OWNER’S

MANUAL FOR

OA SERIES FIREARMS

620-626 Old Pacific Hwy SE

Olympia, WA 98513

(360) 459-7940

WARNING

To avoid accidental firing, BE SURE WEAPON IS CLEAR. Failure to do so

could result in serious injury or death.

Be sure the cam pin is installed in the bolt group. If it isn’t, your

can still fire and will explode, causing injury or death.

DO NOT exchange or switch bolt assemblies from one OA-93/OA-96 to

another. It could cause damage to both you and your weapon. DO NOT

attempt to install a standard AR-15 or M-16 bolt or bolt carrier in your

93/OA-96.

DON’T OVERHEAT YOUR

OA-93/OA-96

Firing

barrel to the

in the chamber for any reason may cookoff (detonate) in as short a period as 10

seconds.

If the cookoff point is felt to be possible, CLEAR YOUR WEAPON AND

ALLOW IT TO COOL.

Sustained rate of fire for the OA-93/OA-96 is 12-15 rounds per minute. This is

the actual rateof fire that this weapon can continue to deliver for an

length of time

Sustained rate of fire should never be exceeded except under circumstances of

extreme urgency.

If your bolt fails to unlock and you try to free it by banging the receiver assembly, keep clear of the muzzle.

If there’s water in the barrel, don’t fire the weapon. It could explode.

If you experience a noticeable difference in sound or recoil, STOP FIRING.

Either condition could indicate an incomplete propellant burn and a bullet still

in the bore. Retract bolt slowly and remove fired cartridge case. Clear weapon

and check for unburned powder grains in the receiver or bore, and for a bullet

in the bore. Remove unburned propellant or bullet from bore before resuming

firing or barrel could explode. If bullet is lodged in bore, take your carbine to a

qualified gunsmith.

If your

rel, remove the round quickly. If you cannot remove the round within 10 sec-

onds, point the OA-93/OA-96 in a safe direction and wait 15 minutes. In this

way, you won’t be injured by a possible ammunition

pen within 10 seconds after contact with a hot chamber. Clear your

93/OA-96.

Use only authorized brass case ammunition that is manufactured in the U.S.A.,

to U.S. specifications. Do not use re-manufactured or imported ammunition.

Please read this manual carefully before attempting to use your OA-93/

OA-96.

Any attempt to do so will cause damage to both you and it.

OA-93/OA-96’s

will rapidly raise the temperature of the barrel to a critical point.

140

rounds, rapidly and continuously will raise the temperature of the

COOKOFF

without seriously overheating.

OA-93/OA-96

POINT. At this temperature, any live round remaining

stops firing with a live round in the chamber of a hot bar-

BARREL. Sustained firing of the

cookoff,

OA-93/OA-96

OA-

indefinite

which could hap-

OA-

TABLE OF CONTENTS

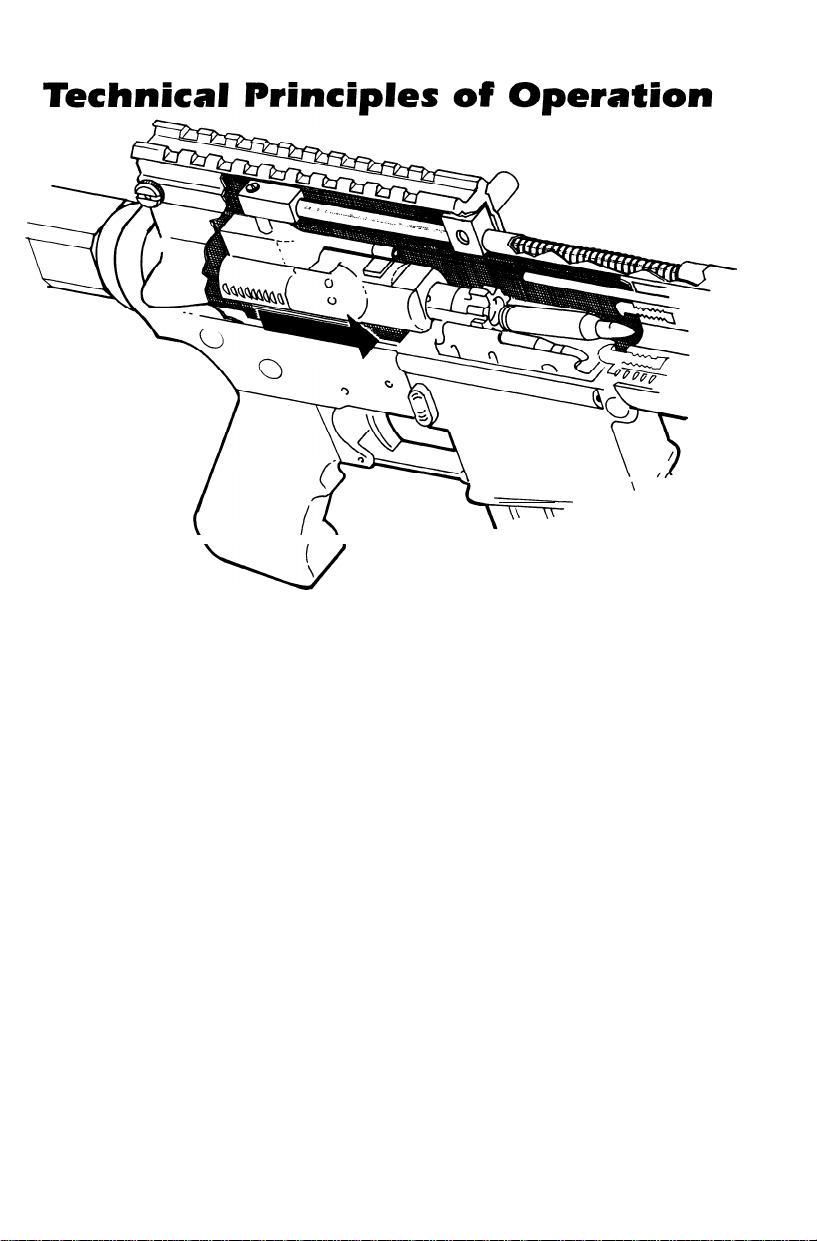

Technical Principles of Operation, OA-93 and OA-96 Series 4

Operating Instructions

Description and Use of Operator’s Controls 5

Loading 6-7

Chambering and Firing 8-9

Clearing 10-12

Operation under Unusual Conditions

Field Stripping

OA-93 Carbine Model 1 15

OA-93/OA-96

OA-93/OA-96 &

Exploded Views, Upper Receiver

Bolt Carrier Disassembly 20

Cleaning and Lubricating Upper Receiver and Barrel Assembly

Bolt Carrier Assembly

Lower Receiver

Bolt and Bolt Carrier Reassembly

Reassembly of OA-93 and OA-96 Series

Function Check

Exploded Views, Stock and Lower Receiver

THIS MANUAL covers all variants of the OA-93/OA-96 series, with separate instructions for all three models. Look at the end of the recoil rod

above the muzzle to determine which instructions to follow.

OA-93 /OA-96 All Models

-

Model 1

Carbine Model 2

33-34

13

14

16

17

18

22

23-25

26

27

29-31

32

OA-93 Carbine

Model 1

OA-93 & OA-96

Model 1

OA-93,OA-96 &

Carbine Model 2

NOTE:

The OA-93 series is an amorphous firearm, available in a variety of barrel

lengths and (depending upon federal restrictions) available with or without a folding stock. For these reasons, the terms

sometimes used interchangeably in this manual.

The OA-96 is a distinct sub-species of the OA-93 family. While it shares

many parts and procedures with the OA-93 series, it is not available with

a folding stock, it has no magazine release sub-assembly, and the magazine is pinned and welded in place. All items referring exclusively to the

OA-96 are marked with a star

(*)

and boxed with a double rule.

pistol

and carbine are

NOTE

Magazine may

8

-

be loaded with bolt assembly open or

closed.

