Page 1

THE PROFESSIONAL DOWNDRAFT

Installation Guide

MODELS:

DD-36SS

DD-30SS

Page 2

1

A MESSAGE TO OUR CUSTOMERS

Thank you for selecting this DCS Downdraft Vent System. Because of its unique features, we have developed

this Installation Guide. It contains valuable information on how to properly install your new Downdraft

Vent System for years of safe and enjoyable cooking.

For your convenience,product questions can be answered by a DCS Customer Care Representative by

phone: 1-888-281-5698, email: support@dcsappliances.com

or by mail:

Fisher & Paykel Appliances,Inc.

Attention: DCS Customer Care

5900 Skylab Road,

Huntington Beach, CA 92647

WAR NI NG

TO REDUCE THE RISK OF A COOKTOP GREASE FIRE:

Never leave surface units unattended at high settings. Boilovers cause

smoking and greasy spillovers that may ignite. Heat oils slowly on low or

medium setting. Always turn the Downdraft “ON” when cooking at high heat

or when cooking flaming foods. Clean ventilating fans frequently. Grease

should not be allowed to accumulate on fan or filter. Use proper pan size.

Always use cookware appropriate for the size of the surface element.

WAR NING

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT OF A COOKTOP

GREASE FIRE, OBSERVE THE FOLLOWING: SMOTHER FLAMES with a closefitting lid, cookie sheet, or metal tray,then turn off the burner. BE CAREFUL TO

PREVENT BURNS. If the flames do not go out immediately EVACUATE AND

CALL THE FIRE DEPARTMENT. NEVER PICK UP A FLAMING PAN - You may be

burned. DO NOT USE WATER, including wet dishcloths or towels - a violent

steam explosion will result. Use an extinguisher ONLY if:

1.You know you have a Class ABC extinguisher, and you already know how to

operate it.

2.The fire is small and contained in the area where it started.

3.The fire department is being called.

4.You can fight the fire with your back to an exit.

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE.

Page 3

2

TABLE OF CONTENTS

SAFETY PRACTICES & PRECAUTIONS ..............................................................................................................................3

PLANNING THE INSTALLATION...........................................................................................................................................4

Venting Requirements...........................................................................................................................................4

Electrical Requirements ........................................................................................................................................4

SPECIFICATIONS .......................................................................................................................................................................5

INSTALLATION INSTRUCTIONS ....................................................................................................................................6-11

Tools Needed ............................................................................................................................................................6

Plan The Ductwork..................................................................................................................................................6

Calculate the Duct Run Length..........................................................................................................................6

Plan And Make The Cutout..................................................................................................................................7

Installing The Downdraft Vent .....................................................................................................................8-11

WIRING DIAGRAM .................................................................................................................................................................12

HOW TO OBTAIN SERVICE..................................................................................................................................................13

WAR RANT Y ........................................................................................................................................................................14-15

Page 4

3

SAFETY PRACTICES & PRECAUTIONS

WAR NING:

ALL WALL AND FLOOR OPENINGS WHERE THE Downdraft IS INSTALLED MUST

BE SEALED.

Consult the cooktop installation instructions given by the manufacturer before making any cutouts.

MOBILE HOME INSTALLATION - The installation of this Downdraft must conform to the Manufactured

Home Construction and Safety Standards, Title 24 CFR, Part 3280 (formerly Federal Standard for

Mobile Home Construction and Safety,Title 24, HUD,Part 280). Four wire power supply must be used

and the appliance wiring must be revised. See Electrical Requirements (page 4).

Venting system MUST terminate outside the home.

DO NOT terminate the ductwork in an attic or other enclosed space.

DO NOT use 4" laundry-type wall caps.

Flexible-type ductwork is not recommended.

DO NOT obstruct the flow of combustion and ventilation air.

Failure to follow venting requirements may result in a fire.

Electrical ground is required on this downdraft ventilation system.

If cold water pipe is interrupted by plastic, non-metallic gaskets or other materials, DO NOT use

for grounding.

DO NOT ground to a gas pipe.

DO NOT have a fuse in the neutral or grounding circuit. A fuse in the neutral or grounding

circuit could result in electrical shock.

Check with a qualified electrician if you are in doubt as to whether the downdraft is properly

grounded.

Failure to follow electrical requirements may result in a fire.

WAR NING:

TO REDUCE THE RISK OF FIRE, ELECTRICAL SHOCK,OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

Use this unit only in the manner intended by the manufacturer. If you have

any questions, contact the manufacturer. Before servicing or cleaning unit,

switch power off at service panel and lock the service disconnecting means

to prevent power from being switched on accidentally. When the service

disconnecting means cannot be locked,securely fasten a prominent warning

device, such as a tag, to the service panel. Installation Work And Electrical

Wiring Must Be Done By Qualified Person(s) In Accordance With All

Applicable Codes And Standards, Including Fire-Rated Construction.

Sufficient air is needed for proper combustion and exhausting of gases from

fuel burning equipment through the flue (chimney) to prevent backdrafting.

