Page 1

SPX SERIES

****** WARNING ******

Unit must not be operated

during building construction

due to excessive airborne

dust and debris. The units

must not be operated under

any circumstances without an

air filter in place.

P ACKAGED AIR CONDITIONING/HEA T PUMP UNITS

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

**WARNING TO INSTALLER, SERVICE PERSONNEL AND OWNER**

Altering the product or replacing part s with non authorized factory parts voids all warranty or implied warranty

and may result in adverse operational performance and/or a possible hazardous safety condition to service

personnel and occupants. Company employees and/or contractors are not authorized to waive this warning.

Current Maintenance Program is available at www.firstco.com under "Product Information".

GENERAL

These instructions give information

relative to the SPX unit only . Refer to

Wall Sleeve and Grille installation

instructions for those components.

The manufacturer assumes no

responsibility for equipment installed

in violation of any code requirements.

For other related equipment refer to

the proper instructions.

The SPX is shipped in one package,

completely assembled. Material in

this shipment has been inspected at

the factory and released to the

transportation agency in good

condition. When received, a visual

inspection of all cartons should be

made immediately. Any evidence of

rough handling or apparent damage

should be noted on the delivery

receipt and the material inspected in

the presence of the carrier’s

representative. If damage is found a

claim should be filed against the

carrier immediately .

HW Units - Note: State of MA.-248 CMR

code of the state of MA. requires a pump

timer (60 seconds on every 6 hours).

See diagram.

