Page 1

DOUBLE DISHDRAWERTM DISHWASHER

DD24DI, DD24DTI & DD24DHTI models

INSTALLATION GUIDE

US CA

59186 A 08.17

Page 2

1 SAFETY AND WARNINGS

!

WARNING!

Electrical Shock Hazard

Before installing the dishwasher, remove the house fuse or open the circuit

breaker. If permanently connecting the dishwasher, be sure the power is

isolated and the dishwasher unplugged.

GROUNDING INSTRUCTIONS

This appliance must be grounded. In the event of a malfunction or breakdown,

grounding will reduce the risk of electric shock by providing a path of least

resistance for electric current. This appliance is equipped with a cord having

an equipment-grounding conductor and a grounding plug. The plug must be

plugged into an appropriate outlet that is installed and grounded in

accordance with all local codes and ordinances. WARNING - Improper

connection of the equipment-grounding conductor can result in a risk of

electric shock. Check with a qualified electrician or service representative if

you are in doubt as to whether the appliance is properly grounded.

If the dishwasher is installed as a permanently connected appliance:

GROUNDING INSTRUCTIONS - This appliance must be connected to a

grounded metal, permanent wiring system, or an equipment-grounding

conductor must be run with the circuit conductors and connected to the

equipment-grounding terminal or lead on the appliance.

Do not modify the power supply plug provided with the appliance - if it will

not fit the outlet, have a proper outlet installed by a qualified electrician. Do

not use an extension cord, adapter plug or multiple outlet box.

Failure to follow this advice may result in electrical shock or death.

IMPORTANT SAFETY INSTRUCTIONS

●

Installation of this dishwasher requires basic mechanical and electrical skills.

●

Be sure to leave these Instructions with the Customer.

●

Installation must comply with your local building, electricity, and plumbing regulations.

●

At the completion of the dishwasher installation, the Installer must perform the Final

Checklist.

●

Remove all packaging materials supplied with the dishwasher.

●

This dishwasher is manufactured for indoor use only.

●

Ensure all water connections are turned OFF. It is the responsibility of the plumber and

electrician to ensure that each installation complies with all Codes and Regulations.

●

The dishwasher MUST be installed to allow for future removal from the enclosure if service

is required.

●

The switched power outlet must be outside the dishwasher cavity, so that it is accessible

after installation.

●

Care should be taken when the appliance is installed or removed to reduce the likelihood

of damage to the power supply cord and hoses.

●

If the dishwasher is to be relocated from one installation to another it must be kept

upright to avoid damage from water spillage.

●

Make sure only new hoses are used for connection (supplied with the dishwasher). Old

hoses should not be reused.

●

Failure to install the dishwasher correctly could invalidate any warranty or liability claims.

●

If the product is installed in a motor vehicle, boat or similar mobile facility, you must bring

the vehicle, boat or mobile facility containing the product to the service shop at your

expense or pay the service technician’s travel to the location of the product.

●

This dishdrawer is intended for connection to the hot-water supply.

●

Failure to install the dishwasher correctly could invalidate any warranty or liability claims.

!

WARNING!

Fitting integrated front panels requires access to electrical service areas.

This work must be performed and certified by a qualified electrical service technician.

Electrical Shock Hazard

WARNING: To reduce the risk of electrical shock, fire, or injury to persons, the

installer must ensure that the dishwasher is completely enclosed at the time

of installation.

Before fitting the front panels and connecting the ‘knock to pause’ module (if

necessary), the installer must ensure that the dishwasher is disconnected from

the power supply.

After installing the front panels, the installer must ensure that the following

components are electrically grounded: the panel bracket and any custom

metal component (e.g. handle) that extends past the rubber seal.

Failure to follow these warnings may result in electrical shock, injury or fire.

!

WARNING!

Cut Hazard

Take care - panel edges are sharp.

Failure to use caution could result in injury or cuts.

1

●

Ensure the product is not plugged in when fitting custom panels.

●

Installation of custom panels requires basic mechanical and electrical skills.

●

Installation must comply with your local building and electricity regulations.

●

Failure to install the custom panels correctly could invalidate any warranty or liability

claims.

IMPORTANT!

SAVE THESE INSTRUCTIONS

The models shown in this installation guide may not be available in all markets and are subject to

change at any time. For current details about model and specification availability in your country,

please go to our website www.fisherpaykel.com or contact your local Fisher & Paykel dealer.

Page 3

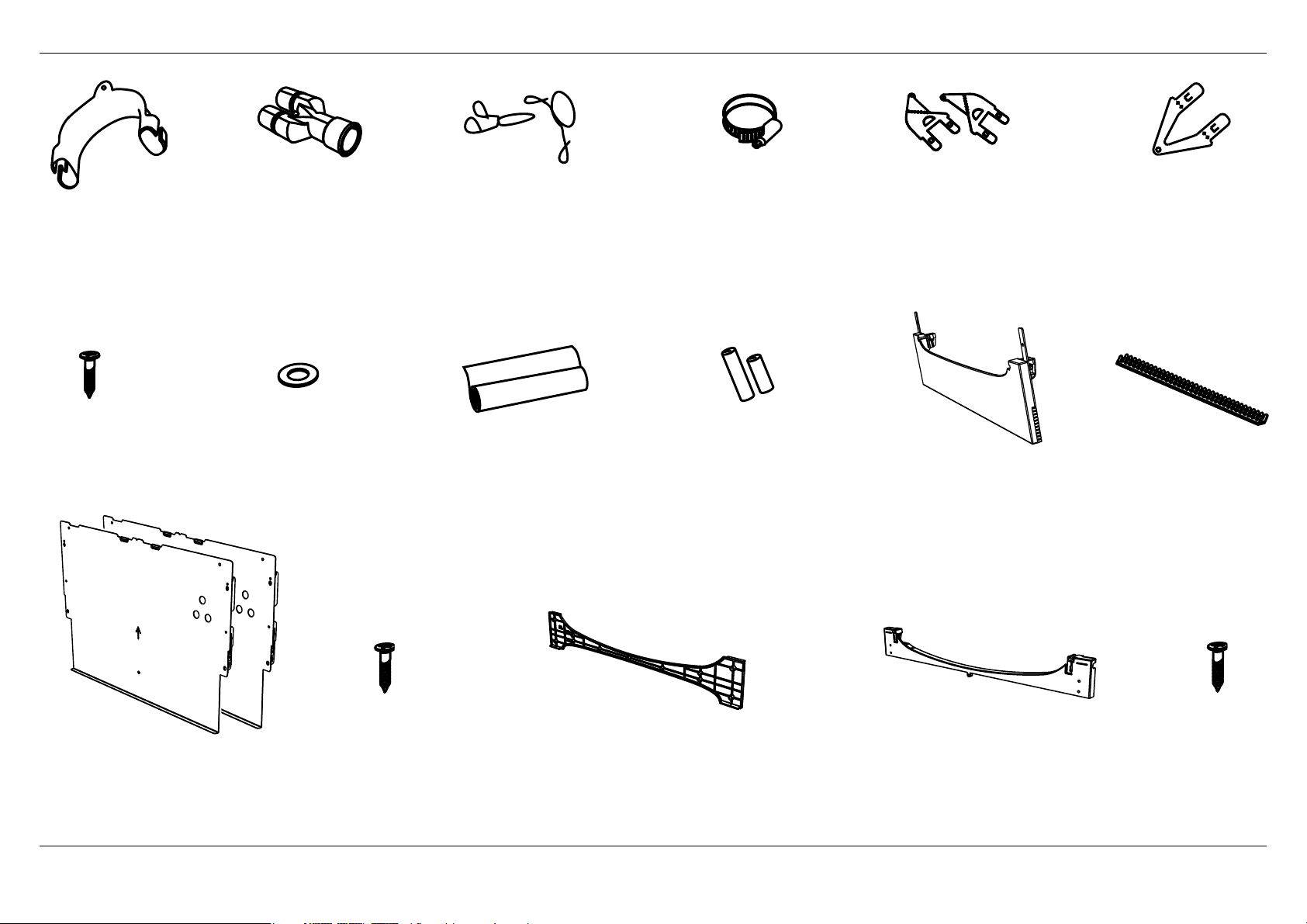

2 PARTS SUPPLIED

Drain hose

support (1)