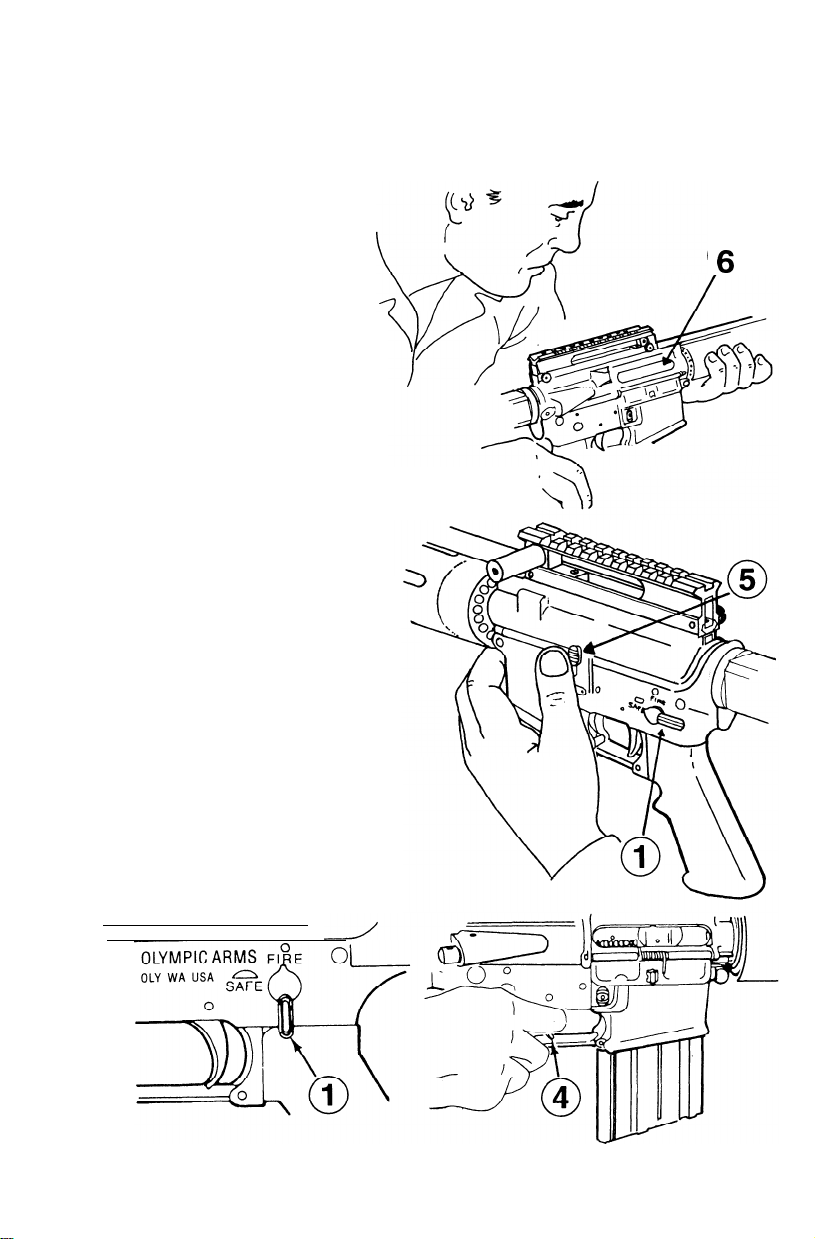

1. Place selector on SAFE.

2. Insert loaded cartridge magazine in magazine well (*OA-96: see page 5

for loading instructions).

.

Face the target, move the selector lever from SAFE to FIRE and bring

3

your weapon up to firing position.

.

Aim your weapon at the target and squeeze the trigger.

4

.

Squeezing the trigger releases the hammer, allowing it to impact the

5

firing pin, which strikes the primer in the round.

.

The primer ignites the propellant in the round.

6

.

Gas from the burning propellant pushes the projectile (bullet) along the

7

barrel of the weapon.

The rifling in the barrel causes the projectile to rotate, which provides

l

8

stability during flight to the target.

.

When the round reaches the approximate end of the barrel, expanding

9

gases from burning propellant pass out through the gas port and into

the gas tube. Gas goes into the bolt carrier assembly, ejects the old cartridge, and chambers a new round.

Operating instructions

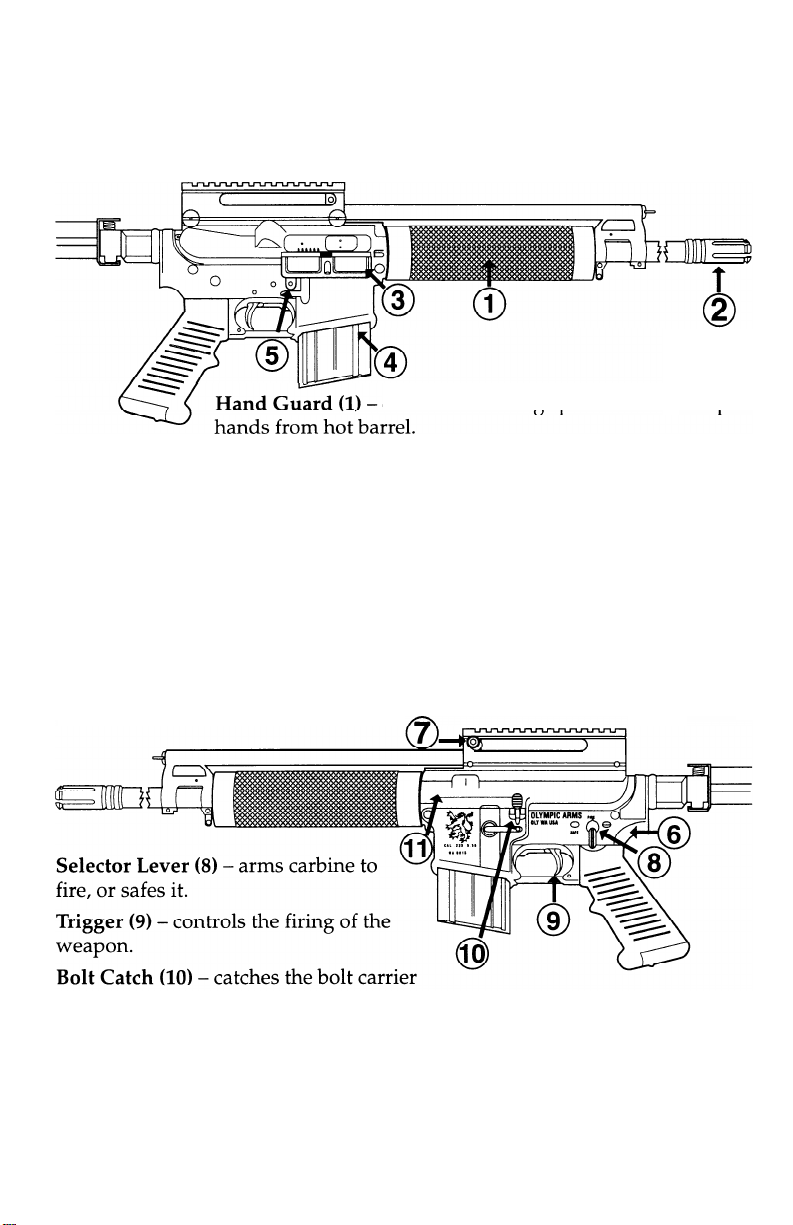

Description and Use of Operator’s Controls

and Indicators

offers checkered gripsurface

(2) -

Flash Suppressor

weapon is fired.

Ejection Port Cover

weapon is not in use. Keep port cover closed when not in use.

Cartridge Magazine

*Magazine Catch Button (5)

weapon when pushed (not present on OA-96).

Lower Receiver

Charging Lever

weapon, and is ambidextrous.

reduces the amount of flash from muzzle when

(3) -

protects upper receiver from foreign matter when

(4) -

supplies ammunition to weapon.

-

releases cartridge magazine (4) from

(6) -

provides firing control for the weapon.

(7) -

cocks weapon when preparing to fire or clearing

and

keeps

when the last round is fired.

Upper Receiver and Barrel Assembly (11)

ing. Houses bolt carrier and recoil assembly.

