Page 1

AIRVO™ 2

Technical Manual

Page 2

This page has intentionally been left

blank.

Page 3

BEFORE YOU START

This Technical Manual is intended for clinical engineering / technical personnel. It defines the technical

specifications, setup, servicing and troubleshooting information, for the AIRVO 2 humidifier. It applies to all

lot numbers from 140910 and above.

OTHER REFERENCES

• Refer to the AIRVO 2 User Manual for detailed instructions for use.

• Watch the AIRVO 2 DVD to learn how to set up and use the AIRVO 2. Also available on YouTube.

• Download the AIRVO 2 Simulator App to learn how to use the AIRVO 2.

You can change settings, simulate faults and test your skills. Available

from the Apple, Google Play and Windows App stores.

• Visit the Fisher & Paykel education & resources website (https://www.fphcare.co.nz/education/) to find

self-paced online courses and local training events.

• If the unit is ever used by multiple patients, the unit must be cleaned and disinfected between patients

according to instructions in the Disinfection Kit Manual (900PT600).

• For further assistance, please contact your Fisher & Paykel Healthcare representative.

•

TABLE OF CONTENTS

1. General information ................................................................................................................................. 4

Package contents ....................................................................................................................................................................... 4

AIRVO 2 and accessories ........................................................................................................................................................ 5

2. Setting up AIRVO 2 for first use ......................................................................................................... 6

Advanced settings ..................................................................................................................................................................... 8

3. Acceptance/performance checks ...................................................................................................... 13

4. Servicing ...................................................................................................................................................... 15

5. Spare Parts .................................................................................................................................................. 16

Appendix A: IEC 60601-1-2 EMC tables ................................................................................................ 19

Appendix B: User interface flow charts ................................................................................................ 21

Appendix C: Default values ........................................................................................................................ 23

Appendix D: Troubleshooting Guide ...................................................................................................... 24

Appendix E: Tube and Chamber Kit labels .......................................................................................... 30

Appendix F: Error Flowchart ..................................................................................................................... 30

3

Page 4

1. GENERAL INFORMATION

The AIRVO 2 is a humidifier with integrated flow generator that delivers warmed and humidified respiratory

gases to spontaneously breathing patients through a variety of patient interfaces.

PACKAGE CONTENTS

AIRVO 2 humidifier

(PT101xx)

Oxygen inlet extension kit

(900PT422)

AIRVO 2 User Manual AIRVO 2 Swingtag AIRVO 2 DVD

Disinfection Kit

(900PT600)

WARNING

UNDER NO CIRCUMSTANCES SHOULD THE

AIRVO 2 BE OPENED OR ANY OF THE SIX

FASTENING SCREWS ON THE UNDERNEATH

SIDE OF THE DEVICE BE LOOSENED.

OPENING THE UNIT WILL AFFECT THE

OXYGEN SEALS INSTALLED INSIDE, WHICH

WILL COMPROMISE THE SAFETY OF THE

DEVICE.

Air filter (x2)

(900PT913)

Power cord

(900PT410xx)

4

Page 5

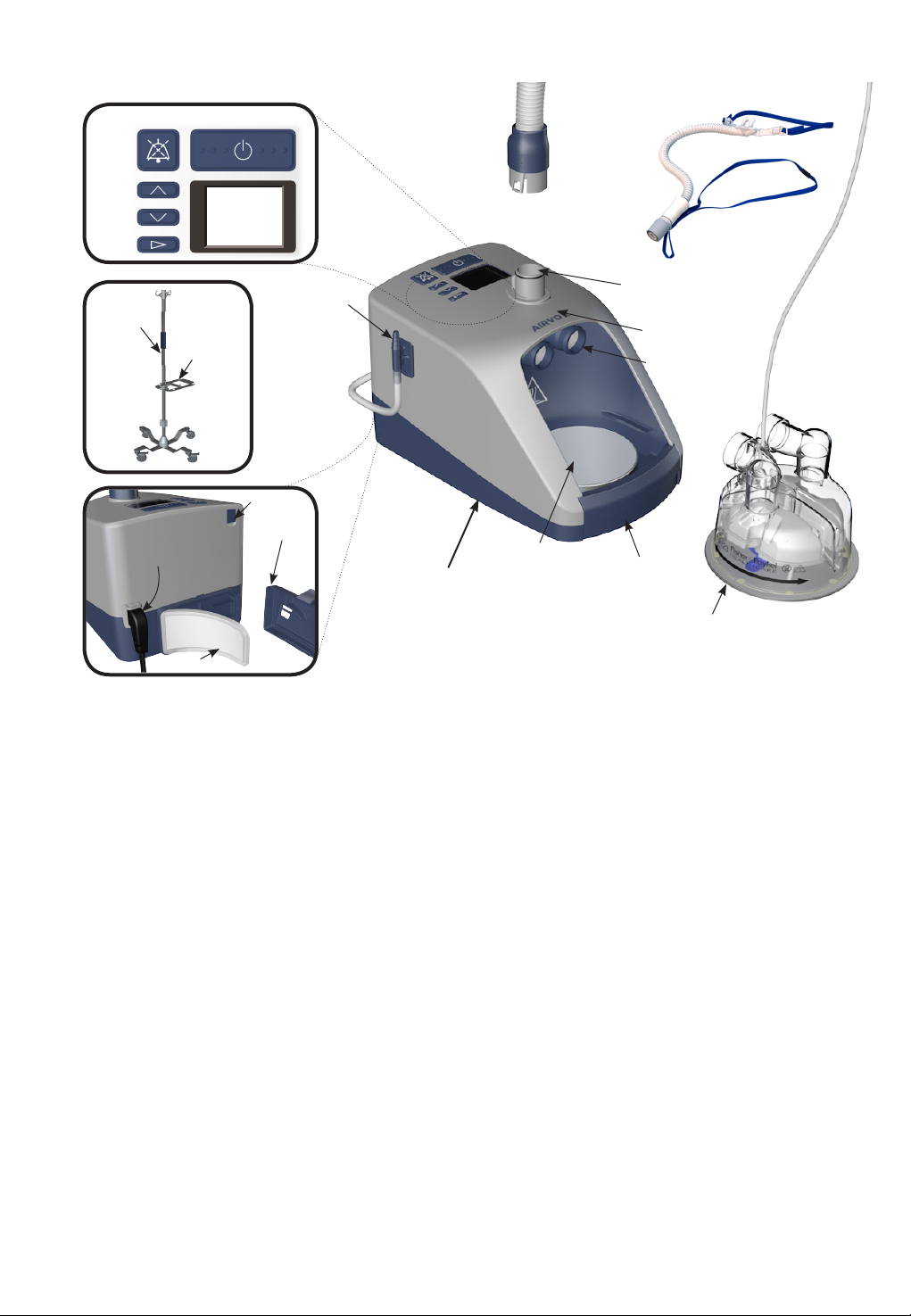

HOSPITAL

STAND

POLE

MOUNTING

TRAY

ON/OFF (STANDBY)

MUTE

UP

DOWN

MODE

AIRVO 2 AND ACCESSORIES

DISPLAY

OXYGEN

INLET PORT

SERIAL PORT

Heated

breathing

tube

Patient

interface

HEATED BREATHING TUBE

CONNECTION PORT

MEASUREMENT POINT OF

DISPLAYED DEW POINT

TEMPERATURE

CHAMBER PORTS

Water chamber

POWER CORD

and

CONNECTOR

AIR FILTER

FILTER COVER

AIRVO 2

(PT101xx)

HEATER

PLATE

FINGER

GUARD

AUTO-FILL WATER

CHAMBER (MR290)

(with adapter fitted)

