Fisher&Paykel IW900 Technical manual

IW900 SERIES WARMER

AND ACCESSORIES

TECHNICAL MANUAL

IW910 Baby Control Mobile Infant Warmer

IW920 Manual Control Mobile Infant Warmer

IW930 Series Baby Control CosyCot™ Infant Warmer

IW950 Series Manual Control CosyCot™ Infant Warmer

IW960 Baby Control Wall Mount CosyCot™ Infant Warmer

IW970 Manual Control Wall Mount CosyCot™ Infant Warmer

IW980 Baby Control Wall Mount Infant Warmer

IW990 Manual Control Wall Mount Infant Warmer

IW900 Series Infant Warmer Accessories

Copyright © 2006 Fisher & Paykel Healthcare Ltd,

Auckland, New Zealand.

Contact Name Address Telephone & Fax

Equipment

Supplier

International

United States

Fisher & Paykel Healthcare Ltd

15 Maurice Paykel Place, East Tamaki,

Auckland 1701

P O Box 14 348, Panmure, Auckland 1134

New Zealand

Fisher & Paykel Healthcare Inc

22982 Alcalde Drive

Suite 101

Laguna Hills

Tel: +64 9 574 0100

Fax: +64 9 574 0158

Website:

Sales info:

Investor info:

www.fphcare.com

info@fphcare.co.nz

investor@fphcare.co.nz

Tel: 1800 446 3908 or

+1 949 470 3900

Fax: +1 949 470 3933

Email:

information@fphcare.com

CA 92653

USA

Australia

Fisher & Paykel Healthcare Pty ltd

36-40 New Street

P O Box 167, Ringwood

Tel: +61 3 9879 5022

Fax: +61 3 9879 5232

Email:

info@fphcare.com.au

Melbourne, Victoria 3134

Australia

China

Fisher & Paykel Healthcare Ltd

Guangzhou Representative Office

Rm. 2203, 22/F Yi An Plaza

Tel: +86 (20) 8363 4286

Fax: +86 (20) 8363 3595

Email:

info@fphcare.cn

33 Jianshe Liuma Lu

Guangzhou 510060

China

France/Benelux

Fisher & Paykel Healthcare SAS

10, avenue du Québec – Bâtiment F5

Silic 512 – Villebon-s/Yvette

Tel: +33 (0)1 64 46 52 01

Fax: +33 (0)1 64 46 52 21

Email:

info@fphcare.fr

91946 Courtaboeuf Cedex

France

Germany/Austria

Fisher & Paykel Healthcare GmbH & Co KG

Hundsberger Straβe 45

73642 Welzheim

Postfach 1103

73636 Welzheim

Germany

Tel: +49 7182 93777 0

Fax: +49 7182 93777 99

Email:

info@fphcare.de

Austria: (Freephone from within Austria)

Tel: 0800 29 31 23

Fax: 0800 29 31 22

India

Fisher & Paykel Healthcare Ltd

th

94/I, 8

1

cross, 13th Main

st

Stage, Rajmahal Villas Extension

Bangalore-560080

Tel: +91 80 5123 6041

+91 80 5123 6042

+91 80 5123 6043

Fax: +91 80 5123 6044

India

Japan

Fisher & Paykel Healthcare KK

Libera Kayaba-cho Bldg. 5th Floor

Tel: +81 (3) 3661 7205

Fax: +81 (3) 3661 7206

3-8-10 Nihonbashi Kayaba-cho

Chuo-ku, Tokyo 103-0025

Japan

United Kingdom

/Ireland

Fisher & Paykel Healthcare Ltd

Unit 16, Cordwallis Park

Clivemont Road

Maidenhead

Berkshire SL6 7BU

United Kingdom

Tel: +44 1628 626 136

Fax: +44 1628 626 146

Email:

info@fphcare.co.uk

Ireland:

Republic of Ireland: 1800 409 011

Northern Ireland: 0800 132 189

Warmer Technical Manual

PART NUMBER :

ISSUE DATE :

ISSUE NUMBER :

PAGE :

185 041 130

October 2006

G

2

Please Read

All maintenance should be undertaken by qualified service personnel.

Fisher & Paykel Healthcare has a policy of continued product improvement and reserves the

right to alter specifications without notice. This manual covers IW900 Series Infant Warmers

and accessories with controller software version up to and including 3.00 and controller

printed circuit board revisions up to and including Rev A.

Warranty

Subject to any agreement to the contrary, the product described in this manual is warranted

against defects in materials and workmanship for one year from the date of shipment.

However, the warranty is void if the product is damaged as a result of mishandling, accident

or misuse. In no event shall the manufacturer be liable for incidental or consequential

damages (eg. loss of use) resulting from breach of warranty. All other expressed and implied

warranties under law is excluded to the extent that it can be lawfully excluded.

Warmer Technical Manual

PART NUMBER :

ISSUE DATE :

ISSUE NUMBER :

PAGE :

185 041 130

October 2006

G

3

CONTENTS

PART 1: DEFINITIONS ................................................................................................................................... 6

PART 2: OPERATION AND GENERAL INFORMATION .............................................................................. 7

2.1 PRODUCT OVERVIEW.................................................................................................................................. 7

2.2 HEATER POWER CONTROL.......................................................................................................................... 8

2.3 CONTROL PANEL ........................................................................................................................................ 9

2.4 ALARMS ................................................................................................................................................... 10

2.5 INFORMATION MODE ................................................................................................................................. 11

2.6 ERROR CODES ......................................................................................................................................... 12

2.7 SPECIFICATION FOR IW910 AND IW920 MOBILE INFANT WARMERS ............................................................ 13

2.8 SPECIFICATION FOR IW93X AND IW95X COSYCOT™ INFANT WARMERS ..................................................... 15

SPECIFICATION FOR IW960 AND IW970 WALL MOUNT COSYCOT™ INFANT WARMERS.......................................... 16

2.9 SPECIFICATION FOR IW980 AND IW990 WALL MOUNT INFANT WARMERS ................................................... 17

2.10 ENVIRONMENTAL SPECIFICATIONS ......................................................................................................... 18

2.11 EQUIPMENT CLASSIFICATIONS ............................................................................................................... 18

2.12 STANDARDS AND APPROVALS ................................................................................................................ 18

PART 3: MAINTENANCE AND SERVICING................................................................................................ 20

3.1 MAINTENANCE SCHEDULE ......................................................................................................................... 20

3.2 SAFETY CHECK ........................................................................................................................................ 20

3.3 SYSTEM CHECK ........................................................................................................................................ 21

3.4 FUNCTIONAL CHECK ................................................................................................................................. 22

3.5 SERVICE PROCEDURES- REPLACEMENT .................................................................................................... 24

3.6 SERVICE PROCEDURES – ADJUSTMENT ..................................................................................................... 27

3.7 RECOMMENDED MAINTENANCE CHECKLIST................................................................................................ 30

PART 4: CLEANING – BEFORE YOU BEGIN............................................................................................. 31

4.1 GENERAL CLEANING ................................................................................................................................. 31

PART 5: IW900 SERIES ELECTRONICS..................................................................................................... 33

5.1 TROUBLESHOOTING FLOW CHART ............................................................................................................. 33

5.2 CIRCUIT OVERVIEW .................................................................................................................................. 34

5.3 CIRCUIT DESCRIPTION .............................................................................................................................. 35

5.4 PCB COMPONENT LOCATIONS .................................................................................................................. 37

5.5 CIRCUIT SCHEMATICS ............................................................................................................................... 40

5.5 CIRCUIT SCHEMATICS, CONTINUED. ........................................................................................................... 47

PART 6: HEAD AND COLUMN.................................................................................................................... 48

6.1 HEAD ASSEMBLY ...................................................................................................................................... 48

6.2 IW900 CONTROLLER ASSEMBLY ............................................................................................................... 51

6.3 IW910/920 MOBILE COLUMN ASSEMBLY ................................................................................................... 53

6.4 IW93X/95X COSYCOT™ COLUMN ASSEMBLY............................................................................................ 56

6.5 IW960/970 WALLMOUNT COSYCOT™ COLUMN ASSEMBLY........................................................................ 63

6.6 IW980/990 WALL MOUNT COLUMN ASSEMBLY .......................................................................................... 65

PART 7: COSYCOT™ BASSINET ............................................................................................................... 67

7.1 BASSINET CHANGE HISTORY ..................................................................................................................... 67

7.2 SIDE PANEL CHANGE HISTORY.................................................................................................................. 68

7.3 BASSINET (3.1) ASSEMBLY (IW93X, IW95X, IW960 & IW970)................................................................... 69

7.4 BASSINET (3) ASSEMBLY (IW93X, IW95X, IW960 & IW970)...................................................................... 71

7.5 BASSINET (2.5) ASSEMBLY (IW93X, IW95X, IW960 & IW970)................................................................... 73

7.6 BASSINET (2.1) ASSEMBLY (IW93X, IW95X).............................................................................................. 75

7.7 BASSINET (2.0) ASSEMBLY (IW93X, IW95X, IW960 & IW970)................................................................... 77

7.8 BASSINET (1.0) ASSEMBLY (IW93X, IW95X, IW960 & IW970)................................................................... 79

7.9 BASSINET SIDE PANEL ASSEMBLY (IW93X, IW95X, IW960 & IW970) ........................................................ 81

7.10 043042190 BASSINET TRANSPORT HANDLE ASSEMBLY ......................................................................... 94

7.11 BASSINET ARMS AND BRAKE ASSEMBLY................................................................................................. 95

7.12 BASSINET TILT LINK ASSEMBLY ............................................................................................................. 97

