Page 1

WHS / WHD / XHS / XHD

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

**WARNING TO INSTALLER, SERVICE PERSONNEL AND OWNER**

Altering the product or replacing parts with non authorized factory parts voids all warranty or implied warranty

and may result in adverse operational performance and/or a possible hazardous safety condition to service

personnel and occupants. Company employees and/or contractors are not authorized to waive this warning.

Current Maintenance Program is available at www.firstco.com under "Product Information".

NOTE: Read the entire installation instruction manual before starting the installation.

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service, maintenance, or use can cause explosion, fire, electrical shock, or other

conditions which may cause personal injury or property damage. Consult a qualified licensed installer, service agency, or

your distributor for information or assistance. The qualified licensed installer or service agency must use factory-authorized

kits or accessories when modifying this product. Refer to the individual instructions packaged with kits or accessories

when installing.

Follow all safety codes. Wear safety glasses and work gloves. Use quenching cloth for brazing operations. Have fire

extinguisher available. Read these instructions thoroughly and follow all warnings or cautions attached to the unit. Consult

local building codes and National Electrical Code (NEC) for special requirements.

Recognize safety information. This is the safety-alert symbol . When you see this symbol on the unit and in instructions manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, CAUTION, and NOTE. These words are used with the safety-alert

symbol. DANGER identifies the most serious hazards which will result in severe personal injury or death. WARNING

signifies hazards which could result in personal injury or death. CAUTION is used to identify unsafe practices which would

result in minor personal injury or product and property damage. NOTE is used to highlight suggestions which will result in

enhanced installation, reliability, or operation.

WARNING: Before installing or servicing unit, always turn off all power to unit. There may be more than

one disconnect switch. Turn off accessory heater power if applicable. Electrical shock can cause personal

injury or death.

1

L4541 9/07

Page 2

GENERAL

The manufacturer assumes no responsibility for equipment installed in violation of any code requirement.

These instructions give information relative to the installation of these air handlers only. For other related equipment refer to

the proper instructions.

Material in this shipment has been inspected at the factory and released to the transportation agency in good condition. When

received, a visual inspection of all cartons should be made immediately. Any evidence of rough handling or apparent damage

should be noted on the delivery receipt and the material inspected in the presence of the carrier’s representative. If damage is

found, a claim should be filed against the carrier immediately.

In keeping with its policy of continuous progress and product improvement, the manufacturer reserves the right to discontinue

or change without notice any or all specifications or designs without incurring obligations.

INTRODUCTION

Model nomenclature for the air handlers described in this installation instruction are as follows:

WHS - Belt Drive Horizontal Air Handler with water coils and exposed insulation.

WHD - Belt Drive Horizontal Air Handler with water coils and double wall lined construction.

XHS - Belt Drive Horizontal Air Handler with direct expansion, water coil and exposed insulation.

XHD - Belt Drive Horizontal Air Handler with direct expansion, water coil and double wall lined construction.

The air handler units are designed for horizontal left or right applications with nominal air capacities of 800 through 8000

CFM. Models incorporate a positive slope plastic drain pan with 3/4” PVC drain coupling. Optional equipment includes,

multiple coil combinations in water and direct expansion, one and two row hot water coils, multiple filter box combinations,

mixing boxes and a large selection of motor / pulley drive selections.

INSTALLATION

The licensed installer must adhere strictly to all local and national code requirements pertaining to the installation of this

equipment.

All air handling units are agency listed for installation with zero inches clearance to combustible materials. This includes the unit

cabinet, discharge plenum and connecting ducts.

Sufficient clearance must be provided around the unit for proper maintenance, filter removal, lubrication, belt adjustment, removal

of coils, drain pan and blower assembly.

Flexible connections on the inlet and outlet duct connections of the unit are recommended.

Installation Precautions

Always use proper tools and equipment.

No wiring or other work should be attempted without first ensuring that the air handler is completely disconnected from the power

source and locked out. Always verify that a good ground connection exists prior to energizing any power sources.

Always review the nameplate on each unit for proper voltage and control configurations. This information is determined from

the components and wiring of the unit and may vary from unit to unit.

