Page 1

SAFETY AND WARNINGS

Important safety precautions!

Particular attention shall be given to the relevant requirements regarding ventilation.

Please make this information available to the person installing the appliance as it could reduce your

installation costs.

This appliance is to be installed and connected to the electricity and gas supply only by an authorised

person.

Installation must comply with your local building and local gas authority codes and electricity

regulations.

Failure to install the appliance correctly could invalidate any warranty or liability claims.

These appliances are registered in: (New Zealand) at www.ess.govt.nz and (Australia) with SAI Global

at www.saiglobal.com.

This gas appliance is suitable for connection to natural gas only. If in doubt, refer to the local gas

network operator or gas supplier to conrm gas type at installation site.

WARNING!

Cut hazard

Take care - panel edges are sharp.

Failure to use caution could result in injury or cuts.

WARNING!

Electrical shock hazard

Disconnect appliance from main power supply before continuing.

Failure to do so could result in electrical shock or death.

Before you install the appliance, please make sure that

the local distribution conditions (nature of gas and pressure) and the adjustment of the appliance

are compatible. For adjustment conditions for this appliance, see ‘Gas rate summary’

a suitable disconnection switch is incorporated in the permanent wiring, mounted and positioned to

comply with the local wiring rules and regulations. A means of disconnection with at least a 3 mm

air gap contact separation in all poles must be incorporated into the xed wiring in accordance with

the wiring rules, unless the local wiring rules allow for alternative means

the appliance is connected to a 220V - 240V 50Hz (10 A) power supply only and earthed via the

power supply cable

there is a power outlet within reach of the power supply cable (900 mm from the centre rear of the

product). This must be accessible after installation. The power supply cable should not touch any

metal parts

if the power supply cable is damaged, it is replaced only by the special cable: Part no. 531953 - Flex

Terminal Block Assy NZ/AU, obtainable from authorised Fisher & Paykel Service Agents

the supply connection point (gas shut-o valve) is accessible after installation

the benchtop is made of a heat resistant material

the installation complies with all the requirements of Australian and New Zealand Gas Installation

Standards (AS5601, NZS5261), including that the product has to be installed so that the surface

temperature of any nearby combustible surface will not exceed 65

O

C above ambient. See 3

‘Clearance Dimensions’.

When you install the appliance

We do not recommend you ush mount or seal this appliance into the bench with silicone or glue.

Doing so will make future servicing dicult. Fisher & Paykel will not be liable for any costs associated

with removing or replacing a sealed-in appliance, nor for repairing any damage that may be incurred

by doing this.

Seal exposed bare edges of the cutout with an oil-based paint or moisture-proof polyurethane to

prevent possible moisture creeping between the cooktop trim and the benchtop.

We do not recommend the use of a down-draught extractor fan with the appliance, as it may distort

the ame pattern, causing uneven heating and reduced cooking performance.

Where this appliance is installed in marine craft or in caravans, it shall not be used as a space heater.

No combustible material or products should be placed on this appliance at any time.

Do not spray aerosols in the vicinity of this appliance while it is in operation.

If, after following the instructions given, the appliance cannot be adjusted to perform correctly,

please refer to the Service & Warranty book for warranty details and your nearest Authorised Service

Centre, Customer Care, or contact us through our website: www.sherpaykel.com.