-

directs the projectile upon fir-

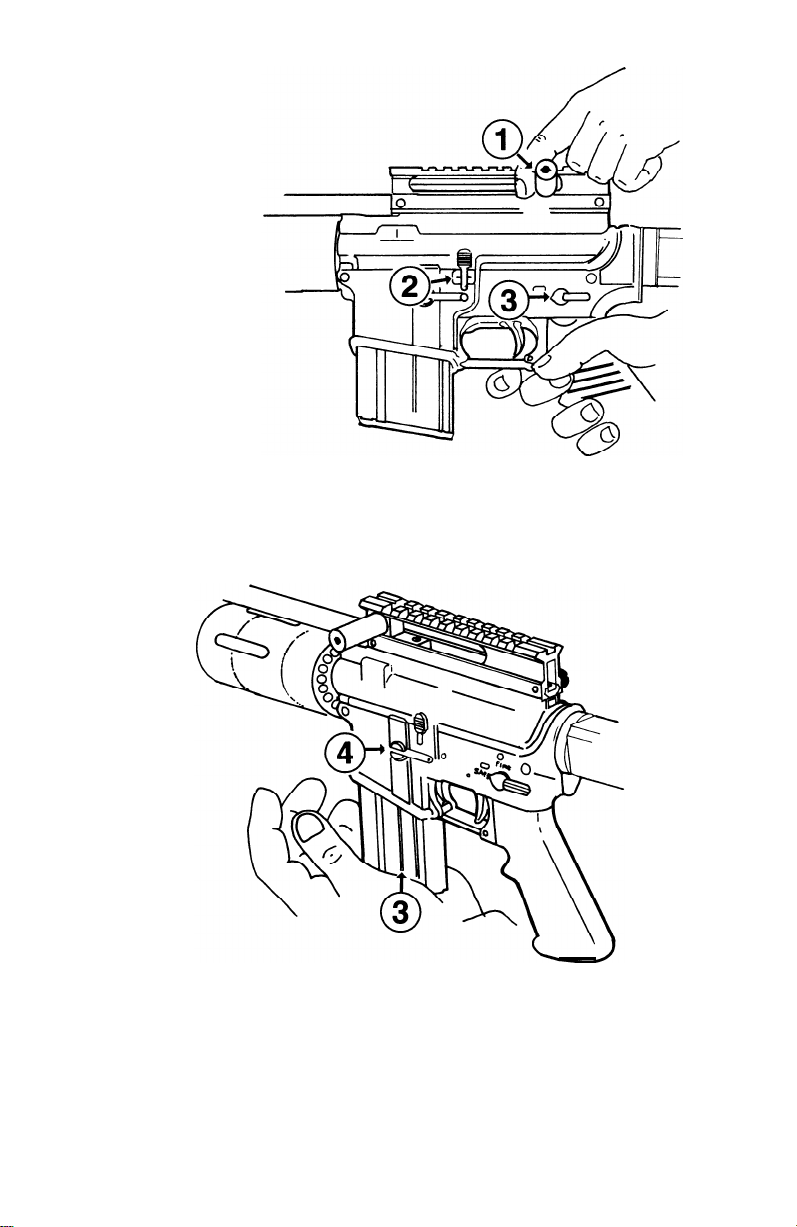

Loading

WARNING! Point

muzzle in

safe direction

1.

Pull charging lever assembly (1) rearward, lock bolt

charging lever. Place selector lever (3) on SAFE.

2.

Pull charging lever assembly (1) rearward and check to see that chamber

is clear. Release charging handle assembly.

a

(2),

and release

NOTE:

Magazine

may be loaded with bolt assembly open

or closed.

3.

Push upward on cartridge magazine (3) until magazine catch (4) engages

and holds cartridge magazine.

4.

Tap upward to make certain cartridge magazine is correctly seated.

*Loading

-

WARNING! Point muzzle

in a safe direction

1. Pull charging lever assembly

(1) rearward and check to see

that chamber is clear. Lock

bolt

(2),

and release charging

lever. Place selector lever (3)

on SAFE.

if

the chamber is

2.

Hold on to upper receiver, press release catch (4) and pivot upper

receiver up and forward. Cartridges may be inserted singly into

magazine well, or in groups of ten by using a stripper clip (5). Insert

stripper clip guide (6) into slot behind mag well and press stripper

clip down until top cartridge is below lip of magazine well. Remove

stripper clip guide.

Operating Procedure

Chambering and Firing a Round

BOLT ASSEMBLY OPEN

2.

1.

Depress upper portion of bolt

catch (1) to release the bolt.

Check charging lever (2) to ensure that bolt is fully forward.

OLYMPIC ARMS

OLY WA USA ssk-

3.

Move selector lever (3) to FIRE.

F,O E

A

01

/

4.

Squeeze the trigger (4) and fire.

Operating

Procedure

Chambering and Firing a Round

BOLT ASSEMBLY CLOSED

(continued)

3.

Release the charging lever (2).

5. Move the selector lever (1) to

FIRE.

4.

Never “ride” the charging lever

(2). Let it go on its own.

6. Squeeze the trigger (3) and

.

fire.

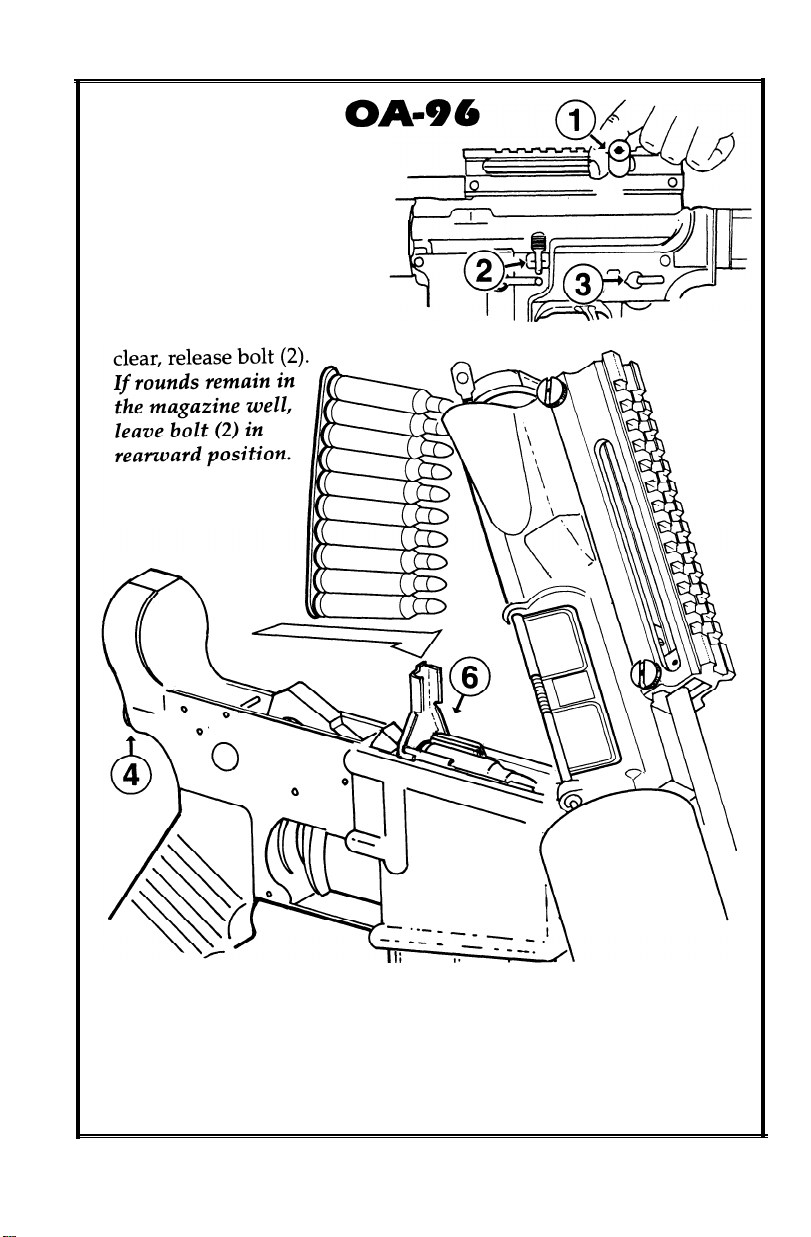

Operating Procedure

Clearing Your OA-93

-

(OA-96 Model

WARNING

To avoid accidental firing, always look into chamber after

clearing your weapon to make

sure it does not contain a round.

Place selector lever (1) on SAFE.

1.

NOTE: If weapon is not cocked,

lever cannot be pointed toward

SAFE.

2. Remove cartridge magazine (2)

by depressing magazine catch

button (3) and pulling cartridge

magazine (2) down.

Page 12)

OLYMPIC ARMS

OLY WA USA

=

F,:E

3.

To lock bolt open, pull charging

lever (4) rearward, press bottom

of bolt catch (5) and allow bolt to

move forward until it engages

bolt catch. Return charging lever

(4) forward.

Operating Procedure

Clearing Your OA-93

(OA-96

NOTE:

Ensure that selector lever is

pointed toward SAFE.

4

.

Check receiver and chamber

(6) to ensure these areas contain no ammunition.

5

.

With selector lever (1) pointing toward SAFE, allow bolt

to go forward by pressing

upper portion of bolt catch (5)

NOTE

If weapon is to be stored, it should

be dry-fired to release tension on

hammer spring.

Model - Page 12)

.

6

0

6.

Place selector lever (1) on FIRE

and squeeze trigger to release

tension on hammer spring (make

sure muzzle is pointed in a safe

direction).

