Page 1

Instruction Manual

D100433X012

Graphite Packing for Sliding-Stem

Graphite Ribbon/Filament Packing for

™

Fisher

Contents

Introduction 1.................................

Scope of Manual 1.............................

Description 1.................................

Storage and Startup 2...........................

Packing Installation 2...........................

Parts Ordering 7................................

Introduction

Scope of Manual

Sliding‐Stem Valves

July 2017

This manual provides instructions for installing graphite ribbon and filament packing in sliding‐stem valves‐‐either as

part of the field maintenance procedure for valves that originally were equipped with this kind of packing or when

field‐replacing other kinds of packing.

Use this manual along with the appropriate valve body instruction manual. Refer to the valve body manual for

disassembly, packing removal, reassembly after the packing has been installed, and for packing part numbers and kits.

Do not install, operate, or maintain this packing without being fully trained and qualified in valve, actuator, and

accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is important to

carefully read, understand, and follow all the contents of this manual, including all safety cautions and warnings. If you

have any questions about these instructions, contact your Emerson sales office or Local Business Partner before

proceeding.

Description

Graphite ribbon/filament packing is a low‐chloride, corrosion‐resistant packing for use with hard‐to‐handle fluids,

especially high‐temperature steam or water. It can be used in temperatures from -18 to 538_C (0 to 1000_F) in

non‐oxidizing service or from -18 to 371_C (0 to 700_F) in oxidizing service. Because the packing rings are certified to

contain no more than 100 ppm of chloride, this packing is also frequently used in radioactive nuclear service and will

withstand a gamma radiation dosage to 1.0 X 10

Graphite ribbon/filament packing comes in three different arrangements of graphite ribbon rings, graphite filament

rings, and sacrificial zinc washers. The three different arrangements are single (figures 1 and 2), double (figure 3), and

leak‐off (figure 4).

7

Rads or 50 R/hour.

www.Fisher.com

Page 2

Graphite Packing for Sliding-Stem

July 2017

The graphite ribbon rings are made from a long ribbon of flexible graphite which is wound into a ring and then pressed

tightly together. The flexible graphite contains a non‐metallic, inorganic, passivating inhibitor for corrosion and

oxidation resistance. Graphite filament rings consist of filaments of graphite braided together. One sacrificial zinc

washer is used under each graphite ring to protect the valve from pitting and corrosion attack.

Instruction Manual

D100433X012

Storage and Startup

If a valve will be stored for a long period of time, remove the packing rings from the packing box to prevent corrosion.

When ordering a valve that will be stored, notify Emerson Automation Solutions and the valve will be shipped from the

factory with the packing box empty and a special packing follower with O‐ring gland seal installed between the

packing flange and bonnet shoulder. All the other packing parts shown in figure 2, 3, or 4 will be shipped with the

control valve assembly but in a separate bag or wrapper.

Leave the special packing follower in place until after any hydrostatic testing is completed. Then remove the follower,

thoroughly air‐dry the packing box, and install all the packing parts according to the appropriate arrangement

drawing. The special packing follower can be saved for future hydrostatic testing, or discarded if it will no longer be

used.

WARNING

Personal injury could result from packing leakage. Valve packing was tightened prior to shipment; however some

readjustment will be required to meet specific service conditions.

CAUTION

When using any packing at low temperatures, frost must not be allowed to form on the valve stem. Valve stem frost can

damage packing as the stem travels through the packing rings.

Packing Installation

Packing parts are subject to normal wear and must be inspected and replaced as necessary. The frequency of

inspection and replacement of parts depends upon the severity of service conditions or the requirements of local,

state, and federal rules and regulations.

WARNING

Avoid personal injury or property damage from sudden release of process pressure or bursting of parts. Before performing

any maintenance operations:

D Do not remove the actuator from the valve while the valve is still pressurized.

D Always wear protective gloves, clothing, and eyewear when performing any maintenance operations to avoid personal

injury.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly open or close the valve.

2

Page 3

Instruction Manual

D100433X012

Graphite Packing for Sliding-Stem

July 2017

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

from both sides of the valve. Drain the process media from both sides of the valve.

D Vent the pneumatic actuator loading pressure and relieve any actuator spring precompression.