When soldering or brazing to the unit, it is recommended to have a fire extinguisher readily available. When soldering close to

valve packages or other components, heat shields or wet rags are required to prevent damage.

When the air handler unit is in operation components are rotating at high speeds.

Units must be installed level to ensure proper drainage and operation.

Be sure that the drain pan is free from foreign material prior to start up.

Check filter media installation to ensure that it is installed correctly. Use the directional arrows or other information on the filter

to determine the proper flow direction.

Ensure that the air distribution system does not exceed the external static rating of the unit.

PROCEDURE 1 – CHECK EQUIPMENT

Unpack unit and move to final location. Remove packaging taking care not to damage unit.

Inspect air handler unit for damage prior to installation. File a claim with shipping company if shipment is damaged.

Carefully inspect blower for rough handling that can cause misalignment or shaft damage.

Locate unit nameplate which contains proper installation information. Check nameplate to be sure unit matches job specifications.

2

Page 3

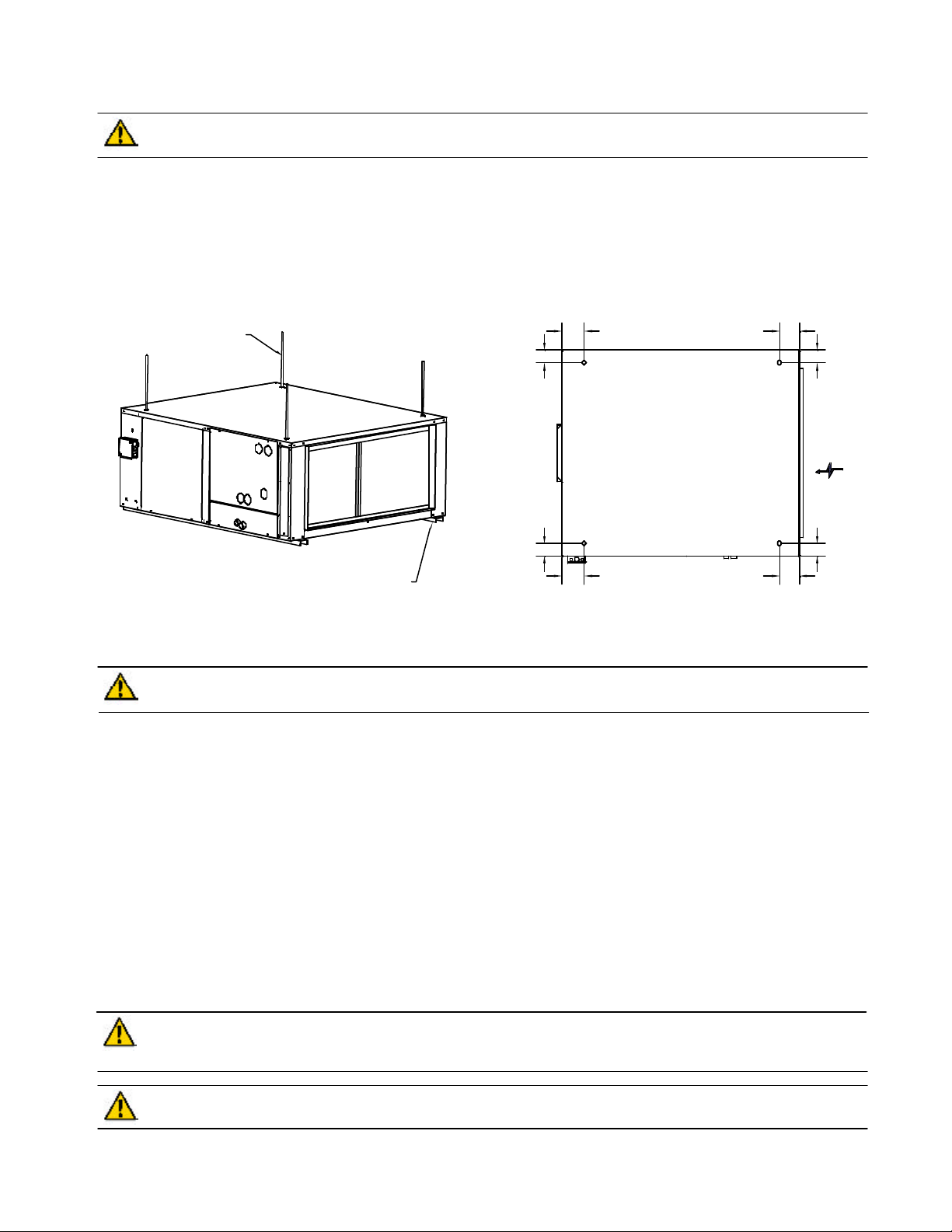

PROCEDURE 2 – MOUNT AIR HANDLER

WARNING: Do not suspend the air handler unit from the top panel. The unit top will not support the weight

of the unit. Equipment damage and severe personal injury or death could result.

All air handler units are agency listed for horizontal installation with zero inches clearance to combustible materials. This

includes the unit cabinet, discharge plenum and connecting ducts. The unit can be floor mounted or suspended with

hanging rods. If hanging rods are used the unit has knockouts in each corner of the top and base panel for the suspension

rods to pass through. It is recommended that angle iron or unistrut be used under the unit for support when suspension

rods are used. Unit vibration isolators are recommended for all installations.

Flexible connections on the inlet and outlet duct connections of the unit are recommended.

SUSPENSION ROD

UNIT MOUNTING ANGLES

5

2 3/4 2 3/4

TOP VIEW

2 3/4 2 3/4

5

4 1/2

AIRFLOW

4 1/2

Figure 1

WARNING: Before installing the unit, determine whether unit weight can be safely supported by the

structure. Failure to follow this WARNING could result in product or property damage and personal injury.

Sufficient clearance must be provided around the unit for proper maintenance, filter removal, lubrication, belt adjustment,

removal of coils, drain pan and blower assembly. This clearance distance should be approximately the same width as the