* Clearing

your OA-96

WARNING! Point muzzle

in a safe direction

1.

Pull charging lever

assembly

lock bolt

charging lever. Place

selector lever (3) on

SAFE.

(1)

rearward,

(2),

and release

2. Press release

Cartridges may be stripped out of the magazine well with your

thumb.

catch (4) and pivot upper receiver up and forward.

Operation Under Unusual

Conditions

NOTE

Unusual conditions are defined as any climatic

condition requiring special maintenance of this

weapon.

Perform the maintenance outlined for the climate

that most applies to your operational area.

Hot, dry climates are usually dusty and sandy areas. They are hot during daylight hours and cool during the night hours.

Dust and sand will get into the weapon and will cause malfunctions and

A.

excessive wear on component working surfaces through abrasive action

during the firing operations.

B.Corrosion is less likely to form on metal parts in a dry climate; therefore,

lubricate internal working surfaces only with a small application of cleaner, lubricant and preservative (always shake CLP prior to use). Do not

lubricate external parts of the weapon. Doing so will only collect dust

and sand, making it more difficult to keep the OA-93/OA-96 clean. Do

not lubricate internal components of the magazines, or the magazine well

on the OA-96.

C. Using additional equipment

protective bags and overall protective cover will help keep dust and sand

from getting into the OA-93/OA-96. Use these items as the situation warrants. As a minimum precaution to keep dust and sand out of your

weapon, keep the ejection port cover closed, a cartridge magazine

installed, and a muzzle cap on your OA-93/OA-96.

NOTE: Before firing, remove the protective cap and keep for later use.

However, it is not dangerous to fire the weapon with the protective cap in

place; the cap will blow off when the first round is fired and may be lost.

HEAVY RAIN

Perform maintenance according to the appropriate climatic condition. Use

additional equipment

and over-all protective cover as the situation warrants. Always keep the

OA-93/OA-96 dry. Using the protective cap will help keep water out of the

barrel. Always drain any water from the barrel before firing. Dry the bore

with a swab and cleaning rod, if necessary

-

protective cap and spare magazine, protective bags

-

i.e., protective cap and spare magazine

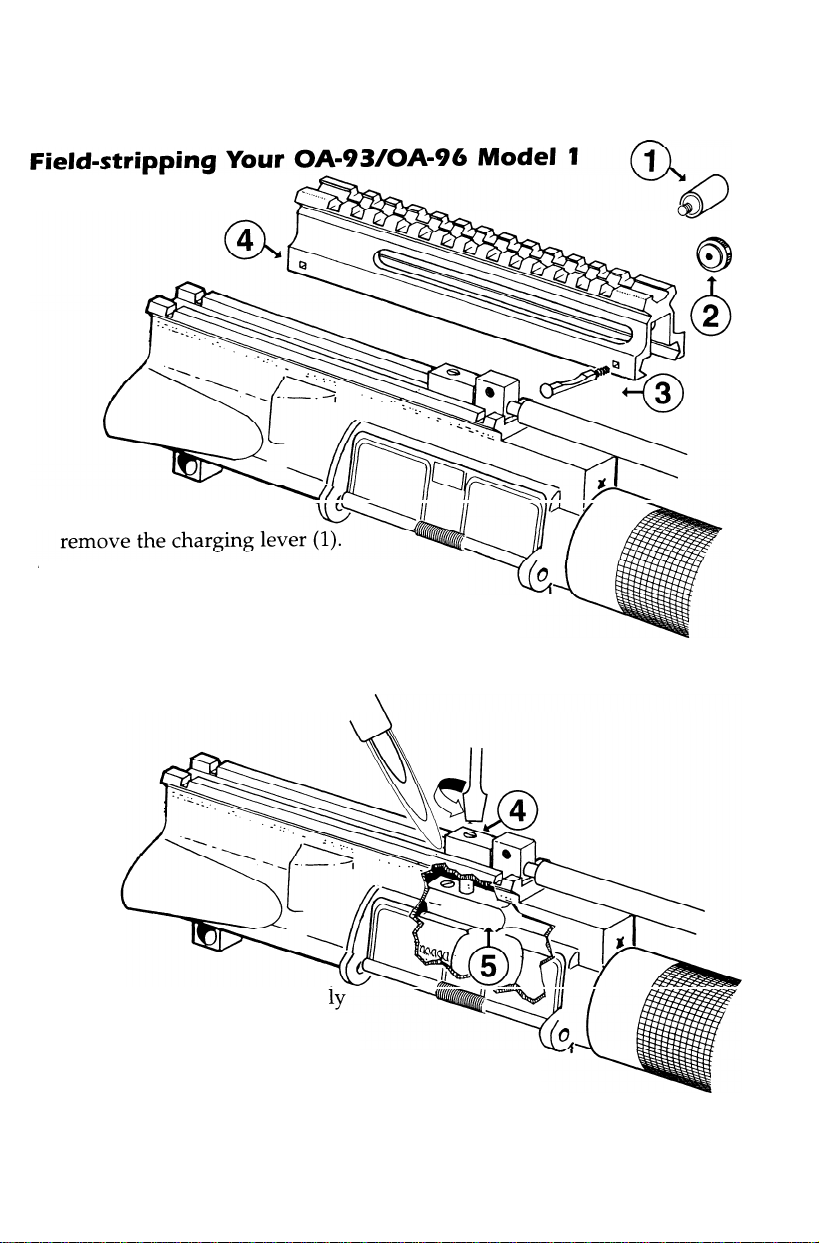

Maintenance Procedures

Field-stripping Your

WARNING: To avoid accidental

firing, be sure weapon is clear. Pull

back charging lever

(2).

chamber

Place selector lever on

(1)

and check

1. Remove sling

2. Remove rear knurled locking

nut (4), using a large standard

screwdriver.

3. Push out rear locking pin (5).

4. OA-93 series: Push out take-

(3),

if any.

and pivot upper receiver away

from lower.

*OA-96: press release button

on the butt of the lower

receiver to pivot upper

receiver away from the lower.

down pin (6) as far as it will go

OA-93 Carbine Model 1: continued next page

go to page 16

l OA-93/OA-96 and Carbine Model 2: go to page

l OA-93/OA-96 Model 1:

17

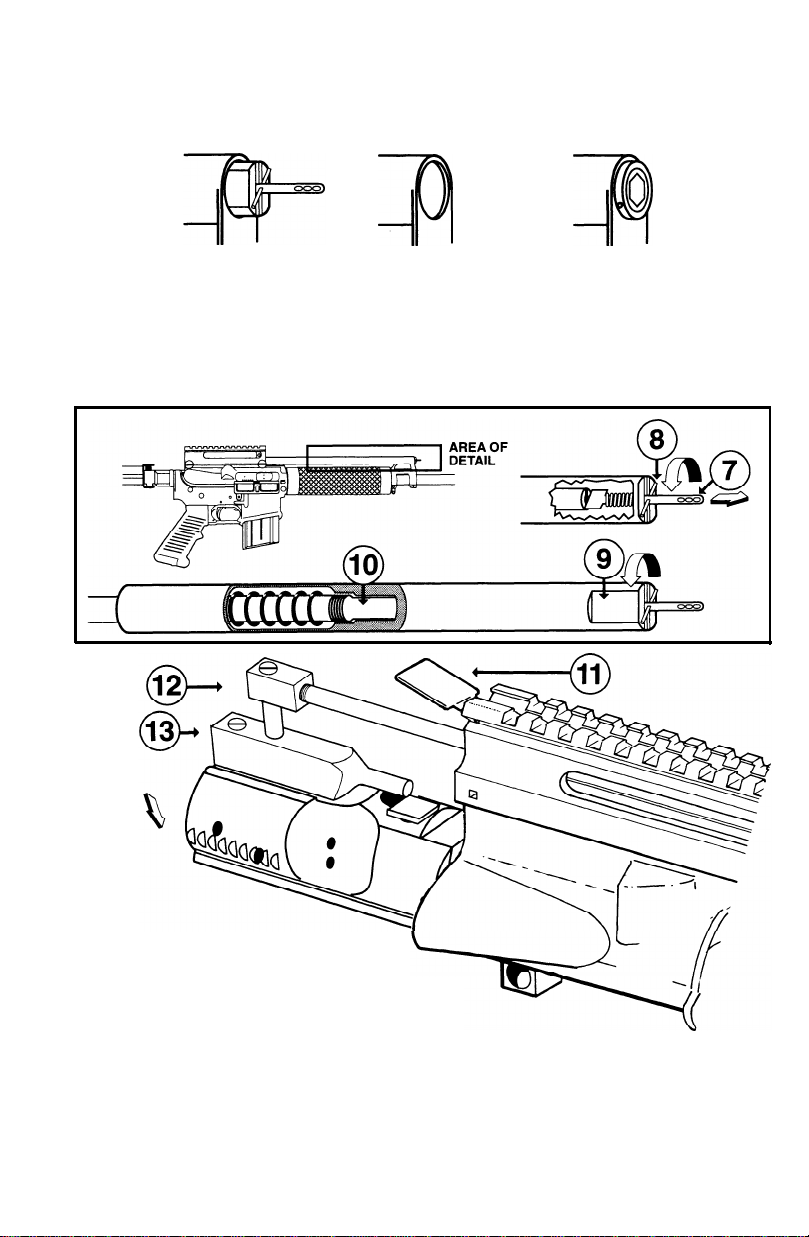

PLEASE NOTE:

fers from the assembly on the

The recoil assembly on the OA-93 Carbine Model 1 dif-

OA-93/OA-96

Model 1. Look at the recoil

rod end above the muzzle to determine which instructions to follow.

