Fisher & Paykel OS302US, OD302MNZ, OS302MNZ, OD302EU, OS302EU Service Manual

...

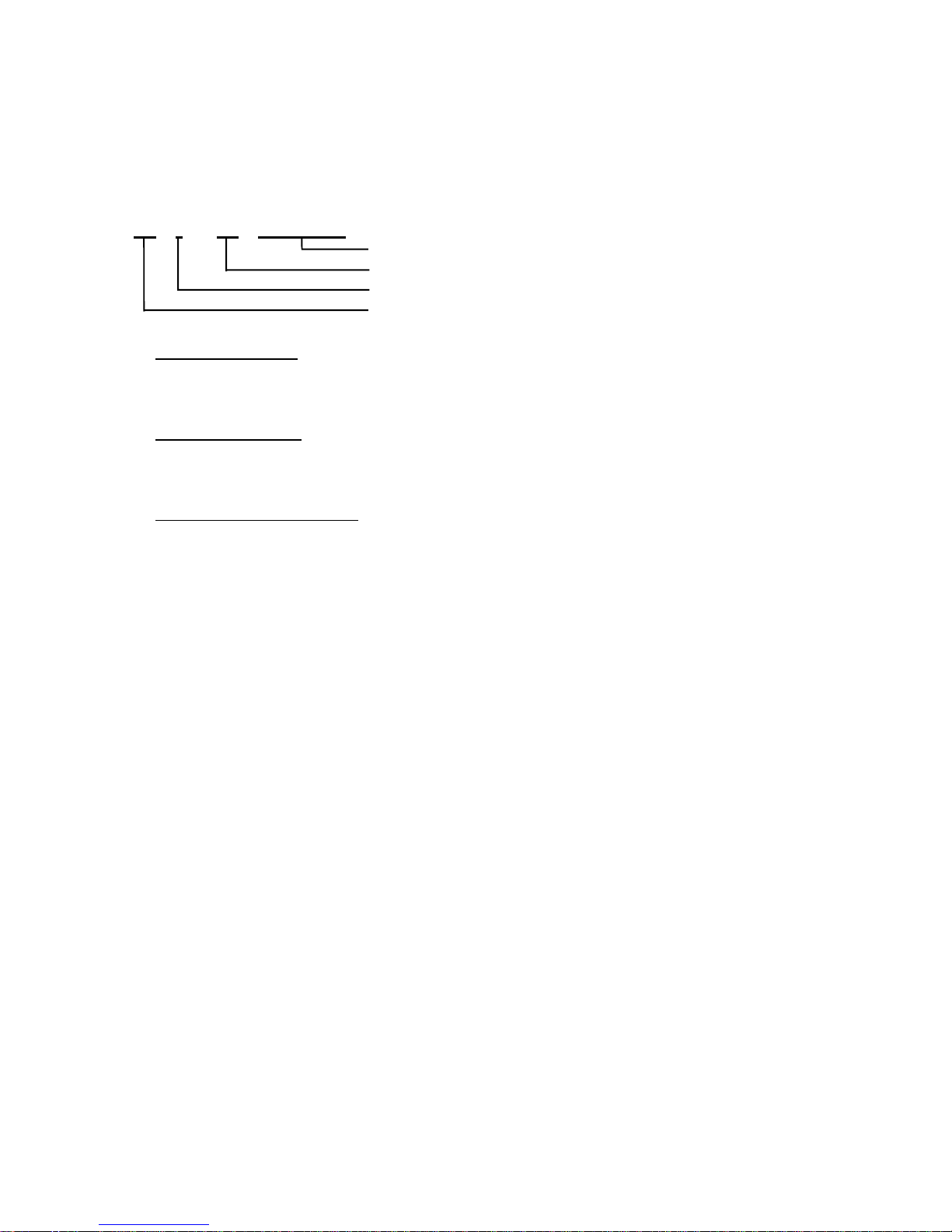

Model OD302 Model OS302

MODELS

OD302US OS302US

OD302MUS OS302MUS

OD302MNZ OS302MNZ

OD302EU OS302EU

546596A

Service Manual 546596A: 302 Series Titan Oven June 2005

Fisher & Paykel Appliances Ltd

78 Springs Road, East Tamaki, PO Box 58-732,

Greenmount,

Auckland, New Zealand

Ph: 09 273 0600, Fax: 09 273 0656

Fisher & Paykel Appliances Inc

5800 Skylab Road, Huntington Beach, California,

CA92647, USA

Ph: 888 936 7872 (F&P), Ph: 888 396 2665 (DCS)

Fisher & Paykel Customer Services Pty Ltd

A.C.N. 003 3335 171, 19 Enterprise Street, Cleveland,

QLD 4163

PO Box 798, Cleveland, QLD 4163

Ph: 07 3826 9100, Fax: 07 3826 9164

Fisher & Paykel Appliances Ltd UK

Pheasant Oak Barn, Hob Lane, Balsall Common,

Warwickshire, CV7 7GX, UK

Ph: 44 1676 531 770, Fax: 44 1676 531 771

Copyright Fisher & Paykel Ltd 2005. All Rights Reserved.

3

Manual 546596A – June 2005 Reprint: June 2005

The specifications and servicing procedures outlined in this manual are subject to change

without notice.

The latest version is indicated by the reprint date and letter and replaces any earlier editions.