unit.

NOTE: Before mounting unit remove red headed shipping bolts and metal bushings under blower

base rails.

IMPORTANT: When unit is installed over a finished ceiling and/or living area, building codes may require a field-supplied

secondary condensate pan to be installed under the entire unit. Some localities may allow the alternative of running a

separate secondary condensate line or applying a field mounted condensate overflow switch. Consult local codes for

additional restrictions or precautions.

NOTE: When installing any air handler over a finished ceiling and/or living area, installation of a secondary drain pan under

entire unit is recommended to avoid damage to ceiling.

CAUTION: Extreme caution must be taken that no internal damage will result if screws or holes are drilled

into the cabinet. Failure to follow this CAUTION could result in product or property damage and minor

personal injury.

CAUTION: The unit should be leveled in such a way that there is slope toward the condensate drain nipple

to assure positive drainage. Failure to follow this CAUTION could result in product or property damage.

3

Page 4

PROCEDURE 3 – AIR DUCTS

All duct work must be installed in accordance with National Fire Protection Association Codes 90A and 90B.

In many cases it is acceptable to use ducting of the same size as the air handler connections. However, unique arrangements or long duct runs must be confirmed by a local professional. The manufacturer will not be responsible for misapplied

equipment.

It is recommended to use flexible connectors between ductwork and the air handler to prevent transmission of vibration.

Connect supply air duct over outside of flanges provided on supply air opening. Secure duct to flange with proper fasteners for type of duct used, and seal duct-to-unit joint. Ducts should be adequately insulated to prevent condensation during

the cooling cycle and to minimize heat loss during the heating cycle.

All return air must be filtered to prevent dirt buildup on the coil surface.

Ductwork Acoustical Treatment

Metal duct systems that do not have a 90 degree elbow and 10 ft. of main duct to first branch takeoff may require internal

acoustical insulation lining. As an alternative, fibrous ductwork may be used if constructed and installed in accordance with

the latest edition of SMACNA construction standard on fibrous glass ducts. Both acoustical lining and fibrous ductwork

shall comply with National Fire Protection Association Standards 90A or 90B as tested by UL Standard 181 for Class 1 air

ducts.

