UNI TEMP

Technical data

Electrical data

Supply voltage

With adapter: 230VAC, 50Hz

Without adapter: 24VAC, 50Hz, ± 10% (Cut the

cable connector)

Power consumption

5VA

Connection cable

2

2x0,75mm , length 2m

Sensor type

KTY 81-210 PVC (cable length 1.5m),

insulation: -30°C to 105°C (adapter set enclosed)

Functional data

Torque

max 15Nm

Rotation time

73s/90°

Manual override

Manual or permanent with pushbutton (for maintenance

purposes)

Position indication

Handle position on controller cover

Recommended mounting

position

All positions except upside down

DIP switch settings

1. Direction of rotation (direct CW / inverse CCW)

2. Different temperature ranges depending on the

application (0°C..100°C, 60°C..85°, 20°C..70°C,

25°C..45°C)

3. Reaction factor x1/x10

Safety

Protection class

II

Degree of protection

IP44 (IEC 60529 (2001-02))

Ambient temperature

0..+55°C

Media temperature

According to valve's specifications

Storage temperature

-20°...+80°C

Maintenance

Maintenance-free

Weight

Approx. 0,7kg (without valve)

Enclosed mounting

kit

FIRŠT (ROTOMIX, ROTOMIX G), ESBE (VRG, VRB), ACASO (TERMOMIX), BARBERI,

FEROTERM, PAW, EURONORM, ESBE, IMP, DANFOSS, BESSER, SELTRON, LOVATO,

TUXHORN, STRAWA, CIMBERIO

UNI TEMP is a constant

temperature controller. It is

designed for mounting on mixing

valve.

It is also equipped with mounting

kit for assembly on mixing valves

of other manufacturers.

Controller has a fixed angle

rotation of 90° and possibility of

manual control.

Adapter

230V/24V

With DIP switches inside actuator

is possible to set the following

parameters:

- Direction of rotation (direct

CW / inverse CCW)

- Different temperature ranges

depending on the application

- Reaction factor x1/x10

24V , 50Hz

It is intended for:

ź maintaining a constant temperature in boiler heating circuit (protection

against condensation),

ź use in under floor heating applications, industrial processes, heat

accumulators,

ź use in domestic hot water systems or swimming pools (individual

systems, SPA, public swimming pools).

FIRŠT-ROTOTEHNIKA, s.p., Radegunda 54, 3330 Mozirje, info@first.si, http://www.first.si

PE VELENJE: Koroška c. 56a, 3320 Velenje, tel:++386 (0)3 898 35 00, fax: ++386 (0)3 898 35 35

cX5-2611-UNI-TEMP-product-info_v3-en.cdr

1

UNI TEMP UNI TEMP

Electrical installation:

Dimensions:

Order information:

Code

Article

Voltage

Time

Torque

21135

UNI TEMP 24VAC

24VAC, 50Hz

73s/90°

max. 15Nm

21136

UNI TEMP 230VAC

230VAC, 50Hz

73s/90°

max. 15Nm

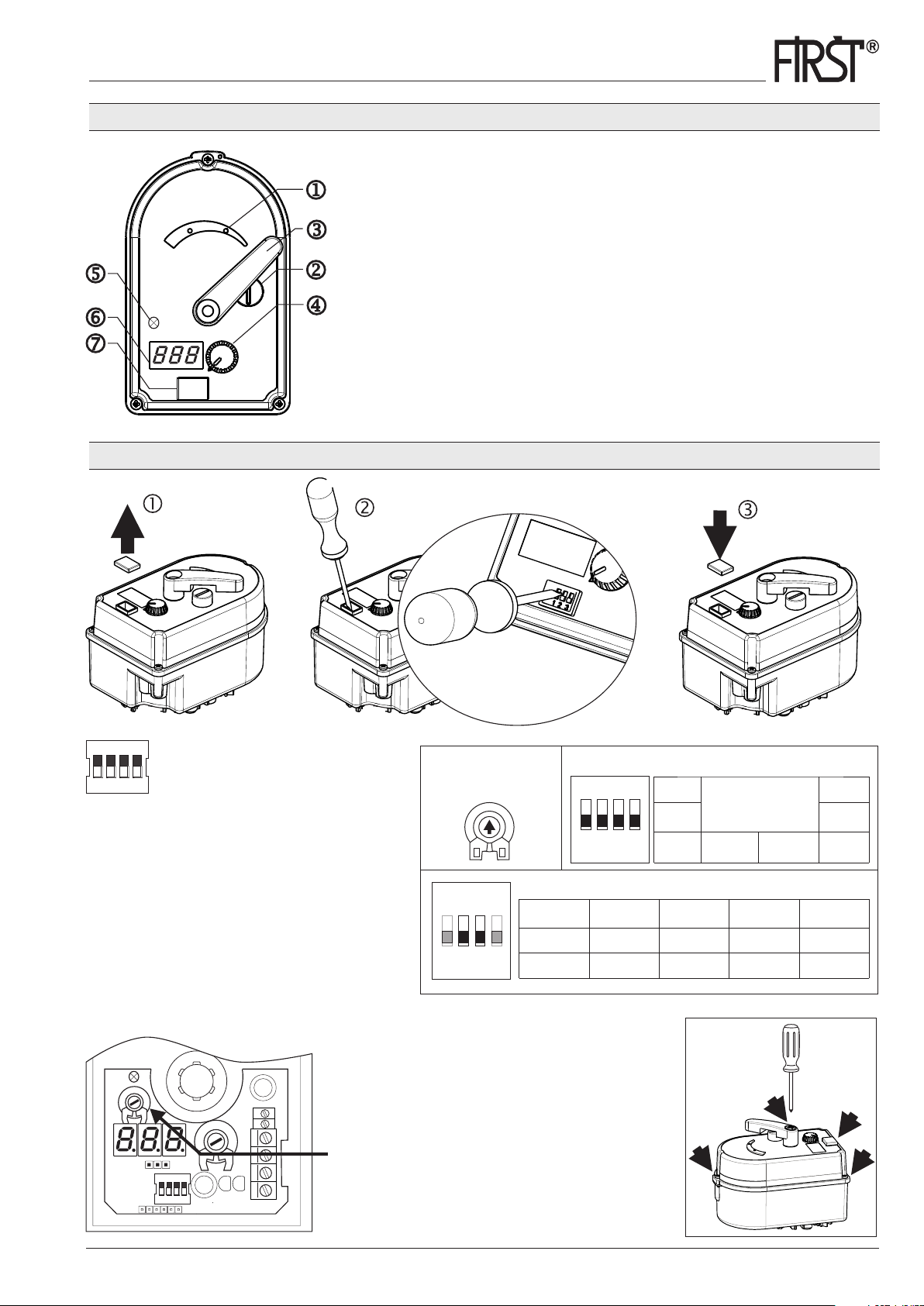

Mounting on the valve:

Mounting kit

UNI TEMP 24VAC

l=1,5m

40

Sensor (VF) KTY81-210

Cut the cable connector

!

24V , 50Hz

1 2 3 4 5

Pin terminal

UNI TEMP 230VAC

Ø6

24V , 50Hz

brown (L)

blue (N)

l=1,5m

Ø6

40

Sensor (VF) KTY81-210

!

230VAC, 50Hz

The equipment must be connected to the electric power

supply in a manner which coplies with the legal

equirements applicable at the place of use.

www.first.si 2

Enclosed mounting kit for following mixing valves: FIRŠT (ROTOMIX, ROTOMIX G), ESBE

(VRG, VRB), ACASO (TERMOMIX), BARBERI, FEROTERM, PAW, EURONORM, ESBE,

IMP, DANFOSS, BESSER, SELTRON, LOVATO, TUXHORN, STRAWA, CIMBERIO.