Service Manual 546596A: 302 Series Titan Oven June 2005

4

Contents

1. SERVICING REQUIREMENTS......................................................................................................................................7

1.1 H

EALTH & SAFETY...........................................................................................................................................................7

1.1.1 Electrical Safety .....................................................................................................................................................7

1.1.2 Electrostatic Discharge..........................................................................................................................................7

1.1.3 Good Working Practices ........................................................................................................................................7

1.1.4 Insulation Test........................................................................................................................................................7

1.1.5 Sheet Metal Edges ..................................................................................................................................................7

1.2 S

PECIALISED TOOLS ......................................................................................................................................................... 8

1.2.1 Static Strap.............................................................................................................................................................8

1.2.2 Fisher & Paykel Smart Tool...................................................................................................................................8

2. TECHNICAL OVERVIEW...............................................................................................................................................9

2.1 O

VEN WEIGHTS ................................................................................................................................................................9

2.2 P

OWER RATING.................................................................................................................................................................9

2.3 O

VEN CAVITY DIMENSIONS..............................................................................................................................................9

2.4 L

OCATION OF SERIAL PLATE ............................................................................................................................................9

2.5 M

ODEL NUMBER ..............................................................................................................................................................9

2.6 S

ERIAL NUMBER .............................................................................................................................................................10

2.7 O

VEN CAVITY FAN (CONVECTION FAN) .........................................................................................................................11

2.8 C

OOLING FAN .................................................................................................................................................................11

2.9 A

CTIVE VENT FAN (EXHAUST FAN) ...............................................................................................................................12

2.10 O

UTER BROIL / GRILL ELEMENT.....................................................................................................................................12

2.11 I

NNER BROIL / GRILL ELEMENT......................................................................................................................................13

2.12 B

AKE ELEMENT ..............................................................................................................................................................13

2.13 F

AN ELEMENT.................................................................................................................................................................13

2.14 S

MOKE ELIMINATOR ELEMENT (CATALYTIC CONVERTER).............................................................................................14

2.15 T

HROAT ELEMENT ..........................................................................................................................................................14

2.16 T

EMPERATURE SENSOR...................................................................................................................................................14

2.17 H

ALOGEN BULBS ............................................................................................................................................................14

2.18 M

EAT PROBE & SOCKET................................................................................................................................................. 15

2.19 D

OOR LOCK MOTOR .......................................................................................................................................................15

2.20 T

EMPERATURE SWITCH MODULE....................................................................................................................................15

2.21 T

EMPERATURE L.C.D MODULE ......................................................................................................................................15

2.22 F

UNCTION SWITCH MODULE...........................................................................................................................................15

2.23 F

UNCTION L.C.D MODULE .............................................................................................................................................15

2.24 C

LOCK MODULE .............................................................................................................................................................16

2.25 P

OWER MODULE .............................................................................................................................................................16

2.26 P

OWER TRANSFORMER ...................................................................................................................................................16

2.27 C

OOLING FAN RESISTOR.................................................................................................................................................17

2.28 T

HERMAL LIMITERS........................................................................................................................................................ 17

2.29 I

SOLATING RELAY .......................................................................................................................................................... 19

2.30 XY-C

APACITOR ..............................................................................................................................................................19

2.31 M

ICRO SWITCHES ...........................................................................................................................................................19

2.32 S

ELF-CLEAN PYROLYTIC CYCLE.....................................................................................................................................20

2.33 O

VEN MODE ELEMENT AND FAN PROFILES ....................................................................................................................21

3. USE & CARE OF THE OVEN........................................................................................................................................22

3.1 S

ETTING THE CLOCK.......................................................................................................................................................22

3.2 O

VEN MODE DIAL AND DISPLAY....................................................................................................................................22

3.3 T

EMPERATURE DIAL AND DISPLAY ................................................................................................................................22

3.4 O

VEN MODES .................................................................................................................................................................22

3.5 A

CTIVE VENT AND COOLING FANS.................................................................................................................................23

3.6 M

INUTE TIMER ...............................................................................................................................................................24

3.7 S

ET AUTOMATIC / DELAYED TIME COOKING .................................................................................................................24

3.8 S

ET AUTOMATIC STOP COOKING....................................................................................................................................25

3.9 U

SER SELECT MODES .....................................................................................................................................................25

3.10 S

ABBATH MODE .............................................................................................................................................................25

3.11 T

EMPERATURE SCALE..................................................................................................................................................... 26

Service Manual 546596A: 302 Series Titan Oven June 2005

5

3.12 SHORT ALERT .................................................................................................................................................................26

3.13 T

IME MODE ....................................................................................................................................................................26

3.14 S

HOW CLOCK.................................................................................................................................................................. 26

3.15 L

ANGUAGE .....................................................................................................................................................................27

3.16 O

VEN RESET ...................................................................................................................................................................27

4. DIAGNOSTICS ................................................................................................................................................................28

4.1 E

NTERING THE SALES MODE & TECHNICIAN MODE.......................................................................................................28

4.2 E

XITING THE TECHNICIAN MODE....................................................................................................................................28

4.3 T

ECHNICIAN MODE NAVIGATION ...................................................................................................................................28

4.4 A

CCESSING TECHNICAL DATA LOG ................................................................................................................................30

4.5 T

ECHNICAL DATA LOG ...................................................................................................................................................30

5. FAULT DIAGNOSTICS.................................................................................................................................................. 31

5.1 SYMPTOM: O

VEN ELECTRICAL COMPONENTS ARE UNRESPONSIVE ..............................................................................31

5.2 SYMPTOM: C

ONTROL BUTTONS OR CLOCK DISPLAY NOT OPERATING CORRECTLY OR UNRESPONSIVE.......................32

5.3 SYMPTOM: T

EMPERATURE OR OVEN MODE SWITCH MODULE IS JAMMED OR LOOSE .................................................32

5.4 SYMPTOM: I

NCORRECT TEMPERATURE OR OVEN MODE DISPLAY AT CORRECT SWITCH POSITION ..............................32

5.5 SYMPTOM: F

AULTY TEMPERATURE OR OVEN MODE L.C.D. MODULES .....................................................................33

5.6 SYMPTOM: “DOORLOCK”

AND “PROBE” SHOWING FOR LOWER CAVITY (DOUBLE OVEN ONLY) ............................33

5.7 SYMPTOM: O

VEN UNDER COOKING ............................................................................................................................34

5.8 SYMPTOM: B

AKING BURNS ON THE TOP ......................................................................................................................34

