Fisher & Paykel DD603-88269, DD603-88270, DD603-88445, DD603-88445-B, DS603-88272 Installation Guide

...Page 1

ishDrawer

part number526607 0

08/2006

(page1of 12)

®

I

TALLATI I T U TI

(NOTE:FORINTEGRATEDPANELPREPARATIONINSTRUCTIONSREFERTOSUPPLIEDSHEET)

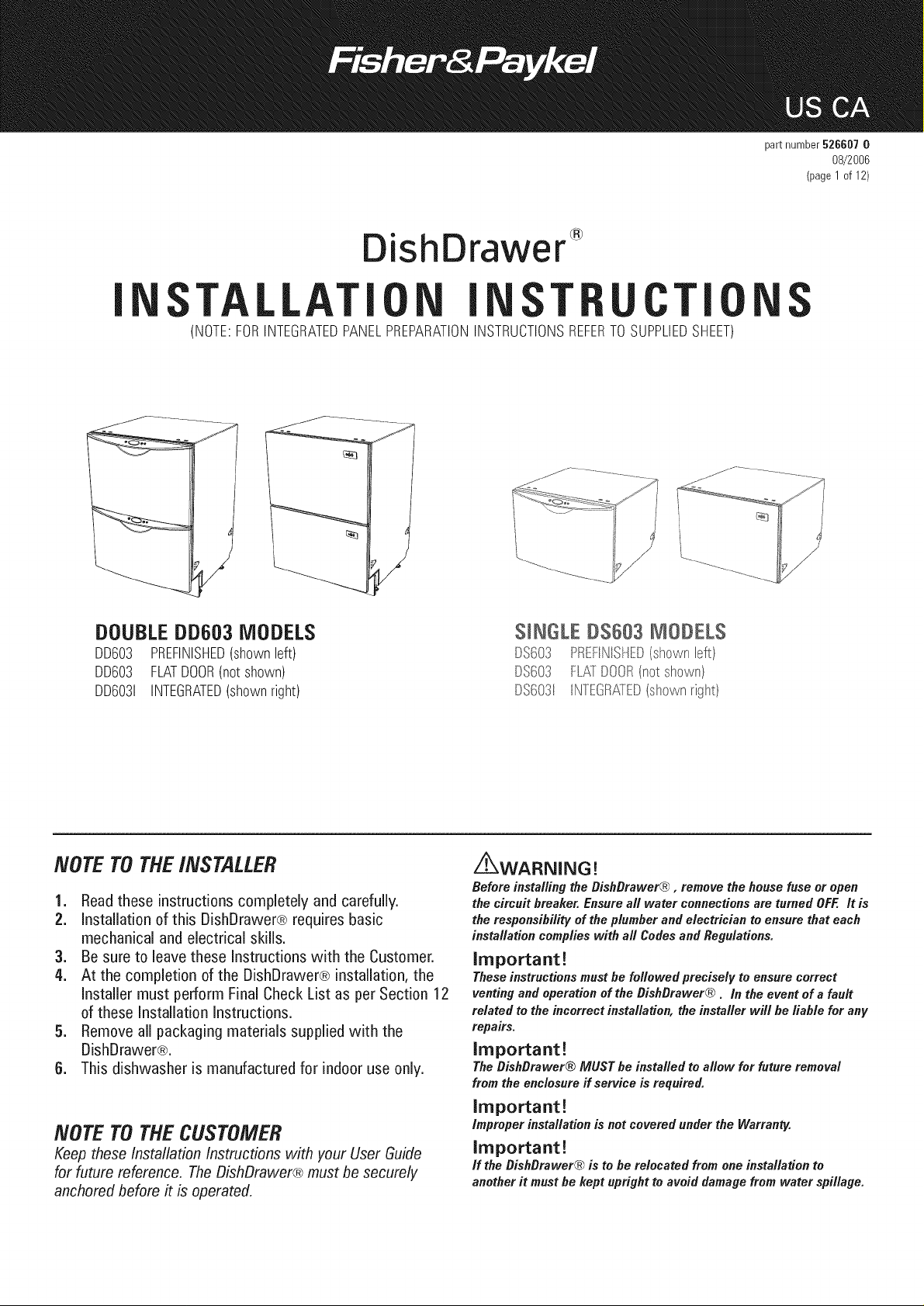

DOUBLEDD603 MODELS

DD603 PREFINISHED(shownleft)

DD603 FLATDOOR(notshown)

DD6031 INTEGRATED(shownright)

SINGLE DS683 MODELS

DS603 PREFINISHED(shownbft}

DS603 FL£ DOOR(not shown}

DS6031 INTEGR£ED(shownright}

NOTE TOTHEiNSTALLER

1. Read these instructions completely and carefully.

2. installation of this DishDrawer® requires basic

mechanical and electrical skills.

3. Be sure to leave these instructions with the Customer.

4. At the completion of the DishDrawer® installation, the

installer must perform Final Check List as per Section 12

of these installation instructions.

5. Remove all packaging materials supplied with the

DishDrawer®.

6. This dishwasher is manufactured for indoor use only.

NOTE TOTHECUSTOMER

Keep these Installation Instructions with your User Guide

for future reference. The DishDrawer® must be securely

anchored before # is operated.

Z_WARNING!