Mounting on the valve:

ROTOMIX F3

Mounting kit

ROTOMIX F4

ROTOMIX F3U

ROTOMIX F4U

FIRŠT (ROTOMIX G), ESBE,

(TERMOMIX), BARBERI, FEROTHERM,

PAW, EURONORM, IMP, DANFOSS,

BESSER

ACASO

ESBE VRB, VRG

1

Code Enclosed mounting kit

58024

2

58025 SELTRON, LOVATO, PAW

58026 LAZZARI, LANDIS

58027 HONEYWELL MS

58028 SIEMENS

58029 MUT

58030 W.I.L.B

58031 CENTRA

58032 MEIBES, WITA, OVENTROP,

58033 TEHNOPLANT, EXCELSIOR,

FIRŠT (ROTOMIX, ROTOMIX

G), ESBE (VRG, VRB),

ACASO (TERMOMIX),

BARBERI, FEROTERM, PAW,

EURONORM, ESBE, IMP,

DANFOSS, BESSER,

SELTRON, LOVATO,

TUXHORN, STRAWA,

CIMBERIO.

By special request

HOLTER HORA BR80

SMD/SMV

KRAMER, DE PALA

www.first.si 3

UNI TEMP

CW

Temperature

range setting

x10

CCW

x1

123

4

DIP

0°C..100°C

60°C..85°

20°C..70°C

25°C..45°C

2

OFF

OFFONON

3

OFFONOFF

ON

Manual control:

Controller behavior diagram as a function of temperature:

Settings:

DIP switch settings

ON

1 2 3 4

LED

COM

Xp

UNI TEMP

1 Mechanical indication.

Indicator can be set according to the valve

assembly

2 Button for manual/auto control

3 Handle for manually controlling the drive, which

also serves for the indication position of the valve

4 Button for adjusting the required temperature.

When adjusting the temperature, the set value

flashes on LCD screen.

5 LED indication of:

- Flash: actuator calibration

- ON: normal operation

6 LCD screen for displaying temperature

7 DIP switches cover

ON

1 2 3 4

With DIP switches inside actuator is

possible to set the following

parameters:

Xp parameter

a proportional control

range of valve

DIP switch settings

DIP 1 Direction of rotation (direct CW /

inverse CCW)

DIP 2,3 Different temperature ranges

min max

1ON2 3 4

depending on the application

(0°C..100°C, 60°C..85°, 20°C..70°C,

Temperature range setting

25°C..45°C)

DIP 4 Reaction factor

NOTE – when changing DIP1 position,

1ON2 3 4

controller calibration is carried out

Xp parameter - a proportional control range of valve (from 10K to 100K)

Trimmer Xp is located inside controller.

To open the controller it is necessary to loosen the

screws on the cover (3x), and handle screw (1x).

Xp parameter - a proportional control range of

valve (from 10K to 100K)

www.first.si 4

www.first.si 4

UNI TEMP

Manual control:

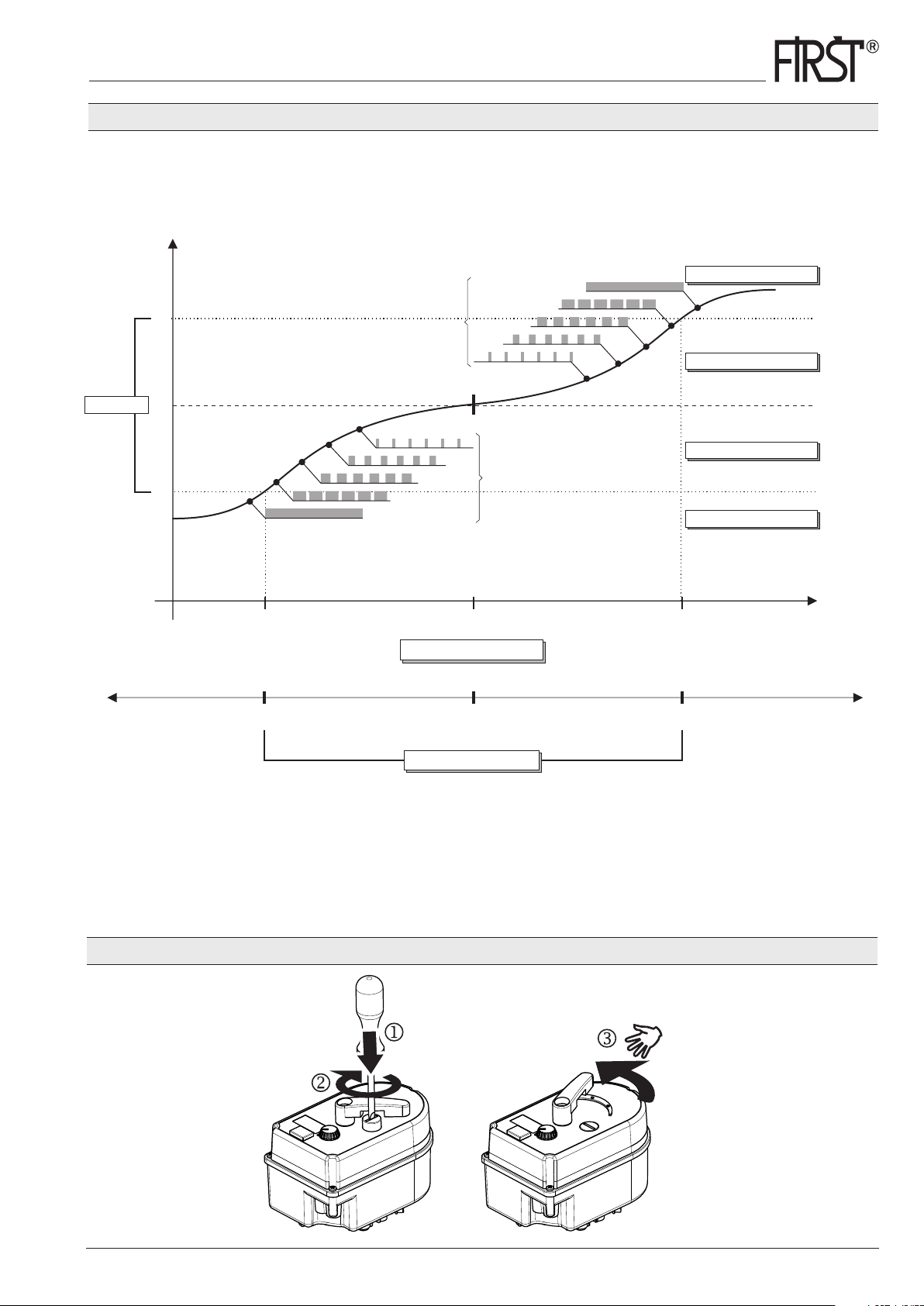

Controller behavior diagram as a function of temperature:

Example:

-Desired temperature: 50 C

-Xp parameter – proportional control range of valve (10K)

T (°C)

°

100% closing

Xp = 10K

55

T 50

=

set

50

45

permanent

valve opening

permanent

valve opening

°C

45°C

Nearer the desired

temperature (50 ),

°C

shorter pulses.

impulse valve

opening

set temperature

impulse valve

opening

Nearer the desired

temperature (50 ),

shorter pulses.

impulse valve

closing

50°C

impulse valve

closing

opening area

closing area

°C

100% opening

permanent

valve closing

t

55°C

permanent

valve closing

When the temperature is

less than 45 , controller

°C

gives continuous signal

for opening mixing valve.

When the temperature is

between 45 and 50 ,

°C °C

controller pulsating

opens mixing valve.

Nearer the desired

temperature (50 ),

°C

shorter pulses.

90°

Xp =10K

When the temperature is

between 50 and 55 ,

controller pulsating

closes mixing valve.

Nearer the desired

temperature (50 ),

shorter pulses.

°C °C

°C

When the temperature is

higher than 55 ,

°C

controller gives

continuous signal for

closing mixing valve.