OA-93 Carbine

Model 1

44

OA-93

Model 1

&

OA-96

8

OA-93/OA-96

Carbine Model 2

Maintenance Procedures

Field-stripping Your OA-93 Carbine Model 1

&

.

5

Grasp knurled recoil rod locking pin (7) and pull out until

detent

pin (8) clears slot in

recoil plug, then twist so that

detent pin rests clear of slot.

.

Grasp recoil plug (9) by the flat

6

edges and unscrew from recoil

rod (10).

Lift access hatch (11) at rear of

.

7

scope mount.

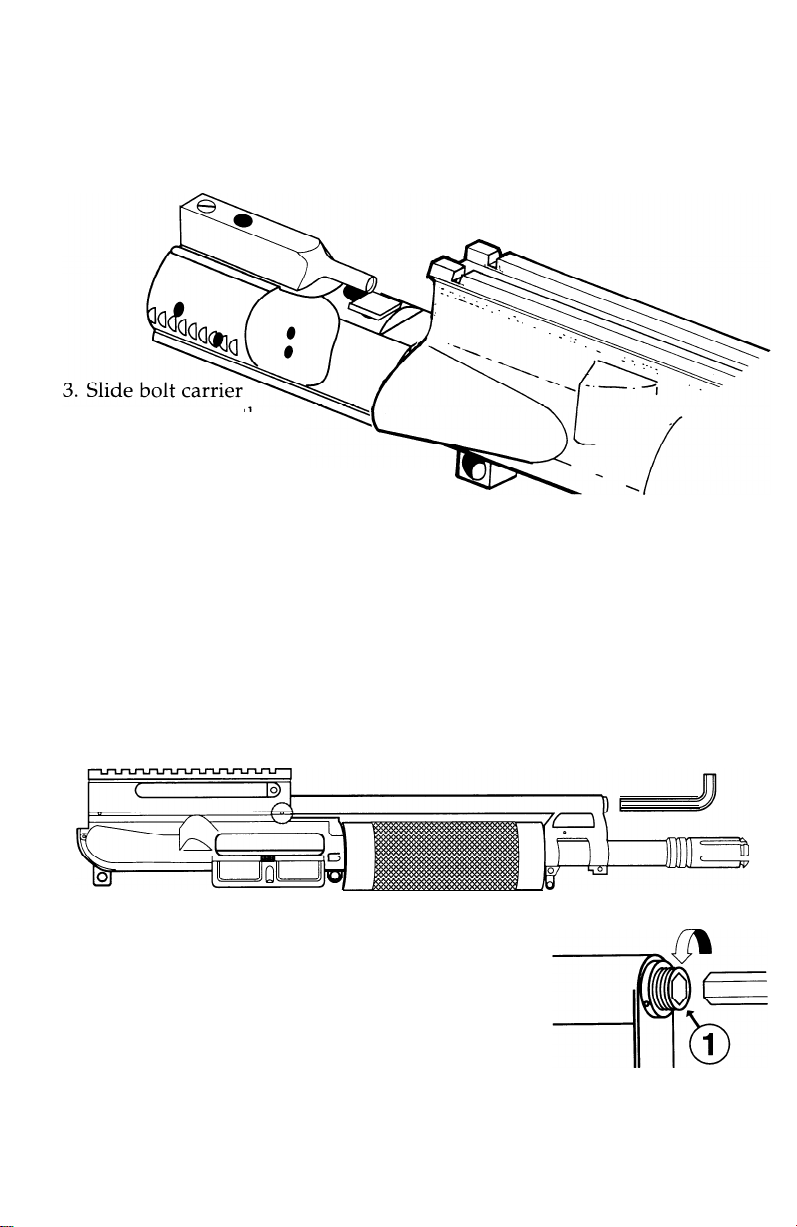

Slide out bolt carrier and recoil

8

l

assembly (12).

Drop bolt carrier, carrier key

9

.

and linking pin (13) free of

recoil assembly.

Maintenance

OA-93/OA-96

Continued from page 14

1. Using a hex wrench,

2. Using a large standard screwdriver,

remove front knurled locking nut

push out front locking pin (3). Note that forward pin is radiused on the side facing up, while

the rear pin is not.

3. Slide off scope mount base (4).

Model 1

(2),

and

4. Using a propane torch, app

heat to the linking pin (4) to

soften the Red Loctite® used in

assembly, then unscrew the

link

key

pin from

(5).

the bolt carrier

Maintenance Procedures

OA-93/OA-96 Model 1

Field-stripping Your

assembly out of the

rear of the upper

receiver.

GO TO PAGE 20, STEP 2

NOTE: the recoil assembly is under constant tension. Do not attempt to

remove the recoil rod link. If you must remove it, be aware that the

spring and recoil rod will shoot out violently when the block is removed.

OA-93/OA-96

Model 1

Maintenance Procedures

OA-93/OA-96

Field-stripping Your

Continued from page

1. Using a hex head wrench, back off the recoil

rod set screw (1) a couple of turns.

GO TO PAGE 19

and Carbine Model 2

OA-93/OA-96 &

14

Carbine Model 2

No.

Description

Scope Mount Nuts

1

Scope Mount Screws

2

Charging Screw

3

Charging Screw Sleeve

4

Charging Lever Block

5

Recoil Rod Link

6

Link Pin (max all)

7

Scope Mount Base

8

Ejection Cover

9

Ejection Cover Hinge Pin

10

Ejection Cover Hinge Pin Clip

11

Ejection Cover Spring

12

13

Bolt Carrier

14

Bolt Carrier Key

15

Bolt T-26

16

Bolt Cam Pin

17

Firing Pin

Firing Pin Retaining Pin

18

Upper Receiver

19

20

Ejector

Stock No.

OA-0007

OA-0006

OA-0008

OA-0009

OA-0010

OA-0012

OA-0011

OA-0005

AR32

AR34

AR35

AR33

OA-0015

OA-0016

AR16

AR39

AR40

OA-0003

AR28

Description

No.

Ejector-Spring

21

Ejector Roll Pin

22

Flash Suppressor Washer

23

Brennan Nil-Flash

24

Vortex Flash Suppressor

25

Hand Guard

26

Barrel

27

Recoil Spring

28

Recoil Rod (2-part)

*29

Bolt Carrier Key Screw

30

Gas Tube

31

Gas Tube Roll Pin

32

Sling Swivel

33

Sling Swivel Pin

34

Sling Swivel Stud

35

Recoil Spring Housing

36

Recoil Rod Locking Pin

*37

Detent Pin

*38

Locking Pin Spring

*39

Front sight taper pins

40

Stock No.

AR30

AR31

AR42

F2-E

F2-C

OA-0018

OA-0017

OA-00 14

OA-0013

AR6

OA-0019

AR62

AR85

AR86

OA-0004

OA-0022

OA-0023

OA-0024

OA-0025

AR59

§41

Bolt carrier TCP (auto) OA-0015-A

42 9mm bolt

†43

Recoil rod (model 1)

‡44

Recoil rod (model 2)

‡45

Recoil rod nut

‡46

Recoil rod set screw

AR3-9

OA-0026

OA-0027

OA-0028

OA-0029

*

Parts exclusive to OA-93 Carbine

† Parts exclusive to

Parts exclusive to

‡

Parts exclusive to OA-93 TCP

§

OA-93/OA-96

OA-93/OA-96

Model 1

Model 2

Maintenance Procedures

OA-93/OA-96

Field-stripping Your

2. Remove the recoil rod locking nut (2). If you

have difficulty gripping the nut, insert a small

hex wrench into the

CAREFUL. The recoil spring will shoot out the

end of the housing as soon as the nut is

removed. Maintain pressure and ease the

spring tension gradually.

and Carbine Model 2

OA-93/OA-96 &

takedown

hole (3). BE

Carbine Model 2

assembly out of the

rear of the upper

receiver.