Follow the heating equipment manufacturer's guideline and safety

standards such as those published by the National Fire Protection

Association (NFPA), and the American Society for Heating, Refrigeration and

Air Conditioning Engineers (ASHRAE), and the local code authorities. When

cutting or drilling into wall or ceiling, do not damage electrical wiring and

other hidden utilities. Ducted fans must always be vented to the outdoors.

Page 5

4

PLANNING THE INSTALLATION

VENTING REQUIREMENTS

Determine which venting method is best for your application. Ductwork can extend either through

the wall or the roof. The length of the ductwork and the number of elbows should be kept to a minimum to provide efficient performance. The size of the ductwork should be uniform. Do not install

two elbows together. Use duct tape to seal all joints in the ductwork system. Use caulking to seal exterior wall or floor opening around the cap. Flexible ductwork is not recommended. If it is used, each

foot of flexible ductwork used is equivalent to two feet of straight metal ductwork when calculating

the duct run length. Thus, a flexible elbow equals two standard elbows. Make sure there is proper

clearance within the wall or floor for exhaust duct before making cutouts. Do not cut a joist or stud

unless absolutely necessary. If a joist or stud must be cut, then a supporting frame must be

constructed.

WAR NING:

To Reduce The Risk Of Fire,Use Only Metal Ductwork.

ELECTRICAL REQUIREMENTS

A 120 volt, 60 Hz AC-only electrical supply is required on a separate 15 amp circuit,fused on both

sides of the line. A time-delay fuse or circuit breaker is recommended. The fuse must be sized per

local codes in accordance with the electrical rating of this unit as specified on the serial/rating plate

located inside the unit near the field wiring compartment.

THIS UNIT MUST BE CONNECTED WITH COPPER WIRE ONLY. Wire sizes must conform to the requirements of the National Electrical Code,ANSI/NFPA 70 -latest edition,and all local codes and ordinances.

Wire size and connections must conform with the rating of the appliance. Copies of the standard listed

above can be obtained from:

National Fire Protection Association

Battery March Park

Quincy,Massachusetts 02269

This appliance should be connected directly to the fuse disconnect (or circuit breaker) through

flexible, armored or non-metallic sheathed copper cable. Allow some slack in the cable so the

appliance can be moved if servicing is ever necessary. A UL Listed, 1/2" conduit connector must be

provided at each end of the power supply cable (at the appliance and at the junction box). When

making the electrical connection, cut a 1-1/4" hole in the wall. A hole cut through wood must be

sanded until smooth. A hole through metal must have a grommet.

NOTE: SUITABLE FOR USE WITH SOLID STATE SPEED CONTROLS.

CAUTION:

For General Ventilating Use Only. Do Not Use To Exhaust Hazardous or

Explosive Materials and Vapors.

