Page 1

WHSC / WHHP SERIES

WALL SLEEVE INSTALLATION

**WARNING T O INST ALLER, SERVICE PERSONNEL AND OWNER**

Altering the product or replacing parts with non authorized factory parts voids all warranty or implied warranty

and may result in adverse operational performance and/or a possible hazardous safety condition to service

personnel and occupants. Company employees and/or contractors are not authorized to waive this warning.

Current Maintenance Program is available at www.firstco.com under "Product Information".

GENERAL

The WHSC/WHHP wall sleeve is

optional for use with WHSC and

WHHP units. These instructions give

information relative to the wall sleeve

installation only. The manufacturer

assumes no responsibility for

equipment installed in violation of any

code requirements. For other related

equipment refer to the proper

instructions.

The wall sleeve is shipped in one

package with required hardware for

installation. Material in this shipment

has been inspected at the factory and

released to the transportation agency

in good condition. When received, a

visual inspection of all cartons should

be made immediately. Any evidence

of rough handling or apparent damage

should be noted on the delivery receipt

and the material inspected in the

presence of the carrier's

representative. If damage is found a

claim should be filed against the

carrier immediately.

INSTALLATION

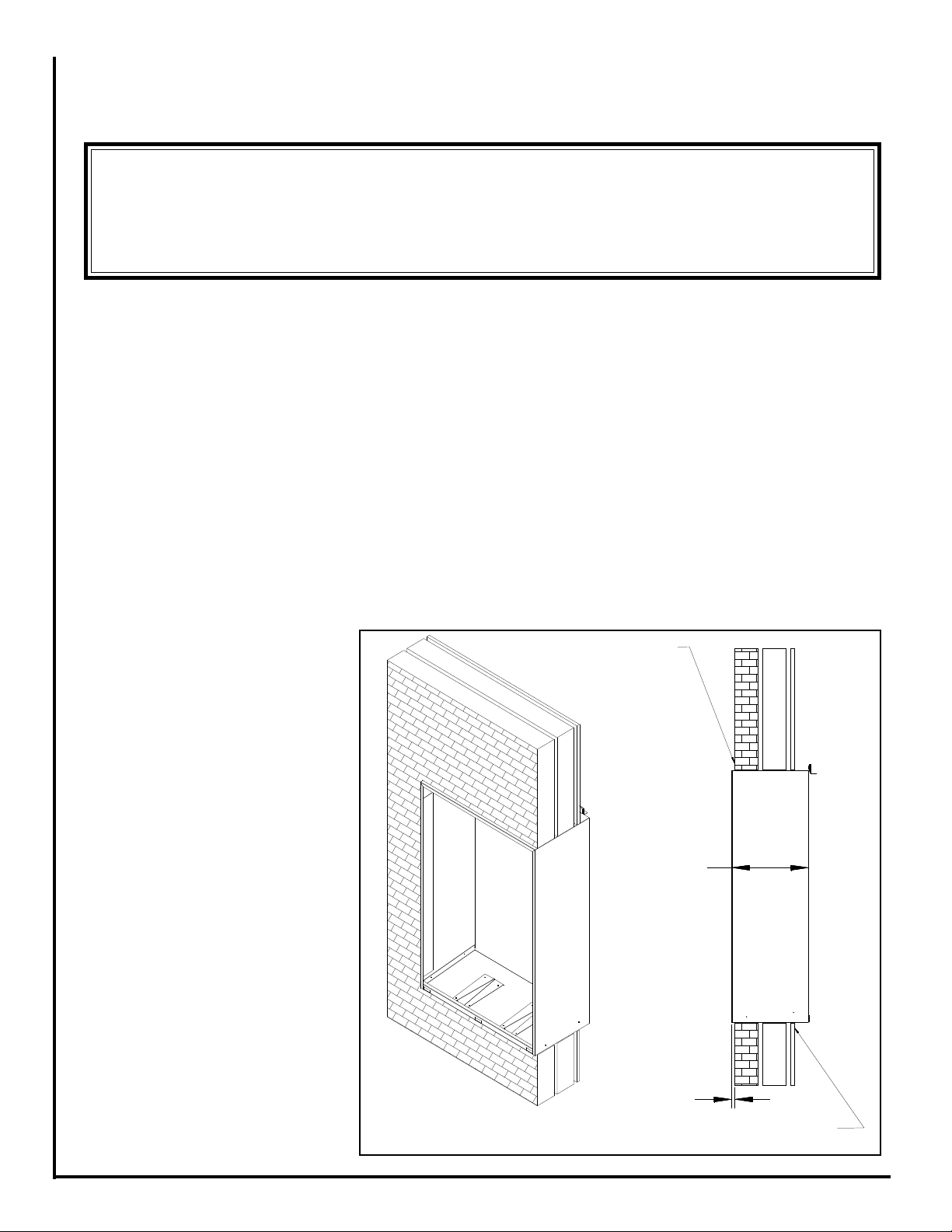