5.9 SYMPTOM: B

AKING BURNS ON THE BOTTOM ...............................................................................................................35

5.10 SYMPTOM: O

VEN SEEMS TO BE FUNCTIONING NORMALLY BUT DOES NOT HEAT..........................................................35

5.11 SYMPTOM: O

VEN HEATS SLOWLY OR FAILS TO REACH PRESET TEMPERATURE ............................................................36

5.12 SYMPTOM: O

VEN LIGHTS DO NOT TURN ON / OFF.......................................................................................................36

5.13 SYMPTOM: F

AULT CODE F1 DISPLAYED IN TECH SELECT ONLY .................................................................................37

5.14 SYMPTOM: F

AULT CODE F2 DISPLAYED......................................................................................................................37

5.15 SYMPTOM: F

AULT CODE F3 DISPLAYED......................................................................................................................37

5.16 SYMPTOM: F

AULT CODE F4 DISPLAYED......................................................................................................................37

5.17 SYMPTOM: F

AULT CODE F5 DISPLAYED......................................................................................................................38

5.18 SYMPTOM: F

AULT CODE F7 DISPLAYED......................................................................................................................38

5.19 T

RACING COOLING FAN FAULTS.....................................................................................................................................38

5.20 T

RACING OVEN CAVITY FAN FAULTS...............................................................................................................................39

5.21 T

RACING OVEN LIGHT FAULTS ........................................................................................................................................39

5.22 T

RACING ELEMENT FAULTS.............................................................................................................................................40

5.23 T

RACING OVEN TEMPERATURE SENSOR FAULTS..............................................................................................................41

5.24 T

RACING THERMAL LIMITER FAULTS .............................................................................................................................. 41

5.25 T

RACING OVEN DOOR SWITCH AND DOOR LOCK SWITCH FAULTS ....................................................................................42

5.26 D

ETERMINING WHICH POWER MODULE IS FAULTY IN A DOUBLE OVEN (F4 OR F5 FAULT CODES) ..................................43

6. WIRING DIAGRAMS .....................................................................................................................................................44

6.1 D

OUBLE OVEN USA WIRING SCHEMATIC ......................................................................................................................44

6.2 S

INGLE OVEN USA WIRING SCHEMATIC........................................................................................................................45

6.3 D

OUBLE OVEN NZ / AUS WIRING SCHEMATIC .............................................................................................................46

6.4 S

INGLE OVEN NZ / AUS WIRING SCHEMATIC ...............................................................................................................47

6.5 D

OUBLE OVEN EU WIRING SCHEMATIC.........................................................................................................................48

6.6 S

INGLE OVEN EU WIRING SCHEMATIC ..........................................................................................................................49

7. SERVICE PROCEDURES ..............................................................................................................................................50

7.1 R

EMOVAL FROM JOINERY CAVITY..................................................................................................................................50

7.2 C

OMPONENTS IN CONTROL PANEL AREA .......................................................................................................................50

7.3 C

OMPONENTS IN BACK PANEL AREA..............................................................................................................................51

7.4 C

OMPONENTS IN SERVICE PANEL AREA .........................................................................................................................51

7.5 R

EASSEMBLY PROCEDURE..............................................................................................................................................51

7.6 F

UNCTION AND TEMPERATURE SWITCH MODULES.........................................................................................................52

7.7 F

UNCTION AND TEMPERATURE L.C.D. MODULES AND LENSES .....................................................................................52

7.8 C

LOCK MODULE OR BUTTONS ........................................................................................................................................53

7.9 P

OWER MODULE.............................................................................................................................................................54

7.10 P

OWER TRANSFORMER ...................................................................................................................................................57

7.11 T

HERMAL LIMITER..........................................................................................................................................................57

7.12 O

VEN TEMPERATURE SENSOR ........................................................................................................................................57

7.13 O

VEN LAMP GLASS AND BULB .......................................................................................................................................58

7.14 O

VEN LAMP ASSEMBLY ..................................................................................................................................................58

Service Manual 546596A: 302 Series Titan Oven June 2005

6

7.15 OVEN ELEMENTS ............................................................................................................................................................60

7.16 C

OOLING FAN .................................................................................................................................................................62

7.17 V

ENT FAN .......................................................................................................................................................................62

7.18 O

VEN CAVITY FAN .........................................................................................................................................................63

7.19 F

AN SHROUD...................................................................................................................................................................63

7.20 R

UNNERS ........................................................................................................................................................................64

7.21 O

VEN DOOR....................................................................................................................................................................64

7.22 O

VEN DOOR – DISASSEMBLY .........................................................................................................................................64

7.23 M

EAT PROBE SOCKET.....................................................................................................................................................67

7.24 O

VEN DOOR LOCK ASSEMBLY........................................................................................................................................68

7.25 C

OMPONENT LOCATION GUIDE.......................................................................................................................................69

Service Manual 546596A: 302 Series Titan Oven June 2005

7

1. Servicing Requirements

1.1 Health & Safety

Note: When servicing the Titan Aerotech oven, health and safety issues must be

considered at all times. Specific safety issues are listed below with their appropriate

icon. These are illustrated throughout the service information to remind service people of

the health and safety issues.

1.1.1 Electrical Safety

WARNING! TO AVOID ELECTRIC SHOCK!

Do not attempt to service this oven without suitable training and

qualifications.

Ensure the mains power has been disconnected before servicing any part of the oven. If

the power is required to be on for electrical fault finding, then extreme care should be

taken not to make contact with electrical components other than with testing probes.

Ensure the oven is turned off when removing any electrical component or connection.

1.1.2 Electrostatic Discharge

An anti-static strap is to be used as electrical static discharge (ESD)

protection when servicing electronic components.

1.1.3 Good Working Practices

Ensure the work areas are kept tidy and free of hazards while servicing the

oven. On completion of the servicing, ensure the oven and work areas are

left clean and tidy.

1.1.4 Insulation Test

Megger test to check insulation.

Warning Short together the phase and neutral terminals to avoid damaging

any electronic circuitry.