Page 6

5

SPECIFICATIONS

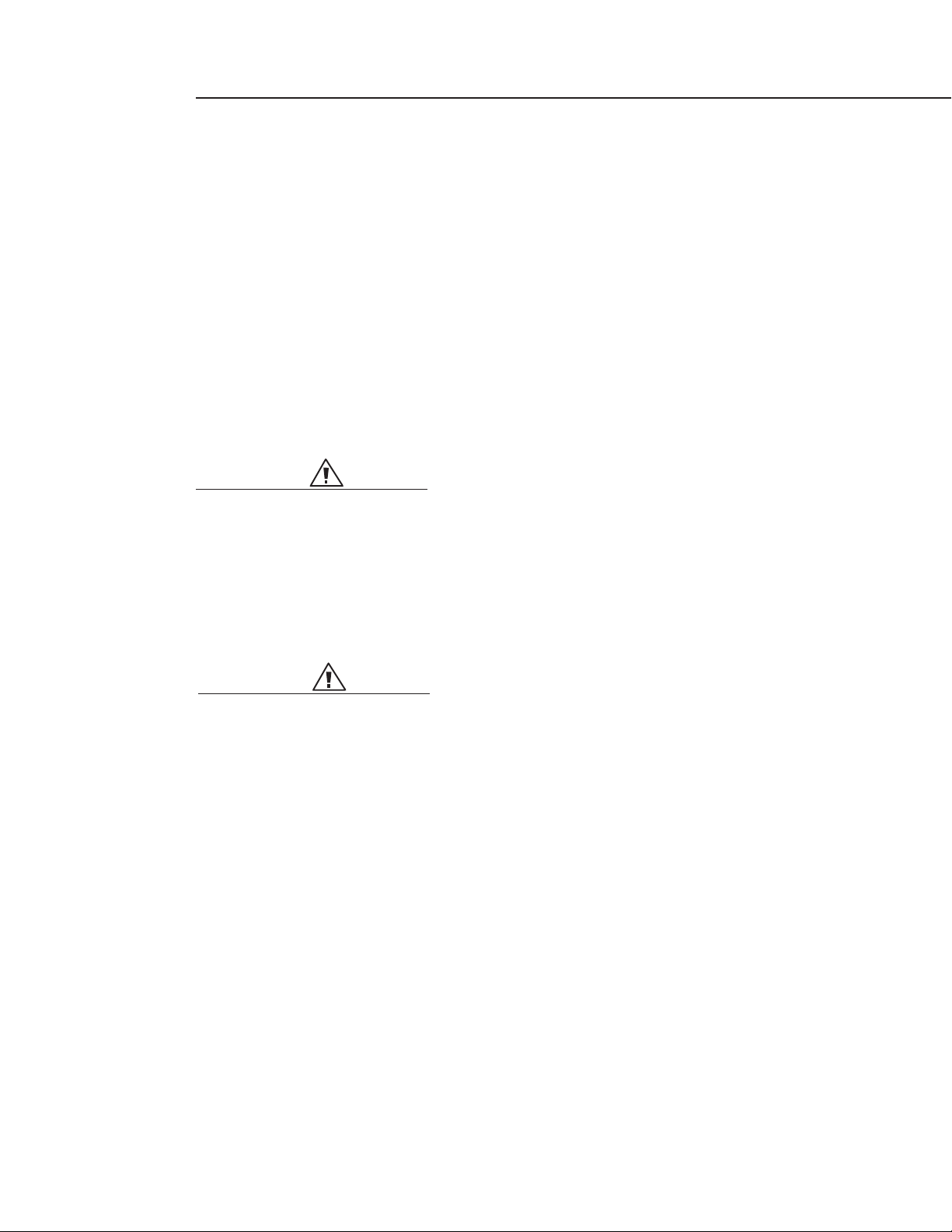

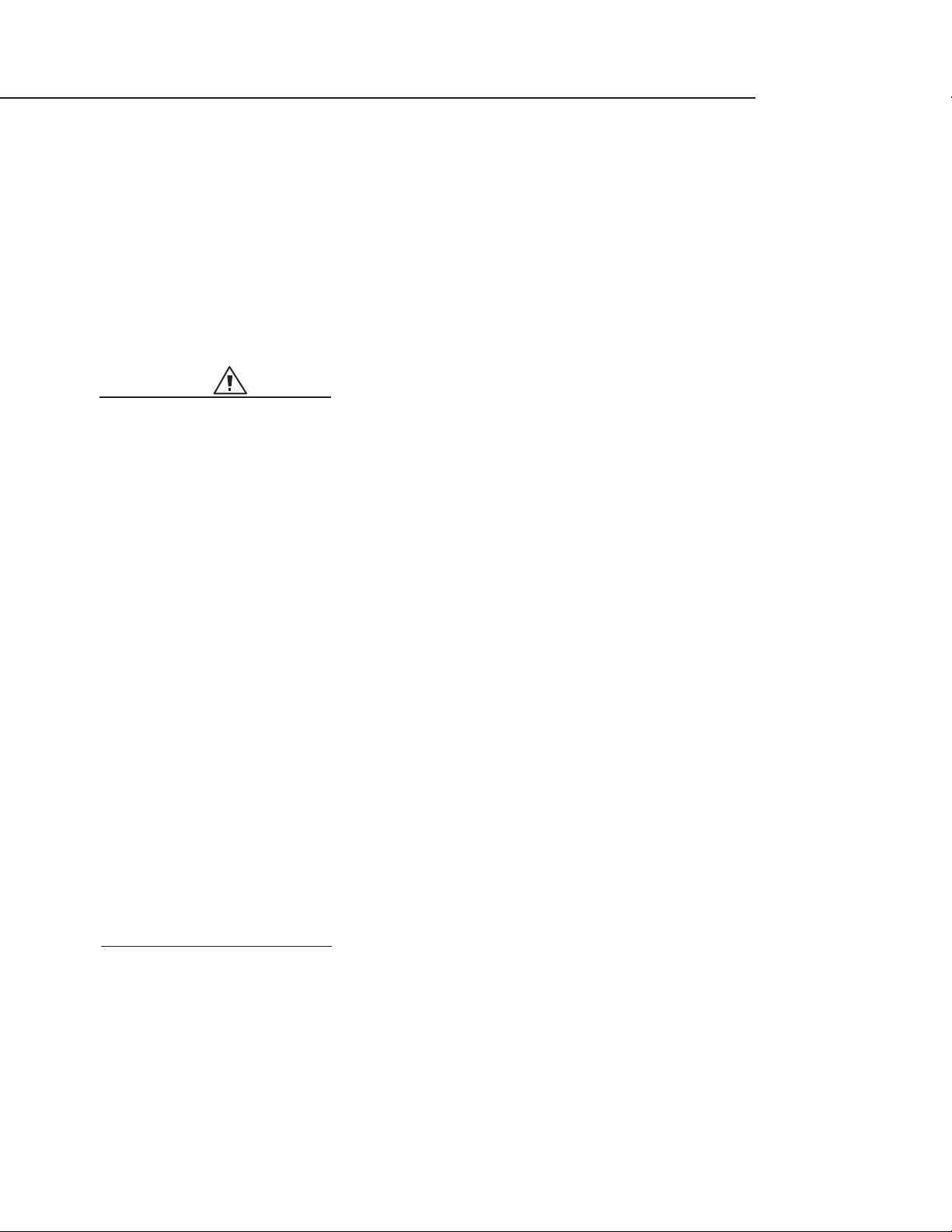

Fig. 01 Downdraft Dimensions

FIG.02 Ductwork Cutout Dimensions

8-1/4"

27" for 30" model

33" for 36" model

30"

or

36"

1-1/2"

3-1/4"

17-3/16"

x 10"

16"

16"

9-3/8"

2-1/8"

4-1/8"

+

1/2 "

min.