Warmer Technical Manual

PART NUMBER :

ISSUE DATE :

ISSUE NUMBER :

PAGE :

185 041 130

October 2006

G

4

PART 8: IW93X/95X COSYCOT™ BASE ASSEMBLY................................................................................98

PART 9: GAS ACCESSORIES....................................................................................................................101

9.2 GAS ACCESSORY SERVICE INFORMATION .................................................................................................103

9.3 498040139 OXYGEN PRESET REGULATOR PARTS LIST ............................................................................105

9.4 900IW101/103/105 OXYGEN GAS SUPPLY MODULES ..............................................................................106

9.5 900IW102/104/106 OXYGEN/AIR GAS SUPPLY MODULES........................................................................110

9.6 900IW110/111/112/113 FLOWMETER MODULES .....................................................................................115

9.7 900IW115/116/117/117G/118/118Y SINGLE FLOWMETERS....................................................................117

9.8 900IW14X GAS CYLINDER BLOCKS (DISCONTINUED FROM 1

ST

MARCH 1999) ...........................................120

9.9 900IW15X GAS ACCESSORY BLOCKS......................................................................................................121

9.10 900IW16X LOW PRESSURE GAS MODULES..........................................................................................124

9.11 900IW171 OXYGEN REGULATOR .........................................................................................................128

9.12 900IW181 SUCTION BLOCK DISS........................................................................................................129

9.13 ASSOCIATED GAS ACCESSORIES ..........................................................................................................130

PART 10: GENERAL ACCESSORIES..........................................................................................................134

10.1 900IW001 DUOSENSE™ SKIN SENSOR ...............................................................................................134

10.2 900IW204/205 X-RAY TRAY ASSEMBLY (IW93X, IW95X, IW960 & IW970)..........................................136

10.3 900IW215 SCALES MOUNTING KIT.......................................................................................................140

10.4 900IW301 SHORT MOUNTING POLE.....................................................................................................141

10.5 900IW302 LONG MOUNTING POLE.......................................................................................................142

10.6 900IW303 SHELF / MEDELA PHOTOTHERAPY MOUNTING BLOCK ...........................................................143

10.7 900IW305 HOOK CABLE / HOSE IW2G ................................................................................................144

10.8 900IW306 ACCESSORY HOOK IW2G...................................................................................................145

10.9 900IW313 IV QUAD HOOK POLE –BENT.................................................................................................146

10.10 900IW314 NATUS PHOTOTHERAPY MOUNTING BRACKET .......................................................................147

10.11 900IW312A/J UPS MOUNTING KIT FOR COSYCOT™ INFANT WARMERS ...............................................148

10.12 900IW401 SIDE SHELF AND SUPPORT BLOCK ......................................................................................152

10.13 900IW408 STORAGE DRAWER SYSTEM ...............................................................................................153

10.14 900IW403/5 STORAGE BINS WITH 900IW308 BIN MOUNTING POLE ......................................................154

PART 11: 900IW130X NEOPUFF MODULE ..............................................................................................155

11.1 PERFORMANCE CHARACTERISTICS AND SPECIFICATIONS .......................................................................155

11.2 CLEANING OF THE NEOPUFF™ INFANT RESUSCITATOR ..........................................................................156

11.3 SERVICE INFORMATION ........................................................................................................................157

11.4 900IW130X NEOPUFF MODULE ASSEMBLY - VERSION 2.....................................................................160

11.5 900IW130X NEOPUFF MODULE ASSEMBLY - VERSION 1 (BEFORE MAY 1999) ....................................162

PART 12: MEDELA PHOTOTHERAPY–900IW501XX/900IW502XX...........................................................164

12.1 PHOTOTHERAPY PERFORMANCE CHARACTERISTICS AND SPECIFICATIONS..............................................164

PHOTOTHERAPY SERVICE INFORMATION .............................................................................................................166

12.2 900IW501XX PHOTOTHERAPY LAMP ....................................................................................................170

12.3 900IW502AX PHOTOTHERAPY POWER MODULE – 230V .......................................................................174

PART 13: WARMER IDENTIFICATION ........................................................................................................178

13.1 INFANT WARMER SERIAL NUMBER EXPLANATION ..................................................................................178

Warmer Technical Manual

PART NUMBER :

ISSUE DATE :

ISSUE NUMBER :

PAGE :

185 041 130

October 2006

G

5

PART 1: Definitions

Attention:

Consult Accompanying Documents

Caution: Electric Shock Hazard

Protective Earth

Alternating Current

Functional Earth

Mute (alarm silence)

Light

Power On

(connect to the mains power supply)

Power Off

(disconnect from the mains power supply)

Power On (only for part of equipment)

25%

25% power level

(Prewarm or Standby Mode)

Baby Mode (Servo mode)

Manual Model

Check Baby

High Temperature Alarm

Low Temperature Alarm

Sensor Disconnect

Power Disconnect

Temperature Sensor

Sensor Temperature ºC

Power Off (only for part of equipment)

Cover the baby’s eyes while phototherapy light

is on.

Wrong and correct positioning of Phototherapy

Lamp head in path of Infant Warmer radiation

Contact your local distributor to recycle waste

electronic goods responsibly

Caution: ESD sensitive

Warning Statement

WARNING

A WARNING statement refers to the conditions when the possibility of

injury to the patient or user exists if a procedure is not followed

correctly.

Caution Statement CAUTION

Type B Equipment

Type BF Applied Part

Timer

Portable and mobile RF

communications equipment

can effect MEDICAL

ELECTRICAL EQUIPMENT

A Caution statement indicates the possibility of damage to the

equipment exists if a procedure is not followed correctly.

Note Statement NOTE:

A Note statement provides additional information intended to clarify

points, procedures or instructions.

Warmer Technical Manual

PART NUMBER :

ISSUE DATE :

ISSUE NUMBER :

PAGE :

185 041 130

October 2006

G

6

PART 2: Operation and General Information

2.1 Product Overview

INTRODUCTION The Fisher & Paykel range of radiant warmers are specifically

designed to provide a controlled source of warmth to Neonates.

MODELS The IW910 Baby Control and IW920 Manual Control Mobile Infant

Warmers provide truly mobile and height adjustable warming

wherever needed.

The IW930 Series Baby Control and IW950 Series Manual Control

CosyCot™ Infant Warmers combines an integrated bassinet with four

base accessory options:

IW931 Standard Size Bassinet & Mattress – Preset Base

IW932 Standard Size Bassinet & Mattress – Electric Elevator Base

IW933 Long Bassinet & Mattress – Preset Base

IW934 Long Bassinet & Mattress – Electric Elevator Base

IW951 Standard Size Bassinet & Mattress – Preset Base

IW952 Standard Size Bassinet & Mattress – Electric Elevator Base

IW953 Long Bassinet & Mattress – Preset Base

IW954 Long Bassinet & Mattress – Electric Elevator Base

To these base models optional accessories can be added to suit

you own particular warming needs

The IW960 Baby Control and IW970 Manual Control Wall Mount

CosyCot™ Infant Warmers combine the integrated CosyCot™

bassinet with the benefits of wall mounting.

The IW980 Baby Control and IW990 Manual Control Wall Mount

Infant Warmers provide discrete and convenient space saving

warming.

HEAT CONTROL In Baby Mode (IW910, IW93x, IW960 & IW980 only), the infant

warmers provide stable control of the baby's skin temperature by

automatically adjusting the heater power to compensate for varying

physiological and environmental conditions. This is achieved using a

microprocessor which measures and updates the baby’s temperature

ten times every second.

In Manual Mode, all infant warmers provide user-adjustable heater

power and the option to monitor the baby’s skin temperature using the

DuoSense™ skin sensor.

In Prewarm Mode all models provide alarm and trouble-free pre-

warming of the heater.

DUOSENSE™ SKIN SENSOR Safety is further enhanced by DuoSense™ skin sensor. This sensor

measures the desired skin temperature using two independent

sensors. These sensors are continuously compared to ensure

accurate and reliable skin temperature measurements.

OPERATING MANUAL This technical manual is intended to be used in conjunction with the

900 Series Operating Manual (see part numbers below) and

Installation and Assembly Instruction Sheets. The operating manuals

must be read thoroughly and all instructions, warnings, cautions and

notes thoroughly understood by all personnel working with warmers

prior to use.

185043372 English/French/Spanish

185043373 German/Swedish/Norwegian

185043374 French/Dutch/Italian/Spanish/Portuguese

Warmer Technical Manual

PART NUMBER :

ISSUE DATE :

ISSUE NUMBER :

PAGE :

185 041 130

October 2006

G

7

2.2 Heater Power Control

2.2.1 Modes of Power Control

PREWARM MODE Power is fixed at 25% (total irradiance at 68 cm < 10 mW/cm

MANUAL MODE Power is adjustable in the range 0% to 100% in 5% steps.

BABY/SERVO MODE Power is automatically controlled according to the measured skin

2.2.2 Description of Power Control

POWER COMPENSATION The actual mains power delivered to the element is not equal to the

In all power delivery modes the amount of mains power delivered to

2

). This

is sufficiently low that minimal alarms need to be active but

sufficiently high that the heating element will keep warm and be

ready for immediate use.

temperature to achieve the desired set temperature. The set

temperature is adjustable from 34.5°C to 37.5°C in 0.1°C steps.

power displayed on the front panel of the controller, as the device is

continually monitoring the mains voltage level and compensating for

any slumps and surges that may occur.

the element is calculated as shown below.

P

PP

DisplayedDelivered

Ceiling

100

2

V

%5.7

2

V

Where:

Displayed

P

Ceiling

V

75%.

is the displayed power level (Power Display).

is the power ceiling (currently 100% for all models).

is the nominal line voltage less 7.5% (e.g. 213V for 230V

P

device).