1.1.5 Sheet Metal Edges

When working around cut sheet metal edges use appropriate gloves or

protection to eliminate the chance of receiving a laceration.

Service Manual 546596A: 302 Series Titan Oven June 2005

8

1.2 Specialised Tools

1.2.1 Static Strap

The static strap is to be used as E.S.D. protection when replacing or handling electronic

components.

1.2.2 Fisher & Paykel Smart Tool

Handheld computer supplied in protective case with F&P diagnostics software and

service information loaded:

P/N 813140 (includes light pen P/N 425930).

Service Manual 546596A: 302 Series Titan Oven June 2005

9

2. Technical Overview

2.1 Oven Weights

OS302 Weight: 190 lbs. (86 Kg)

OD302 Weight: 340 lbs. (154 Kg)

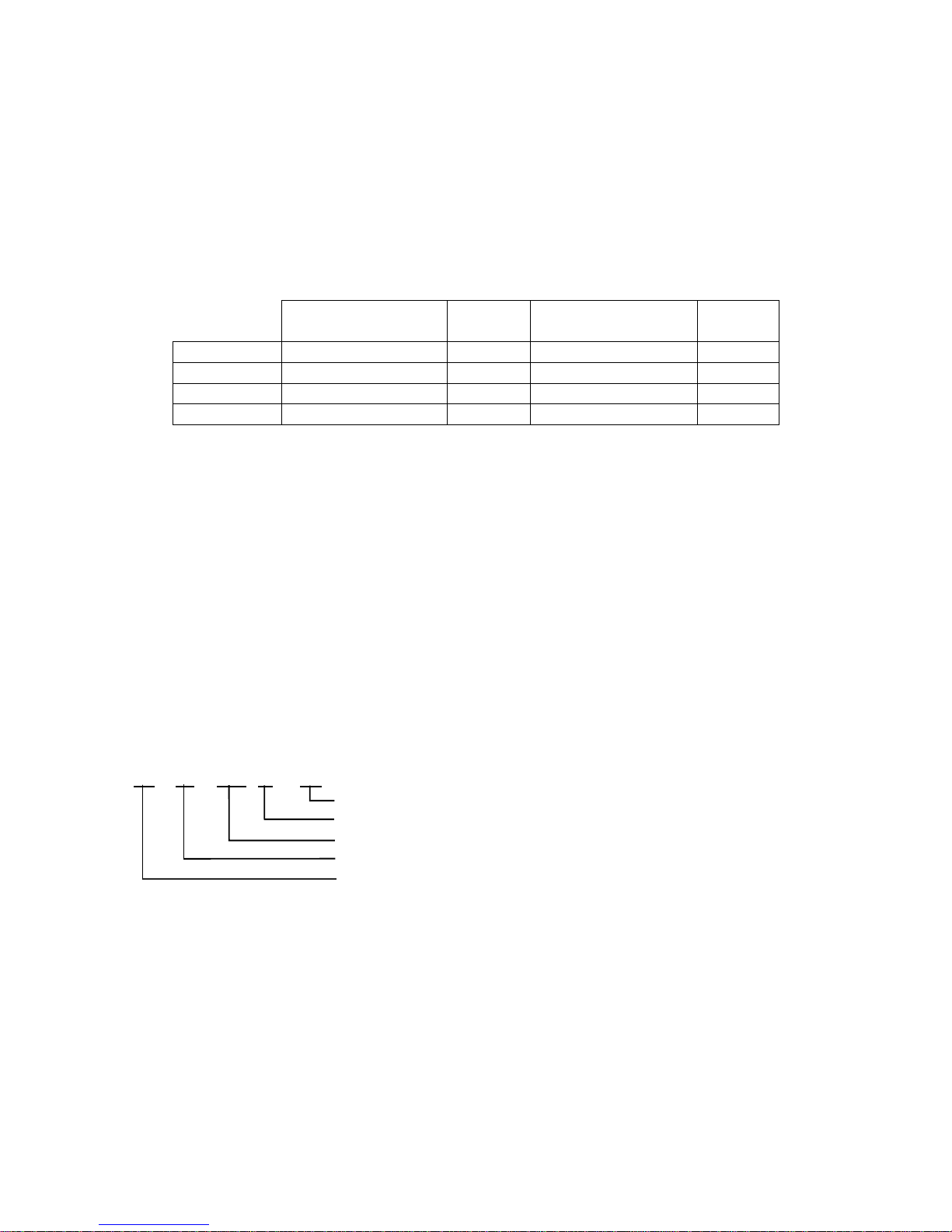

2.2 Power Rating

Single Supply

Voltage

Rating Double Supply

Voltage

Rating

USA / Can

3wire 120/240v 5.1kW 3wire 120/240v 9.2kW

USA / Can

120/208v 3.9kW 120/208v 7kW

NZ / AUS

220/240v 4.7kW 220/240v 8.5kW

EU

220/240V 4.7kW 220/240V 7.6kW

2.3 Oven Cavity Dimensions

Width 24” (610mm)

Height 16” (405mm)

Depth 16” (405mm)

Cavity Volume 3.5 cu ft (0.1 m3)

2.4 Location of Serial Plate

The product serial plate is located on the left-hand side behind the grill, between the

control panel and the oven door (top oven door on dual oven models).

2.5 Model Number

The model number contains the following information:

OD30 2 M

Finish (M = Iridium)

Series

Product Width (inches)

Single or Double Oven

Product Type (Oven)

Service Manual 546596A: 302 Series Titan Oven June 2005

10

2.6 Serial Number

The serial number consists of three letters and six digits and contains the following

information:

Example:

MI M 123456

Sequential Serial Number

Manufacturing Plant Code

FISHERPAYKUL Code indicates month of manufacture

CUMBERLAND Code indicates year of manufacture

Cumberland Code

LetterCUMBERL AND

Year1234567890

Fisherpaykul Code

LetterFI SHERPAYKUL

Month123456789101112

Manufacturing Plant Code

A Laundry – Australia

F Refrigeration – New Zealand

M Range & Dishwasher

N Laundry – New Zealand

Q Refrigeration - Australia

In the example above, the appliance was manufactured in the second month of the third

year (2003) at the Range & Dishwasher plant.