5

Page 6

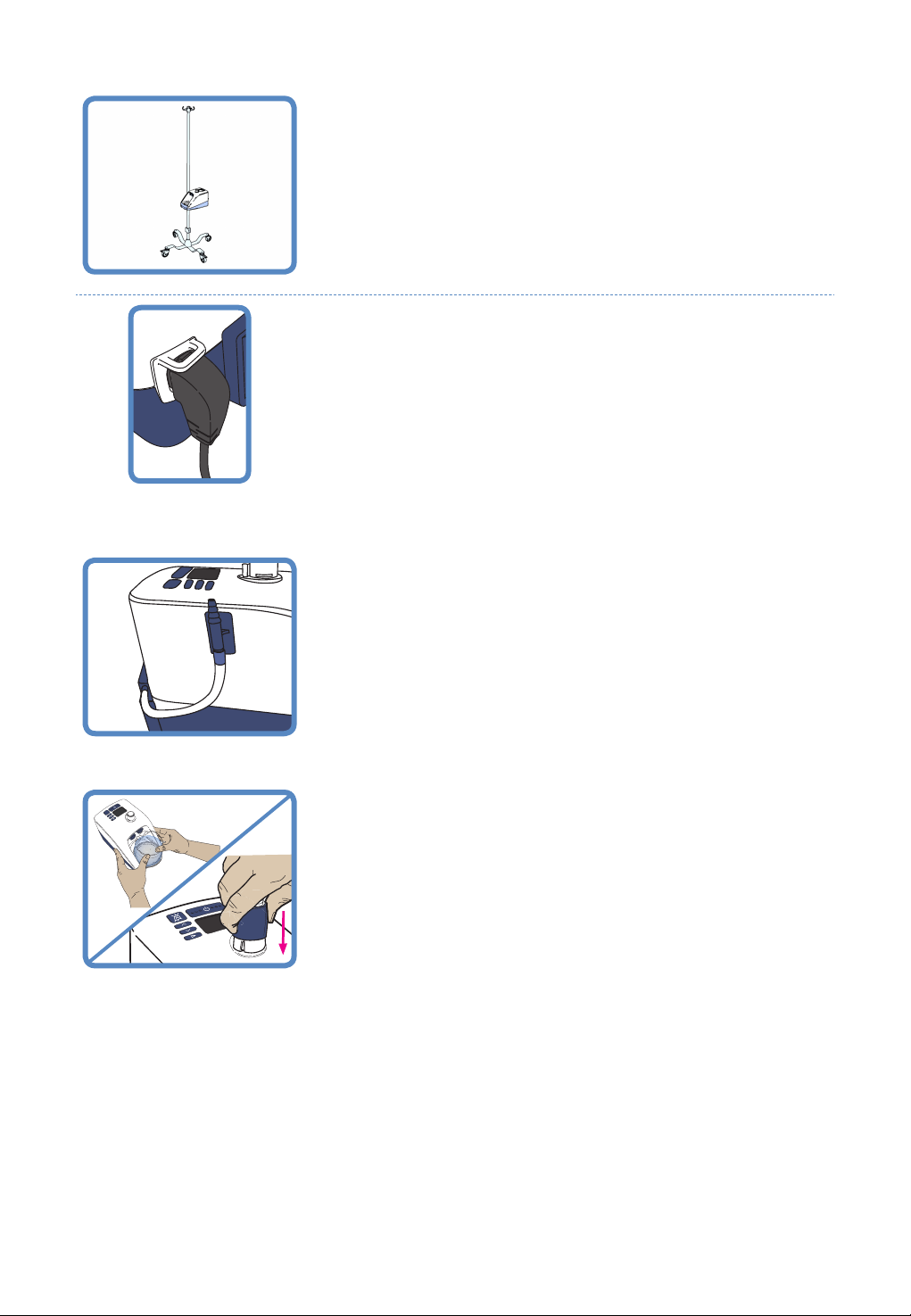

2. SETTING UP AIRVO 2 FOR FIRST USE

1. REMOVE THE AIRVO 2 FROM ITS PACKAGING

Place the AIRVO 2 on the 900PT405 pole mounting tray, on the

900PT421 hospital stand.

2. CONNECT THE POWER CORD

Plug the power cord connector into the socket on the back of the

AIRVO 2.

3. ATTACH THE OXYGEN INLET EXTENSION KIT

Refer to the instruction sheet included with the kit itself.

4. ATTACH WATER CHAMBER AND HEATED BREATHING TUBE

The water chamber and heated breathing tube must be connected to

carry out the following setup and testing procedures.

If you have not been supplied with a reusable HC360 water chamber, you

can use an MR290 chamber instead.

6

Page 7

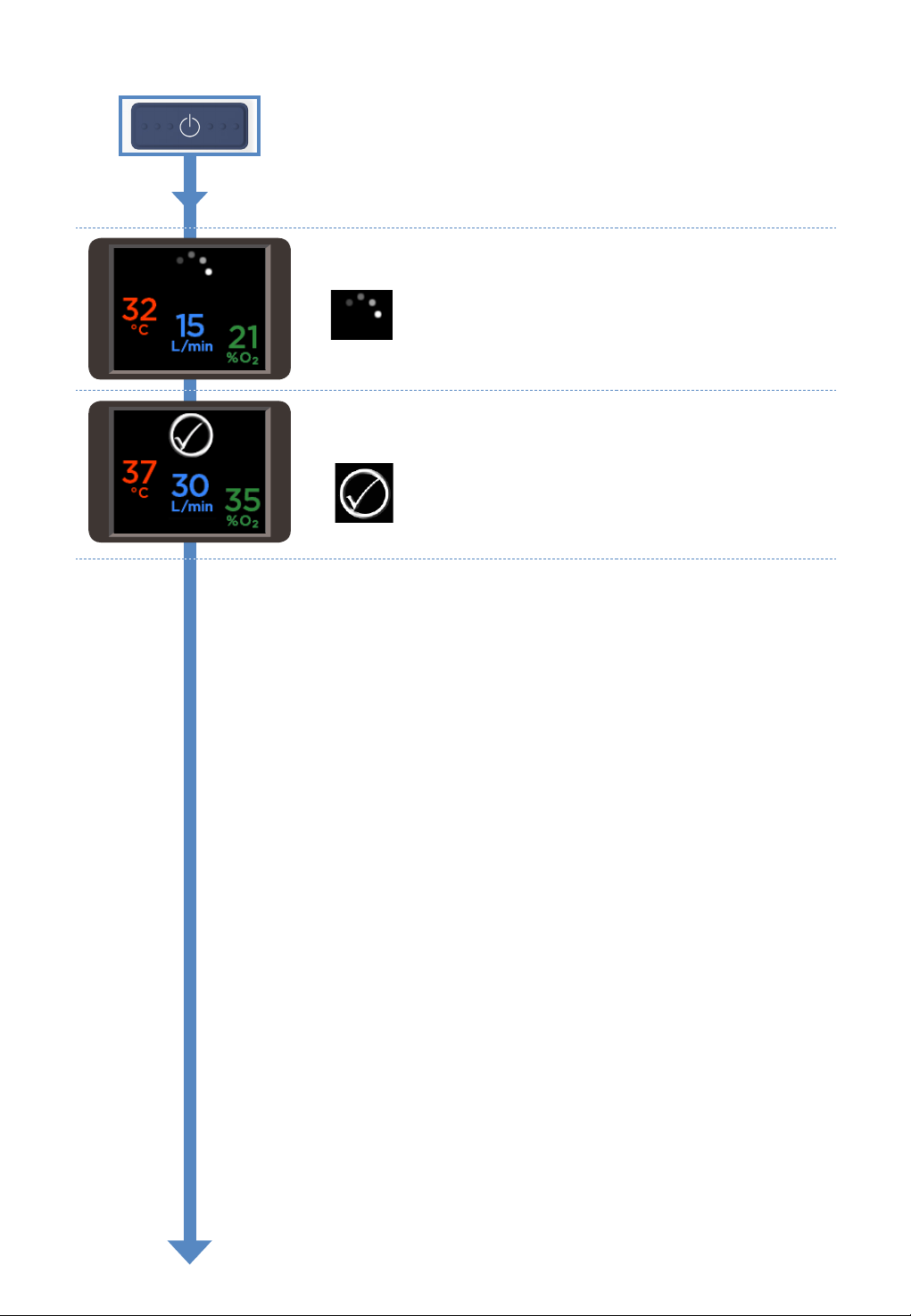

5. SWITCH ON UNIT

Switch on the unit by pressing the On/O button.

6. WARM-UP

The unit will begin to warm up.

“Warm-up” symbol

7. READY FOR USE

The “Ready for use” symbol means that the system is ready for the

patient to use.

