Page 1

B350LP PLUG-IN DETECTOR BASE

INSTALLATION INSTRUCTIONS

Before installing detectors, please thoroughly read the system wiring and installation manuals, and manual I56-407,

Guide for Proper Use of System Smoke Detectors,

zoning, and special applications. Copies of these manuals are available from Fire•Lite.

GENERAL DESCRIPTION

The B350LP Plug-in Detector Base is used with Fire•Lite models CP350 ionization, SD350 and SD350T photoelectronic detectors, and H350 and H350R heat detectors

The B350LP base is intended for use in a 2-wire addressable system, with screw terminals provided f or power (+ and –),

and remote annunciator connections. Communication takes place over the power (+ and –) lines.

BASE TERMINALS

NO. FUNCTION

1 Power (–), Remote Annunciator (–)

2 Power (+)

3 Remote Annunciator (+)

which provides detailed information on detector spacing, placement,

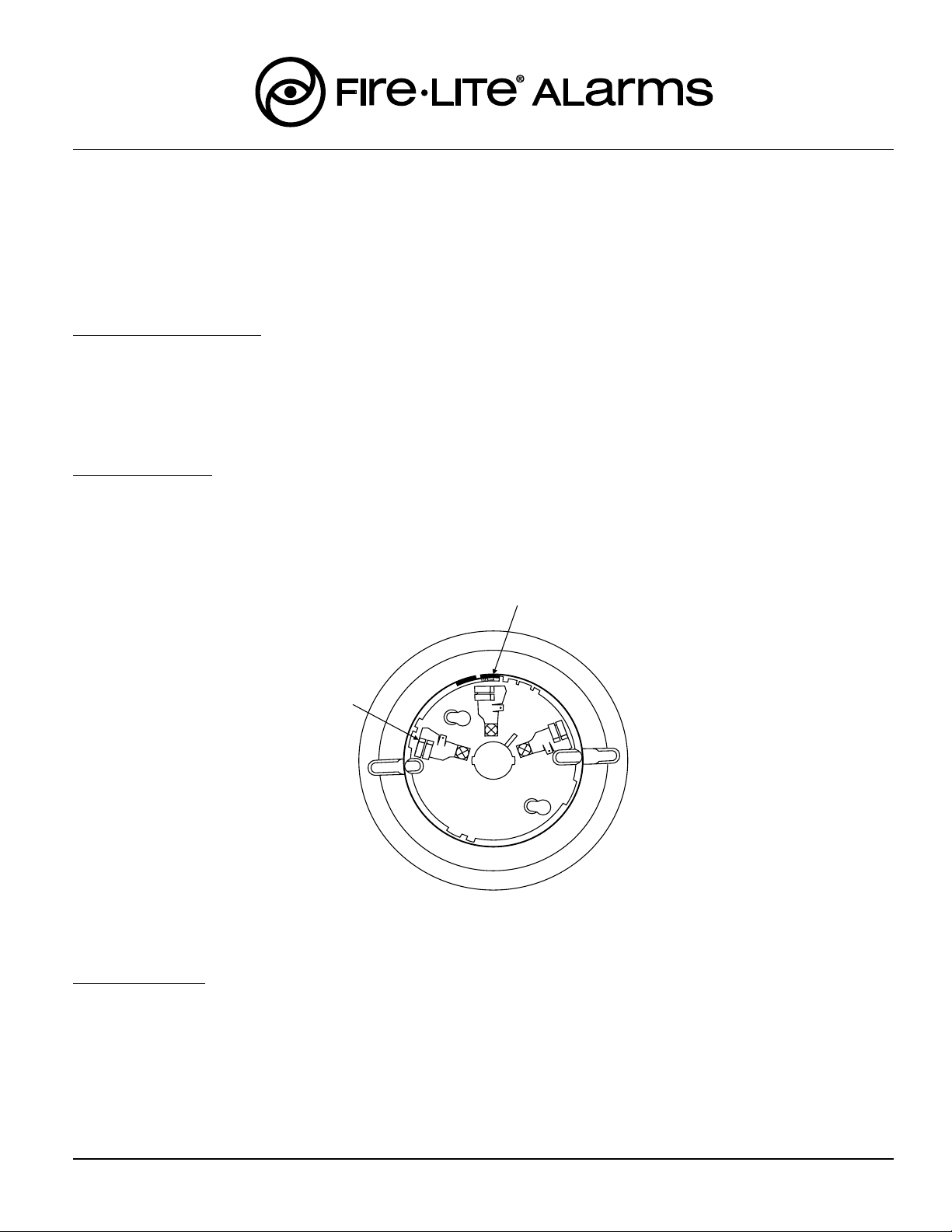

TAMPER PROOF

TAB

BASE

TERMINALS

2

3

1

Figure 1. Terminal Layout

SPECIFICATIONS

Diameter: 6.1 inches (155 mm)

