TECHNICAL MANUAL

RESPIRATORY HUMIDIFIERS

MODELS:

MR730

MR720

MR700

MR480

Revision F

Issued March 2001

Fisher & Paykel Healthcare Ltd

Auckland, New Zealand

ii

National Office:

Fisher & Paykel Healthcare Ltd

P.O. Box 14348, Panmure

Auckland, New Zealand

Telephone: +64-9-574 0100

Facsimile: +64-9-574 0158

Technical Manual for Respiratory Humidifier

MR730 Dual Servo

MR720 Dual Servo (anaesthesia)

MR700 Dual Servo

MR480 Single Servo

Fisher & Paykel Healthcare have a policy of continued product improvement and reserve the right to alter specifications

without notice.

Revision F changes,

Section Description of Change

6.0 Routine Performance test shortened (Dynamic test removed).

7.33 Software Compatability Updated

8.10 Spares list additions

9.0 Change history updated

Appendix B Maintenance Schedule Changed for Temperature Probes

Appendix D Cleaning Procedures Rewritten

Appendix E Dynamic performance check made an optional extra

Ref. 185040646 *MR730/720/700/480 Technical Manual ¯ Revision F ¯ Issued March 2001

iii

CONTENTS PAGE

1.0 MR700 SERIES GENERAL SPECIFICATIONS................................................................................1

1.1 Electrical Specifications ................................................................................................................................................................1

1.1.1 Models MR730/720/700...................................................................................................................................................1

1.1.2 Model MR480....................................................................................................................................................................1

1.1.3 Common Electrical Specifications (All Models) ...........................................................................................................1

1.2 Standards and Approvals................................................................................................................................................................1

1.3 Temperature Control......................................................................................................................................................................1

1.4 Temperature Sensing.....................................................................................................................................................................1

1.5 Temperature Display......................................................................................................................................................................2

1.6 Glossary of Abbreviations..............................................................................................................................................................2

2.0 OPERATING CONTROLS AND MODES ..........................................................................................3

2.1 Adjustable Controls ........................................................................................................................................................................3

2.1.1 Airway Temperature Control..........................................................................................................................................3

2.1.2 Chamber Control (Heater Wire On Mode Only)..........................................................................................................3

2.2 Push Switches..................................................................................................................................................................................3

2.2.1 Mute Button......................................................................................................................................................................3

2.2.2 Chamber Temp Button.....................................................................................................................................................3

2.2.3 Standby Button (MR700/720/730 only) .........................................................................................................................4

2.2.4 Heater Wire Switch (MR720, MR730 only) ...................................................................................................................4

2.3 Power Up Sequences .......................................................................................................................................................................4

2.3.1 Version 1.0 Software.........................................................................................................................................................4

2.3.2 Version 2.0 and Version 3.0 Software ............................................................................................................................4

2.4 Heater Wire On Mode (All models except MR480)..................................................................................................................4

2.5 MR730/720 in Heater Wire Off Mode and MR480..................................................................................................................4

2.6 Warm Up Mode.................................................................................................................................................................................5

2.6.1 Warm up mode exiting conditions (low temperature alarm enabled):.......................................................................5

2.6.2 MR720 (Version 2.0, 3.0 Software).................................................................................................................................5

2.7 Standby Mode....................................................................................................................................................................................5

2.7.1 MR700/MR730 (All software versions), MR720 (Version 1.0 Only).........................................................................5

2.7.2 MR720 Standby Mode (Version 2.0 and 3.0 software only)......................................................................................5

3.0 ALARMS AND INDICATORS.............................................................................................................6

3.1 Temperature Probe Alarm .............................................................................................................................................................6

3.2 Alarms In Heater Wire Mode (MR700/720/730 only).............................................................................................................6

3.2.1 Heater Wire Alarm............................................................................................................................................................6

3.2.2 Airway temperature High Alarm .....................................................................................................................................6

3.2.3 Airway temperature Low Alarm ......................................................................................................................................6

3.2.4 Chamber Temp High Alarm.............................................................................................................................................7

3.2.5 Chamber Temp Low Alarm activation...........................................................................................................................7

3.2.6 Set Low Warning..............................................................................................................................................................7

3.3 Temperature Alarms in Non Heater Wire Mode (includes MR480).....................................................................................7

3.3.1 Heater Wire Alarm............................................................................................................................................................7

3.3.2 Airway Temperature High Alarm...................................................................................................................................7

3.3.3 Airway Temperature Low Alarm....................................................................................................................................7

3.4 Audio Alarm.....................................................................................................................................................................................8

3.5 Safety Protection (All Models)......................................................................................................................................................8

3.5.1 Temperature Deviations..................................................................................................................................................8

3.5.2 Microprocessor Watch Dog...........................................................................................................................................8

Ref. 185040646 *MR730/720/700/480 Technical Manual ¯ Revision F ¯ Issued March 2001

iv

4.0 CIRCUIT OPERATION.........................................................................................................................9

4.1 Introduction......................................................................................................................................................................................9

4.2 Control Board..................................................................................................................................................................................9

4.2.1 Control Thermistors.........................................................................................................................................................9

4.2.2 Input Analog Switches U8 and U9................................................................................................................................9

4.2.3 Analog to Digital Converter U10 b,d,e..........................................................................................................................9

4.2.4 Processor Control U3.......................................................................................................................................................9

4.2.5 Power Line Interrupt (Revisions D/F PCBs) ...............................................................................................................10

4.2.6 Power Line Interrupt (Revision H PCB and later)......................................................................................................10

4.2.7 41 °C Comparator ............................................................................................................................................................10

4.2.8 Heaterplate Overtemperature........................................................................................................................................10

4.2.9 Watch Dog......................................................................................................................................................................10

4.3 Power Board...................................................................................................................................................................................11

4.3.1 Revision D/F PCBs.........................................................................................................................................................11

4.3.2 Revision H AND J PCBs ...............................................................................................................................................11

4.4 Probe Temperature versus Thermistor Resistance...............................................................................................................11

5.0 CALIBRATION ....................................................................................................................................12

5.1 Introduction....................................................................................................................................................................................12

5.2 Equipment Required ......................................................................................................................................................................12

5.3 Calibration Procedure for Models with Revision D PCBs or earlier..................................................................................12

5.4 Calibration Procedure for Models with Revision F PCBs or later......................................................................................12

6.0 PERFORMANCE CHECK..................................................................................................................14

6.1 Introduction....................................................................................................................................................................................14

6.2 Performance Check MR730/720/700......................................................................................................................................14

6.2.1 Equipment Setup Notes:................................................................................................................................................14

6.2.2 Setup................................................................................................................................................................................14

6.2.3 Temperature Control Check MR700/720/730..............................................................................................................14

6.2.4 Alarms check MR700/720/730......................................................................................................................................15

6.3 Performance Check (MR480)....................................................................................................................................................15

6.3.1 Equipment Required.......................................................................................................................................................15

6.3.2 Setup................................................................................................................................................................................15

6.3.3 Temperature Control Check (MR480)..........................................................................................................................15

6.3.4 Alarms check - MR480...................................................................................................................................................16

6.4 Dual Probe Temperature Test....................................................................................................................................................16

6.4.1 Equipment Required.......................................................................................................................................................16

6.4.2 Test Procedure................................................................................................................................................................16

7.0 SERVICING INFORMATION............................................................................................................17

7.1 Introduction....................................................................................................................................................................................17

7.2 Printed Circuit Board Removal..................................................................................................................................................17

7.2.1 Control PCB.....................................................................................................................................................................17

7.2.2 Power PCB.......................................................................................................................................................................17

7.3 COMPATABILITY.......................................................................................................................................................................17

7.3.1 Hardware compatability.................................................................................................................................................17

7.3.2 MR480 Transformers .....................................................................................................................................................18

7.3.3 Software compatability..................................................................................................................................................18

7.4 Heaterplate .....................................................................................................................................................................................18

7.4.1 Heaterplates with screw-in standoffs..........................................................................................................................19

7.5 Fault Location................................................................................................................................................................................19

7.6 Screw Torque Settings.................................................................................................................................................................19

Ref. 185040646 *MR730/720/700/480 Technical Manual ¯ Revision F ¯ Issued March 2001

v

8.0 SCHEMATICS, PART LISTS AND MECHANICAL DRAWINGS................................................20

8.1 MR700 Series Circuit Layout Block Diagram......................................................................................................................20

8.2 Component Layout - Revision H and J PCB.............................................................................................................................21

8.3 Component Layout - Revision F PCB........................................................................................................................................22

8.4 Link Pad Locations for Programming Control Options - Revision H and J PCB............................................................23

8.5 Circuit Diagrams - Revision H and J PCB Control PCB ...................................................................................................25

8.6 Circuit Diagrams - Revision H and J PCB Power PCB......................................................................................................26

8.7 Circuit Diagrams - Revision F PCB Control PCB..............................................................................................................27

8.8 Circuit Diagrams - Revision F PCB Power PCB ................................................................................................................28

8.9 Electrical Parts List .....................................................................................................................................................................29

8.9.1 Control Board Components: (Revision h and later PCBs) ........................................................................................29