GO TO PAGE 20, STEP 1

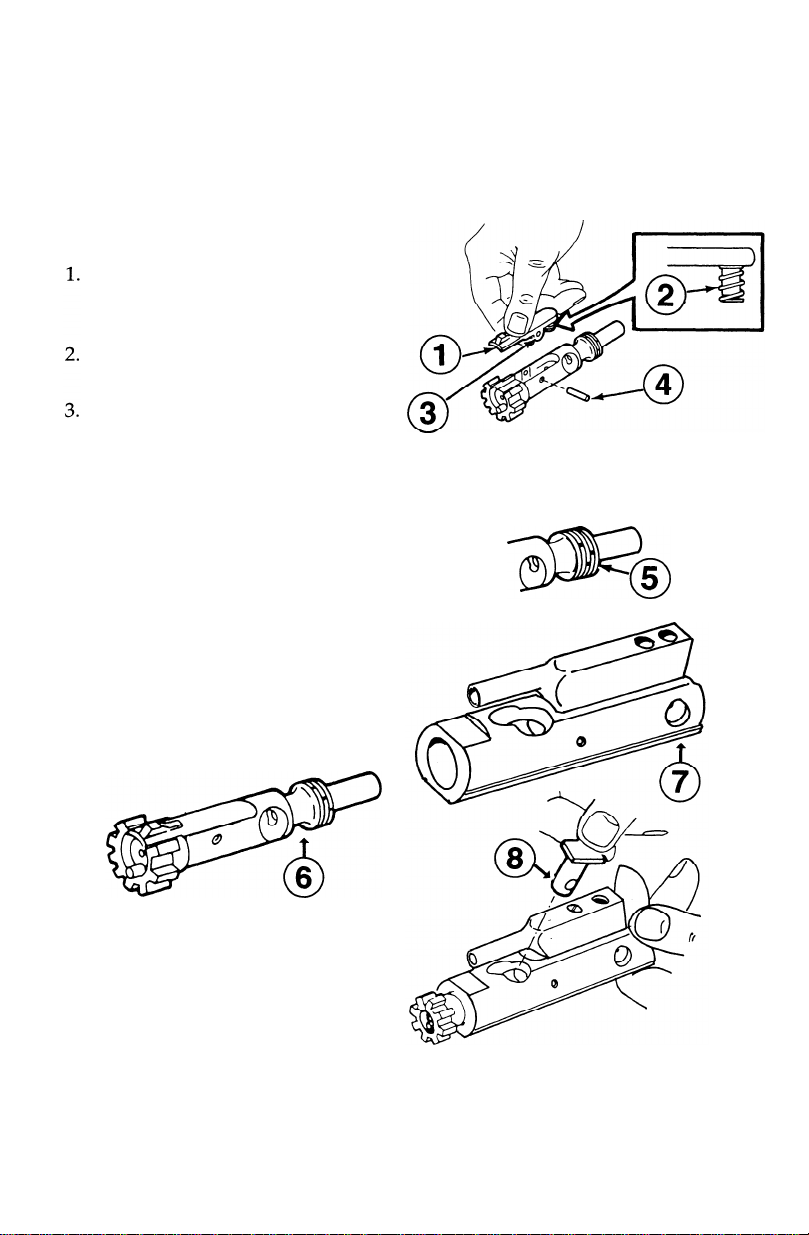

Bolt Carrier Disassembly

NOTE: The following illustrations

show the link pin removed from

the bolt carrier key. If you are disassembling an OA-93/OA-96

Model 1, the link pin must be

removed. It is not necessary to

remove it on the OA-93/OA-96

Model 2, or the OA-93 Carbine.

The only time you must

the link pin on these models is

when you wish to remove the bolt

carrier key from the bolt carrier.

To remove the link pin: use a

propane torch to apply heat to the

base of the link pin (1) to soften

the Red Loctite

Use a standard

unscrew link pin from bolt carrier

key. BE CAREFUL NOT TO BURN

YOURSELF ON THE HOT LINK

-

use a pair of heavy gloves

PIN

for this step.

used in assembly.

screwdriver to

remove

cedures

2.

Move bolt assembly (6) forward

to unlocked position and

remove firing pin retaining pin

(7). Do not open or close split

end of firing pin retaining pin

(7).

Push in on bolt assembly (6) to

3.

put in locked position.

4.

Catch firing pin (8) as it drops

out of rear of bolt carrier assem-

bly

(9).

\

6

0

Maintenance Procedures

Bolt Carrier Disassembly

5.

Give bolt cam pin (5) a quarterturn and lift out.

Remove bolt assembly (2) from

6.

bolt carrier assembly (1).

NOTE: Disassemble extractor and

spring assembly only when

dirty or damaged.

7.

Press top of extractor (6) to check

that spring works.

8.

Use dummy round or ballpoin

pen to remove extractor pin (7).

CAUTION:

from

9.

Remove extractor (8) and spring

assembly (9). Do not remove

spring assembly (9) from extractor (8).

10

Reassemble in reverse order. Be

sure to use Red Loctite when installing flash suppressor (if removed)

and link pin (#1, page 20).

Do not separate insert

spring

assembly

(9).

.

Maintenance Procedures

Cleaning and Lubricating

Upper Receiver and Barrel Assembly

NOTE:

Use cleaner, lubricant and preservative (CLP) on the following areas:

A

B

C

D

Do

not reverse direction of the bore brush while it is in the bore.

.

.

.

.

1

.2.Use cleaning rod, bore brush and CLP. Run rod through chamber, barrel

(1) and flash suppressor (2).

Install chamber brush on cleaning rod, dip in CLP, and insert in chamber

(4) and locking lugs (5). Clean by pushing and twisting cleaning rod.

Cleaning and Lubricating

Upper Receiver and Barrel

3. Lightly lubricate bore and

chamber, outer surface of barrel

and recoil spring tube, and surfaces under hand guards.

4. Lubricate locking lugs (3).

NOTE: Do not over-lubricate your OA-93/OA-96. Excess oil will attract dirt

and grit, and lead to excessive wear. Wipe off excess before reassembling.

Assembly

Maintenance

Procedures

Cleaning and Lubricating Bolt Carrier Assembly

CAUTION: Do not use firing pin to clean inner surfaces of bolt or bolt carrier assembly.

Clean the bolt carrier key (2)

1.

Clean all parts and outer surfaces of the bolt carrier assembly

(1) with a swab saturated with

.4.Remove carbon deposits and dirt

3

from locking lugs (3) with bore

brush dipped in CLP.

Clean areas behind bolt rings (4)

and under lip of extractor (5).

2.

with a worn bore brush dipped

in CLP. Dry with a pipe cleaner.

Use a pipe cleaner to apply a

light coating of CLP to carrier

.

key

5.

Inspect firing pin retaining pin

(6) for bends, breaks, or dents.

Maintenance Procedures

Cleaning and Lubricating

Bolt Carrier Assembly (Continued)

Inspect bolt assembly (7) for

cracks and fractures, especially

in the cam pin hole area.

Inspect bolt cam pin (8)

cracks or chips.

Inspect firing pin (9) for

cracks, or blunted tip.

LUBRICATION

1.

Lightly lubricate firing pin (1)

and firing pin recess (2) in bolt

assembly.

2.

Generously lubricate outside of

bolt cam pin (3) and firing pin

retaining pin (4) with CLP. Make

certain to lubricate bolt assembly

cam pin hole

and outside of bolt assembly (7).

(5),

bolt rings

(6),

0%

7

W

Dry the inside of the bolt carrier

3.

key (8) with a pipe cleaner, and

place one drop of CLP inside

key.

4

Lightly lubricate with CLP the

inner and outer surfaces of the

bolt carrier assembly (9). Generously lubricate the slide (10) and

cam pin area (11) of bolt carrier

assembly.

Maintenance Procedures

Cleaning and Lubricating the Lower Receiver

NOTE: The lower receiver should only be disassembled by

qualified gunsmith. If you need to do repairs on your lower

receiver, write to Olympic Arms and request part number H-7,

U.S. Marine Corps Technical Manual (TM

CAUTION: Do not use a steel or

05538C-23&P/2).

wire brush or any type of abrasive material to clean aluminum

a

Wipe dirt from trigger (1) with a

swab.