1

IZONA CookSurface

Installation instructions

CG903ML & CG903MLD models

NZ AU

Page 2

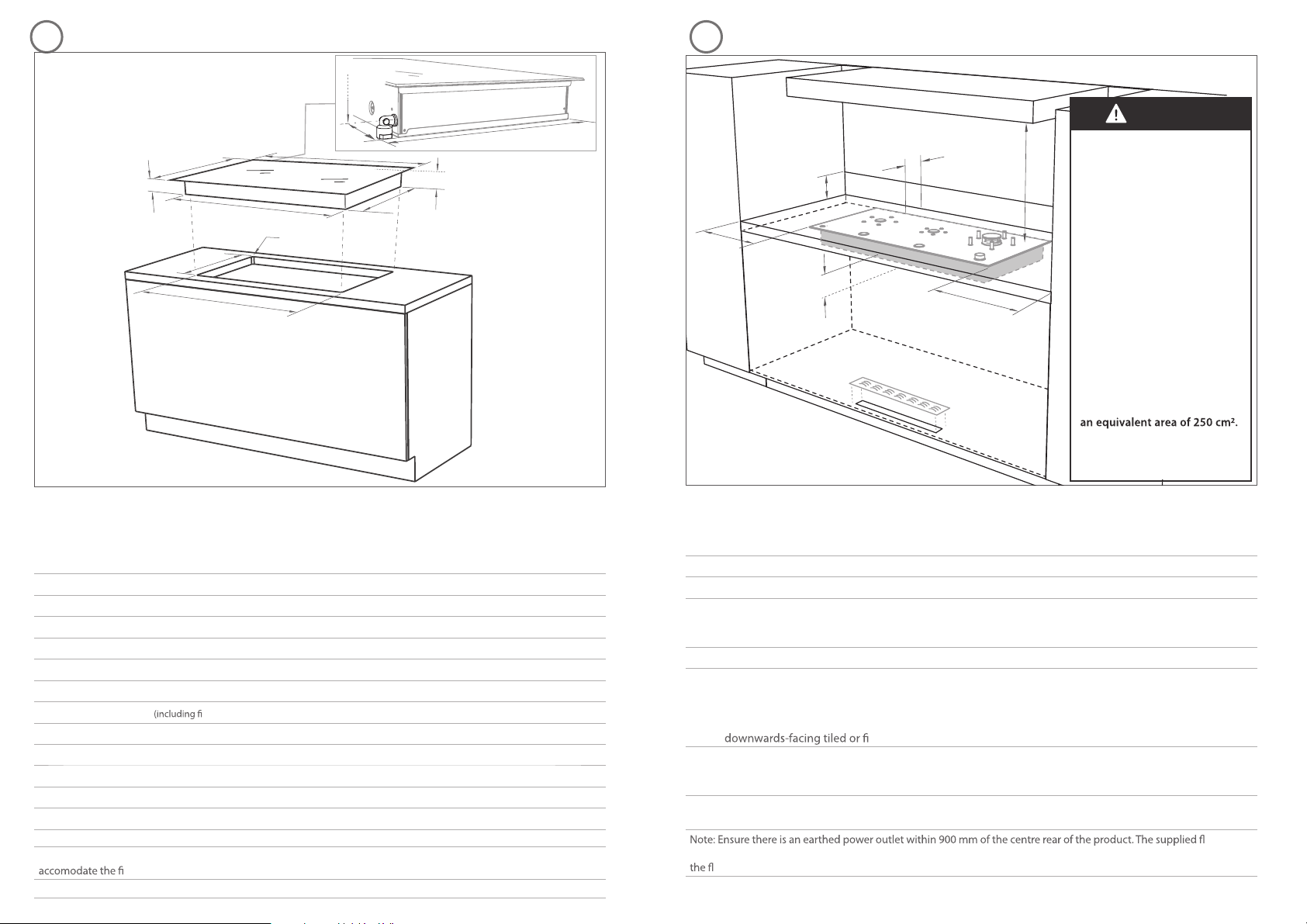

PRODUCT & CABINETRY DIMENSIONS CLEARANCE DIMENSIONS

Product and cabinetry dimensions (mm)

CG903ML

IZONA

CG903MLD

IZONA DEEP

A

overall height of product (including retracted dials/pan supports) 96 96

B

overall width of product 900 900

C

overall depth of product 410 530

D

height of chassis (below top of bench) 89 89

E

width of chassis 856 856

F

depth of chassis 384 480

G

depth of chassis tted elbow*) 424 480

H

overall width of cutout 865 865

I

overall depth of cutout 390 494

J

corner radius of cutout max. 10 max. 10

K

distance from top of bench to centre of gas inlet on product 64 64

L

distance from edge of chassis to gas inlet on product 20 20

Note: *(CG903ML models only) If benchtop thickness exceeds 50 mm, additional cutout space will be required to

tted elbow.