23-9/16"

3/8"

26-1/8"

17-9/16"

3-1/4"

4-1/8"

3/8"

10"

4-1/8"

+

1/2"

min.

+

1/2"

min.

Page 7

45° Elbow 5.0 feet

90° Elbow 7.0 feet

90° Flat Elbow 12.0 feet

Wall Cap 0.0 feet

6

INSTALLATION INSTRUCTIONS

TOOLS NEEDED FOR INSTALLATION PARTS SUPPLIED FOR INSTALLATION

Saber Saw or Jig Saw 6 Mounting Brackets

Drill 2 End Caps

1-1/4 Wood Drill Bit 16 Screws

Pliers 1 Backdraft Damper

Phillips Screwdriver

Flat Blade Screwdriver

Wire Stripper or Utility Knife

Metal Snips

Measuring Tape or Ruler

Level

Pencil

Caulking Gun

Duct Tape

PA RTS NEEDED FOR INSTALLATION

2 Conduit Connectors

Power Supply Cable

1 Wall or Roof Cap

All Metal Ductwork

PLAN THE DUCTWORK

The DCS 36” and 30” downdraft vent system can be

ducted in four different directions; down, left, right or

back using a 3-1/4" X 10" rectangular vent. Fig. 03

illustrates venting options. Fig. 02 shows the ductwork

cutout dimensions.

CALCULATE THE DUCT RUN LENGTH

The ductwork length should not exceed 35 equivalent

feet for 3-1/4" X 10" duct, or 60 equivalent feet for 9"

round duct. Calculate the length of the ductwork by

adding the equivalent feet listed in Fig. 04 for each piece

of duct in the complete system. An example is given in Fig. 05. For best results, use no more than

three 90° elbows. Make sure that there is a minimum of 24" of straight duct between elbows if more

than one is used. Do not install two elbows together. Round duct is recommended instead of

rectangular duct especially if elbows are needed. Rectangular duct should transition to round as soon

as possible (6” round minimum).

9 Feet Straight Duct 9.0 feet

2 - 90° Elbows 14.0 feet

Wall Cap 0.0 feet

Total System 23.0 feet

FIG.03 Ducting

FIG.04

FIG.05

VENTING DOWN VENTING LEFT

VENTINGRIGHT VENTING

BACK

Page 8

7

PLAN AND MAKE THE CUTOUT

It is recommended that the installer draw the cooktop and downdraft cutouts on the countertop

before making any cutouts to avoid mistakes. Fig. 06 shows the cutout dimensions for DCS CT-365

and CT-304 and for all other cooktops see Fig. 06a (page 8). Fig. 07 shows the tolerances between the

cooktop and the downdraft. These tolerances must be observed for proper installation.

WAR NING:

When planning the cutout for the downdraft:

Draw both the cooktop and downdraft cutouts on the countertop before

making any cuts.

Check that there is enough room in the cabinet for both. Failure to follow

these warnings could result in damage to the countertop.

WAR NING:

These tolerances must be observed!

B

CAUTION:

36" min. to

combustible

material ,

from cooking

surface

A

C

D

E

F

G

H

K

I

J

electrical

and

gas supply

As defined in the “National Fuel Gas Code” (ANSI Z223.1, latest edition).

NOTE: See manufacturer's recommendations for ducting specifications.

NOTE: When installing a 30" Cooktop with a Downdraft (DD-30SS), a minimum of

a 26" cabinetry depth is required.

L

INSTALLATION INSTRUCTIONS

Fig. 06

DCS CT-365 AND CT-304 DROP-IN COOKTOP

CUT-OUT DIMENSIONS (WITH DOWNDRAFT)

A) 18” min.

B) 13” max.

C) 5” min. to combustibles∆

D) 19-3/4” depth

E) 34-3/4” width for CT-365

28-5/8” width for CT-304

F) 33-1/2” width for DD36

27-1/2” width for DD30

G) 1/2” min.

H) 2-1/2”

I) 9”

J) 26-1/2”

K) Min. 36” for CT-365

Min.30” for CT-304

L) 26”Min.