8.9.2 Power Board Components: (Revision h and later PCBs)..........................................................................................31

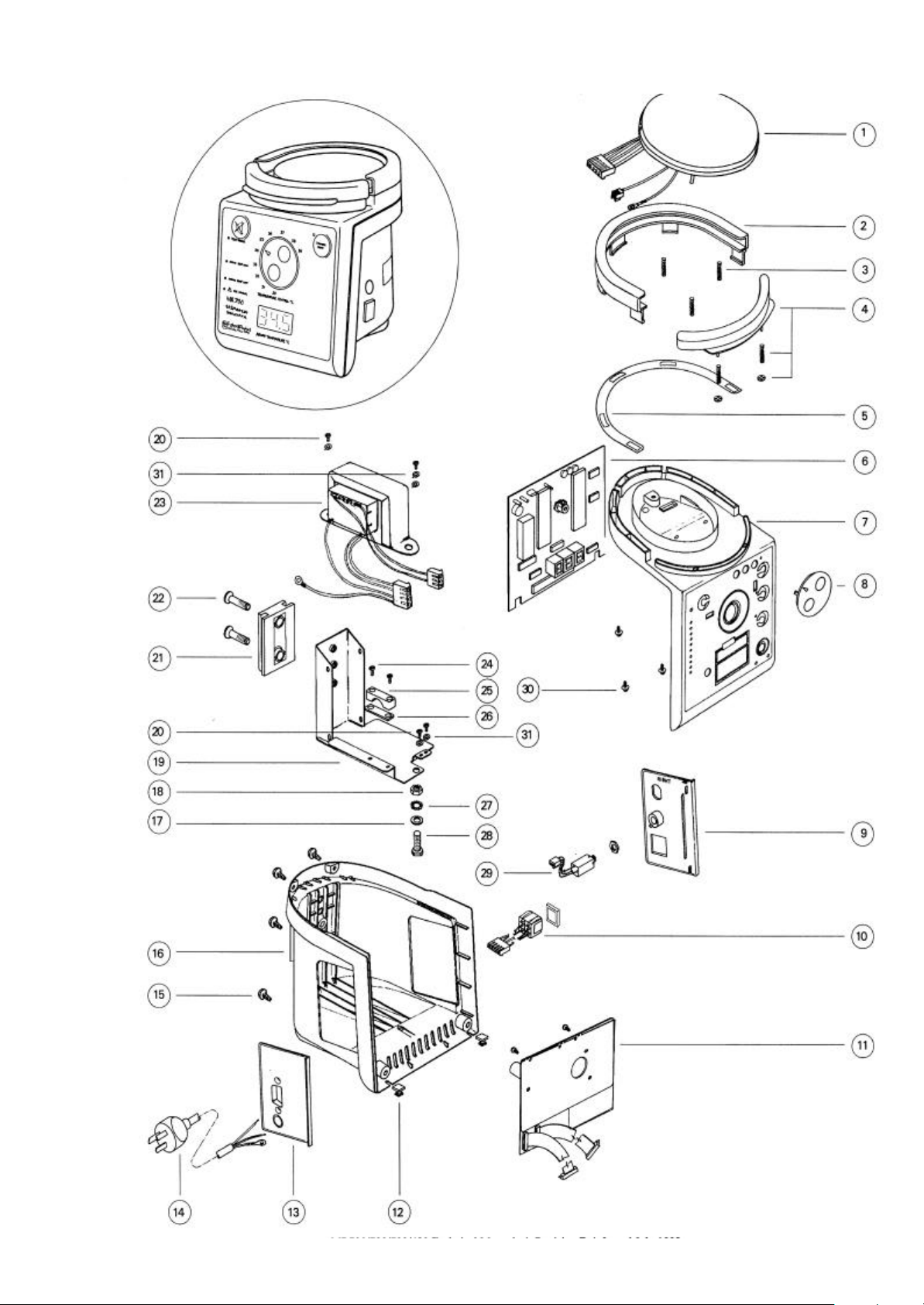

8.10 Mechanical Parts List.................................................................................................................................................................32

8.10.1 MR480 Mechanical Parts...............................................................................................................................................32

8.10.2 Exploded Diagrams: MR480..........................................................................................................................................33

8.10.3 MR730/720/700 Mechanical Parts................................................................................................................................34

8.10.4 Exploded Diagrams: MR730/720/700............................................................................................................................36

8.10.5 Heaterplate Assembly Parts (MR730/720/700/480)...................................................................................................37

8.10.6 Exploded Diagrams:Heaterplate Assembly MR730/720/700/480 (Inverted View).................................................38

8.11 PCB Identification Diagram.......................................................................................................................................................39

8.12 Power PCB Harness Connection Diagram..............................................................................................................................40

9.0 PRODUCT CHANGE HISTORY........................................................................................................41

9.1 Model Number Explanation.........................................................................................................................................................42

9.2 Serial Number Explanation.........................................................................................................................................................42

APPENDIX A................................................................................................................................................43

A1 Calibration Mode ..........................................................................................................................................................................43

A2 Engineering Menu........................................................................................................................................................................43

A2.1 Engineering display functions: Heater Wire Mode...................................................................................................43

A2.2 Engineering Functions: Non Heater Wire Mode.......................................................................................................44

A2.3 Integral Display...............................................................................................................................................................44

A3 Programming Control Options..................................................................................................................................................44

A4 Error Codes ...................................................................................................................................................................................44

A5 MR700 Series Humidifier Serial Data Interface...................................................................................................................45

A5.1 Serial Data Format...........................................................................................................................................................45

A5.2 Status Information..........................................................................................................................................................45

A5.3 Remote Standby..............................................................................................................................................................46

A5.4 Serial Data Interface Connector ....................................................................................................................................47

APPENDIX B................................................................................................................................................48

B1 Maintenance Schedule.................................................................................................................................................................48

B1.1 Monthly ...........................................................................................................................................................................48

B1.2 Three Monthly................................................................................................................................................................48

B1.3 Annually ..........................................................................................................................................................................48

B1.4 Annually Or In Accordance With Relevant Country Regulations.........................................................................48

B2 Maintenance Schedule Checklist ..............................................................................................................................................49

APPENDIX C................................................................................................................................................50

C1 Troubleshooting Guide For The MR700 Series Respiratory Humidifiers .......................................................................50

C1.1 Low Temperature............................................................................................................................................................50

Ref. 185040646 *MR730/720/700/480 Technical Manual ¯ Revision F ¯ Issued March 2001

vi

C.1.2 High Temperature...........................................................................................................................................................51

C.1.3 Temperature Fluctuating...............................................................................................................................................51

C.1.4 Excessive Water In Circuit............................................................................................................................................51

C1.5 Low humidity..................................................................................................................................................................52

C1.6 Alarms ..............................................................................................................................................................................52

C1.7 Temperature display......................................................................................................................................................53

C1.8 Breathing circuit leak.....................................................................................................................................................53

C1.9 External water leak..........................................................................................................................................................53

C1.10 LED on.............................................................................................................................................................................53