Phillips

5/8” (16mm)

screws (9)

Drain hose

joiner (1)

for inlet hose (1)

(comes already

fitted)

Wire clip (2)

(for securing

Drain hose joiner)

Moisture protection

tape (1)

(to prevent moisture

damage to cabinetry)

Clamp (1)

(for securing

Drain hose joiner)

Hexagonal

socket for feet

adjustment (2)

(long & short)

Side mounting

bracket kit

(A and B) (2)

OPTIONAL

Prefinished toekick (1) Rubber washer

Top

mounting

brackets (2)

OPTIONAL

Edge Protector (1)

(If the services hole

is through a metal

partition, the hole must

be protected with the

Edge Protector supplied

to prevent damage to the

power cord or hoses.)

Panel bracket (2)

& Knock-to-Pause Module (2)

(shipped fixed to product)

If the Drain hoses supplied are not long enough to reach your services, you must use a Drain Hose Extension Kit P/N 525798 which will extend the drain

hoses by 11’ 10” (3.6m). The kit is available from the nearest Fisher & Paykel Authorized Service Center, or Toll free 1.888.936.7872 or www.fisherpaykel.com

Panel mounting

screws (12)

Toekick mounting bracket cutting

template (1)

(To enable a custom toekick panel to be

cut to fit the product profile dependant

on the depth of the toekick )

Toekick mounting bracket (1)

(A custom toekick panel of any

material with thickness 3/8”- 3/4”

(9 - 19mm) can be screwed to the

Toekick mounting bracket)

Toekick

mounting

screws (5)