Page 9

8

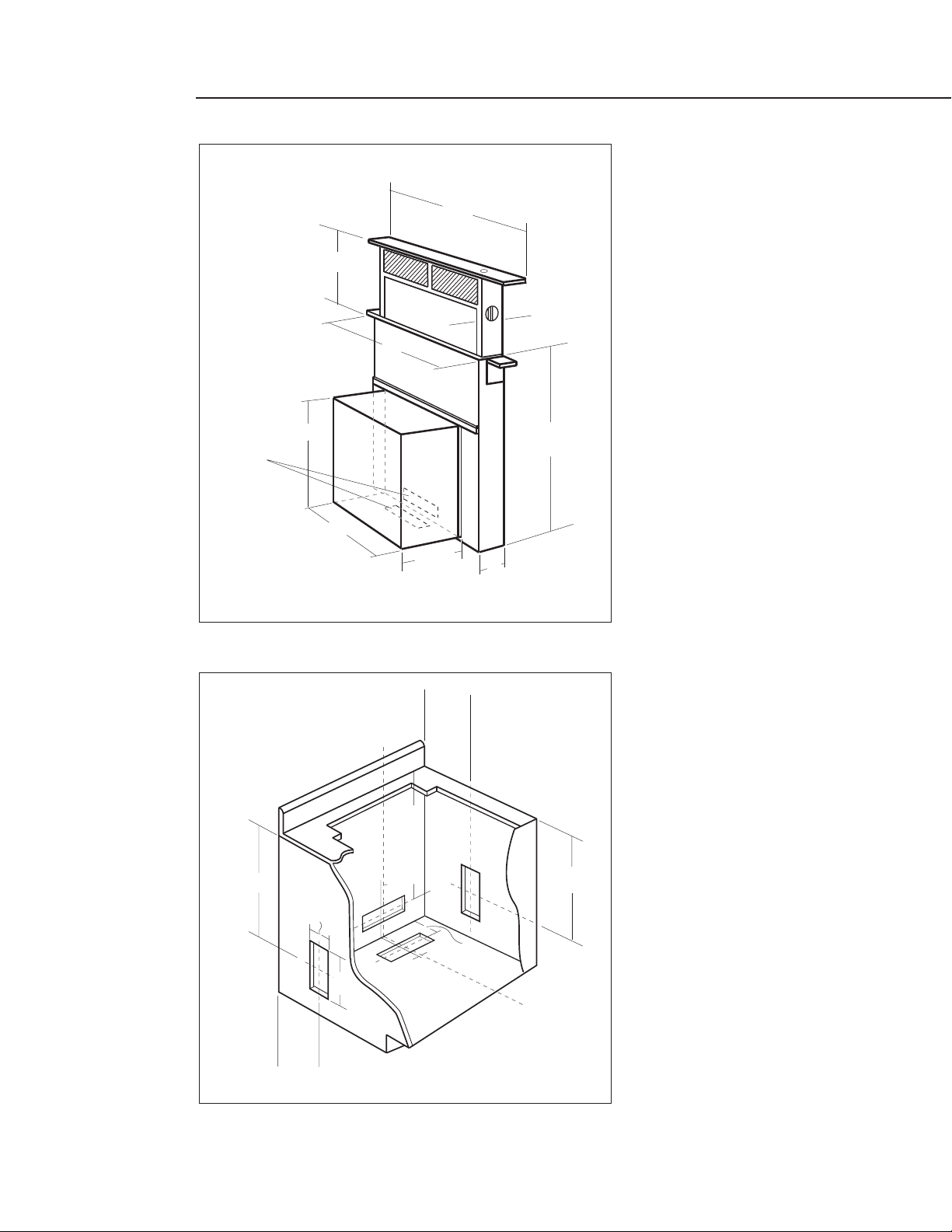

INSTALLING DOWNDRAFT VENT

1) Remove the unit from the carton

and place on a flat surface for

assembly. Cover the surface to

prevent accidental damage.

Remove all downdraft parts

including the 6 mounting

brackets, 2 end caps, 16 screws,

literature package,and backdraft

damper.

2) Attach the overcounter support

arms to the left and right sides of

the downdraft body as indicated

in Fig. 08. Two short screws are

provided. Attach the end caps to

the left and right sides of the

downdraft over the overcounter

support arms. Attach the lower

support legs to left and right

sides of the downdraft into the

threaded slots on each side.

INSTALLATION INSTRUCTIONS

Fig. 06a

FIG.07

DROP-IN COOKTOP (MISC.BRAND)

CUT-OUT DIMENSIONS (WITH DOWNDRAFT)

Rear of Downdraft Cutout

Rear Edge of Cooktop

5" Min.

clearance

to combustible

surface

1/2" Min.

1-3/4"

*

33-1/2" (DD-36)

27-1/2" (DD-30)

* Measured from the rear edge of cooktop to rear of downdraft

cutout. It is recommended that the installer draw the cooktop

and downdraft cutouts on the countertop before making any

cutouts to avoid mistakes.

36 "

3/4"

25 "

CUTOUT DEPTH

COOKTOP

22-1/2"

24 "

V

E

N

T

1/4"

1/2" min.

3/4"

COOKTOP

1-7/8"

1/4"

FRONT

VENT

COUNT ERTOP

Page 10

9

INSTALLING DOWNDRAFT

(continued)

The lower support legs have

holes for mounting to the

cabinet floor and can be

installed on both sides

depending upon the length

required. Determine if the

holes should be in the front or

on the sides.

3) Carefully insert the unit into

the cutout. Due to the size and

weight, two people are

recommended when lifting

this unit. Make sure that the

downdraft is fully seated in the

cutout and the support arms

rest firmly on the countertop.