Service Manual 546596A: 302 Series Titan Oven June 2005

11

2.7 Oven Cavity Fan (Convection Fan)

The oven cavity fan will turn on eight seconds after a mode is selected.

The fan should always operate when the fan element is on.

Operational Modes: True Aero

Aero Bake

Aero Pastry

Aero Broil / Grill

Roast (first 20 minutes only)

Warm

Bake (pre-heat assistance only)

Pastry Bake (pre-heat assistance only)

Voltage: 240

VAC

Wattage: 35 watts

Frequency: 60 HZ

2.8 Cooling Fan

The cooling fan will turn on as soon as the oven mode is moved from the ‘OFF ‘

position. It will turn off after eight seconds if a temperature isn’t selected.

The cooling fan will only turn off if the oven cavity has cooled below 300°F (150°C)

after use.

If the oven cavity temperature is above 550°F (290°C) the cooling fan will run at high

speed.

During the Self-Clean Cycle the cooling fan in the cavity being cleaned will run at high

speed, the other cavity will run on low (in a double oven).

NZ/AUS/EU U.S

Voltage: 230/240 VAC 115/120 VAC

Frequency: 50/60 HZ 60 HZ

Wattage: 60 watt 56 watt

Service Manual 546596A: 302 Series Titan Oven June 2005

12

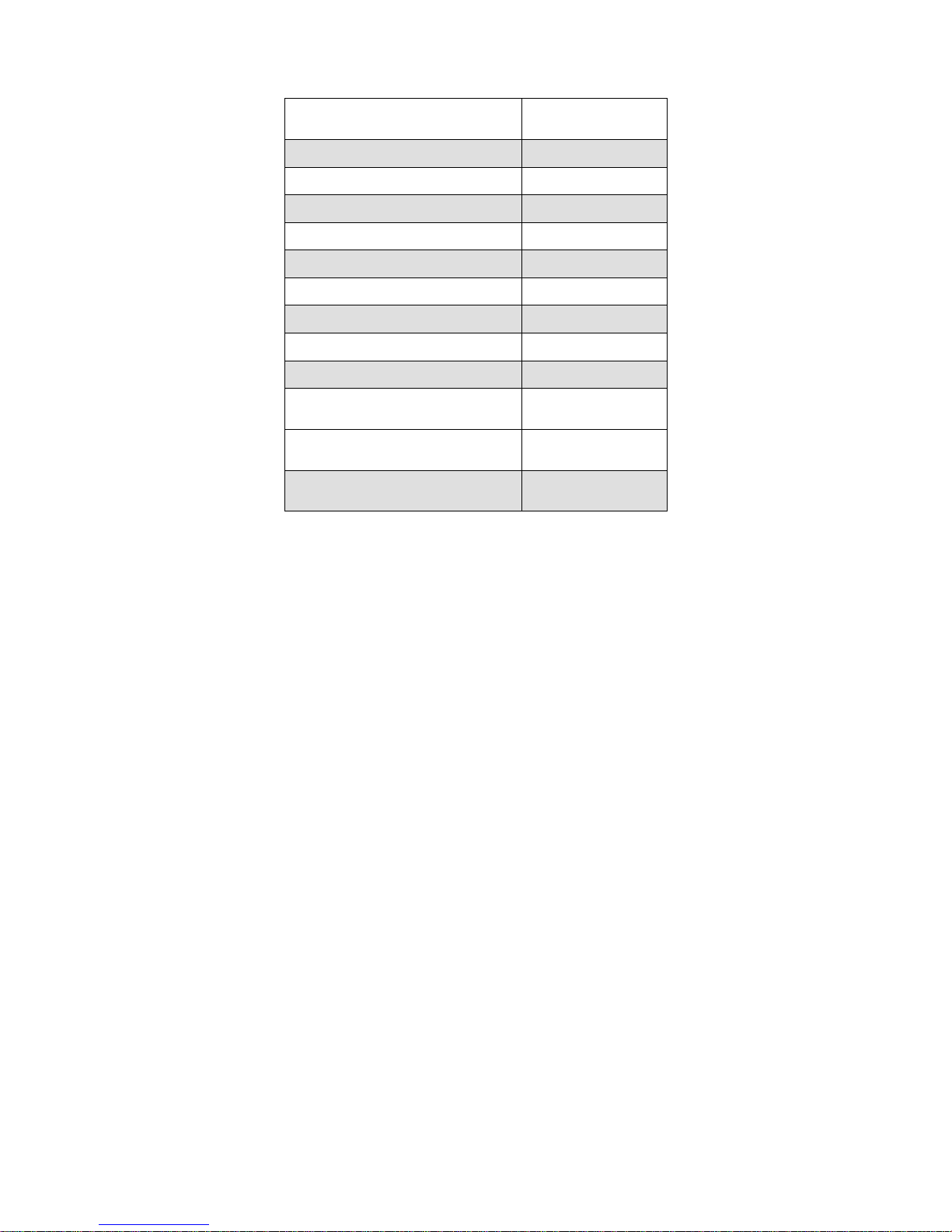

Cooling Fan Speeds*

Oven Mode

Cooling Fan

Speed

Bake

Low

Low

Aero Bake

Low

Low

Warm

Low

Low

True Aero

Low

Low

Maxi Broil / Grill

Hi

Low

Broil / Grill

Hi

Low

Aero Broil / Grill

Hi

Low

Pastry Bake

Low

Low

Aero Pastry

Low

Low

Roast

(Aero Broil / Grill 1

st

20 min)

Hi

Low

Roast

(Bake for remainder)

Low

Low

Self-Clean Cycle

Hi

Low

*The top speed refers to single ovens or the

cavity being used in a double oven.