Mounting: 4 inch (102 mm) square box with or without plaster ring

Min. Depth: 1.5 inches (38 mm)

4 inch Octagon Box, Min. Depth – 1.5 inches (38 mm)

3-1/2 inch Octagon Box, Min. Depth – 1.5 inches (38 mm)

Single Gang Box, Min. Depth – 1.5 inches (38 mm)

A78-1318-00

F400-21-00 1 I56-954-01R

Fire•Lite Alarms, Inc., One Fire•Lite Place, Northford, CT 06472, 203-484-7161

Page 2

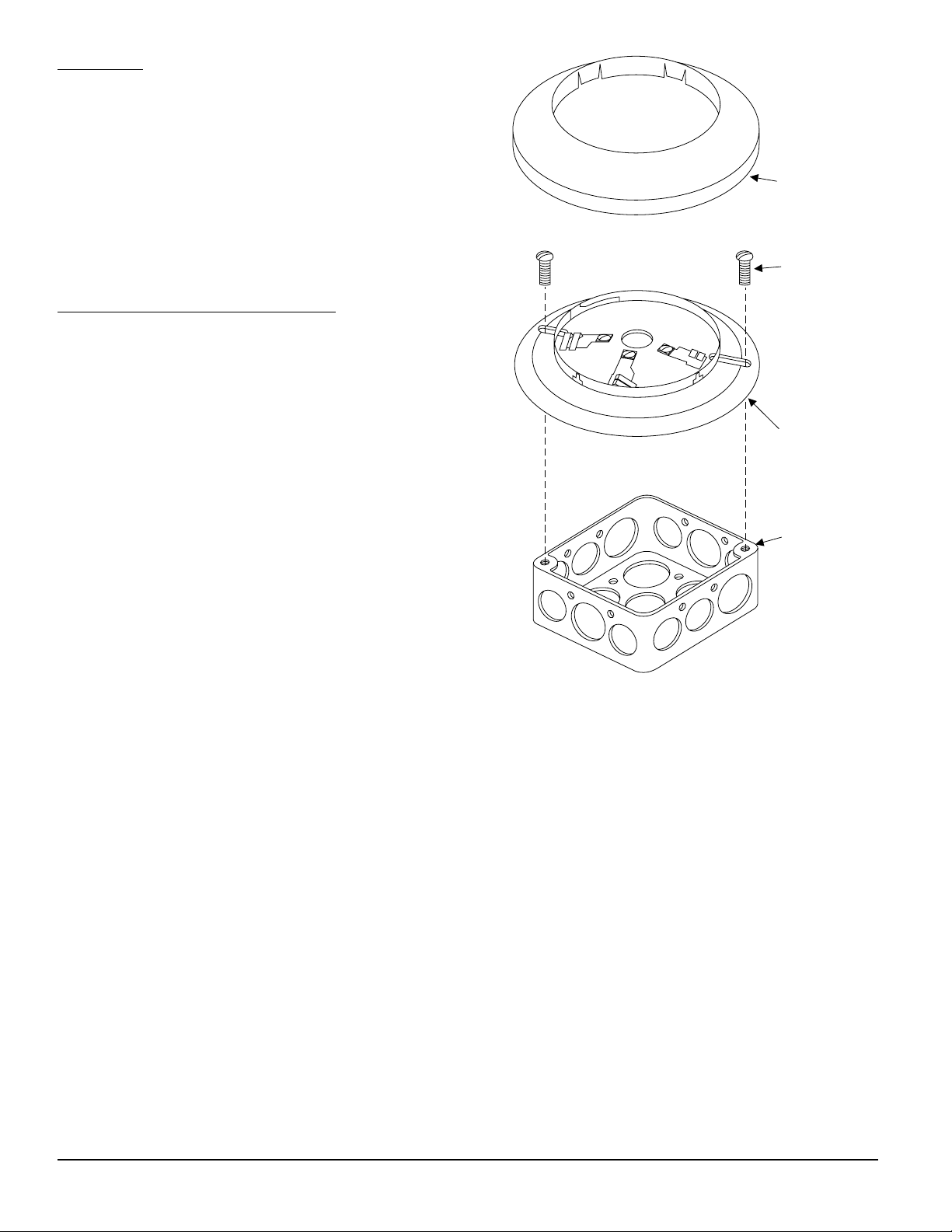

MOUNTING

SNAP ON

DECORATIVE

RING

SCREWS (NOT

SUPPLIED)

