Fisher & Paykel DD603-88445, DD603I, DS603I, DS603SS Installation Guide

ishDrawer

part number526607 0

08/2006

(page1of 12)

®

I

TALLATI I T U TI

(NOTE:FORINTEGRATEDPANELPREPARATIONINSTRUCTIONSREFERTOSUPPLIEDSHEET)

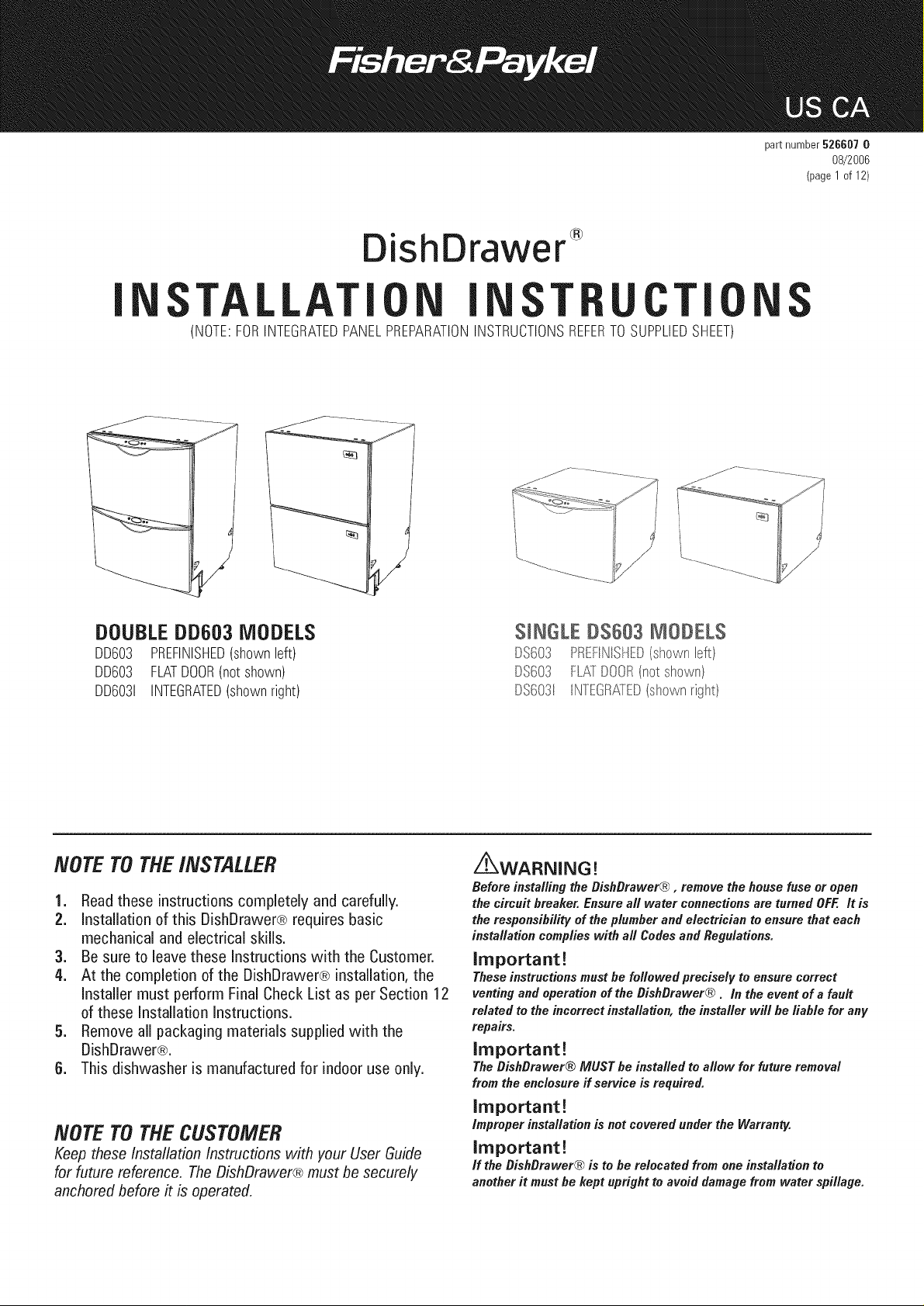

DOUBLEDD603 MODELS

DD603 PREFINISHED(shownleft)

DD603 FLATDOOR(notshown)

DD6031 INTEGRATED(shownright)

SINGLE DS683 MODELS

DS603 PREFINISHED(shownbft}

DS603 FL£ DOOR(not shown}

DS6031 INTEGR£ED(shownright}

NOTE TOTHEiNSTALLER

1. Read these instructions completely and carefully.

2. installation of this DishDrawer® requires basic

mechanical and electrical skills.