Use a swab dipped in CLP and a

cleaning brush to clean powder

fouling, corrosion and dirt from

outside parts of lower receiver.

Clean the inside of the lower

receiver (2) with a swab dipped

in

CLP.

Wipe dry.

4.

5.

Examine lower receiver for

rosion or damage. Also check for

broken or bent trigger

or damaged selector lever

any cracks, dents, or breaks. If

you think the parts are bad, see a

reputable gunsmith.

Lightly lubricate inside of lower

receiver with CLP. Generously

lubricate takedown (5) and pivot

pins (4) with

CLP.

(l),

cor-

bent

(3),

or

Maintenance Procedures

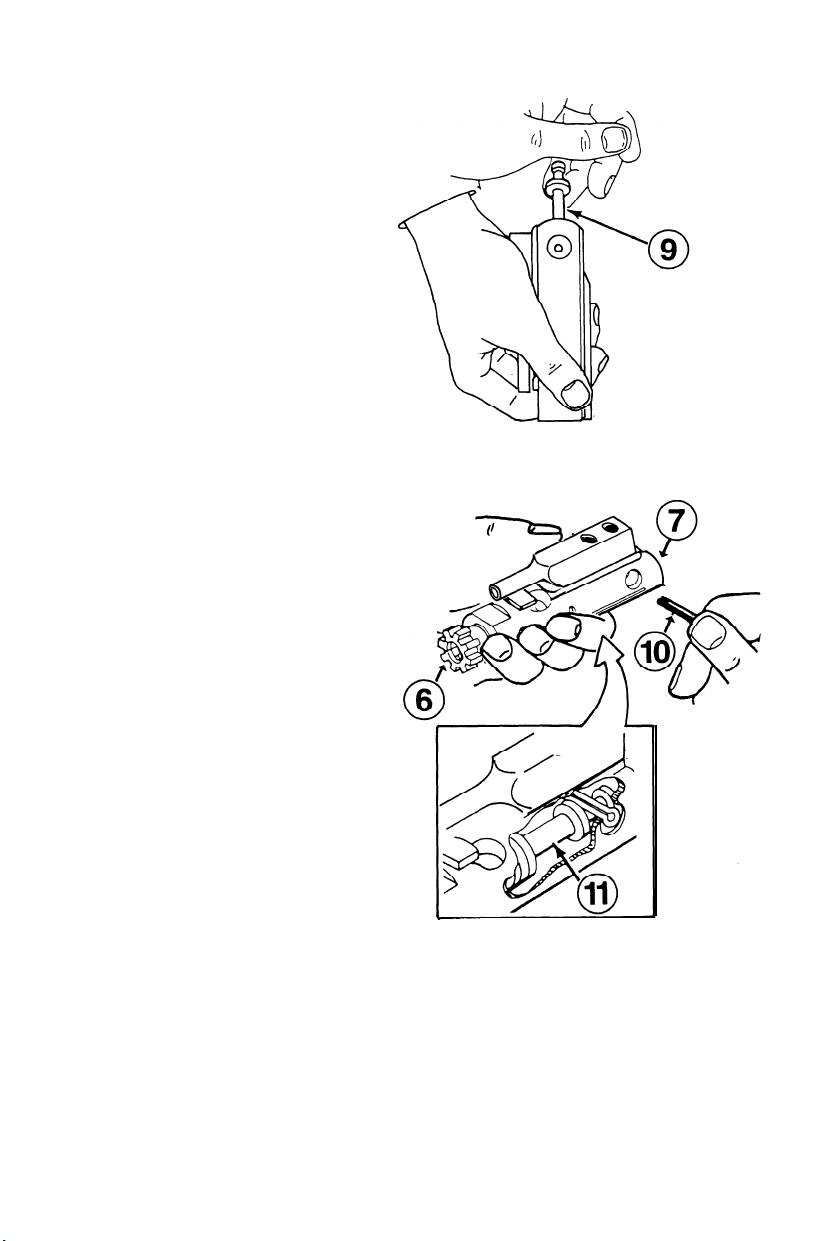

Bolt Carrier Assembly

NOTE: New extractor has silicone

insert with spring. Be careful

not to lose it.

If the spring comes loose, seat

the large end of spring in the

extractor.

Insert extractor (1) and spring

assembly (2) into bolt.

Push extractor (1) and spring

assembly (2) down. Align hole

(3) with hole in bolt and insert

extractor pin (4).

4. Stagger gaps in bolt rings (5) to

stop gas loss. (Pistol caliber

bolts have no gas rings).

WARNING: Don’t switch bolt

assemblies between weapons.

=0

5

5

.

Slide bolt assembly (6) into bolt

carrier assembly (7).

6.

Insert bolt cam pin (8) and give it

a 1/4 turn.

Maintenance Procedures

Bolt Carrier Assembly

7.

Drop firing pin (9) into opening

and seat.

Push bolt assembly (6) back and re-

8.

place firing pin retaining pin (10).

NOTE: Firing pin

out when bolt carrier assembly is

turned upside down.

Turn bolt carrier assembly (7) over

9.

and try to shake out the firing pin.

(11)

should not fall

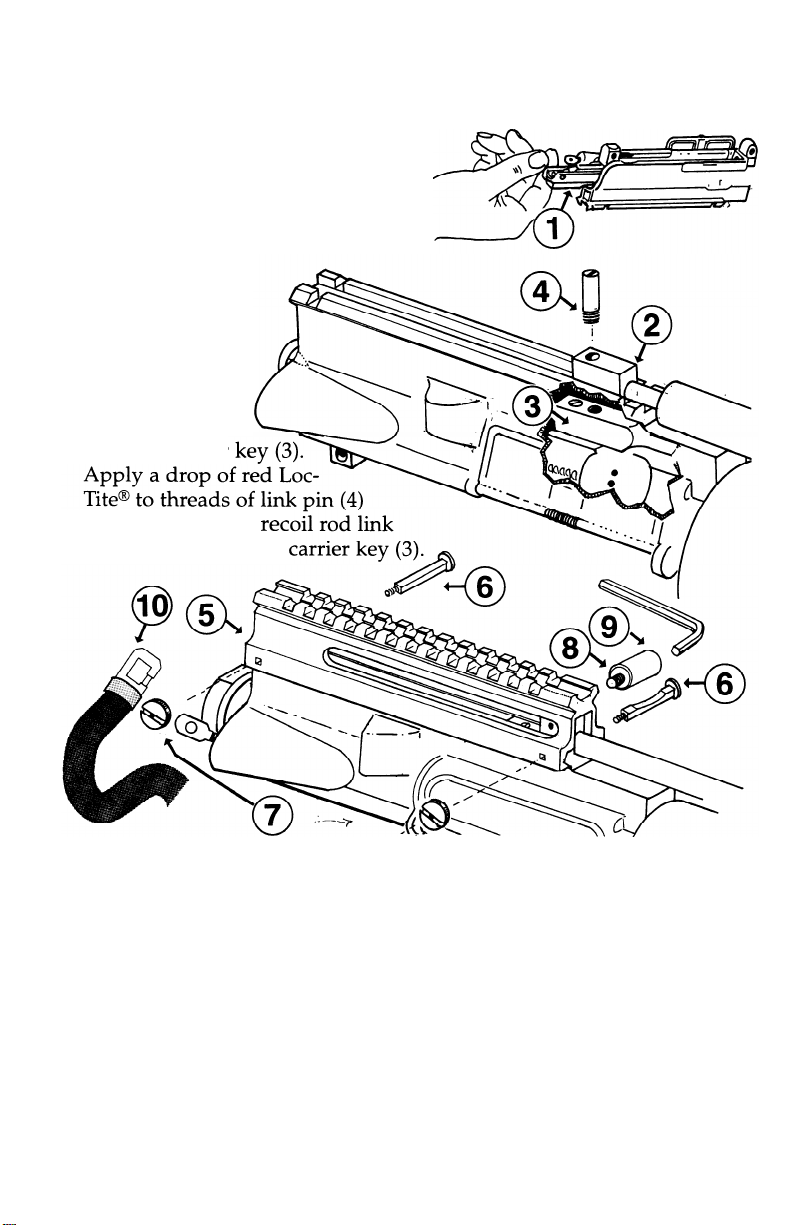

Maintenance Procedures

OA-93 Carbine Model 1 Reassembly

If for any reason you unscrewed

the link pin from the bolt carrier

key, replace it now. Place one

drop of Red

ward hole (1) and screw in link

(2) firmly.

pin

Loctite®

in the for-

insert link pin (2) into recoil rod link (6).