V

is the current line voltage.

P

Delivered

is the actual amount of mains power delivered to the

element. Actual power delivered should be constant for constant

power displayed.

RESOLUTION AND DUTY CYCLE Power to the element is controlled with a triac and switched only on

mains zero crossings to maximise electromagnetic compatibility.

When in Baby Mode, the power is controlled to a resolution of 1%.

Power is delivered in an optimally smooth pattern of mains pulses

which repeats every 2 seconds at 50 Hz (1.7 seconds at 60 Hz).

This even power control helps to reduce ripple in the baby or

patients skin temperature. The power level is automatically adjusted

ten times every second.

Warmer Technical Manual

PART NUMBER :

ISSUE DATE :

ISSUE NUMBER :

PAGE :

185 041 130

October 2006

G

8

2.3 Control Panel

2.3.1 All Infant Warmer Models

LIGHT INDICATOR AND BUTTON The Light Button toggles the examination light off and on. The Light

PREWARM INDICATOR AND BUTTON The Prewarm Button begins Prewarm Mode. The Prewarm Indicator

MANUAL INDICATOR AND BUTTON The Manual Button begins Manual Mode. The Manual Indicator will

APGAR INDICATOR AND BUTTON The Apgar Button starts an Apgar timer with Apgar tones at 1 min, 3

TIMER DISPLAY Displays the current time of the Apgar timer, timer 1 and timer 2

BABY SKIN TEMPERATURE DISPLAY Displays the current baby skin temperature when a skin sensor is

Indicator is lit when the light is on and extinguished when the light is

off. If the light fails during use a short tone will sound and the light

indicator will extinguish. If the light is turned on with a faulty bulb,

the indicator will turn on, there will be a short tone and the indicator

will extinguish.

will be lit if the button is pushed.

be lit if the button is pushed.

min (optional), 5 min, and 10 min. The indicator lights while the

Apgar timer is active to help distinguish it from a count down timer.

The Apgar timer will blank at 60 minutes. Re-pressing the button will

clear the timer.

when they are active. Also used by Information Mode.

inserted in Manual Mode or Baby Mode. Displays 'HI' if the

temperature exceeds 50°C. Displays '---' in the event of a sensor

disconnect alarm. Blanks when in Prewarm Mode or when no skin

sensor is inserted in manual mode.

POWER DISPLAY Displays the current output power level in the range 0% to 100% in

5% steps.

CONTROL KNOB Adjusts set temperature in Baby Mode and set power level in

Manual Mode. Adjusts preset start times when either the Timer 1

Button or the Timer 2 Button is held down (IW910, IW93x, IW960 &

IW980 only). Also used in Information Mode (see Section

2.3.2 IW910, IW93x, IW960 and IW980 Servo Control Models

BABY INDICATOR AND BUTTON The Baby Button begins Baby Mode. The Baby Indicator will be lit if

the button is pushed.

TIMER1 BUTTON Starts Timer 1 at the preset start time. Holding the button down

allows the Timer 1 preset start time to be adjusted with the control

knob. Re-pressing the button will clear the timer.

TIMER2 BUTTON Starts Timer 2 at the preset start time. Holding the button down

allows the Timer 2 preset start time to be adjusted with the control

knob. Re-pressing the button will clear the timer.

MUTE BUTTON Inactive unless one of the following alarms is active: Sensor

Disconnect alarm, High Temperature alarm, Low Temperature alarm

and Check Baby alarm. In each case pressing the Mute Button

silences the audible alarm (for 10 minutes) and in the case of the

Check Baby alarm it cancels the visual alarm as well (for another 15

minutes).

2.5).

SET TEMPERATURE DISPLAY Displays the current set temperature when in Baby Mode. Blanks in

Prewarm Mode or Manual Mode. Also used by Information Mode.

Warmer Technical Manual

PART NUMBER :

ISSUE DATE :

ISSUE NUMBER :

PAGE :

185 041 130

October 2006

G

9

2.4 Alarms

2.4.1 IW910, IW93x, IW960 and IW980 Servo Control Models

CHECK BABY ALARM In Baby Mode this alarm means the output power has been at 100%

for at least 15 minutes indicating that the baby is slow rising to the

set temperature and should be checked. In Manual Mode this alarm

means the output power has been above 25% for at least 15

minutes indicating that the baby should be checked.

HIGH SKIN TEMP. ALARM In Baby Mode this alarm means the baby skin temperature exceeds

the set temperature by at least 1.0°C. In Prewarm Mode or Manual

Mode this alarm means the baby skin temperature exceeds 39°C.

LOW SKIN TEMP. ALARM In Baby Mode this alarm means the set temperature exceeds the

baby skin temperature by at least 1.0°C. This alarm is not active in

Prewarm Mode and Manual Mode. This alarm is disabled for 15

minutes each time baby mode is started and re-enabled each time

the skin temperature gets within 0.5°C of set temperature.

SENSOR DISCONNECT ALARM In Baby Mode this alarm means a problem has been detected with

the skin temperature sensor. This may mean: (a) If '---' is flashing

on the Baby Skin Temperature Display the sensor plug is not

inserted fully into the socket, and/or (b) that one of the thermistor

beads within the DuoSense™ skin sensor does not agree with the

other so that the sensor can no longer be considered accurate. A

bead mismatch alarm occurs within 25 seconds of the sensor being

plugged in. Both meanings apply in Baby Mode, meaning (b) only

applies in Manual Mode and neither apply in Prewarm Mode.

2.4.2 IW920, IW95x, IW970 and IW990 Manual Control Models

CHECK BABY ALARM This alarm has three meanings:

(a) Manual Mode 15 Minutes

The infant warmer has been running in Manual Mode at over 25%

power for more than 15 minutes. The baby should be checked.

(b) Skin Temperature > 39°C

This alarm is accompanied by a flashing Baby Skin Temperature

Display (which is > 39°C). The baby should be checked.

(c) Skin Sensor Faulty

The DuoSense™ skin sensor feature of the infant warmer has

detected a fault with the skin sensor. This alarm is accompanied by

a flashing Baby Skin Temperature Display. Ensure that the skin

sensor is fully plugged in. If skin sensor is faulty then discard it.

2.4.3 All Models

SEE MANUAL ALARM If the LED is flashing then the software has detected a hazard, has

shut down the heater and entered this alarm state. If the warmer is

able to power up again an error code corresponding to the meaning

of the alarm can be obtained with use of the Information Mode (the

error code is preserved in non-volatile memory).

If the LED is on constantly and is accompanied by a rapidly pulsing

two-tone alarm then the hardware watchdog circuit has detected a

micro-controller failure.

If the LED is on constantly and is accompanied by a constant tone

then the overheat protector in the heater has tripped.

POWER FAIL ALARM When this alarm is flashing the power to the warmer has failed.

NOTE: that this may mean the power switch (located on the front

panel) is on while the power at the supply wall outlet is switched off.

Warmer Technical Manual

PART NUMBER :

ISSUE DATE :

ISSUE NUMBER :

PAGE :

185 041 130

October 2006

G

10

2.5 Information Mode

Information Mode allows additional information about the warmer to be obtained by the front panel

controls and displays. Information mode is intended for use by technical personnel only and should not

be used while the warmer is in use. Information mode is used for calibration and diagnostics.

ENTERING INFORMATION MODE Depress one of the power mode buttons (Prewarm, Manual or Baby)

NOTE: If the option is enabled which requires the Baby Button to be

EXITING INFORMATION MODE Press one of the power mode buttons (Prewarm, Manual or Baby).

USE OF INFORMATION MODE The Set Temperature Display shows the engineering information

AVAILABLE INFORMATION EIN Meaning of the Timer Display

0 Device configuration (see below for a list of configurations).

1 ROM software version x100 (e.g. 0230 is version 2.30).

2 Present power level (%) in 1% steps.

3 Patient temperature x100 (e.g. 3670 is 36.70°C).

NOTE: 0401 is displayed when the skin sensor is disconnected.

4 Over Temperature reference calibration x100 (e.g. 3950 is

5 Line voltage as a % of the unit’s nominal voltage.

6 Preset options (see below for a list of the options).

7 Error code for last flashing See Manual alarm (see section 2.4

and hold it down. Rotate the control knob in any direction for two

complete revolutions. Continue rotating the control knob slowly in

the same direction, the mode indicator light will extinguish at one

point. If this point is passed the indicator will come back on, rotate

the knob back until the point where the indicator is extinguished is

reached. Then release the button.

held down to change Set Temperature then the Baby Button can not

be used to enter information mode.

number (EIN) which indicates what information is being displayed.

The control knob adjusts the Engineering Information Number (EIN).

The Timer Display shows the selected item of information.

39.50°C).

for a list of the possible error codes).

CONFIGURATION NUMBERS EIN #0 shows the device configuration. The possible configurations

are:

Num. Model

0 Used for manufacture only.

1 IW910, IW93x, IW960 or IW980 Baby Control Infant Warmers.

2 IW920, IW95x, IW970 or IW990 Manual Control Infant

Warmers.

3 PW810 Servo Control Patient Warmers

4 PW820 Servo Control Surgical Warmers

PRESET OPTIONS EIN #6 shows which preset options are enabled using one digit of

the Timer Display per option (1 means enabled and 0 means

disabled). The four digits A, B, C and D, from left to right, have the

following meanings:

Digit Option

A Must hold down the Baby Button to change Set Temperature.

B Full volume alarms.

C 3 minute Apgar tone.

D 15 minute Manual Mode alarm.