Before installing the BishBrawer@ , remove the house fuse or open

the circuitbreaker. Ensureall water connectionsare turned OFF.It is

the responsibilityof the plumber andelectrician to ensure thateach

installationcomplieswith all CodesandRegulations.

Important!

These instructions must be followed precisely to ensure correct

venting and operation of the BishBrawer® . In the event of a fault

related to the incorrect installation, the installer will be liable for any

repairs.

important!

The BishBrawer® MUST be installed to allow for future removal

from the enclosure ff service is required.

important!

improperinstallationis not covered under the Warranty.

Important!

if the BishBrawer® is to berelocated from one installation to

another it must be kept upright to avoid damage from water spillage.

Page 2

._.BEFORE YOU START- DOUBLE S#NGLE MODELS

DishDrawer

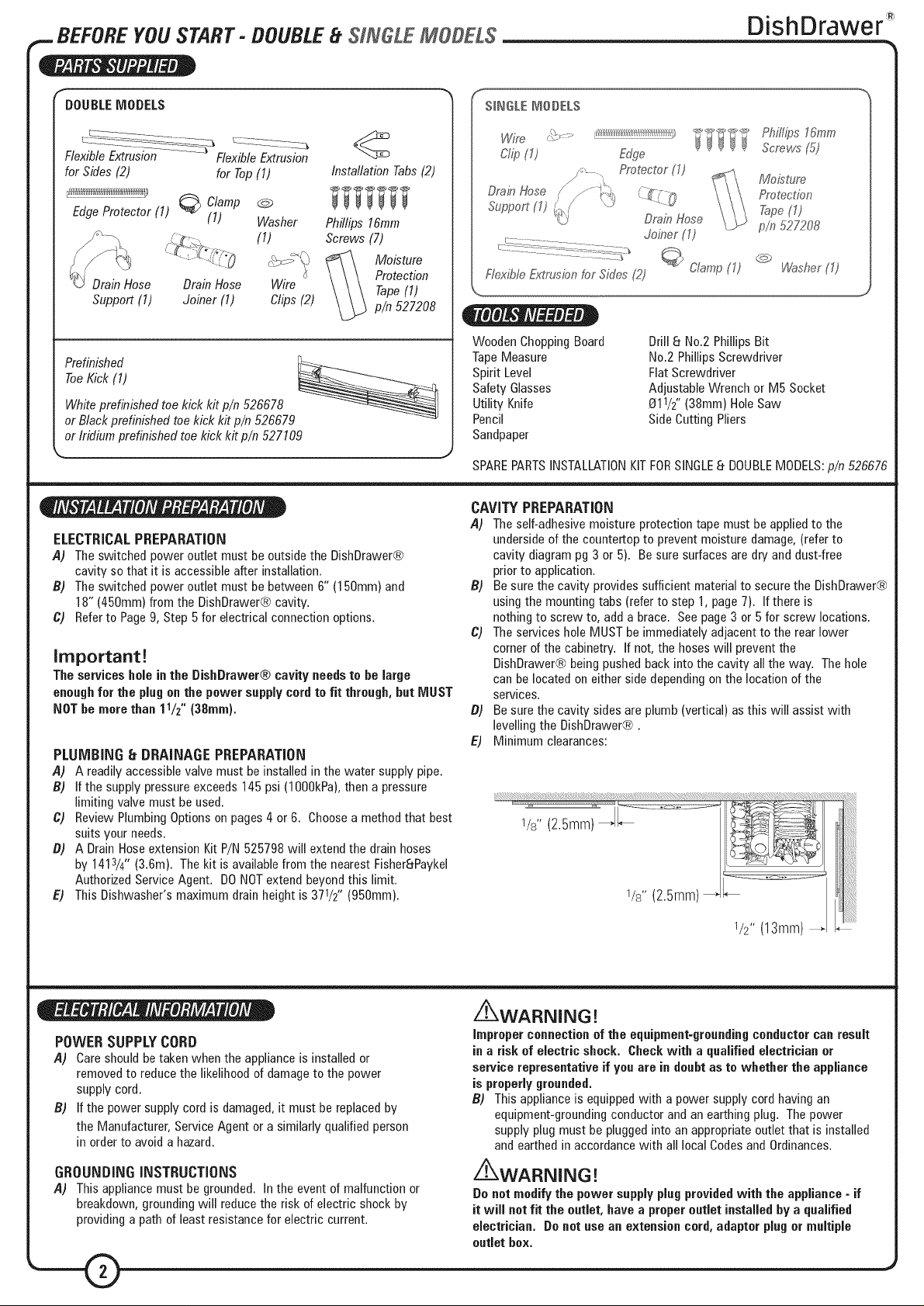

DOUBLEMODELS

FlexibleExtrusion ........ FlexibleExtrusion

for Sides(2) for Top(1)

EdgeProtector (1) @ Clamp @

(1) Washer

(1)

DrainHose DrainHose Wire

Support (1) Joiner (1) Clips(2)

ToeKick (1)

Prefinished

Whiteprefinished toe kickkit p/n 526678

or Blackprefinished toekick kit p/n 526679

or Iridium prefinishedtoekick kit p/n 527109

ELECTRICAL PREPARATION

A) Theswitched power outlet must beoutsidethe DishDrawer®

cavity so that it is accessibleafter installation.

B) Theswitched poweroutlet must bebetween6" (150mm) and

18"(450mm) from the DishDrawer®cavity.

