Page 1

Annunciator

12 Clintonville Road

Northford, CT 06472

203-484-7161

FAX: 203-484-7118

Modules

for Fire•Lite

Fire Alarm Control Panels

Document # 15390

8/2/96 Revision:

P/N 15390:D ECN 9

D

Page 2

Installation Precautions

Adherence to the following will aid in problem-free

installation with long-term reliability:

WARNING - Several different sources of power can be

connected to the fire alarm control panel. Disconnect all

sources of power before servicing. Control unit and

associated equipment may be damaged by removing and/

or inserting cards, modules, or interconnecting cables while

the unit is energized. Do not attempt to install, service,

or operate this unit until this manual is read and understood.

CAUTION - System Reacceptance Test after Software

Changes: To ensure proper system operation, this product

must be tested in accordance with NFPA 72-1993 Chapter

7 after any programming operation or change in sitespecific software. Reacceptance testing is required after

any change, addition or deletion of system components,

or after any modification, repair or adjustment to system

hardware or wiring.

All components, circuits, system operations, or software

functions known to be affected by a change must be 100%

tested. In addition, to ensure that other operations are not

inadvertently affected, at least 10% of initiating devices

that are not directly affected by the change, up to a

maximum of 50 devices, must be tested and proper

system operation verified.

This system meets NFPA requirements for

operation at 0-49

humidity of 85% RH (non-condensing) at 30O C/86

F. However, the useful life of the system's standby

batteries and the electronic components may be

adversely affected by extreme temperature ranges

and humidity. Therefore, it is recommended that this

system and its peripherals be installed in an

environment with a nominal room temperature of 1527O C/60-80O F.

O

C/32-120O F and at a relative

O

Like all solid state electronic devices, this system may

operate erratically or can be damaged when subjected to

lightning induced transients. Although no system is completely

immune from lightning transients and interferences, proper

grounding will reduce susceptibility. Overhead or outside

aerial wiring is not recommended, due to an increased susceptibility to nearby lightning strikes. Consult with the Technical

Services Department if any problems are anticipated or encountered.

Disconnect AC power and batteries prior to removing or

inserting circuit boards. Failure to do so can damage circuits.

Remove all electronic assemblies prior to any drilling, filing,

reaming, or punching of the enclosure. When possible, make

all cable entries from the sides or rear. Before making

modifications, verify that they will not interfere with battery,

transformer, and printed circuit board location.

Do not tighten screw terminals more than 9 in-lbs. Over

tightening may damage threads, resulting in reduced terminal

contact pressure and difficulty with screw terminal removal.

This system contains static-sensitive components. Always

ground yourself with a proper wrist strap before handling any

circuits so that static charges are removed from the body. Use

static suppressive packaging to protect electronic assemblies

removed from the unit.

Follow the instructions in the installation, operating, and programming manuals. These instructions must be followed to avoid

damage to the control panel and associated equipment. FACP

operation and reliability depend upon proper installation.

Verify that wire sizes are adequate for all initiating and

indicating device loops. Most devices cannot tolerate

more than a 10% I.R. drop from the specified device

voltage.

Fire Alarm System Limitations

An automatic fire alarm system - typically made up of smoke

detectors, heat detectors, manual pull stations, audible warning devices, and a fire alarm control with remote notification

capability can provide early warning of a developing fire. Such

a system, however, does not assure protection against property damage or loss of life resulting from a fire.

Any fire alarm system may fail for a variety of reasons:

Smoke detectors may not sense fire where smoke cannot

reach the detectors such as in chimneys, in walls, or roofs, or

on the other side of closed doors. Smoke detectors also may

not sense a fire on another level or floor of a building. A

second floor detector, for example, may not sense a first floor

or basement fire. Furthermore, all types of smoke detectors

- both ionization and photoelectric types, have sensing limitations. No type of smoke detector can sense every kind of

fire caused by carelessness and safety hazards like smoking

in bed, violent explosions, escaping gas, improper storage of

flammable materials, overloaded electrical circuits, children

playing with matches, or arson.

IMPORTANT! Smoke detectors must be installed in the

same room as the control panel and in rooms used by the

system for the connection of alarm transmission wiring,

communications, signaling, and/or power. If detectors are

not so located, a developing fire may damage the alarm

system, crippling its ability to report a fire.

While installing a fire alarm system may make lower insurance rates possible, it is not a substitute for fire insurance!

Audible warning devices such as bells may not alert people

if these devices are located on the other side of closed or

partly open doors or are located on another floor of a building.

A fire alarm system will not operate without any electrical

power. If AC power fails, the system will operate from

standby batteries only for a specified time.

Rate-of-Rise heat detectors may be subject to reduced

sensitivity over time. For this reason, the rate-of-rise feature

of each detector should be tested at least once per year by

a qualified fire protection specialist.

Equipment used in the system may not be technically

compatible with the control. It is essential to use only

equipment listed for service with your control panel.

Telephone lines needed to transmit alarm signals from a

premise to a central monitoring station may be out of service

or temporarily disabled.

The most common cause of fire alarm malfunctions, however, is inadequate maintenance. All devices and system

wiring should be tested and maintained by professional fire

alarm installers following written procedures supplied with

each device. System inspection and testing should be scheduled monthly or as required by National and/or local fire codes.

Adequate written records of all inspections should be kept.

Technical Publishing Document PRECAUSM.PM6 07/12/96

Page 3

Table of Contents

Section One: Annunciators...........................................................................4

Section Two: Annunciator Inventory .............................................................5

Section Three: Design Considerations..........................................................8

Table 3-1: Typical Wire Resistance Chart...................................................8

Section Four: Annunciator Installation......................................................11

Figure 1: Installing the Enclosure.............................................................13

Figure 2: Terminating the Shield ..............................................................13

Figure 3: Slide-In Labels ..........................................................................16

Figure 4: Terminal Wiring ..........................................................................16

Figure 5: Mounting the Trim Ring .............................................................17

Figure 6: Applying the Annunciator Label ................................................17

Figure 7: Ann unciator Options .................................................................18

Figure 8: Main Power Supply Connections ...............................................19

Section Five: Operating the Annunciators ................................................20

Figure 9: Operating the AFM-16ATX........................................................20

Figure 10: Operating the AEM-16ATF......................................................21

Figure 11: Operating the AFM-32AX .......................................................22

Figure 12: Operating the AEM-32AF .......................................................23

Section Six: Annunciators and the Sensiscan 2000 .................................24

Figure 13: Connecting the EIA-485 Loop..................................................24

Figure 14: Configuring Annunciators f or Sensiscan 2000.........................26

Table 6-1: Annunciator Point Functions.....................................................27

Slide-in Labels..................................................................... Center of Manual

15390 Rev D 8/2/96 P/N 15390:D

3

Page 4

Section One: Annunciators

Fire•Lite annunciator modules provide the Sensiscan 2000 with up to 32 remote serially

connected annunciators, each with a capacity of 64 points.

The annunciator modules provide arrays of LEDs to indicate, at a remote location, the

status of circuits within the system. Annunciator points in a Sensiscan 2000 directly follow

the circuit arrangement of modules installed in the cabinet.

Control of common system functions such as signal silence, system reset, and local

annunciation controls (local acknowledge and lamp test) may be accomplished through

the annunciator's integral membrane push switches.

Communication between the FACP and the annunciators is accomplished over a powerlimited two-wire serial interface employing an EIA-485 communication standard. Power

is provided via a separate power-limited power loop from the control panel which is

inherently supervised by the FACP (loss of power results in an annunciator communication failure at the control panel). The annunciator can also be powered from a remote UL

listed power-limited power supply.

There are two basic annunciator types, alarm and alarm/trouble, each with its own

expander module.

4

15390 Rev D 8/2/96 P/N 15390:D

Page 5

Section T wo:

Annunciator Inventory

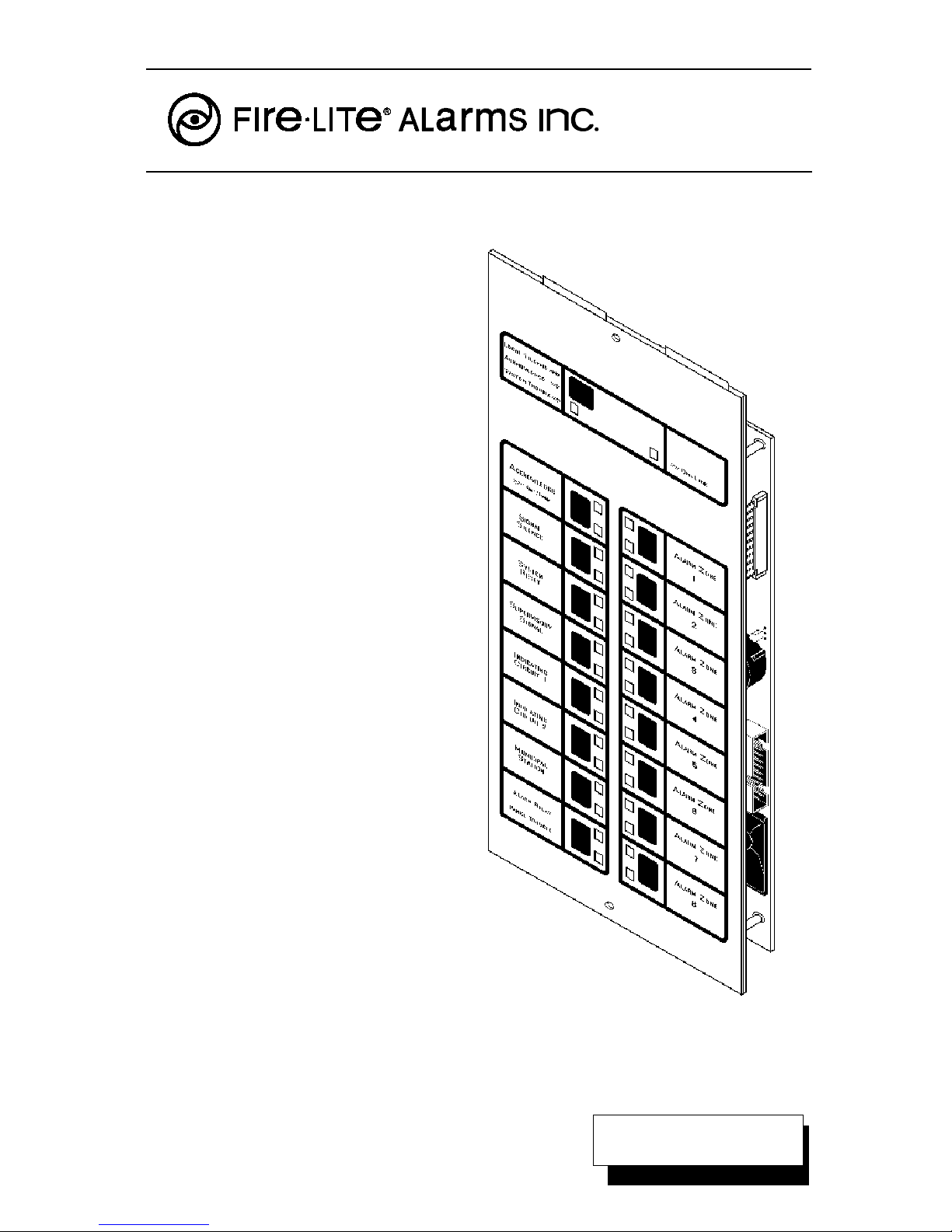

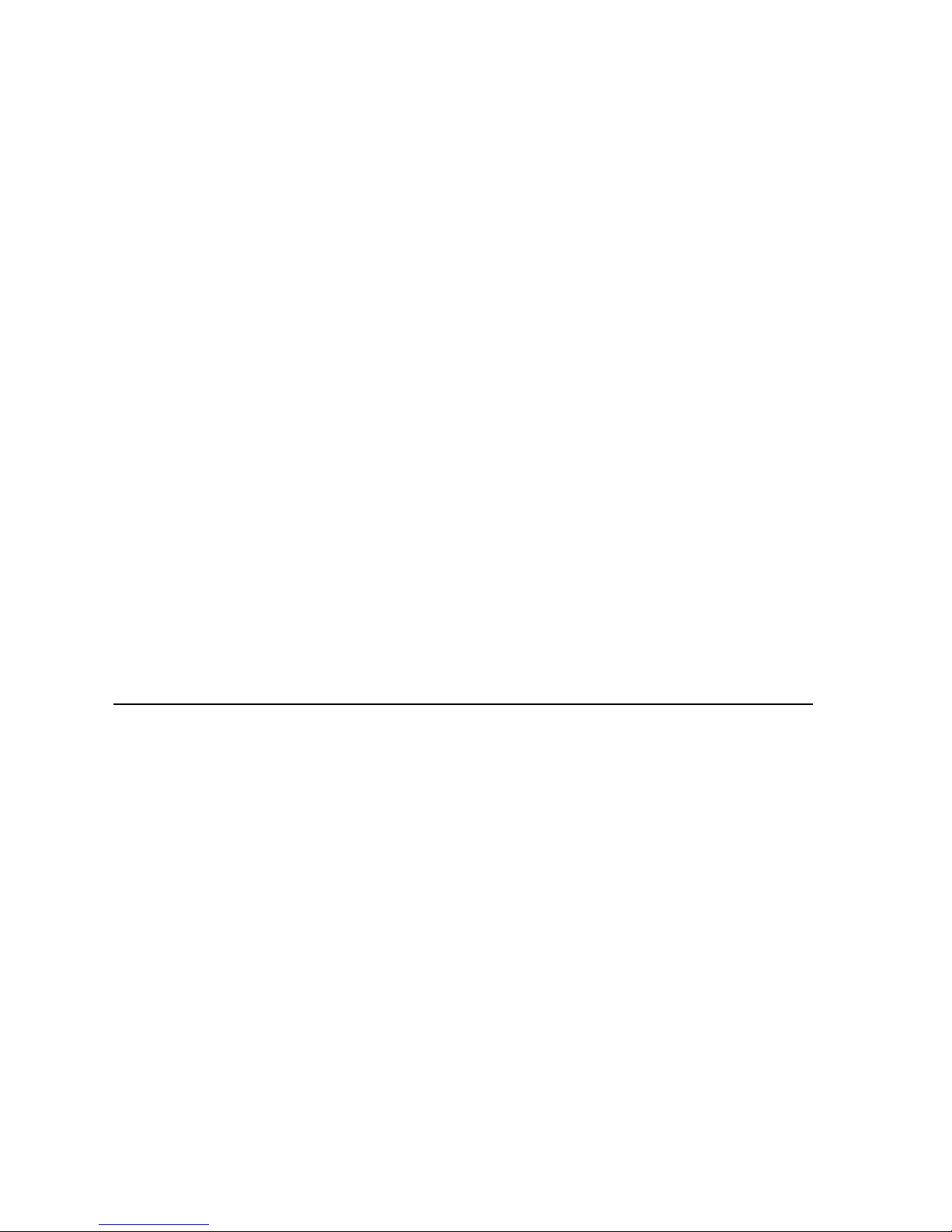

AFM-16ATX

The Annunciator Control Module-16ATX contains 16 red

alarm and 16 yellow trouble LEDs, 16 momentary touch-pad

switches for controlling each point, a system trouble LED,

an ON LINE/POWER LED, and a local piezo sounder with

a silence/acknowledge switch for audible indication of alarm

and trouble conditions at each annunciator.

AEM-16ATF

The Annunciator Expander Module-16ATF expands the

AFM-16ATX by 16 system points. The AEM-16ATF is

identical in size and in frontal appearance to the AFM16ATX. One to three of these expander modules can be

supported by an AFM-16ATX, to a maximum of 64 system

points. Note: The AEM-16ATF cannot be used to expand

the AFM-32AX.

ABM-16ATF

The Annunciator Blank Module-16ATF is a dress plate

identical in appearance to the front panel of the AFM-16ATX

and AEM-16ATF modules. The blank module is used to

cover unused module positions in an annunciator backbox.

AFM-32AX

The Annunciator Control Module-32AX contains 32 red

alarm LEDs, a system trouble LED, an ON LINE/POWER

LED, and a local piezo sounder with a silence/acknowledge

switch for audible indication of alarm and trouble conditions

at each annunciator.

AEM-32AF

The Annunciator Expander Module-32AF expands the AFM32AX by 32 system points. The AEM-32AF is identical in

frontal appearance to the AFM-32AX. One expander module can be supported by an AFM-32AX, providing a maximum of 64 points. Note: The AEM-32AF cannot be used to

expand the AFM-16ATX.

ABM-32AF

The Annunciator Blank Module-32AF is a dress plate identical in appearance to the front panel of the AFM-32AX and

AEM–32AF modules. The blank module is used to cover

unused module positions in an annunciator backbox.