2

Page 4

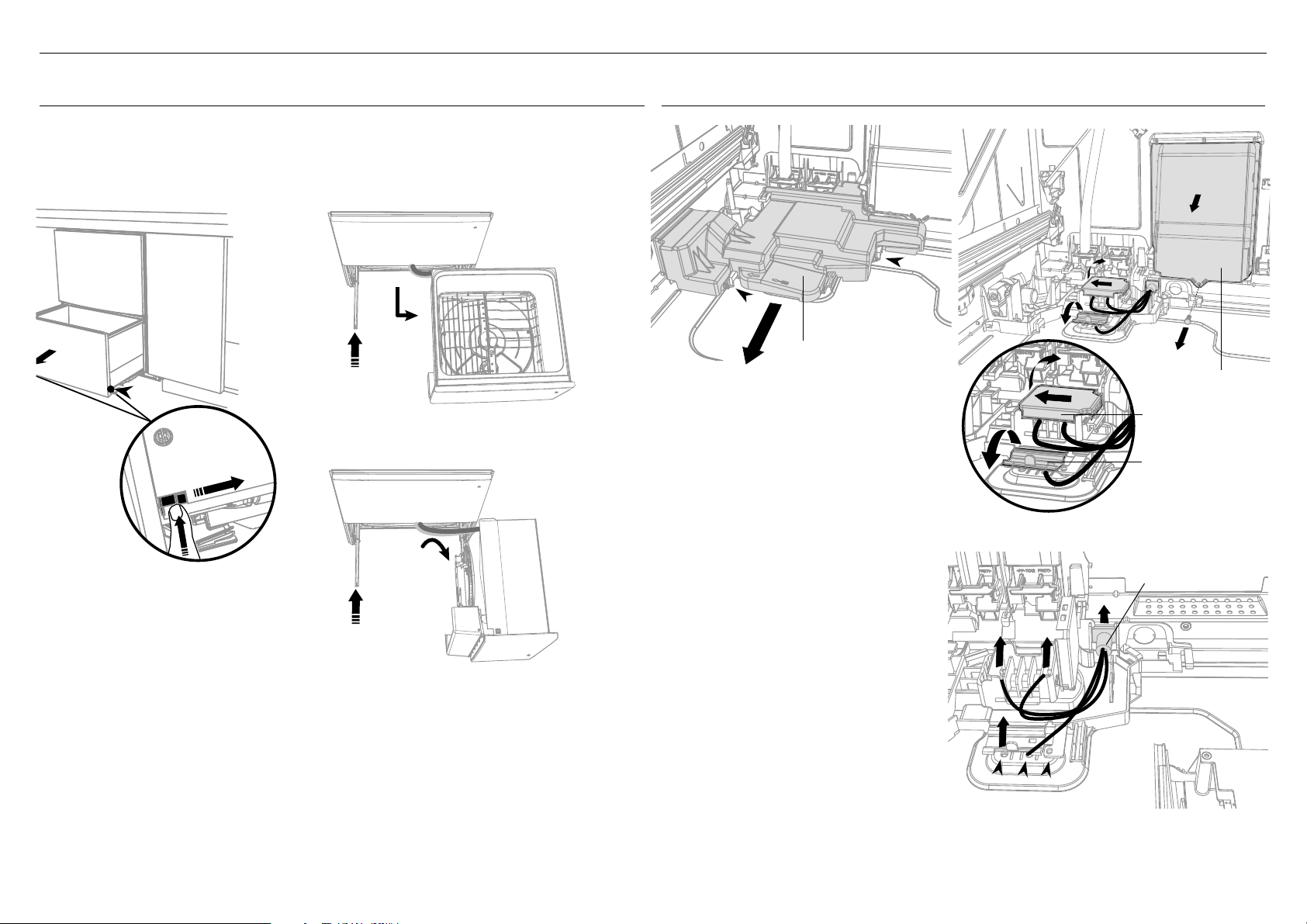

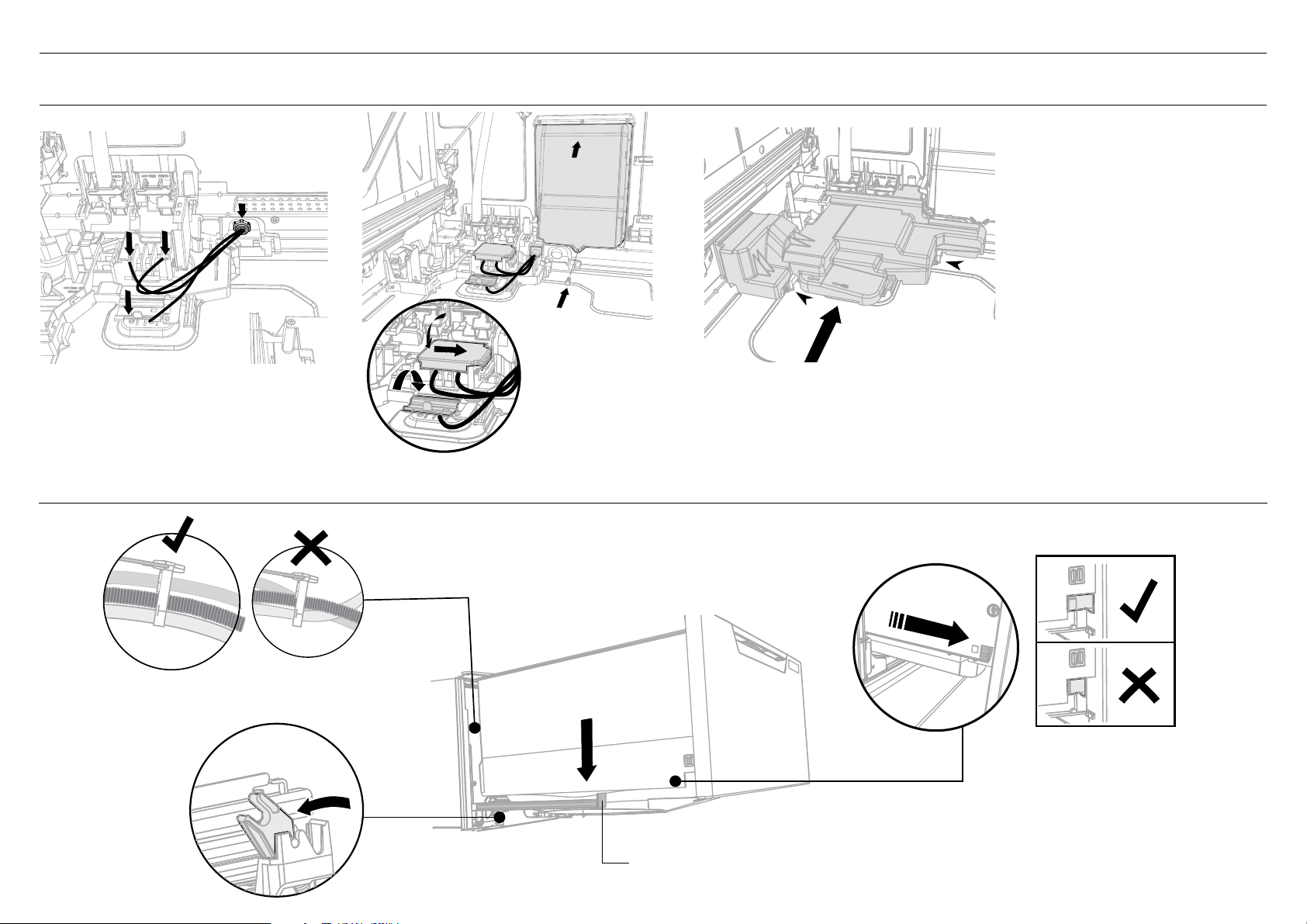

3 OPTIONALLY HARD WIRING PRIOR TO INSTALLATION

3-A REMOVE THE LOWER DRAWER 3-B REMOVE THE ACCESS COVER & REMOVE POWER

To prevent kinked hoses

Either sit the drawer down on the left

hand side (recommended) or rotate the

drawer clockwise, resting it on its side after

removal.

3

1

2

4” (100 mm)

Press the release tabs

in on either side and

push back to release

drawer from runners.

Lift drawer off runners.

4

Push drawer

runners back in

on either side.

4

Push drawer

runners back in

on either side.

3

Sit the drawer down

3

Rotate the drawer

clockwise (max. 90

and rest on side.

Clip

1

Clip

1

Access cover

1 With a flat-bladed screwdriver, push

in the clips and slide out the access

cover.

2 Unscrew the electronics module

cover.

3 Carefully pull out the electronics

module and rest on the chassis base

out of the way.

4 With a screwdriver, unclip the plastic

harness cover and hinge open.

5 Slide the terminal block cover

sideways to unlock and hinge open

to access the terminal block.

6 Unscrew the Live, Neutral and Earth

wires as shown.

7 Unscrew the three screws on the

base as shown and remove the cord

o

)

from the product.

4

6

5

Remove existing

power cord

7

2

Electronics

module

Terminal

Block cover

7

3

Page 5

3-C TERMINATE MAINS WIRING AS SHOWN AND REPLACE MODULE AND COVERS

8

9

IMPORTANT!

Ensure the mains wires are routed

UNDERNEATH all other harness

wiring from the electronics module.

3 OPTIONALLY HARD WIRING PRIOR TO INSTALLATION

12

13

11

10

14

8 Fit a suitable cable clamp for the

conduit through the metal knockout.

Ensure wiring is routed through or

under under housing ribs.

9 Screw down the Live, Neutral and

Earth wires correctly.

10 Push the plastic harness cover back

over. It should clip back into place

11 Fold down and slide back the

terminal block cover.

12 Refit the electronics module back

into position, being careful of wiring.

13 Replace the screw securing the

electronics module.

14 Slide the access cover back,

ensuring the 2 clips shown are fully

locked in place.

NOTE: Use copper conductors

only.

Before refitting the

drawer, ensure the hoses

are not twisted and the

latches at the rear of

each drawer runner are

facing forward.

2

3-D REFIT THE DRAWER ONTO THE RUNNERS & CLOSE

Lift or rotate counter-clockwise the

drawer back onto the drawer runners

on either side.

4” (100 mm)

3

1

Release tab

4

Pull the release tabs forward on both

sides 4” (100 mm). Ensure the tabs are

fully pulled forward and click into place.