3. Be sure to leave these instructions with the Customer.

4. At the completion of the DishDrawer® installation, the

installer must perform Final Check List as per Section 12

of these installation instructions.

5. Remove all packaging materials supplied with the

DishDrawer®.

6. This dishwasher is manufactured for indoor use only.

NOTE TOTHECUSTOMER

Keep these Installation Instructions with your User Guide

for future reference. The DishDrawer® must be securely

anchored before # is operated.

Z_WARNING!

Before installing the BishBrawer@ , remove the house fuse or open

the circuitbreaker. Ensureall water connectionsare turned OFF.It is

the responsibilityof the plumber andelectrician to ensure thateach

installationcomplieswith all CodesandRegulations.

Important!

These instructions must be followed precisely to ensure correct

venting and operation of the BishBrawer® . In the event of a fault

related to the incorrect installation, the installer will be liable for any

repairs.

important!

The BishBrawer® MUST be installed to allow for future removal

from the enclosure ff service is required.

important!

improperinstallationis not covered under the Warranty.

Important!

if the BishBrawer® is to berelocated from one installation to

another it must be kept upright to avoid damage from water spillage.

._.BEFORE YOU START- DOUBLE S#NGLE MODELS

DishDrawer

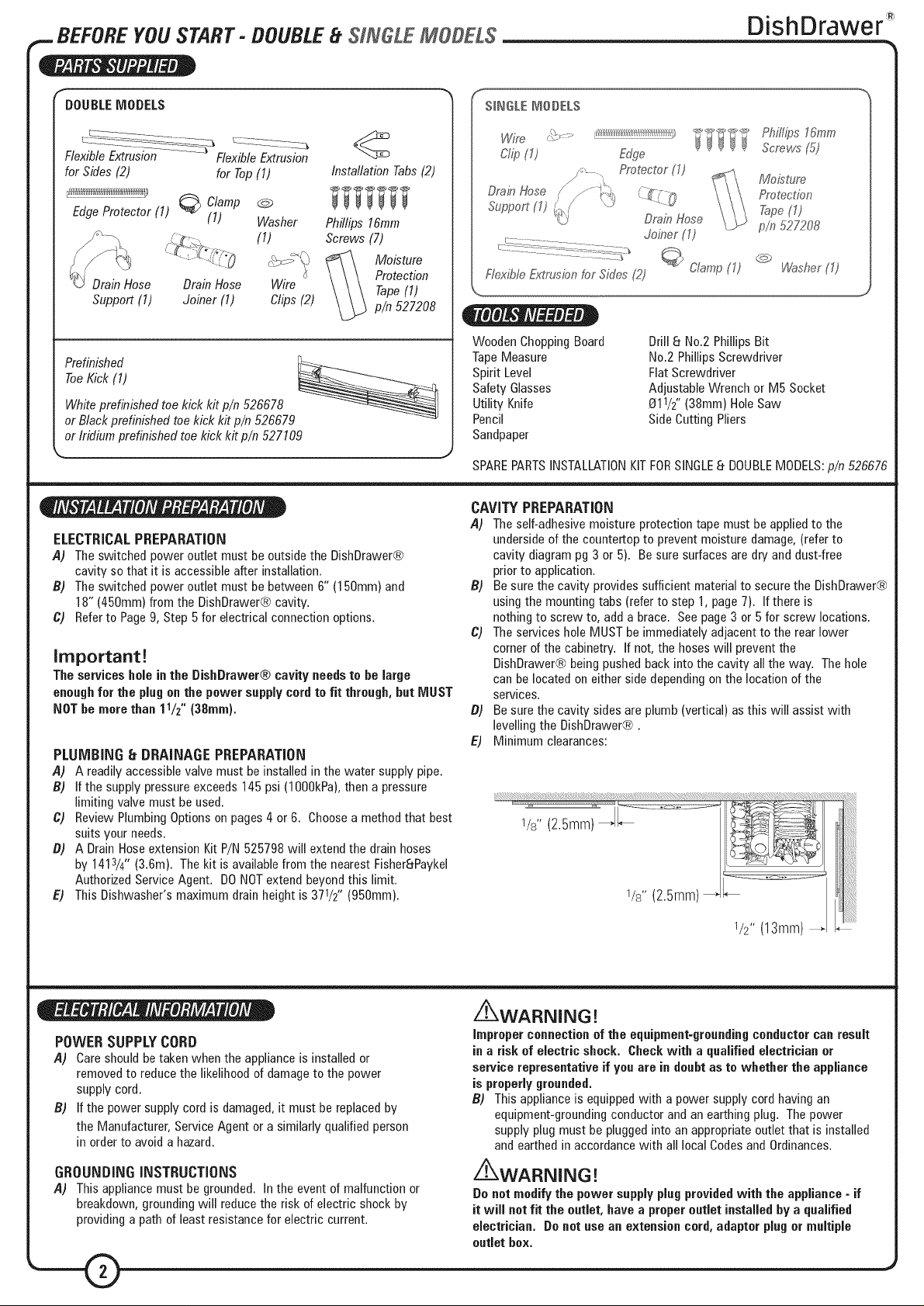

DOUBLEMODELS

FlexibleExtrusion ........ FlexibleExtrusion

for Sides(2) for Top(1)

EdgeProtector (1) @ Clamp @

(1) Washer

(1)

DrainHose DrainHose Wire

Support (1) Joiner (1) Clips(2)

ToeKick (1)

Prefinished

Whiteprefinished toe kickkit p/n 526678

or Blackprefinished toekick kit p/n 526679

or Iridium prefinishedtoekick kit p/n 527109

ELECTRICAL PREPARATION

A) Theswitched power outlet must beoutsidethe DishDrawer®

cavity so that it is accessibleafter installation.

B) Theswitched poweroutlet must bebetween6" (150mm) and

18"(450mm) from the DishDrawer®cavity.

C) Referto Page9, Step5 for electricalconnectionoptions.

Installation Tabs(2)

Phillips 16ram

Screws (7)

Moisture

Protection

Tape(1)

p/n 527208