15390 Rev D 8/2/96 P/N 15390:D

5

Page 6

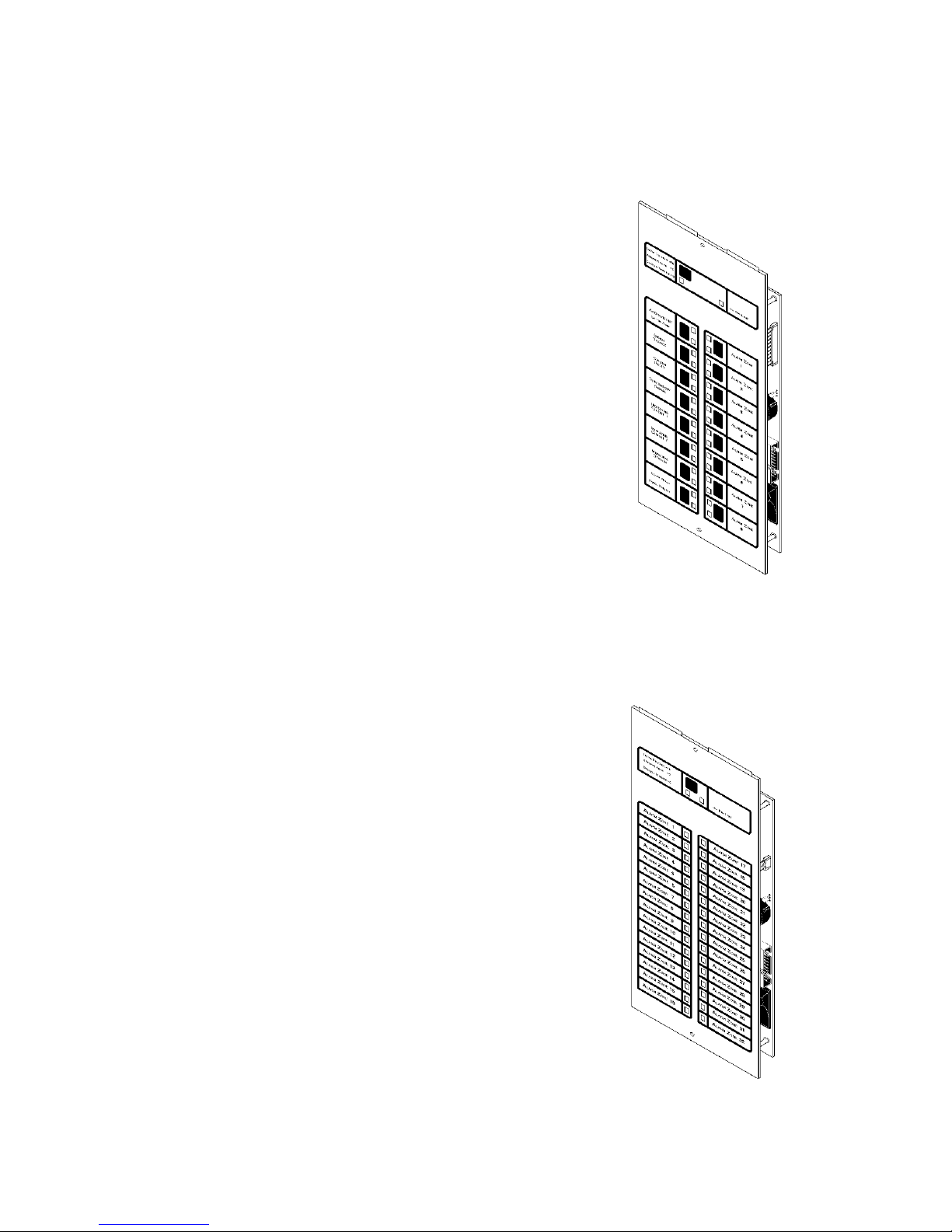

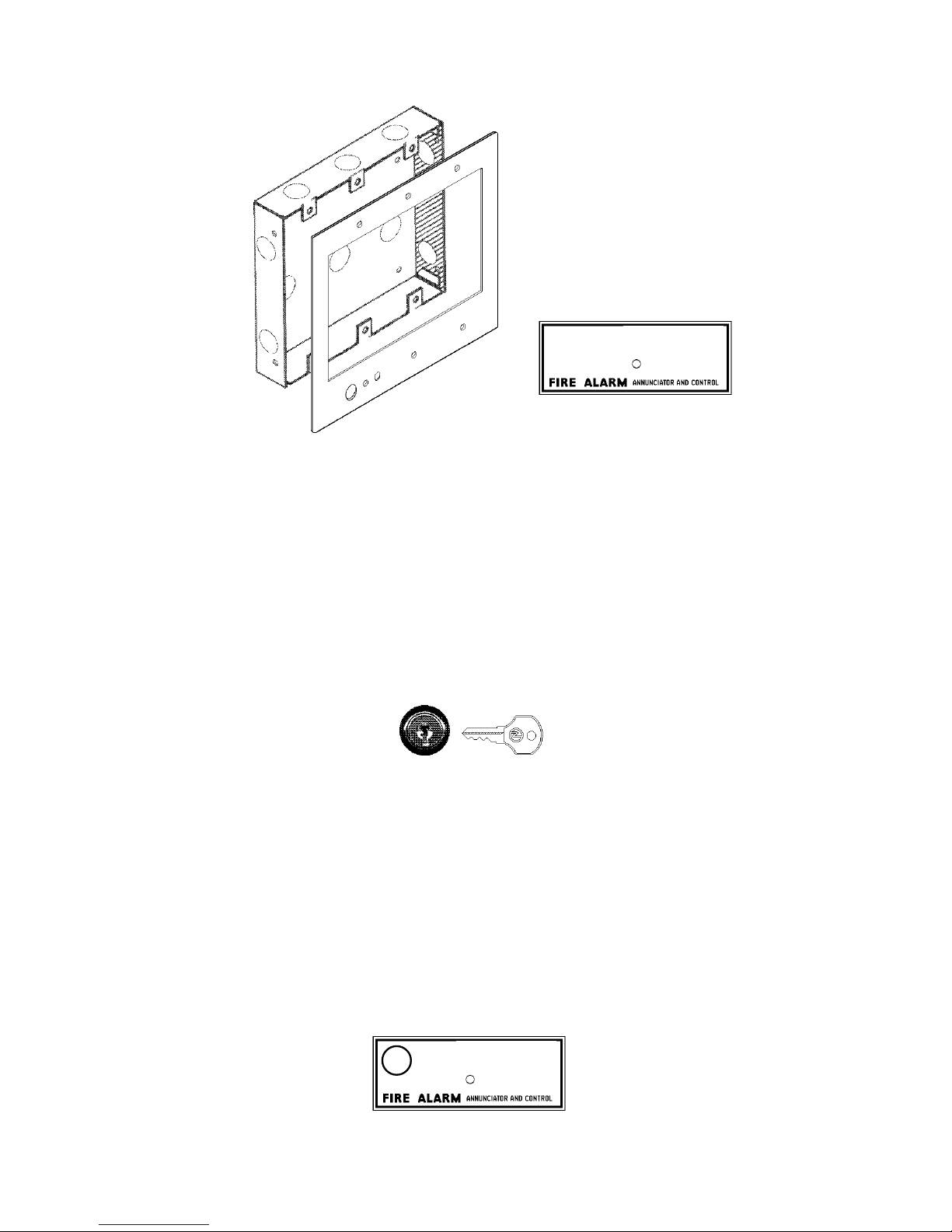

ABS-1F

The Annunciator Surface Box-1F provides for the remote mounting of a single AFM-16ATX or AFM-32AX annunciator in a surfacemount enclosure. Knockouts are provided for use with 1/2" conduit. The annunciator mounts directly to the ABS-1F without a

dress plate. (H = 8-1/2" W = 4-1/2" D = 1-3/8")

ABS-2F

(not illustrated)

The Annunciator Surface Box-2F provides for the surface mounting of one AFM-16ATX/AEM-16ATF combination or one AFM32AX/AEM-32AF combination. Knockouts are provided for use

with 1/2" conduit. The annunciator module mounts directly to the

ABS-2F without a dress plate. (H=8-1/2" W=8-15/16" D=1-3/8")

Note: The ABS-1F and ABS-2F will not support the installation of

the AKS-1F Annunciator Key Switch.

ABF-1F

The Annunciator Flush Box-1F provides for the

remote mounting of a single AFM-16ATX or

AFM-32AX annunciator in a flush-mount enclosure. Knockouts are provided for use with 1/2"

conduit. The ABF-1F includes a trim plate

(height=11" width=6-1/4"), mounting hardware,

and an adhesive-backed Annunciator Label for

the dress plate. (H = 9-15/16" W = 4-5/8" D =

2-1/2")

ABF-2F

(not illustrated)

The Annunciator Flush Box-2F provides for the

flush mounting of one AFM-16ATX/AEM-16ATF

combination or one AFM-32AX/AEM-32AF combination. Includes a trim plate (H=11" W=10-5/

8") and adhesive-backed Annunciator Label.

(H=9-15/16" W=9-3/16" D=2-1/2")

6

Annunciator Label

15390 Rev D 8/2/96 P/N 15390:D

Page 7

Annunciator Label

ABF-4F

The Annunciator Flush Box-4F provides for the remote mounting of one to four

AFM-16ATX/AEM-16ATF modules. Knockouts are provided for use with 1/2"

conduit. The flush-mounted ABF-4F includes a trim plate (H=11" W=19-3/8")

and an Annunciator Label. (H=9 - 15/16" W=17 - 3/8" D=2 - 1/2")

AKS-1F

The Annunciator Key Switch-1F provides access security for the control switches

on the AFM-16ATX. The key switch kit includes a key and hardware for mounting

to the trim plate of one of the flush-mount type annunciator enclosures. Also

included is an adhesive-backed Annunciator Label for use with the key switch/

dress plate assembly.

Note: The AKS-1F can only be employed with a flush-mount type backbox.

Annunciator Label

15390 Rev D 8/2/96 P/N 15390:D

7

Page 8

Section Three:

Design Considerations

Limits

Up to 32 annunciators may be installed on an EIA-485 circuit. The actual number of

annunciator modules may be larger depending on the number of expander modules

employed.