PROCEDURE 4 – ELECTRICAL CONNECTIONS

NOTE: Before proceeding with electrical connections, make certain that supply voltage, frequency, and phase are as

specified on unit rating plate. Be sure that electrical service provided by the utility is sufficient to handle the additional load

imposed by this equipment. See unit wiring label for proper field high and low voltage wiring. Make all electrical connections in accordance with NEC and any local codes or ordinances that may apply. Use copper wire only.

WARNING: If a disconnect switch is to be mounted on the unit, select a location where drill or fastener will

not contact electrical or internal components. Electrical shock can cause personal injury or death.

DANGER: Service and maintenance to internal components and wiring must not be performed until the

main disconnect switch is turned off. Failure to do so will result in electrical shock causing personal injury

or death.

Line-Voltage Connections

All units are provided with wiring diagrams and nameplate data to provide information required for necessary field wiring,

A 4” x 4” electrical box is standard on all units for proper connection of power supply. An optional starter control is available

and should be wired in accordance to the diagram on the control.

Unit must be permanently grounded in accordance with NEC and local codes.

Check all factory wiring per unit wiring diagram and inspect factory wiring connections to be sure none were loosened in

transit or installation.

WARNING: Any devices such as starter controls or thermostats that have been furnished by the manufac-

turer for field installation must be wired in strict accordance with the wiring diagram that is supplied with

the unit. Failure to do so could result in electrical shock causing personal injury, death or damage to

components and will void all warranties.

Ground Connections

WARNING: The cabinet must have an uninterrupted or unbroken ground according to NEC, ANSI/NFPA 70

and local codes to minimize personal injury if an electrical fault should occur. The ground may consist of

electrical wire or metal conduit when installed in accordance with existing electrical codes. (See Ground/

Conduit Note below.) Failure to follow this warning could result in an electrical shock, fire, or death.

NOTE: Use agency listed conduit and conduit connector to connect supply wire(s) to unit and obtain proper grounding. If

conduit connection uses reducing washers, a separate ground wire must be used.

4

Page 5

PROCEDURE 5 – COIL PIPING

Piping Precautions

All piping should be supported independently of the coils. Swing joints or flexible fittings should be provided to absorb

expansion and contraction strains. Rigid piping reduces the effectiveness of unit vibration isolators.

Water supply should be connected so that the entering water is on the leaving air side of the coil.

Flush all field water piping prior to connection to water coils to remove debris.

Use wet cotton rags to cool valve bodies when soldering.

Open all valves (midway for hand valves, manually open on motorized valves) prior to soldering.

When soldering to bronze or brass, heat the piping while in the socket/cup and begin introducing the solder when the flux

boils rapidly. Avoid direct flame into the solder joint.

Heat can only be applied to the cup of the valve body for a minimal time before damage occurs (even with the use of wet

rags).

Avoid rapid quenching of solder joints as this will produce joints of inferior quality.

Connect all piping per accepted industry standards and observe all regulations governing installation of piping systems.

When all connections are complete the system must be pressure tested. Repair any solder joint leaks and gently tighten

any leaking valve packing nuts and piping accessories as required. Hydronic systems are not designed to hold pressurized

air and should only be tested with water.

CAUTION: Low temperature ambient air or cold leaving air from DX coil can cause coil freeze-ups. A

freeze-stat (field supplied) or other means (glycol) should be incorporated to prevent coil freezing. The

manufacturer is not responsible for damage caused by these conditions. Failure to do so will result in

equipment and structure damage.

Water Coil Piping

Chilled / Hot water coil connections (1,2,4, 6 and 8 row) are 3/4 “ nominal (7/8” OD) copper on the 8/12 WH, 1” nominal (1-1/8

OD)on the 16/20 WH and 1-1/4 “ nominal (1-3/8” OD) copper on the 30/40/60/80 WH. When soldering to coil, use a heat sink

/ shield to prevent damage to the rubber grommets on the coil access panel. When all connections are complete, pressure test

the system with water. Repair any solder joint leaks and gently tighten any leaking valve packing nuts and piping accessories

as required.After system has been proven leak free, all lines and valve control packages must be insulated to prevent condensate drippage or insulated as specified on the building plans.