Note: when the button

for manual operation is

in <MAN> position,

controller stays in

temporary position

irrespective of control

signal.

www.first.si

Examples:

UNI TEMP UNI TEMP

FIRŠT-ROTOTEHNIKA, s.p.,

Radegunda 54, 3330 Mozirje

info@first.si, http://www.first.si

PE VELENJE:

Koroška c. 56a, 3320 Velenje

tel: 03 / 898 35 00, fax: 03 / 898 35 35

In compliance with standards

All our products fulfil the essential safety and protection requirements for CE conformity marking according to the

following directives: EMC directive: 2004/108/EEC / LV directive: 2006/95/EEC / PAH directive 2005/69/EEC.

In compliance with standards:

EN 60730-2-14; 1997 + A1:2001 + A11:2005 + A2:2008

EN60730-1:2000 + A12:2003 + A12:2004 + A14:2005 + A16:2007 + A2:2008

EN 55014-1:2006

EN 61000-3-2:2006

EN 61000-3-3:2006

EN 62233:2008

ZEK 01.2-08

Safety notes:

ź The actuator has been designed for use in stationary heating, ventilation and air-

conditioning systems and is not allowed to be used outside the specified field of

application, especially in aircraft or in any other airborne means of transport.

ź Caution power supply voltage – 24VAC.

ź It may only be installed by suitably trained personnel. All applicable legal or

institutional installation regulations must be complied with.

ź The device must be protected from moisture and is not recommended for use in

external applications.

ź The device may only be opened at the manufacturer's site. It does not contain any

parts that can be replaced or repaired by the user.

ź The cable must not be removed from the device.

ź The device contains electrical and electronic components and is not allowed to be

disposed of as household refuse. All locally valid regulations and requirements

must be observed.