C) Referto Page9, Step5 for electricalconnectionoptions.

Installation Tabs(2)

Phillips 16ram

Screws (7)

Moisture

Protection

Tape(1)

p/n 527208

Important!

The services hole inthe DishDrawer® cavityneedsto be large

enoughfor the plugon the power supply cordto fit through, but MUST

NOTbe more than 11/z" (38ram).

PLUMBING 8 DRAINAGE PREPARATION

,4) A readily accessiblevalvemust be installed in the water supply pipe.

B) If the supply pressureexceeds145psi (1000kPa),thena pressure

limiting valve must be used.

C) Review PlumbingOptionson pages4 or 6. Choosea methodthat best

suitsyour needs.

B) A DrainHoseextensionKitP/N 525798will extendthe drain hoses

by 1413/4"(3.6m). Thekit is availablefrom the nearestFisherSPaykel

AuthorizedServiceAgent. DONOTextend beyondthis limit.

E) This Dishwasher'smaximum drainheightis 371/2'' (950mm).

SINGLEMODELS

Ph%t?s16ram

Screws(5)

DrainHose

Support(1) _./

Ftexib/eExtrusionfor Sk:/es(2)

WoodenChoppingBoard

TapeMeasure

Spirit Level

Safety Glasses

Utility Knife

Pencil

Sandpaper

SPAREPARTSINSTALLATIONKITFORSINGLE8 DOUBLEMODELS:p/n526676

CAVITY PREPARATION

A) Theself-adhesivemoisture protectiontape must be appliedto the

undersideofthe countertopto prevent moisture damage,(referto

cavity diagrampg 3 or 5). Besuresurfaces aredry and dust-free

priorto application.

B) Besure the cavity provides sufficient materialto securethe DishDrawer®

usingthemountingtabs (referto step 1,page7). Ifthere is

nothingto screw to, add a brace. Seepage3 or 5for screw locations.

C) The serviceshole MUSTbeimmediately adjacentto the rearlower

cornerofthe cabinetry. If not, the hoseswill preventthe

DishDrawer®beingpushedback intothe cavity allthe way. Thehole

canbe locatedon eitherside dependingonthe location ofthe

services.

B) Besure the cavity sides areplumb (vertical) asthis will assist with

levellingthe DishDrawer®.

E) Minimum clearances:

/ /

'<_'J DrainHose

Joiner (1)

_ Clamp(1)

Drill8 No.2 PhillipsBit

No.2 PhillipsScrewdriver

FlatScrewdriver

AdjustableWrench or M5 Socket

O11/2"(38mm)HoleSaw

SideCuttingPliers

Moisture

Protection

Ta-pe_'1,_

p/n 527208

C_

[,¢'#sher(1)

POWER SUPPLY CORD

A) Careshouldbetaken when the applianceis installedor

removedto reducethe likelihoodof damageto the power

supply cord.

B) If the power supply cordis damaged,it must be replacedby

the Manufacturer,ServiceAgent or asimilarly qualified person

in orderto avoida hazard.

GROUNDING INSTRUCTIONS

A) This appliancemust be grounded. In the event of malfunction or

breakdown,groundingwill reducethe risk of electric shockby

providinga path of leastresistancefor electric current.

/_WARNING!

Improper connectionof the equipment-groundingconductorcanresult

in a risk of electricshock. Check with a qualified electrician or

service representativeif you are in doubt as to whether the appliance

is properlygrounded.

B) This applianceis equippedwith a power supply cordhaving an

equipment-groundingconductorandan earthingplug. Thepower

supply plug mustbe plugged intoan appropriateoutletthat is installed

andearthedin accordancewith all localCodesand Ordinances.

z_WARNING!

Donot modify the power supplyplugprovidedwith the appliance - if

it wiJJnotfit the outlet, have a properoutletinstalled by a qualified

electrician. Donotuse an extension cord,adaptor plugor multiple

outlet box.