CAUTION: Many valve packages will not physically allow all components to fit over an auxiliary drain pan.

It is the installers responsibility to capture all condensation or insulate the piping to ensure adequate

condensation prevention.

Direct Expansion Coil Piping

Liquid and Suction lines should be sized in accordance to the outdoor manufacturer recommendation. Reduce if required at the

evaporator coil. Maximum line length and installation of oil transport traps and risers are to be determined by the installer per

accepted industry practices. The expansion valves provided from the manufacturer are bidirectional for cooling or heat pump

use. TXV check valves are internal on 08 - 20XH and external on 30 - 80XH due to flow limitations.

When all connections are complete, evacuate the system and pressure test with nitrogen. Repair any solder joint leaks as

required. Follow the charging recommendations of the outdoor manufacturer for final evacuation and charging.

It is also required that the suction line be adequately insulated to prevent condensation. Failure to follow this could result in

property damage.

CAUTION: Expansion valve is refrigerant specific. Make sure the correct expansion valve (R-22 or

R-410A) is on the air handler in accordance to the refrigerant used in the outdoor condensing unit. The

manufacturer is not responsible for damage caused by improper matching. Failure to do so will result in

equipment damage.

CAUTION: When connecting piping or valve kits to the air handler, do not bend or reposition the coil header

tubing for alignment purposes. This could cause a tubing fracture resulting in a water or refrigerant leak.

Failure to do so will result in equipment and structure damage.

5

Page 6

PROCEDURE 6 – DRAIN PAN

Drain pans have a 3/4 in primary and a 1/2 in secondary PVC coupling for condensate drain connection. Pans are designed

with positive slope to the drain couplings and can be removed from the unit for cleaning. To facilitate cleaning, unions

should be installed on the drain lines close to the drain pan coupling so the drain pan and drain pan door can be removed

together. See figure 2.

For drain pan removal refer to the maintenance section.

Figure 2 - Drain Pan with access door removed

NOTE: If unit is located in or above a living space where damage may result from condensate overflow, a field-supplied

external condensate pan should be installed underneath the entire unit, and a secondary condensate line (with appropriate

trap) should be run from the unit into the pan. Any condensate in this external condensate pan should be drained to a

noticeable place. As an alternative to using an external condensate pan, some localities may allow the use of a separate

condensate line (with appropriate trap) to a place where the condensate will be noticeable. The owner of the structure must

be informed that when condensate flows from the secondary drain or external condensate pan, the unit requires servicing, or

water damage will occur.

PROCEDURE 7 – CONDENSATE DRAIN

Units are equipped with a 3/4 in primary and a 1/2 in secondary PVC coupling for condensate drain connection. Condensate

drain lines must be installed with adequate slope away from the unit to assure positive drainage. Drain lines and traps

should run full size from the drain pan connection. The drain lines must have a properly designed trap. The trap depth and

distance between the trap outlet and the drain pan outlet should be twice the static pressure in the drain pan section under

normal operation for the trap to remain sealed. See figure 3. Prime all traps, test for leaks, and insulate traps if located

above a living area.

CAUTION: Shallow running traps are inadequate and DO NOT allow proper condensate drainage. See

figure 4. Failure to follow this CAUTION could result in product and property damage.

NOTE: If a Condensate Overflow Shut-off Switch, that is designed to be installed in the drain line, is used in place of a

secondary drain line, then the cut-off switch should be located in the primary drain line between the unit and the P-trap.

NOTE: Condensate drain lines should be pitched downward at a minimum of 1 in. for every 10 ft. of length. Consult local

codes for additional restrictions or precautions.

Pressure P (inH2O)

at the drain pan

DO NOT USE SHALLOW RUNNING TRAPS !

2P

2P

Figure 4 - Insufficient Condensate TrapFigure 3 - Recommended Condensate Trap

6

Page 7

PROCEDURE 8 – AIR FILTER

The air filter should be cleaned or replaced every 30 days or more frequently if severe conditions exist. Always replace the filter

with the same type as originally furnished.