“Ready for use” symbol

7

Page 8

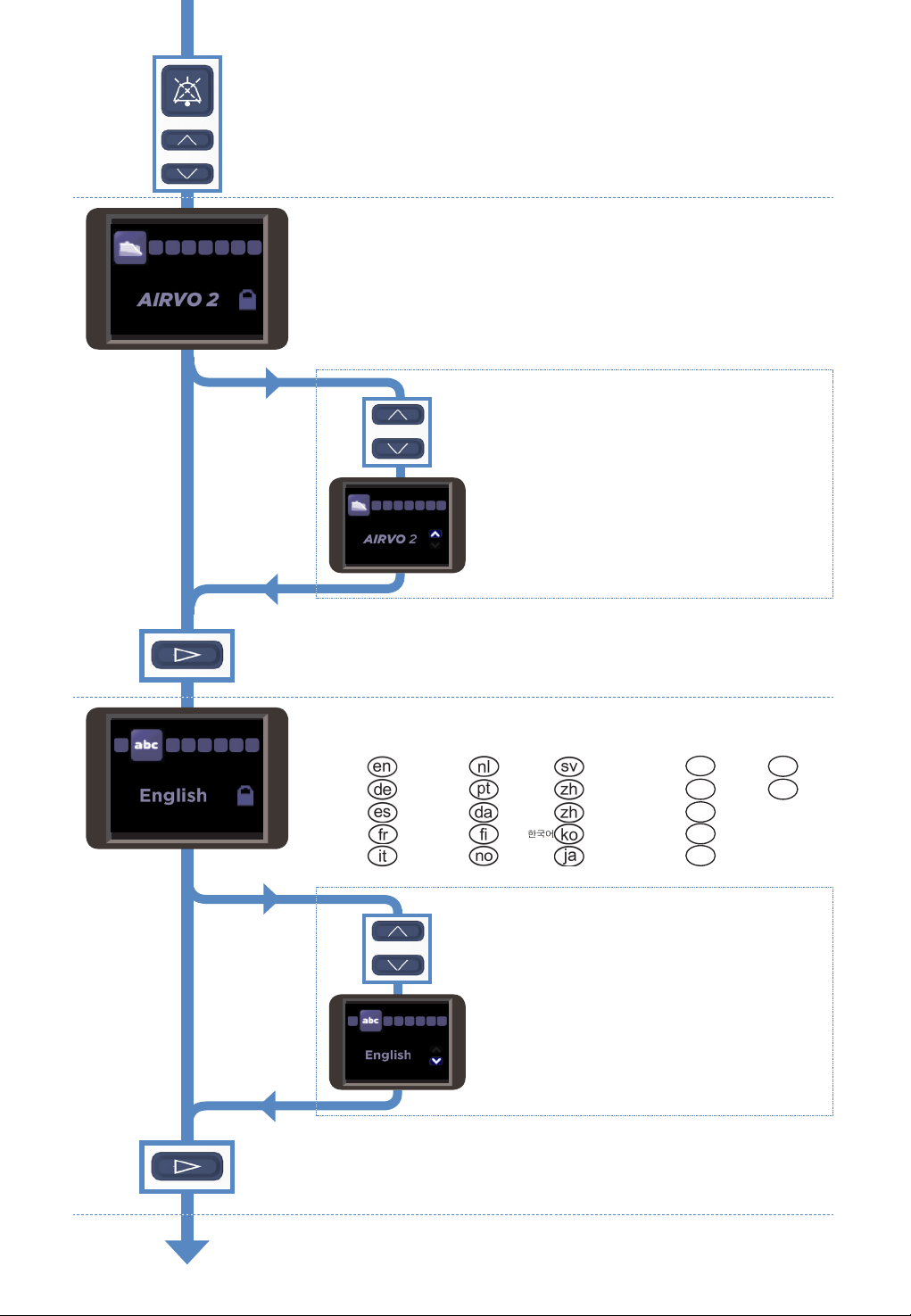

ADVANCED SETTINGS

pl

ar

ru

tr

he

el

ro

When you see the “Warm-up” or “Ready for use” symbols, hold a

combination of three buttons (Up, Down and Mute) for 5 seconds, to

view and change advanced settings.

This button combination is for use by clinical engineering / technical

personnel only.

AIRVO 2 / myAIRVO 2 MODE

You can change the unit from “AIRVO” (hospital) mode to “myAIRVO”

(home / long-term care) mode, eg. for patients going home.

Contact Fisher & Paykel Healthcare for a myAIRVO 2 User Manual.

To change the mode:

Hold the Up and Down buttons for 3 seconds to

“unlock” the setting.

Use the Up button to select myAIRVO 2.

Press the Mode button to confirm the change and/or move on to the

next screen. Note that the unit will reset itself if it is switched between

AIRVO 2 and myAIRVO 2 modes.

LANGUAGE

You can set the AIRVO 2 / myAIRVO 2 to one of 22 language settings:

English Nederlands Svenska Polski

Deutsch Português

Español Dansk

Français Suomi Ελληνικά

Italiano Norsk

简体中文

繁体中文

日本語

[simp.]

[trad.]

Русский

עברית

Română

To change the language:

Hold the Up and Down buttons for 3 seconds to

“unlock” the setting.

Use the Up and Down buttons to select the desired

language.

العربية

Türkçe

Press the Mode button to confirm the change and/or move on to the

next screen.

8

Page 9

95

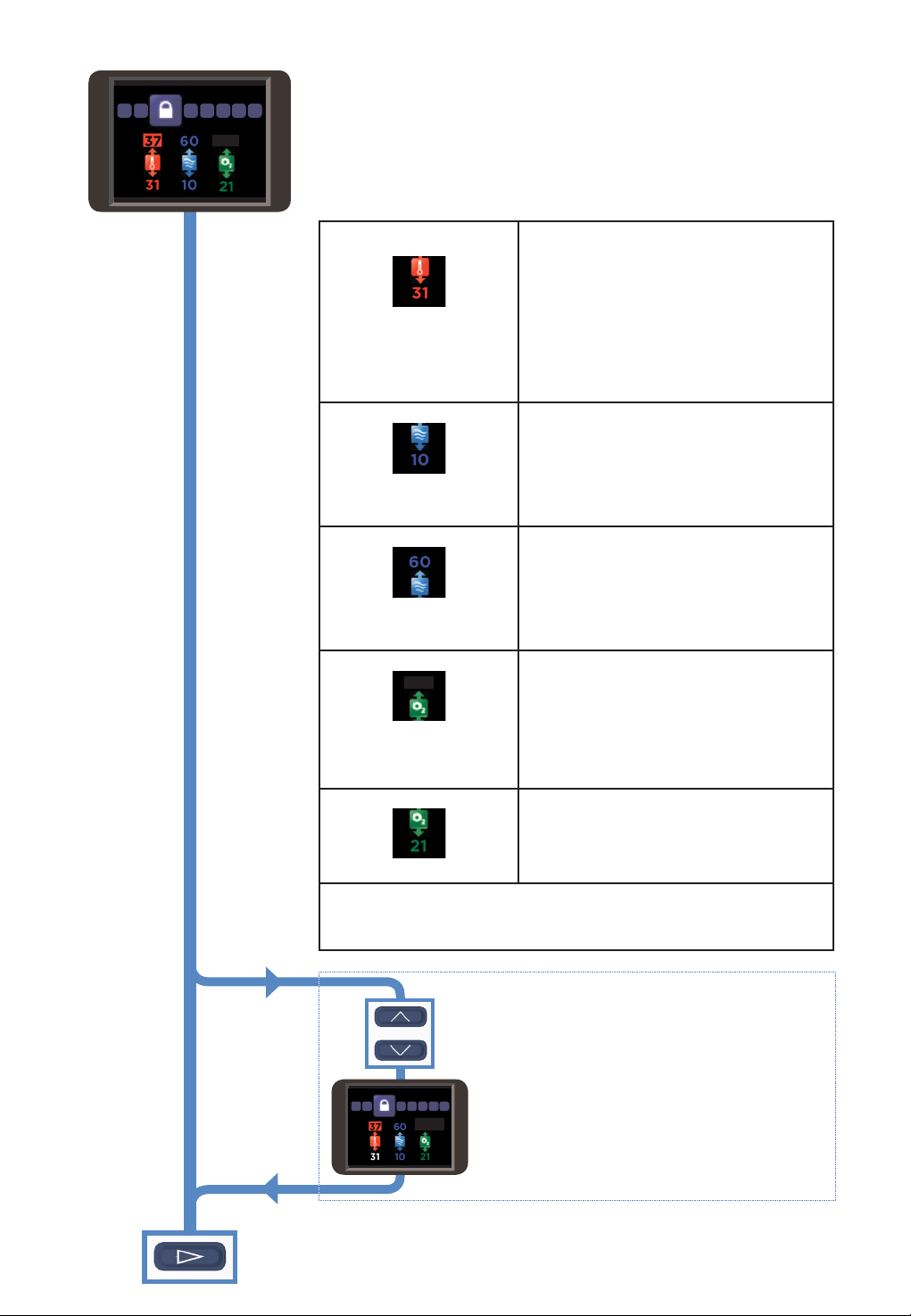

ENVIRONMENT SETTINGS (FOR DEFAULT MODE)

A clinician may change the “Environment Settings”, to customise

individual AIRVOs for dierent environments (eg. intensive care, general

care areas, emergency departments). The “Environment Settings”

chosen will put limits on the “Patient Settings” that the operator can

choose when in normal use.

This screen defines the “Environment Settings” for the AIRVO 2 when in

Default Mode (ie. non-“Junior Mode”).

Minimum dew-point

temperature (°C)

Minimum flow (L/min) The lowest flow that the operator will be able to

Maximum flow (L/min) The highest flow that the operator will be able

Maximum oxygen fraction (%) The highest oxygen fraction that the operator

95

Minimum oxygen fraction (%) The lowest oxygen fraction that the operator

Note that, for Oxygen display, this is a measurement only, not a control setting. The

operator changes the measured oxygen fraction by altering the AIRVO 2 target

flow setting and the flow of oxygen connected to the unit (e.g. from a flowmeter)

- there is no closed-loop control.

The lowest target dew-point temperature that

the operator will be able to select.

Possible Settings: 31, 34, 37 °C

If this is set to 31, the operator can select a target

dew-point temperature between 31 and 37. ie. 31,

34 or 37 (°C).

If the patient is tracheostomised, a clinician may

wish to set this value to 37, so that the operator

can only select a target dew-point temperature

between 37 and 37, ie. only 37 (°C).