2.9 Active Vent Fan (Exhaust Fan)

The vent fan will operate for the first thirteen minutes of all oven modes except Warm

(does not operate) and Self-Clean Cycle, Broil / Grill modes (runs continuously).

Voltage: 230/240 VAC

Frequency: 50/60 HZ

Wattage: 18 watt

2.10 Outer Broil / Grill Element

The outer broil / grill element will turn on eight seconds after a mode is selected.

Operational Modes: Bake

Aero Bake

Warm

Maxi Broil / Grill

Aero Broil / Grill

Roast

Self-Clean

Voltage: 230/240 VAC

Wattage: 1500 watt

Service Manual 546596A: 302 Series Titan Oven June 2005

13

2.11 Inner Broil / Grill Element

The inner broil / grill element will turn on eight seconds after a mode is selected.

Operational Modes: Broil / Grill

Maxi Broil / Grill

Aero Broil / Grill

Roast (first 20 minutes only)

Self-Clean

Voltage: 230/240

VAC

Wattage: 2900 watt

2.12 Bake Element

The bake element is concealed under the cavity base and will turn on eight seconds after

a mode is selected.

Operational Modes: True Aero (pre-heat assistance only)

Bake

Aero Bake

Warm

Pastry Bake

Aero Pastry

Roast

Self-Clean

Voltage: 230/240

VAC

Wattage: 1500 watt

2.13 Fan Element

The fan element and oven fan will turn on eight seconds after a mode is selected.

Operational Modes: True Aero

Bake (pre-heat assistance only)

Aero Bake

Aero Pastry (pre-heat assistance only)

Pastry Bake (pre-heat assistance only)

Voltage: 230/240 VAC

Wattage: 2500 watt

Service Manual 546596A: 302 Series Titan Oven June 2005

14

2.14 Smoke Eliminator Element (Catalytic Converter)

(This is a non-serviceable part)

The smoke eliminator element is designed to neutralise gases produced during cooking.

Operational Modes: Broil / Grill

Aero Broil / Grill

Maxi Broil / Grill

Self clean

Bake

Aero Bake

Pastry Bake

Aero Pastry

Roast

True Aero

Voltage: 230/240 VAC

Wattage: 150 watt

2.15 Throat Element

(This is a non-serviceable part)

The throat element is designed to ensure all parts near the front of the oven cavity reach

the required temperatures during the Self-Clean Cycle.

Operational Modes: Self-Clean

Voltage: 230/240 VAC

Wattage: 540 watt

2.16 Temperature Sensor

Voltage: 5 VDC

Max current: 2 mA

Max ambient temp: 1000°F (540°C)

Resistance: 1080.2 ohms +/– 5.2 ohms at 70°F (21.11°C)

2.17 Halogen Bulbs

The oven cavity lights will come on when the door is opened or when an oven mode

is selected.

The lights will turn off when the door is closed (if no oven mode is selected) or if the

programmed oven cook time has finished.

There are three soft start halogen bulbs in each oven cavity.

Voltage: 12 VAC

Wattage: 20 watt

Service Manual 546596A: 302 Series Titan Oven June 2005

15

2.18 Meat Probe & Socket

Voltage: 5 VDC

Figure 2.18

2.19 Door Lock Motor

The door lock will only operate during the Self-Clean Cycle and is designed to stop the

oven door being opened when very high temperatures and potentially dangerous fumes

are produced in the oven cavity.

Voltage: 12

VDC

Duty cycle: On 2 sec Off 5 sec

Stall current: under 0.5 Amp

2.20 Temperature Switch Module

The temperature switch module controls the

temperature settings of the oven. It has a data link

to the clock module.

Current Draw: 72 mA

Figure 2.20

2.21 Temperature L.C.D Module

The temperature LCD module is controlled by the

clock module. It displays the temperature set by the

temperature switch module.

Current Draw: 72 mA

Figure 2.21

2.22 Function Switch Module

The function switch module sets the oven mode to

be used. It has a data link to the clock module.

Current Draw: 72 mA

Figure 2.22

2.23 Function L.C.D Module

The function LCD module is controlled by the clock

module. It displays the oven mode selected by the

function switch module.

Current Draw: 72 mA

Figure 2.23

Service Manual 546596A: 302 Series Titan Oven June 2005

16

2.24 Clock Module

The clock module contains a flash micro-controller that

controls all oven electrical components. Data can be

accessed from the micro-controller using the Fisher &

Paykel Smart Tool light pen or comms. connection.

Current Draw: 200 mA

Figure 2.24

2.25 Power Module

Figure 2.25

The power module is a Fisher & Paykel specific P.C.B. that drives oven lights, fans,

elements and lock motors. It also monitors the sensors and micro-switches and provides

power to the control panel.

Voltage: 12 VAC

2.26 Power Transformer

USA 12v/120v 60hz

NZ/AUS/EU 12v/240v 50hz

Service Manual 546596A: 302 Series Titan Oven June 2005

17

2.27 Cooling Fan Resistor

Power Rating: 50 watt

Resistance: 220 Ohms

Max Ambient Temp: 85°C (185°F)

2.28 Thermal Limiters

If a thermal limiter has tripped there will be no continuity across the contacts.

Limiter Locations for US/NZ/AUS Products

TL1

TL2

MTL

Figure 2.28a

Note: TL = Thermal Limiter

MTL = Microtemp limiter

Double ovens have thermal limiters 1,2 & 3

and a microtemp limiter.

Single ovens have thermal limiter 1 and a

microtemp limiter.

TL3

Figure 2.28b

Service Manual 546596A: 302 Series Titan Oven June 2005

18

Limiter Locations for EU Products

TL4

TL1

MTL

Figure 2.28c

Note: TL = Thermal Limiter

MTL = Microtemp thermal limiter

Double ovens have thermal limiters 1, 3, 4

& 5 and a microtemp limiter.

