First Co SPXA User Manual

SPX SERIES

****** WARNING ******

Unit must not be operated

during building construction

due to excessive airborne

dust and debris. The units

must not be operated under

any circumstances without an

air filter in place.

P ACKAGED AIR CONDITIONING/HEA T PUMP UNITS

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

**WARNING TO INSTALLER, SERVICE PERSONNEL AND OWNER**

Altering the product or replacing part s with non authorized factory parts voids all warranty or implied warranty

and may result in adverse operational performance and/or a possible hazardous safety condition to service

personnel and occupants. Company employees and/or contractors are not authorized to waive this warning.

Current Maintenance Program is available at www.firstco.com under "Product Information".

GENERAL

These instructions give information

relative to the SPX unit only . Refer to

Wall Sleeve and Grille installation

instructions for those components.

The manufacturer assumes no

responsibility for equipment installed

in violation of any code requirements.

For other related equipment refer to

the proper instructions.

The SPX is shipped in one package,

completely assembled. Material in

this shipment has been inspected at

the factory and released to the

transportation agency in good

condition. When received, a visual

inspection of all cartons should be

made immediately. Any evidence of

rough handling or apparent damage

should be noted on the delivery

receipt and the material inspected in

the presence of the carrier’s

representative. If damage is found a

claim should be filed against the

carrier immediately .

HW Units - Note: State of MA.-248 CMR

code of the state of MA. requires a pump

timer (60 seconds on every 6 hours).

See diagram.

