Page 1

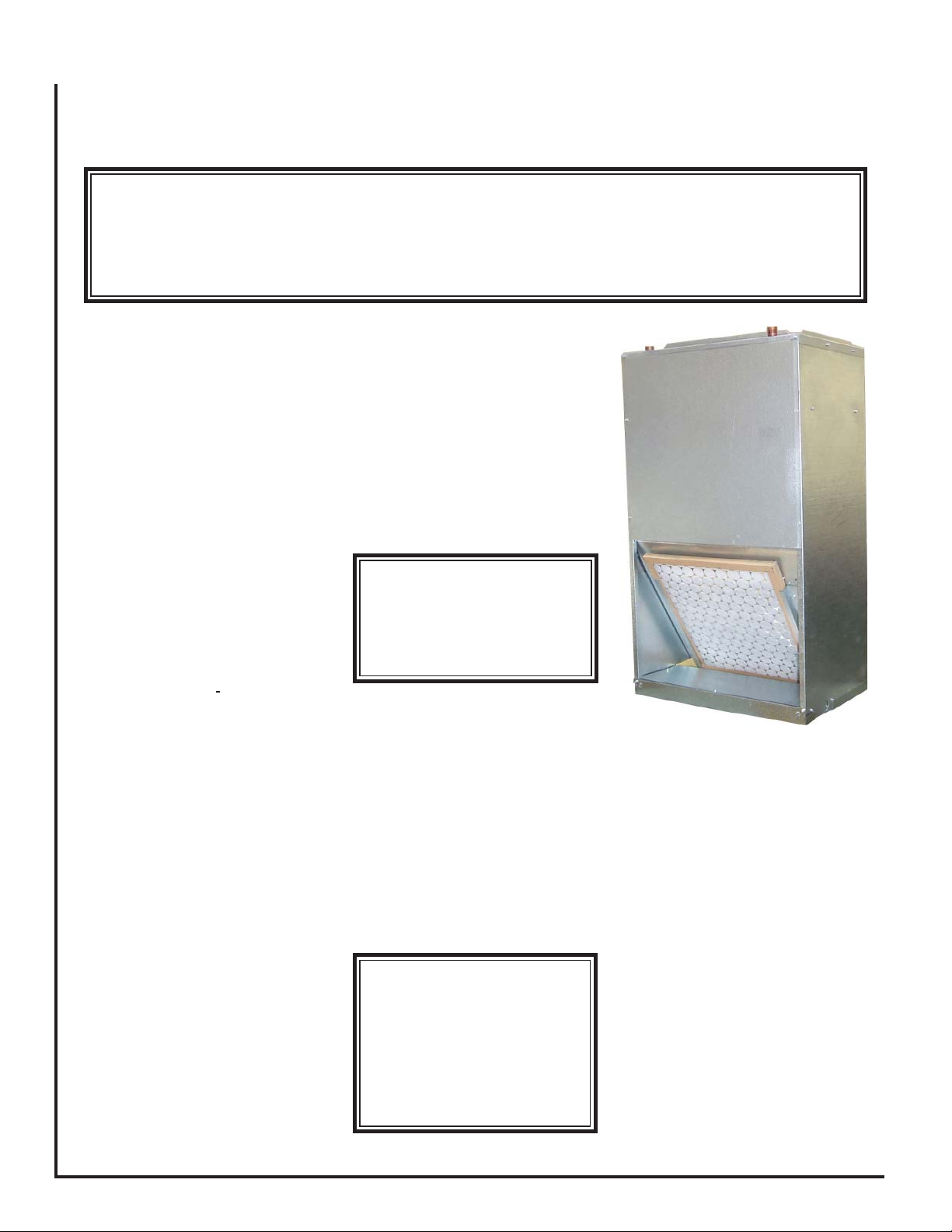

UC(S)-HW SERIES FAN COIL UNIT

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

**WARNING TO INSTALLER, SERVICE PERSONNEL AND OWNER**

Altering the product or replacing parts with non authorized factory parts voids all warranty or implied warranty

and may result in adverse operational performance and/or a possible hazardous safety condition to service

personnel and occupants. Company employees and/or contractors are not authorized to waive this warning.