Installation diagrams for illustration purposes only

Note: Gas inlet connection is

located in the back left corner.

Clearances (mm)

CG903ML

IZONA

CG903MLD

IZONA

DEEP

A

minimum clearance from left edge of product to nearest combustible surface 60 60

B

minimum clearance from right edge of product to nearest combustible surface 80 80

C

minimum clearance from rear edge of product to:

nearest combustible surface

nearest non-combustible surface

100

10

10

10

D

minimum height of non-combustible material when used on adjacent walls 150 150

E

minimum clearance from glass surface to:

rangehood

any other overhead exhaust fan

downward facing combustible surface

re resistant surface

650

800

650

500

650

800

650

500

F

minimum clearance below top of benchtop to:

combustible surface

Fisher & Paykel oven or nearest non-combustible surface

115

100

115

100

G

cutout measuring 50 x 500 mm for air intake grill. Ensure air can easily enter the area around the base of

the product from the room in which the product is installed

exible

hose must be used between the product gas inlet and the connector on the wall which should be 650 - 750 mm above

oor and towards the left-hand end of the product. It should be accessible with the product installed.

A

B

C

G

D

E

F

32

A

B

C

E

D

F

H

I

J

K

L

G*

WARNING!

The CookSurface requires

adequate air supply to fully

function. The base of the

CookSurface must have direct

unrestricted ventilation to the

room where the CookSurface

is installed. Do not ventilate

the base area to an external

area that can be at dierent

air pressure to that of the

burners. You may ventilate

from adjacent cupboards, but

ensure that the available air

supply will not be restricted.

The ventilation area must

be 500 x 50 mm or of an

equivalent area. If the 50 mm

wide slot is not possible due

to the width of the available

toe recess, increase the length

of the slot so as to maintain

An air intake grill is provided.

Ensure that the grill is not

covered or obstructed.