(1 ) It is recommended that the sleeve

protruded 3/8" to 1/2" beyond the

outside finished wall, (see fig. 1).

Install wall sleeve into precut

opening 27-5/8" wide x 45-3/4"

high.

Make sure wall sleeve is square

before securing.

(2) Fasten wall sleeve to wall studs,

drill holes or nail through sleeve as

required in 6 places.

SEAL AROUND SLEEVE

AND OUTSIDE WALL

WARNING - Sleeve must be

fastened to the wall studs and not

the finished wall.

(3 ) After installing wall sleeve place a

bead of silicone sealant or other

high grade non-hardening sealing

compound approved for exterior

use around the perimeter of the

wall sleeve face outside. Also

seal around the sleeves perimeter

and the finished inside wall, as

shown in (figure 1).

CAUTION - If using the optional

arichitectural grille then install it before

setting the unit using the screws holding the original coil guard. See fig. 2

SLEEVE HARDWARE

The following items are packaged in

the WHSC/WHHP Sleeve Kit:

(1) Sleeve Assembly

(1) Frame mounting angle

(2) 1/4" - Split Lock Washers

(2) 1/4" - Flat Washers

(2) 1/4" - 20 x 3/4 Hex Bolt

(4) #8 x 1/2" Lg. Screws

(2) Rubber Isolation Grommets

Figure 1

(13.0)

WALL SLEEVE

0.38

MINIMUM

SEAL AROUND SLEEVE

AND INSIDE WALL

L25901 10/13

Page 2

INSTALLING WHSC/WHHP

**MAINTENANCE UPDATES**

For a current copy of the

Maintenance Program log on

to www.firstco.com and

look under "Product Information"