Important!

The services hole inthe DishDrawer® cavityneedsto be large

enoughfor the plugon the power supply cordto fit through, but MUST

NOTbe more than 11/z" (38ram).

PLUMBING 8 DRAINAGE PREPARATION

,4) A readily accessiblevalvemust be installed in the water supply pipe.

B) If the supply pressureexceeds145psi (1000kPa),thena pressure

limiting valve must be used.

C) Review PlumbingOptionson pages4 or 6. Choosea methodthat best

suitsyour needs.

B) A DrainHoseextensionKitP/N 525798will extendthe drain hoses

by 1413/4"(3.6m). Thekit is availablefrom the nearestFisherSPaykel

AuthorizedServiceAgent. DONOTextend beyondthis limit.

E) This Dishwasher'smaximum drainheightis 371/2'' (950mm).

SINGLEMODELS

Ph%t?s16ram

Screws(5)

DrainHose

Support(1) _./

Ftexib/eExtrusionfor Sk:/es(2)

WoodenChoppingBoard

TapeMeasure

Spirit Level

Safety Glasses

Utility Knife

Pencil

Sandpaper

SPAREPARTSINSTALLATIONKITFORSINGLE8 DOUBLEMODELS:p/n526676

CAVITY PREPARATION

A) Theself-adhesivemoisture protectiontape must be appliedto the

undersideofthe countertopto prevent moisture damage,(referto

cavity diagrampg 3 or 5). Besuresurfaces aredry and dust-free

priorto application.

B) Besure the cavity provides sufficient materialto securethe DishDrawer®

usingthemountingtabs (referto step 1,page7). Ifthere is

nothingto screw to, add a brace. Seepage3 or 5for screw locations.

C) The serviceshole MUSTbeimmediately adjacentto the rearlower

cornerofthe cabinetry. If not, the hoseswill preventthe

DishDrawer®beingpushedback intothe cavity allthe way. Thehole

canbe locatedon eitherside dependingonthe location ofthe

services.

B) Besure the cavity sides areplumb (vertical) asthis will assist with

levellingthe DishDrawer®.

E) Minimum clearances:

/ /

'<_'J DrainHose

Joiner (1)

_ Clamp(1)

Drill8 No.2 PhillipsBit

No.2 PhillipsScrewdriver

FlatScrewdriver

AdjustableWrench or M5 Socket

O11/2"(38mm)HoleSaw

SideCuttingPliers

Moisture

Protection

Ta-pe_'1,_

p/n 527208

C_

[,¢'#sher(1)

POWER SUPPLY CORD

A) Careshouldbetaken when the applianceis installedor

removedto reducethe likelihoodof damageto the power

supply cord.