DETECTOR

BASE

BOX (NOT

SUPPLIED)

This detector base mounts directly to 3-1/2 inch and 4

inch octagon boxes , 4 inch square boxes (with or without plaster rings) and single gang boxes. To mount, remove the decorativ e ring by turning it in either direction

to unhook the snaps, then separate the ring from the

base. Install the base on the box using the scre ws supplied with the junction box and the appropriate mounting slots in the base. Place the decorative ring on the

base and rotate it in either direction until it snaps into

place (see Figure 2).

INSTALLATION WIRING GUIDELINES

All wiring must be installed in compliance with all applicable local codes and any special requirements of the

authority having jurisdiction, using the proper wire

size. The conductors used to connect smoke detectors

to control panels and accessory devices should be

color-coded to reduce the likelihood of wiring errors.

Improper connections can prevent a system from responding properly in the event of a fire.

For signal wiring (the wiring between interconnected

detectors), it is recommended that the wire be no

smaller than AWG 18. However, the screws and

clamping plate in the base can accommodate wire

sizes up to AWG 12. The use of twisted pair wiring or

shielded cable for the power (+ and –) loop is recommended to minimize the effects of electrical interference.

If shielded cable is used, the shield connection to and

from the detector must be continuous by using wire

nuts, crimping, or soldering, as appropriate for a reliable connection.

Make electrical connections by stripping about 3/8

molded in base), sliding the bare end of the wire under the clamping plate, and tightening the clamping plate screw. Do

not loop the wire under the clamping plate.

"

(10 mm) of insulation from the end of the wire (use strip gauge

Figure 2. Mounting Detector to Box

A78-1175-13

The zone wiring of the detector base should be checked before the detector heads are installed in them. The wiring

should be checked for continuity and polarity in the base, and dielectric tests should be performed.

The base includes a label for recording the zone, address, and type of detector being installed. This inf ormation is important to set the address of the detector head that will later be plugged into the base and to verify the type required for that

location.

F400-21-00 2 I56-954-01R

Page 3

REMOTE ANNUNCIATOR

+-

+

CAUTION: Do not loop wire under terminal 1 or 2.

Break wire run to provide supervision of connections.

2

3

1

A78-1253-00

CONTROL PANEL

U.L. LISTED COMPATIBLE

2

3

1

-

+

CLASS A OPTIONAL WIRING

2

3

1

Figure 3. Typical Wiring Diagram for 2-wire loop

TAMPER-RESISTANCE

Note: Do NOT use the tamper-resistant capability if the XR2 Removal Tool will be used.

The Tamper Resistant Tab, in the Detector Mounting Bracket, can make the detector tamper-resistant by making it necessary to use a small screwdriver or similar tool to detach the detector from the base.

To make the detector tamper-resistant, use needle-nose pliers to break the smaller tab at the scribed line on the tamper

resistant tab. Figures 1 and 4A show the location of this tab on the detector mounting bracket.

To remove the detector from the base after it has been made tamper resistant, remove the decorative ring by rotating it

in either direction and pulling it away from the base. Then, insert a small screwdriver into the notch, as indicated in Figure 4B, and press the plastic lever toward the mounting surface before rotating the detector counterclockwise for removal.

A78-1175-03

PLASTIC LEVER

BREAK TAB AT

DOTTED LINE BY

TWISTING TOWARD

CENTER OF BASE.

USE SMALL-BLADED

SCREWDRIVER TO

PUSH PLASTIC LEVER

IN DIRECTION OF

ARROW.

Figure 4A. Enabling the Figure 4B. Removing the Detector

Tamper-Resistant Capability Head from the Base

F400-21-00 3 I56-954-01R

Page 4

REMOTE ANNUNCIATOR, MODEL RA400Z

Connect the remote annunciator between terminals 1 and 3 using the spade lug terminal included. The spade lug terminal is connected to the base terminal as shown in Figure 5.

It is not acceptable for three stripped wires to be under the same wiring terminal unless they are separated by a washer

or a lug like the spade lug supplied with the model RA400Z. See Figure 5 for installation.

STRIPPED WIRE

WIRE WITH

SPADE LUG

A78-1473-00

Figure 5. Connection to Remote Annunciator Terminal.

Please refer to insert for the Limitations of Fire Alarm Systems

F400-21-00 4 I56-954-01R

©2000 Fire•Lite

Loading...

Loading...