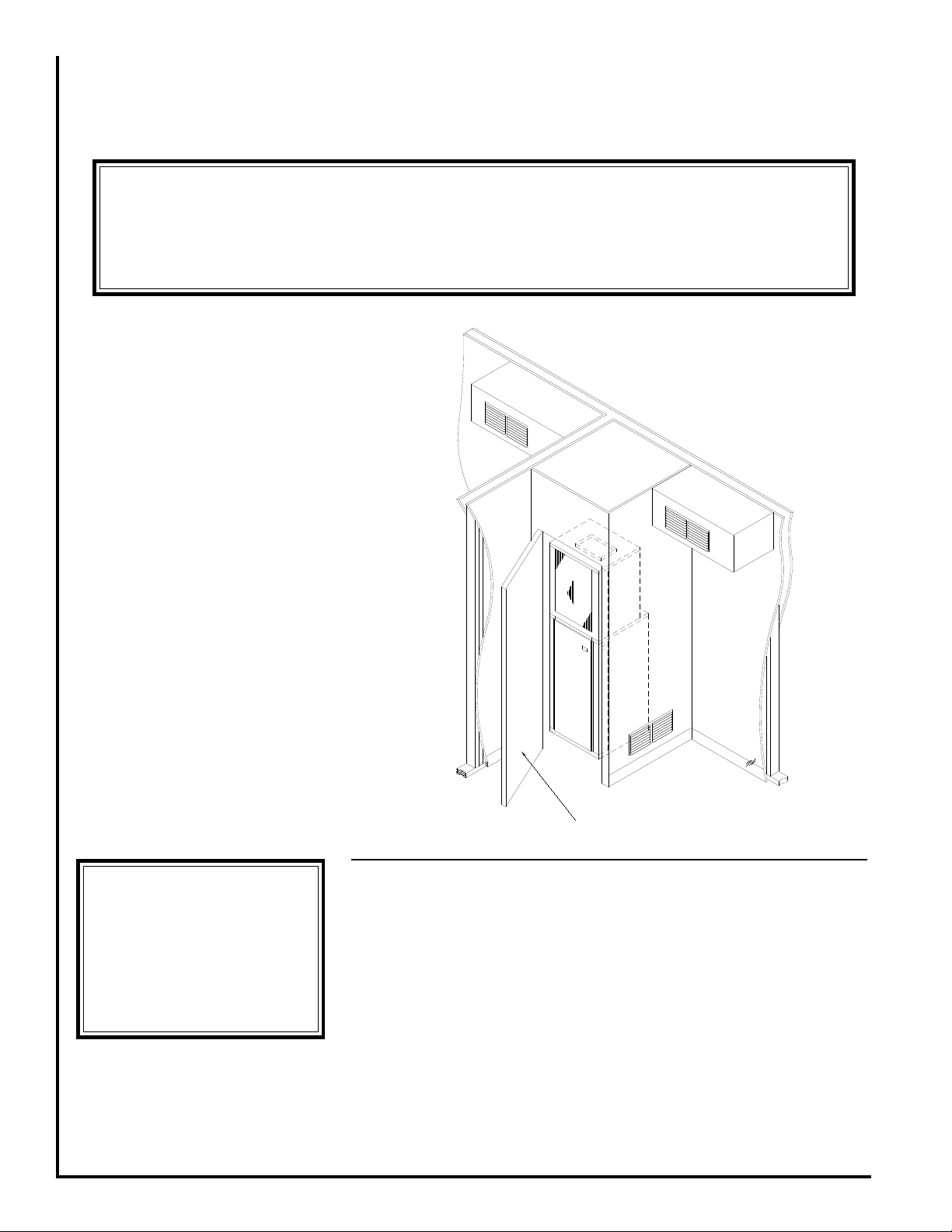

Figure 1 - Typical Suite Installation

P ACKING LIST

Items packed inside the unit:

(1 ) Filter Bracket

(1 ) Filter Clip

LOCA TION

The SPX is designed for throughthe-wall installation. The interior

portion of the unit is surrounded by a

closet with a rear access (Fig. 1). The

vertical discharge allows for ducting

to the top of the room for best air

circulation and elimination of cold

drafts on occupants. The exterior

(grille side) of the unit must have no

obstructions (trees, landscape

materials, etc.) within 18 inches. Do

not locate two units adjacent to each

1

other on an inside corner or where they

may exhaust into each other.

Provisions should be made to allow

access to the indoor side of the unit

for installation and inspection. The

closet or access panel opening must

be centered with the exterior wall

opening and be at least 24” wide by

84” tall. Three (3) inches of

unobstructed space is required on all

sides of the SPX to allow for adequate

air flow. At least 27 inches of

unobstructed space should be provided

in front of the access door to permit

L268 2/09

Electrical

****** W ARNING ******

Make sure a high grade nonhardening sealant approved for

exterior use has been applied

between edge of the sleeve and

the structure, on the inside and

outside walls, to prevent air

and water from migrating

inside (Fig. 4).

****** WARNING ******

There must be a minimum 3"

clearance maintained around

the SPX chassis on all sides for

adequate airflow to achieve

optimum performance. These

guidelines give minimum spacing requirements only. It is

acceptable to go beyond these

limits at any time.

****** WARNING ******

After sleeve installation ensure

that the sleeve seal is in contact

with the sleeve sides. Any air

gaps must be sealed or

outdoor air and/or water

leakage will occur.

****** W ARNING ******

Architectural Grille must be

installed prior to the

installation of the SPX unit into

the sleeve.