INTO SLEEVE

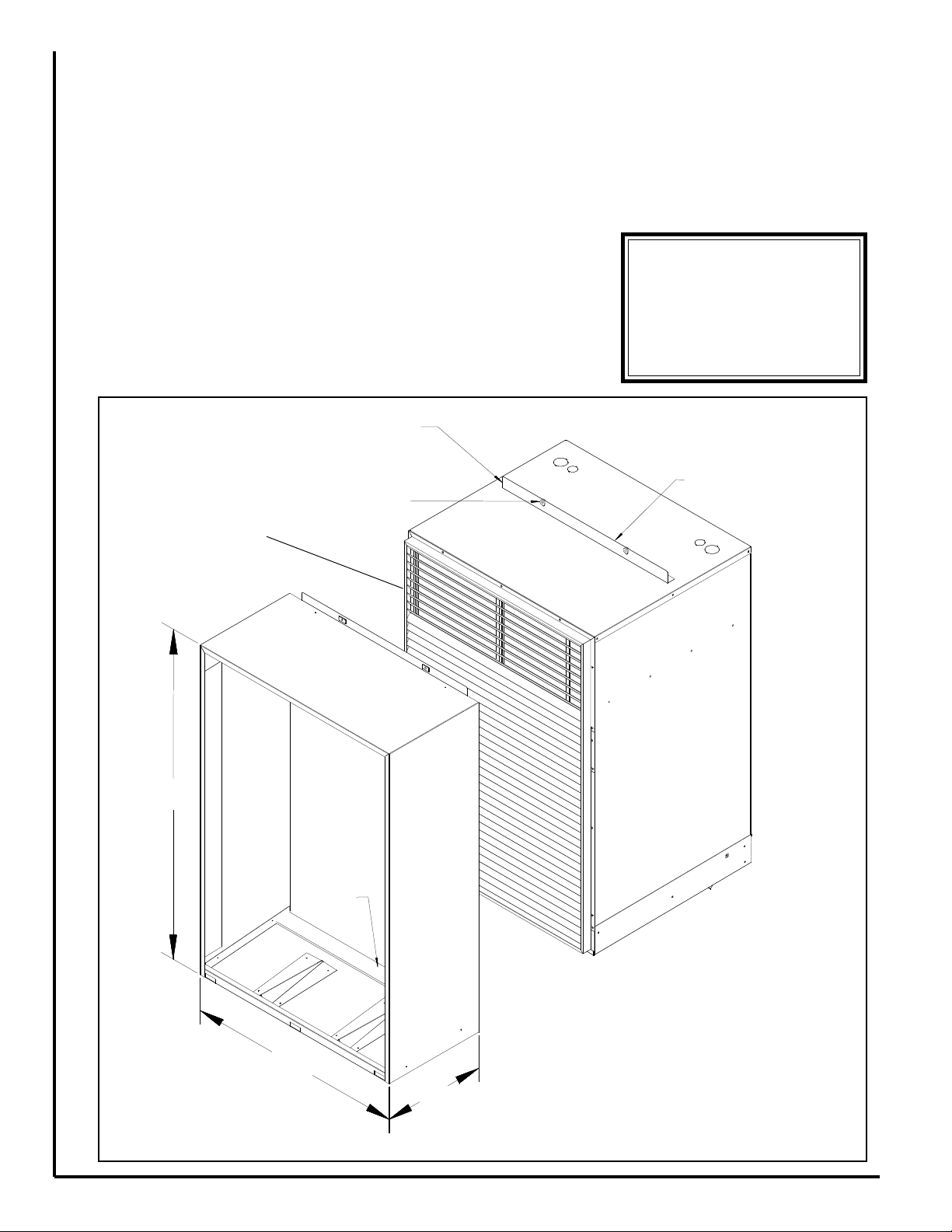

(1 ) After the sleeve is secured, install

the WHSC or WHHP unit into the

sleeve. Set the bottom edge of the

unit on the opening edge of the

sleeve. With the top of the unit

tilted slightly backwards, apply

primary force towards the bottom

of the unit while pushing forward

until the unit comes to a stop on

the sleeve face. The mounting

flange on the WHSC or WHHP

should then mate up flush with the

sleeve flange.

TOP BRACKET

ATTACH WITH FOUR

SCREWS PROVIDED

ISOLATION

ARCHITECTURAL GRILL

SHOWN HERE

USE ORIGINAL COIL

GUARD SCREWS

GROMMETS (2)

NOTE: Make sure isolation

grommets are installed on sleeve

flange (see. fig. 2).

(2) Before bolting the unit to the

sleeve apply a bead of silicone

sealant approved for exterior use

between the sleeve and the unit

top and both sides. The flange on

top of the unit may be temporarily

removed to facilitate ease of

applying sealant on top of unit.

(3 ) Using the 1/4" - 20 hex bolts and

washers, secure the unit at the

flange while the sealant is still

tacky.

NOTE: Check one last time for

complete seal around the unit and

sleeve and the sleeve and wall.

CABINET DIMPLES

BENEATH BRKT

45.5

SEAL

STRIP

Figure 2

27.5

13.0

Loading...

Loading...