Current Maintenance Program is available at www.fi rstco.com under "Product Information".

GENERAL

The manufacturer assumes no responsibility for equipment installed in violation

of any code requirement.

These instructions give information relative to the installation of UC-HW fan coil

units only. For other related equipment

refer to the proper instructions.

Material in this shipment has been

inspected at the factory and released to

the transportation agency in good condition. When received, a visual inspection

of all cartons should be made immediately. Any evidence of rough handling

or apparent damage should be noted

on the delivery receipt and the material

inspected in the presence of the carrier's

representative. If damage is found, a

claim should be fi led against the carrier

immediately.

FAN COIL UNIT

The installer must adhere strictly to all

local and national code requirements

pertaining to the installation of this equipment.

These units are designed to be installed

vertically in the upfl ow position by the

following mounting means:

Hung on closet wall

Using mounting kit 90PK3, air handler

may be wall mounted. Brackets and

screws are provided for both the closet

wall and the air handler.

It is recommended that sound isolating material be installed to prevent any

undesired transfer of sound.

Recessed in a wall

Installation of the fan coil recessed into

a partition wall with it's recommended

framing is shown in fi gure 1. Note: the

front face of the unit must be installed

fl ush with the dry wall. This application

requires the optional louvered wall panel

which must be ordered separately. Wall

panel with frame is secured to the studs

by screws or nails after the dry wall has

been installed. Refer to fi gure 2 and 3.

Closet Platform Front Return

Fan coil is to be set on a platform and

secured by screws or nails. Suffi cient

space for drain piping is required under

the platform.

All fan coil units are U.L. Listed for installation with zero inches clearance to

combustible materials. This includes the

****** WARNING ******

Extreme caution must be

taken that no internal damage

will result if screws or holes

are drilled into the cabinet.

fan coil cabinet, discharge plenum and

connecting ducts. Suffi cient clearance

must be provided at the front of the fan

coil to allow access to electrical controls

and removal of the motor /blower assembly for servicing. This clearance distance

should be approximately the same as the

depth dimension of the fan coil unit.

****** WARNING ******

Unit must not be operated

during building construction

due to excessive airborne

dust and debris. The unit

must not be operated under

any circumstances without

an air fi lter in place.

AIR DISTRIBUTION

DUCTS

All duct work must be installed in ac-

cordance with National Fire Protection

Association Codes 90A and 90B. Ducts

should be adequately insulated to prevent condensation during the cooling

cycle and to minimize heat loss during

the heating cycle. All return air must be

fi ltered to prevent dirt buildup on the coil

surface. If there is no ducted return, applicable installation codes may limit the

unit to installation only in a single story

residence. In many cases it is acceptable

to use ducting of the same size as the

fan coil connections. However, unique

arrangements or long duct runs must be

confi rmed by a local professional. The

manufacturer will not be responsible for

misapplied equipment.

L2465 4/08

Page 2

ELECTRICAL

All wiring must comply with local and

national code requirements. Units are

provided with wiring diagrams and

plate data to provide information required

for necessary fi eld wiring. Refer to fi gure

2 for points of entry of the wiring into the

cabinet.

name-

****** WARNING ******

Any devices such as fan

switches or thermostats that

have been furnished by the

factory for fi eld installation

must be wired in strict accordance with the wiring diagram

that is supplied with the unit.

Failure to do so could result

in damage to components

and will void all warranties.

These units may be provided with a

Class 2 transformer for 24-volt control

circuits. Should any add-on equipment also have a Class 2 transformer

furnished, care must be taken to prevent interconnecting outputs of the two

transformers by using a thermostat with

isolating contacts.

INSTALLATION

PRECAUTIONS

Installation of this fan coil should only

be performed by a licensed contractor to

ensure proper installation and the safety

of the installer. The following are some

precautions to be followed for typical

installations.

• Always use proper tools and equip-

ment.

• No wiring or other work should be at-

tempted without fi rst ensuring that the fan

coil is completely disconnected from the

power source and locked out. Always

verify that a good ground connection

exists prior to energizing any power

sources.

• Always review the nameplate on each

unit for proper voltage and control confi g-

urations. This information is determined

from the components and wiring of the

unit and may vary from unit to unit.