D Use lock‐out procedures to be sure that the above measures stay in effect while you work on the equipment.

D The valve packing box may contain process fluids that are pressurized, even when the valve has been removed from the

pipeline. Process fluids may spray out under pressure when removing the packing hardware or packing rings, or when

loosening the packing box pipe plug.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

1. Refer to the appropriate valve body and actuator instruction manuals. Disassemble the control valve as required to

gain access to the packing box. Remove the packing box components.

2. Examine the valve stem. The surface that contacts the packing must be smooth and free of scratches and nicks. If

another style of graphite packing had been installed, the packing may have left a black deposit of graphite coating

on the stem. If this deposit has built up or has affected the valve stem finish, the stem should be polished to a 0.1

micro‐meter (4 micro‐inch) RMS finish.

3. Thoroughly clean and dry the packing cavity, valve stem, and all metal packing parts (packing box ring, lantern ring,

and packing follower). Also, clean the threads of the packing flange studs and nuts (figure 1). Lubricate these

threads and the faces of the packing flange nuts during the remainder of the installation with a moly disulfide or

equivalent type of lubricant.

4. Select the correct installation figure reference according to the valve design and packing arrangement (single,

double, or leak‐off).

5. Install the metal packing parts (figures 2, 3, or 4) that go to the bottom of the packing cavity.

WARNING

To avoid valve leakage during operation or personal injury, it is necessary, when installing the packing, to avoid trapping

air between the rings and to give side support to the rings so they do not spread out under the compression of adding more

rings. This may be accomplished by installing only one ring at a time.

6. Install only one packing ring at a time. Push each of the new packing rings into the packing box until it presses

against the ring below it.

If installing double or leak‐off packing, start the last lower packing ring and then force all the lower packing rings and

lantern ring(s) all the way into the packing cavity. Then install the upper packing rings in the same manner.