4

Page 6

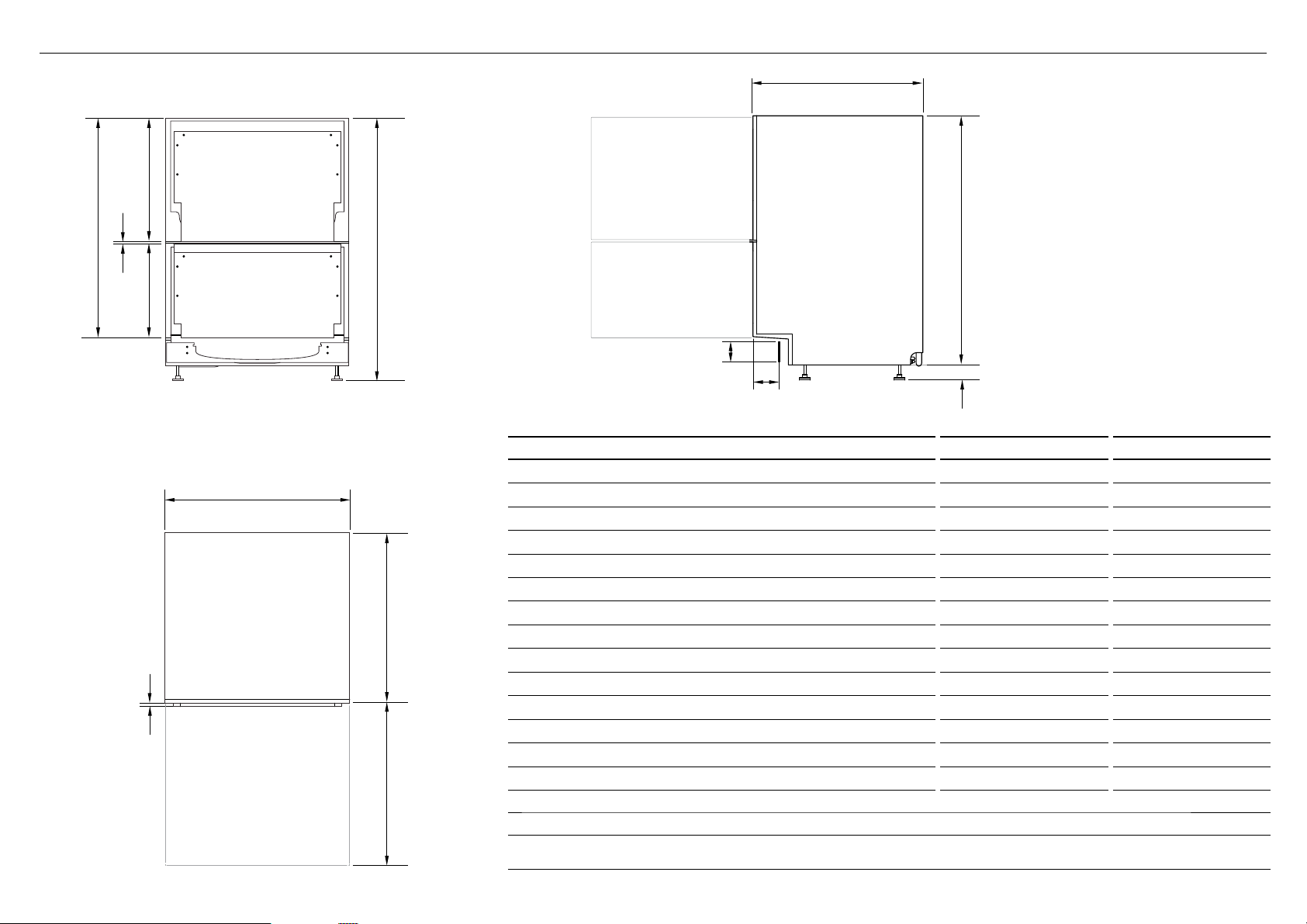

H

4 PRODUCT DIMENSIONS

C

G

A

F

J

I

K

L

PROFILEFRONT

M

STANDARD

HEIGHT

MODELS

DD24DI

PRODUCT DIMENSIONS INCHES (MM) INCHES (MM)

Overall height of product

A

B

D

E

N

5

PLAN

Overall width of product

B

Overall depth of product

C

Depth of chassis (to back of front drawer panel)

D

Depth of drawer front panel

E

Height of chassis

F

Height of drawer front panels

G

Height of upper drawer front panel

H

Height of lower drawer front panel

I

Ventilation gap between drawer front panels

J

Height of toekick (customisable)

K

Depth from front of drawer panel to front of toekick (adjustable)

L

Height of leveling feet (adjustable)

M

Maximum extension of drawer

N

1

includes 1/16” (2mm) high bracket slots 2 depending on adjustment of leveling feet 3 assuming front panel thickness of 11/16” (18mm)

4

adjustable to match toekick recess on adjoining cabinetry

5

assuming custom toekick panel thickness of 11/16” (18mm); if recess is between 1 15/16”-3 5/16” (50-84mm) deep, the panel will need to be cut out -

see step ‘Custom panel calculations’

1, 2

3

1

4, 5

2

3

32 5/16 - 34 5/8” (820-880) 34 - 36 3/8” (864-924)

23 9/16” (599) 23 9/16” (599)

22 1/2” (571) 22 1/2” (571)

21 3/4” (553) 21 3/4” (553)

5/8” - 13/16” (16-20) 13/16” (20)

31 15/16” (811) 33 11/16” (855)

min. 28 1/4” (717) 29 15/16” (761)

min 15 11/16” (398) min. 17 3/8” (442)

12 1/4” - 14 3/16” (311-360) 12 1/4” - 14 3/16” (311-360)

5/16” (8) 5/16” (8)

2 1/4” - 4 5/8” (58-118) 2 1/4” - 4 5/8” (58-118)

1 9/16” - 3 15/16” (40-100) 1 9/16” - 3 15/16” (40-100)

3/8 - 2 11/16” (9-69) 3/8 - 2 11/16” (9-69)

21 7/16” (545) 21 7/16” (545)