CAUTION: Never operate unit without a filter or with filter access door removed. Damage to blower motor

or coil can result. Failure to follow this CAUTION could result in personal injury or product and property

damage.

IMPORTANT: Factory authorized filters must be used when locating the filter inside the unit. For those applications where

access to an internal filter is impractical, a field-supplied filter must be installed in the return duct system

PROCEDURE 8 – UNIT START-UP

DANGER: Service and maintenance to internal components and wiring must not be performed until the

main disconnect switch is turned off. Failure to do so will result in electrical shock causing personal injury

or death.

Pre-start Check

Check that supply voltage matches nameplate data.

Ensure that the unit is properly grounded.

With power off, ensure that the blower wheel rotates freely and quietly.

Check that the refrigerant or water coil, valves and piping have been leak checked and insulated as required.

Ensure that all air has been vented from the water coils.

Install all panels.

Install any filters which may have been removed during the installation process.

Ensure that the air distribution system external static pressure and the unit cabinet static pressure does not exceed the rated

performance of the motor / pulley combination installed in the air handler.

Before start-up, all of the components should be given a thorough check. Optimal operation of this equipment requires

cleanliness. Often after installation of this equipment additional construction activities occur. Care must be taken to protect the

equipment from debris during these construction phases.

CAUTION: The fan coil unit should not be energized until the water coils and all water lines have been

purged of air. Failure to follow this CAUTION could result in product and property damage.

WARNING: The manufacturer does not warrant equipment subjected to abuse. Metal chips, dust, drywall

tape, paint over spray, etc. can void warranties and liability for equipment failure, personal injury and

property damage.

Blower Speed Adjustment

Adjustment of blower speed is made by loosening the set screw in the outer (movable) pulley face and turning this face half or

full turns only, so that the adjusting set screw will be positioned precisely over the flat on the pulley hub. Speed is reduced by

adjusting the pulley faces so that they are further apart; speed is increased with faces closer together. Check all of the pulleys'

set screws for tightness.

When increasing blower speed always check the amperage draw of the motor against the motor nameplate maximum amperage

rating. All doors, ducts, filter, grilles and other components must be in place for this test.

CAUTION: Leaving air temperature must not exceed 150 degrees. Failure to follow this CAUTION could

result in the motor cutting out on over temperature cutout. At high altitude conditions, the blower motor may

cutout at a lower LAT.

7

Page 8

CARE AND MAINTENANCE

For continuing high performance, and to minimize possible equipment failure, it is essential that periodic maintenance be

performed on this equipment. For a current copy of the detailed Maintenance Program, log on to www.firstco.com and look

under “Product Information”.

DANGER: Disconnect all power to unit before servicing. The disconnect (when used) does not disconnect

power to the line side of the disconnect, but does allow safe service to all other parts of the unit. If the unit

does not have a disconnect, disregard the foregoing. Instead, make sure that a disconnecting means is

within sight from, and is readily accessible from, the unit. Disconnect all power to the unit before performing

any maintenance or service on it. Failure to follow this warning can cause electrical shock, fire, personal

injury or death.

To achieve maximum performance and service life of each piece of equipment a formal schedule of regular maintenance should

be established and maintained by a certified contractor.

The following is provided as a recommended maintenance schedule. Specific instructions for maintenance procedures are given

after the check list.

Monthly Check List

Inspect the unit air filters. Clean or replace as required.

Inspect the drain pan to be sure it is clean to permit the flow of condensate through the drain lines.

Inspect the fan belt for wear and alignment. Replace or adjust as required.

Yearly Check List

Clean the blower motor and oil if required.

Inspect the air handler unit casing for corrosion and loose fasteners.

Inspect the blower wheel and housing. Clean if necessary.

Check the motor pulley and blower pulley for alignment and tighten their set screws. Adjust belt tension if necessary.

Inspect all coil connections for leaks. Inspect the coil fins for excessive dirt or damage. Clean or repair if required.

Inspect electrical connections for tightness and controls for proper operating each heating and cooling season.