(If assembly binds, try turning your

Screw forward part of recoil

3.

rod (7) firmly onto rear part of

OA-93/OA-96

REA OF

ETAIL

upside down.

the pin drop into the slot on

the end of the rear recoil rod.

recoil rod (8). 5.Turn locking pin (10) until it

4.

Pull out and turn detent pin

(9) until you feel the paddle of

GO TO PAGE 31

snaps into the groove on the

end of the recoil rod.

Mahtenance Procedures

OA-93/OA-96

1.

Turn upper receiver upside down

and slide in bolt carrier assembly (1).

2. Align holes in

recoil rod link

and bolt

Model 1 Reassembly

(2)

carrier

and press through

(2). Screw firmly into

3.

Slide on scope mount base (5).

Push in scope mount screws

(6),

making sure that the for-

ward screw has radiused side

facing upward. Tighten down

scope mount nuts (7) with

large standard screwdriver.

NOTE: These screws are

ambidextrous, and can be

inserted from either side.

4. Slide charging screw (8) into

ret

charging screw sleeve (9).

Apply blue Loctite® to the

threads of the charging screw

and fasten assembly to charging lever block with a

hex head wrench. NOTE: This

assembly is ambidextrous,

and can be attached to either

side of the charging lever

block.

5. Re-attach sling

(10),

if any.

5/32”

GO TO PAGE 31

Maintenance Procedures

OA-93/OA-96 &

If for any reason you unscrewed

the link pin from the bolt carrier

key, replace it now. Place one

drop of Red

ward hole (1) and screw in link

pin (2) firmly.

.

1

Loctite®

Carbine Model 2 Reassem

in the for-

insert link pin (2) into recoil rod link (4).

Lift access hatch (5) and slide in bolt carrier assembly (6).

.

2

(If assembly binds, try turning your OA-93/OA-96 upside down).

__

.

Use the recoil

3

compress the spring into the

recoil spring housing and

screw it down. If you have

difficulty gripping the nut,

rod nut (7) to

a

insert a small hex wrench into

the

takedown

hole (8). BE

CAREFUL. The

will

shoot out the end of the

.-.

e

I

recoil spring

.

8

II P

housing if pressure is removed.

Tighten down the recoil rod set

4.

screw

(9).

GO

TO PAGE 31

U,

II I

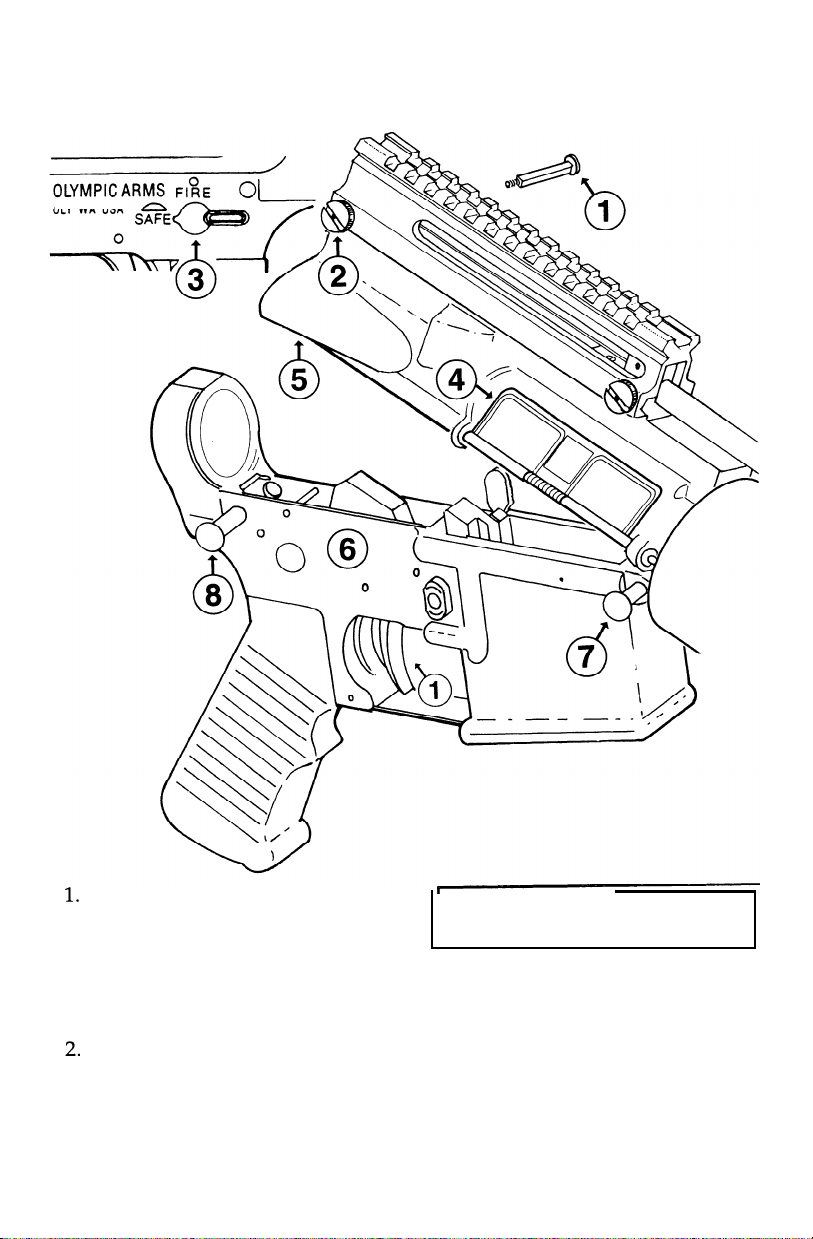

Maintenance Procedures

OA-93/OA-96

OLY WA USA

Final Reassembly ALL MODELS

OA-93/OA-96 Model 2 and

OA-93 Carbine only: Insert

rear scope mount screw (1) and

tighten down scope mount nut

(2) with large standard screwdriver.

Move selector lever (3) to

SAFE, and close ejection port

cover (4) before closing upper

receiver.

*OA-96:

Close upper receiver

on lower receiver.

3

OA-93 All Models: Join upper

.

receiver (5) and lower receiver

(6). Align the pivot pin holes

and push pivot pin (7) in.

.

Close upper receiver and lower

4

receiver. Push in takedown pin

(8).

Maintenance Procedures

Function Check

WARNING: To avoid accidental firing,

be sure cartridge magazine is

moved and chamber is clear.

-1

1.

charging screw

(I)

to rear

release. Place selector lever (2)

SAFE. Squeeze trigger (3). Hammer

should not fall.

re-

and

on

OLYMPIC ARMS

OLY WA USA

0

/

Place selector lever (2) on FIRE.

2.

0

SAFE

0

F,'E

A

01

/

2

Squeeze trigger (3). Hammer should

fall. Hold trigger to the rear. Pull

charging screw (4) to rear and release. Release trigger (3). You should

hear a click as you release the trigger.

Squeeze again; hammer should fall.

No. Description

1 Lower Receiver

2 Pistol Grip Screw

3 Grip Screw Washer

4 Pistol Grip A-2

5 Safety Spring

6 Safety Detent

7 Trigger

8 Trigger Spring

9 Trigger Pin

10 Hammer Pin

11

Trigger Guard

Stock No.

OA-0001

AR72

AR73

AR71A

AR84

AR83

AR91

AR94

AR64

AR64

AR92

12 Trigger Guard Roll Pin AR93

13 Disconnector

14

Disconnector Spring

15

Takedown

16

Takedown

17 Takedown

Pin

Pin Detent

Pin Detent Spring

AR26

AR27

AR88

AR89

AR90

‡18 Magazine Catch Button AR70

‡19 Magazine Catch Spring AR69

‡20 Magazine Catch

21 Bolt Catch

22 Bolt Catch Plunger

23 Bolt Catch Roll Pin

24 Bolt Catch Spring

25

Safety Selector

AR68

AR7

AR8

AR9

AR10

AR82

#

Description

26

Hammer

27

Hammer Spring

‡28

‡29

Takedown

Takedown

Pin, Rear

Pin Detent, Rear

Stock No.

AR63

AR65

AR88

AR89

‡30

Takedown

Pin Detent Spring

AR90

5x40 Set Screw

‡31

†32

Folding Stock Bolts OA-0030

†33

Folding Stock

†34

Folding Stock Spacer OA-0032

†35

Locking Ring

† Parts exclusive to

OA-0002

OA-0031

OA-0033

OA-93

Carbine only

‡ Parts exclusive to OA-93 pistol only

(not applicable to OA-96)

-

Loading...

Loading...