TALL

HEIGHT

MODELS

DD24DTI

DD24DHTI

Page 7

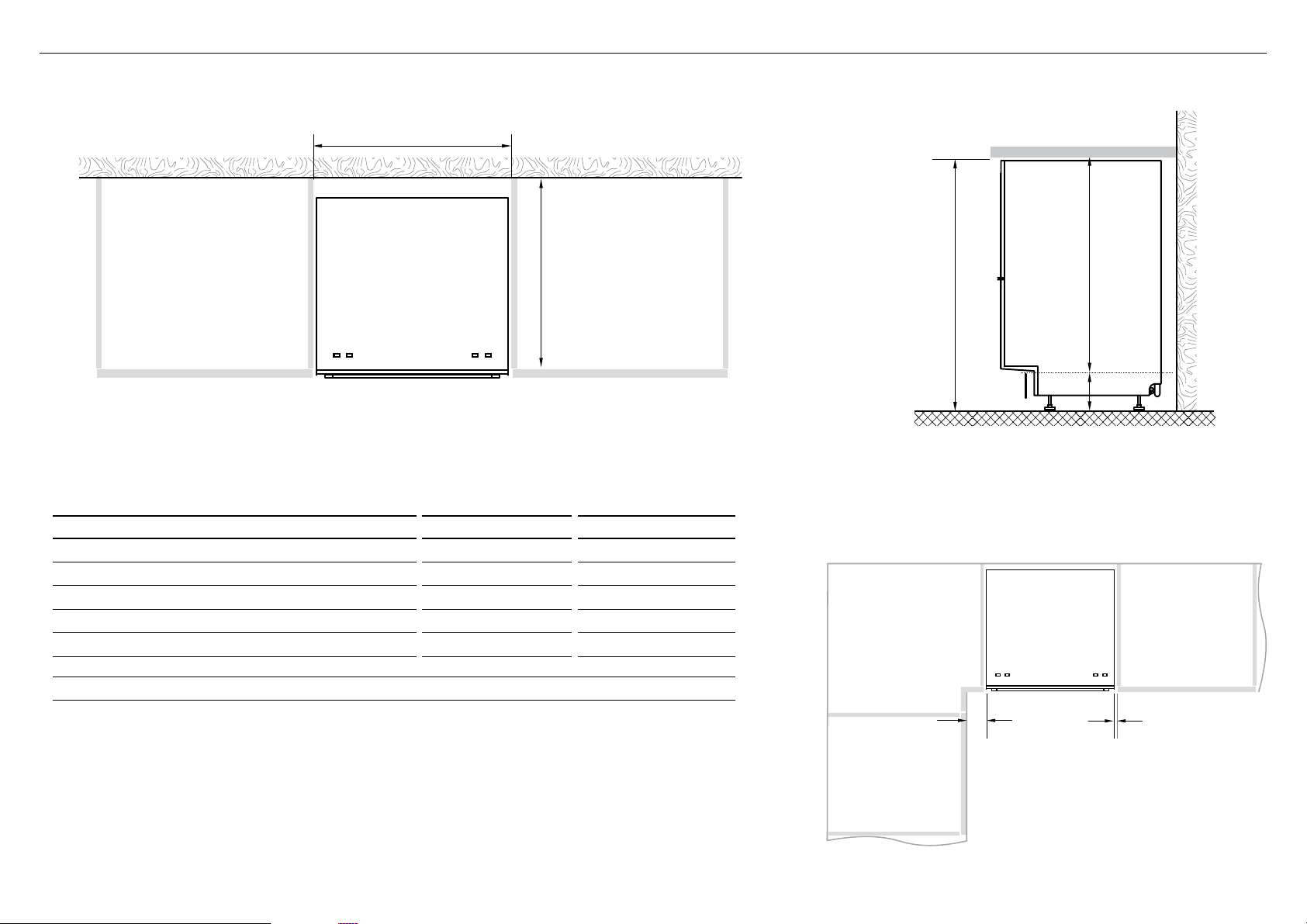

P

5 CABINETRY DIMENSIONS

Q

Bracket slots

PLAN

STANDARD

HEIGHT

MODELS

DD24DI

CABINETRY DIMENSIONS INCHES (MM) INCHES (MM)

Inside height of cavity* min. 32 5/16” (820) min. 34” (864)

O

Inside width of cavity 23 5/8” (600) 23 5/8” (600)

P

Inside depth of cavity min. 22 1/16” (560) min. 22 1/16” (560)

Q

Recommended height of adjacent cabinet space 30” (762) 30” (762)

R

Height of toekick space*

S

* depending on adjustment of leveling feet

2 3/8 - 4 3/4” (60-120) 3 15/16” - 6 5/16” (100-160)

TALL

HEIGHT

MODELS

DD24DTI

DD24DHTI

R

O

S

PROFILE

Minimum clearances from adjacent cabinetry

min. 1/2” (13 mm)

clearance from a

corner cupboard

min. 1/16” (2 mm)

clearance

to adjacent

cupboard door

6

Page 8

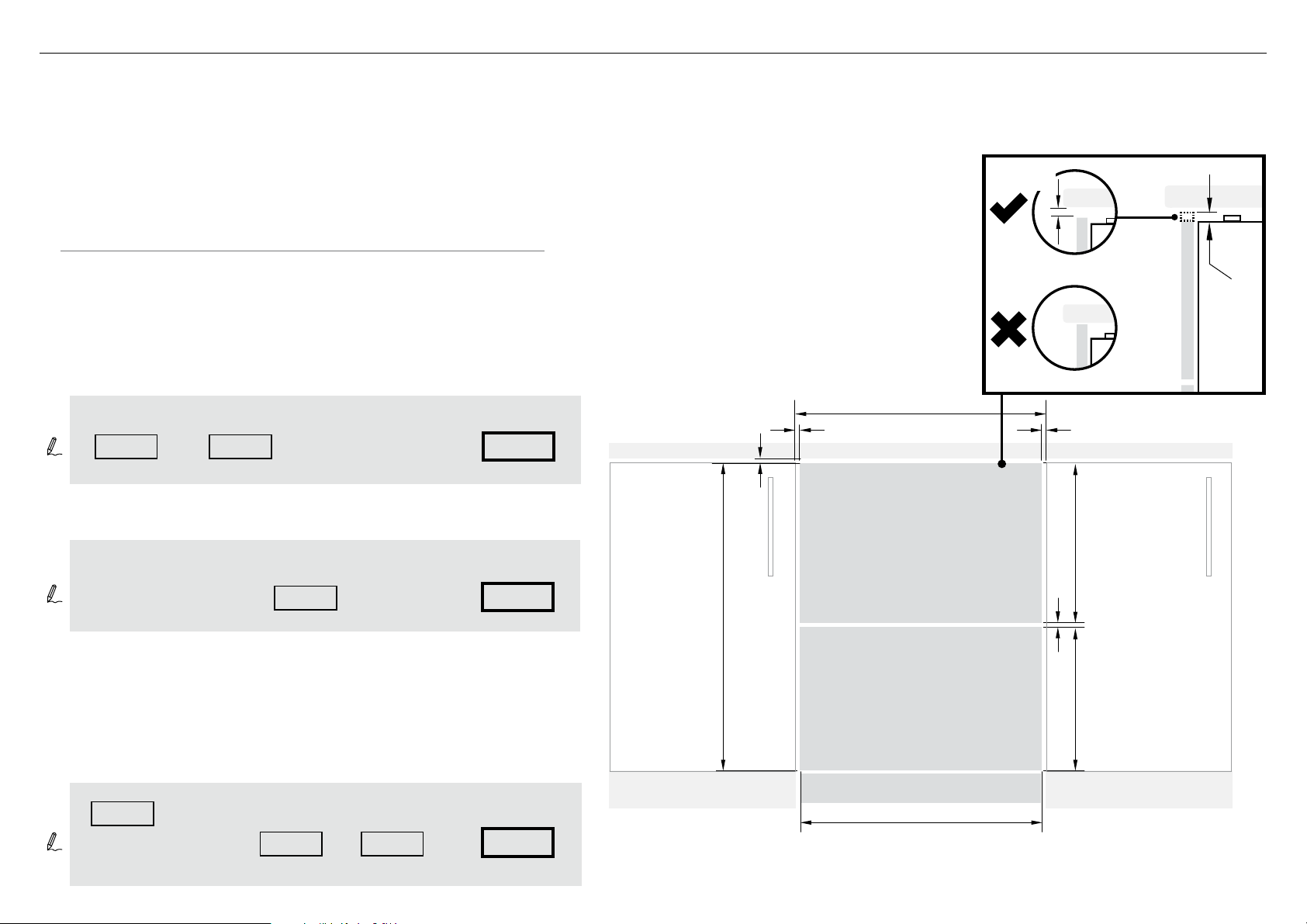

6 CUSTOM DRAWER PANEL SPECIFICATIONS

FRONT PANEL MATERIAL SPECIFICATIONS

●

5/8 - 13/16” (16 - 20mm) panel thickness.

●

Adequately sealed to withstand moisture (122OF/50OC @ 80% RH)

Because of it being a hot and wet environment generally, the back and sides of the

panel should be completely sealed with a waterproof vapor barrier (ie polyurethane)

to prevent damage to the panel.

●

The back of the panel (including any integrated handle) should be completely flush

so that the seal between the panel and the rubber trim is maintained.

●

Installation outside these specs may result in condensation on cabinetry surfaces.

●

Maximum weight of each panel: 20lb (9kg)

The following calculations assume the top of the upper panel is

aligned with the top of the adjacent cabinetry.

The final panel/cabinetry alignment is achieved by adjusting the feet:

WIDTH OF ALL PANELS

Measure A (the width between adjacent door/drawer fronts)

and write it in the first box below, then complete the equation.