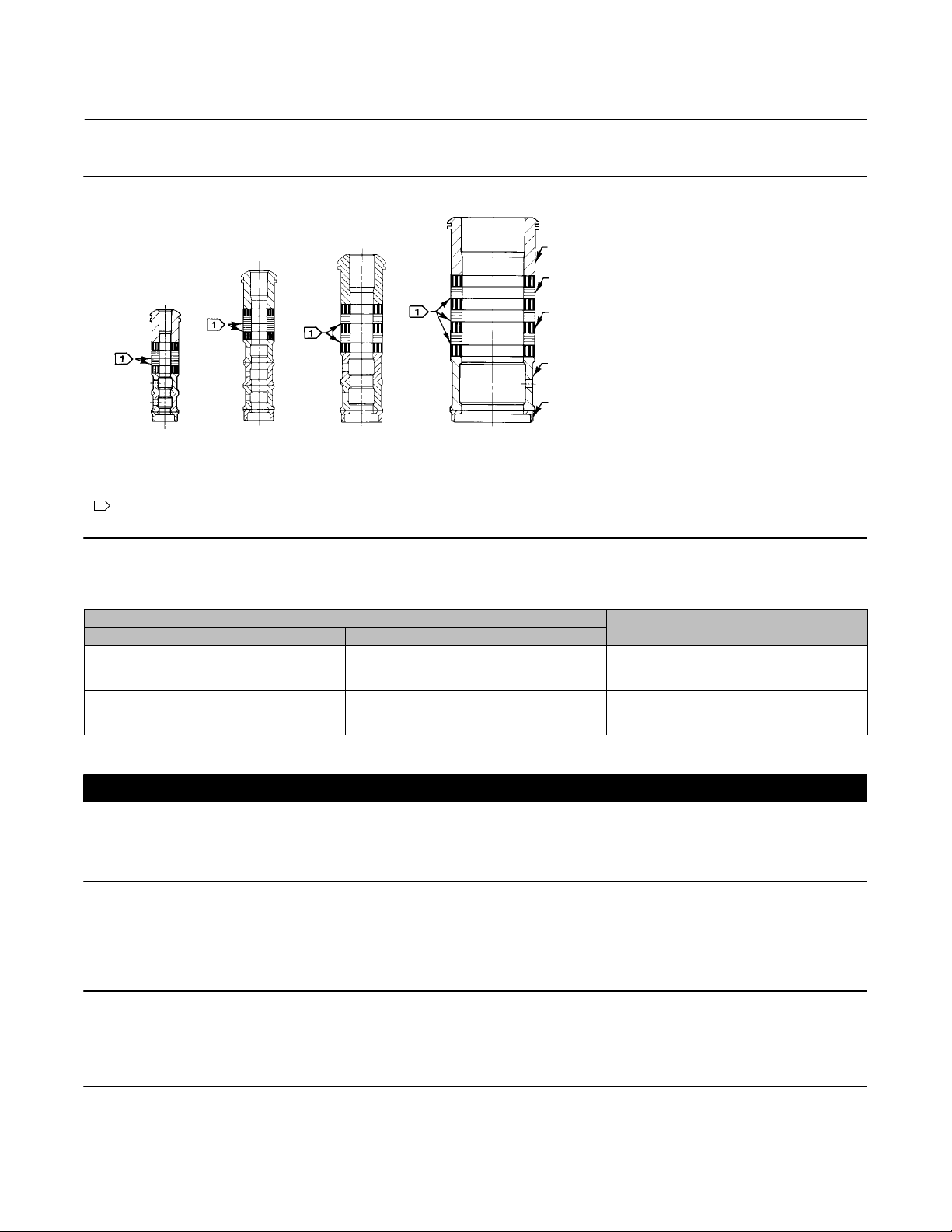

Figure 1. Typical Single Packing Arrangement Shown Installed in Bonnet

PACKING FLANGE STUD

PACKING FLANGE NUT

PACKING FLANGE

GRAPHITE

FILAMENT

PACKING RINGS

LANTERN RINGS

PACKING BOX

RING

A5507

PACKING FOLLOWER

GRAPHITE RIBBON

PACKING RINGS

SACRIFICIAL ZINC WASHER

3

Page 4

Graphite Packing for Sliding-Stem

July 2017

Figure 2. Single Packing Arrangements

Instruction Manual

D100433X012

PACKING FOLLOWER

GRAPHITE RIBBON

PACKING RING

GRAPHITE FILAMENT

PACKING RING

LANTERN RING

14A3411‐A

9.5 mm

(3/8 INCH)

STEM

NOTE:

1

0.102mm (0.004 INCH) THICK SACRIFICIAL ZINC WASHERS;

USE ONLY ONE BELOW EACH GRAPHITE RIBBON RING.

A5513

13A9775‐B

12.7 mm

(1/2 INCH)

STEM

13A9776‐B

19.1, 25.4, & 31.8 mm

(3/4, 1, & 1‐1/4 INCH)

STEM

14A3419‐A

50.8mm

(2‐INCH)

STEM

PACKING BOX

RING

Table 1. Single Packing Arrangements

STEM DIAMETER

mm Inch

9.5

12.7

19.1

25.4

31.8

50.8

3/8

1/2

3/4

1‐1/4

1

2

ARRANGEMENT

ASSEMBLY DRAWING

14A3411

13A9775

13A9776

14A2340

14A3412

14A3419

CAUTION

Loss of packing performance and damage to the valve stem could result if metal parts such as the packing follower come in

contact with the valve stem. When installing packing parts or making packing adjustments, make sure that the inside

diameter of the packing follower does not contact the valve stem.

7. Replace the packing follower, packing flange, and packing flange nuts.

Note

If the packing needs additional tightening after the valve is in service, the packing flange nuts may be tightened to the

recommended maximum torque. Excessive valve stem friction may result if the recommended maximum torque is exceeded. The

recommended minimum torque is necessary to maintain a stem seal.

4

Page 5

Instruction Manual

D100433X012

Figure 3. Double Packing Arrangements

14A2153‐B

9.5 mm

(3/8 INCH)

STEM

NOTE:

1

0.102mm (0.004 INCH) THICK SACRIFICIAL ZINC WASHERS;

USE ONLY ONE BELOW EACH GRAPHITE RIBBON RING.