Note: The maximum dew-point temperature

setting is always 37 °C in Default Mode.

select.

Possible Settings: 10 to 60 in increments of 5 L/min,

always less than or equal to Maximum Flow setting.

Example: If this is set to 10, the operator will be

able to select flows down to 10 L/min.

If this is set to 25, the operator will be able to

select flows down to 25 L/min.

to select.

Possible Settings: 10 to 60 in increments of 5 L/min,

always greater than or equal to Minimum Flow setting.

Example: If this is set to 60, the operator can

select flows up to 60 L/min.

If this is set to 35, the operator can select flows up

to 35 L/min.

may set the unit to.

Possible settings: 30 - 100% in increments of 5% O2.

The unit will alarm if the measured oxygen

fraction exceeds this value.

Note: Even if this ‘Maximum oxygen fraction‘

setting is set to 100%, any time the measured

oxygen fraction exceeds 95%, the oxygen reading

will pulse red and the device will beep.

may set the unit to.

Possible settings: 21 or 25% O2.

When set to 25% the unit will alarm if the

measured oxygen fraction is below this value. This

allows detection of oxygen being disconnected.

To change the environment settings:

Hold the Up and Down buttons for 3 seconds to

“unlock” the first setting.

95

Use the Up and Down buttons to change the setting,

then press the Mode button to progress to the next

setting.

Press the Mode button to confirm the change and/or move on to the

next screen.

9

Page 10

95

100

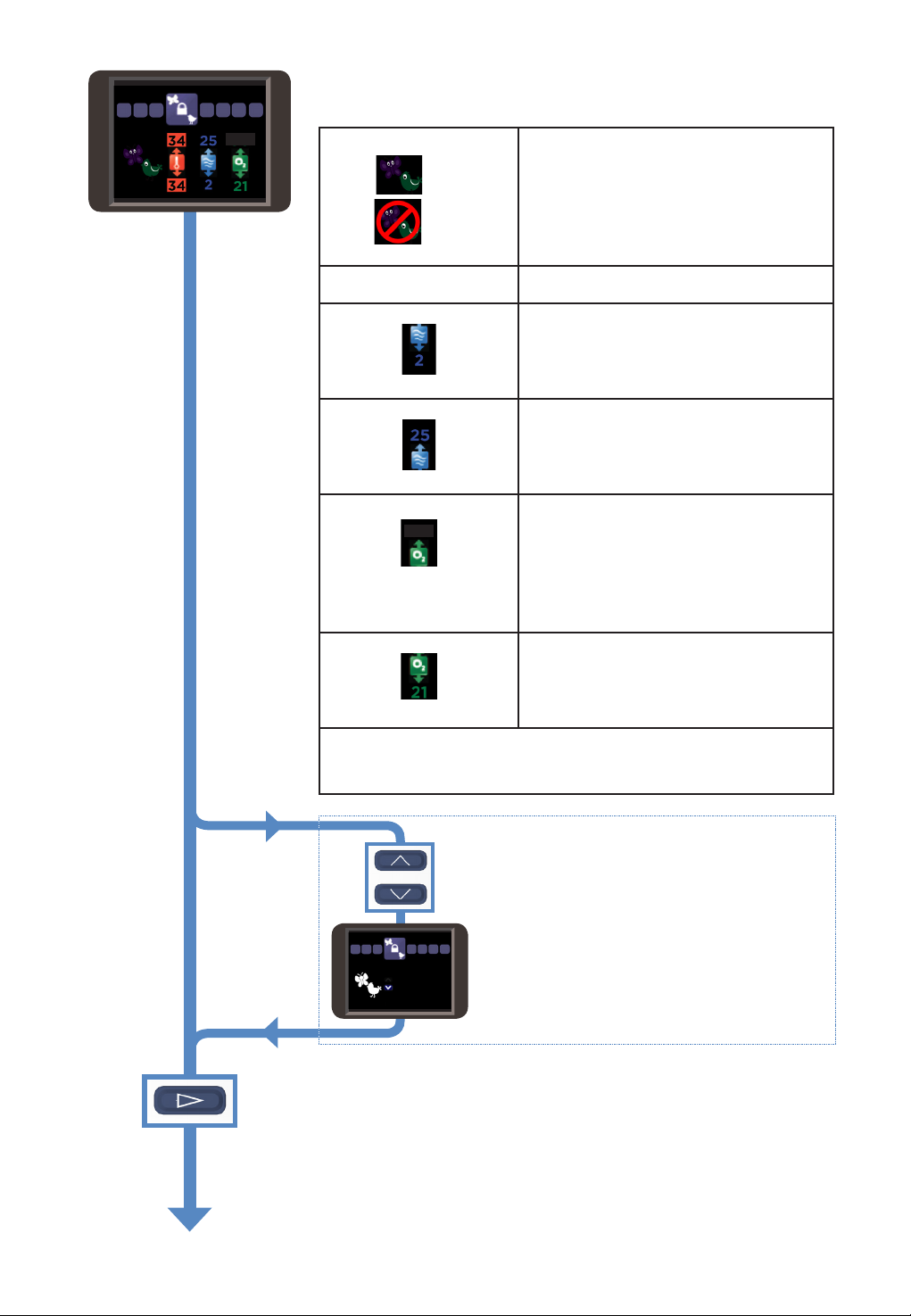

ENVIRONMENT SETTINGS (FOR JUNIOR MODE)

This screen defines the “Environment Settings” for the AIRVO 2 when in

Junior Mode.

Junior Mode Enable/Disable

Enabled

Disabled

Dew-point

temperature (°C)

Minimum flow (L/min) The lowest flow that the operator will be able to

Maximum flow (L/min) The highest flow that the operator will be able

Maximum oxygen fraction (%)

95

Minimum oxygen fraction (%) The lowest oxygen fraction that the operator

Note that, for Oxygen display, this is a measurement only, not a control setting. The

operator changes the measured oxygen fraction by altering the AIRVO 2 target

flow setting and the flow of oxygen connected to the unit (e.g. from a flowmeter)

- there is no closed-loop control.

When this option is enabled (default), the

operator can enter Junior Mode from the Home

Screen, by holding the Mode button for 5

seconds.

When this option is disabled, entering Junior

mode is not possible.

Consider disabling this option if the unit will never

be used on pediatric patients.

The only dew-point setting in Junior Mode is

34 °C.

select.

Possible Settings: 2 to 25 in increments of 1 L/min,

always less than or equal to Maximum Flow setting.

If this is set to 10, the operator will be able to

select flows down to 10 L/min.

to select.

Possible Settings: 2 to 25 in increments of 1 L/min,

always greater than or equal to Minimum Flow setting.

If this is set to 15, the operator can select flows up

to 15 L/min.

The highest oxygen fraction that the operator

may set the unit to.

Possible settings: 30 - 100% in increments of 5% O2.

The unit will alarm if the measured oxygen

fraction exceeds this value.

Note: Even if this ‘Maximum oxygen fraction‘

setting is set to 100%, any time the measured

oxygen fraction exceeds 95%, the oxygen reading

will pulse red and the device will beep.

may set the unit to.

Possible settings: 21 or 25% O2.

When set to 25% the unit will alarm if the

measured oxygen fraction is below this value. This

allows detection of oxygen being disconnected.

To change the environment settings:

Hold the Up and Down buttons for 3 seconds to

“unlock” the first setting.

Use the Up and Down buttons to change the setting,

then press the Mode button to progress to the next

setting.

Press the Mode button to confirm the change and/or move on to the

next screen..

10

Page 11

25

FLOW INCREMENT SETTINGS

This screen defines the “Flow Increment Settings” for the AIRVO 2 when

in either Default Mode or Junior Mode.

You can define the flow rate above which the increments are 5 L/min

and below which the increments are 1 L/min.

To change the environment settings:

Hold the Up and Down buttons for 3 seconds to

“unlock” the setting.

Use the Up and Down buttons to change the setting.

25

Press the Mode button to confirm the change and/or move on to the

next screen.

Flows > 25 L/min will increment in steps of 5 L/min

Flows < 25 L/min will increment in steps of 1 L/min

DISINFECTION STOP-GATE SETTINGS

This screen defines the “Disinfection Stop-Gate Settings” for the

AIRVO 2 when in either Default Mode or Junior Mode.

Confirmation required

At startup, disinfection number and time

information is shown, confirmation from the

operator is required before progressing to

warmup

Confirmation not required (default)

At startup, disinfection number and time

information is shown before progressing to

warmup

To change the environment settings:

Hold the Up and Down buttons for 3 seconds to

“unlock” the setting.

Use the Up and Down buttons to change the setting.

Press the Mode button to confirm the change and/or move on to the

next screen.

11

Page 12

OXYGEN INPUT SETTINGS

This screen defines the “Oxygen Input Settings” for the AIRVO 2 when

in either Default Mode or Junior Mode.

The 100% setting is for hospital oxygen supplies, liquid oxygen or

standard bottled oxygen and is the default setting for AIRVO 2.