4) Adjust the lower support legs

until both rest firmly on the

cabinet floor. Place a level

vertically on the front side of

the blower box to make sure

that the unit is level and not leaning to

the front or rear. Once the unit is properly

aligned,mark a starter hole on the cabinet

floor where the lower support legs will

attach to the cabinet floor.

5) Remove the unit from the cabinet. Drill

starter holes in the cabinet floor for the

leg screws.

6) DCS downdrafts are shipped from the

factory ready to vent in the down

position. If you need to vent back, left or

right, then the blower must be repositioned.

To vent to the left or the right:

Four hex nuts attach the blower box to the

downdraft body. Remove all four nuts and

carefully remove the blower box. To vent left

or right, simply rotate the blower box 90° to

the left or right and re-assemble.

To vent to the rear:

Venting to the rear requires that the blower be

repositioned inside the blower box as

indicated in Fig. 09. The blower is attached to the blower box by 6 screws. Remove the blower from

the blower box. Note the position of the angle mounting rails on each side of the blower. To vent to

the rear,both mounting rails must be repositioned on the blower as illustrated in Fig.10. Attach the

mounting rails as indicated. Re-attach the blower to the blower box. Re-attach the blower box to

INSTALLATION INSTRUCTIONS

FIG.08

FIG.09

FIG.10

UNDER COUNTER

MOUNT BRACKETS

OVER COUNTER

SUPPORT ARMS

LOWER SUPPORT LEGS

end cap

Venting Left, Right or Down

Venting to the Rear

Page 11

10

INSTALLING DOWNDRAFT (continued)

the downdraft. The square metal frame must be attached to the mouth of the blower. The exhaust

knockout on the rear must be removed. A metal plate and two screws are supplied in the hardware

package to cover the unused exhaust exit.

CAUTION:

Make sure that the wiring cable connecting the blower to the field wiring

compartment remains securely attached under the two cable clamps.

7) Attach the Backdraft Damper.

8) Remove the field wiring compartment cover and determine which direction the wiring will run

from the appliance to the wiring box and remove the wiring knockout.

9) Insert the downdraft unit into the countertop cutout. Make sure that the unit is firmly placed at

the rear of the cutout. Fasten the legs to the cabinet floor using the two longer Phillips head

screws supplied in the hardware package.

WAR NING:

When attaching the Under Counter Mounting Brackets:

DO NOT drill into the countertop surface.

Check that the mounting screws are the proper length and will not extend

through the countertop surface when tightened. Failure to follow these

warnings could result in damage to the countertop surface.

10) Attach the downdraft to the countertop using the undercounter mounting brackets (Fig. 08). This

system is designed to adjust to different countertop thicknesses. Using the small Phillips head

machine screws in the hardware package, attach one undercounter mounting bracket to the slot

on the upper right corner of the unit. Attach the other end of the bracket to the underside of the

countertop.

11) Thread the power supply cable through the wiring knockout into the field wiring compartment.

Connect the three white wires

together with a twist-on wire

connector. Connect the two

black wires with a twist-on wire

connector. Attach the Green (or

Green and Yellow) ground wire

to the eyelet with the green

grounding screw. Replace the

field wiring compartment cover.