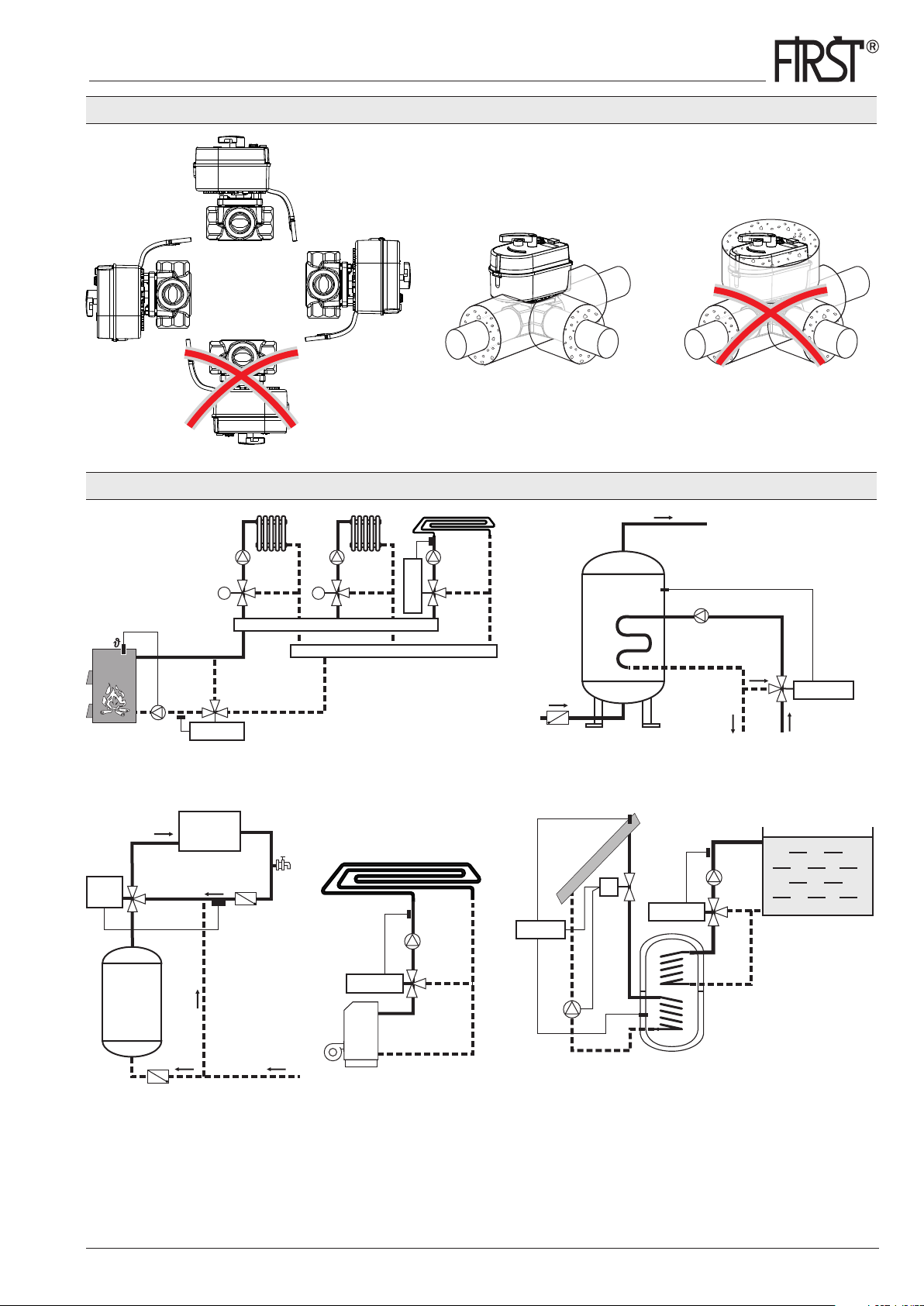

Recommended mounting position

Examples:

M M

UNI TEMP

Solid fuel boiler - Maintain a constant temperature in

heating circuit

UNI

TEMP

UNI TEMP

UNI TEMP

UNI TEMP

Maintain a constant temperature of heat reservoir

M

UNI TEMP

DTC10 0/2

Maintain a constant temperature in

sanitary water circuit

www.first.si 6

Floor heating - Maintain a

constant temperature of

heating circuit

Solar pool heating - Maintain a constant temperature of

heating circuit

ROTOTERM

FIRŠT-ROTOTEHNIKA, s.p.,

Radegunda 54, 3330 Mozirje

info@first.si, http://www.first.si

PE VELENJE:

Koroška c. 56a, 3320 Velenje

tel: 03 / 898 35 00, fax: 03 / 898 35 35

In compliance with standards

All our products fulfil the essential safety and protection requirements for CE conformity marking according to the

following directives: EMC directive: 2004/108/EEC / LV directive: 2006/95/EEC / PAH directive 2005/69/EEC.

In compliance with standards:

EN 60730-2-14; 1997 + A1:2001 + A11:2005 + A2:2008

EN60730-1:2000 + A12:2003 + A12:2004 + A14:2005 + A16:2007 + A2:2008

EN 55014-1:2006

EN 61000-3-2:2006

EN 61000-3-3:2006

EN 62233:2008

ZEK 01.2-08

Safety notes:

ź The actuator has been designed for use in stationary heating, ventilation and air-

conditioning systems and is not allowed to be used outside the specified field of

application, especially in aircraft or in any other airborne means of transport.

ź Caution power supply voltage – 24VAC.

ź It may only be installed by suitably trained personnel. All applicable legal or

institutional installation regulations must be complied with.

ź The device must be protected from moisture and is not recommended for use in

external applications.

ź The device may only be opened at the manufacturer's site. It does not contain any

parts that can be replaced or repaired by the user.

ź The cable must not be removed from the device.

ź The device contains electrical and electronic components and is not allowed to be

disposed of as household refuse. All locally valid regulations and requirements

must be observed.

Examples:

MR-TR

UNI

TEMP

M

Floor heating regulation

from radiator heating circuit

We reserve the right to modify the instructions and the technical data of the product without prior notice.

www.first.si 7

Loading...

Loading...