• When soldering or brazing to the

unit, it is recommended to have a fi re

extinguisher readily available. When

soldering close to valve packages or

other components, heat shields or wet

rags are required to prevent damage.

• When the fan coil unit is in opera-

tion components are rotating at high

speeds.

• Units must be installed level to ensure

proper drainage and operation.

• Check unit prior to operation to ensure

that the condensate water will drain toward the drain connection. An overfl ow

drain or an auxiliary drain pan under the

fan coil may be required as a back up to

a clogged primary drain.

• On units with plastic drain pans DO

NOT tighten more than hand tight.

• Be sure that the drain pan is free from

foreign material prior to start up.

• Check fi lter media installation to en-

sure that it is installed correctly. Use the

directional arrows or other information

on the fi lter to determine the proper fl ow

direction.

NOISE

These fan coil units are designed for

quiet operation, however, all air conditioning equipment will transfer some amount

of noise to the conditioned space. This

should be taken into consideration when

planning the location of the equipment.

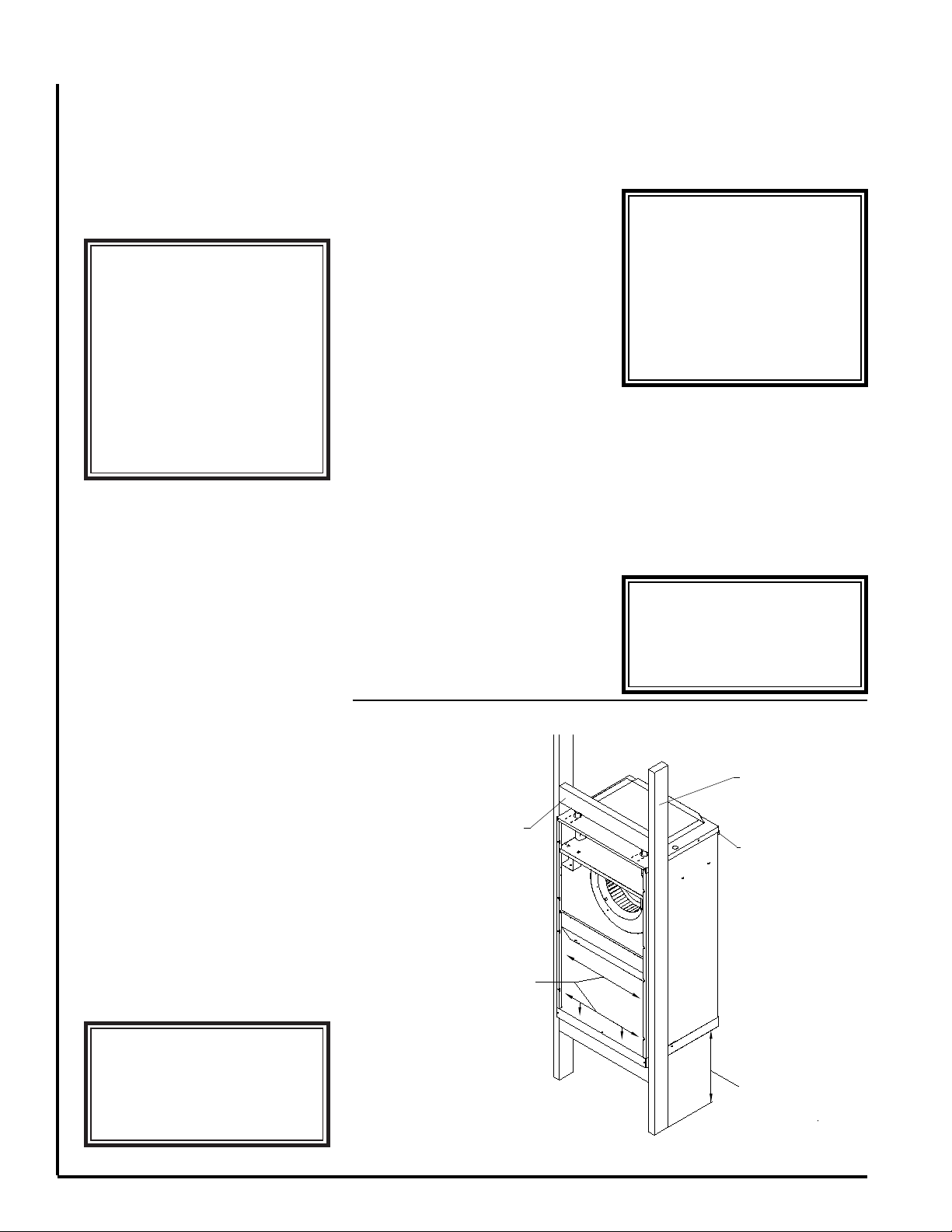

UC-HW RECESSED WALL MOUNTING

CROSS MEMBER - TOP & BOTTOM

(PLACE UPPER CROSS MEMBER

3" ABOVE UC UNIT)

ATTACH UNIT TO FRAME USING

6 SCREWS / NAILS IN CABINET AT

LOCATIONS SHOWN

COOLING COIL PIPING

These fan coil units are supplied with

a direct expansion refrigerant coil. The

suction and liquid lines must be sized in

accordance with the outdoor unit manufacturer's recommendations.

****** WARNING ******

When connecting piping to

fan coil units, do not bend or

reposition the coil header tubing for alignment purposes.

This could cause a tubing

fracture resulting in a water

leak when water pressure is

applied to the system.

For front drain applications a tab must

be removed from the inner front edge of

the unit as shown in Fig 5. This operation must be performed after the unit is

installed to prevent damage to the front

of the unit.

For installation of a thermostatic expansion valve see Fig. 6.

****** WARNING ******

Failure to perform modifi ca-

tions for front drain installation may result in structural

and equipment damage.

VERTICAL

2 X 4

BRACKET PLACEMENT FOR

HANGING IN A CLOSET

MOUNT UNIT FLUSH

WITH DRY WALL

(1/2" MIN. IN FRONT

OF WALL STUD)