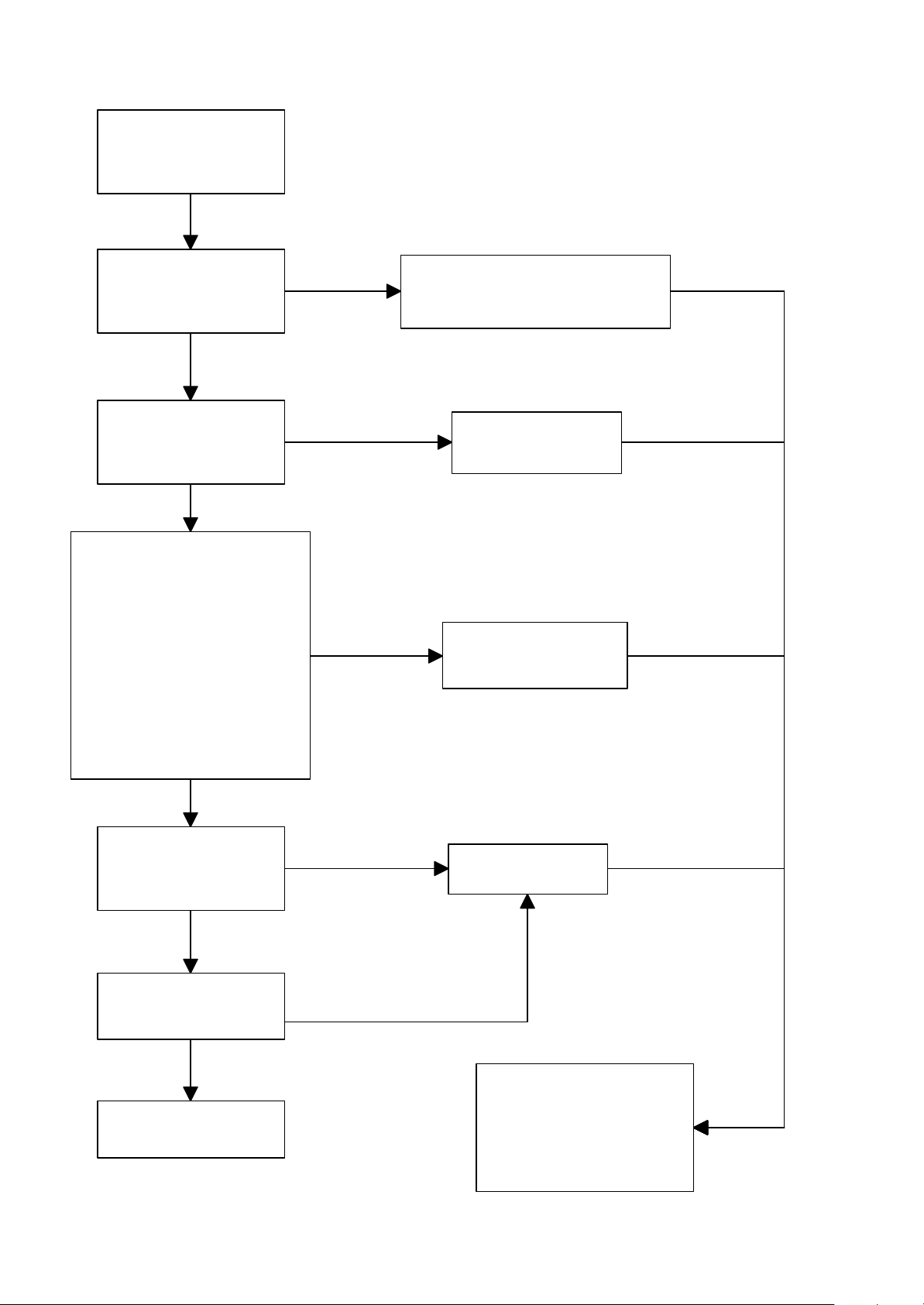

C2 MR700 Series Fault Flow Chart For No Go Condition..........................................................................................................54

APPENDIX D...............................................................................................................................................55

D1 Cleaning of Humidifier Heater Bases.......................................................................................................................................55

D2 Cleaning of Airway Temperature Probes.................................................................................................................................55

APPENDIX E................................................................................................................................................56

e1 Additional Dynamic Performance Check of Humidifiers......................................................................................................56

E2 Performance Check MR730/720/700......................................................................................................................................56

E2.1 Equipment Setup............................................................................................................................................................56

E.2.2 Setup................................................................................................................................................................................56

E.2.3 Dynamic Test Sequence (MR730/720/700).................................................................................................................57

E.3 Performance Check (MR480)....................................................................................................................................................57

E.3.1 Equipment Setup............................................................................................................................................................57

E.3.2 Setup................................................................................................................................................................................58

E.3.3 Dynamic Test Procedure (MR480)...............................................................................................................................58

Ref. 185040646 *MR730/720/700/480 Technical Manual ¯ Revision F ¯ Issued March 2001

1

1.0 MR700 SERIES GENERAL SPECIFICATIONS_________________________

This documentation defines the technical specifications of the MR730, MR720, MR700 and MR480 respiratory

humidifiers, it also includes maintenance and repair procedures.

The MR730/720 models are Heated Wire humidifiers with the option of disabling the Heater Wire.

The MR720 has a lower alarm limit and an extended warmup mode for use in Anaesthesia.

The MR700 model is exclusively a Heated Wire humidifier.

The MR480 model is a non Heated Wire humidifier.

1.1 ELECTRICAL SPECIFICATIONS

1.1.1 MODELS MR730/720/700

Supply Voltage 230 ± 25 V

127 ± 12 V

115 V

100 ± 10 V

Supply Frequency 50 or 60 Hz

Supply Current 1.0 A maximum at 230 V

1.9 A maximum at 127 V

2.0 A maximum at 115 V

2.4 A maximum at 100 V

Heater Wire Capacity 60 W

1.1.2 MODEL MR480

Supply Voltage: 230 ± 25 V

115 V

100 ±10 V

Supply Frequency 50 or 60 Hz

Supply Current 0.7 A maximum at 230 V

1.4 A maximum at 115 V

1.6 A maximum at 100 V

1.1.3 COMMON ELECTRICAL SPECIFICATIONS (ALL MODELS )

Heaterplate Power 150 W

Heaterplate Overheat Protector Operates at 118 ± 6 °C

1.2 STANDARDS AND APPROVALS

Classification under: CSA-C22.2 No.125 , UL2601

IEC601-1, AS3200.1, EN60601-1

Class 1

Type B

Drip Proof

Continuous Operation

Not to be used in the presence of flammable anaesthetics.

1.3 TEMPERATURE CONTROL

PID (Proportional Integral Derivative) control of Heater Wire (in Heated Wire mode operation only) and heaterplate.

1.4 TEMPERATURE SENSING

Temperature measurement using standard characteristic thermistors (YSI 400 compatible) mounted in fast response

temperature probes, located at the patient end of the delivery tube and at the humidifying chamber outlet.

Ref. 185040646 MR730/720/700/480 Technical Manual ¯ Revision F ¯ Issued March 2001

1.5 TEMPERATURE DISPLAY

Three digit 14mm 7 segment LED (Light Emitting Diode) display.

Range 5.0 to 80.0 °C. Below 5.0 °C displays ‘Lo’. Above 80.0 °C displays ‘Hi’.

Accuracy 25.0 ± 0.3 °C to 45.0 ± 0.3 °C.

1.6 GLOSSARY OF ABBREVIATIONS

EOH The End Of Hose temperature.

OFFSET The temperature difference of the TOP from the SET.

SET The temperature Set potentiometer. Sets the controlling temperature of the EOH.

TOP The temperature at the Top of the humidification chamber.

RSD Remote Shut Down.

2

Ref. 185040646 MR730/720/700/480 Technical Manual ¯ Revision F ¯ Issued March 2001

3

2.0 OPERATING CONTROLS AND M ODES _____________________________

2.1 ADJUSTABLE CONTROLS

2.1.1 AIRWAY TEMPERATURE CONTROL

Selects the airway controlling temperature. The range of adjustment is from 31 to 40 °C over a linear scale marked in

degrees on the front panel.

The temperature can be set with a resolution of 0.1 °C. The set temperature is flashed on the display when the control

knob is rotated and continues to be flashed for five seconds after the last adjustment.

2.1.2 CHAMBER CONTROL (HEATER WIRE ON MODE ONLY)

The temperature of the gas leaving the chamber is regulated by the Chamber Control knob, it sets the difference between

the chamber outlet temperature and the airway temperature delivered to the patient. The setting of the Chamber Control,

when added to the setting of the Temperature Control, determines the chamber outlet set temperature. This Chamber

Control has a linear range of adjustment from -5 to +2 °C marked in one degree steps and can be set with a resolution of

0.5 °C. The value is flashed on the Airway display as the control knob is rotated and continues to be flashed for five

seconds after the last adjustment.

Every humidifier is also supplied with a fixed chamber control knob. This prevents inadvertent adjustment of the

chamber control by preadjusting the existing knob to the desired setting and then replacing the normal knob with the

fixed knob.

2.2 PUSH SWITCHES

2.2.1 MUTE BUTTON

A momentary push will disable an audible alarm for 3 minutes (except low temperature alarm in non heater wire mode

which is 10 minutes).

A secondary function is that in conjunction with the Chamber Temp switch enables entry to the engineering menu (refer

Appendix A2).

On every initial push of the mute button a momentary audio beep indicates function operation.

2.2.2 CHAMBER TEMP BUTTON

MR700 Series Humidifiers with Version 1.0 Software:

Operation of this switch causes the airway temperature display to momentarily blank then show the chamber outlet

temperature. A green LED adjacent to the switch is enabled to indicate that this function is active. On release of this

switch the display reverts immediately to show the airway temperature.

This button is used in conjunction with the mute to enter the engineering menu (refer Appendix A2).

MR700 Series Humidifiers with Version 2.0 and Version 3.0 Software:

Operation of this switch causes the airway temperature display to momentarily blank then show the chamber outlet

temperature. A green LED adjacent to the switch is enabled to indicate that this function is active. On release of this

switch the display continues to show the chamber outlet temperature for 2 seconds before blanking momentarily and

reverting to show the airway temperature.

This button is used in conjunction with the mute to enter the engineering menu (refer Appendix A2).

Ref. 185040646 MR730/720/700/480 Technical Manual ¯ Revision F ¯ Issued March 2001

2.2.3 STANDBY BUTTON (MR700/720/730 ONLY )

This button has to be depressed for one second to enter or exit the standby mode. When the adjacent amber LED starts

to flash (100/minute) the button can then be released and the Humidifier remains in the standby mode.

To exit Standby mode press the Standby button for 1 second, the amber LED will then turn off. An audio beep accompanies a change in the Standby mode state.

2.2.4 HEATER WIRE SWITCH (MR720, MR730 ONLY )

This is a latching, push operated, switch which selects between the heater wire mode and non-heater wire mode. The

adjacent green LED, if on, indicates that the humidifier is operating in the heater wire mode. Pressing this switch will

cause an audible beep and the LED changes to indicate the new state. A heater wire alarm will commence if switching to

the heater wire mode with heater wire disconnected or if switching to the non heater wire mode if a heater wire is

connected.