Page 3

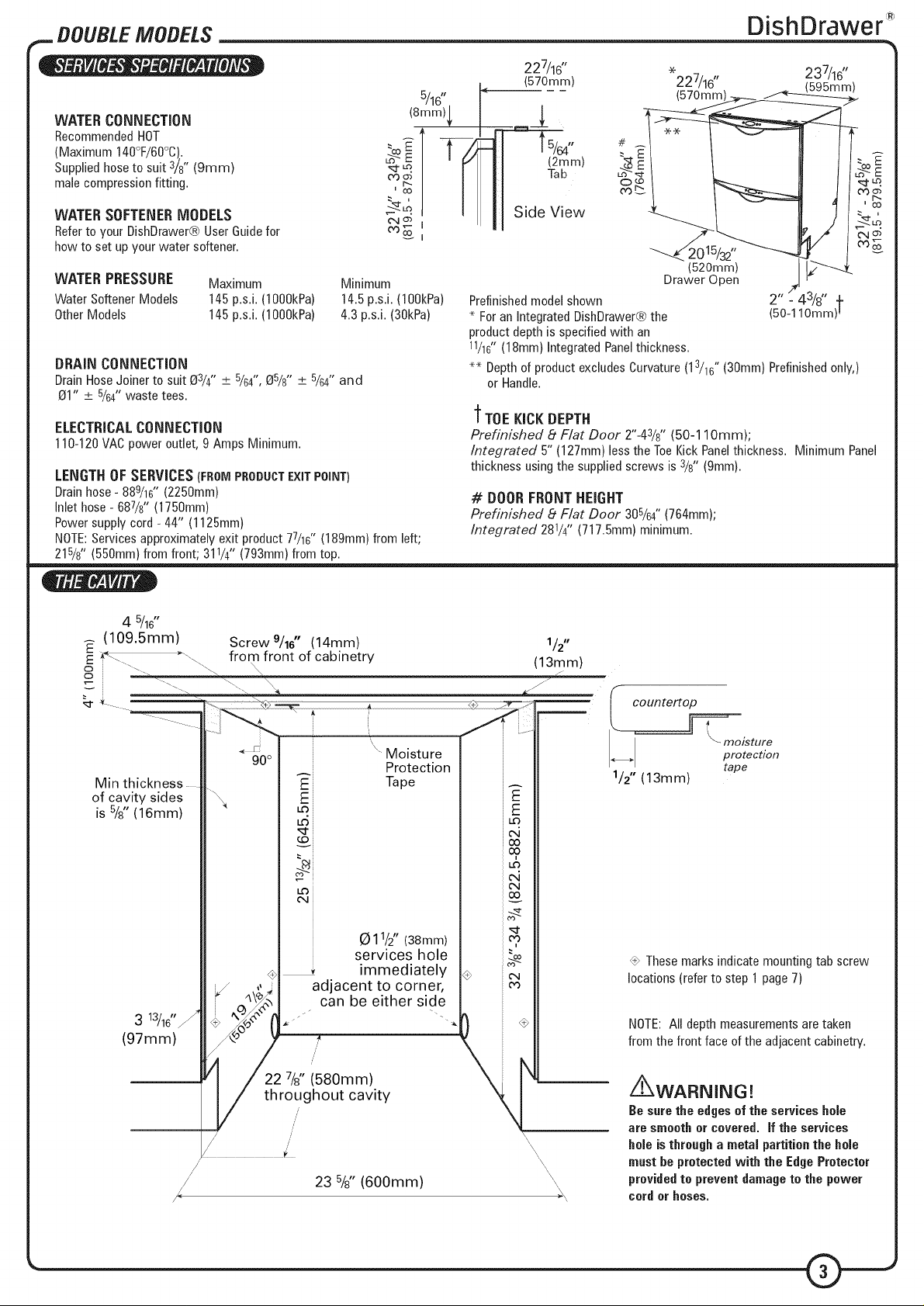

,.. DOUBLEMODELS

DishDrawer

5/16" k --.

WATER CONNECTION

RecommendedHOT

(Maximum 140°F/60°0).

Suppliedhoseto suit 3/8"(gmm)

malecompressionfitting.

WATER SOFTENER MODELS

Referto your DishDrawer® UserGuidefor

how to set upyour water softener.

WATER PRESSURE Maximum Minimum

WaterSoftener Models 145p.s.i.(1000kPa) 14.5 p.s.i. (100kPa)

OtherModels 145p.s.i.(1000kPa) 4.3p.s.i. (30kPa)

BRAIN CONNECTION

DrainHoseJoiner to suitO3/4'' +_5/64",O5/8'' +_5/64" and

O1" +_5/84"waste tees.

ELECTRICALCONNECTION

110-120VACpoweroutlet,9 AmpsMinimum.

LENGTH OF SERVICES (FROMPRODUCTEXITPOINT)

Drainhose- 889/16" (2250mm)

Inlet hose- 687/8" (1750mm)

Powersupply cord- 44" (1125mm)

NOTE:Servicesapproximatelyexit product 77/16'' (189mm)from left;

215/8'' (550mm)from front; 311/4'' (793mm) from top.

/Smm) |

_ " _/ | I (2rnm)

_'_o_ [ |l Tab

227/16"

I_ (57°L_m)

#

Prefinished model shown 2" - 43/8" +

* For an Integrated DishDrawer® the (50-1 lOmm) !

product depth is specified with an

11/16"(18mm} Integrated Panel thickness.

** Depth of product excludes Curvature (13/18" (30mm} Prefinished only,}

or Handle.

%

227/16"

{578mm)

(520mm)

Drawer Open

237/16"

(595mm)

"_TOE KICK DEPTH

Prefinished 8 F/at Door 2"-43/8" (50-1 lOmm);

/ntegrated 5" (127mm)less the ToeKick Panelthickness. Minimum Panel

thicknessusingthe suppliedscrews is 3/8"(gmm).

# BOOR FRONT HEIGHT

Prefinished 8 F/at Door 305/64"(764mm);

/ntegrated 281/4'' (717.5mm)minimum.

4 5/16"

(109.5mm!,

Min thickness

of cavity sides

is 5/8"(16mm)

Screw 9/16" (14mm) 1/2"

from front of cabinetry (13m m)

• z

f

,,<............ _ _....... _" [ countert

.................................... _\ [i _ ....................... _ l °_r=,_

< _ " Moisture n

90° Protection tape

A_

E Tape

LO::

r.D_

C_4_

0 11/2"(38mm)

services hole

÷ _ immediately

,, j adjacent to corner,

A

t._

m,

E

E

1/2" (13mm)

Thesemarksindicatemountingtab screw

locations(referto step 1 page7)

_, can be either side

NOTE:All depth measurementsare taken

from the front face ofthe adjacentcabinetry.