****** WARNING ******

Do not touch any rotating

component with any object.

Damage to the equipment and

personal injury can occur.

LEAVE SUFFICIENT

SPACE FOR DRAIN

PIPING

10" TO 12" MINIMUM

RECOMMENDED

SUPPORT FRAMING

Figure 1

Page 3

Condensate drain lines must be installed

with adequate slope away from the unit

to assure positive drainage. Since the

drain pan is located on the suction side of

the blower, a negative pressure exists at

the drain pan and a minimum trap of 1-1/2

inches must be provided in the drain line

to assure proper drainage.

****** WARNING ******

On units with plastic drain

pans the drain connections

must be made hand tight

only.

NOTE: If a Condensate Overfl ow Shut-

off Switch, that is designed to be installed

in the drain line, is used in

secondary drain line, then the cut-off

switch should be located in the primary

drain line between the fan coil unit and

the P-trap.

HOT WATER COIL

PIPING PRECAUTIONS

• Flush all fi eld piping prior to connection

to remove all debris.

• Use wet cotton rags to cool valve bodies when soldering.

• Open all valves (midway for hand

valves, manually open on motorized

valves) prior to soldering.

•When soldering to bronze or brass, heat

the piping while in the socket/cup and

begin introducing the solder when the

fl ux boils rapidly. Avoid direct fl ame into

the solder joint.

• Heat can only be applied to the cup of

the valve body for a minimal time before

damage occurs (even with the use of

wet rags.

place of a

• Avoid rapid quenching of solder joints as

this will produce joints of inferior quality.

• Connect all piping per accepted industry

standards and observe all regulations

governing installation of piping systems.

When all connections are complete the

system must be pressure tested. Repair

any solder joint leaks and gently tighten

any leaking valve packing nuts and piping accessories as required. Hydronic

systems are not designed to hold pressurized air and should only be tested

with water.

HOT WATER COIL PIPING

Refer to Flow Control Module instal-

lation instructions for proper pump installation, if used.

The hot water coil connections are 3/4

inch nominal (7/8” OD) copper. The hot

water supply to the fan coil should be on

the right when facing the fan coil upright

and from the front.

****** WARNING ******

An expansion tank may be required if a back-fl ow preven-

ter is installed in the system.