NOTE: The options are preset to distributor requirements during

manufacture. Options A, B and C may be altered at a later date with

use of a PC and software available from your distributor. Option D

may not be altered as it is a requirement of the IEC60601-2-21

Infant Warmer standard.

Warmer Technical Manual

PART NUMBER :

ISSUE DATE :

ISSUE NUMBER :

PAGE :

185 041 130

October 2006

G

11

2.6 Error Codes

EIN #7 shows the error code corresponding to the last See Manual alarm. This value is kept in nonvolatile memory and is updated every time a new error code occurs.

NOTE: Error codes are retained indefinitely and may only change when a new error occurs.

See section

The possible error codes are:

2.5 for access to Information Mode.

Code Name Meaning

0

1-2

5

NONE

TEMPERATURE

MUX

BEADS SHORTED

No error has occurred.

Temperature multiplexer is not responding

correctly. Temperature cannot be measured.

The two thermistor beads in the DuoSense™

skin sensor are detected to have shorted

together. The skin sensor should be checked.

Using Figure 10.1.2, check that contact A is

not shorted to contact B. If the skin sensor is

operating correctly, then there may be a short

Actions to be taken

Contact distributor.

Check DuoSense™

skin sensor

operating correctly.

If the skin sensor is

operating correctly,

contact distrubitor.

circuit within the unit itself.

7

11

13

14

STACK OVERFLOW

BUTTON MUX

BAD FREQUENCY

FAILED ADC

The microprocessor stack has overflowed

indicating microprocessor or memory failure.

Button multiplexer is not responding correctly.

Buttons cannot be sensed.

Bad Frequency (the device could not sense

the frequency of the mains power supply at

power up).

One of the regular series of ADC conversions

Contact distributor.

Contact distributor.

Change mains wall

power outlet. If

error still detected,

contact distrubitor.

Contact distributor.

failed to complete in the normal time. This

suggests that the internal hardware on the

microcontroller has failed and the temperature

readings along with other readings can no

15

LED TOGGLE

longer be relied on.

Bad LED Toggle (the display driver, U1, which

Contact distributor.

drives the LEDs and displays and scans the

16

17

BUFFER

OVERFLOW

MISSING PULSES

buttons was detected to be faulty).

Serial Buffer Overflow (the RS232 output

serial communications buffer was detected to

have overflowed).

Missing Triac Firing (the triac which controls

power to the element was sensed as

delivering insufficient/uncontrolled power to

the element).

NOTE: This error may mean the one of the

Contact distributor.

Change mains wall

power outlet. If

error still detected,

contact distrubitor.

backup hardware circuits has independently

detected a fault and disconnected power from

18

19

SPURIOUS PULSES

RELAY OUT

the element.

Spurious Triac Firing (the triac which controls

power to the element was sensed as

delivering additional/uncontrolled power to the

element).

Relay Out (the relay which isolates the

Change mains wall

power outlet. If

error still detected,

contact distrubitor.

Contact distributor.

element in the event of continuous full power

to the element or hardware watchdog failure is

detected to have opened).

Warmer Technical Manual

PART NUMBER :

ISSUE DATE :

ISSUE NUMBER :

PAGE :

185 041 130

October 2006

G

12

20-28

30

31

34

35

36

EEPROM ERROR

NOT CONFIGURED

STUCK BUTTON

LIGHT CIRCUIT

FAULTY

TEMPERATURE

PROBLEM

DEVICE UNTESTED

Non-volatile memory error (a problem was

detected with the non-volatile memory - most

of these errors can be recovered from by

switching the device off then on again).

A device configuration is not selected. The

device is configured during manufacture and

cannot run if a particular model variant has not

been set.

One of the buttons is stuck down. This can be

caused by holding one of the buttons down

while the device is turned on.

The light has been detected as turned on

when it should be turned off. There is either a

fault in the light control circuitry or the light

sense circuitry.

Measurement from the temperature

references are so far out of tolerance that

auto-calibration of the skin sensor

temperatures is impossible. It is likely that the

temperature circuit is faulty.

Contact distributor.

Turn mains power

switch off. Turn

warmer on again. If

error code is still

present, contact

distributor.

Contact distributor.

Turn mains power

switch off. Turn

warmer on again,

without touching

control panel. If

error code is still

present, contact

distributor.

Contact distributor.

Contact distributor.

Contact distributor.

2.7 Specification for IW910 and IW920 Mobile Infant Warmers

2.7.1 Electrical Specifications

SUPPLY VOLTAGE AND CURRENT 230 V~ ± 20 V~ 2.2 A~ maximum

120 V~ 4.2 A~ maximum

100 V~ ± 10 V~ 5.1 A~ maximum

SUPPLY FREQUENCY 50/60 Hz

NOMINAL POWER CONSUMPTION 230 V~ model 510 W

120 V~ model 510 W

100 V~ model 510 W

HEATER POWER 450 W

Mattress irradiance is 32 mW/cm² at 100% heater power and 68 cm (26.8”) heater grill

LIGHT POWER

Maximum intensity is 400 lux at 68cm (26.8”) heater grill to mattress distance

TEMPERATURE RANGE

TEMPERATURE MEASUREMENT

Sensor accuracy of ± 0.1°C

Skin temperature control resolution of 0.01°C

to mattress distance

20 W

Set temperature from 34.5°C to 37.5°C in 0.1°C steps

Displayed range of 4.0°C to 50.0°C in 0.1°C steps

TEMPERATURE SENSOR Twin YSI 400 compatible thermistors with 100 M insulation at 500V

2.7.2 Mechanical Specifications

HEIGHT Adjustable from 151 cm to 191 cm (59.4" to 75.2")

To suit bassinets from 71 cm to 111 cm (28" to 43.7")

Warmer Technical Manual

between all electrical contacts and the skin surface

PART NUMBER :

ISSUE DATE :

ISSUE NUMBER :

PAGE :

185 041 130

October 2006

G

13

WIDTH 65 cm (25.6”)

DEPTH 110 cm (43.3”)

WEIGHT WITHOUT ACCESSORIES 22 kg (48.5 lb)

MAXIMUM LOADING 4 kg (8.8lb) of Accessories, 26 kg (57.3 lb) total weight

HEATER HEAD ROTATION -130º to +130º from centre position

CASTORS 5 x Ø 50 mm (2”), all locking

Warmer Technical Manual

PART NUMBER :

ISSUE DATE :

ISSUE NUMBER :

PAGE :

185 041 130

October 2006

G

14

2.8 Specification for IW93x and IW95x CosyCot™ Infant Warmers

2.8.1 Electrical Specifications

SUPPLY VOLTAGE AND CURRENT Voltage Controller only Including Accessories

120 V~ 4.2 A~ maximum 12 A~ maximum

100 V~ ± 10 V~ 5.1 A~ maximum 12 A~ maximum

SUPPLY FREQUENCY 50/60 Hz

POWER CONSUMPTION Including accessories (max) 230 V~ model 2300 W

120 V~ model 1440 W

100 V~ model 1200 W

Controller and heater only 510 W

230 V~ ± 20 V~ 2.2 A~ maximum 10 A~ maximum

HEATER POWER

Mattress irradiance is 32 mW/cm² at 100% heater power and 68 cm (26.8”) heater grill

LIGHT POWER

Maximum intensity is 400 lux at 68cm (26.8”) heater grill to mattress distance

TEMPERATURE RANGE

TEMPERATURE MEASUREMENT Displayed range of 4.0°C to 50.0°C in 0.1°C steps

Sensor accuracy of ± 0.1°C

Skin temperature control resolution of 0.01°C

TEMPERATURE SENSOR Twin YSI 400 compatible thermistors with 100 M insulation at 500V

AUXILLARY POWER OUTLET 2A max – For medical rated devices only (IEC60601-1)

2.8.2 Mechanical Specifications

HEIGHT Adjustable from 170 cm to 186 cm (66.9” – 73.2”)

With 900IW005x electric elevator module

170.5, 180 or 184 cm (67.1”, 70.9” or 72.4”)

With standard fixed height option

WIDTH

77 cm (30.3”) - Excluding shelves

110 cm to 129 cm (43.3” – 50.8”)

DEPTH

Depends on accessories fitted, bassinet size and bassinet height

WEIGHT WITHOUT ACCESSORIES

450 W

to mattress distance

20 W

Set temperature from 34.5°C to 37.5°C in 0.1°C steps

between all electrical contacts and the skin surface

60.8 kg (134 lb)

If manufactured before February 2004, 54.5 kg (120 lb)

MAXIMUM LOADING

HEATER GRILL TO MATTRESS

HEATER HEAD ROTATION -130º to +130º from centre position - Depends on installation

MATTRESS HEIGHT

With 900IW005x electric elevator option

87.8 cm to 103.6 cm (34.6” – 40.8”)

68cm (26.8”)

54.2 kg (119 lb) of Accessories, 115kg (253lb) total weight

If manufactured before February 2004, 60.5 kg (133 lb) of Accessories

88.4, 97.5 or 101.9 cm (34.8”, 38.4” or 40.1”)

With standard fixed height option

BASSINET SIZE (STANDARD)

Standard Mattress size 62 cm x 62 cm (24.4” x 24.4”)

BASSINET SIZE (LONG – 900IW212)

Long mattress size 62cm x 72cm (24.4” x 28.4”)

BASSINET SIDE PANEL HEIGHT

If manufactured before February 2004 15cm

TILTING POSITIONS -10° to +10° in ½° increments

CASTORS

4 x Ø 100 mm (4”) all locking

65 cm x 65 cm (25.6” x 25.6’)