2.3 POWER UP SEQUENCES

2.3.1 VERSION 1.0 SOFTWARE

After switch on the humidifier goes through the following sequence. Note that each displayed information is flashed for

2 seconds.

4

• Watchdog circuit test If successful the ‘SEE MANUAL’ LED lights briefly.

• Display Test All indicator LEDs are illuminated and ‘8.8.8.’ is displayed on the Airway

• Temperature Control Setting eg ‘37.0’ is displayed

• Chamber Control setting If heater wire mode is selected then the chamber control setting is displayed

• Software Version Number ‘1.0’

• Maximum Heaterplate setting eg ‘110’

• Audio Beep

2.3.2 VERSION 2.0 AND VERSION 3.0 SOFTWARE

After switch on the humidifier goes through the following sequence. Note that each information is displayed for 2

seconds, then the display is momentarily blanked.

• Watchdog circuit test If successful the ‘SEE MANUAL’ LED lights briefly.

• Display Test All indicator LEDs are illuminated and ‘8.8.8.’ is displayed on the Airway

• Model Number eg ‘730’

• Software Version Number eg ‘2.0’

• Temperature Control Setting eg ‘37.0’ is displayed

• Chamber Control setting If heater wire mode is selected then the chamber control setting is displayed

• Maximum Heaterplate setting eg ‘110’

• Audio Beep

Temperature display

eg ‘-1.0’. Not applicable for MR480

Temperature display

eg ‘-1.0’. Not applicable for MR480

2.4 HEATER W IRE ON MODE (ALL MODELS EXCEPT MR480)

In the Heater Wire On Mode (heater wire switch green LED on) the heaterplate and heater wire are regulated to maintain

the desired temperature and humidity, within close limits. To minimise rainout or maximise humidification, the chamber

outlet temperature can be adjusted to control at a fixed offset from the set airway temperature. The front panel Chamber

Control knob is used for this purpose, see § 2.1.2 above.

2.5 MR730/720 IN HEATER W IRE OFF MODE AND MR480

In the non Heater Wire mode of the MR730/720 (heater wire switch green LED off) the delivery temperature is maintained

by heaterplate control only. The sensor at the delivery hose end controls the heaterplate to deliver the selected

temperature. The sensor at the chamber outlet is employed in a backup safety mode, to limit the chamber outlet

temperature to a maximum of 66 °C. In this way safety at low flow rates (below 5 l/minute) is enhanced at the sacrifice of

some low flow performance.

Ref. 185040646 MR730/720/700/480 Technical Manual ¯ Revision F ¯ Issued March 2001

5

2.6 W ARM UP MODE

After initial turn on, warm up mode is entered. In this mode the Low temperature alarm is disabled. The Low temperature alarm is

enabled when warm up mode is exited.

2.6.1 WARM UP MODE EXITING CONDITIONS (LOW TEMPERATURE ALARM ENABLED):

• (MR700/MR730(All versions) and MR720(version 1.0) in Heater Wire Mode)

Warm Up mode continues until the Software Detects-

Either: The airway temperature reaches within 0.8 °C of the Temperature Control set point.

Or: The airway temperature has not increased by 2 °C for at least 4 minutes (2 minutes for version 3.0 software).

Or: The airway temperature has not got within 2 °C of the set point after ten minutes from switch on.

• (MR700/MR730(all versions) and MR720(version 1.0) in Non Heater Wire Mode and MR480)

Warm Up mode continues until the Software Detects-

Either: The airway temperature gets above 30 °C.

Or: The airway temperature has not increased by 2 °C within 15 minutes.

Or: The airway temperature has increased by 2 °C within 15 minutes but still has not reached 30 °C after a further 15

minutes.

Note:In this mode the audio alarm is not enabled until 30 seconds after the Airway Temp Low LED switches on.

At this time the heaterplate circuit switches off, pressing mute will silence the alarm for 10 minutes, during

which time the heaterplate power is enabled

2.6.2 MR720 (V ERSION 2.0, 3.0 SOFTWARE)

If the above warm up exiting conditions are not initially met the MR720 will automatically enter the standby mode for 20

minutes for version 2.0 software and 30 minutes for version 3.0 software (refer § 2.7.2).

2.7 STANDBY MODE

2.7.1 MR700/MR730 (ALL SOFTWARE VERSIONS), MR720 (V ERSION 1.0 ONLY)

The standby mode can be entered or exited by depressing the standby button for 1 second. A beep will be emitted once

successful entered or exited standby mode (refer § 2.2.3).

In the standby mode all Low Temperature alarms are inhibited, the heaterplate is controlled to a nominal 40.0 °C and the

heater wire is on a 15 % duty cycle.

Standby mode is automatically exited after 20 minutes (30 minutes for version 3.0 software) and the warm up mode is

entered (the low temperature alarms remain disabled - refer § 2.6).

A Remote Standby request (see Appendix A5.3) enables the standby mode and turns the standby amber LED permanently on.

2.7.2 MR720 STANDBY MODE (VERSION 2.0 AND 3.0 SOFTWARE ONLY)

The MR720 has a special feature where it will go into a standby mode automatically after turn on if the warm up exiting

conditions are not met. This standby mode time is 20 minutes for version 2.0 and 30 minutes for version 3.0 software.

While in standby mode, if the airway temperature increases by 2 °C at any time, the MR720 will exit stand by mode and

enter warm up mode. The unit then monitors the warm-up exiting conditions(see § 2.6.1 and 2.6.2), and if these are not

met, then the unit re-enters Standby mode.

Ref. 185040646 MR730/720/700/480 Technical Manual ¯ Revision F ¯ Issued March 2001

6

3.0 ALARMS AND INDICATORS _____________________________________

3.1 TEMPERATURE PROBE ALARM

If the airway temperature probe is disconnected or develops a low or high resistance the Temperature Probe alarm will be

enabled. Indication is by a ‘- - -' message on the airway temperature display plus a flashing Temperature Probe red LED

and an audio alarm.

Five specific fault types can be diagnosed and are displayed by the sequence of ‘decimal points’ in the display, as

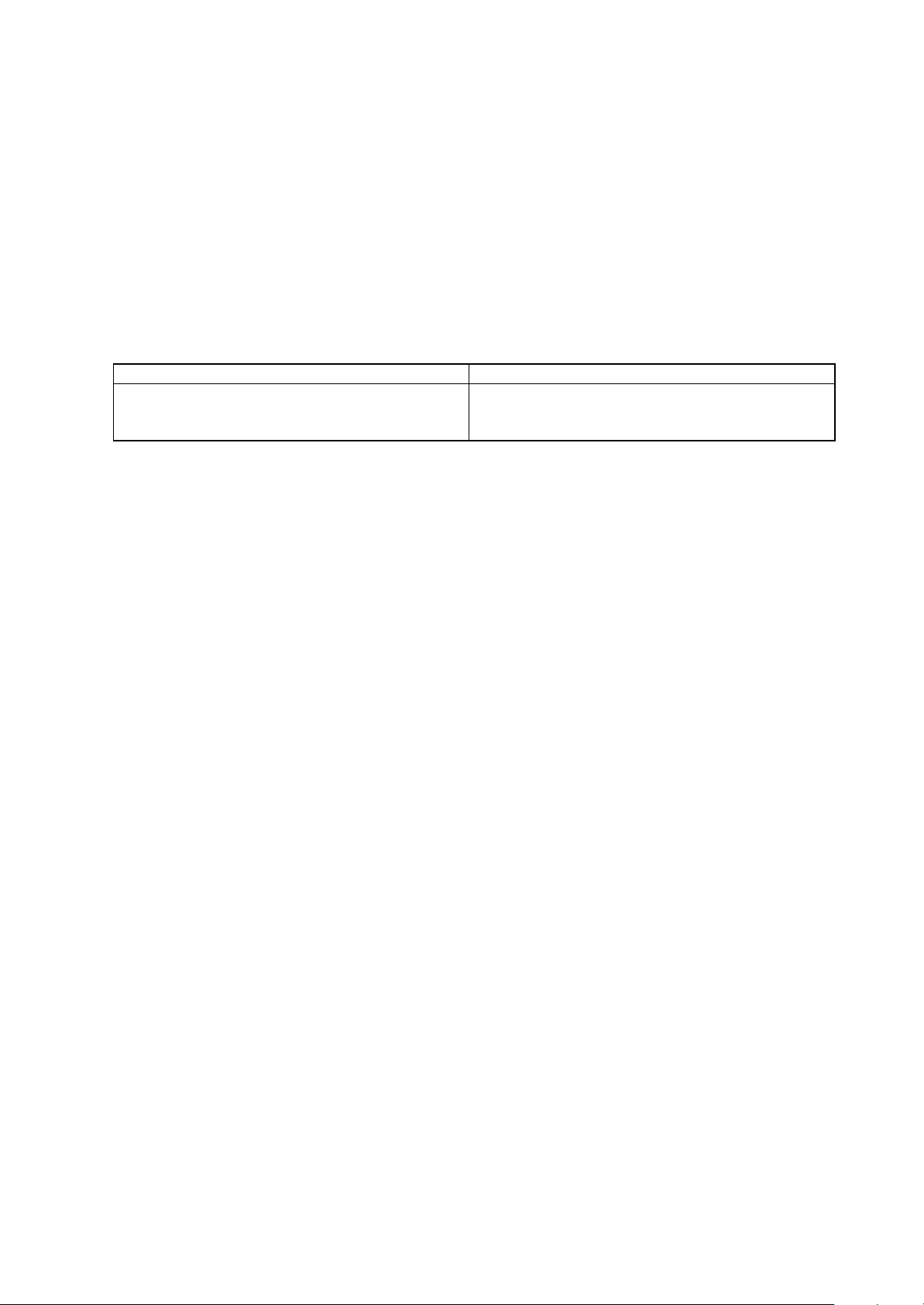

shown below:

a

b

c

d

e

The faults (a to d) above are checked for at a rate of about twice per second. The final fault (e) which does not

immediately cause any apparent operating anomaly is checked twice a minute.