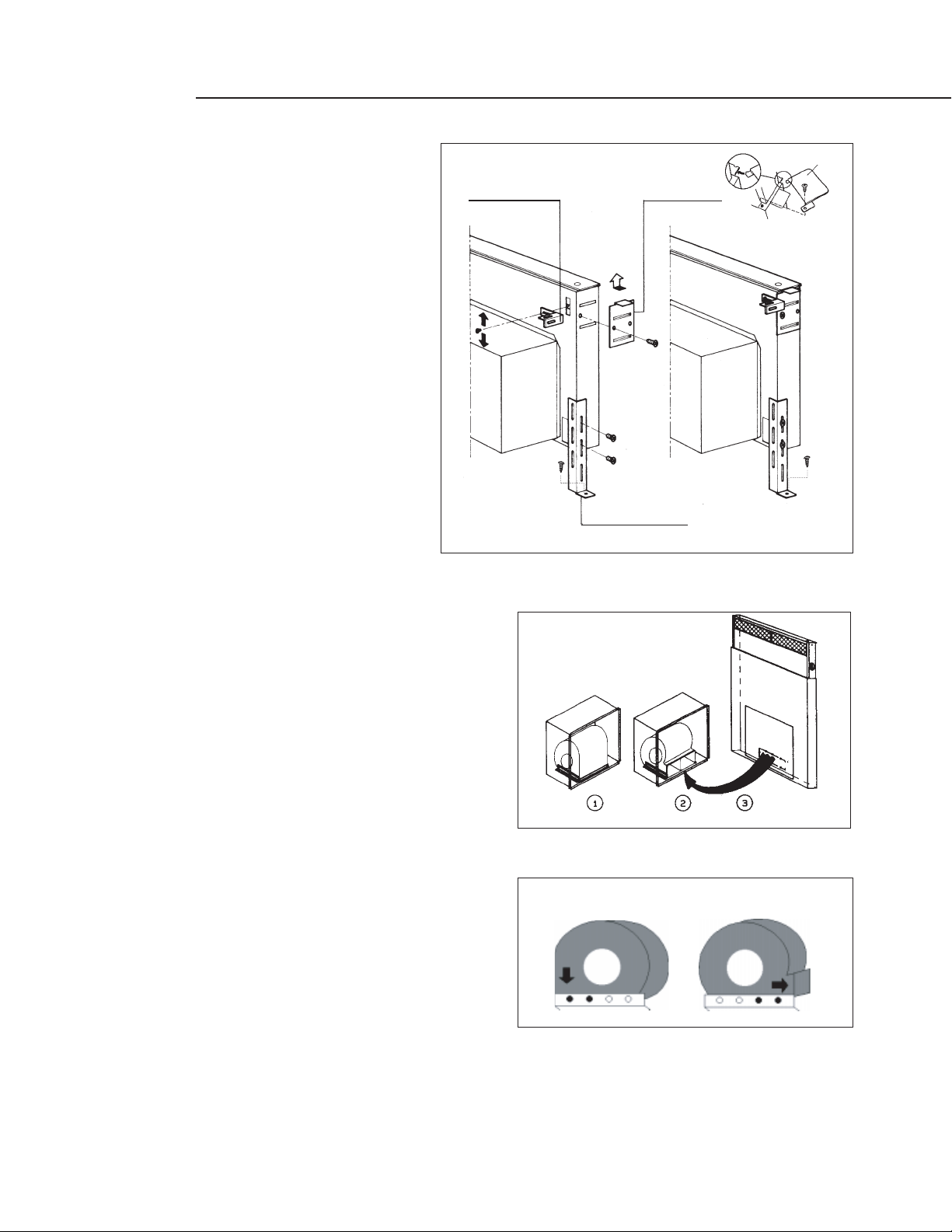

12) Turn the power supply on. Push

and hold the Up/Down button

momentarily. The downdraft will

rise out of the countertop and

stop in the fully extended

position. Position the top strip

over the the top of the

downdraft, lining up the fixing

hooks and the hole for the push

button. Snap into place. Turn the blower on. The blower control switch is located on the right

hand side of the plenum as indicated in Fig. 11. If the blower does not work, refer to section

entitled "If The Blower Does Not Operate" located on page 11"

INSTALLATION INSTRUCTIONS

FIG.11

Up/Down

Button

Blower Control

Switch

Knock-out

Wiring

Box

Grounding

Screw

Wiring Box Cover

Page 12

11

INSTALLING DOWNDRAFT (continued)

13) Connect the ductwork to the Backdraft damper. Seal all joints with duct tape and vent to the

outside of the home.

14) Install the cooktop according to the cooktop manufacturer's instructions. Check to make sure

that the rear edge of the cooktop overlaps the front edge of the downdraft by 3/8".

IF THE BLOWER DOES NOT OPERATE:

1) Check that the circuit breaker is not tripped or the house fuse blown.

2) Check that the grease filters are properly installed. (See the section on Safety Microswitches

page 4 of Use and Care Guide).

3) Disconnect the power supply and check that the wiring connections have been made properly.

INSTALLATION INSTRUCTIONS

Page 13

12

WIRING DIAGRAM

GEAR

MOTOR

BLU

WHT

WHT

BLK

WHT

BLK

BLK

BLK

WIRING

BOX

LINE IN

120 VAC

60 Hz

GRN

WHT

ISWITCH

DOWN N.C.

SWITCH

UP N.C.

BLK BLK

BLK BLK

BLK

BLK

BLK

WHT

SPEED

CONTROL

SWITCH

FAN N.O.

SWITCH

FILTER N.O.

N.O.

WHT

11 UF

PUSH

BUTTON

BLOWER

MOTOR

M

8/50K-A120

BLU

BLU

Page 14

13

SERVICE

HOW TO OBTAIN SERVICE:

Before you call for service:

1) Is the circuit breaker tripped or the fuse blown?

2) Is there a power outage in the area?

3) Are the grease filters properly installed?

4) Will the unit go up/down and the motor control is ON?

For warranty service, contact DCS Customer Care at (888) 281-5698. Before you call, please have the

following information ready:

Model Number

Serial Number

Date of installation

A brief description of the problem

Your satisfaction is of the utmost importance to us. If a problem cannot be resolved to your satisfaction,

please write at:

Write:

Fisher & Paykel Appliances,Inc.

Attention: DCS Customer Care

5900 Skylab Road

Huntington Beach, CA 92647

Page 15

14

WARRANT Y

LIMITED WARRANTY

When you purchase a new DCS Ventilation Product for personal or consumer use you automatically

receive a One year Limited Warranty covering parts and labor for the entire product, and a Five year

Limited Warranty on the switches and motor (parts only) for servicing within the 48 mainland United

States,Hawaii,Washington D.C and Canada.In Alaska the Limited Warranty is the same except that you

must pay to ship the Product to the service shop or for the service technician’s travel to your home.