65cm x 75cm (25.5” x 29.5”)

16.5cm (14cm front & rear) - Measured from the bassinet

If manufactured before February 2004 -10° to +10° continuous adjustment

Warmer Technical Manual

PART NUMBER :

ISSUE DATE :

ISSUE NUMBER :

PAGE :

185 041 130

October 2006

G

15

Specification for IW960 and IW970 Wall Mount CosyCot™ Infant Warmers

2.8.3 Electrical Specifications

SUPPLY VOLTAGE AND CURRENT Voltage Controller only Including Accessories

230 V~ ± 20 V~ 2.2 A~ maximum 10 A~ maximum

120 V~ 4.2 A~ maximum 12 A~ maximum

100 V~ ± 10 V~ 5.1 A~ maximum 12 A~ maximum

SUPPLY FREQUENCY 50/60 Hz

POWER CONSUMPTION Including accessories (max) 230 V~ model 2300 W

120 V~ model 1440 W

100 V~ model 1200 W

Controller and heater only 510 W

HEATER POWER

Mattress irradiance is 32 mW/cm² at 100% heater power and 68 cm (26.8”) heater grill

LIGHT POWER

Maximum intensity is 400 lux at 68cm (26.8”) heater grill to mattress distance

TEMPERATURE RANGE

TEMPERATURE MEASUREMENT

Sensor accuracy of ± 0.1°C

Skin temperature control resolution of 0.01°C

TEMPERATURE SENSOR Twin YSI 400 compatible thermistors with 100 M insulation at 500V

AUXILLARY POWER OUTLET 2A max – For medical rated devices only (IEC60601-1)

2.8.4 Mechanical Specifications

HEIGHT Adjustable from 150 cm (59.0”)

67.5 cm (26.6”)

WIDTH

Excluding shelves

DEPTH 88 -98cm (34.6” - 38.6”)

WEIGHT WITHOUT ACCESSORIES

450 W

to mattress distance

20 W

Set temperature from 34.5°C to 37.5°C in 0.1°C steps

Displayed range of 4.0°C to 50.0°C in 0.1°C steps

between all electrical contacts and the skin surface

40 kg (88 lb)

HEATER GRILL TO MATTRESS 68cm (26.8”)

HEATER HEAD ROTATION -130º to +130º from centre position

Depends on installation

MATTRESS HEIGHT

BASSINET SIZE (STANDARD)

Standard Mattress size 62 cm x 62 cm (24.4” x 24.4”)

BASSINET SIZE (LONG – 900IW212)

Long mattress size 62cm x 72cm (24.4” x 28.4”)

BASSINET SIDE PANEL HEIGHT

TILTING POSITIONS -10° to +10° continuous adjustment

Dependent on installation.

65 cm x 65 cm (25.5” x 25.5’)

65cm x 75cm (25.5” x 29.5”)

15cm - Measured from the bassinet

Warmer Technical Manual

PART NUMBER :

ISSUE DATE :

ISSUE NUMBER :

PAGE :

185 041 130

October 2006

G

16

2.9 Specification for IW980 and IW990 Wall Mount Infant Warmers

2.9.1 Electrical Specifications

SUPPLY VOLTAGE AND CURRENT 230 V~ ± 20 V~ 2.2 A~ maximum

120 V~ 4.2 A~ maximum

100 V~ ± 10 V~ 5.1 A~ maximum

SUPPLY FREQUENCY 50/60 Hz

NOMINAL POWER CONSUMPTION 230 V~ model 510 W

120 V~ model 510 W

100 V~ model 510 W

HEATER POWER 450 W

Mattress irradiance is 32 mW/cm² at 100% heater power and 68 cm (26.8”) heater grill

to mattress distance

LIGHT POWER

Maximum intensity is 400 lux at 68cm (26.8”) heater grill to mattress distance

TEMPERATURE RANGE

TEMPERATURE MEASUREMENT

Sensor accuracy of ± 0.1°C

Skin temperature control resolution of 0.01°C

TEMPERATURE SENSOR Twin YSI 400 compatible thermistors with 100 M insulation at 500V

2.9.2 Mechanical Specifications

HEIGHT 36 cm (14.2”)

20 cm (7.9”)

WIDTH

DEPTH 76 cm (29.9”)

WEIGHT WITHOUT ACCESSORIES 7.4 kg (16.3 lb)

HEATER HEAD ROTATION -130º to +130º from centre position

Depends on installation

20 W

Set temperature from 34.5°C to 37.5°C in 0.1°C steps

Displayed range of 4.0°C to 50.0°C in 0.1°C steps

between all electrical contacts and the skin surface

Warmer Technical Manual

PART NUMBER :

ISSUE DATE :

ISSUE NUMBER :

PAGE :

185 041 130

October 2006

G

17

2.10 Environmental Specifications

OPERATING TRANSPORT STORAGE

TEMPERATURE

HUMIDITY 0% to 90%RH 0% to 90%RH 0% to 90%RH

VIBRATION Normal Nursery Normal Transport

Handling Handling

2.11 Equipment Classifications

Class I, Type B

with Class II, Type BF applied part

Continuous operation

Not classified against ingress of liquids

Not suitable for use in the presence of flammable anaesthetics

2.12 Standards and Approvals

Designed to conform to the requirements of:

IEC 60601-2-21

IEC 60601-1

IEC 60601-1-2

UL 2601-1

AS 3200.1.0

CAN/CSA C22.2 No. 601.1

EN 60601-1

ISO 8382 *

18°C to 30°C -10°C to 60°C -10°C to 60°C

*Neopuff™ Infant Resuscitators only

2.14 Electromagnetic environment

2.15 Material statements

The IW900 series warmer and accessories do not contain patient contacting PVC devices plasticized

with DEHP.

Warmer Technical Manual

PART NUMBER :

ISSUE DATE :

ISSUE NUMBER :

PAGE :

185 041 130

October 2006

G

18

Intentionally Blank

Warmer Technical Manual

PART NUMBER :

ISSUE DATE :

ISSUE NUMBER :

PAGE :

185 041 130

October 2006

G

19

PART 3: Maintenance and Servicing

WARNING

All maintenance should be undertaken by qualified service personnel.

3.1 Maintenance Schedule

Fisher and Paykel Healthcare recommend that the following Safety, Performance and Functional

checks be performed at least annually for all models covered by this manual. It is important to follow

hospital and local regulations if more frequent checks are stipulated.

NOTE: A maintenance check sheet is provided in 3.7.

Equipment

Depending on the extent of the service check and the accessories included on your warmer the

following equipment may be required.

Safety Analyser: IEC60601-1 to class BF

Thermometer: 30 – 40C 0.1C

Pressure Gauge: 0 – 100psi 5% fsd

Pressure Gauge: 0 – 100cm H

Flowmeter: 0 – 15 L/min 5% fsd

Suction gauge: 0 – 200 mm Hg 2.5% fsd

Test Lung: 500RD106

Calibrated Voltmeter

0 2% fsd

2

All electronics are calibrated during manufacture. Regular calibration is not necessary. A check of

calibration is included in the Performance Check.

3.2 Safety Check

WARNING Connect the power cord only to a properly grounded wall receptacle that is approved

for hospital use and of the correct voltage. DO NOT use extension cords or an AC receptacle

box for this device.

The unit should be tested to the current medical electrical standards for in-house testing for

each specific country (example, refer to UL2601-1 for USA, EN60601-1 for Europe, AS/NZS 3551

for Australia and New Zealand). This should be done prior to initial use and at least annually

thereafter.

NOTE: To conduct an earth test, the test lead should be attached to a bolt located under a plastic cap at the top

of the column – refer diagram

NOTE: The Transport Handle is not earthed but is protected in accordance with clause 17a)3) of IEC60601-1.

To verify safety conduct a Patient Leakage Current Test under normal operating conditions. The pass

criterion is less than 0.01 mA DC or 0.1 mA AC.

NOTE: The Medela Phototherapy Unit is double insulated. To verify safety conduct a Patient Leakage Current

Test on the metal arm under normal operating conditions. The pass criterion is less than 0.01 mA DC or

0.1 mA AC.

NOTE: For neoBLUE-mini phototherapy refer to 185043921 service manual

6.2.2 part 5.

Warmer Technical Manual

PART NUMBER :

ISSUE DATE :

ISSUE NUMBER :

PAGE :

185 041 130

October 2006

G

20

3.3 System Check

This procedure is the recommended performance check for Fisher & Paykel Radiant Warmers. A

check of calibration is included.

ALARMS CHECK

POWERFAIL CHECK

STUCK BUTTON

CALIBRATION CHECK

1. Switch the Power Switch on. Check that the increasing pitch start up sound

occurs and that the following alarm indicators, depending on the model,

flash momentarily: Check Baby, High Temperature, Low Temperature, and

Sensor Disconnect depending on model.

2. Unplug the power cord from the wall supply socket. Check that the Power

Fail Indicator flashes and audible alarm sounds.

3. Press and hold Prewarm/Standby Button. Reconnect the power cord to the

wall supply. Check that the warmer starts correctly and that the See Manual

indicator flashes and audible alarm sounds. Release the Prewarm/Standby

Button.

NOTE: This check causes a Stuck Button error to occur which will be logged as

the last error that occurred as accessible via Information Mode.

4. Switch the Power Switch off then on again. Check that the warmer starts up

normally.

5. Enter Information Mode (refer section 2.5) and select EIN #5.

6. Ensure that the light is off. Measure the mains voltage at the wall outlet

supplying the warmer, using a calibrated voltmeter.

7. Calculate and record the measured voltage as a percentage of the devices

nominal supply voltage which will be 100V, 120V or 230V.