A Temperature Probe Alarm immediately shuts down both heater wire and heaterplate.

Once the alarm condition has been removed the humidifier will enter warm up mode (refer § 2.6).

3.2 ALARMS IN HEATER W IRE MODE (MR700/720/730 ONLY)

3.2.1 HEATER WIRE ALARM

If the heater wire is disconnected or there is a fault with the heater wire circuit, then the Heater Wire alarm LED will start

flashing and the audio alarm will be enabled. Both heater wire and heaterplate circuits will be shutdown. The display will

continue to indicate the temperature sensor reading (unless the heater wire fuse is open circuit).

- - -

- - -.

- -.-

- -.-.

-.- -

Temperature Probe not plugged in.Low temperature (~ 0 °C)

Open circuit chamber outlet probe

Open circuit in common lead in probe cable.

Open circuit patient airway probe

Very low temperature (~ 0 °C)

Short circuit chamber outlet probe

Very high temperature (~ 100 °C)

Short circuit patient airway probe

Very high temperature (~ 100 °C)

Short in probe cable between patient airway probe and chamber outlet probe

An open circuit heater wire fuse is indicated by ‘F-2’ appearing on the Airway Temperature display.

On MR720/730 if the Heater Wire is connected but switched off, the alarm will sound (refer § 2.2.4).

Note: If ‘F-2’ is displayed and the F2 fuse is intact then check the calibration of the 41 °C overheat (refer § 5).

3.2.2 AIRWAY TEMPERATURE HIGH ALARM

The red Airway Temp High LED will flash and an audible alarm will sound if the gas temperature being delivered to the

patient is 2 °C higher than the Temperature Control setting. A high temperature alarm instantly disables both heater

circuits.

3.2.3 AIRWAY TEMPERATURE LOW ALARM

The red Airway Temp Low LED will flash and an audible alarm will sound if the gas temperature being delivered to the

patient is 2 °C lower (4 °C for MR720 model) than the Temperature Control setting. If Airway Temperature Low alarm

condition persists for more than 100 seconds the heaterplate and heater wire circuits will switch off. Pressing the mute

button will silence the Audio alarm and resume heat for a further 100 seconds, the Airway Temperature Low LED will

continue to flash. This alarm is disabled during warm-up. See § 2.6.1.

If the airway temperature drops below 5°C the display will show ‘LO’ and an audible alarm will sound.

Ref. 185040646 MR730/720/700/480 Technical Manual ¯ Revision F ¯ Issued March 2001

3.2.4 CHAMBER TEMP HIGH ALARM

This alarm will activate if:

• The temperature of gas leaving the humidification chamber outlet is more than 4 °C higher than the chamber set

temperature for more than 20 minutes. (The chamber set temperature is the sum of the Temperature Control

setting and the Chamber Control setting).

• The temperature of the gas leaving the humidification chamber outlet exceeds the chamber set temperature by

10 °C or more.

This alarm causes the heater circuits to switch off and the ‘Chamber Temp High’ amber LED indicator to start flashing.

The audio alarm (which can be muted) is also enabled. This alarm remains active until the high temperature condition is

cleared.

3.2.5 CHAMBER TEMP LOW ALARM ACTIVATION

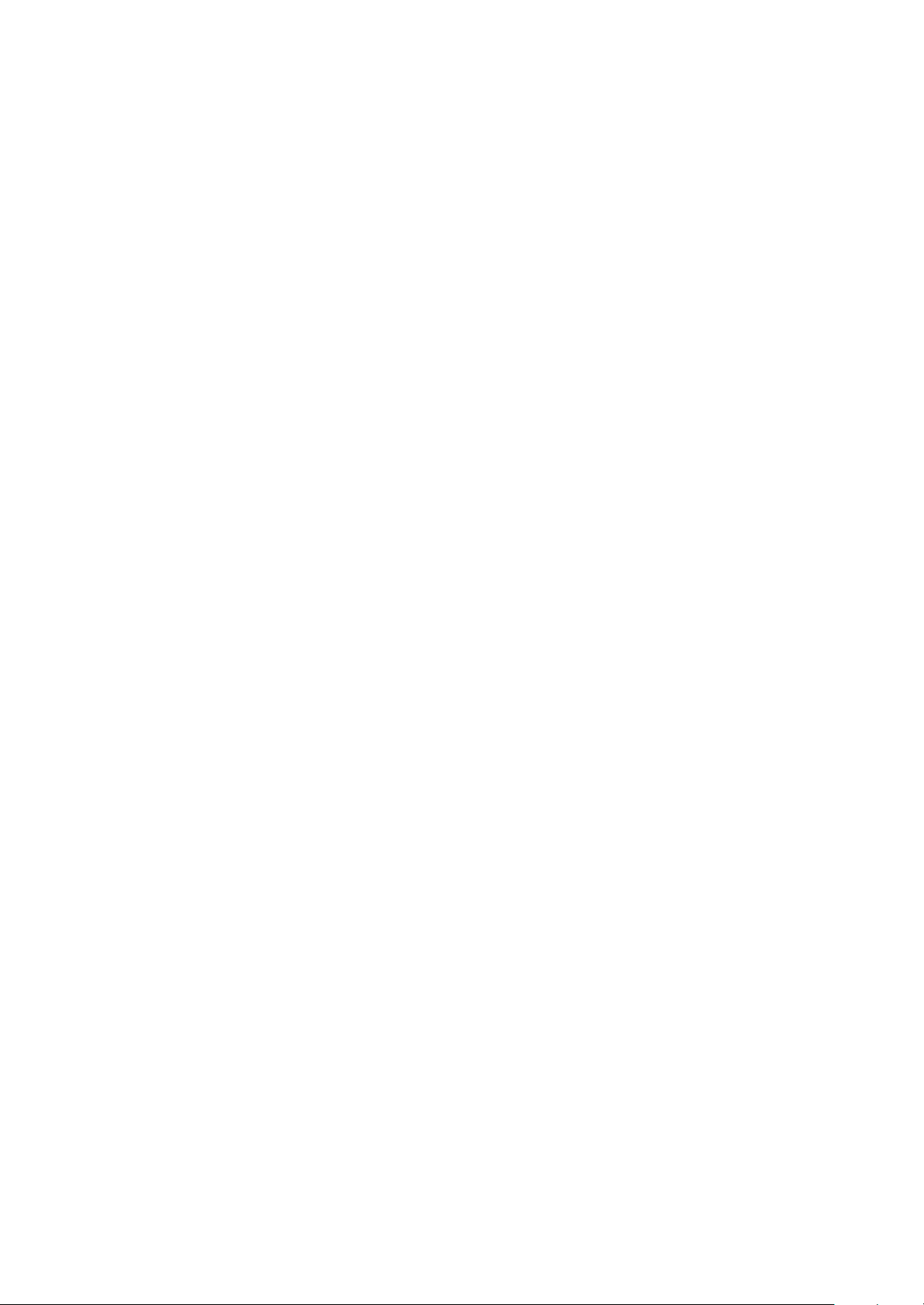

For Chamber Set Temperature < 35 °C For Chamber Set Temperature ≥≥ 35 °C

The temperature of gas leaving the humidification

chamber outlet is less than 4 °C lower than the

chamber set temperature for more than 20 minutes.

The Chamber Temp Low alarm amber LED will begin to flash and the audio alarm is enabled. This alarm remains active

until the low temperature condition is cleared. Pushing the mute button will silence the Audio alarm.

7

The temperature of gas leaving the humidification

chamber outlet is less than 31 °C for more than 20

minutes.

3.2.6 SET LOW WARNING

Version 1.0 and Version 2.0 Software

This alarm will activate if the chamber set temperature is below 31.0 °C. In this case the Set Low amber LED will

immediately be enabled and remain on, until such time as the chamber set temperature is adjusted above 31.0 °C. There is

no audible alarm.

Version 3.0 Software

This alarm will activate if either the chamber set temperature or Temperature Control setting is below 34.0 °C.

In these cases the Set Low amber LED will immediately be enabled and remain on, until such time as the set airway or

chamber set temperature is adjusted above 34.0 °C. There is no audible alarm.