The 95% setting is for use with oxygen concentrators.

To change the environment settings:

Hold the Up and Down buttons for 3 seconds to

“unlock” the setting.

Use the Up and Down buttons to change the setting.

Press the Mode button to confirm the change and/or move on to the

next screen.

TRANSPORT MODE SETTINGS

This screen defines the “Transport Mode Settings” for the AIRVO 2

when in either Default Mode or Junior Mode.

Transport Mode enabled

Transport mode may be activated by the operator.

(see “Transport mode” in the AIRVO 2 User

Manual)

Transport Mode disabled (default)

Transport mode may not be activated by the

operator..

To change the environment settings:

Hold the Up and Down buttons for 3 seconds to

“unlock” the setting.

Use the Up and Down buttons to change the setting.

Press the Mode button to return to the “Warm-up”/”Ready for use”

screen. You can now conduct the Performance/Acceptance checks..

12

Page 13

3. ACCEPTANCE/PERFORMANCE CHECKS

This section contains performance checks which can be carried out on the AIRVO 2, however there is

no manufacturer requirement to carry out these checks on a routine basis. These checks test the basic

functions of the unit, the operation of the flow sensor and the audible alarm signal.

SENSOR CHECKS

To ensure quality and patient safety, Fisher & Paykel Healthcare undertakes stringent testing to each

and every unit manufactured. The AIRVO 2’s sensors, measuring temperature, flow and oxygen, have

been carefully designed to exacting criteria, and are calibrated and tested in our controlled work

environment to strict limits. Furthermore, the AIRVO 2 itself carries out regular self-checks during

normal use, comparing sensor readings against expected values.

Do not perform additional tests of internal sensor accuracy, as these often produce erroneous

results due to limitations of the external test environment and equipment used, particularly given the

temperature, humidity content and/or flow of the gases being delivered by the AIRVO 2.

ACCEPTANCE/PERFORMANCE CHECKS

The acceptance/performance checks should be conducted under the following ambient conditions:

Temperature: 22 ± 2°C, Humidity: 50 ± 5% RH.

The following equipment is required:

AIRVO 2 humidifier MR290 chamber

(or alternatively a

HC360 chamber)

Heated breathing tube

(from 900PT500 or

900PT501 kit)

Nasal interface

(OPT842, OPT844 or

OPT846)

A. HEATERPLATE TEST

1. Add 150 mL of room temperature (not hot) water to the water chamber and fit the chamber onto the

heater plate of the device. Fit the chamber tightly on to the chamber ports.

2. Connect the heated breathing tube to the Heated Breathing Tube Connection port. Connect the nasal

cannula interface to the heated breathing tube.

3. Turn on the device, by pressing the power button for 2 seconds. Warm-up bars will be displayed as the

unit warms up. Ensure the flow is set to 30 L/min.

4. Check that the “Ready for use” symbol (a “tick” or “check”) is displayed within 30 minutes.

B. “CHECK FOR LEAKS” TEST

After the “Ready for use” symbol is displayed, the “Check for leaks” sensor test can be tested as follows:

1. Remove the chamber completely from the unit.

2. Check that the display shows the “Check for leaks” error (in the appropriate language) and that the

audible alarm sounds, within 2 minutes.

3. Reconnect the chamber and check that this flashing display disappears, the audible alarm stops and the

display reverts back to the Warm-up/Ready-for-use screen.

13

Page 14

C. “CHECK FOR BLOCKAGES” TEST

After completing the “Check for leaks” test, the “Check for blockages” test can be tested as follows:

1. Disconnect the cannula from the Heated Breathing Tube.

2. Completely block the end of the Heated Breathing Tube with your hand.

3. Check that the display shows the “Check for blockages” error (in the appropriate language) and that the

audible alarm sounds, within 30 seconds.

4. Unblock the end of tube and check that this flashing display disappears, the audible alarm stops and the

display reverts back to the previous display.

5. Reconnect the cannula to the Heated Breathing Tube.

D. “CHECK TUBE” TEST

After completing the above flow tests, the Tube Missing alarm can be tested as follows:

1. Remove the Heated Breathing Tube (pull the blue sleeve up first).

2. Check that within 10 seconds the display flashes the Breathing Tube symbol and the alarm sounds.

3. Refit the Heated Breathing Tube, check the alarm stops and that the display reverts back to the previous

display.

Note: If any of the tests above fail, please contact your Fisher & Paykel Healthcare representative.

14

Page 15

4. SERVICING

AIRVO 2 and myAIRVO 2 humidifiers do NOT require routine servicing or calibration.

The only checks that can be carried out are the Acceptance/Performance Checks in the previous section,

and the Electrical Safety Test detailed below.

WARNING

UNDER NO CIRCUMSTANCES SHOULD THE

AIRVO 2 BE OPENED OR ANY OF THE SIX

FASTENING SCREWS ON THE UNDERNEATH

SIDE OF THE DEVICE BE LOOSENED. OPENING

THE UNIT WILL AFFECT THE OXYGEN

SEALS INSTALLED INSIDE, WHICH WILL

COMPROMISE THE SAFETY OF THE DEVICE.

ELECTRICAL SAFETY TESTS

To test for electrical safety perform the following electrical safety tests and any others required by local

regulations.

Inspection Check the power cord for damage - cuts, stretching, wear, adequate cable restraint, bent

Insulation Resistance Use a 500 VDC insulation tester to measure the resistance between the mains plug phase pin

pins. Replace with F&P approved cord if necessary.

and the heaterplate* - it should be > 10 Mohm. Repeat test from the mains plug neutral pin to

the heaterplate*.

* Note: The exposed surface of the heaterplate is anodised (high resistance). Contact MUST

be made to the bottom lip of the heaterplate at the front of the device to make proper

connection - depress the finger guard and slip the tester probe beneath the heaterplate to

ensure contact to unanodised aluminium.

STORAGE AND DISPOSAL

Refer to AIRVO 2 User Manual.

15

Page 16

5. SPARE PARTS

5.1 POWER CORDS

900PT410AZ (Aus/NZ)

900PT410EW (European)

900PT410UK (UK)

900PT410US (US/Canada)

900PT410KR (Korea)

900PT410JP (Japan)

16

Page 17

5.2 FOR AIRVO

Non-Return Valve (2-pack)

Serial Port Cover (10-pack)

900PT911

900PT912

AIRVO 2 Filter Holder

900PT913

Air Filter (2-pack)

900PT422

Oxygen Inlet Kit

900PT407

AIRVO Outlet O-Ring (10-pack)

5.3 FOR DISINFECTION

Disinfection Kit

Disinfection Filter

Cleaning Sponge Stick

Disinfection Storage Cover

900PT408

900PT600

900PT601

(2-pack)

900PT602

(20-pack)

900PT603

(20-pack)

17

Page 18

5.4 HARDWARE

900PT405

Pole Mounting Tray

900PT421

Mobile Pole Stand

900PT423

Hook for 900PT421

900PT426

Plastic Basket

900PT427

Oxygen Bottle Holder

900PT409

3M Dual Lock Pad (4 pairs)

18

Page 19

APPENDIX A: IEC60601-1-2 EMC TABLES

14 of 17

Appendix A: IEC60601-1-2 EMC tables

Guidance and manufacturer's declaration - electromagnetic emissions

The device is intended for use in the electromagnetic environment specified below. The customer or the user of the device should

ensure that it is used in such an environment.

Emissions test Compliance Electromagnetic environment - guidance

RF emissions

CISPR 11

Group 1

The device uses RF energy only for its internal function. Therefore, its RF

emissions are very low and are not likely to cause any interference in

nearby electronic equipment.

RF emissions

CISPR 11

Class B Applicable for countries with 100-115V and 220-240V mains voltage.

Harmonic emissions

IEC 61000-3-2

Class A

Voltage fluctuations/

flicker emissions

IEC61000-3-3

Complies

The device is suitable for use in all establishments, including domestic

establishments and those directly connected to the public low-voltage

power supply network that supplies buildings used for domestic purposes

15 of 17

Guidance and manufacturer's declaration - electromagnetic immunity

The device is intended for use in the electromagnetic environment specified below. The customer or the user of device should ensure that it is used in

such an environment.

Immunity

test

IEC60601

test level

Compliance level

Electromagnetic environment

- guidance

±2kV ,±4kV, ±6kV contact ±2 kV,±4kV, ±6 kV contact

Electrostatic

discharge (ESD)

±2 kV ,±4kV, ±8 kV air ±2 kV ,±4kV, ±8 kV air

IEC61000-4-2

Floors should be wood, concrete or ceramic tile. If

floors are covered with synthetic material, the

relative humidity should be at least 30%.

±2 kV for power

supply lines

±2 kV

Electrical fast

transient/burst

±1 kV for input/output See note 2 below

IEC61000-4-4

lines

Mains power quality should be that of a typical

commercial or hospital environment.