A5514

14A1849‐B 14A1780‐B

12.7 mm

(1/2 INCH)

STEM

14A3418‐A

19.1, 25.4, & 31.8 mm

(3/4, 1, & 1‐1/4 INCH)

STEM

Graphite Packing for Sliding-Stem

July 2017

PACKING FOLLOWER

GRAPHITE RIBBON

PACKING RING

GRAPHITE FILAMENT

PACKING RING

LANTERN RING

PACKING BOX

RING

50.8mm

(2‐INCH)

STEM

Table 2. Double Packing Arrangements

STEM DIAMETER

mm Inch

9.5

12.7

19.1

25.4

31.8

50.8

3/8

1/2

3/4

1‐1/4

1

2

ARRANGEMENT

ASSEMBLY DRAWING

14A2153

14A1849

14A1780

14A3413

14A3414

14A3418

8. Evenly tighten the packing flange nuts to force the packing rings against the lantern ring(s). Continue to evenly

tighten the nuts until the maximum recommended torque shown in table 4 is reached. Then, loosen the packing

flange nuts and retighten to the recommended minimum torque in table 4.

9. Reassemble the control valve assembly according to the instructions in the appropriate instruction manual.

5

Page 6

Graphite Packing for Sliding-Stem

July 2017

Figure 4. Leak‐Off Packing Arrangements

15A5377‐B

9.5 mm

(3/8 INCH)

STEM

NOTE:

1

0.102mm (0.004 INCH) THICK SACRIFICIAL ZINC WASHERS;

USE ONLY ONE BELOW EACH GRAPHITE RIBBON RING.

A5508

14A3415‐A

12.7, 19.1 mm

(1/2, 3/4 INCH)

STEM

15A5378‐B 15A5472‐A

25.4 mm

(1‐INCH)

STEM

15A7085‐A

31.8 mm

(1‐1/4 INCH)

STEM

Instruction Manual

D100433X012

PACKING FOLLOWER

GRAPHITE RIBBON

PACKING RING

LANTERN RING

GRAPHITE FILAMENT

PACKING RING

PACKING BOX

RING

50.8mm

(2‐INCH)