/ 22r7/{' (580mm) X \t oughout cavity

23 %" (600mm)

i_WARNING!

Be surethe edges of the services hole

are smooth or covered. If the services

holeis through a metal partitionthe hole

must beprotectedwith the EdgeProtector

providedto preventdamagete the power

cordor hoses.

Page 4

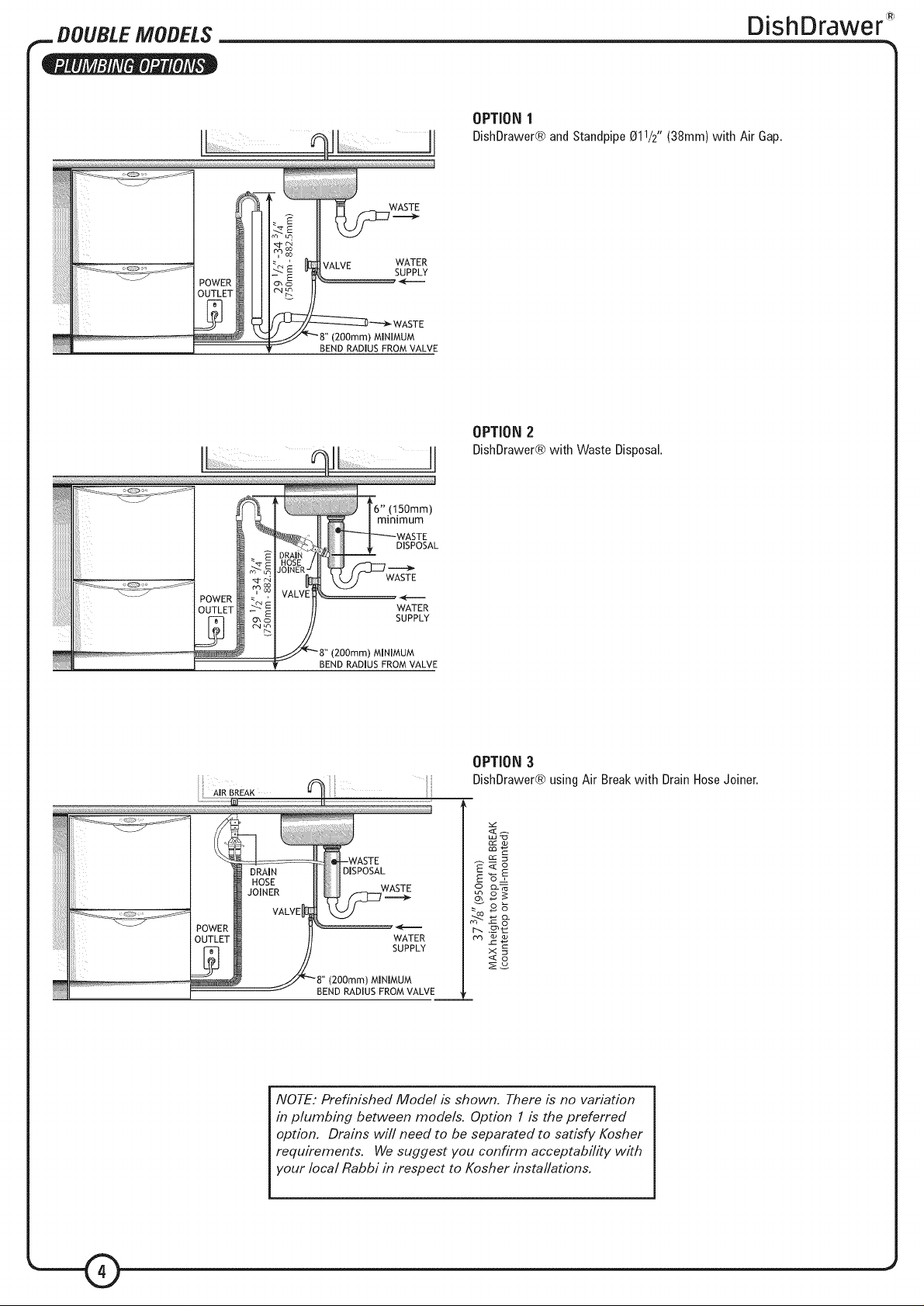

DOUBLEMODELS

DishDrawer

OPTION1

DishDrawer®andStandpipeO11/2"(38mm)with AirGap.

VALVE WATER

_ _--"_'- WASTE

(2O0mm) MINIMUM

BEND RADIUS FROM VALVE

BEND RADIUS FROM VALVL

SUPPLY

OPTION2

DishDrawer®withWasteDisposal.

OPTION3

DishDrawer®usingAirBreakwith DrainHoseJoiner.

cz= o_

DISPOSAL

WASTE

WATER

SUPPLY

(2O0mm) MINIMUM

BEND RADIUS FROM VALVE

NOTE." Prefinished Mode/is shown. There is no variation

in plumbing between mode/s. Option 1 is the preferred

option. Drains wi// need to be separated to satisfy Kosher

requirements. We suggest you confirm acceptabi/ity with

your/oca/Rabbi in respect to Kosher insta//ations.