If strainers are installed in the valve packages, clean per manufactures directions.

CAUTION: As with any mechanical equipment, personal injury can result from sharp metal edges, etc.,

therefore, care should be taken when removing and working on metal parts.

Pulley Alignment and Belt Tension

Belt tension and pulley alignment should be checked annually. Belt tension is adjusted by loosening the four motor mounting

plate bolts and then turning the motor slide adjusting screws clockwise to tighten the belt or counter clockwise to loosen the

belt. See figure 5. A deflection of 3/16 in per foot of span should be obtained by pressing the belt in the middle of the span with

a force of 5 to 7 pounds. See figure 6. Retighten motor mounting plate bolts. Recheck belt tension, readjust if necessary. Alignment

of pulley grooves is made by locating the motor pulley on the motor shaft and securing with setscrew. Then align the blower

pulley on the blower shaft such that the two pulleys are aligned straight with each other, secure blower pulley by tightening set

screw. For blower speed adjustment refer to that section.

DEFLECTION

SPAN

Figure 5 - Motor Base Figure 6 - Belt Tension

8

Page 9

Hinged Doors

Larger units, 7.5 ton and larger, have hinged doors that can be lifted off for

component access. This allows free access for blower or motor assembly

replacement. Enough side clearance is needed to open the doors at

least 80 degrees to remove them.

Use the door width as a simple guide for side clearance.

CAUTION: Doors are heavy sheetmetal assemblies. If you are going to lift them off then wear gloves and have

a plan for getting them down from the unit and back. Ensure that no one is standing or working under you in

the event you lose your grip and drop the door.

Blower

Inspect the bearings for wear. They are ball bearing, self-aligning and grease packed. Replace if required. Inspect the thrust

collars for end play and alignment of wheel. Check the blades for accumulations of dirt and clean in order to avoid imbalance

and vibration. Check mounting brackets, base bolts and isolation material.

Motor

Check motor connections to ensure that they are secure and made in accordance with the wiring diagram.

The blower motor should be cleaned annually and if it has oiling ports, it should be oiled with a good grade of SAE 20 oil. Normally

a few drops of oil in each bearing is sufficient.

Coil

Any dust or other contaminants which accumulate on the heat transfer surfaces interferes with the air flow and impairs heat

transfer. The coil must be kept clean by cleaning with low pressure compressed air or flushing / rinsing with water (a detergent

is advisable for greasy surfaces).

For severe conditions the air handlers coils are designed for removal. The coils may be removed one at a time starting with the

last coil in the air stream. Disconnect piping from all coils. Remove drain pan door by loosening the two thumb screws. Next

remove the coil panel door. Supply side coils are removed first by removing 3 screws holding the coil to the return side coil and

pulling the coil straight out. The final coil is removed by removing three screws holding the coil support bracket to the cabinet

and pulling it straight out. When this coil is reinstalled the coil support bracket on the opposite coil end must slide in behind

the cabinet corner post.

WARNING: Coils are heavy. When removing coils from the unit have an appropriate lifting device that can

handle the coil weight. Coil fins and end sheets are sharp and can cause severe personal injury. Failure to

do so will result in personal injury and equipment damage.

Filter

The air filter should be cleaned or replaced every 30 days or more frequently if severe conditions exist. Always replace the filter

with the same type as originally furnished.

Drain Piping

The drain should always be connected or piped to an acceptable disposal point sloped away from the unit. Check the drain line

for restrictions or blockage before summer operation and monthly during the cooling season.

Drain Pan

The drain pan should be clean to allow proper condensate flow. Remove any accumulation of residue from the drain pan and

inspect. To remove the drain pan, disconnect condensate piping at unions if used. Loosen drain pan door thumb screws. Drain

pan and drain pan door can be pulled out of the unit. Drain pan can be cleaned with mild detergent. When drain pan is reinstalled

it must be centered under the coil supports and pushed in completely so the drain pan door can be reinstalled.

Maintenance Updates

A current copy of the Maintenance Program log can be found at www.firstco.com under “Product Information”.

9

Loading...

Loading...