B) If the power supply cordis damaged,it must be replacedby

the Manufacturer,ServiceAgent or asimilarly qualified person

in orderto avoida hazard.

GROUNDING INSTRUCTIONS

A) This appliancemust be grounded. In the event of malfunction or

breakdown,groundingwill reducethe risk of electric shockby

providinga path of leastresistancefor electric current.

/_WARNING!

Improper connectionof the equipment-groundingconductorcanresult

in a risk of electricshock. Check with a qualified electrician or

service representativeif you are in doubt as to whether the appliance

is properlygrounded.

B) This applianceis equippedwith a power supply cordhaving an

equipment-groundingconductorandan earthingplug. Thepower

supply plug mustbe plugged intoan appropriateoutletthat is installed

andearthedin accordancewith all localCodesand Ordinances.

z_WARNING!

Donot modify the power supplyplugprovidedwith the appliance - if

it wiJJnotfit the outlet, have a properoutletinstalled by a qualified

electrician. Donotuse an extension cord,adaptor plugor multiple

outlet box.

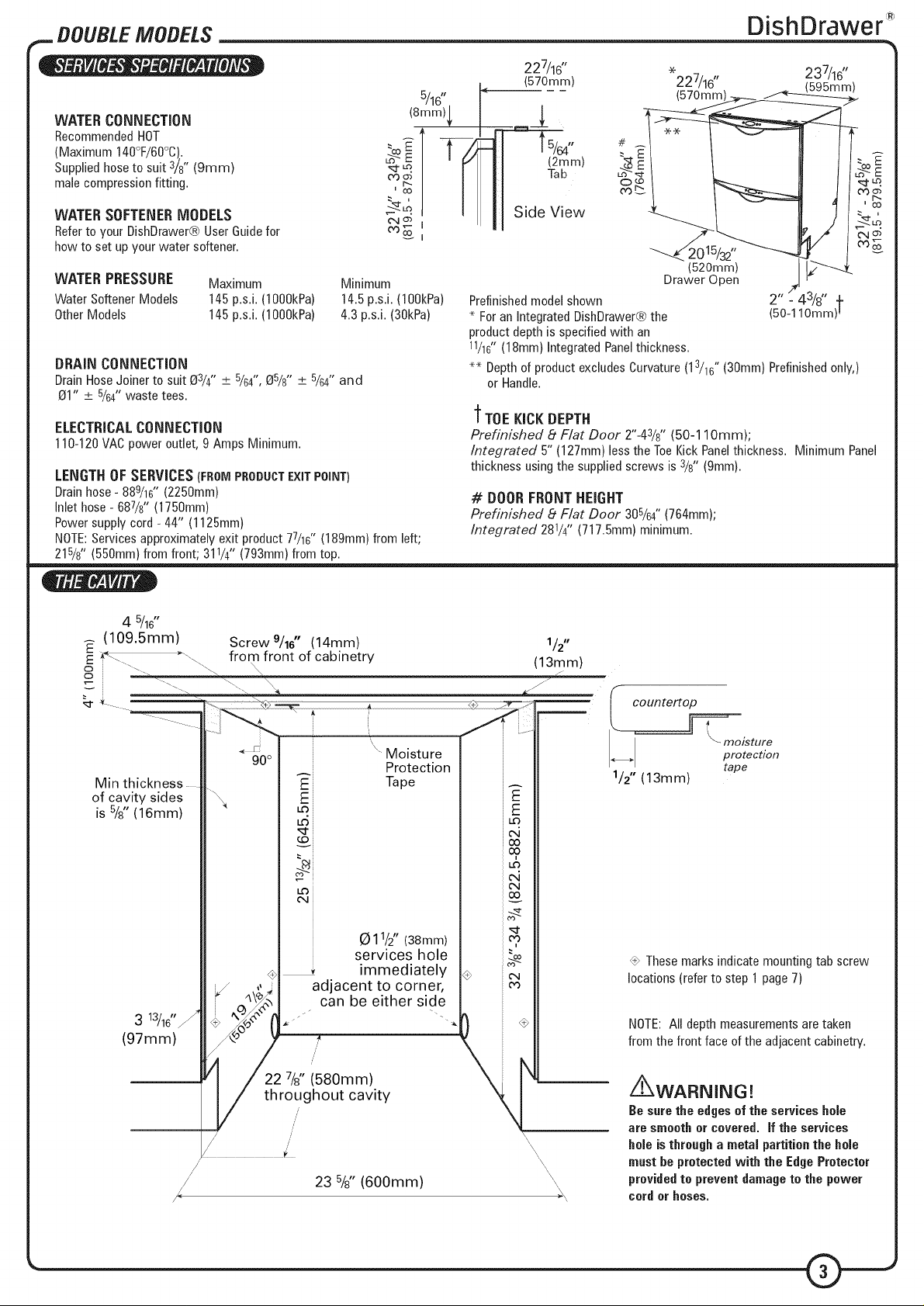

,.. DOUBLEMODELS

DishDrawer

5/16" k --.

WATER CONNECTION

RecommendedHOT

(Maximum 140°F/60°0).

Suppliedhoseto suit 3/8"(gmm)

malecompressionfitting.

WATER SOFTENER MODELS

Referto your DishDrawer® UserGuidefor

how to set upyour water softener.

WATER PRESSURE Maximum Minimum

WaterSoftener Models 145p.s.i.(1000kPa) 14.5 p.s.i. (100kPa)

OtherModels 145p.s.i.(1000kPa) 4.3p.s.i. (30kPa)

BRAIN CONNECTION

DrainHoseJoiner to suitO3/4'' +_5/64",O5/8'' +_5/64" and

O1" +_5/84"waste tees.

ELECTRICALCONNECTION

110-120VACpoweroutlet,9 AmpsMinimum.

LENGTH OF SERVICES (FROMPRODUCTEXITPOINT)

Drainhose- 889/16" (2250mm)

