ohm for Phase 2, 3 & Phase 4. For Phase 5 and 6 Smart

Drive the nominal resistance should be around 32 ohms.

2) Check the Rotor Positional Sensor, Stator brass bridge terminal point and

associated harness for water, mechanical damage or corrosion.

Tertiary Source: Motor Controller module.

Action

If all the above show no signs of fault then replace the Motor Controller module.

Also check for water leaks from the cooling chamber or valves that could possibly

come in contact with the Motor Controller and fix the leak before replacing with new

Motor Controller module.

133. (10000101) Phase 1 to 4 - Repetitive Current Trip

The Motor Controller has detected excess current in the motor or electronic

switches. This fault is a more severe occurrence than Fault Number 132 but has

identical fault sources and fault service procedure.

134. (10000110) Phase 4 - Single Current Trip & Rotor Position Error

The Motor Controller module has detected an excessive motor current and a Rotor

Position Sensor error simultaneously. See fault codes 130 and 132 for service

procedure.

136. (10001000) Phase 1 to 6 - Motor Stall

The Motor Controller has been unable to start the motor. Possible causes of this

fault are: Faulty motor harness, faulty or jammed motor, seized bearings or seals,

faulty Motor Controller module, faulty Rotor Position Sensor or harness.

Primary Source: Wiring.

Action:

Measure / check the motor harness, connectors and motor for discontinuity. This

can be done by taking a resistance measurement between phases of the motor

harness at the Motor Controller module end. Nominal resistance should be around

12.2 ohm for Phase 2,3 & Phase 4. For Phase 5 and 6 onwards the nominal

resistance should be around 32 ohms.

Secondary Source: Motor.

Action:

1) Check free rotation of the agitator and basket by rotating by hand. Bearings

and seals may be seized.

2) Check the Rotor Position Sensor and associated harness for water,

mechanical damage or corrosion.

Tertiary Source: Motor Controller module.

Action:

If the primary and secondary checks pass inspection then replace the Motor

Controller module.

144. (10010000) Phase 1 – Motor Controller Software Trap

The Motor Controller has developed a fault.

Page 39

517766 March 2003

- 39 -

Primary Source: – Motor Controller

Action:

1. Power off for 5 seconds and try again.

2. Check connections between the Display Module and the Motor

Controller

3. Replace Motor Controller

160. (10100000) Phase 1 to 6 – Basket Engaged

The basket has re-engaged itself during agitate. Possible causes for this are a leak

in the air bell, the basket is over-loaded with clothes, the clutch has jammed or is

fouled with a foreign object.

Primary Source: Mechanical.

Action:

1) Check that the rotating basket assembly is not jammed to the agitator with

any foreign object that may be caught under the agitator skirt.

2) Check that the clutch teeth are not locked together with dirt, lint, etc.

3) Make sure the basket is not overloaded with too many clothes.

4) If none of the above appear to be at fault, then check the air bell at the

bottom of the basket for leaks.

Secondary Source: Motor Controller module. (Phase 1 to 4 only)

Action:

If the machine is empty of water at fault it is possible that the pump circuit is faulty

and has caused a pump out during wash. This would cause the basket to reengage during agitate and the Motor Controller module to display this fault.

Replace Motor Controller module.

161. (10100001) Phase 2 to 6 - Hardware / EEPROM Supply Mismatch