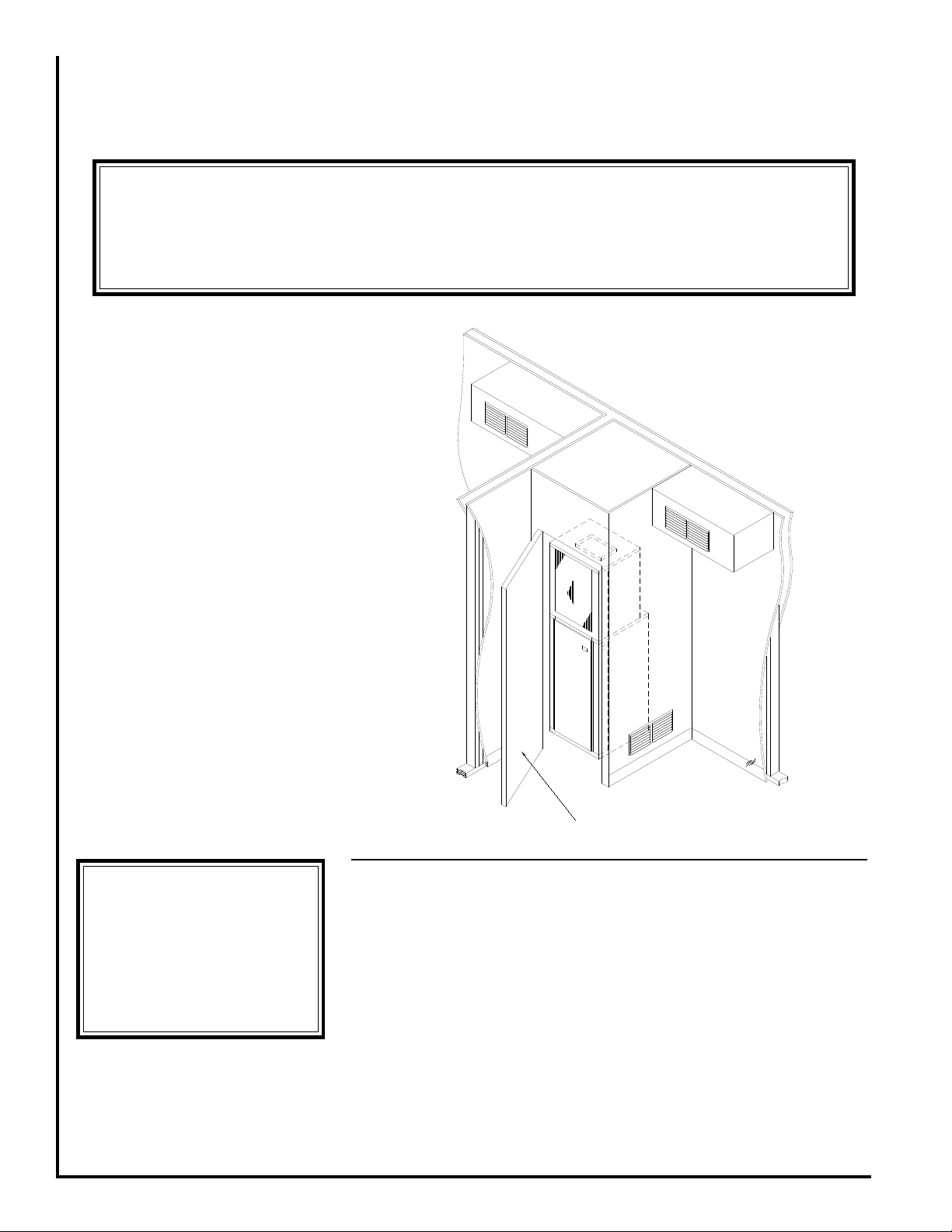

Figure 1 - Typical Suite Installation

P ACKING LIST

Items packed inside the unit:

(1 ) Filter Bracket

(1 ) Filter Clip

LOCA TION

The SPX is designed for throughthe-wall installation. The interior

portion of the unit is surrounded by a

closet with a rear access (Fig. 1). The

vertical discharge allows for ducting

to the top of the room for best air

circulation and elimination of cold

drafts on occupants. The exterior

(grille side) of the unit must have no

obstructions (trees, landscape

materials, etc.) within 18 inches. Do

not locate two units adjacent to each

1

other on an inside corner or where they

may exhaust into each other.

Provisions should be made to allow

access to the indoor side of the unit

for installation and inspection. The

closet or access panel opening must

be centered with the exterior wall

opening and be at least 24” wide by

84” tall. Three (3) inches of

unobstructed space is required on all

sides of the SPX to allow for adequate

air flow. At least 27 inches of

unobstructed space should be provided

in front of the access door to permit

L268 2/09

Page 2

Electrical

****** W ARNING ******

Make sure a high grade nonhardening sealant approved for

exterior use has been applied

between edge of the sleeve and

the structure, on the inside and

outside walls, to prevent air

and water from migrating

inside (Fig. 4).

****** WARNING ******

There must be a minimum 3"

clearance maintained around

the SPX chassis on all sides for

adequate airflow to achieve

optimum performance. These

guidelines give minimum spacing requirements only. It is

acceptable to go beyond these

limits at any time.

****** WARNING ******

After sleeve installation ensure

that the sleeve seal is in contact

with the sleeve sides. Any air

gaps must be sealed or

outdoor air and/or water

leakage will occur.

****** W ARNING ******

Architectural Grille must be

installed prior to the

installation of the SPX unit into

the sleeve.