Flush

Page 3

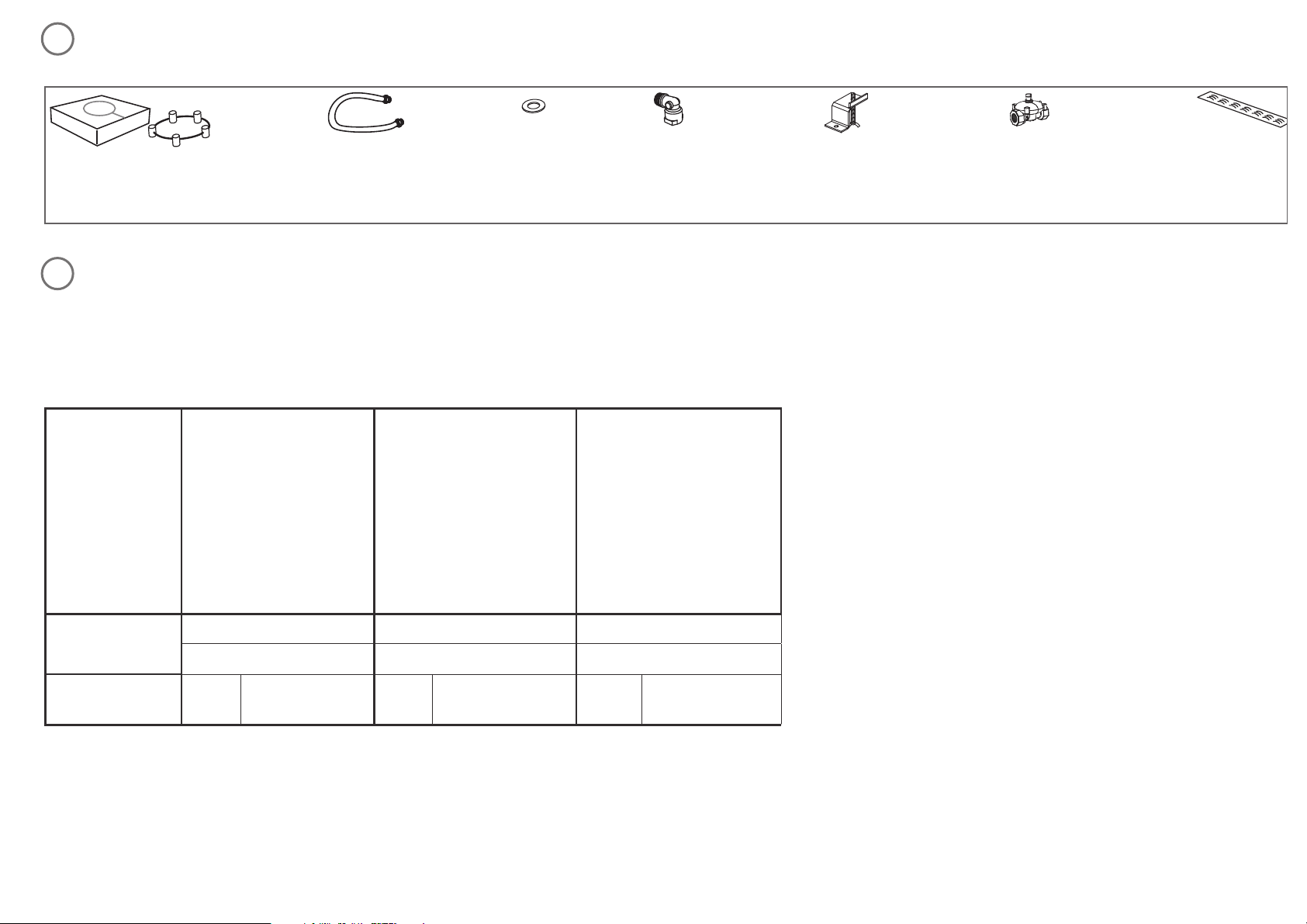

PARTS SUPPLIED

Wok stand (1)

Flexible

hose (1)

Blue washer (1)

GAS RATE SUMMARY

All appliances are factory set for natural gas and are not currently convertable to LPG.

NZ AU

Injector orice (mm)

Nominal rating (MJ/h)

Injector orice (mm)

Nominal rating (MJ/h)

Injector orice (mm)

Nominal rating (MJ/h)

NG (1.0 kPa)*

SMALL MEDIUM WOK

NG NG NG

CG903ML &

CG903MLD

1.09Y 7.2 1.15Y 8.0 1.65 12.8

*Nominal pressure with the two smaller burners on High.

Elbow

3

/

8

“ NPT (1) Clamping

brackets (4)

and screws (4)

NG regulator (1) Air intake

grill (1) and

screws (6)

4

5

Page 4

FLUSH MOUNTING INSTALLATION

(NOT RECOMMENDED)

A

B

C

E

D

F

H

H

Top view

I

H

I

I

I

I

Product and cabinetry dimensions (mm)

CG903ML

IZONA

CG903MLD

IZONA

DEEP

A

overall height of product (including dials/pan supports) 96 96

B

overall width of product 900 900

C

overall depth of product 410 530

D

height of chassis (below top of bench) 94 94

E

width of chassis 856 856

F

depth of chassis 384 480

G

depth of chassis tted elbow) 424 480

H

overall width of routered recess 905 905

H

I

width of cutout 865 865

I

overall depth of routered recess 415 535

I

I

depth of cutout 390 494

J

corner radius of cutout max. 10 max. 10

K

distance from top of bench to centre of gas inlet on product 64 64

L

distance from edge of chassis to gas inlet on product 20 20

M

corner radius of routered recess max. 2 max. 2

N

height of routered recess 5 5

M

K

L

M

N

J

1

1

2

2

x 4

20-50 mm

5 mm

3

min. 150 OC rated

TO REMOVE PRODUCT

1

2

BA

DC

F

E

WARNING!