STEM

Table 3. Leak-Off Packing Arrangements

STEM DIAMETER

mm Inch

9.5

12.7

19.1

25.4

31.8

50.8

3/8

1/2

3/4

1

1‐1/4

2

ARRANGEMENT

ASSEMBLY DRAWING

15A5377

14A2485

14A3415

15A5378

15A7085

15A5472

6

Page 7

Instruction Manual

D100433X012

Graphite Packing for Sliding-Stem

July 2017

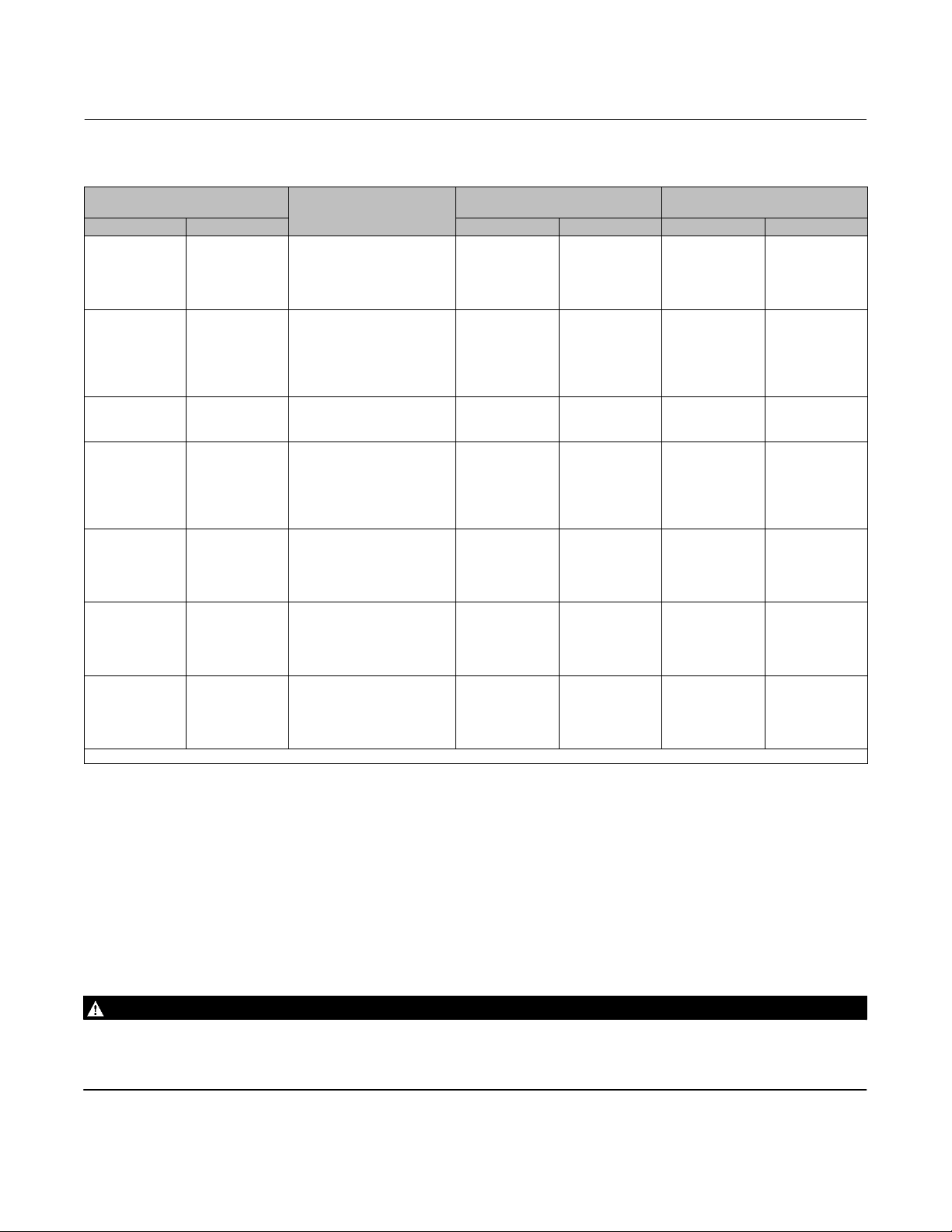

Table 4. Recommended Packing Flange Nut Torques

VALVE STEM

DIAMETER

mm Inch NSm LbfSft NSm LbfSft

9.5 3/8

12.7 1/2

15.9 5/8

19.1 3/4

25.4 1

31.8 1‐1/4

50.8 2

1. With lubricated packing flange studs.

VALVE RATING

CL150

CL300

CL600

CL900

CL1500

CL150

CL300

CL600

CL900

CL1500

CL2500

CL150

CL300

CL600

CL150

CL300

CL600

CL900

CL1500

CL2500

CL300

CL600

CL900

CL1500

CL2500

CL300

CL600

CL900

CL1500

CL2500

CL300

CL600

CL900

CL1500

CL2500

(1)

MAXIMUM MINIMUM

5

7

8

10

12

8

10

14

18

22

24

7

8

12

16

20

30

41

50

61

37

50

62

77

91

49

66

83

102

122

65

91

119

146

170

4

5

6

7

9

6

7

10

13

16

18

5

6

9

12

15

22

30

37

45

27

37

46

57

67

36

49

61

75

90

48

67

88

108

125

3

4

5

7

8

5

7

10

12

15

18

4

5

8

11

14

20

27

34

41

24

34

42

52

61

32

45

56

68

81

43

61

80

98

115

2

3

4

5

6

4

5

7

9

11

13

3

4

6

8

10

15

20

25

30

18

25

31

38

45

24

33

41

50

60

32

45

59

72

85

Parts Ordering

Refer to the appropriate valve body instruction manual for all bonnet packing parts.

Determine the parts needed from the appropriate packing arrangement in figures, 2, 3, or 4. Include the serial number

of the valve in all correspondence concerning replacement parts or maintenance.

WARNING

Use only genuine Fisher replacement parts. Components that are not supplied by Emerson Automation Solutions should

not, under any circumstances, be used in any Fisher valve, because they may void your warranty, might adversely affect the

performance of the valve, and could cause personal injury and property damage.

7

Page 8

Graphite Packing for Sliding-Stem

July 2017

Instruction Manual

D100433X012

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher is a mark owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric Co. Emerson Automation Solutions,

Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Automation Solutions

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Cernay 68700 France

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

8

E 1990, 2017 Fisher Controls International LLC. All rights reserved.

Loading...

Loading...