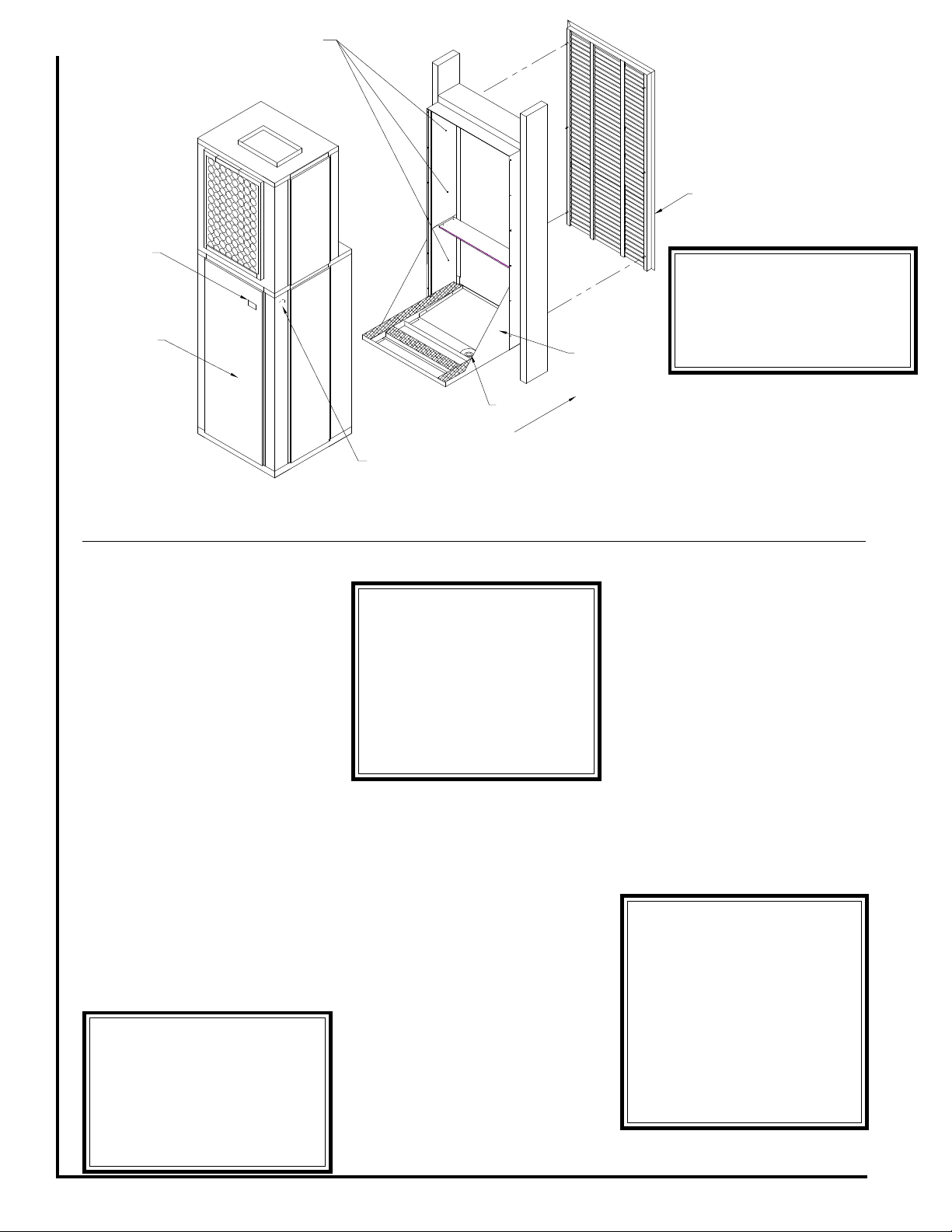

Disconnect

Rear Access

Panel

Approximate

Fastener

Locations

Architectural

Grille

Wall Sleeve

Drain

Outside

Electrical Service

Knock-out

removal of the unit should repair and

inspection be required.

For installations requiring access

panels refer to unit brochure for panel

dimensions.

W ALL SLEEVE

INST ALLATION

Refer to installation instructions

packed with wall sleeve to assemble

and mount it in the wall. Before unit

installation, make sure sleeve

components are not damaged, drain

line is unobstructed and leak free.

Check all seals to ensure that they are

in position and un-damaged. Ensure

that the bottom of the wall sleeve is

pitched 1/2 bubble toward the outside

of the building so that rain water will

drain to the outside (Fig. 4). Securely

fasten the Architectural grille to the

front of the sleeve using the supplied

hardware.

Figure 2 - General Assembly

The unit comes with a factory

supplied disconnect, however, the

contractor is responsible for providing

over current protection on the branch

circuit. Refer to the unit wiring diagram

for single point electrical connection.

These units are provided with a

Class 2 transformer for 24 volt control

circuits. Should any add-on

equipment also have a Class 2

transformer furnished, care must be

taken to prevent interconnecting

outputs of the two transformers by

using a thermostat with isolating

contacts.

ELECTRICAL

All wiring must comply with local

and national code requirements. Any

alteration of the internal wiring will void

UL certification and manufacturer’s

warranty.

Nameplate data indicates the

operating voltage, phase, ampacity,

maximum over current protection and

minimum voltage. Units must never

be installed or operated where voltage

exceeds the nameplate voltage by

more than 10%. Failure of the

compressor as a result of operation

with improper voltage voids the

compressor replacement warranty.

2

Page 3

INST ALLATION

***** WARNING *****

SPX Heat Pump units operate with the reversing

valve energized in the

HEATING mode. The

thermostat must be wired

or configured accordingly or the unit will not

operate properly.

****** WARNING ******

After removing the construction debris guard, check the

bottom of the pan to ensure

that it is sloped one half

bubble toward the outside.

Ensure that the bottom of the

pan and drain are clear of obstruction and operational.

****** WARNING ******

If unit is not sealed completely, water and/or outside

air will infiltrate into the closet.

1. Ensure that properly sized duct

work is in place to mate to the supply

connection on the SPX.

2. Remove the two clips holding the

unit to the shipping pallet and remove

unit from the shipping pallet.

3. Before setting unit into closet,

remove upper side access panels and

inspect the evaporator blower to

ensure that the wheel turns freely

without rubbing on the housing.

Note: Remove the styrofoam shipping block supporting the blower

assembly.

Replace upper access doors prior to

completing installation.

4. Remove disconnect and the rear

access door to get to the loose items

described in the packing list. Check

all electrical connections and check

the condenser fan to see that it turns

freely. Note nameplate voltage, amperage and fuse size for proper power

supply .