We do not recommend ush

mounting and sealing as servicing

requires the CookSurface to be

removed from the benchtop. The

owner carries all risk for ush

mounting the CookSurface.

The owner must ensure the

CookSurface has been cut out

from the benchtop before

servicing can be carried out. Fisher

& Paykel will not be liable for any

costs associated with removing

or replacing a ush-mounted

and/or sealed-in product, nor for

repairing any damage that may be

incurred by doing this.

G

6

Ensure silicone does

not leak underneath glass.

Fresh air from

outside cabinetry

view from below

Ret existing

screw to secure

into basepan

For benchtops thicker than

50 mm, reverse the clamping

brackets, as shown in 11

Apply tape/foam

inside recess to stop

silicone leaking underneath.

Page 5

REMOVE FROM PACKAGING ENSURE THERE IS ADEQUATE AIR SUPPLY

FIT THE ELBOW & FLEXIBLE HOSE LOWER GENTLY INTO THE CUTOUT

87

19 0

PTFE

” NPT

1

2

1

1

2

A

Ensure there is enough

exible hose looped to

allow for removing

appliance for servicing.

A

Important!

The exible hose supplied

must be used to enable servicing.

500 mm

50 mm

A A

The CookSurface requires adequate air supply to fully function. The base of the CookSurface must have direct

unrestricted ventilation to the room where the CookSurface is installed. Do not ventilate the base area to an

external area that can be at dierent air pressure to that of the burners. You may ventilate from adjacent

cupboards, but ensure that the available air supply will not be restricted. The ventilation area must be

500 x 50 mm or of an equivalent area. If the 50 mm wide slot is not possible due to the width of the available toe

recess, increase the length of the slot so as to maintain an equivalent area of 250 cm

2

. An air intake grill is provided.

Ensure that the grill is not covered or obstructed.

Page 6

SECURE THE PRODUCT TO THE BENCHTOP CONNECT TO THE GAS & ELECTRICAL SUPPLY

CHECK FOR GAS LEAKS TEST OPERATION

1 32 4

A

Test operation by

lighting all burners.

13 14

11 12

GAS

ON

A

GAS

ON

20-50 mm

1

2

50+ mm

1

2

x 4

A

Fresh air from

outside cabinetry

Fresh air from

outside cabinetry

Ret existing

screw to secure

into basepan

view from below

For benchtops thicker than 50 mm,

reverse the clamping brackets, as shown

Ret existing

screw to secure

into basepan

NG

NG

½ “ BSP

A

Ensure the blue washer is tted

B

Page 7

www.sherpaykel.co.nz www.sherpaykel.com.au 599760A NZ AU 03.09

FINAL CHECKLIST

TO BE COMPLETED BY THE INSTALLER

Have you installed the clamping brackets?

Have you allowed for adequate air supply to the product?

Have you used the supplied exible hose and blue washer?

Have you leak-tested all connections?

Is the regulator set to the correct working pressure?

Have you placed the supplied duplicate data plate on an adjacent surface?

Is the CookSurface earthed?

Check that the power supply cable is NOT touching the CookSurface.

OPERATION:

Do all burners ignite both individually and in combination?

Are the ames consistent and appropriately sized?

Have you demonstrated the basic operation to the customer?

Installer’s name:

Installer’s signature:

Installation company:

Date of installation:

LEAVE THESE INSTRUCTIONS WITH THE CUSTOMER

15

Loading...

Loading...