3.3 TEMPERATURE ALARMS IN NON HEATER W IRE MODE (INCLUDES MR480)

3.3.1 HEATER WIRE ALARM

This indicates that a heater wire has been connected when the non heater wire mode has been selected (Heater Wire

‘On’ LED is off). In this case the Heater Wire alarm LED will be flashing, the audio alarm begins and the heaterplate is

switched off.

3.3.2 AIRWAY TEMPERATURE HIGH ALARM

The red Airway Temp High LED will flash and an audible alarm will sound if the gas temperature being delivered to the

patient is 41 °C or higher. Power to the heaterplate is immediately shut off.

3.3.3 AIRWAY TEMPERATURE LOW ALARM

The red Airway Temp Low LED will flash and an audible alarm will sound if the gas temperature being delivered to the

patient is 29.5 °C or less.

The audio alarm is not enabled for 30 seconds after the low temperature LED begins flashing.

Ref. 185040646 MR730/720/700/480 Technical Manual ¯ Revision F ¯ Issued March 2001

Pushing the mute button mutes the audio alarm for ten minutes and restores power to the heaterplate during this time.

The Airway Temp Low LED will continue to flash. This alarm is disabled during warmup. See § 2.6.2.

If the airway temperature drops below 5°C the display will show ‘LO’ and an audible alarm will sound.

3.4 AUDIO ALARM

A choice of the ISO draft standard audio alarm or a gliding tone can be selected by the programming control link (L1).

Refer Appendix A3.

A momentary depression of the mute button will silence the audio alarm for about 3 minutes (except for a low

temperature alarm in no heater wire mode. See § 3.3.3. The relevant LED indicators remain flashing until the alarm

condition clears. Any new alarm condition occurring within a mute delay will cause the audio alarm to be re-enabled.

3.5 SAFETY PROTECTION (ALL MODELS)

3.5.1 TEMPERATURE DEVIATIONS

An over temperature alarm condition causes an immediate shut down of both heater circuits. In the case of a Low

Temperature alarm, pressing Mute causes heating to recommence, the Low Temperature LED however remains on until

the fault has cleared. There are two independent backup over temperature protection circuits.

8

Firstly, an over temperature protection circuit independent of the microprocessor control continuously monitors the

airway thermistor sensor. This backup protection is preset to disconnect the heating circuits at 41.0 °C.Secondly, a

bimetallic thermostat fixed to the heaterplate operates if the heaterplate temperature exceeds 118 ± 6 °C and cuts out the

mains active supply. On cooling, this protector can only be reset by gaining access to the under surface of the

heaterplate and manually depressing the red reset button.

Heaterplate temperature is limited to 110 °C max during normal operation (80 °C for MR720). Optional heaterplate limits of

50, 80 and 90 °C can be selected. (Refer Appendix A3).

3.5.2 MICROPROCESSOR WATCH DOG

A control loop in the operating software continuously monitors for correct operation. Should a fault be detected a

hardware reset circuit attempts to reinitialise the microprocessor. If this is not successful additional hardware disables

the heating circuit, blanks the display and turns the Humidifier Fault red LED on.

The watch dog circuit is tested at turn on by deliberately halting the processor and forcing initialisation.

Ref. 185040646 MR730/720/700/480 Technical Manual ¯ Revision F ¯ Issued March 2001

9

4.0 CIRCUIT OPERATION_________________________________________

4.1 INTRODUCTION

This section describes briefly the operation of each of the circuit sections. Refer to the circuit diagrams in § 8.5 to 8.8.

4.2 CONTROL BOARD

The one basic control board, with various discreet hardware changes, provides the controlling functions for the

MR730/720/700/480 range of humidifiers. Each model however is controlled by a unique software version.

4.2.1 CONTROL THERMISTORS

Three standard characteristic thermistors control all temperature functions:

• One thermistor is mounted in a probe at the end of the delivery hose to measure delivered airway temperature

(connector J4-1,3). This temperature is indicated by the digital display on the humidifier front panel.

• A second thermistor mounted in a probe measures the chamber tem perature at the top of the humidifying

chamber (connector J4-2,3). In heater wire mode this thermistor is used to monitor and control the chamber

outlet temperature.

• A third thermistor is permanently mounted in intimate contact with the heaterplate (HP) (connector J3-1,3). This

prevents excessive heaterplate temperatures during a warm up cycle.

4.2.2 INPUT ANALOG SWITCHES U8 AND U9

The 1 by 8 analog switch (U8) selects under processor control (PB0-3) various input signals and reference potentials.

Selected sequentially are potentials giving; (0-3): the position of the temperature set potentiometer VR3, and offset

potentiometer VR2. (4-6): calibration temperatures of 9, 34.5 and 60 °C across resistors R18, R17 and R16, and from (7):

the heaterplate (HP) thermistor.

From the 3 by 2 analog switch (U9) under processor control (PB4-6) the airway temperature and the chamber outlet

temperatures from the dual probe temperature sensor are also read.

4.2.3 ANALOG TO DIGITAL CONVERTER U10 B,D,E

The temperature probe inputs are filtered by the C30, C31, R28, R26, C19, C20 network for EMI suppression. The selected

output of the analog switch network U8, U9 is fed to pin 10 of U10d, a low pass operational amplifier with a gain of 11.

This stage is filtered with C23 to give protection from any voltage transients appearing at its input. The integrating stage

U10b rests for most of the time (50 to 60ms) with R35 connected (through an analog switch in U9) across the integrating

capacitor C22 holding it in a discharged state. With VR5 and R34 connected to the non-inverting input of U10b the stage

has a ‘static' gain of about 0.5 giving a resting level of about -2.5 to -3 V at the output pin 1.

Under processor control (PB6) when the switch section of U9 across C22 is opened the output of U10b ramps up (0.1-5

ms). This rising ramp voltage is fed via R36 to the comparator stage U10e where it is referenced via R41 to the output

voltage level of U10d. When the ramp voltage exceeds the threshold level of U10d the output of the comparator stage

U10e switches high. This fast rising edge, assisted by the speed up capacitor C24, is fed to the RST 6.5 interrupt input of

U3.

4.2.4 PROCESSOR CONTROL U3

After selecting one of the 10 input signals through the switch network of U8, U9 there is a 50 to 60ms pause to allow

U10d to settle. At this point the switch across the integrator U10b is opened initiating a linear ramp output and the 14 bit

counter in U4 is started. Within a time period of 100 ns to 5 ms the ramp will cause a RST6.5 interrupt to occur. The

processor on responding to the interrupt, first stops the counter, then closes the switch across the integrator readying it

for the next cycle. The input switch network U8, U9 can now be stepped to the next input. The 14 bit counter can now be

read and its value equated to the input signal. In this way all 10 input channels are continuously scanned. VR5 is set

Ref. 185040646 MR730/720/700/480 Technical Manual ¯ Revision F ¯ Issued March 2001

during calibration to give the desired ramp rate. Thus all points are scanned once every 500 to 600 ms, self calibration

performed, and the digital display updated.

4.2.5 POWER LINE INTERRUPT (REVISIONS D/F PCBS)

A sample of the power supply frequency is derived from the power transformer 22 Vac secondary via R56 and Q1,

buffered by Schmitt trigger U5f and fed to the RST7.5 interrupt of U3. The operating software determines the supply

frequency facilitating the generation of a real time clock and also enabling a zero crossing detector for triac switching.

The ADC is also phase synchronised with the line frequency thus eliminating any common error from this source.

4.2.6 POWER LINE INTERRUPT (REVISION H PCB AND LATER)

The zero crossing is derived from the 10 Vac secondary. Resistor R61 ensures that the secondary is ground referenced

when the diodes D13 to D16 are not conducting. Network R1, R69, and C2 removes any unwanted noise from the zero

crossing circuit. The operating software determines the supply frequency facilitating the generation of a real time clock

and also enabling a zero crossing detector for triac switching. The ADC is also phase synchronised with the line

frequency thus eliminating any common error from this source.

4.2.7 41 °C COMPARATOR

10

Operational amplifier U10c is a protection circuit to sense excessive delivery temperature rise. The non inverting input

pin 5 is connected directly (via connector J4-1) to the patient airway thermistor. The inverting input goes to an

adjustable divider network R32, VR4, R33. VR4 is set during calibration to ensure that the output pin 7 of U10c is low

above an input temperature of 41 °C. This low output (OVHT) is fed via the isolating diode resistor networks D19, R55

and D20, R61 to clamp the bases of switching transistors Q10 and Q12. In this way, a patient airway temperature greater

than 41 °C causes both heaters to be shut down.

A watch dog failure, which is a high output from U5g, is communicated via isolating diode D11 and resistor R31 to the

inverting input of U10c. This also ensures that both heater control circuits are clamped off in the event of a processor

crash.

4.2.8 HEATERPLATE OVERTEMPERATURE

Thermistor HP senses the heaterplate temperature. Should the heaterplate exceed the maximum heaterplate limit (default

110 °C) during normal operation, power to the heaterplate is discontinued until it cools below this limiting temperature.