±1 kV differential mode ±1 kV

Surge

±2 kV common mode ±2 kV

IEC 61000-4-5

Mains power quality should be that of a typical

commercial or hospital environment.

<5 % UT <5 % UT

(>95 % dip in UT) (>95 % dip in UT)

for 0.5 cycle for 0.5 cycle

40 % UT 40 % UT

(60 % dip in UT) (60 % dip in UT)

for 5 cycles for 5 cycles

Voltage dips, short

interruptions and

voltage variations

on power supply

input lines

70 % UT 70 % UT

IEC 61000-4-11 (30 % dip in UT) (30 % dip in UT)

for 25 cycles for 25 cycles

<5 % UT <5 % UT

(>95 % dip in UT) (>95 % dip in UT)

for 5 sec for 5 sec

Mains power quality should be that of a typical

commercial or hospital environment. If the user of

the device requires continued operation during

power interruptions, it is recommended the device

be powered from an uninterruptible power supply

or a battery.

3 A/m 3 A/m

Power frequency

(50/60 Hz)

magnetic field

IEC 61000-4-8

Power frequency magnetic fields should be at

levels characteristic of a typical location in a typical

commercial or hospital environment.

NOTE 1: UT is the a.c. mains voltage prior to application of the test level.

NOTE 2: This testing is not necessary for the safe operation of the device.

19

Page 20

16 of 17

Guidance and manufacturer's declaration - electromagnetic immunity

17 of 17

The device is intended for use in the electromagnetic environment specified below. The customer or the user of the device should ensure that it is used in such

an environment.

Immunity test

Conducted RF 3 Vrms 3 Vrms

IEC 61000-4-6 150 kHz to 80 MHz

Radiated RF 3 V/m 3 V/m

IEC 61000-4-3 80 MHz to 2,5 GHz

IEC60601 test

level

Compliance level Electromagnetic environment - guidance

Portable and mobile RF communications equipment should be

used no closer to any part of the device, including cables, than the

recommended separation distance calculated from the equation

applicable to the frequency of the transmitter.

Recommended separation distance

d = 1.2 √

P

P 80 MHz to 800 MHz

d = 1.2 √

P 800 MHz to 2.5 GHz

d = 2.3 √

NOTE 1: At 80 MHz and 800 MHz, the higher frequency range applies.

NOTE 2: These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and reflection from structures, objects and

people.

a

Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless) telephones and land mobile radios, amateur radio, AM and FM

radio broadcast and TV broadcast cannot be predicted theoretically with accuracy. To assess the electromagnetic environment due to fixed RF transmitters,

an electromagnetic site survey should be considered. If the measured field strength in the location in which the device is used exceeds the applicable RF

compliance level above, the device should be observed to verify normal operation. If abnormal performance is observed, additional measures may be

necessary, such as re-orienting or relocating the device.

b

Over the frequency range 150 kHz to 80 MHz, field strengths should be less than 3 V/m.

where P is the maximum output power rating of the transmitter in

watts (W) according to the transmitter manufacturer and d is the

recommended separation distance in metres (m).

Field strengths from fixed RF transmitters, as determined by an

electromagnetic site survey,ª should be less than the compliance

level in each frequency range

Interference may occur in the vicinity of equipment marked with

the following symbol:

b

.

Recommended separation distances between portable and mobile RF communications equipment

and the device

The device is intended for use in the electromagnetic environment in which radiated RF disturbances are controlled. The customer or the user of the device

can help prevent electromagnetic interference by maintaining a minimum distance between portable and mobile RF communications equipment (transmitters)

and the device as recommended below, according to the maximum output power of the communications equipment.

Separation distance according to frequency of transmitter

Rated maximum output power 150 kHz to 80 MHz 80 MHz to 800 MHz 800 MHz to 2.5 GHz

of transmitter

W

0.01 0.12 0.12 0.23

0.1 0.38 0.38 0.73

1 1.2 1.2 2.3

10 3.8 3.8 7.3

100 12 12 23

For transmitters rated at maximum output power not listed above, the recommended separation distance d in metres (m) can be estimated using the equation

applicable to the frequency of the transmitter, where P is the maximum output power rating of the transmitter in watts (W) according to the transmitter

manufacturer.

NOTE 1: At 80 MHz and 800 MHz, the separation distance for the higher frequency range applies.

NOTE 2: These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and reflection from structures, objects and

people.

d = 1.2 √

P d =1.2 √P d = 2.3 √P

20

m

Page 21

APPENDIX B: USER INTERFACE FLOW CHARTS

AIRVO 2

Junior Mode

New Target

Settings

Wait for

time out 60s

Oxygen

is left on

Disconnect

Oxygen

Disinfection:

Hold

5 s

Hold

3s

Last

#4

17 days

14 hours

ago

Last

Disinfection:

#5

2 days

4 hours

ago

Environment Settings

Hold

Press

Hold

AIRVO 2

V6.72

5 s

AIRVO 2

Transport

Mode

Hold

5 s

5 s

[Machine Data]

English

Hold

3s

Press

English

Press

Hold

3s

37 60

31 10

90

60

37

10

21

Hold

Hold

3s

After 3

scrolls

3s

Press

Press

Hold

3s

90 90

60 25

37

313110 2

21

90

21

90

21

onitor patient O2

Patient Settings

Press

Press

90

25

34

2

21

34

60

30

10

Hold

3s

Press

34

34

21

Hold

3s

Press

30

Hold

95%

100%

Hold

3s

Press

3s

Press

100%

Hold

3s

19:23

timer

reaches

00:00

Transport

Mode

Press

Non-Transport

Mode

Press

Hold

5 s

Wait for

19:55

Hold

5 s

time out 60s

21

Page 22

DISINFECTION

1000 hours use

- Replace lter

Press

Press

Any key

Press Press

Now

Later

Press

Now

Later

Filter timer

remains at 1000

hrs +

Time

Filter timer is

reset to 0 hrs

Wait for

time out 60s

22

Page 23

APPENDIX C: DEFAULT VALUES

The following values are default non-alarm settings set by the factory:

Parameter Model Mode Value Unit

Default set dewpoint

temperature

Max set dewpoint

temperature

Min set dewpoint

temperature

Default set flow AIRVO 2 Default 30 L/min

Max set flow AIRVO 2 or myAIRVO 2 Default 60 L/min

Min set flow AIRVO 2 or myAIRVO 2 Default 10 L/min

Default upper oxygen limit

Max upper oxygen limit

Min upper oxygen limit AIRVO 2 or myAIRVO 2 Default or Junior 30 %

Default lower oxygen limit AIRVO 2 or myAIRVO 2 Default or Junior 21 %

Max lower oxygen limit AIRVO 2 or myAIRVO 2 Default or Junior 25 %

Min lower oxygen limit AIRVO 2 or myAIRVO 2 Default or Junior 21 %

Language AIRVO 2 or myAIRVO 2 Default or Junior English

Flow Increment Crossover AIRVO 2 or myAIRVO 2 Default or Junior 25 L/min

Oxygen Input

Disinfection Stop-Gate AIRVO 2 Default or Junior

Transport Mode AIRVO 2 Default or Junior Disabled

Day/Night mode myAIRVO 2 Default or Junior Day

AIRVO 2 or myAIRVO 2 Default 37 °C

AIRVO 2 or myAIRVO 2 Junior 34 °C

AIRVO 2 or myAIRVO 2 Default 37 °C

AIRVO 2 or myAIRVO 2 Junior 34 °C

AIRVO 2 or myAIRVO 2 Default 31 °C

AIRVO 2 or myAIRVO 2 Junior 34 °C

myAIRVO 2 Default 25 L/min

AIRVO 2 or myAIRVO 2 Junior 15 L/min

AIRVO 2 or myAIRVO 2 Junior 25 L/min

AIRVO 2 or myAIRVO 2 Junior 2 L/min

AIRVO 2 Default or Junior 95 %

myAIRVO 2 Default or Junior 90 %

AIRVO 2 Default or Junior 100 %

myAIRVO 2 Default or Junior 90 %

AIRVO 2 Default or Junior 100 %

myAIRVO 2 Default or Junior 95 %

Confirmation not required

23

Page 24

APPENDIX D: TROUBLESHOOTING GUIDE

This Troubleshooting Guide is intended for technical users, including clinical/biomedical engineers and

technical personnel, of the AIRVO™ 2 humidifier. It applies to all AIRVO 2 humidifiers from lot numbers

140910 and above.

If this troubleshooting guide does not resolve your issue, please contact your local Fisher & Paykel

Healthcare representative.

D.1 AIRVO does not turn on

A. Press and hold the ON/OFF button for at least 2 seconds.

B. Is the AIRVO 2 plugged into mains power?

C. Is the power cord securely inserted into the back of the AIRVO 2?

D. Is the power cord damaged?

• If yes, replace the damaged cord. See Section 5.1 for a 900PT410xx replacement power cord.

• If no, try using another power cord.

E. Connect the AIRVO 2 into another power outlet.

F. Connect a different electrical device into the same power outlet. Turn on the device to confirm that the

power outlet is working.