Note: The ‘upper panel extension’ B

allows for the top of the upper panel to

extend above the chassis where required,

however a min. 1/16” (2mm) gap to

the countertop must be maintained.

min. 1/16”

(2mm)

B

Clearance to adjacent

A

cabinet front

- 2x =

(min. 1/16” (2mm))

HEIGHT OF THE UPPER PANEL

Minimum height

DD24DI models:

15 11/16”

DD24DTI/DD24DHTI models:

17 3/8”

Note: The ‘upper panel extension’ B allows for the top of the upper

panel to extend above the chassis where required, however a

min. 1/16” (2mm) gap to the countertop must be maintained.

HEIGHT OF THE LOWER PANEL

Measure C (door/drawer height (or equivalent)) and write it in the

first box below, then complete the equation.

(398mm)

(442mm)

Upper Panel extension

+

(0”/0mm recommended)

B

C

DD24DI models:

(min 28 1/4” (717mm) +

DD24DTI/DD24DHTI models:

(min 30” (762mm) +

7

B)

Height of

Upper Panel

--

B)

Ventilation Gap

(min. 5/16” (8mm))

(23 7/16”-24 3/16” (596-615mm))

WIDTH OF PANEL

HEIGHT OF

UPPER PANEL

=

HEIGHT OF

LOWER PANEL

=

(min. 12 1/4” (311mm))

min. 1/16” (2mm)

C

A

UPPER PANEL

LOWER PANEL

TOEKICK PANEL

WIDTH OF ALL PANELS

min. 1/16” (2mm)min. 1/16” (2mm)

HEIGHT OF

UPPER PANEL

Ventilation Gap

(min. 5/16” (8mm))

HEIGHT OF

LOWER PANEL

Page 9

7 CUSTOM TOEKICK PANEL SPECIFICATIONS

TOEKICK PANEL MATERIAL SPECIFICATIONS

●

min. 3/8” (9mm) panel thickness if using supplied screws

●

Adequately sealed to withstand moisture (122OF/50OC @ 80% RH)

●

You may choose to affix your custom toekick panel either by screwing

it or gluing it to the supplied mounting bracket.

HEIGHT OF THE TOEKICK PANEL

Measure D (height from the top of adjacent cabinet door fronts to the floor)

and write it in the first box below, then complete the equation.

D

B

Upper Panel

extension

(0”/0mm

recommended)

height from top

of product to

toekick panel

mounting point

DD24DI models:

29 1/2”

31 1/4”

(750mm)

DD24DTI/DD24DHTI models:

(794mm)

Clearance to floor

(min. 1/2” (12mm))

HEIGHT OF

TOEKICK PANEL

=-- -

(min. 2 1/4” (58))

Toekick Depth

Depth is measured from FRONT of door panel

(assuming thickness ~ 11/16” (18mm) to front

face of custom toekick label

NO CUTOUT

CUSTOM TOEKICK PANEL

For a Toekick Depth

1 9/16” (40mm)

Height from top

of product to

toekick panel

mounting point

DD24DI models:

D

29 1/2”

DD24DTI/DD24DHTI models:

31 1/4”

(750mm)

(794mm)

Toekick mounting bracket

cutting template:

PROFILE A

CUSTOM TOEKICK PANEL

For a Toekick Depth

1 9/16” - 3 7/16”

(40mm - 88mm)

Toekick mounting bracket

1 9/16” (40mm)

1 9/16” - 3 7/16”

(40mm - 88mm)

cutting template:

PROFILE B

CUSTOM TOEKICK PANEL

HEIGHT OF

TOEKICK PANEL

Clearance to floor

(min. 1/2” (12mm))

For a Toekick Depth

3 7/16” - 3 15/16”

(88mm - 100mm)

3 7/16” - 3 15/16”

(88mm - 100mm)

8

Page 10

COUNTERTOP

3/8”

(10 mm)

Moisture

protection

tape must

be applied.

8 CAVITY PREPARATION

IMPORTANT!

The power outlet

must be located in a

cabinet adjacent to the

dishwasher cavity.

110-120 VAC max. 15 A

Water Connection

Recommended HOT

(Maximum 140°F/60°C).

Supplied hose to

suit 3⁄8” (9 mm) male

compression fitting.

These marks indicate

formed bracket screw

locations, if securing by

drawer removal.

If there is no side

partition, you can

construct timber

bracing as something

to secure into.

Services hole

Can be located either side of dishwasher, preferably

at the bottom of the cavity, as shown. If adequate

clearance, services hole can be made higher to clear

toekick space. If hole is higher, ensure drain hose(s)

are routed straight into the waste connection.

●

If the hole is through wood, make sure its edges are

smooth and rounded.

●

If the hole is through metal, ensure you fit the supplied

Edge Protector to prevent damage to the power cord.

9

ø max. 1 1/2”

(38 mm)

max. 17 11⁄16”

(450 mm)

Water Pressure

Water softener models

Max. 1 MPa (145 psi)

Min. 0.1 MPa (14.5 psi)

Models without water softener

Max. 1 MPa (145 psi)

Min. 0.03 MPa (4.3 psi)

Kosher requirements

Drains will need to be

separated to satisfy

kosher requirements.

We suggest you confirm

acceptability with your

local rabbi in respect to

kosher installations.

min. 7 7⁄8” (200 mm)

Page 11

9 MAXIMUM DISTANCE OF HOSES & CORD FROM CHASSIS EDGE

LEFT HAND SIDE RIGHT HAND SIDE

Drain hoses - 78 1/2” (2000mm)

Inlet hose - 64 3/4” (1650mm)

Power cord (excl.plug) - 29 1/2” (750mm)

Drain hoses - 70 1/2” (1800mm)

Inlet hose - 49” (1250mm)

Power cord (excl.plug) - 27 1/2” (700mm)

10

Page 12

NOW CHOOSE WHICH INSTALLATION METHOD (A) OR (B)

IS MORE SUITABLE FOR YOUR CABINETRY...

!0 RECOMMENDED METHOD (A) - SECURE WITHOUT DRAWER REMOVAL (FRAMELESS CABINETRY ONLY)

!0-A ATTACH SIDE MOUNTING BRACKETS !1-A PULL THROUGH HOSES & PUSH INTO THE CAVITY

Clip all four side mounting brackets

into their slots using a flat-bladed

screwdriver. Ensure they’re securely

fitted before sliding product into cavity.

AB

optionally attach the

two top mounting

brackets

(x2)

Initially level the product

When fitting brackets,

ensure the ends are

not pushed down into

the chassis.

B

A

A

B

A

The mounting slots are in pairs, one on

each side diagonally across the product.

A bracket must match A slot and B

bracket must match B slot.

When fitting brackets, ensure the

ends are not pushed down into

the chassis.

11

B

You can raise or lower

the product by twisting

the feet. Then take

care when pushing the

product into the cavity

that you do not bend the

feet.

As you push product

in, pull through hoses

and cord, ensuring

they don’t get kinked

or twisted.

Page 13

!2-A SECURE TO THE CABINETRY ON THE SIDES

!3-A OPTIONALLY SECURE TO THE CABINETRY ABOVE

Using a small

Philips screwdriver,

screw through the

trim moulding,

securing the side

mounting bracket

to the cabinetry.

Do not damage

the rubber

trimseal.

Open the

drawer halfway.

Using a flat

bladed

screwdriver,

prise the gray

rubber plug out

of the trim

moulding.

2

Repeat for all

four brackets.

1

Replace the gray

rubber plug back into

the trim moulding

and ensure the trim

seal is facing forward.