E<o

E'_z

c_O_

r=8-

r-_ ._

©

Page 5

SINGLE MODELS

DishDrawer

(570ram)

(8mm)

WATER CONNECTION

RecommendedHOT

(Maximum 140"F/60°C)_

SuppBiedhoseto suit 3}s"{9mm) male

compressionfitting_

WATER SOFTENER MODELS

Referto ,four DishDrawer_ UserGuide

for howto set up,four water soffener_

WATER PRESSURE Maxim_,_m Mhsimum

WaterSoftener Models 145p_sJ_(10OOkPa) 14_5FsJ. (10OkPa)

OtherModels 145p.sJ.(1000kPa) 4.3p.sJ. (30kPa)

#RA_N CONNECTION

DrainHoseJoiner to suit 8s/4" ::.+.:5/64" and85}s'' ::.+.:5/G4"waste tees.

ELECTRICALCONNECTION

110_120VACpoweroutle%4_5AmpsMinimum_

WEIGHT

Full93 Ib(42kg) Prefinished

Empty62 [b (28kg} Prdinished

....... (570ram)

Side View

(4Ogmm)

Refinished model shown

_For an Integrated DishDrawer_ the producL depth is specified with an

11/16"(18ram} Integrated Panel thickness_

_ Depth of product excludes Curvature (13/1G" (30ram} o

prefinished onlv}, or Handle.

LENGTH OF SERVICES (FROMPRODUCTEXITPOH_T)

Drainhose_889/1G'' (2250mm)

hlet hose_ 68%" (1750mm}

Powersupplv cord _44" (1125mm}

NOTE:Servicesapproximatelvexit product 77/1G'' (189mm}from left;

215/s'' (550ram)from front; 15_/f' (393mm)from toF

O - •

v

%

(97mm)

Moisture

Protection Tape

Q11/2" (38mm) services

hole immediately

adjacent to corner,

/'_can be either side

227/8" {580ram)

/ throughout cavity

235/8" (600mm)

(13mm)

/

J , "- FFIO/$rUFe

i. _ protection

1/2" (13mm)

tape

Minimum

thickness of

_mportant!

Adjacent cabinetrV must

not extend above

cavity base,

These marks indicate mounLing

tab screw locations

(refer to step 1 page 7)

NOTE: All depth measurements are taken

from the front face of the adjacent cabineLry.

NOTE: To align drawer front to adiacent

cabinetry, the producL to countertop

clearance can be increased from l}s" (3ram}.

Be sure the e_ges of the services bole

are smooth or coyote& [f the services

bo_eis through a metal #artitio# the

bo_em_st be £roteote_ with the E_ge

Protector £rovi_e_ to £reve_t _ama#e to

the #ower cor_ or hoses.

Page 6

SIN#LE MODELS

WASTE

WASTE

(200ram/MNi,,'_U M

BEND RADIUS FROM VALVE

11

DishDrawer

OPTION1

DbhDrawer@andStandpipe811/2"(38ram)withAirGap.

OPTION 2

DishDrawer@with Waste Disposal.

BREAK

_6" !150mm}

mm[mum

DISPOSAL

WATER

SUPPLY

OPTION 3

DBshDrawer@usinfj Air Breakwith Drain HoseJoiner.

tY_ o_ o_

BEND RADIUS FROM VALVE

NOTE: Pre£,;_/shed Model ,@shown. X4ere ,@no var/at,;on

,@p/umb,@g between models. Option 1is t,4epreferred

opt,;on. Dra/'ns _;/'f need to be separated to sat,@fyKosher

requbements. _4/_,sudgest you con_{;rm acceptab,;//ty with

your local Rabbi ,;n respect to Kosher ,;nstaL/ationso

Page 7

_ iNSTALLATiONiNSTRUCTiONS

PLEASE NOTE: Yourmodelof DishDrawer®may differfrom the modelshown in the installation

diagrams,Installationis similarfor all modelsforeither Singleor Doublemodels,hformation re_erring

to Singlemodelsonly is highlightedir_blue,installation diagrams have beensimplifiedto enaNe

clearerinstruction. FORiNTEGRATEDPRODUCTSFOLLOWTHEiNTEGRATEDPANELPREPARATION

iNSTRUCTiONSP/N 526608,BEFOREMOVINGTHEPRODUCTiNTOTHECAVITY.

STEP1: MOVING THEPRODUCTINTOTHECAVITY

MOUNTING TAB OPTIONS

Themountingtabs are inpairs, oneon eachside of the product.Theyare

usedto securethe productto the cavity sides,installation requirestwo

sets of tab pairs be used. DOUBLEMODELSONLY- Q and_) tab pairs

OR_ and _ tab pairs may be used. All tabs would beoptimum.

ifthe top installationtabs _ areto be used,fit to the chassisby

O

inserting into the top slotsas shown. Ensurethe tabs arefully

lockedin place.

Optional Flexible Extrusion

g

ifthe cavity is 24"x 341/2"(610mm x 876mm)flexible extrusions

can beattachedalong the top andsides of the product. Openthe

drawer(s)to exposethe chassistrim. Removeextrusionbacking

andadhereto the sideandtop of DishDrawer®. Referto the

drawing for correctplacement.

Be surethat extrusions do not preventthe drawer from closing

completely.

DishDrawe¢

READTHESEiNSTRUCTiONS

COMPLETELYANDCAREFULLY.

_WARNING!

Be careful of

sharpedges.

Important!

DONOTpush

middle of drawer(s).

STEP2: REMOVINGTHETUB

O Check for obstructionsthat interferewith

cavity any may sliding

the product back. DOUBLEMODELSONLY- loosenthe feet first.