Inlet hose- 687/8" (1750mm)

Powersupply cord- 44" (1125mm)

NOTE:Servicesapproximatelyexit product 77/16'' (189mm)from left;

215/8'' (550mm)from front; 311/4'' (793mm) from top.

/Smm) |

_ " _/ | I (2rnm)

_'_o_ [ |l Tab

227/16"

I_ (57°L_m)

#

Prefinished model shown 2" - 43/8" +

* For an Integrated DishDrawer® the (50-1 lOmm) !

product depth is specified with an

11/16"(18mm} Integrated Panel thickness.

** Depth of product excludes Curvature (13/18" (30mm} Prefinished only,}

or Handle.

%

227/16"

{578mm)

(520mm)

Drawer Open

237/16"

(595mm)

"_TOE KICK DEPTH

Prefinished 8 F/at Door 2"-43/8" (50-1 lOmm);

/ntegrated 5" (127mm)less the ToeKick Panelthickness. Minimum Panel

thicknessusingthe suppliedscrews is 3/8"(gmm).

# BOOR FRONT HEIGHT

Prefinished 8 F/at Door 305/64"(764mm);

/ntegrated 281/4'' (717.5mm)minimum.

4 5/16"

(109.5mm!,

Min thickness

of cavity sides

is 5/8"(16mm)

Screw 9/16" (14mm) 1/2"

from front of cabinetry (13m m)

• z

f

,,<............ _ _....... _" [ countert

.................................... _\ [i _ ....................... _ l °_r=,_

< _ " Moisture n

90° Protection tape

A_

E Tape

LO::

r.D_

C_4_

0 11/2"(38mm)

services hole

÷ _ immediately

,, j adjacent to corner,

A

t._

m,

E

E

1/2" (13mm)

Thesemarksindicatemountingtab screw

locations(referto step 1 page7)

_, can be either side

NOTE:All depth measurementsare taken

from the front face ofthe adjacentcabinetry.

/ 22r7/{' (580mm) X \t oughout cavity

23 %" (600mm)

i_WARNING!

Be surethe edges of the services hole

are smooth or covered. If the services

holeis through a metal partitionthe hole

must beprotectedwith the EdgeProtector

providedto preventdamagete the power

cordor hoses.