Under certain operating conditions, for increased safety, lower maximum heaterplate temperatures can be selected. (See

Appendix A3: Programming Control Options.) Also mounted on the heaterplate is a mechanical 118 °C cut out which will

give protection should the electronic control system fail. This mechanical cut out is connected in series with the power

transformer primary and thus causes complete shut down of the humidifier should a serious fault develop. See § 3.5.1.

4.2.9 WATCH DOG

During operation the processor is continually monitored for correct function. This is done by changing the state of

output port PB7 of U4 every 16.6 or 20 ms (power line frequency interrupt). This square wave, buffered by U5b, is fed to

the charge pump circuitry C16, D4, D5 and C15 which ensures that pin 13 of U5g is held hard up. Should this square

wave be interrupted for any reason, C15 will discharge through R3 giving a high output from pin 12, which drives the

trap interrupt input of U3. This high trap input forces re-initialisation of the processor which may or may not be

successful depending on the nature of the fault. The purpose of this is to ensure that if the processor should fail, and is

unable to re-initialise, it fails in a safe mode. The watch dog circuit is tested every time the humidifier is turned on by

deliberately halting program execution and waiting for initialisation via the watch dog. To indicate that the processor has

failed the high output of U5g also turns on Q3 which lights the ‘see manual’ LED10 and also turns off the display I.C. U7

to blank the digital display.

Ref. 185040646 MR730/720/700/480 Technical Manual ¯ Revision F ¯ Issued March 2001

4.3 POWER BOARD

4.3.1 REVISION D/F PCBS

A bridge rectifier (D13 to D16) supplies power to the 5 V regulator Q7 mounted on the heat sink. This circuit is protected

by a 1 A fuse (F1) mounted on the circuit board. The 5 V negative supply stabilized by Q8, is derived from the voltage

doubling network D17, D18.

The Heater Wire (HHC) is controlled by triac Q9 which is mounted on the heat sink. Q9 is switched by the optoisolator

U11 which in turn is driven by Q10. Q10 is controlled directly from an output port of U4 on the control board.

The resistor R52 connected to the anode of Q9 provides a signal through (HHS) to U5d and U4. This signal, with

processor interpretation, provides the information to determine if the Heater Wire is connected or open circuit and also

the integrity of fuse F2, the 4 A fuse supplying power to the Heater Wire.

Triac Q11 (mounted on the heatsink) is controlled by optoisolator U12, which in turn is controlled by Q12, and HPC.

Transistors Q5 and Q6 are a RS232 level driver for the serial data interface.

4.3.2 REVISION H AND J PCBS

A bridge rectifier (D13 to D16) supplies power to the 5 V regulator Q7 mounted on the heat sink. This circuit is protected

by a 1 A fuse (F1) mounted on the circuit board. The 5 V negative supply stabilized by Q8, is derived from the voltage

doubling network D17, D18.

11

The Heater Wire (HHC) is controlled by triac Q9 which is mounted on the heat sink. Q9 is switched by the optoisolator,

U11, which in turn is driven by Q10. Q10 is controlled directly from an output port of U4 on the control board (HHC).

Resistor R9, C6 form a snubber on the triac. Capacitors C8, C32 balance the heater wire with respect to ground.

Heater wire sensing is accomplished through the optoisolator U13 and associated components R51, R52, D21, R66 and

R67. R51 and R52 limit the current through the LED when the triac is on or off. With the triac off and a heater wire

connected then the optoisolator will remain off. Otherwise if a heater wire is not connected then the optoisolator will be

turned on and off in synchronisation with the secondary cycle. The output of the optoisolator feeds U4 on the control

board. This signal, with processor interpretation, provides the information to determine if the Heater Wire is connected

or open circuit and also the integrity of fuse F2, the 4 A fuse supplying power to the Heater Wire.

Q11 controls power to the heaterplate and is under control of optoisolator U12 and transistor Q12 via an output port

(HPC) on U4 on the control board. Resistors R64, R57 limit the gate current to the triac and with C33 form a snubber for

the triac and the optoisolator.

Transistors Q5 and Q6 are an RS232 level driver for the serial data interface.

4.4 PROBE TEMPERATURE VERSUS THERMISTOR RESISTANCE

TEMP (± 0.2 °C) RESISTANCE (Ω) TEMP (± 0.2 °C) RESISTANCE (Ω)

0 7352.8 36 1411.3

9 4702.2 37 1355.0

28 1976.6 38 1301.0

29 1893.3 39 1249.2

30 1814.4 40 1199.6

31 1739.2 41 1152.3

32 1667.2 42 1107.3

33 1598.2 43 1064.5

34 1532.9 44 1023.1

35 1470.6 60 560.3

Ref. 185040646 MR730/720/700/480 Technical Manual ¯ Revision F ¯ Issued March 2001

12

5.0 CALIBRATION______________________________________________

5.1 INTRODUCTION

Calibration should be performed after any servicing involving the printed circuit boards. After calibration, perform a

performance check as outlined in § 6.0.

Note: For instructions on disassembly of the unit, refer to § 7.0.

Calibration is facilitated by entering a special Calibration mode. See Appendix A1.

There are only two adjustments VR4 (the 41 °C comparator stage) and VR5 ( setting of the span of the A to D converter).

This calibration procedure may be carried out if the unit is thought to be out of calibration (E0x to E7x error messages in

the display) or if any of the circuit boards have been replaced or repaired. In particular any repair that may have altered

the potential of the ± 5 V rails or component change associated with the A to D converter would require a calibration

check.

Calibration should be checked and performed after the unit has been running for at least twenty minutes; ie after the unit

has warmed up.

5.2 EQUIPMENT REQUIRED

♦ 41 °C calibration probe, available in MR700 series calibration kit (Fisher & Paykel part no. 900MR548).

For models with Revision D PCB and earlier:

♦ Heater Wire module.

♦ For MR480 only - jumper connector cable, which consists of two easy hooks connected in series with a 100mm

length of cable and a 22 kΩ resistor.

5.3 CALIBRATION PROCEDURE FOR MODELS WITH REVISION D PCBS OR EARLIER

(Before Serial Number 92XXAAA05495) (See § 9.0 for change history).

1 With models MR730/720/700 ensure that a Heater Wire module is connected, and that the Heater Wire switch is

on (Heater Wire On LED should be on).

2 Plug in the 41 °C calibration probe.

3 Gain access to the adjustment potentiometers VR4 and VR5, by removing the control board from the humidifier

front panel.

4 With model MR480 only connect the jumper cable from pin 7 of U10 to the cathode end of D7 on the control

board.

5 With the Chamber Temp button held down turn on the power switch. Display should show -16 Using the Chamber Temp button step through to number -47 Adjust VR4 slowly so the display just changes from vertical to horizontal bars (|||||| to ===). Back off VR4 and

recheck that VR4 is not rotated past this display transition point.

8 Using the Chamber Temp button step to number -59 Remove the 41 °C calibration probe.

10 Adjust VR5 for a display reading of zero. ( 0)

(This value may drift over time. A deviation of up to ± 2.0 will not affect circuit performance.)

11 Calibration is complete; do performance check (§ 6.0).

5.4 CALIBRATION PROCEDURE FOR MODELS WITH REVISION F PCBS OR LATER

(See § 9.0 for serial number details)

Ref. 185040646 MR730/720/700/480 Technical Manual ¯ Revision F ¯ Issued March 2001

13

1 Plug in the 41 °C calibration probe.

2 Gain access to the adjustment potentiometers VR4 and VR5, by removing the control board from the humidifier

front panel.

3 With the Chamber Temp button held down turn on the power switch. Display should show -14 Using the Chamber Temp button step through to number -45 Starting with a vertical bar display adjust VR4 so the display changes to an all 8 display. If VR4 is rotated too

far the display becomes all horizontal bars (||.||.||. thru 8.8.8. to ===). The correct point is where all the

segments of the all 8 display are of equal brightness.

6 Using the Chamber Temp button step to number -57 Remove the 41 °C calibration probe.

8 Adjust VR5 for a display reading of zero. (0)

(This value may drift over time. A deviation of up to ± 2.0 will not affect circuit performance.)

9 Calibration is complete; do performance check (§ 6.0)

Ref. 185040646 MR730/720/700/480 Technical Manual ¯ Revision F ¯ Issued March 2001

14

6.0 PERFORMANCE CHECK_______________________________________

6.1 INTRODUCTION

This procedure should be used to check the operation and calibration of the MR730/720/700/480. This performance

check should be performed after any servicing, and annually as part of the routine maintenance procedure (see

Appendix B).

Performance can be monitored during the test by using the functions of the Engineering Menu. See Appendix A2.

If there is a desire to confirm the full dynamic operation of the Humidifier, such as after servicing, a full test of the

temperature control of the Humidifier may be performed, see tests detailed in Addendix E.

6.2 PERFORMANCE CHECK MR730/720/700

6.2.1 EQUIPMENT SETUP NOTES:

♦ 34.5 °C and 41°C test probes, available in MR700 series calibration kit (Fisher & Paykel part no. 900MR548).