8. Check that the top display reads the calculated percentage (± 5%).

9. Select EIN #4.

LIGHT CHECK

POWER MODE CHECK

TIMER MODE CHECK

HEATER CONTROL

TEMPERATURE

MEASUREMENT

10. Check that the top display reads 3950 ± 20 (39.50 ± 0.2°C). Exit

Information Mode.

11. Press the Light Button, check the light turns on. Re-press the Light Button

and check that the light turns off.

12. Press each power mode button (Prewarm, Manual, Baby if applicable) and

check that its respective indicator is lit when the button is pressed.

13. Ensure that the Timer Display is blanked. Press the Apgar Button and

check that the Apgar Indicator is lit and the time display starts counting.

Press the Timer 1 Button and the Timer 2 Button in turn and check that the

corresponding preset time for each appears on the Timer Display and that

the time starts counting down.

14. For all models:

Select Manual Mode and set the output power level to 0% (all segments of

the power bar are extinguished). Wait 1 minute and check that no heat is

being given off by the element. Set the output power level to 100% (all

segments of the power bar are lit).

15. For all models:

Check condition of skin sensor lead and sensor head.

Connect a skin sensor to the infant warmer and immerse the sensor end in

water that is warmed to a temperature in the range 35.0°C to 37.0°C. Use a

calibrated thermometer to check the temperature on the Skin Temperature

Display is accurate to within ± 0.2°C.

To check warmer calibration only - 043042566 check probe may be used,

refer to section

10.1.3

16. Switch the Power Switch off.

Warmer Technical Manual

PART NUMBER :

ISSUE DATE :

ISSUE NUMBER :

PAGE :

185 041 130

October 2006

G

21

3.4 Functional Check

WARMER HEAD

Refer section

MOBILE WARMERS

Refer section

COSYCOTTM BASE

Refer section

ELECTRIC ELEVATOR

(If fitted)

Refer section

BASSINET MOUNTING

ASSEMBLY

If manufactured after February

2004 refer section

If manufactured before February

2004 refer section

TRANSPORT HANDLE

(If fitted) Refer to section

STORAGE DRAWER

(If fitted) Refer section

STORAGE BINS

(If fitted)

Refer section

GAS SUPPLY MANIFOLDS

(If fitted)

GAS HOSES

FLOWMETERS

(If fitted)

SUCTION

(If fitted)

NEOPUFF MODULE

(If fitted)

UPS (UNINTERRUPTIBLE

POWER SUPPLY)

(If fitted)

MEDELA PHOTOTHERAPY

(If fitted)

6.2.2.

6.3.2.

8.1.4

8.1.4

7.10

7.12

7.10

10.13

10.14

1. Ensure the head is secure and that it can rotate smoothly. If required

Head Pivot Nut (1) can be adjusted using a bent wire tool (171042012).

If the central détente is not sufficiently positive, Washer Pivot (3)

should be replaced.

2. Ensure everything is secure, in particular the stabiliser weight bolt (18)

is tight and that the pole (10) is fully engaged into the warmer support

bracket (1) and the stabiliser weight (13).

3. Ensure all four base to column bolts (11) are fully tightened 9-11.5Nm.

Check castors roll and lock.

4. Check operation of up/down buttons (28) and safety interlock rocker

switch (27). Inspect underside of base assembly for any sign of

damage or wear. Grease plastic/metal interface sections. Check arm

pivot actuator for signs of bending, replace using kit 043042714.

Replace retention clips 625060035 as necessary on vacuum formed

base.

5. Ensure that the bassinet pivot bolts (5) and arm mounting bolts (19)

are tight. Check the operation of the tilt mechanism for smooth

movement and no slipping. Adjust actuation cable as outlined in

section

3.6.8 if required.

6. Ensure all four M10 x 30 bolts (5), all four M8 x 50 CSK bolts (4) and all

six M8 grub screws (2).are tight. Check the operation of the tilt

mechanism for smooth movement and no slipping. Adjust actuation

cable as outlined in section

3.6.7 if required.

7. Check operation of handle and release collars (4).

8. Ensure the drawer slides smoothly. If required clean and grease the

sliders with a food grade, non-drying grease.

9. Check that the bins rotate smoothly about the bin mounting pole (8)

and that the pole itself remains stationary. Ensure the two bin pole

bolts (3) are tight and that the bins are orientated in line with the

bassinet when in the central détente position.

10. Every six months the regulator output pressure (if fitted) should be

verified with an independent pressure gauge to ensure 50-60psi

(344.7–413.7kPa) is maintained. The adjustment procedure is detailed

in section

section

9.2.2. Test for leaks annually using the procedure outlined in

9.2.1.

11. Check for any visual signs of wear, damage or deterioration to the gas

hose and o-rings, and ensure there is no movement of crimped

components away from the hose. Exchange gas hoses as per national

or hospital regulations and guidelines.

12. Perform a visual operation check and flow test at 8LPM. For further

information refer to the Precision Medical Flowmeter User Manual.

13. Refer to manufacturers manual for maintenance & servicing

requirements.

14. Check the Neopuff in accordance with section 11.3.3.

15. Check operation, unplug from wall and check that it powers the warmer

for >10 mins. Refer to the PowerVar UPS operating manual supplied

with the unit for maintenance, troubleshooting, and technical support.

16. Check whether the Lamp Replacement Warning Light is lit. Refer to

section

referring to section

12.1.6 to test the warning light. Replace lamps if required

12.1.4. Check the cable is free from cuts and

abrasions and the securing ‘P’ clip is intact. Check the grommet where

Warmer Technical Manual

PART NUMBER :

ISSUE DATE :

ISSUE NUMBER :

PAGE :

185 041 130

October 2006

G

22

the cable enters arm is in good condition. Check the grille is firmly

attached. Check that the head only swivels when twisted by hand and

does not turn of its own accord.

Warmer Technical Manual

PART NUMBER :

ISSUE DATE :

ISSUE NUMBER :

PAGE :

185 041 130

October 2006

G

23

3.5 Service Procedures- Replacement

Anti-Static procedures must be observed when handling printed circuit boards (PCB’s). Qualified

service technicians should carry out all servicing.

3.5.1 Replacement of Halogen Lamp.

a. If the warmer has been running then allow one hour for the heater and lamp to cool.

b. Unplug the mains cable which supplies power to the unit. Turn off the UPS if installed

c. Unlatch the wire clips from the front of the head and remove the screw underneath the front of the

head which secures the lower case to the upper case. The rear screw will also need to be removed

on heads manufactured after August 2002.

d. Support the front of the head and pull both sides of the lower case down to open.

e. Pull the halogen lamp out. Using gloves to protect the new lamp, install by pushing into receptacle.

Use only 12V 20W 50 mm halogen lamps (Fisher and Paykel part # 424040069).

f. Close the lower casing of the head and replace the securing screws and wire clips.

g. Press the lower case along both sides to ensure it is clipped firmly into place.

3.5.2 Replacement of Controller Fuses.

a. Unplug the power cable from the wall supply outlet. Turn off the UPS if installed.

b. Remove the four screws that secure the front control panel to the column (located behind the

column).

c. Pull the front panel away from the column until the printed circuit boards are revealed.

d. Disconnect J12 (ribbon cable) from the control PCB. Disconnect J3 (ribbon cable) from the power

PCB. Disconnect J6 and J13 (power switch) from the power PCB. Remove the front panel.

e. Controller fuses F1, F2, F3, F4 and F5 are located on the power PCB. Replace as necessary.

f. Hold the control panel beside the column and reconnect connectors J12, J3, J6 and J13. .

g. Replace the front panel checking that it does not interfere with any wiring harnesses, in particular

ribbon cable (7) on controller assembly diagram

h. Replace the four screws.

6.2.2

3.5.3 Replacement of Supply PCB Fuses (IW93x, IW95x, IW960 and IW970 models only)

These include fuses for the Electric Elevator Module (if fitted), the Power Outlet (if fitted) and any

accessories that may be fitted. Refer to the photo in section

5.4.3 for fuse positions.

a. Unplug the power cable from the wall supply outlet. Turn off the UPS if installed.

b. If 900IW403/405 Storage Bins are fitted these must be removed by unscrewing the eight M8x16

screws shown as part 5 in section

10.14.

c. Remove the four screws that secure the power inlet/outlet module to the column (located behind

the column).

d. Supply PCB fuses F1, F2, F3, F4 and F5 are located on the back of the Inlet/Outlet Module. Fuse

F4 is common to all of the accessories; fuse F1 is for the Electric Elevator Module, fuse F5 is for

the outlet socket and fuse F2 and F3 are for other accessories.

e. Replace the power inlet/outlet module including the four retaining screws.

f. Replace 900IW403/405 Storage Bins.

3.5.4 Replacement of Printed Circuit Boards.

Refer to photos in section

5.4 for PCB component identification. PCB’s are not repaired, and individual

electronic components are not available. Replacement PCB’s are available – refer to section

spare part order numbers.

a. Carry out steps a. to d. of section

3.5.2.

b. To remove the control PCB from the front panel disconnect J2 (skin sensor) then release the

plastic clips beginning with the ones down the right hand side as viewed from the back.

c. To remove the power PCB from the column disconnect J8, J7, J10, J9 then remove phase and

neutral from J5. Unscrew the two 4mm self-tapping screws holding the heat sink to the column.

d. When replacing the power PCBs ensure it is securely held in the column extrusion groove on the

right hand side and by the two screws in the heat sink. Ensure that all of the 7 plastic

clips/connectors on the control PCB are secure.

e. When replacing the control PCB into the front panel, first remove the control knob (from the front

panel) so that it can be re-aligned to the rotary encoder on the control PCB afterwards.