Single ovens have thermal limiters 1 & 4

and a microtemp limiter.

TL3

TL5

Figure 2.28d

MTL (Microtemp Limiter)

This is a non-resettable thermal limiter positioned to detect

electronics area over temperature caused by a cooling fan

failure. It will cut power to the power transformers,

disabling the oven when tripped.

Capacity Rating: 25 Amps at 240

VAC.

Trip Temperatures: 200°F (93°C)

Figure 2.28e

TL 1 & TL 2

These are non-resettable thermal limiters positioned to

detect the upper cooling fan failure on a double oven. They

will cut power to the oven elements when tripped.

Capacity Rating: 25 Amps at 240 VAC.

Trip Temperatures: 175°F (80°C)

Figure 2.28f

TL 3

This is a non-resettable thermal limiter positioned to detect lower cooling fan failure on a double

oven. It will cut power to the oven elements when tripped.

Capacity Rating: 25 Amps at 240 VAC.

Trip Temperatures: 230°F (110°C)

Service Manual 546596A: 302 Series Titan Oven June 2005

19

TL 4 (EU Products Only)

This is a resettable thermal limiter positioned to detect the

upper cooling fan failure on a double oven. It will cut power

to the oven elements when tripped.

Capacity Rating: 16 Amps at 250 VAC.

Trip Temperatures: 175°F (80°C)

Figure 2.28g

TL 5 (EU Products Only)

This is a resettable thermal limiter positioned to detect lower cooling fan failure.

It will cut power to the oven elements when tripped.

Capacity Rating: 16 Amps at 250 VAC.

Trip Temperatures: 230°F (110°C)

2.29 Isolating Relay

(Double Line Break Relay)

This relay switches the elements, cavity fan and vent

fan on the opposite side to the power module relay

switches.

It is only energised when an oven mode is selected.

Coil Voltage: 12 VDC

Coil Input: 1 watt

Figure 2.29

2.30 XY-Capacitor

This capacitor provides surge protection for the oven.

Voltage: 250 VAC

Class: X2Y2

Temp Range: -105 to 210°F (- 40 to 100°C)

2.31 Micro Switches

There are three micro switches in the door lock assembly.

Voltage 12 VDC

Service Manual 546596A: 302 Series Titan Oven June 2005

20

2.32 Self-Clean Pyrolytic Cycle

Duration: 3hrs

Pyro Temp: 925°F (500°C)

Heat-up time: 50 minutes approx.

Holding time: 100 minutes approx.

Cool-down time: 30 minutes

If a Self-Clean Cycle will not start, check that there are no meat probes inserted and that

the control knobs of the cavity not being cleaned (in a double oven) are in the ‘OFF’

position.

The oven self-clean mode operates by heating the oven to a temperature of

approximately 885°F (473°C). This burns off and breaks down soil and grease deposits.

The ash residue that remains can simply be removed from the cool oven with a damp

cloth or sponge. The self-clean cycle normally takes about three hours.

To start a Self-Clean Cycle

1. Turn the oven mode dial until ‘Self Clean’ appears in the display.

2. Select the maximum temperature using the temperature dial.

‘000’ will appear in the temperature display. This will change to when the

cycle begins.

‘Door Lock’ and ‘Clean’ will show in the clock display.

The door lock will automatically activate once the Self-Clean mode and maximum

temperature have been selected.

A countdown of minutes remaining will be shown in the clock display.

The Broil / Grill inner element, the throat element, the smoke eliminator element and the

vent fan operate during the Self-Clean Cycle. Additionally, during the first fifteen seconds

of each minute the bake element is on and during the third fifteen seconds of each

minute the Broil / Grill outer element is on.

The cooling fan for the cavity being cleaned will be on high speed. The cooling fan for

the other cavity will be on low speed.

During the Self-Clean Cycle in a double oven, the cavity not being cleaned cannot be

operated in any mode.

The oven heats to its cleaning temperature of 885°F (473°C) and maintains this

temperature until approximately 2½ hours into the cycle.

The elements then turn off and the cool down period commences. When the

temperature reduces to 356°F (180°C) the door will unlock and the ‘Door Lock’ display

will disappear from the clock display.

When the self-clean cycle has finished, ‘Clean’ and ‘00:00’ will flash in the clock display

until it is returned to manual operation. Press the PUSH TO CLEAR button and turn the

oven mode and temperature dials to the OFF position to do this.

At the completion of the self-clean cycle, there may be grey ash deposited on the inside

of the oven. The amount of ash is dependent on the amount of soil in the oven before

cleaning. To remove the ash, wait until the oven has completely cooled. The bulk of the

ash is easily removed with a small brush or dry cloth, then wiped over with a damp cloth.

The self-clean mode can be cancelled at any time by turning the oven dials to ‘OFF’.

‘Clean End’ will appear in the oven mode display but if the oven temperature has already

reached 482°F (250°C) the door lock will remain activated until the oven cools to 356°F

(180°C).