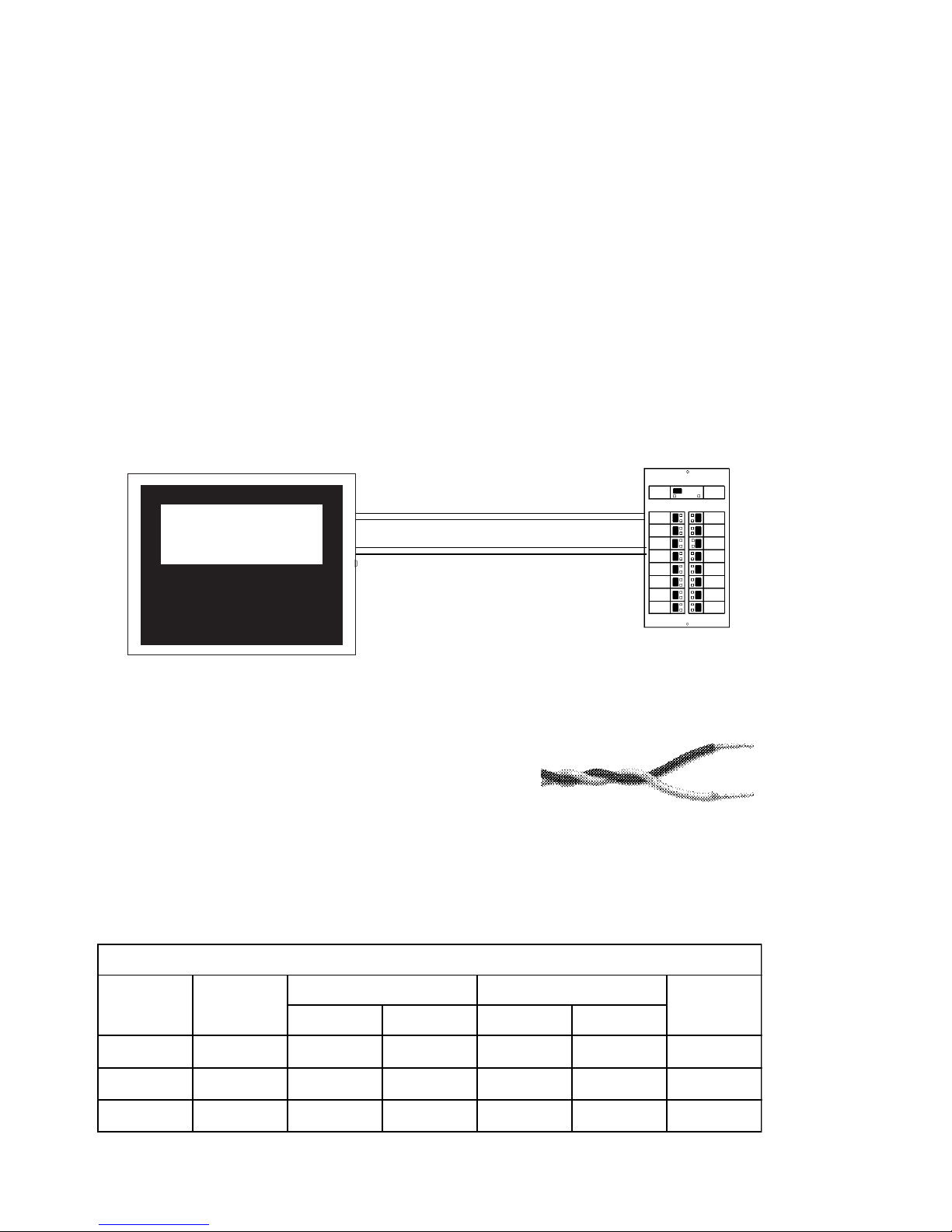

Wire Runs

Communication between the Control Panel and the annunciator is accomplished over a

power-limited two-wire EIA-485 serial interface. This communication, including the

wiring, is supervised by the fire alarm control panel. Power for the annunciators is

provided via a separate power-limited power loop from the control panel which is

inherently supervised (loss of power also results in a communication failure at the control

panel).

Fire Alarm Control Panel

Annunciator Power

(14 to 18 AWG )

Two-wire EIA-485 Circuit

(Maximum of 6,000 feet)

Annunciator

Wiring Specifications

The EIA-485 circuit cannot be T-Tapped; it must be wired in a continuous fashion from

the control panel to the annunciator. The maximum wiring distance between the

panel and the last annunciator is 6,000 feet @ 16 AWG.

The wiring size must be a 14 AWG to 18 AWG twisted

shielded pair cable having a Characteristic Impedance of

120 ohms, +/- 20%. Limit the total wire resistance to 100 ohms on the EIA485 circuit, and 10 ohms on the annunciator power circuit. Do not run cable adjacent to,

or in the same conduit as, 120 volts AC service, noisy electrical circuits that are powering

mechanical bells or horns, audio circuits above 25 volts (RMS), motor control circuits, or

SCR power circuits. Twisted-shielded wiring should be used for EIA-485 circuits that are

not contained entirely in conduit.

STANDARD ANNEALED COPPER WIRE

Wire Size

A.W.G.

14 64 4110 0.00323 2.58 2.97 12.4

16 51 2580 0.00203 4.09 4.73 7.82

18 40 1620 0.00128 6.51 7.51 4.92

Diameter in

Mils

Circ. Mils Sq. Inch @ 77 F. @ 149 F.

Table 3-1: Typical Wire Resistance Chart

8

Cross Section Ohms per 1000 ft.

15390 Rev D 8/2/96 P/N 15390:D

Pounds per

1000 ft.

Page 9

5

5

5

5

1234

1234

1234

1234

1234

1234

Receive Only Annunciators

For redundant annunciation of system points, annunciators can be configured as

"Receive Only" annunciators. Receive Only annunciators are not fully supervisable.

Receive Only annunciators intercept information being transmitted to a "Receive/

Transmit" annunciator so that information can be duplicated at an intermediate display

location. When configured for Receive Only operation, they cannot send information to

the system, therefore they cannot perform remote functions such as Acknowledge,

Silence, or Reset. Control switches on Receive Only annunciators can be used only for

local functions, such as lamp test. Wiring to Receive Only annunciators may be

supervised by installing the modules "upstream" of fully-supervised Receive/Transmit

annunciators along the EIA-485 line.

Receive/Transmit Annunciators

Annunciators that are configured to serve as full function annunciators can both receive

status information as well as transmit commands to the control panel. This allows the

annunciator to remotely execute functions of the control panel in addition to displaying the

status of the system.

Fire Alarm

Control Panel

Two-wire

EIA-485

Circuit

"Receive Only" Annunciator

Annunciator Expander

Full Function "Receive/

Transmit"

234

234

234

234

15390 Rev D 8/2/96 P/N 15390:D

Annunciator Expander

9

Page 10

Electrical Ratings

Input Voltage: 24 volts DC (power-limited).

Current Draw from 24 volt DC Input: Standby Alarm

AFM-16ATX/AFM-32AX 0.040 amps 0.056 amps

AEM-16ATF/AEM-32AF 0.002 amps 0.018 amps

Data Communications Port: EIA-485 operating at 20 Kbaud (power-limited).

Annunciator Power Requirements

Annunciators draw their power from the control panel and must be considered when

calculating the primary and secondary power supply requirements for the system. Each

annunciator module is accounted for in the power calculations outlined in the respective

installation manual. However, if the current draw dedicated to the annunciators must be

calculated as a separate figure, use the equations below.

Column A

Number of AFM modules [ ] X 0.040 = amps

The 0.040 amps can be reduced to 0.030 for modules

with Piezo Disable or Flash Inhibit modes selected.

Number of AEM modules [ ] X 0.002 = amps

Column B

Sum Column A for Total Annunciator Standby Current = amps

Number of AFM and AEM modules assumed to be

in alarm simultaneously [ ] X 0.018 = amps

Entering the total

Number of AFM and AEM modules

in above will allow for the

simultaneous illumination of all LEDs. When the alarm system specification permits,

calculations can be based on a 10% alarm loading capacity. For 10% capacity, enter 10%

of the total number of AFM and AEM modules multiplied by the number of remote

annunciator locations, but do not enter less than one.

Sum Column B for Total Annunciator Alarm Current = amps

The Total Annunciator Alarm Current cannot exceed 200 mA from the MPS-24BF, or

1 amp from the MPS-24AF.

10

15390 Rev D 8/2/96 P/N 15390:D

Page 11

Section Four:

Annunciator Installation

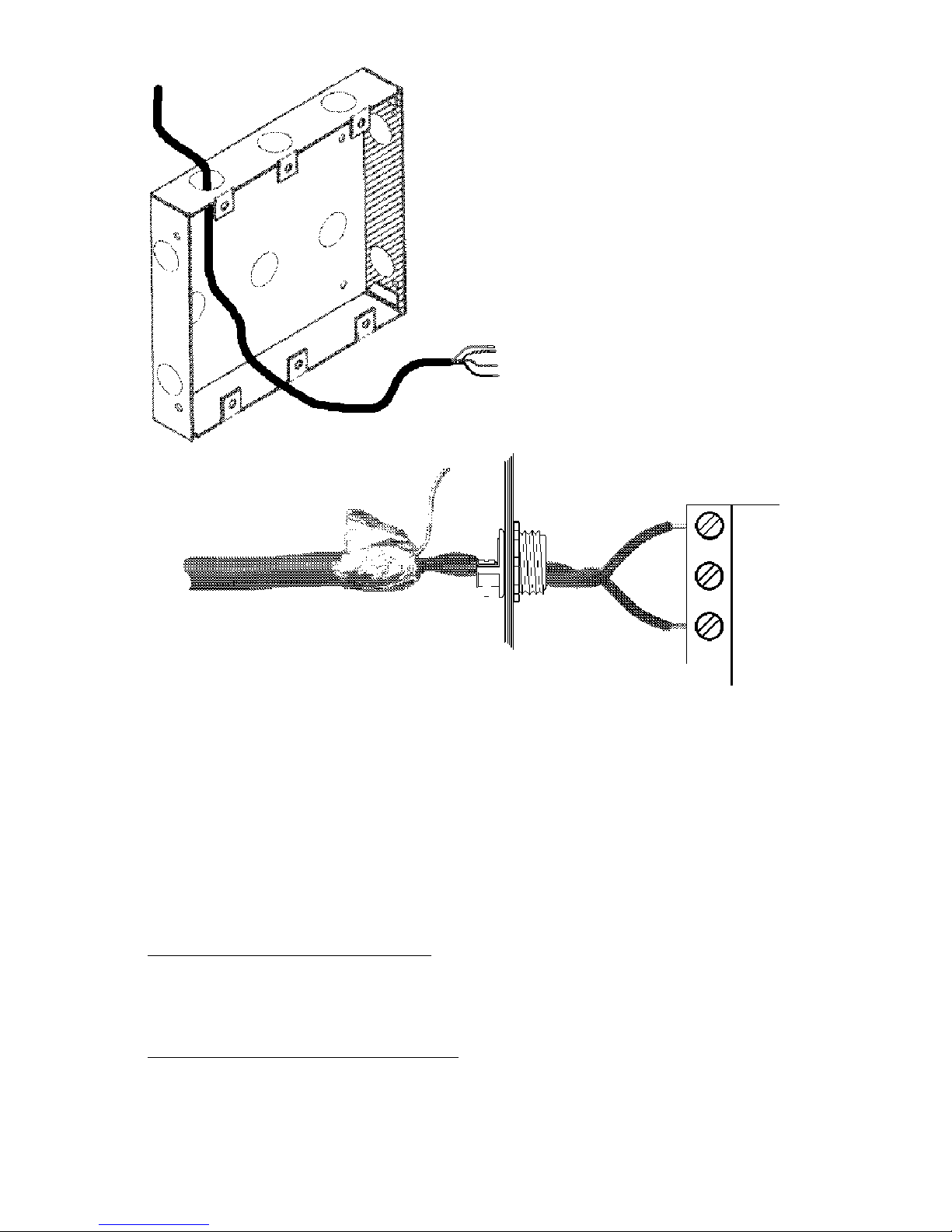

Mounting the cabinet or backbox

Select an appropriate knockout on the enclosure. Mount the cabinet or backbox. Ground

the enclosure to a solid metallic ground, such as a grounded cold water pipe. Pull all

annunciator wiring into the enclosure as illustrated in Figures 1 and 2. Connect

annunciator wiring to the removable terminal blocks as illustrated in Figure 4.

Note: A 120-ohm End-of-Line Resistor (Part Number 71244 supplied with the annunciator) must be installed at the last annunciator on the EIA-485 circuit. Remove the ELRs

installed on all annunciators except the last.

Installing the annunciators

Insert the custom display labels into the annunciator and expanders (see Figure 3). Set

the dip switches on the AFM-32AX or AFM-16ATX annunciator as outlined in Section Six.

Turn the dress plate over and place down on a surface with the threaded studs facing up.

Position the AFM-32AX or AFM-16ATX annunciator over the threaded studs on the dress

plate and secure with the two nuts and lock washers provided as illustrated in Figure 5.

ABF-1F Installation Only

Remove the backing from the gummed Annunciator Label and affix the label to

the dress plate as illustrated in Figure 6. If employing an AKS-1F, mount to the

dress plate. Plug the AKS-1F switch leads to Connector J4 on the Annunciator

(see Figure 7). Plug the two annunciator terminal blocks into the annunciator.

Place the annunciator/dress plate assembly into the backbox and secure with

two screws.

Annunciator installation in an ABF-1F is complete.

ABF-2F/ABF-4F Installation Only

Remove the backing from the gummed Annunciator Label and affix the label to

the dress plate as illustrated in Figure 7. If employing an AKS-1F, mount to the

dress plate. Plug the AKS-1F switch leads to Connector J4 on the Annunciator.

Installing the expanders

Plug one end of an Annunciator Expander Ribbon Cable into Connector J2 on the AFM32AX or AFM-16ATX. Install the first AEM-16ATF or AEM-32AF expander module in the

second dress plate position. Connect the expander ribbon from the annunciator to

Connector J3 on this expander.

ABF-2F Installation Only

Plug the two annunciator terminal blocks into the AFM-16ATX or the first AFM32AX. Place the annunciator/dress plate assembly into the ABF-2F backbox.

Secure the assembly with the screws provided.

Annunciator installation in an ABF-2F is complete.

15390 Rev D 8/2/96 P/N 15390:D

11

Page 12

Completing expander connections

AFM-16ATX/AEM-16ATF

Installation Only

If installing one AFM-16ATX with three

AEM-16ATF expanders in the same dress

plate, perform the following installation

steps:

Connect one end of an expander ribbon

to Connector J2 on the first expander.

Install the second AEM-16ATF expander

in the third dress plate position. Connect

the other end of the expander ribbon

from the first expander to Connector J3

on the second expander.

Connect one end of a ribbon cable to

Connector J2 on the second expander.

Install the third AEM-16ATF expander in

the fourth dress plate position. Connect

the other end of the ribbon cable from the

second expander to Connector J3 on the

third expander.

Completing installation in a cabinet or an ABF-4F

Plug the two annunciator terminal blocks into the AFM-16ATX or the first AFM-32AX.

Place the annunciator/dress plate assembly into the cabinet or ABF-4F backbox. Secure

the assembly with the screws provided. Apply primary (AC) power, followed by

secondary (battery backup) power.

Programming and testing the annunciators

This completes annunciator installation. After programming the fire alarm control panel

to accept the annunciators, fully test the Annunciator Control System by ensuring that

each switch performs its intended function, that each LED lights, and that the annunciators can perform the functions outlined in the section, "Operating the Annunciator."

12

15390 Rev D 8/2/96 P/N 15390:D

Page 13

Figure 1:

Installing the Enclosure

Mount the backbox or cabinet and pull all annunciator wiring into the enclosure.

Enclosure

Annunciator

Figure 2: Terminating the Shield

The EIA-485 circuit must be wired using a twisted-shielded pair cable having a Characteristic Impedance of 120 ohms, +/- 20%. Do not run cable adjacent to, or in the same

conduit as, 120-volt AC service, noisy electrical circuits that are powering mechanical

bells or horns, audio circuits above 25 VRMS, motor control circuits, or SCR power circuits.

All enclosures, including the FACP backbox, must be connected to earth ground! Never

use the shield for grounding purposes.

Control Panel only.

When the EIA-485 shield is in conduit: connect it to system reference (

The shield can enter the cabinet, but must be insulated from the cabinet (not electrical

contact). Between annunciators, wire-nut multiple shields together (which can be inside

of the respective enclosure, but can not contact the enclosure.)

When the EIA-485 shield is not in conduit: Terminate the shield at the outside of the FACP

backbox (ground). Do not allow the shield to enter or even touch the cabinet. Between

annunciators, wire-nut multiple shields together

Terminate the EIA-485 shield at the Fire Alarm

system common).

outside of

the respective enclosures.

15390 Rev D 8/2/96 P/N 15390:D

13

Page 14

Remove center pages for Slide-In Labels

AFM-16ATX/AEM-16ATF Labels

Two labels are required for the AFM-16ATX/AEM-16ATF - one for the left-hand side and

one for the right-hand side of each module. Each label has a distinctive format.

Set A

Factory-printed zone labels:

These slide-in annunciator labels provide for alarm zones 1

through 56. A blank label for custom labeling is also included.

Set B

Factory-printed system/zone labels:

This set provides labels for system control functions such as

Acknowledge, Signal Silence, Supervisory, and alarm zones 1

through 56.

Set C

Custom labels:

These blank labels provide for customized information by the user.

If information is to be typed onto these labels, they should be

reproduced on a copy machine so that the entire page can be

inserted into a typewriter.

Effective Window Size

The size of the visible portion of an AFM-16ATX label window is 9/

16" high by 1" across. Using a pitch of 10 characters per inch at

six lines per inch, up to three lines of 10 characters each may be

typed within this window space.

1"

9/16"

14

15390 Rev D 8/2/96 P/N 15390:D

Page 15

Remove center pages for Slide-In Labels

AFM-32AX/AEM-32AF Labels

Two labels are required for the AFM-32AX/AEM-32AF - one for the left-hand side and one

for the right-hand side of the face plate. Each label has a distinctive format.

Set E

Factory-printed zone labels:

These slide-in annunciator labels provide for alarm zones 1

through 32.

Set F

Factory-printed system/custom labels:

These slide-in annunciator labels provide for system control

functions such as Acknowledge, Signal Silence, Supervisory, and

for custom information to be entered into the remaining 56 circuits.

Set G

Factory-printed system/zone labels:

These slide-in annunciator labels provide for system control

functions such as Acknowledge, Signal Silence, Supervisory, and

for alarm zones 1 through 56.

Set H

Custom User Labels:

These blank labels can be customized by the user. If information

is to be typed onto these labels, they should be reproduced on a

copy machine so that the entire page can be inserted into a

typewriter.