G. The AIRVO 2 may be ‘on’ with a broken display.

Turn the AIRVO 2 on without the heated breathing tube and check that the audible alarm activates.

D.2 Power out (black screen)

The auditory alarm will sound for at least 120 seconds.

The most likely cause is a dislodged or disconnected power cord.

A. Please follow the instructions in Section D.1.

Note: Press “audio pause” button to permanently silence the alarm ( ).

The device will not automatically restart.

D.3 “Check tube”

Fig. 1

or “E38“

A. Is the heated breathing tube attached correctly?

• Even if it appears to be, unplug and reconnect the heated breathing

tube.

B. Is the heated breathing tube visibly damaged?

• Check the electrical pins and the tube itself.

C. Try using a new heated breathing tube.

Figure 1

24

Page 25

D.4 “Check for blockages”

Fig. 2

or “E121”

D.4.1 WATER CHAMBER AND NON-RETURN VALVE

A. Have the silicone flaps of the non-return valve, found inside the left-hand

chamber port, been displaced

Fig. 3

?

• If yes, return them to the correct position using a non-sharp tool, such

as a pair of non-sharp tweezers

Fig. 5

.

Note: If the Non-return valve is damaged or missing, replace with part

900PT911. Upon replacement, ensure the spine is sitting vertically

Fig. 5

.

If placed horizontally, this may cause the bottom flap to open due to

gravity

Fig. 4

. This may cause both “Check for leaks” and “Check for blockages”

warnings.

B. Is the MR290 water chamber overfilled above the black line?

• If yes, replace with a new water chamber. Contact your local Fisher &

Paykel Healthcare representative about the faulty chamber.

D.4.2 HEATED BREATHING TUBE

A. Is the heated breathing tube visibly blocked or kinked

Fig. 6

?

D.4.3 PATIENT INTERFACE AND AIRVO MODE

A. Is the patient interface visibly blocked or kinked?

B. Should the unit be in Junior mode

Fig. 7

?

• If the AIRVO is in Default mode and the 900PT531 Junior tube is used

with the OPT316 and OPT318 cannula interfaces it may generate a

“Check for blockages” alarm.

See Appendix E for identification of the Default and Junior Tube and

Chamber Kits, according to their labels.

C. Are you using an unsuitable cannula?

• The OPT312 and OPT314 cannot be used with the AIRVO 2.

See the User Manual for information regarding patient interfaces.

D.4.4 AIR FILTER

A. Is the air filter significantly discolored/dirty?

• Replace with part 900PT913.

Note: A prompt

Fig. 8

for filter change will occur at the start of the Disinfection

Cycle once the AIRVO 2 has counted 1,000 hours of use. Choose ‘Now’ or

‘Later’

Fig. 9

by using the “up” or “down” buttons and press the “mode” button

( ) to confirm. Selecting ‘Now‘ will zero the counter. Selecting “Later“

will activate the prompt at the start of the next Disinfection Cycle.

B. Is there a foreign object blocking the air filter or filter holder?

D.4.5 CONDENSATION

Please see Section D.12.

D.4.5 ALTITUDE

A. The myAIRVO 2 is designed to operate at an altitude below 2,000 meters.

Figure 2

Figure 3

Figure 6

Figure 4

Figure 5

25

Figure 7

Figure 8

Figure 9

Page 26

D.5 “Check for leaks”

Fig. 10

or “E122”

The most likely cause is a missing water chamber or the existing chamber has

not been pushed into place correctly.

D.5.1 WATER CHAMBER

A. Is the water chamber fitted correctly? Even if it appears to be:

• Remove the water chamber.

• Push the chamber on firmly, until the finger guard “clicks” into place

Fig. 11

.

Warning: The heater-plate and base of the water chamber may be hot.

D.5.2 HEATED BREATHING TUBE

A. Is the heated breathing tube attached to the device correctly?

Even if it appears to be:

• Disconnect the heated breathing tube.

• Check that the black O-ring is in place

Fig.12

.

If the O-ring is damaged or missing, replace with part 900PT408.

• Reconnect the heated breathing tube.

B. Confirm that the heated breathing tube is not visibly damaged.

D.5.3 PATIENT INTERFACE

A. Is the patient interface correctly fitted to the heated breathing tube?

• Even if it appears to be, disconnect and reconnect the patient interface.

It should make a “click” sound when it is connected properly.

B. Should the unit be in Default (adult) mode?

• If the AIRVO is in Junior mode and the 900PT501 Default tube is used

with the OPT842/44/46/70 or RT013 interfaces, it may generate a

“Check for leaks” alarm.

See Appendix E for identification of the Default and Junior Tube and

Chamber Kits, according to their labels.

D.5.4 AIR FILTER & FILTER COVER

A. Is the air filter and filter cover (at the back of the device) correctly fitted, as

per the User Manual?

Figure 10

Figure 11

Figure 12

26

Page 27

D.6 “O2 too low”

Fig. 13

The measured oxygen level has fallen below the allowed limit.

A. Adjust the level of oxygen from the oxygen source as necessary, i.e. increase

the oxygen flow rate through the oxygen flow meter.

B. Is the oxygen source (wall or cylinder flow meter) turned on?

C. Is the oxygen source empty or faulty?

D. Is the “AIRVO 2 oxygen inlet kit”

Fig. 14

installed correctly, as per the

instructions included with part 900PT422 and confirmed that there are no

kinks in the “AIRVO 2 oxygen inlet kit” oxygen tubing?

E. Is the oxygen source tubing correctly and securely fitted to the AIRVO 2?

F. Allow the device to sufficiently warm up; rapid changes in temperature can

affect the sensor.

G. Is the minimum oxygen limit set to 25%?

• A prompt will appear with an option to change this lower limit to 21 %.

Select “Yes” or “No” by using the “Up“ and “Down” buttons. Press the

“mode” button ( ) to confirm selection

Fig. 15

.

See Section 2 - Advanced Settings to change this lower oxygen limit.

Figure 13

D.7 “O2 too high”

Fig. 16

The measured oxygen level has risen above the allowed limit.

A. Adjust the level of oxygen from the oxygen source as necessary, i.e. decrease

the oxygen flow rate through the oxygen flow meter.

B. See Section 2 - Advanced Settings to change this lower oxygen limit.

D.8 “Cannot reach target flow”

Fig. 17

A. Press the “mode” button ( ) to continue normal operation at a lower

(maximum achievable) flow rate.

B. Is the target flow setting too high for the patient interface?

• Check the swing tag/User Manual for the appropriate flow range for each

patient interface.

Note: If the AIRVO 2 cannot reach the target flow setting, it will automatically

select a maximum achievable flow rate and prompt the user to press the

“mode” button ( ) to confirm.

C. Follow steps in Section D.4 — “Check for blockages”.

D. Is the altitude above 2,000 m?

The AIRVO 2 is designed to operate at an altitude below 2,000 meters.

Figure 14

Figure 15

27

Figure 16

Figure 17

Page 28

D.9 “Cannot reach target temperature”

Fig. 18

The most likely cause is operating the AIRVO 2 at a high flow rate in a cold room.

Consider decreasing the target flow setting.

A. Press “mode” button ( ) to continue.

Note: The humidity level may be compromised.

B. Is the ambient room temperature below 18 °C (64 °F)?

• If yes, proactive management of condensation may be required.

See Section D.12 on prevention and management of condensation.

Figure 18

D.10 “Check water”

Fig. 19

A. Is the water bag empty?

If yes, refill or replace the water bag and press the “mode” button ( ) to

reset the alarm.

B. Is the water chamber empty?

• If yes, replace the water chamber as it may be damaged.

Warning: The heater-plate and base of the water chamber may be hot.

C. Is there a kink in the fluid line, preventing water from flowing into the

chamber?

D. Open the vent cap near the water bag spike. This allows the pressure to

equalize, letting the water flow into the water chamber.

D.11 “Check operating conditions”

Fig. 20

This alarm may be caused by a sudden change in ambient room temperature,

e.g. storing the unit in a cold place, then using it in a warm place.

A. Is the ambient room temperature less than 10 °C (50 °F) or greater than

30 °C (86 °F)?

B. Leave the unit running for 30 minutes.

Switch the unit off, then restart.

Figure 19

28

Figure 20

Page 29

D.13 Exxx

Fig. 23

A. Follow the instructions in Appendix F if a fault with an error code is

displayed on the AIRVO screen.

D.12 Condensation

D.12.1 PREVENTION OF EXCESSIVE CONDENSATION

A. Is the AIRVO 2 being used in ambient conditions between 18 – 28 °C

(64 - 82 °F)?

B. Is the AIRVO 2 placed below head height

C. Is there a local source of cooling acting on the heated breathing tube?

D.12.2 CONDENSATION MANAGEMENT

A. Implement a system to check the heated breathing tube for condensate

B. If condensation is present, drain it back into the water chamber

C. If condensate persists, consider turning the target temperature down.

D.12 Condensation

D.12.1 PREVENTION OF EXCESSIVE CONDENSATION

A. Is the AIRVO 2 being used in ambient conditions between 18 – 28 °C

(64 - 82 °F)?