Service Manual 546596A: 302 Series Titan Oven June 2005

21

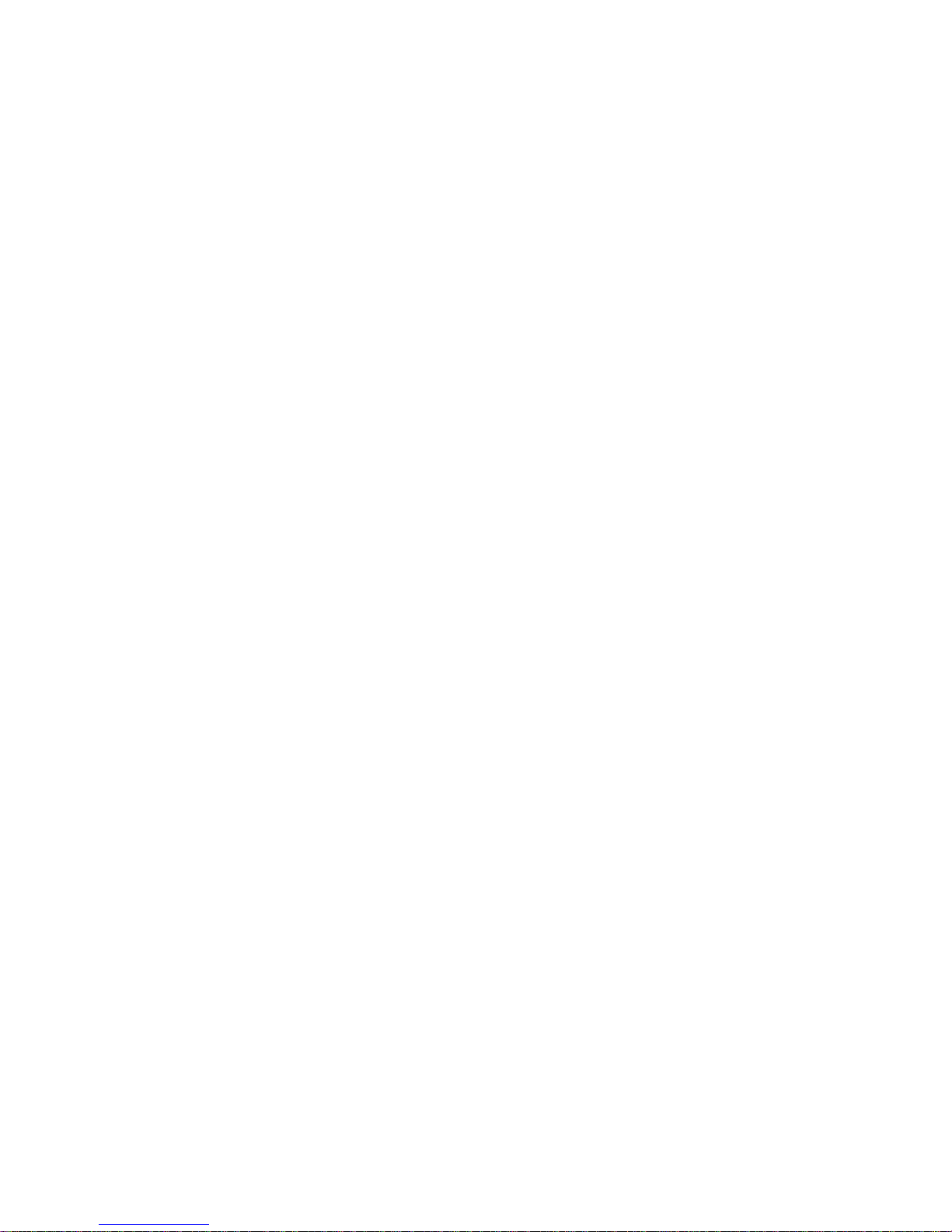

2.33 Oven Mode Element and Fan Profiles

If the oven door is opened during use the oven fan and elements will turn off until it is

closed again.

Oven

Mode

Name

Oven

Fan

Cool

Fan

Speed

Vent

Fan

Broil/Grill

Outer

Element

Broil/Grill

Inner

Element

Bake

Element

Fan

Element

Throat

Element

Smoke

Elim.

Bake

(on for

pre-heat

only)

Low

Low

(on for first

13 mins)

ON ON

(on for pre-

heat only)

ON

Aero

Bake

ON

Low

Low

(on for first

13 mins)

ON ON ON ON

Warm ON

Low

Low

ON ON

True

Aero

ON

Low

Low

(on for first

13 mins)

(on for pre-

heat only)

ON ON

Maxi

Broil/Grill

OFF

Hi

Low

ON ON ON ON

Broil/Grill OFF

Hi

Low

ON ON ON

Aero

Broil/Grill

ON

Hi

Low

ON ON ON ON

Pastry

Bake

(on for

pre-heat

only)

Low

Low

(on for first

13 mins)

ON

(on for pre-

heat only)

ON

Aero

Pastry

ON

Low

Low

(on for first

13 mins)

ON

(on for pre-

heat only)

ON

Roast

(Aero

Broil/Grill 1

st

20Min)

ON

Hi

Low

(on for first

13 mins)

ON

(on for first

20 mins)

ON

Roast

(Bake for

remainder)

OFF

Low

Low

(on for first

13 mins)

ON ON ON

Heating Profile for Self-Clean Pyrolitic Cycle

Self Clean

(0-15sec)

OFF

Hi

Low

ON ON ON ON ON

(15-30sec)

OFF

Hi

Low

ON ON ON ON

(30-45sec)

OFF

Hi

Low

ON ON ON ON ON

(45-60sec)

OFF

Hi

Low

ON ON ON ON

Service Manual 546596A: 302 Series Titan Oven June 2005

22

3. Use & Care of the oven

3.1 Setting the Clock

The clock has a default 12 hour display and a minute timer function. ‘AM 12:00’ will show

and the colon will flash when the oven has been turned on at the wall. While the colon is

flashing, rotate the PUSH TO CLEAR knob until the correct time of day is displayed.

Press CLOCK or wait 8 seconds until the colon stops flashing to adopt the time that has

been set.

3.2 Oven Mode Dial and Display

This is turned to select the desired oven mode. When the mode is set the lights and

cooling fan will come on.

3.3 Temperature Dial and Display

This is turned to select the desired temperature.

3.4 Oven Modes

The oven has 9 cooking modes plus Warm and Self Clean. These use different

combinations of elements and the oven fan as follows:

• True Aero. A concealed heating element surrounding the fan in

the rear of the oven heats air, which is then blown into the oven

cavity.

• Aero Bake. The oven fan circulates hot air from the upper outer

and the bake elements.

• Bake. Heat comes from the upper outer and the bake elements.

• Aero Pastry. Heat comes from the bake element and is

circulated throughout the oven cavity by the oven fan.

• Pastry Bake. Uses the heat from the bake element only.

Loading...

Loading...