O Pushproductinto cavityto suit adjacent cabinetry. Do not push

middleof drawer(s). Be sure inlet, drainhose(s)and power supply

cordare not restricted or damagedby carefully pullingall excess

lengththroughthe serviceshole,while the product is being pushed

back intothe cavity.

FORSINGLE MODELS, check that the base of the prod_,Jc[is not

howe& Do not rest single models on your knee when moving them

into the cavity.

Important! (SmNGLEMO#ELSO[_L¥/,

The preduct may mere, Mark chassis pesitieH eu cavity,

g SINGLEMODELSONLYtGently openthe drawer and mark[he

chassispositionon the cavity, beforeremovingthe tub.

Openthe drawer (bottom drawerin DOUBLEMODELS).Release

the tub bydepressingthe right handtub clip and pushingit back

13/16" (30mm). Repeatonthe lefthandside.

4,

g Lift the tub up off the drawer runners.

Q Slide both runnersbackinto the product.

Q Place the tub onto the floor.

For SINGLE MODELS, depending on the height of the cavity, the tub

will need to be supported, eg on a chair.

Page 8

._ INSTALLATION INSTRUCTIONS

STEP3: ADJUSTINGTHEFEET(DOUBLEMODELSONLY)

DishDrawe¢

DOUBLE MODELS ONLY

Adjust the heightofthe productto suitthe cabinetry,by turning the

feetfrom inside the product usingawrench or M5 socket.

TIP - gently take the load off each foot using the slide and

then turn by hand.

NOTE." For integrated products, the upper pane/may be

a/igned with the top of the adjacent cabinetry, provided

a minimum 3/16" (5mm)c/earance from the counter is

maintained.

Important!

The productmust be levelled to within 3/32" (2.Smm)from front to

back, and side to side.

Important!

The productshould NOTsupport any part of the kitchen cabinetry.

TIP- Place a spirit level on the drawer runners to level the

product.

STEP4: SECURINGTHEPRODUCT

_]_ SINGLE MODELS ONLY

Checkthe position ofthe chassisis still where marked onthe cavity,

beforesecuringthe product.

Therearefour 5/8"(16mm)roundholes,two onthe left andtwo

the right handside in the sound insulation. Theseprovideaccessto

the mountingtabs.

Tosecurethe product to the cabinetry usea 5/8"(16mm)

Phillipsscrew ineach mountingtab.

Makesure the sound insulationis positionedcorrectlybefore

continuinginstallation.

_ DOUBLE MODELS ONLY

Screw the two top tabs to the undersideof bench. Usethe supplied

Phillips5/8" (16mm) screws. Tabscanaccommodatea maximum of

3/4"(19mm)vertical gap.

on

Page 9

_. iNSTALLATiONiNSTRUCTiONS

STEP5: ELECTRICALCONNECTION

DishDrawer

POWER

OUTLET

Thisview shows the bottom left-handrearcornerwith the cover removed

_WARNING!

The productMUST NOTbe

pluggedin at this stage.

_Be surethereis a power outletin reachof the suppliedpower cord.

ifthere is not a suitable outletavailablethen haveoneinstalled by a

qualifiedelectrician.

Do not use an extensioncord.

_ Alternatively,the DishDrawer® be permanentlyconnectedto amay

flexible conduit.

Removethe power supply cord. Removeroundknock-outfor cable

clamp. Fitsuitablecable clampfor the conduitandterminate the

wiring as shown. Terminatethe groundwire usingthe saddlethat

was usedonthe existing earth.

i_WARNING!

If permanentlyconnectingbe

sure the power isisolated.

Z_WARNING!

Thismust only be donebya certified person.

STEP6: REFITTING THE TUB

TUB CLIR _

Important!

Before refitting the tub, he sure the hosesare not twisted and the

latches at the rear of each drawer runner are facing forward.

_To refitthe make both of the latches the ofeach

drawerrunnerarefacing forward. Ensurehoses are hooping

upward. Placethe tub onthe half opendrawer runnersandclose

the drawer.

_ Checkthetub clips have reseton both sides of the tub. If not, pull

the tub clipsforward until the tub clip button is reset.

tub, sure at rear

Important!

Besure the tub clipson both sides are reset.

Page 10

._ iNSTALLATiONiNSTRUCTiONS

STEP7: CONNECTINGTHEDRAIN HOSE(S)

DRAIN

HOSE

q[-VENT

WATER

SUPPLY

DishDrawe¢

DishDrawer®with HoseJoiner(see PlumbingOptions).

Remember to slip the wire clip(s) on the drain hose(s) first,

Slipa wire clip overeach drainhose,then pushthe hoses into

the DrainHoseJoiner firmly, 5 clicks. Positionthewire clip(s)

betweenthetwo positioning ribs onthe DrainHoseJoiner.

Attach the DrainHoseJoiner to the waste tee (see Plumbing

Options).Ensurea snugfit. Ifrequireda hose clamp may beused.

WASTE

n

When using the standpipeoption (see PlumbingOptions),hose(s)

shouldnot extendfurtherthan 43/4'' (120mm) downthe standpipe,

in orderto prevent siphoning.

Attach the DrainHoseSupportto the cabinetry(with the screw

supplied)to preventsiphoningandto keepthe drain hose(s)

from kinking. If required,the DrainHose(s)may betrimmed to a

suitablelength.