The top mounting

brackets will only

(x2)

bend upwards a

maximum of 3⁄8”

(10 mm).

3

!4-A AFTER SECURING, REFER TO ‘FIT THE SUPPLIED TOEKICK PANEL’ STEP

12

Page 14

!0 ALTERNATIVE METHOD (B) - SECURE BY DRAWER REMOVAL

!0-B PULL THROUGH HOSES & PUSH INTO THE CAVITY !1-B REMOVE THE LOWER DRAWER

optionally attach the

two top mounting

brackets

(x2)

Initially level the product

You can raise or lower

the product by twisting

the feet. Then take

care when pushing the

product into the cavity

that you do not bend the

feet.

13

When fitting brackets,

ensure the ends are

not pushed down into

the chassis.

As you push product

in, pull through hoses

and cord, ensuring

they don’t get kinked

or twisted.

1

2

4” (100mm)

Press the release tabs

in on either side and

push back to release

drawer from runners.

Lift drawer off runners.

To prevent kinked hoses

Either sit the drawer down on the left

hand side (recommended) or rotate the

drawer clockwise, resting it on its side after

removal.

3

4

Push drawer

runners back in

on either side.

Sit the drawer down

3

4

Push drawer

runners back in

on either side.

Rotate the drawer

clockwise (max. 90

and rest on side.

o

)

Page 15

!2-B SECURE TO THE CABINETRY ON THE SIDES !3-B OPTIONALLY SECURE TO THE CABINETRY ABOVE

For further adjustment,

using the most appropriate

length Hexagonal socket

supplied, fully extend

levelling feet up to

required distance by hand.

Secure using two pairs

of formed brackets.

Repeat on the other

side of the chassis.

(x2)

The top mounting

brackets will only

bend upwards a

maximum of 3⁄8”

(10 mm).

x4

Before refitting the

drawer, ensure the hoses

are not twisted and the

latches at the rear of

each drawer runner are

facing forward.

Hexagonal

socket

2

Ensure product is level and

aligning with cabinetry.

1

!4-B REFIT THE DRAWER ONTO THE RUNNERS

Lift or rotate counterclockwise the

drawer back onto the drawer runners

on either side.

3

4

4” (100mm)

Pull the release tabs forward on both

sides 4” (100mm). Ensure the tabs are

fully pulled forward and click into place.

Release tab

14

Page 16

!5 INSTALLING CUSTOM FRONT DRAWER PANELS

1

1

!5-B REMOVE BOTH PANEL BRACKETS FROM PRODUCT

WARNING!

Side Pin

1

Remove side pins and gently

pull off the panel bracket

slightly.

Electrical Shock Hazard

Before continuing, ensure that the product is

disconnected from the power supply.

Failure to follow this warning may result in

electrical shock, injury or fire.

2

1

!5-B REMOVE THE KNOCK-TO-PAUSE MODULE

Knock-to-Pause module

Repeat for the other drawer.

1 Disconnect the Earth Wire

from the bracket

2 Unplug the knock sensor

from the controller.

Repeat for the other drawer.

15

Remove the Knock-to-Pause

module from the back of the

bracket.

Repeat for the other bracket.

3

Page 17

!5 INSTALLING CUSTOM FRONT DRAWER PANELS

2

3

2

5/8” (16mm)

(x6)

4

1

1

2

5/8” (16mm)

(x3)

!5-C ATTACH CUSTOM PANELS TO PANEL BRACKETS

There must be at least

3 screws used each side.

!5-D ATTACH KNOCK-TO-PAUSE MODULES

TO CUSTOM PANELS

IMPORTANT!

Break off and discard the tab

at the top of the Lower Panel

Bracket.

Align bottom of each custom

panel with the bottom of each

bracket.

IMPORTANT!

●

Ensure the Knock-To-Pause

module is orientated correctly

before attaching.

●

Ensure the module is centralized

in the holes and not in contact

with the bracket.

Attach the Knock-To-Pause

module to the back of the custom

panel through the 3 holes cut into

the panel bracket as shown.

Use all 3 screws provided.

Repeat for the other module.

16

Page 18

!5 INSTALLING CUSTOM FRONT DRAWER PANELS

!5-E CONNECT THE KNOCK-TO-PAUSE MODULE

TO THE CONTROLLER

Controller

Ensure the Knock-To-Pause Module

Cable is connected to the UI1 Port.

Repeat for the other drawer.

!5-F RECONNECT THE EARTH WIRE TO THE

PANEL BRACKET

Electrical Shock Hazard

To earth the panel bracket, connect the earth

wire from the product to one of the tabs.

Any custom metal component (e.g. handle)

that extends past the rubber seal must be

earthed too.

Failure to follow these warnings may result

in electrical shock, injury or fire.

WARNING!

Reconnect the

Earth Wire to the

Panel bracket.

Repeat for the

other drawer.

17

!5-G ATTACH CUSTOM PANELS TO PRODUCT

Push the Custom Panel on to

the drawer and reinsert the

side pins on each side.

2

1

Repeat for the other drawer.

Side Pin

2

!5-H ADJUST CUSTOM PANEL HEIGHT TO

ALIGN CABINETRY GAPS

With the front panels fitted, insert

an appropriately sized Philips

screwdriver into the hole above the

side pin and rotate the panels up or

down to align the gaps

in your cabinetry.

Repeat on the other side if necessary.

Each panel has a maximum travel of

1/16” (2mm) up or down.

IMPORTANT!

Ensure that you maintain a minimum

of 5/16” (8mm) ventilation gap

between the upper and lower panels.

+ or 1/16” (2mm)

Page 19

!6 FITTING A CUSTOM TOEKICK PANEL

9

Toekick Depth

NO CUTOUT

CUSTOM TOEKICK PANEL

For a Toekick Depth

1 9/16” (40mm)

Toekick mounting bracket

cutting template:

PROFILE A

CUSTOM TOEKICK PANEL

For a Toekick Depth

1 9/16” - 3 7/16”

(40mm - 88mm)

Toekick mounting bracket

cutting template:

PROFILE B

CUSTOM TOEKICK PANEL

For a Toekick Depth

3 7/16” - 3 15/16”

(88mm - 100mm)

Custom Toekick Panel

1 9/16” (40mm)

1 9/16” - 3 7/16”

(40mm - 88mm)

3 7/16” - 3 15/16”

(88mm - 100mm)

Depth is measured from FRONT of door

panel (assuming thickness ~ 11/16” (18mm)

to front face of custom toekick label

If you require a cutout in your custom

1

toekick panel, choose the most

appropriate cutout profile (A or B)

depending on the final depth of your

toekick panel.

Toekick mounting bracket

cutting template

1

PROFILE B

PROFILE A

5

Toekick mounting

bracket

2

3

Custom toekick panel

Place the Toekick mounting bracket cutting

template onto your toekick panel. Ensure they

are centered and the template rests on the

top surface of the panel.

Secure template to panel either by clamping

or using the supplied mounting screws.

Toekick mounting bracket

cutting template

2

3

4

After marking the panel, carefully cut or

4

router out the desired profile. Use the

template as a cutting guide.

IMPORTANT!

Ensure all bare edges are sealed appropriately.

6

Place the Toekick mounting bracket onto your

5

toekick panel. Ensure they are centered and

the top of the template aligns with the top

surface of the panel.