5. The SPX is equipped with bend out

flanges (Fig. 3), next to the evaporator

coil, for the purpose of attaching a

return air duct. If ducted return air is

required these flanges must be bent

90 degrees away from the face of the

evaporator coil along the perforations.

Note: If the unit will not be connected

to a fixed return duct these flanges

must be broken off of the unit.

6. If an air filter is to be applied to the

unit install the filter bracket by inserting the tab portion of the rack between

the insulation and middle plate under

the drain pan (Fig. 3). Place a 20” x

24” x 1” filter into the filter rack. Insert the two tabs on the filter clip into

the slots above the evaporator and

hook the front flange under the filter

flange to hold the filter in place.

7. A fresh air make up vent is located

on the lower left side door (Fig. 3).

Remove one screw and rotate the

plate to expose the desired amount

of vent opening. Replace the screw to

hold the door in desired location.

8. Ensure that the wall sleeve is

installed squarely and is secure before

installing the unit.

Note: After removing the construction

debris guard, inspect the sleeve seal,

which is supplied with the sleeve, to

ensure that it is properly secured and

aligned (Fig. 2). Use a high grade nonhardening sealant to close any gaps

that may exist between the seal and

the wall of the sleeve.

9. After the seal is inspected, lift the

unit onto the base of the sleeve and

slide the unit forward to engage the

seal. The unit is fully engaged when

the upper housing of the SPX is 1/2”

away from the top inside edge of the

sleeve.

10. Check that the unit is completely

seated on all four sides against the

wall sleeve seals.

If necessary seal any openings that

may exist.

1 1. Connect properly sized electrical

service to the disconnect block.

12. Install a factory approved or

equivalent thermostat according to

Ducted Return

Air Flanges

Thermostat

Connection

Fresh Air

V ent

Figure 3 - Filter Bracket Detail

3

Filter

Bracket

Air

Filter

Electrical

Disconnect

Filter

Retainer

Page 4

directions furnished with the

****** WARNING ******

SPX units must not be operated

under any circumstances without an air filter in place.

****** WARNING ******

All panels must be installed

and disconnect switch must

be in place before operating

unit.

thermostat. The thermostat should be

located on an inside wall where it will

not be affected by drafts, sunlight or

any other heat producing appliances.

Connect thermostat wires to the

thermostat following the wiring diagram

attached to the unit.

13. Connect low voltage thermostat

wires from remote thermostat to the

SPX unit (Fig. 3).

14. Install ductwork onto unit discharge and ensure that the connection is leak free. A flexible boot connection may be desirable to provide

for more convenient installation and

removal of the SPX unit.

15. Replace the rear access panel

and disconnect.

CONDENSATE DRAIN

The SPX is designed so that the

wall sleeve is the principle drain pan.

Drain tubing is factory installed which

drains evaporator condensate

through the bottom of the unit which

then is allowed to drain into the wall

sleeve pan.

Note: When preparing unit for

installation check to ensure that the

drain tubing from the evaporator is

securely attached to the copper nipple

in the pan under the compressor. The

wall sleeve has a 3/4 NPT nipple

located in the bottom for connection

to a drain (Fig. 4). A trap may be

required in the condensate drain line

to prevent sewer gas from escaping

into the room.

Prior to unit installation ensure that

the drain is unobstructed and leak

free.

20” x 24” x 1” field supplied throwaway

type filter.

2. Use the filter kit supplied with the

access panel which accepts a

20” x 20” x 1” throwaway type filter.

3. Install a filter in the return grille

mounted in the wall. Any field

installation of an air filter means must

provide for use of a disposable filter

which is no smaller than the face area

of the evaporator coil.

The air filter should be cleaned or

replaced every 30 days or more

frequently if severe conditions exist.

EV APORA T OR BLOWER

SPEEDS

The unit contains a direct drive,

multi-speed blower. The proper speeds

have been preset at the factory for

heating and cooling. Refer to wiring

diagram for recommended blower

speeds for specific models.

Return

Air

SPX Unit

OPERA TING

INSTRUCTIONS

Operation of the unit is automatic

and will provide heating and cooling

depending on the setting of the

thermostat.

Note: Loosen compressor mounting

nuts if unit vibration is excessive.

SYSTEM CHECK

Cooling/Electric Heat Units

1. Set thermostat system switch to

“Off” position and fan switch to “Auto”

position. Apply power to the SPX unit.

Sealant

AIR FILTER

All indoor return air must be filtered.

The preferred methods are:

1. Use the factory supplied filter kit

which attaches to the inlet of the

evaporator and accepts a

To Condensate

6” min.

4

1/2 Bubble

Drain

1/4” min.