All piping between the water heater

and fan coil unit should be copper and

should not exceed 200 feet of total piping. It is recommended that 3/4” nominal

(7/8” OD) piping should be used on all

UC-HW units to prevent excessive head

pressure losses. (Consult the factory for

other piping applications.)

It is also recommended that all pip-

ing be adequately insulated to prevent

freezing when piping is run in an unconditioned space.

Solder Connections - All copper

joints in the water lines must be made

with

low temperature - non lead

solder.

"T" Connections (at the water

heater)-

Water lines to and from the fan coil unit

must be taken from the horizontal connection of the "T" fi ttings in the vertical hot

and cold water supply lines at the water

heater. This ensures that any air in the

system will be purged each time water is

used in the dwelling. See fi gure 4.

Isolation Valves - Two valves are

recommended to be installed within the

circulating loop to permit servicing

of the system if required and to assist in

purging the system.

NOTE: Hot water coil freeze protection

is available for applications where the

fan coil is located in ambient air locations

(attics, crawl spaces, etc.) or within structures that may be unoccupied during

freezing conditions. Consult the factory

for additional information.

OPERA TION AND

MAINTENANCE

Pre-start Check

• Check that supply voltage matches

nameplate data.

• Ensure that the unit is properly

grounded.

• With power off, check blower wheel

set screw for tightness and ensure that

the blower wheels rotates freely and

quietly.

• Check that the refrigerant coil connections and piping have been leak checked

and insulated as required.

• Check that the water coil, valves and

piping have been leak checked and insulated as required.

• Ensure that all air has been vented

from the hot water coil.

THERMOSTAT

WIRING

UC WALL PANEL FRAME

(PANEL ASSEMBLY IS

ORDERED SEPARATELY)

CROSS MEMBER

(ON EDGE)

INSTALLED UNIT

TOP VIEW

WATER

OUTLET

Figure 2

2 X 4

POWER

SUPPLY WIRING

LIQUID LINE

SUCTION LINE

2 x 4 WALL STUD

WALL STUD

DRY WALL

WATER

INLET

DRY WALL

SCREW

WALL PANEL

FRAME

DETAIL OF WALL PANEL FRAME

Note: Front edge of unit to

be fl ush with dry wall.

INSTALLATION

Figure 3

Page 4

****** WARNING ******

• Always wear eye protection.

• When fan coil is operating,

some components are operating

at high speeds. Personal injury

can result from touching these

items with any object

• All electrical and service

access panels must be returned

and secured in their proper

place.

• Clear surrounding area of all

tools, equipment and debris.

• Check the entire unit to ensure

it's cleanliness.

NOTE: It may require purging several gallons of water so have a means

of discarding the water.

• Install all panels.

• Install any fi lters which may have

been removed during the installation

process.

Start-up and Maintenance

Before start-up, all of the components

should be given a thorough check. Optimal operation of this equipment requires

cleanliness. Often after installlation of

this equipment additional construction

activities occur. Care must be taken to

protect the equipment from debris during

these construction phases.

Fan

The fan should be inspected and

cleaned, in conjunction with maintenance of the motor and bearings. It is

important to keep the wheel clean in

order to avoid imbalance and vibration.

Motor

Check motor connections to ensure

that they are secure and made in accordance with the wiring diagram.

The blower motor should be cleaned

annually.

Coil

Any dust or other contaminants which

accumulate on the heat transfer surfaces

interferes with the air fl ow and impairs

heat transfer. The coil must be kept clean

by any of the following methods.

• Cleaning with low pressure compressed air.

• Flushing or rinsing with water (a detergent is advisable for greasy surfaces).

Filter

The air fi lter should be cleaned or re-

placed every 30 days or more frequently

if severe conditions exist. Always replace

the fi lter with the same type as originally

furnished.

****** WARNING ******

The manufacturer does NOT

WARRANT equipment subjected to abuse. Metal chips,

dust, drywall tape, paint over

spray, etc. can void warranties and liability for equipment failure, personal injury

and property damage.

Drain Piping

The drain should always be:

• Connected or piped to an acceptable

disposal point sloped away from the

unit at least 1/8" per foot

• Checked before summer operation

• Periodically checked during summer

operation

Preventative Maintenance

T o achieve maximum performance and

service life of each piece of equipment a

formal schedule of regular maintenance

should be established and maintained by

a licensed contractor.