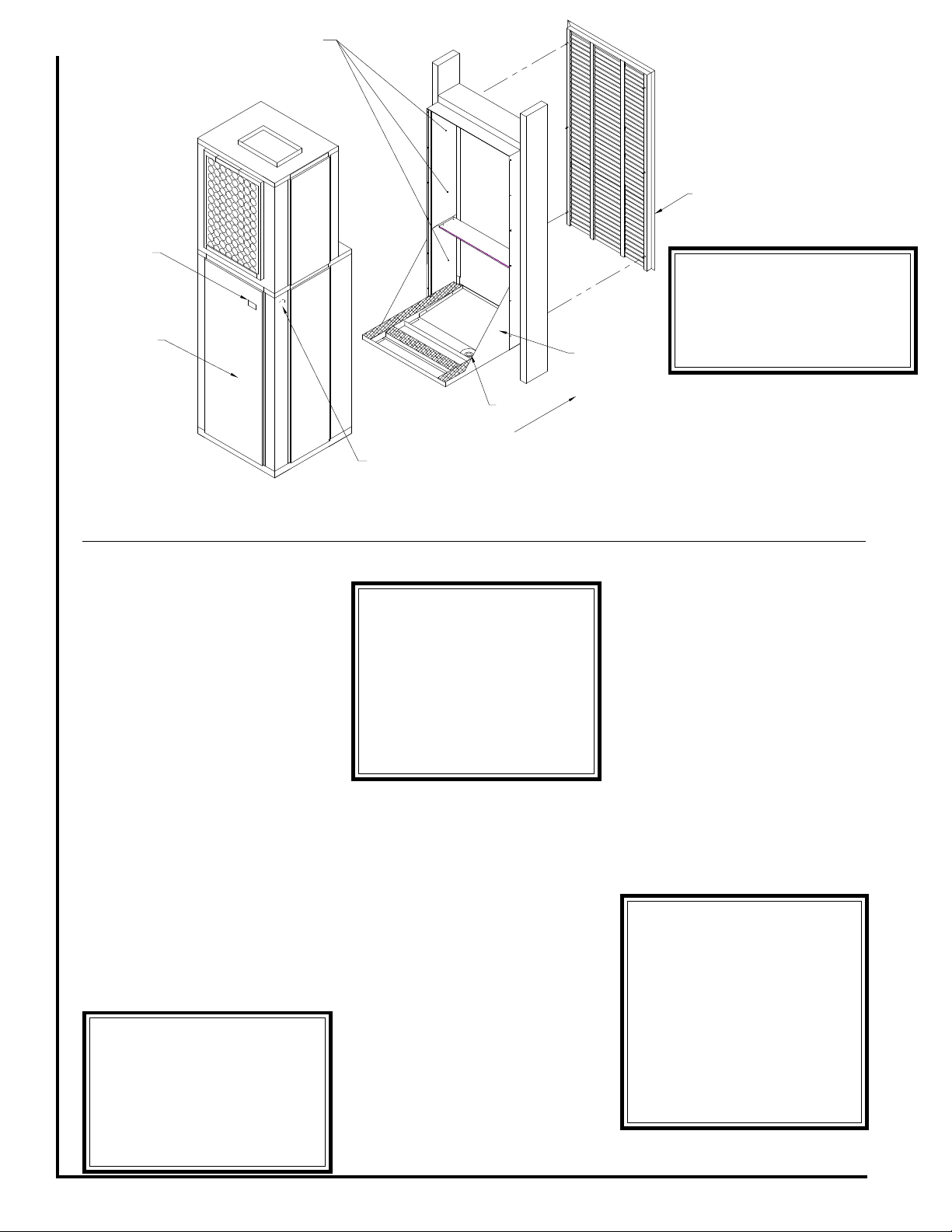

Disconnect

Rear Access

Panel

Approximate

Fastener

Locations

Architectural

Grille

Wall Sleeve

Drain

Outside

Electrical Service

Knock-out

removal of the unit should repair and

inspection be required.

For installations requiring access

panels refer to unit brochure for panel

dimensions.

W ALL SLEEVE

INST ALLATION

Refer to installation instructions

packed with wall sleeve to assemble

and mount it in the wall. Before unit

installation, make sure sleeve

components are not damaged, drain

line is unobstructed and leak free.

Check all seals to ensure that they are

in position and un-damaged. Ensure

that the bottom of the wall sleeve is

pitched 1/2 bubble toward the outside

of the building so that rain water will

drain to the outside (Fig. 4). Securely

fasten the Architectural grille to the

front of the sleeve using the supplied

hardware.

Figure 2 - General Assembly

The unit comes with a factory

supplied disconnect, however, the

contractor is responsible for providing

over current protection on the branch

circuit. Refer to the unit wiring diagram

for single point electrical connection.

These units are provided with a

Class 2 transformer for 24 volt control

circuits. Should any add-on

equipment also have a Class 2

transformer furnished, care must be

taken to prevent interconnecting

outputs of the two transformers by

using a thermostat with isolating

contacts.

ELECTRICAL

All wiring must comply with local

and national code requirements. Any

alteration of the internal wiring will void

UL certification and manufacturer’s

warranty.

Nameplate data indicates the

operating voltage, phase, ampacity,

maximum over current protection and

minimum voltage. Units must never

be installed or operated where voltage

exceeds the nameplate voltage by

more than 10%. Failure of the

compressor as a result of operation

with improper voltage voids the

compressor replacement warranty.

2

Loading...

Loading...