Figure 4 - Side View

Page 5

Note: The SPX employs a random

****** WARNING ******

Replace all access panels

before turning on main power.

****** WARNING ******

It is illegal to discharge

refrigerant into the

atmosphere. Use proper

reclaiming methods and

equipment when installing or

servicing this unit. Service

should be performed by a

QUALIFIED service agency.

The refrigerant system

contained in the unit normally

requires no maintenance

since it is a closed, selfcontained system.

****** W ARNING ******

SPX Heat Pump units operate

with the reversing valve

energized in the HEATING

mode. The thermostat must

be wired or configured

accordingly or the unit will not

operate properly.

**MAINTENANCE UPDATES**

For a current copy of the

Maintenance Program log on

to www.firstco.com and

look under "Product Information"

reset timer which delays unit operation

up to 3 minutes following initial power

application. Electronic thermostats

may also employ internal reset timers

which may further delay any changes

which are made to the operation of the

unit.

2. Set fan switch to “On”, indoor

blower should operate after the reset

timer cycle is complete.

3. Return fan switch to “Auto”, indoor

blower should de-energize.

4. Set system switch to “Cool” and

lower thermostat set point to coldest

setting. The compressor should

energize as well as the outdoor fan

and indoor blower.

5. Return thermostat set-point to a

temperature warmer than room

temperature and the compressor and

outdoor fan should de-energize. The

indoor blower should remain in

operation for an additional 45

seconds, then de-energize.

Note: The SPX employs a

compressor short cycle delay (~ 3

minutes) which will not allow the

compressor to immediately restart

following shut down. Additional

delays may be experienced if using

an electronic digital thermostat.

6. Move system switch to “Heat” and

raise thermostat to a set point higher

than room temperature. The indoor

blower and electric heating

element(s) should energize.

7. Return system switch to “Off”

position.

Note: The SPX features a low ambient

compressor lock out switch which will

not let the compressor energize in

either cooling or heat pump mode

when the outdoor ambient temperature

is below 40 degrees F .

SYSTEM CHECK

Heat Pump Units

1. Set thermostat system switch to

“Off” position and fan switch to “Auto”

position. Apply power to the SPX unit.

Note: The SPX employs a random

reset timer which delays unit

operation up to 3 minutes following

initial power application. Electronic

thermostats may also employ internal

reset timers which may further delay

any changes which are made to the

operation of the unit.

2. Set fan switch to “On”, blower

should operate after the reset timer

cycle is complete.

3. Return fan switch to “Auto”, blower

should de-energize.

4. Set system switch to “Cool” and

lower thermostat set point to coldest

setting. The compressor should

energize as well as the outdoor fan

and indoor blower.

5. Return thermostat set-point to a

temperature warmer than room

temperature and the compressor and

outdoor fan should de-energize.The

indoor blower should remain in

operation for an additional 45

seconds, then de-energize.

Note: The SPX employs a short cycle

delay (~ 3 minutes) which will not allow the compressor to immediately

restart following shut down. Additional

delays may be experienced if using

an electronic digital thermostat.

6. Move system switch to “Heat” and

raise thermostat to a set point slightly

higher than room temperature (less

than 2 degrees). The compressor,

outdoor fan and indoor blower should

energize.

7. Raise set point to more than 2

degrees and the electric heaters

should energize. The compressor and

condenser fan will immediately deenergize. The compressor will remain

locked out and the electric heat

operating until the thermostat satisfies.

Note: The SPX employs a

compressor lock out which will not

allow the compressor and electric

heaters to energize at the same time.

8. Lower the set point to less than

room temperature and the system

should de-energize.

9. Return system switch to “Off”

position.

5

MAINTENANCE

Periodic maintenance is limited to:

1. Replacing the air filter monthly or

more frequently if unusual conditions

are encountered. Air filter size is

20" x 24" x 1" when using the factory

filter frame and 20” x 20” x 1” when

unsing the access panel.

2. Cleaning the outdoor coil of foreign

material such as lint, dust, leaves or

other obstructions as necessary.

3. Checking drain line and removing

obstructions as necessary .

If servicing or major repairs are

required, the complete unit can be

removed as follows:

1. Disconnect the electrical power

circuit supplying the unit.

2. Remove disconnect pull and low

voltage thermostat connector.

3. Remove rear access panel.

4. Remove supply duct from top of

unit.

5. Slide unit back out of sleeve.

6. Unit may be removed from closet.

To reinstall unit, use the installation

procedure outlined above.

Page 6

STATE OF MASSACHUSETTS PIPING DIAGRAM

UNITS WITH HOT WATER HEATING

6

Loading...

Loading...