HEATING CYCLE

START - UP

1) Fill the water heater. Open a hot

water faucet while fi lling the water

heater to vent the air. When the tank

is full and all the air is purged, close

the faucet.

2) Ignite the water heater and set the

thermostat to 140 degrees.

3) Purge the air handler's hot water coil

and lines.

NOTE: It may require purging several gallons of water so either have

a bucket available or a means of

discarding the water.

Close valve number 2 and open valve

number 3. (See fi gure 4 ) Next, open

the air bleed valve. When all of the air

is purged from the lines close valve

number 3 and open valve number 2.

After all the air is purged from the coil

and lines, open both valve number 1

and 2 and close the air bleed valve.

4) Switch the room thermostat to the

"Heat" position and raise the tem-

perature setting to a position approximately ten degrees above room

temperature.

****** WARNING ******

To prevent pump damage,

the fan coil unit should not

be energized for heating until the hot water coil and all

water lines have been purged

of air.

The pump should energize and begin

circulating the hot water through the

coil. If the pump is operating properly

and the water temperature in the water heater has reached the set point,

then the hot water inlet at the fan coil

unit will be hot. If the pump is running

but hot water is not circulating, open

the air bleed valve long enough to

purge any remaining air from the hot

water lines and coil. This will allow the

pump to begin circulating hot water.

****** WARNING ******

Hot water can cause scalding. A hot water mixing valve

can be applied to the system

to temper domestic water

draw.

5) The water heater thermostat should

be adjusted so that the water temperature entering the hot water coil is as

close to 140 degrees as possible with

the system energized and operating

long enough for all temperatures to

stabilize.

PUMP REPLACEMENT

(If Flow Control Module is installed)

Disconnect electrical power before

servicing the unit.

T o replace the circulator pump, close

the isolation valves and relieve the water

pressure within the heating loop. Disconnect the pump's 1 15 volt power lines

within the control box and remove the

four hex head screws securing the pump

motor to the pump's volute.

Reverse the above steps for reas-

sembling the pump, however make sure

that the pump or volute has the rubber

o-ring in place before assembling.

Page 5

CHECK VALVE

HOT WATER COIL

2

3

HOT WATER

SUPPLY TO

HOUSE

HOT

WATER

HEATER

FLOW

FLOW

WATER SUPPLY

TO HEATER

FLOW CONTROL MODULE

CONSIST OF: PUMP, CHECK

VALVE AND BLEED VALVE

BLEED

VALVE

1)

ISOLATION VALVE: SUPPLY LINE2)

ISOLATION VALVE: RETURN LINE3)

FLOW

1

FLOW CONTROL

MODULE

REPLACEMENT

Disconnect electrical power before

servicing the unit.

To replace the internal check valve,

close the isolation valves and relieve the

water pressure within the heating

Remove the four hex head screws securing the pump motor to the pump's volute

and remove. The check valve is located

in the volute.

Rotate the check valve to release and

remove from the volute.

loop.

Reverse the above steps for reinstalling a check valve, however make sure

that the pump or volute has the rubber

o-ring in place before assembling.

TYPICAL PIPING SCHEMATIC

w / Flow Control Module

**MAINTENANCE UPDATES**

For a current copy of the

Maintenance Program log

on to www.fi rstco.com and

look under "Product Information"

Figure 4

Page 6

FRONT DRAIN APPLICATIONS

Cut along dashed lines to

slot and remove

For front drain applications cut as shown and

remove metal tab to allow drain piping to slope

away from the drain pan properly. Ensure that the

drain piping has proper slope and is able to drain.

****** WARNING ******

If secondary drain is not being used it must be

plugged to prevent leakage which will cause

structrual and equipment damage.

Figure 5

THERMOSTATIC EXPANSION VALVE INSTALLATION

Install expansion valves as shown with directional arrow

toward the coil. Attach the TXV bulb to the vertical suction line as shown with the tubing on top. External equalizer is to be attached to the 1/4" fl are connector. Ensure

that a service valve core is not installed before attaching

the equalizer line. Wrap the bulb with insulation tape to

completly seal the bulb from ambient air.

Figure 6

Loading...

Loading...