♦ Α heated wire breathing circuit of any length, single use or reusable.( If a single use circuit is used, ensure there is a

gas flow through it of at least 2 l/minute to prevent overheating of the circuit.)

♦ Heater wire adaptor for connection to a MR700 series humidifier

♦ A Humidification Chamber filled with water to recommended level (water at room temperature.)

♦ A temperature probe is not used in the circuit in this test.

6.2.2 SETUP

1 Connect the heated circuit to the humidifier , ensure the circuit is not covered to prevent overheating of the

tubing. Remember there must be an airflow of at least 2 l/min for single use circuits.

2 Plug in the 34.5 °C test probe to the humidifier.

3 Slide the humidification chamber on to the humidifier.

4 Plug in the humidifier and turn the power on. For the MR720 and MR730, ensure the heater wire switch is ‘on’

(heater wire LED will light).

6.2.3 TEMPERATURE CONTROL CHECK MR700/720/730

1 Turn the Temperature Control knob to 33.0 ± 0.2 °C and Chamber Control to 0. (Note the Temperature Control

and Chamber Control settings will be displayed as the control knobs are adjusted.

2 Check the display reads 34.5 ± 0.2 °C and that the ‘Set Low’ warning light is on (units with version 3 software

only).

3 Push the Chamber temp. button and check for a 34.5 ± 0.2 °C reading on the temperature display.

4 Run for 5 minutes without interruption.

5 After 5 minutes Check:

Heaterplate is warm or cold.(Less than 60 °C , see ‘hP’ in the engineering menu).

Heater Wire cold (feel the wire or circuit, should be cold to touch).

6 Turn the Temperature Control knob to 36.0 ± 0.2 °C and leave Chamber Control set at 0.

7 Run for at least 20 minutes without interruption.

8 After 20 minutes Check:

Heaterplate hot (Greater than 80 °C, see ‘hP’ in the engineering menu.

Heater Wire hot (feel the wire or circuit, should be warm to touch).

CAUTION: THE WATER IN THE CHAMBER MAY BE NEAR BOILING AT THIS STAGE

Ref. 185040646 MR730/720/700/480 Technical Manual ¯ Revision F ¯ Issued March 2001

6.2.4 ALARMS CHECK MR700/720/730

1 Rotate Temperature Control knob to 37 and check for an Airway Temperature Low alarm. (For an MR720 set to

40 °C and check for an Airway Temperature Low alarm).

2 Rotate Temperature Control knob to 32 and check for an Airway Temperature High alarm.

3 If ‘set low’ light is not already on, rotate the chamber control to -1.5 and check that the ‘set low’ light comes on

(all software versions).

4 Rotate the Temperature Control knob back to 36 and check that alarms cease and set low LED is off..

5 Disconnect the Heater Wire plug and check for audio alarm and Heater Wire alarm light.

6 Reconnect the heater wire. For MR720/730 models, turn the Heater Wire off and check for audio alarm and

Heater Wire alarm light.

7 Disconnect the 34.5°C temperature probe and check that the Temperature Probe LED flashes and gives an

audio alarm.

8 Insert the 41°C temperature probe into the humidifier and check that the Airway Temperature High LED flashes

and the audio alarm sounds.

9 Push the Mute button and check that the audio alarm is silenced

10 Go to the engineering menu and check that the heaterplate duty cycle (Cdc) and heater wire duty cycle (Edc)

are starting to decrease, this may take a few seconds.

15

11 Turn off the humidifier.

12 Humidi fier is now ready for service.

6.3 PERFORMANCE CHECK (MR480)

6.3.1 EQUIPMENT REQUIRED

♦ 34.5 °C and 41 °C test probes, available in MR700 series calibration kit (Fisher & Paykel part no. 900MR548).

♦ A Full Humidification Chamber

6.3.2 SETUP

1 Slide the humidification chamber on to the heaterbase.

6.3.3 TEMPERATURE CONTROL CHECK (MR480)

1 Plug in the 34.5 °C test probe.

2 Turn the Temperature Control knob to 32.0 °C.

3 Turn on the humidifier main power switch.

4 Check that 32.0 ± 0.2 °C flashes on the display during initialisation.

5 Check for a display reading of 34.5 ± 0.2 °C after initialisation.

6 Push the Chamber Temp. button and check for a reading of 34.5 ± 0.2 °C.

7 Run for 5 minutes without interuption. If mains power is interupted test will have to be restarted.

8 After 5 minutes check the following in ‘Engineering mode’ (see Appendix A2):

Set 32

hp ≤ 60

9 Turn off the humidifier.

10 Turn the Temperature Control knob to 36.0 ± 0.2 °C (check correct setting is displayed when the control is

adjusted).

11 Run for 25 minutes.

12 After 25 minutes check the engineering menu (appendix A2.2):

Set 36

hp ≥ 70

Ref. 185040646 MR730/720/700/480 Technical Manual ¯ Revision F ¯ Issued March 2001

6.3.4 ALARMS CHECK - MR480

1 Disconnect the 34.5°C temperature probe and check that the Temperatur e Probe LED flashes and gives an

audio alarm.

2 Insert the 41°C temperature probe into the humidifier and check that the Airway Temperature High LED flashes

and the audio alarm sounds.

3 Push the Mute button and check that the audio alarm is silenced

4 Go to the engineering menu and check that the heaterplate duty cycle (dc) is starting to decrease, this may take

a few seconds.

5 Turn off the humidifier.

6 Humidifier is now ready for use.

6.4 DUAL PROBE TEMPERATURE TEST

This test is recommended to be performed on all temperature probes every three months or if there is any doubt as to the

accuracy of the temperature probe. This test allows the operator to compare the temperature readings of both probes

(chamber and airway) firstly to one another, and secondly to a glass thermometer for absolute verification of temperature

if so desired. (Using a water bath and thermometer is the most reliable method to check the temperature probe accuracy.)

6.4.1 EQUIPMENT REQUIRED

16

♦ Dual Temperature probe to be tested.

♦ Glass thermometer accurate to ±1°C.

♦ Cup of warm water (Ambient to 40 °C).

♦ Heater wire if using humidifier in heater wire mode.

6.4.2 TEST PROCEDURE

1 Plug the dual probe plug into the Humidifier, if in Heater Wire mode ensure a heater wire assembly is

connected.

2 Turn on the mains power.

3 Insert both temperature probes into a container filled with water at a temperature between ambient and 40 °C.

As temperature gradients can be quite large it is recommended that the two probes be held together with a

rubber band during this test and the water constantly stirred.

4 Place the thermometer in the water alongside the probes and allow two minutes for the temperatures to

stabilise. It is recommended that the water be constantly stirred during this test.

5 Enter the Engineering menu (refer Appendix A2) and select ‘CP’ (compare probes) option. The display will

alternate between the airway and chamber temperatures (chamber temperature is displayed with all decimal

points turned on).

6 Check the temperature difference between chamber and airway probes as indicated by the display, it should not

exceed 1.5 °C.

7 Ensure that the temperature reading of the chamber and airway probes are both within 1.5 °C of the

thermometer reading.

Ref. 185040646 MR730/720/700/480 Technical Manual ¯ Revision F ¯ Issued March 2001

17

7.0 SERVICING INFORMATION _____________________________________

7.1 INTRODUCTION

This section provides information for servicing the MR730/720/700/480 Humidifier. The electronic circuitry is contained

on two separate circuit boards, the power board and control board.

Please note the following:

• Follow ESD precautions when handling circuit boards.

• After replacing or modifying a circuit board, go through the calibration and performance tests outlined in § 5

and 6.

• After any repair involving opening of the humidifier, go through the electrical safety tests outlined in Appendix

B2.

• When replacing any screws, refer to torque settings in § 7.6.

7.2 PRINTED CIRCUIT BOARD REMOVAL

7.2.1 CONTROL PCB

The front panel and heaterplate assembly is separated from the humidifier body by removing the 4 fixing screws from the

rear of the humidifier body. The front panel assembly can now be moved aside and the two ribbon cable connectors (J1

and J2) disconnected from the rear of the control board. If the front panel is now positioned face down the three plastic

retaining latches protruding through the board can be moved in the appropriate direction to release the board. This is

facilitated if a slight upward finger pressure is maintained on either edge of the board, when the latches release, the

board will pop up leaving the push on control knobs behind in the front panel.

7.2.2 POWER PCB

Separate the case front from the humidifier body and disconnect the two ribbon cable connectors joining the Power PCB

and Control PCB (J1 and J2). Cut the cable tie holding the heaterplate and chassis wires together.

The power board and heat sink assembly can now be removed by flexing the case sides away from the top edge of the

board and moving the board forward slightly to disengage from the case. The board should now be lifted slightly to

clear the lower retaining guides and moved further forward to gain access to the various wiring harness connectors

which can now be detached. Before removing the PCB, unscrew the mains cord connections and cut the cable tie

holding the mains cord in place.

7.3 COMPATABILITY

7.3.1 HARDWARE COMPATABILITY

• If a revision D or earlier power or control PCB needs to be replaced, then both PCBs need to be upgraded together

to ensure correct performance. Revision F and later PCBs can be replaced individually.