Products for use in Canada must be purchased through the Canadian distribution channel to ensure

regulatory compliance.

If the Product is installed in a motor vehicle, boat or similar mobile facility, you receive the same One

year Limited Warranty, but you must bring the vehicle, boat or mobile facility containing the Product

to the service shop at your expense or pay the service technician’s travel to the location of the Product.

FISHER & PAYKEL UNDERTAKES TO:

Repair without cost to the owner either for material or labor any part of the Product,the serial number

of which appears on the Product, which is found to be defective. In Alaska, you must pay to ship the

Product to the service shop or for the service technician’s travel to your home. If the Product is

installed in a motor vehicle,boat or similar mobile facility,you must bring it to the service shop at your

expense or pay for the service technician’s travel to the location of the Product. If we are unable to

repair a defective part of the Product after a reasonable number of attempts, at our option we may

replace the part or the Product, or we may provide you a full refund of the purchase price of the

Product (not including installation or other charges).

This warranty extends to the original purchaser and any succeeding owner of the Product for products

purchased for ordinary single-family home use. All service under this Limited Warranty shall be

provided by Fisher & Paykel or its Authorized DCS Service Agent during normal business hours.

HOW LONG DOES THIS LIMITED WARRANTY LAST?

Our liability under this Limited Warranty for the entire product expires ONE YEAR from the date of

purchase of the Product by the first consumer. Our liability under this Limited Warranty for the

switches and motor (parts only) expires FIVE YEARS from the date of purchase of the Product by the

first consumer.

Our liability under any implied warranties, including the implied warranty of merchantability (an

unwritten warranty that the Product is fit for ordinary use) also expires ONE YEAR (or such longer

period as required by applicable law) from the date of purchase of the Product by the first consumer.

Some states do not allow limitations on how long an implied warranty lasts, so this limit on implied

warranties may not apply to you.

THIS WARRANTY DOES NOT COVER:

A. Service calls that are not related to any defect in the Product. The cost of a service call will be

charged if the problem is not found to be a defect of the Product.For example:

1. Correct faulty installation of the Product.

2. Instruct you how to use the Product.

3. Replace house fuses, reset circuit breakers, correct house wiring or plumbing, or replace light

bulbs.

4. Correct fault(s) caused by the user.

5. Change the set-up of the Product.

6. Unauthorized modifications of the Product.

Page 16

15

WARRANT Y

7. Noise or vibration that is considered normal, for example, drain/fan sounds, regeneration

noises or user warning beeps.

8. Correcting damage caused by pests, for example, rats,cockroaches etc.

B. Defects caused by factors other than:

1. Normal domestic use or

2. Use in accordance with the Product’s User Guide.

C. Defects to the Product caused by accident, neglect,misuse, fire,flood or Act of God.

D. The cost of repairs carried out by non-authorized repairers or the cost of correcting such

unauthorized repairs.

E. Travel Fees and associated charges incurred when the product is installed in a location with limited

or restricted access. (i.e. airplane flights, ferry charges, isolated geographic areas).

F. Normal recommended maintenance as set forth in the Product’s User Guide.

If you have an installation problem contact your dealer or installer.You are responsible for providing

adequate electrical, exhausting and other connection facilities. We are not responsible for

consequential or incidental damages (the cost of repairing or replacing other property damaged if the

Product is defective or any of your expenses caused if the Product is defective). Some states do not

allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you.

HOW TO GET SERVICE

Please read your User Guide. If you then have any questions about operating the Product, need the

name of your local DCS Authorized Service Agent,or believe the Product is defective and wish service

under this Limited Warranty, please contact your dealer or call us at:

TOLL FREE 1-888-281 5698 or contact us through our web site: www.dcsappliances.com.

You may be required to provide reasonable proof of the date of purchase of the Product before the

Product will be serviced under this Limited Warranty.

COMMERCIAL USE

This warranty applies to appliances used in residential applications; it does not cover their use in

commercial situations.

NO OTHER WARRANTIES

This Limited Warranty is the complete and exclusive agreement between you and Fisher & Paykel

regarding any defect in the Product. None of our employees (or our Authorized Service Agents) are

authorised to make any addition or modification to this Limited Warranty.

Warrantor: Fisher & Paykel Appliances, Inc.

If you need further help concerning this Limited Warranty,please call us at the above number,or write

to:

Fisher & Paykel Appliances, Inc.

5900 Skylab Road, Huntington Beach, CA 92647

This Limited Warranty gives you specific legal rights, and you may also have other rights which vary

from state to state.

Page 17

Fisher & Paykel Appliances,Inc.

5900 Skylab Road, Huntington Beach, CA 92647

Customer Care: 888.281.5698

Fax: 714.372.7003

www.dcsappliances.com

Part No. 17493 Rev. C

Litho in USA 02/2005

As product improvement is an ongoing process at DCS,

we reserve the right to change specifications or design

without notice.

DCS améliore constamment ses produits et se réserve le

droit de modifier les spécifications ou la conception de

ses produits sans aucun préavis.

Loading...

Loading...