STANDPIPE

(see Plumbin9

Options 1 or 2)

STEP8: CONNECTINGTHEINLETHOSE

Important?

Minimum holesize to be connectedto the waste tee is 1/z"

(12.7mm).

Be sure the DrainHose(s)are fully extended te preventsagging

(see diagramte the left).

The DrainHosesupport must be used.

DrainHosejoinermust not support weight of hoses. Keep

excess lengthef Drain Hoseen the DishDrawer® side ef the

DrainHosesupport or trim te suit.

i_WARNING?

DONOTplugthe productin

at this stage.

_ Connectthe Inlet Hoseto the water supply. Be surethe sealing

washer is in place. Thehose couplingmust betightened a further

halfturn after seal contact.

Important?

DONOTcut the inlet hose.

TIP - Turn the water valve ON to check for any leaks,

Alternatively flexible stainless steel hose can be plumbed directly to

the inlet valve using a 3/8" brass adaptor (p/n 526161) available from

the nearest Fisher 8 Paykel Authorized Service Agent.

NOTE," SINGLE MODELS DO NOT HA VE A TOE KICK _0

INSTALL PROCEED _0 STEP 12 F/NAL CHECK L/S_

Page 11

._ INSTALLATION INSTRUCTIONS

STEP9: MEASURINGTHETOEKICK(DOUBLEMODELS ONLY)

_ Partiallyopenthe bottomdrawer. Turn PrefinishedToeKick

/

/

|

DishDrawer

upsidedown and holdvertically againstthe bottom edgeof the

Tub side (not the drawer front).

Mark the position ofthe bottomedge of the Tubsideonthe ToeKick.

Choosethe nearestgrooveto the pencilmarkwhich will result

in the shortestToeKick.

STEP

10:

TRIMMING THETOEKICK (DOUBLEMODELS ONLY)

©

Important!

Before cutting ensurethe Toe Kickis positionedon a wooden

choppingboardto avoid damageto surrounding area.

_On the chosen groovecut downthe vertical ribs at the centreand

the endsusing a knife. Cut alongfull lengthwith a knife.TurnToe

Kick over,bendand then cut from front. Sandor scrapebottom edge

to remove rough patches.

Z_WARNING!

Remove all sharp edges

_To avoida cutting hazardremoveall sharpedgesafter trimming.

_ RemoveToeKicktabs bysnappingthem off.

Page 12

_. iNSTALLATiONiNSTRUCTiONS

STEP11 FITTINGTHETOEKICKTOTHEPRODUCT(DOUBLEMODELS ONLY)

DishDrawer

Toekick

®

mountingrails

_ Partlyopenbottomdrawer. PositionToeKickbehinddoor and slide

ontothe mountingrails onthe undersideof tub.

_ Closebottom drawer, checkif flush with adjacentcabinetry.

If requiredopendrawer andadjust.

Note," C/earance between Toe Kick and floor must be

15/32" (12ram) minimum,

When ToeKick is in position, openbottom drawer and gentlyfasten

the ToeKickscrews, on eachside.

Important!

DONOTovertighten screws.

Overtighteningwill damagethe pJasticmounting detail.

STEP12: FINAL CHECKLIST (DOUBLE AND S/NGLE MODELS)

0

Besureproduct is level,securelyfastened to the cabinetry and

opensandclosesfreely. TheDishDrawer® must befree to close

with no resistancefrom the cabinetry.

0

Besurethe inlet hoseto valveconnectionis tightened a further half

turn after seal contact.

0

Besureany knock-outs or plugs indrain connectionhave been

drilledout and drainconnectionhasbeen made.

0

TurnONthe power andwater supply. The DishDrawer®should

beepand light up.

0

Openthe drawer(s)and check operationof Wash ProgramControl

Panelandcheckthe sprayarm(s)are in placeandfreeto rotate.

0

Onthe Wash ProgramControlPanelselect Rinseandclosethe

drawer(s). Startthe programby pressingthe Start!Pausebutton.

0

After the Rinseprogramhasfinished, besurethe machinehasrun

anddrainedcorrectly.

0

Checkwater supply anddrainageconnectionfor leakage.

0

Repeat for each Drawer.

0

LEAVE ALL LITERATURE WITH CUSTOMER,

STEP13: CUSTOMERCARE

TROUBLESHOOTING

0 Excessivewater remainingabovethe filter plate, after the

rinsecycle; checkfor kinkeddrainhosesor blockedwaste

connection.

0 No water supply;checkwater is connected,ONandthere is

the specifiedwater pressure.

0 DishDrawer® does not light up when the tub is opened;

be surepower is connectedand is switched ON.

0 Water aroundwater supply and drainageconnections-

check connections,existing plumbingand hosesfor leaks.

0 if a fault occurs, consultthe FaultCodeSectionofthe

UserGuide.

0 if unable to resolve, contact your Customer Care Centre.

if you haveany questionsconcerningthe installation of this DishDrawer®,

pleasecontact your Fisher8 PaykelAuthorizedServiceAgent.

FOR THE UNITED STATES OF AMERICA (USA) 8 CANADA

Fisher8 PaykelAppliances

5900 SkylabRoad

HuntingtonBeach

CA 92647

PHONE TOLL FREE 1888 9 F/VP USA

1888 9 367 872

wwwo usa° fisherpagkelo corn

Loading...

Loading...