• If the room is less than 18 °C (64 °F), condensation is more likely to

occur.

B. Is there a local source of cooling acting on the heated breathing tube?

• A fan to cool the patient,

• An air-conditioning unit, vent or an open window?

• Are you able to remove or minimize these sources of cooling, e.g.

redirect the fan, cooling the patient, away from the heated breathing

tube?

D.12.2 CONDENSATION MANAGEMENT

A. Implement a system to check the heated breathing tube for condensate

regularly.

B. Is the AIRVO 2 placed below head height

Fig. 21

?

• This will allow condensate to drain towards the water chamber, away

from the patient.

C. If condensation is present, drain it back into the water chamber

Fig. 22

:

• Disconnect the patient interface from the heated breathing tube.

• Drain the tube by lifting the patient end of the tube, allowing the

condensate to run into the water chamber.

• At higher target flow rates, it may be necessary to first reduce the target

flow rate to 30 L/min or below, to ensure the condensate drains into the

water chamber.

D. If condensate persists, consider turning the target temperature down.

• A lower target temperature will decrease the humidity output of the

AIRVO 2, decreasing the level of condensation.

Note: The temperature and humidity level delivered to the patient will also

be reduced.

Figure 21

Figure 22

29

Figure 23

Page 30

APPENDIX E: TUBE AND CHAMBER KIT LABELS

AIRVO

TM

2

900PT531

Tube and Chamber Kit (Junior)

PEDIATRICINFANT

Single

Use

Fisher & Paykel Healthcare Ltd. 15 Maurice Paykel Place, East Tamaki,

Auckland 2013, New Zealand

Cordwallis Park, Clivemont Road, Maidenhead, Berkshire, SL6 7BU, UK

Rx Only

0123

Fisher & Paykel Healthcare Ltd. Unit 16,

Made in New Zealand

Label for default (adult)

Tube and Chamber Kit

Label for Junior

Tube and Chamber kit

APPENDIX F: ERROR FLOWCHART

The following pages provide troubleshooting advice for fault / error / “E” codes that may appear during use of the AIRVO 2.

30

Page 31

Error Range/s: 1-10 11-33, 38-41, 44-50,

141-157

34-37, 42-43, 70-73,

75-78

61-69, 74, 91-106

Error Type: Motor Heated breathing tube Disinfection tube Chamber

Write down the

error code and what

happened before it

appeared.

Was the unit dropped,

shaken or wet?

Turn o Airvo 2.

Disconnect Airvo 2

from mains supply,

wait 5 seconds, then

reconnect.

Turn on Airvo 2.

If problem

persists:

return Airvo 2 to

Fisher & Paykel

Healthcare.

Write down the error code

and what happened before it

appeared.

Had the user just connected or

replaced the breathing tube?

Was there a “Check tube” error

shown?

Check that the tube is

connected properly.

Turn o Airvo 2.

Disconnect Airvo 2 from mains

supply, wait 5 seconds, then

reconnect.

Turn on Airvo 2.

If problem persists:

Repeat this process with a new

tube.

If problem

solved:

return faulty tube

to Fisher & Paykel

Healthcare.

Write down the error code

and what happened before it

appeared.

How far through the

disinfection cycle was the

user? Was anything changed

(filter, tube, etc) half-way

through?

Check that the tube,

disinfection filter and air

filter on back of the unit are

connected properly.

Turn o Airvo 2.

Disconnect Airvo 2 from mains

supply, wait 5 seconds, then

reconnect.

Turn on Airvo 2 (ie. start the

disinfection cycle again).

If problem persists:

Repeat this process with

another tube.

If problem solved:

return faulty disinfection

tube to Fisher & Paykel

Healthcare.

Write down the error code and

what happened before it appeared.

Is the Airvo 2 being used in a cold or

hot room? Was it stored overnight

in a cold place? Did the user add hot

water to the chamber instead of room-

temperature water?

Check that the chamber is

connected properly to the Airvo 2,

that it isn’t overfilled and that hot

water hasn’t been added.

Turn o Airvo 2.

Disconnect Airvo 2 from mains supply,

wait 30 minutes for temperatures to

stabilize, then reconnect.

Turn on Airvo 2.

If problem persists:

Return Airvo 2 to Fisher & Paykel

Healthcare.

If problem persists:

Return Airvo 2 to Fisher &

Paykel Healthcare.

If problem persists:

Return Airvo 2 to Fisher &

Paykel Healthcare.

31

Page 32

Error Range/s: 81-85, 111, 171 121-122 131-135 161 181-192

Error Type: Internal Error Flow Temperature Brownout Oxygen sensor

Write down the

error code and what

happened before it

appeared.

Turn o Airvo 2.

Disconnect Airvo 2

from mains supply,

wait 5 seconds, then

reconnect.

Turn on Airvo 2.

If problem persists:

return Airvo 2 to Fisher

& Paykel Healthcare.

Write down the

error code and what

happened before it

appeared.

Did the Airvo 2 display a

“Check leaks” or “Check

blockages” alarm?

Turn o Airvo 2.

Disconnect Airvo 2

from mains supply,

wait 5 seconds, then

reconnect.

Turn on Airvo 2.

Check that the air

filter on the back of the

unit is fitted correctly.

Check that the tube and

chamber are both fitted

correctly.

If this error occurred

during a disinfection

cycle, check that the

disinfection tube and

filter are both installed

properly.

Write down the

error code and what

happened before it

appeared.

How long had the

Airvo 2 been running?

Is the Airvo 2 being

used in a hot or cold

environment?

Turn o Airvo 2.

Disconnect Airvo 2

from mains supply,

wait 5 seconds, then

reconnect.

Turn on Airvo 2.

If problem persists:

Return Airvo 2 to Fisher

& Paykel Healthcare.

Check

other electrical

equipment nearby

and try another

power outlet.

If problem

persists:

Return Airvo 2 to

Fisher & Paykel

Healthcare.

Write down the error

code and what happened

before it appeared.

Is the Airvo 2 being used in

a cold or hot room? Was it

stored overnight in a cold

place?

Turn o Airvo 2.

Disconnect Airvo 2 from

mains supply, wait 30

minutes for temperatures

to stabilize, then reconnect.

Turn on Airvo 2.

If problem

persists:

Return Airvo 2 to

Fisher & Paykel

Healthcare.

If problem persists:

Return Airvo 2 to Fisher

& Paykel Healthcare.

32

Page 33

For more information please contact

your local Fisher & Paykel Healthcare representative

Manufacturer

Fisher & Paykel Healthcare Ltd

15 Maurice Paykel Place

East Tamaki, Auckland 2013

PO Box 14 348, Panmure

Auckland 1741

New Zealand

Tel: +64 9 574 0100

Fax: +64 9 574 0158

Email: info@fphcare.com

Web: www.fphcare.com

Australia

Fisher & Paykel Healthcare Pty Limited

36-40 New Street,

PO Box 167

Ringwood, Melbourne

Victoria 3134, Australia

Tel: +61 3 9879 5022

Fax: +61 3 9879 5232

Austria

Tel: 0800 29 31 23

Fax: 0800 29 31 22

Benelux

Tel: +31 40 216 3555

Fax: +31 40 216 3554

China

Tel: +86 20 3205 3486

Fax: +86 20 3205 2132

France

Tel: +33 1 6446 5201

Fax: +33 1 6446 5221

Germany

Tel: +49 7181 98599 0

Fax: +49 7181 98599 66

India

Tel: +91 80 4284 4000

Fax: +91 80 4123 6044

Irish Republic

Tel: 1800 409 011

Italy

Tel: +39 06 7839 2939

Fax: +39 06 7814 7709

Spain

Tel: +34 902 013 346

Fax: +34 902 013 379

Sweden

Tel: +46 8 564 76 680

Fax: +46 8 36 63 10

Switzerland

Tel: 0800 83 47 63

Fax: 0800 83 47 54

Taiwan

Tel: +886 2 8751 1739

Fax: +886 2 8751 5625

Turkey

Fisher Paykel Sağlık Ürünleri Ticaret

Limited Şirketi,

Alinteri Bulvari 1161/1 Sokak No. 12-14,

P.O. Box 06371 Ostim,

Ankara, Turkey

Tel: +90 312 354 34 12

Fax: +90 312 354 31 01

UK

Fisher & Paykel Healthcare Ltd

Unit 16, Cordwallis Park

Clivemont Road, Maidenhead

Berkshire SL6 7BU, UK

Tel: +44 1628 626 136

Fax: +44 1628 626 146

USA/Canada

Tel: +1 800 446 3908

or +1 949 453 4000

Fax: +1 949 453 4001

REF 185047911 REV E © 2014-11 Fisher & Paykel Healthcare Limited

0123

www.fphcare.com

Loading...

Loading...