Effective Window Size

The size of the visible portion of an AFM-32AX/AEM-32AF label

window is 1/2" high by 1-3/8" across. Using a pitch of 10

characters per inch at six lines per inch, up to two lines of 13

characters may be typed within this window space.

1-3/8"

1/2"

15390 Rev D 8/2/96 P/N 15390:D

15

Page 16

Figure 3: Slide-In Labels

Remove the center pages of this manual. If

using the custom user display labels, type

the appropriate information on the labels.

Carefully cut out the labels and insert them

into the annunciator by slipping them into

the label slots on the back side of the

annunciator face plate.

Note: To ensure the best fit, cut directly

along the dotted line surrounding each label.

Figure 4: Terminal Wiring

• Do not "T-Tap" the EIA-485 circuit which must

be power-limited. It will not function properly.

Wire as shown below.

• Leave the 120-ohm resistor installed across

the EIA-485 Out terminals at the last annun-

ciator on the circuit (see below). Remove this

resistor from all other annunciators.

• Connect Earth Ground to a mounting screw

on the backbox or cabinet.

• Connect 24 VDC Power to the annunciator.

This power must be power-limited but need

not be supervised by a power supervision

relay since it is inherently supervised by the

control panel (loss of communications is registered during loss of power to the annunciator).

Control

Panel

First Annunciator Last Annunciator

EIA-485 In ( - )

EIA-485 Out ( - )

EIA-485 Out (+)

EIA-485 In (+)

Common In (-)

Common Out (-)

Power In (+24 VDC)

Power Out (+24 VDC)

Earth Ground

TB2

4

3

2

1

TB1

5

4

3

2

1

EIA-485 (-)

EIA-485 (+)

Wiring Multiple Annunciators (6000-ft max run)

16

-

-

TB2

+

+

15390 Rev D 8/2/96 P/N 15390:D

ELR

Part #

71244

-

-

TB2

+

+

Page 17

Figure 5: Mounting the Trim Ring

Position the annunciator over the threaded studs on

the dress plate and secure with two nuts and lock

washers provided.

AFM

Dress

Plate

Figure 6: Applying the Annunciator Label

Remove backing from adhesive-backed Annunciator Label and affix the

label to the bottom of the dress plate as illustrated.

Note: If an AKS-1F Annunciator Key Switch is to be installed, use the

label supplied with the kit.

15390 Rev D 8/2/96 P/N 15390:D

17

Page 18

Figure 7:

Annunciator Options

If employing an Annunciator Key Switch (AKS1F), mount the switch to the dress plate (ABF-1F

Dress Plate illustrated below). Plug the switch leads

from the AKS-1F into Connector J4 on the annunciator.

ABF-1F (back view)

18

15390 Rev D 8/2/96 P/N 15390:D

Page 19

Figure 8: Main Power Supply Connections

The annunciator can be powered by an MPS-24AF or an MPS-24BF. The power run to

the annunciator need not contain a Power Supervision Relay since loss of power is

inherently supervised through communication loss.

MPS-24AF Main Power Supply

Connect the power run for the AFM to MPS-24AF TB3 Terminals 1 (+) and 2 (-) (1 amp

max). The total amount of current drawn from these terminals cannot exceed that rating

in standby or in alarm.

24 VDC Power (+)

to AFM TB1-3

MPS-24AF

Common ( - )

to AFM TB1-5

MPS-24BF Main Power Supply

Connect the power run to MPS-24BF TB2 Terminals 1 (+) and 2 (-). No more than 200

mA current can be drawn from these terminals in standby or alarm.

24 VDC Power (+)

to AFM TB1-3

( - ) Common

to AFM TB1-5

MPS-24BF

15390 Rev D 8/2/96 P/N 15390:D

19

Page 20

Section Five:

Operating the Annunciators

For a complete description of annunciator operation for various specific applications,

refer to Sensiscan 2000 Manual, Document 15017.

Figure 9: Operating the AFM-16ATX

Local Silence/Acknowledge

Switch

This switch serves two purposes:

1) When pressed, it first lights all the LEDs on the

AFM-16ATX (except the On Line LED) and then

each expander and also sounds the piezo (provided it hasn't been disabled) for as long as the

switch is held down.

2) It acknowledges all status changes for both the

annunciator and the expanders. Flashing LEDs

will latch on solid and the piezo will be silenced.

On Line LED

This green indicator flashes during communication with the control panel.

System Trouble LED

This yellow indicator lights for all trouble conditions in the system (not just for those points or

zones mapped to the annunciator/expanders).

16 Annunciator Points

Note 1:

If the annunciator loses communication with the control panel, all the yellow trouble LEDs will

flash.

20

Control Switch

Functions as a local Lamp Test for the two LEDs

dedicated to a point.

Control switches can be used to execute such

system functions as ACKNOWLEDGE, SIGNAL

SILENCE, and SYSTEM RESET. Switches can

also be used to control the states of various output

circuits.

Red LED

Yellow LED

15390 Rev D 8/2/96 P/N 15390:D

Page 21

Figure 10: Operating the AEM-16ATF

Lamp Test Switch

When pressed, it lights all the LEDs on the AEM16ATF expander (except the On Line LED).

These LEDs are not functional on expanders.

Control Switch

Functions as a local Lamp Test for the two LEDs

dedicated to this point.

Control switches can be used to execute such

system functions as ACKNOWLEDGE, SIGNAL

SILENCE, and SYSTEM RESET. Switches can

also be used to control the states of various

output circuits.

Red LED

Yellow LED

16 Expander Points

Note 1:

If the annunciator loses communication with the control panel, all the yellow trouble LEDs will

flash.

Note 2:

Simultaneous manual activation of the two switches in any row of the annunciator or an expander will cause the state of all the points on that module to

change state.

15390 Rev D 8/2/96 P/N 15390:D

One row

21

Page 22

Figure 11: Operating the AFM-32AX

This switch serves two purposes:

Local Silence/Acknowledge

Switch

1) When pressed, it first lights all the LEDs on the

annunciator (except the On Line LED) then on the

expander and also sounds the piezo (provided it

hasn't been disabled) for as long as the switch is

held down.

2) It acknowledges all status changes for the

AFM-32AX. Flashing LEDs will latch on solid and

the piezo will be silenced.

On Line LED

This green indicator flashes during communication with the control panel.

System Trouble LED

This yellow indicator lights for all trouble conditions in the system (not just for those points or

zones mapped to the annunciator).

32 Annunciator Points

If the annunciator loses communication with the

control panel, the yellow System Trouble LED will flash.

22

Red Alarm LED

15390 Rev D 8/2/96 P/N 15390:D

Page 23

Figure 12: Operating the AEM-32AF

Lamp Test Switch

When pressed, it lights all the LEDs on the

expander (except the On Line LED).

These LEDs are not functional on expanders.

32 Annunciator Points

15390 Rev D 8/2/96 P/N 15390:D

Red Alarm LED

23

Page 24

Section Six:

Annunciators and the Sensiscan 2000

Capabilities

When installed with a Sensiscan 2000, an annunciator can annunciate the status of

initiating and notification circuits, relays, and several system control functions. Each

annunciator LED is automatically assigned to one and only one system point:

Circuits: IZ-8F, IZ-4F Initiating Device Circuits (alarm and trouble)

IC-4F/ICE-4F Notification Appliance Circuits (trouble)*

CR-4F/CRE-4F Control Relays (trouble)*

TC-2F circuits (trouble)*

TC-4F circuits (trouble)*

* Indication of output circuit activation can be obtained by programming the CPU for

"OUTPUT STATUS."

System Acknowledge

Controls: Signal Silence

System Reset

Activate Notification Circuits 1 and 2, the Remote Signalling

Municipal Tie circuit, and the Alarm Relay.

System Trouble Indication

Communication between the CPU and the Annunciator Control System is accomplished

over a two-wire EIA-485 serial interface. This communication circuit is supervised by the

FACP. Loss of communication results in "System Trouble" and "Module Failure"

indications at the FACP CPU.

Installation Requirements

The EIA-485 circuit that drives the annunciator must be connected to the CPU as

illustrated below.

Supervised and Power-limited

EIA-485 (-)

to AFM TB2 Terminal # 4

(+) EIA-485

to AFM TB2 Terminal # 1

Figure 13: Connecting the EIA-485 Loop

24

15390 Rev D 8/2/96 P/N 15390:D

Page 25

Installing Modules in the Sensiscan 2000:

The annunciator begins annunciation with the CPU and continues with the annunciation

of circuits on the module installed directly after the CPU. To ensure full employment of

annunciator points, mount Sensiscan 2000 modules that require annunciation in the CPU

row first, then in the second row, etc. Modules with circuits that need not be annunciated

by the AFM should be installed further down in the cabinet.

Note that without invoking the Eight-Point-Shift, the first eight points

would be dedicated to CPU functions, not circuits off of the first

module.

15390 Rev D 8/2/96 P/N 15390:D

25

Page 26

Figure 14: Configuring Annunciators for Sensiscan 2000

DIP switches must be set before the annunciator will operate properly.