Secure template to panel using the supplied

6

toekick mounting screws.

7

Slide the toekick onto the mounting rails

7

either side and screw the toekick onto

the bottom of tub on either side.

IMPORTANT!

Do not overtighten screw.

18

Page 20

Prefinished Toekick Panel

!6 FIT THE SUPPLIED PREFINISHED TOEKICK PANEL (IF PREFERRED)

2

2

Mark this point

on the toekick

with a pencil

Where the toekick

meets the bottom

of the tub is the

cut-off point

1

1

3

3

5

5

7

7

19

Lay the toekick face down on

a chopping board or similiar

4

4

Turn the toekick over and

score along the same line

6

6

Smooth the edge with a file.

Be careful of sharp edges.

8

8

19

Score along with a knife Gently snap off the excess Snap off the two end tabs

19

Slide the toekick onto

the mounting rails

either side and screw

the toekick onto the

bottom of tub on

either side.

IMPORTANT!

Do not overtighten screw.

9

9

Page 21

!7 THERE ARE THREE DIFFERENT PLUMBING AND DRAINAGE OPTIONS. CHOOSE WHICH IS MORE SUITABLE.

DRAINAGE OPTION 1

Dishwasher and Ø 1 1/2” (38 mm) Standpipe

Screw Drain hose

support to back wall

at correct height

If space is limited

for fixing, push

hose through drain

hose support

to required height

2

max.

4 3/4”

(120mm)

29 1/2”-34 3/4”

(750-882.5 mm)

IMPORTANT!

Ensure that drain

connection will comply with

local plumbing regulations.

1

1 1/2“

(38mm)

step 18

29 1/2 - 34 3/4” (750-883 mm)

min. 19 11/16” (500 mm)

min. R 8”

(200 mm)

20

Page 22

Dishwasher using Dual Air Gap/Break with Drain Hose Joiner

IMPORTANT!

We recommend the use of a

commercially available Dual

(Double) Air Gap/Break Kit.

This provides totally

separate draining for each

drawer and eliminates

possible “cross draining”

problems

Secure both drain

hoses to a Dual Air

Gap/Break

DRAINAGE OPTION 2

Drain hose Drain hose

2

1

21

IMPORTANT!

Ensure that drain

connection will comply with

local plumbing regulations.

step 18

37 3/8” (950 mm)

Max. height to top

of Air Break

(countertop or

wall mounted)

min. R 8”

(200 mm)

Page 23

DRAINAGE OPTION 3

Dishwasher using drain hose joiner onto sink trap/waste tee

Screw Drain hose

support to back wall

at correct height

If space is limited

for fixing, push

hose through drain

hose support

to required height

2

max.

4 3/4”

(120mm)

29 1/2”-34 3/4”

(750-882.5 mm)

1

Supplied drain

hose joiner to suit

Ø 3/4” (19 mm)

waste tee

3

IMPORTANT!

Ensure that drain

connection will comply with

local plumbing regulations.

step 18

min. R 8”

(200 mm)

Ensure drain hose is routed

straight to joiner. Remove excess

drain hose material if necessary.

Do not shorten the inlet hose.

29 1/2 - 34 3/4” (750-883 mm)

min. 19 11/16” (500 mm)

22

Page 24

!8 CONNECT INLET HOSE TO HOT WATER !9 SWITCH PRODUCT ON

o

180

No leaks!

Ensure the supplied

rubber washer is

fitted inside the

Tighten coupling

with spanner.

coupling.

1

2

@0 TROUBLESHOOTING

●

Excessive water remaining above the filter plate, after the rinse cycle. (This is displayed as an A3 fault. See user guide ‘How to attend to a fault’)

Check for a kinked drain hose, blocked or incorrectly drilled out waste connection, highloop not properly installed, drain hose not routed correctly or spray arms not in place.

●

No water supply. (This is displayed as an A1 fault. See user guide ‘How to attend to a fault’)

Check water is connected and turned on.

●

The dishwasher is beeping continuously

There is a fault. See section ‘How to attend to a fault’ in the User guide for further information and instructions.

●

No program indicator lights up when the drawer is opened

Ensure power is connected and is switched on. If it is and still no indicator ligths up, see the ‘Preference options’ section of the ‘Quick start guide’.

An option called ‘Open drawer auto power-on’ may need to be turned on.

●

Water around water supply and drainage connections

Check connections, existing plumbing and hoses for leaks. Check rubber washer and hose clamp are correctly fitted.

●

If product is tipping

Ensure the product is secured to the cabinetry.

●

If front panels are misaligned

Check and relevel product. Check the cabinetry is square. For Integrated models, check and adjust front panel alignment if necessary.

●

Drawer doesn’t close properly

Ensure nothing is obstructing the drawer from closing properly eg hoses or drawer latches.

●

If a problem occurs, consult the ‘Troubleshooting’ section of the User guide.

●

If after checking these points you still need assistance, please refer to the Service & Warranty book for warranty details and your nearest Authorized Service Center, or contact us through our

website, listed below.

23

Page 25

TO BE COMPLETED BY THE INSTALLER

@1 FINAL CHECKLIST

Check all parts are installed.

Ensure that all panels and parts thereof are secure and final electrical tests have been

conducted in accordance with local electrical regulations.

Ensure product is level, securely fastened to the cabinetry and opens and closes freely.

The drawers must be free to fully close with no resistance from the cabinetry.

Ensure inlet hose to water supply has supplied rubber washer fitted, and that it’s

tightened a further half turn after seal contact.

Ensure any knockouts or plugs in drain connection have been drilled out and drain

connection has been made.

The drain hose joiner must not support the weight of excess hose material. Keep drain

hose as fully extended as possible to prevent sagging. Any excess length of drain hose

should be kept on the dishwasher side of the highloop.

If connecting the drain hose to the sink trap, ensure the Highloop is a minimum 5 7/8”

(150mm) higher than the drain hose joiner.

Ensure any packaging or tape securing the racks is removed from the drawers.

Water softener models only: adjust the water softener setting from the default setting to

suit the water hardness of the area.

See the Quick start guide and section ‘Water softener’ in the User guide.

Turn on the power and water supplies, then open the drawers. You should hear a

beep and see a program indicator light up on the internal control panel.

Check the spray arms are in place, mounted correctly and free to rotate, by

physically rotating by hand.

Spray arm

Add three cups of water into the drawer. Press

until the indicator of the ‘Rinse’

program lights up. Close the drawer and press to start the program.

Repeat for the other drawer.

When the test cycle is in process check the knock sensor is working by knocking

twice on the door to pause the wash program.

After the Rinse program has finished, ensure the dishwasher has run and drained

correctly.

Check the water supply has correctly shut off and drainage connection for leakage.

Complete and keep for safe reference:

Model

Serial No.

Purchase Date

Purchaser

Dealer Address

Installer’s Name

Installer’s Signature

Installation Company

Installation Date

FISHERPAYKEL.COM

Copyright © Fisher & Paykel Appliances 2017. All rights reserved.

The product specifications in this booklet apply to the specific products

and models described at the date of issue. Under our policy of continuous

product improvement, these specifications may change at any time. You

should therefore check with your Dealer to ensure this booklet correctly

describes the product currently available.

24

Page 26

26

Loading...

Loading...