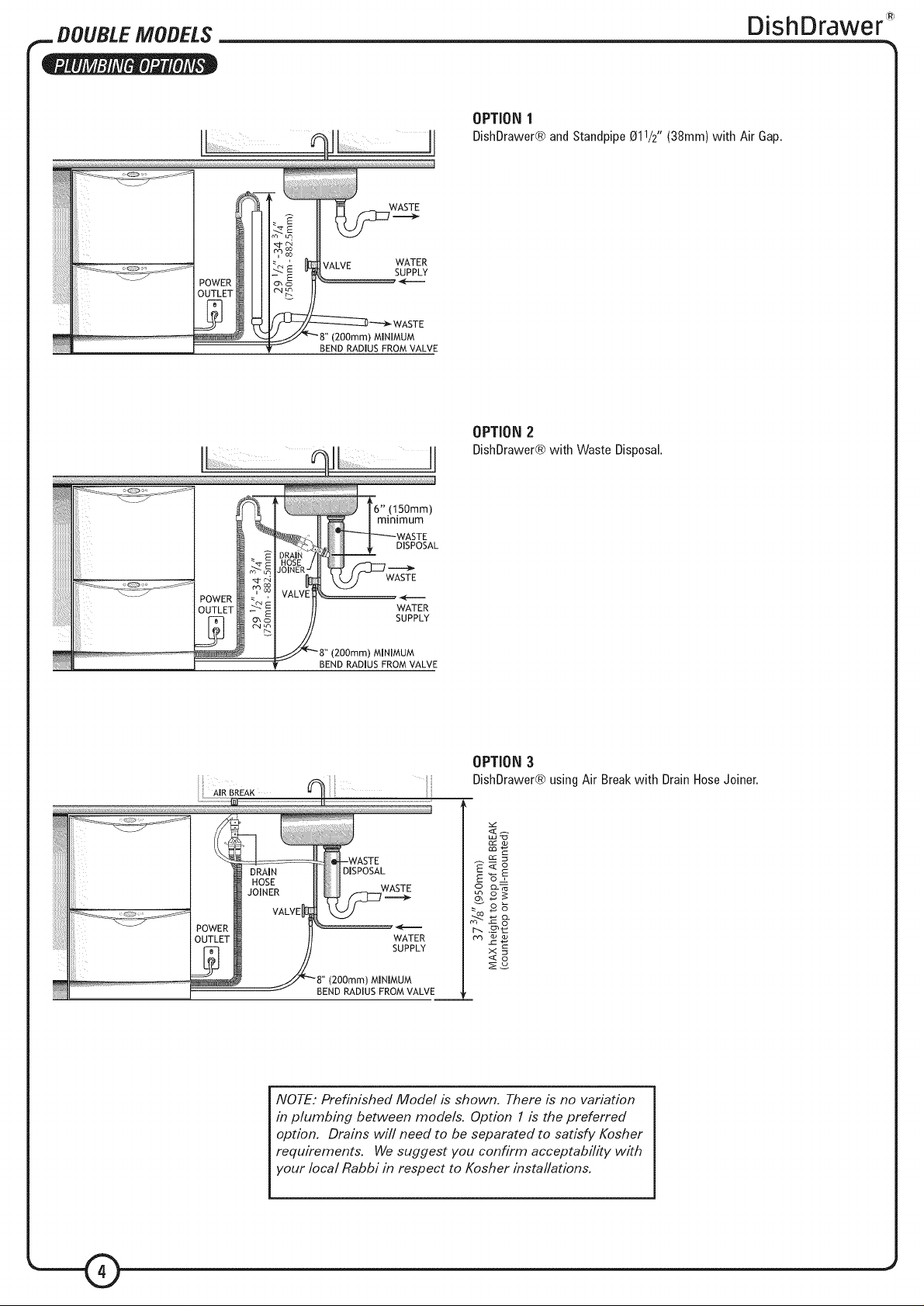

DOUBLEMODELS

DishDrawer

OPTION1

DishDrawer®andStandpipeO11/2"(38mm)with AirGap.

VALVE WATER

_ _--"_'- WASTE

(2O0mm) MINIMUM

BEND RADIUS FROM VALVE

BEND RADIUS FROM VALVL

SUPPLY

OPTION2

DishDrawer®withWasteDisposal.

OPTION3

DishDrawer®usingAirBreakwith DrainHoseJoiner.

cz= o_

DISPOSAL

WASTE

WATER

SUPPLY

(2O0mm) MINIMUM

BEND RADIUS FROM VALVE

NOTE." Prefinished Mode/is shown. There is no variation

in plumbing between mode/s. Option 1 is the preferred

option. Drains wi// need to be separated to satisfy Kosher

requirements. We suggest you confirm acceptabi/ity with

your/oca/Rabbi in respect to Kosher insta//ations.

E<o

E'_z

c_O_

r=8-

r-_ ._

©

Loading...

Loading...