Annunciator Key Switch

(AKS-1) Connector

DOWN POSITION = ON

DIP Switch

DIP Switch settings:

1. Not Used: This switch must be set "OFF".

None One Two Three

UP (OPEN) = OFF

DIP Switch

2. Expanders Installed: OFF ON OFF ON

3. Expanders Installed: OFF OFF ON ON

4. Eight-Point Shift: Set switch "ON" to shift the CPU functions from the first eight annunciator

positions to expander positions 57-64.

5. Receive Only: Set this switch "ON" for each annunciator that will provide the same information

as another annunciator in a different location (when two or more annunciators hold the same address,

all but one must be configured as "Receive Only" annunciators).

6. Piezo Disable: Set this switch "ON" to disable the piezo from sounding for any event.

7. Switch Inhibit: To disable the point control switches on the annunciator from executing system

control functions, set this switch "ON." When inhibited, the switches will serve as local Lamp Test

switches only. In addition, the Acknowledge/Lamp Test switch will function only in a local capacity,

unrecognized by the System.

Note: For Canadian applications, when annunciator point control

switches are enabled (Switch 7 'OFF'), the AKS-1F or a similar listed enclosure must be employed.

8. Flash Inhibit: Set this switch "ON" to disable the flashing of LEDs associated with unacknowledged events.

Flash Inhibit also disables the piezo from sounding.

26

15390 Rev D 8/2/96 P/N 15390:D

Page 27

Annunciator Operation

Annunciator points "track" or follow those system points they are programmed to

annunciate; they do not latch. Table 6-1 outlines the annunciation of various System

circuits and functions. Note: Control Switches marked "not used" will still function as local

LAMP TEST or local ACKNOWLEDGE switches for their respective points.

Table 6-1: Annunciator Point Functions

AFM-16ATX & AEM-16ATF

M

O

Circuit Type

IZ-8F circuit

IC-4F/ICE-4F circuit

D

U

L

CR-4F/CRE-4F circuit

E

S

C

P

U

2

0

0

TC-2F, TC-4F

VC-4F, DC-4F circuit

ANNUNCIATOR

POINT # 1

ANNUNCIATOR

POINT # 2

ANNUNCIATOR

POINT # 3

ANNUNCIATOR

POINT # 4

ANNUNCIATOR

POINT # 5

ANNUNCIATOR

POINT # 6

1

0

ANNUNCIATOR

POINT # 7

ANNUNCIATOR

POINT # 8

AFM-32AX

& AEM-32AF

Red LED

Indicates alarm

status of circuit

Indicates Activation

Indicates Activation

Indicates Activation

Indicates

System Alarm

not used

not used

not used

Indicates that Notification

Circuit 1 has been activated

Indicates that Notification

Circuit 2 has been activated

Indicates that the Remote

Signalling Municipal Tie

has been activated

Indicates that

the Alarm Relay

has been

activated

Yellow LED

3

Indicates trouble

status of circuit

Indicates trouble

status of circuit

Indicates trouble

status of relay

Indicates trouble

status of relay

System Trouble

Indicates that signals

have been silenced

Supervisory condition

Indicates trouble

status of circuit

Indicates trouble

status of circuit

Indicates trouble

status of circuit

Module Trouble,

Power Failure or

Disabled Circuit(s)

Indicates

not used

Indicates

Indicates

Control Switch

not used

Control

Notification Circuit

Controls

Relays

Remote Switch

Functions

Functions as an

ACKNOWLEDGE

Functions as a

SIGNAL SILENCE

Functions as a

SYSTEM RESET

not used

Controls Notification

Circuit 1

Controls Notification

Circuit 2

Controls

Remote Signalling

Municipal Tie

Controls

Alarm Relay

2

1 If the Eight-Point Shift (DIP switch # 4) is set "ON", the eight CPU functions will be shifted from

annunciator points 1 thru 8 to points 57 thru 64 (provided those points exist in the system).

2 These control switches are active only if all of these conditions are set:

a) Receive Only (DIP Switch # 5) is set to "OFF." b) Switch Inhibit (DIP Switch # 7) is set to "OFF."

3 If an IZ-8F or IZ-4F circuit is programmed on the system as a supervisory point,

yellow LEDs will be illuminated for a supervisory condition. Illumination of the yellow LED alone

indicates a trouble condition (open circuit) on the IZ-8F supervisory circuit.

4 If a UDACT-F is employed on a system with an annunciator, point assignments for the first eight

yellow LEDs on the annunciator will change. Refer to the UDACT-F Manual and the appropriate

FACP Manual.