5.4 for

Warmer Technical Manual

PART NUMBER :

ISSUE DATE :

ISSUE NUMBER :

PAGE :

185 041 130

October 2006

G

24

3.5.5 Replacement of Balance spring (IW910 and IW920 models only)

a. Unscrew plastic locking nut on adjustable pole, and remove upper pole with heater and controller.

b. Remove spring from lower pole.

c. Replace spring and refit upper pole.

3.5.6 Replacement of Castors (IW910 and IW920 models only)

a. Grip castor and pull out of mobile base.

b. Push new castor home into castor hole.

3.5.7 Replacement of Castors (IW93x and IW95x models only)

a. Lock castor and unscrew from leg.

b. Lock new castor and screw into leg ensuring that the circlip security plate (39) remains positioned

over the circlip (14) (refer diagram

8.1.4).

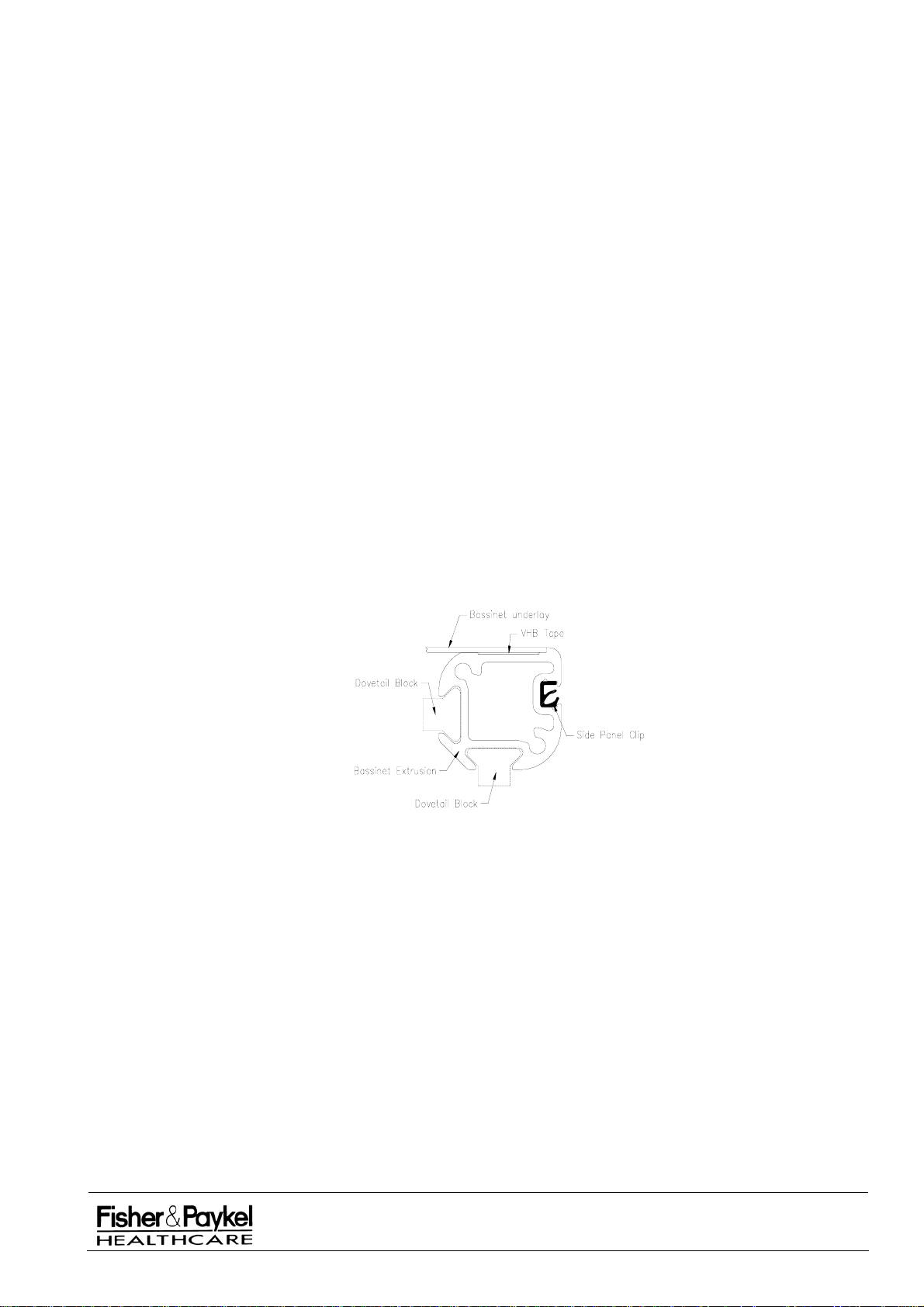

3.5.8 Replacement/ Addition of Acetal Side Panel Clips (CosyCot™ models with bassinets prior to version 2.5 only)

Please refer to section

a. Follow section

7.6 for part reference details.

3.5.9 to remove the left-hand corner cap from the side of the bassinet on which

changes are to be made.

b. Ensure that the Acetal Side Panel Clip(24) is the correct way up and slide the required number into

the rectangular gap located on the inside of the Corner Block (3), positioning it into the groove of

the bassinet extrusion.

c. Slide the Side Panel Clip along the Bassinet Extrusion (4) until in the desired location. To access

all four sides, all four Corner Caps will need to be removed. Reassemble Corner Cap in reverse

order.

NOTE: Too many clips may result in unnecessary force and therefore potential damage to the side

panel. To meet IEC 60601-2-21 regulations at least two Acetal clips should remain on each side of

the bassinet.

Correct Orientation of the Acetal Side panel Clip (693041413)

Warmer Technical Manual

PART NUMBER :

ISSUE DATE :

ISSUE NUMBER :

PAGE :

185 041 130

October 2006

G

25

3.5.9 Replacement of Bassinet Corner Caps (IW93x, IW95x, IW960 & IW970 models only)

Refer to Bassinet Assembly diagram

7.3.2

a. Remove all relevant side panels. Unscrew bolt (17) using a 5mm Allen key. For the front two

corners the rear handle (10) should be removed from each corner prior to unscrewing bolt (17).

b. When fitting a replacement plastic corner cap (694042167), ensure the two lugs locate under the

top surface of the corner block (3). Tighten bolt (17) to a torque of 3Nm.

c. Replace rear handle (10).

NOTE: For version 2.5 and version 3.0 bassinets the corner cap part number is 694042167.

For version 2.1 bassinets the corner cap part number is 694042134

For version 2.0 and 1.0 bassinets the corner cap part number is 641040819

3.5.10 Upgrading of Corner Cap Dummy Axles - (CosyCot™ models with bassinets prior to version

2.5 only)

Refer to section

7.2.1 for details of the dummy axle change history. It is advised to replace the corner

cap bushes (653040121) at the same time as exchanging dummy axles. The side panel sliding axle will

need to be upgraded at the same time as the dummy axle to ensure correct operation. Refer to section

7.2.1 for the correct dummy axle and sliding axle combinations.

a. Follow steps a – c in section

3.5.9 to remove the corner cap.

b. Slide out the two dummy axles in each corner cap and remove the urethane bushes with a pair of

pliers.

c. Push a bush halfway into the corner cap before inserting the dummy axle. A thin smear of a silicon

grease should be applied to each oval axle stem prior to insertion.

3.5.11 Upgrading of Side Panel Sliding Axles

Refer to section

7.2.1 for details of the sliding axle change history. The sliding axles were modified in

February 2001 to accept the lengthened dummy axles. All side panels made after this date will work

with all versions of dummy axle. If you have an earlier version of the side panels then the sliding axles

will need to be changed if they are to be fitted to a new version dummy axle.

a. Remove each side panel from the bassinet

b. Push one of the two sliding axles back to expose the grub screw which retains it. Using a 1.5mm

Allen key remove the grub screw and slowly release the sliding axle.

NOTE: The spring force could eject the sliding axle out of the extrusion if it is not securely held.

c. Repeat step b on the other sliding axle and discard both sliding axles.

d. Replace with one of the new sliding axles and use Loctite 272 to secure the grub screw back into

the extrusion. Do not wind the grub screw fully in; at least 1mm should be left exposed to ensure

the sliding axles are trapped in the slot.

e. Replace the spring and then carefully push the second sliding axle in place and reinstall the grub

screw using Loctite 272.

Warmer Technical Manual

PART NUMBER :

ISSUE DATE :

ISSUE NUMBER :

PAGE :

185 041 130

October 2006

G

26

3.6 Service Procedures – Adjustment

3.6.1 Infant Warmer setup procedure for base servicing

a. Disconnect all power and gas from the warmer and remove UPS modules, Side shelves,

phototherapy lamps, gas cylinders and any other loose apparatus on the warmer.

b. Push the warmer from the front until the rear castors swivel round underneath the rear legs. Lock

the rear castors.

c. Stand behind the column and swing the head over to one side before carefully pulling the warmer

column towards you so that the entire warmer pivots on the locked rear castors. Pre-position two

chairs or stools in line with the column with one stool close to the base and gently lower the column

onto them so that the entire warmer rests on the back of the column and no weight is on the base.

Ensure the warmer cannot tip sideways when resting on the chairs/stools.