15390 Rev D 8/2/96 P/N 15390:D

both

the red and

27

Page 28

28

15390 Rev D 8/2/96 P/N 15390:D

Page 29

Set A

Label 1

LOCAL SILENCE AND

ACKNOWLEDGE

Set A

Label 2

Set A

Label 3

LAMP TEST

Set A

Label 4

SYSTEM TROUBLE

Cut out along dotted line

and insert into the lefthand side of AFM-16ATX

ALARM ZONE

1

ALARM ZONE

2

ALARM ZONE

3

ALARM ZONE

4

ON-LINE

Cut out along dotted line

and insert into the righthand side of AFM-16ATX

ALARM ZONE

9

ALARM ZONE

10

ALARM ZONE

11

ALARM ZONE

12

Cut out along dotted line

and insert into the lefthand side of AEM-16ATF

ALARM ZONE

17

ALARM ZONE

18

ALARM ZONE

19

ALARM ZONE

20

Cut out along dotted line

and insert into the righthand side of AEM-16ATF

ALARM ZONE

25

ALARM ZONE

26

ALARM ZONE

27

ALARM ZONE

28

ALARM ZONE

5

ALARM ZONE

6

ALARM ZONE

7

ALARM ZONE

8

ALARM ZONE

13

ALARM ZONE

14

ALARM ZONE

15

ALARM ZONE

16

ALARM ZONE

21

ALARM ZONE

22

ALARM ZONE

23

ALARM ZONE

24

ALARM ZONE

29

ALARM ZONE

30

ALARM ZONE

31

ALARM ZONE

32

Page 30

Set E

Label 1

Set E

Label 2

Set F

Label 1

LOCAL SILENCE AND

ACKNOWLEDGE

SYSTEM TROUBLE SYSTEM TROUBLE

Cut out along dotted line

and insert into the lefthand side of AFM-32AX

ALARM ZONE 1

ALARM ZONE 2

ALARM ZONE 3

ALARM ZONE 4

ALARM ZONE 5

ALARM ZONE 6

ON-LINE

Cut out along dotted line

and insert into the righthand side of AFM-32AX

ALARM ZONE 17

ALARM ZONE 18

ALARM ZONE 19

ALARM ZONE 20

ALARM ZONE 21

ALARM ZONE 22

LOCAL SILENCE AND

ACKNOWLEDGE

Cut out along dotted line

and insert into the lefthand side of AFM-32AX

SYSTEM ALARM

IND. CIRCUIT 1

ND. CIRCUIT 2

I

ALARM ZONE 7

ALARM ZONE 8

ALARM ZONE 9

ALARM ZONE 10

ALARM ZONE 11

ALARM ZONE 12

ALARM ZONE 13

ALARM ZONE 14

ALARM ZONE 15

ALARM ZONE 16

ALARM ZONE 23

ALARM ZONE 24

ALARM ZONE 25

ALARM ZONE 26

ALARM ZONE 27

ALARM ZONE 28

ALARM ZONE 29

ALARM ZONE 30

ALARM ZONE 31

ALARM ZONE 32

UNICIPAL TIE

M

ALARM RELAY

ALARM ZONE 1

ALARM ZONE 2

ALARM ZONE 3

ALARM ZONE 4

ALARM ZONE 5

ALARM ZONE 6

ALARM ZONE 7

ALARM ZONE 8

Page 31

Set A

Label 5

Set A

Label 6

Set A

Label 7

Set A

Label 8

LAMP TEST

Cut out along dotted line

and insert into the lefthand side of AEM-16ATF

ALARM ZONE

33

ALARM ZONE

34

ALARM ZONE

35

Cut out along dotted line

and insert into the righthand side of AEM-16ATF

ALARM ZONE

41

ALARM ZONE

42

ALARM ZONE

43

LAMP TEST

Cut out along dotted line

and insert into the lefthand side of AEM-16ATF

ALARM ZONE

49

ALARM ZONE

50

ALARM ZONE

51

Cut out along dotted line

and insert into the righthand side of AEM-16ATF

ALARM ZONE

36

ALARM ZONE

37

ALARM ZONE

38

ALARM ZONE

39

ALARM ZONE

40

ALARM ZONE

44

ALARM ZONE

45

ALARM ZONE

46

ALARM ZONE

47

ALARM ZONE

48

ALARM ZONE

52

ALARM ZONE

53

ALARM ZONE

54

ALARM ZONE

55

ALARM ZONE

56

Page 32

Set F

Label 2

ON-LINE

Set F

Label 3

LAMP TEST

Set F

Label 4

Cut out along dotted line

and insert into the righthand side of AFM-32AX

Cut out along dotted line

and insert into the lefthand side of AFM-32AX

Cut out along dotted line

and insert into the righthand side of AFM-32AX

Page 33

Set B

Label 1

LOCAL SILENCE AND

ACKNOWLEDGE

Set B

Label 2

Set B

Label 3

LAMP TEST

Set B

Label 4

SYSTEM TROUBLE

Cut out along dotted line

and insert into the lefthand side of AFM-16ATX

ACKNOWLEDGE

System Alarm/Trouble

SIGNAL

SILENCE

SYSTEM

RESET

SUPERVISORY

SIGNAL

ON-LINE

Cut out along dotted line

and insert into the righthand side of AFM-16ATX

ALARM ZONE

1

ALARM ZONE

2

ALARM ZONE

3

ALARM ZONE

4

Cut out along dotted line

and insert into the lefthand side of AEM-16ATF

ALARM ZONE

9

ALARM ZONE

10

ALARM ZONE

11

ALARM ZONE

12

Cut out along dotted line

and insert into the righthand side of AEM-16ATF

ALARM ZONE

17

ALARM ZONE

18

ALARM ZONE

19

ALARM ZONE

20

INDICATING

CIRCUIT 1

INDICATING

CIRCUIT 2

MUNICIPAL

STATION

ALARM RELAY

PANEL TROUBLE

ALARM ZONE

5

ALARM ZONE

6

ALARM ZONE

7

ALARM ZONE

8

ALARM ZONE

13

ALARM ZONE

14

ALARM ZONE

15

ALARM ZONE

16

ALARM ZONE

21

ALARM ZONE

22

ALARM ZONE

23

ALARM ZONE

24

Page 34

Set G

Label 1

LOCAL SILENCE AND

ACKNOWLEDGE

Set G

Label 2

Set G

Label 3

LAMP TEST

SYSTEM TROUBLE

Cut out along dotted line

and insert into the lefthand side of AFM-32AX

SYSTEM ALARM

IND. CIRCUIT 1

ND. CIRCUIT 2

I

UNICIPAL TIE

M

ON-LINE

Cut out along dotted line

and insert into the righthand side of AFM-32AX

ALARM ZONE 9

ALARM ZONE 10

ALARM ZONE 11

ALARM ZONE 12

ALARM ZONE 13

ALARM ZONE 14

ALARM ZONE 15

Cut out along dotted line

and insert into the lefthand side of AEM-32AF

ALARM ZONE 25

ALARM ZONE 26

ALARM ZONE 27

ALARM ZONE 28

ALARM ZONE 29

ALARM ZONE 30

ALARM ZONE 31

ALARM RELAY

ALARM ZONE 1

ALARM ZONE 2

ALARM ZONE 3

ALARM ZONE 4

ALARM ZONE 5

ALARM ZONE 6

ALARM ZONE 7

ALARM ZONE 8

ALARM ZONE 16

ALARM ZONE 17

ALARM ZONE 18

ALARM ZONE 19

ALARM ZONE 20

ALARM ZONE 21

ALARM ZONE 22

ALARM ZONE 23

ALARM ZONE 24

ALARM ZONE 32

ALARM ZONE 33

ALARM ZONE 34

ALARM ZONE 35

ALARM ZONE 36

ALARM ZONE 37

ALARM ZONE 38

ALARM ZONE 39

ALARM ZONE 40

Page 35

Set B

Label 5

Set B

Label 6

Set B

Label 7

Set B

Label 8

LAMP TEST

Cut out along dotted line

and insert into the lefthand side of AEM-16ATF

ALARM ZONE

25

ALARM ZONE

26

ALARM ZONE

27

Cut out along dotted line

and insert into the righthand side of AEM-16ATF

ALARM ZONE

33

ALARM ZONE

34

ALARM ZONE

35

LAMP TEST

Cut out along dotted line

and insert into the lefthand side of AEM-16ATF

ALARM ZONE

41

ALARM ZONE

42

ALARM ZONE

43

Cut out along dotted line

and insert into the righthand side of AEM-16ATF

ALARM ZONE

49

ALARM ZONE

50

ALARM ZONE

51

ALARM ZONE

28

ALARM ZONE

29

ALARM ZONE

30

ALARM ZONE

31

ALARM ZONE

32

ALARM ZONE

36

ALARM ZONE

37

ALARM ZONE

38

ALARM ZONE

39

ALARM ZONE

40

ALARM ZONE

44

ALARM ZONE

45

ALARM ZONE

46

ALARM ZONE

47

ALARM ZONE

48

ALARM ZONE

52

ALARM ZONE

53

ALARM ZONE

54

ALARM ZONE

55

ALARM ZONE

56

Page 36

Set G

Label 4

Cut out along dotted line

and insert into the righthand side of AEM-32AF

ALARM ZONE 41

ALARM ZONE 42

ALARM ZONE 43

ALARM ZONE 44

ALARM ZONE 45

ALARM ZONE 46

ALARM ZONE 47

ALARM ZONE 48

ALARM ZONE 49

ALARM ZONE 50

ALARM ZONE 51

ALARM ZONE 52

ALARM ZONE 53

ALARM ZONE 54

ALARM ZONE 55

ALARM ZONE 56

Page 37

Set C

Label 1

LOCAL SILENCE AND

ACKNOWLEDGE

Set C

Label 2

Set C

Label 3

LAMP TEST

Set C

Label 4

SYSTEM TROUBLE

Cut out along dotted line

and insert into the lefthand side of AFM-16ATX

ON-LINE

Cut out along dotted line

and insert into the righthand side of AFM-16ATX

Cut out along dotted line

and insert into the lefthand side of AEM-16ATF

Cut out along dotted line

and insert into the righthand side of AEM-16ATF

Page 38

Set H

Label 4

Set H

Label 5 (extra)

LOCAL SILENCE AND

ACKNOWLEDGE

Set H

Label 6 (extra)

Cut out along dotted line

and insert into the righthand side of AEM-32AF

SYSTEM TROUBLE

Cut out along dotted line

and insert into the lefthand side of AFM-32AX

ON-LINE

Cut out along dotted line

and insert into the righthand side of AFM-32AX

Page 39

Set C

Label 5

Set C

Label 6

Set C

Label 7

Set C

Label 8

LAMP TEST

Cut out along dotted line

and insert into the lefthand side of AEM-16ATF

Cut out along dotted line

and insert into the righthand side of AEM-16ATF

LAMP TEST

Cut out along dotted line

and insert into the lefthand side of AEM-16ATF

Cut out along dotted line

and insert into the righthand side of AEM-16ATF

Page 40

Set H

Label 1

LOCAL SILENCE AND

ACKNOWLEDGE

Set H

Label 2

Set H

Label 3

LAMP TEST

SYSTEM TROUBLE

Cut out along dotted line

and insert into the lefthand side of AFM-32AX

ON-LINE

Cut out along dotted line

and insert into the righthand side of AFM-32AX

Cut out along dotted line

and insert into the lefthand side of AEM-32AX

Page 41

Limited W arranty

Fire-Lite® warrants its products to be free from defects in materials and w orkmanship

for eighteen (18) months from the date of manufacture, under normal use and

service. Products are date stamped at time of manufacture . The sole and exclusive

obligation of Fire-Lite

and labor, any part which is defective in materials or workmanship under normal

use and service. For products not under Fire-Lite

control, the warranty is eighteen (18) months from date of original purchase by

®

Fire-Lite

's distributor unless the installation instructions or catalog sets for th a

shorter period, in which case the shorter period shall apply. This warranty is void if

the product is altered, repaired or serviced by anyone other than Fire-Lite

authorized distributors or if there is a failure to maintain the products and systems

in which they operate in a proper and workable manner. In case of defect, secure

a Return Material A uthorization f orm from our customer service department. Return

product, transportation prepaid, to Fire-Lite

Connecticut 06472-1653.

®

is to repair or replace, at its option, free of charge for parts

®

manufacturing date-stamp

®

or its

®

, 12 Clintonville Road, Northford,

This writing constitutes the only warranty made by Fire-Lite

®

products. Fire-Lite

does not represent that its products will prevent any loss by

®

with respect to its

fire or otherwise, or that its products will in all cases provide the protection for

®

which they are installed or intended. Buyer acknowledges that Fire-Lite

is not an

insurer and assumes no risk for loss or damages or the cost of any inconvenience,

transportation, damage, misuse, abuse, accident or similar incident.

Fire-Lite

®

GIVES NO WARRANTY, EXPRESSED OR IMPLIED, OF

MERCHANTABILITY, FITNESS FOR ANY PARTICULAR PURPOSE, OR

OTHERWISE WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE

HEREOF. UNDER NO CIRCUMSTANCES SHALL Fire-Lite

®

BE LIABLE FOR ANY

LOSS OF OR DAMAGE TO PROPERTY, DIRECT, INCIDENTAL OR

CONSEQUENTIAL, ARISING OUT OF THE USE OF, OR INABILITY TO USE

®

Fire-Lite

PRODUCTS. FUR THERMORE, Fire-Lite® SHALL NOT BE LIABLE FOR

ANY PERSONAL INJURY OR DEATH WHICH MAY ARISE IN THE COURSE OF,

OR AS A RESUL T OF, PERSONAL, COMMERCIAL OR INDUSTRIAL USE OF ITS

PRODUCTS.

This warranty replaces all previous warranties and is the only warranty made by

Fire-Lite

®

. No increase or alteration, written or verbal, of the obligation of this

warranty is authorized.

"Fire-Lite" is a registered trademark.

Technical Publishing Document WARFSM-C.PM6 04/02/96

12 Clintonville Road,

Nor thford, CT 06472

Phone: (203) 484-7161

FAX: (203) 484-7118

Loading...

Loading...