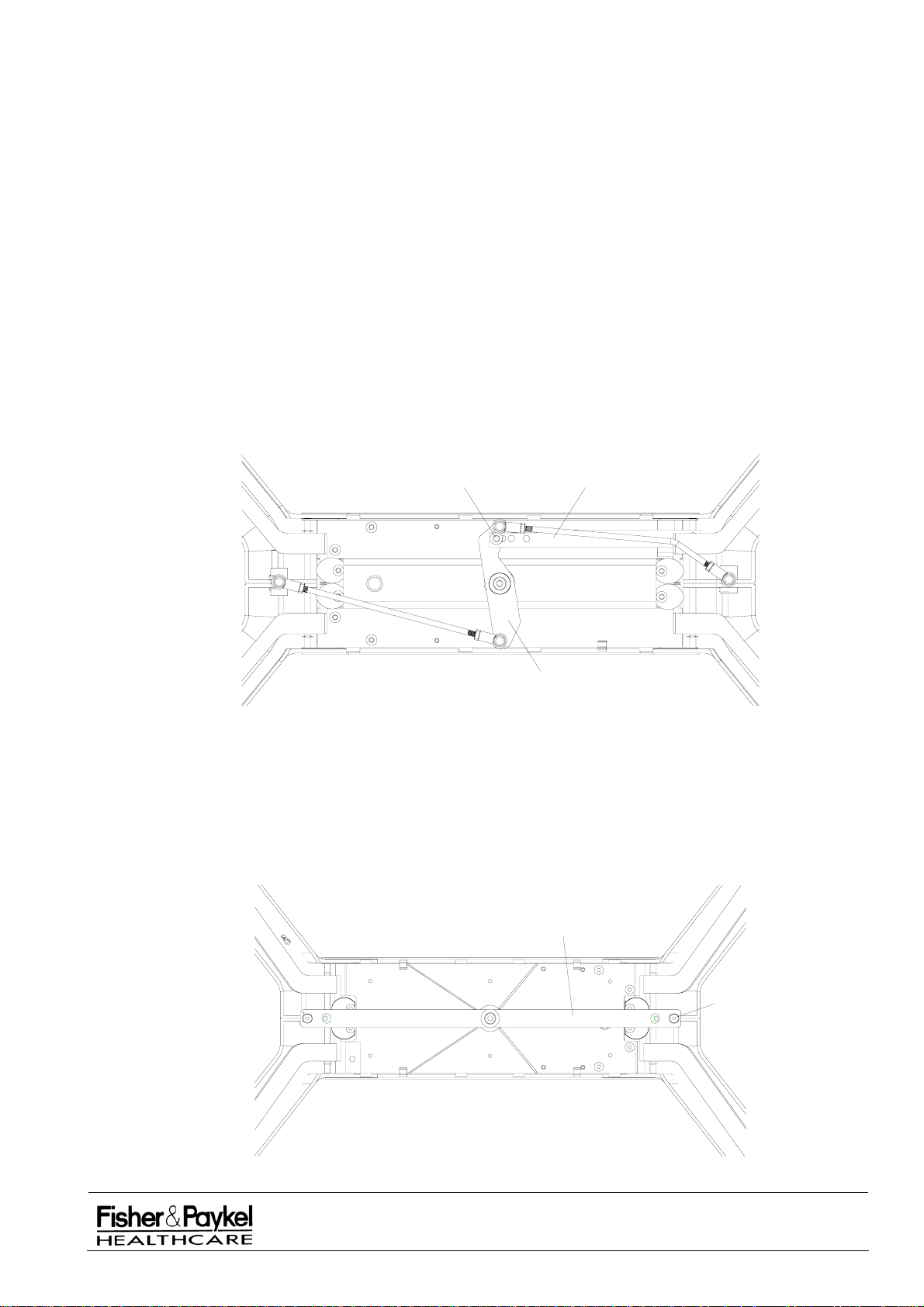

3.6.2 Pre-set Base Height Adjustment (IW93x and IW95x models with preset bases only)

For Warmers Manufactured before February 2004

Preset bases manufactured prior to Feubruary 2004 can have the bassinet height adjusted to 88.4, 97.5

or 101.9 cm (34.8”, 38.4” or 40.1”) by repositioning the lock bar. Refer to Figure 3.6.3 below. Using a

17mm spanner and 6mm Allen key remove the M10 x 30 screw and Nyloc nut (1). Pull both sets of legs

together until the desired hole on the lock bar (2) lines up with the hole in the pivot arm (3). Replace the

M10 screw and Nyloc nut (1) and fully tighten.

1 2

3.6.3 Figure of under side of preset CosyCot

3

TM

warmer base Manufactured before February 2004

For Warmers Manufactured after February 2004

Preset bases manufactured after February 2004 can have the bassinet height adjusted to 90.5 or 100.5

cm (35.6”or 39.6”). Refer to Figure 3.6.4 below. Using a 5mm Allen key remove the two M8x25 screws

(2). Pull the legs together until the other set of holes on the base adjustment bar (1) line up with the

holes on the legs.Replace the M8 screw and fully tighten. There are only two adjustment points for this

system.

1

2

Warmer Technical Manual

PART NUMBER :

ISSUE DATE :

ISSUE NUMBER :

PAGE :

185 041 130

October 2006

G

27

3.6.4 Figure of underside of preset CosyCotTM Warmer Base Manufactured after February 2004

3.6.5 Base Level Adjustment (IW93x and IW95x models only)

NOTE: Required on warmers with electric elevator bases and preset bases manufactured pre-February

2004. After this date a new preset system means that base level adjustment is not required.

If the base or column are not level, then adjustment of the straight tie rod is required. The straight tie

rod is located underneath the base between the centre pivot and the rear legs.

a. Undo the lock nut that secures the straight tie rod to the ball joints.

b. In the middle of the rod is a flat section that should be used for adjustment. Use the 6 mm wrench

(part of the tool kit) to turn the rod. One full clockwise turn of the rod (thread M8 x 1.25) will lower

the column down by approximately 4 mm. Hence, one full anti-clockwise turn of the rod will lift the

column end up by approximately 4 mm.

c. Adjust to level column and base.

d. Tighten the lock nut.

NOTE: When the rod is assembled, the ball joints remaining threaded portions are:

Leg side: 10 mm (full length is 20 mm)

Pivot side: 10 mm (full length is 25 mm)

CAUTION

A maximum of four full clockwise turns are allowed (remaining threaded portion 5 mm).

3.6.6 Castor Angle Adjustment (IW93x & IW95x models only prior to serial No. 9795AEA00436)

If the castor is not vertical to the floor, adjustment of the link arms is required. The link arms are located

underneath the leg. Castor angle cannot be adjusted on warmers after the above serial number – refer

PART 13: for serial number identification.

to

a. Undo the lock nuts that secure the straight tie rod to the ball joints.

b. In the middle of the arm are two holes spaced at 90°. Use a 3mm Allen key or a 3mm bar to turn

the arm. One full clockwise turn of the arm (thread M10 x 1.5) will move the castor outwards by

approximately 3 mm. Hence, one full anti clockwise turn of the arm will move the castor inwards by

approximately 3 mm.

c. Adjust the castor to the vertical position.

d. Tighten the lock nuts.

NOTE: When the arm is assembled the remaining threaded portions on both sides are 13 mm

(including 8mm thick lock nuts).

CAUTION

A maximum of ten full turns clockwise are allowed (thus the remaining threaded portion will

be 10 mm).

Warmer Technical Manual

PART NUMBER :

ISSUE DATE :

ISSUE NUMBER :

PAGE :

185 041 130

October 2006

G

28

3.6.7 Bassinet Clutch Adjustment (IW93x, IW95x, IW960 & IW970 models only)

If the bassinet can be tilted without actuating the rear handle, or pulling the two handles together

doesn't allow tilting of the bassinet, then the bassinet tilt clutch requires adjustment.

Adjustment is performed with the adjuster screw (for fine alterations) or by moving the cable support

block (for coarse alterations).

If Bassinet Clutch is too tight (i.e. bassinet can not be tilted):

a. Loosen lock nut on adjuster screw and wind screw out. If screw is already fully wound out then

cable support block will have to be moved.

b. Use a 4mm ball ended Allen key to loosen the two grub screws securing the cable support block to

the bassinet frame.

NOTE: On version three bassinets (manufactured from November 2002) a single M8 cap screw has

replaced the two grub screws, a 5mm Allen key is required to loosen this screw.

c. Wind the adjuster screw approximately half way out.

d. Butt the adjuster screw against the cable sheath by sliding the cable support block towards the rear

of the warmer.

e. Fix the cable support block in position by tightening the two grub screws.

f. Move the bassinet tilt brake handle backwards as far as it will go and wind adjuster screw out to

take up tension.

g. Tighten adjuster screw lock nut.

h. Pull the bassinet rear handle forwards and check brake release operation.

If Bassinet Clutch is too loose (i.e. bassinet can be tilted without using the bassinet handles):

a. Loosen lock nut on adjuster screw and wind screw in. If screw is already fully wound in then cable

support block will have to be moved.

b. Use a 4mm ball ended Allen key to loosen the two grub screws securing the cable support block to

the bassinet frame.

NOTE: On version three bassinets (manufactured from November 2002) a single M8 cap screw has

replaced the two grub screws, a 5mm Allen key is required to loosen this screw.

c. Wind the adjuster screw approximately half way in.

d. Follow steps d to h above.

If the clutch is still loose the actuator spring can be tightened. Referring to diagram in section

using a ball ended 4mm Allen key on the M5 screw (part 15) and a 6mm open spanner on the brass

actuator (part 12) tighten the spring by winding the screw in. The 12mm washer (part 16) should

coincide with a line on the lower tilt link molding (part 7). Cleaning the tilt brake sliders (part 10) with

alcohol to remove any particles can also improve the clutch performance.

3.6.8 Bassinet Brake Adjustment (For CosyCot

brake system)