Filmetrics F20 User Manual

Operations Manual

for the

FILMETRICS F20

Thin-Film Analyzer

Revision 6.1.0

Copyright © 2011 by Filmetrics, Inc.

All Rights Reserved

Welcome

What is the F20 used for?

The Filmetrics F20 is used to measure the thickness and optical constants (n and k) of dielectric and semiconductor thin films. Measured films must be optically smooth and within the thickness range set by the system configuration requirements specified in Performance Specifications. Commonly measured films include semiconductor process films such as oxides, nitrides, resists, and polysilicon, optical coatings such as hardness and anti-reflection coatings, flat panel display films such as polyimides, resist, and cell gaps, and the various coatings used in CD and DVD manufacture.

Safety, Maintenance and Care

This symbol indicates information or instructions that must be read and carefully followed to prevent hazards, injury to the operator, or damage to the instrument.

This symbol indicates a potential shock hazard. Areas marked with this symbol should be serviced by a trained service technician.

This symbol indicates that the product conforms to the WEEE (Waste in Electrical and Electronic Equipment) Directive 2002/96/EC.

This symbol indicates that the product meets the applicable EU safety, health and environmental protection directive requirements.

This label indicates the Model Number and Serial Number of the instrument. This information may be necessary when contacting Filmetrics for assistance.

Disclaimer:Use of this instrument in a manner inconsistent with the information and directions included in this manual may impair the protections designed into the product resulting in danger to the operator or damage to the instrument

Installation Location: When deciding on a location for the instrument, ensure that the instrument in installed in a well-ventilated location. Enclosing the unit, or blocking the vent holes, may impair the performance of the instrument of damage the internal components.

Cleaning:The need for periodic cleaning of the system is based on the cleanliness of the environment in which the system is installed. Only the external surfaces are to be cleaned. Cleaning and maintenance of all internal components is to be performed by a trained service technician. Do not use aerosol, or spray, cleaners as they may contaminate the sensitive optical surfaces on the instrument.

Before performing any service on the instrument ensure that the main power is disconnected.

Cleanroom, or low lint, wipes should be used to wipe down the system. A mixture of Isopropyl Alcohol (IPA) and De-ionized Water (DI H2O) at 70% DI H2O: 30% IPA is to be used for cleaning. Undiluted IPA may be used, if the 70:30 DI and IPA mixture is not available, but extra care must be taken. Avoid using stronger solvents, such as acetone, as these may compromise the surface finish.

Avoid excessive pressure on any surface when cleaning. Excessive force may bend a component, which would damage the system, or cause the system to be out of alignment.

Start with the top of the system and work down. Use slow motions, in a straight line, from the back to the front of the surface being cleaned. Change the cleaning wipe periodically to avoid re-depos- iting material back onto the surface being cleaned. Allow all cleaned surfaces to dry completely before restoring power to the system.

CE Mandated Warnings

Please read the following instructions carefully to prevent potential shock or fire hazards. This manual should be retained for future use

Bitte lesen Sie die nachstehende Anleitung sorgfältig durch um Stromschlag und Feuergefahr zu vermeiden. Diese Betriebsanleitung sollte für späteren Gebrauch sorgfältig aufbewahrt werden.

Preghiamo di leggere accuratamente, le sequenti Instruzioni, per evitare Prossiomi Incendi e Correnti.

Shock Hazard - Do Not Enter

Achtung Hochspannung - Nicht Berühren

Attenzione Corrent-Forte - Prego non toccare

The front panel’s switch is not the power disconnect device. The power cord should be removed after use.

Der Kippschalter an der Vorderseite unterbricht nicht die Stromzuführung. Das Stromkabel sollte nach Gebrauch aus dem Gerät herausgezogen werden.

L’interutore nella parete frontale non blocca le Corrente. La Corrente viene.

Never expose the unit to water or liquids. Avoid direct sun.

Bringe das Gerät nicht mit Wasser oder einer anderen Flüssigkeiten in Berührung. Vermeide direkte Sonneneinstrahlung.

Evitare contatto con acqua oppure liquidi Infiammabili al Macchineggio. Auche entrate di Sole.

Do not insert any objects into the unit.

Keinen Gegenstand in das Gerät einbringen. Do non inseriamo any obietta into gli unità. Non mettere ogetti dentro la Macchina.

Do not use near open flame or heat.

Das Gerät nicht in der Nähe einer offenen Flamme oder Hitze benutzen. Non mettere la Macchina vicino a fuochi oppure Riscaldamenti.

The unit should never be enclosed or blocked.

Das Gerät darf nicht eingeschlossen oder blockiert werden.

La Macchina non chinderla per nessun motivo.

Connect unit only to a properly measured supply. Use only three wire cord which is provided with the unit.

Schließen Sie das Gerät nur an eine ordnungsgemäss vermessene Stromsversorgung an. Verwende nur ein dreiadriges Kabel, wie es auch mit dem Gerät ausgeliefert wird. Montare solo con misura normata. Adoperando solo 3 cavi elettrici cosi come e fornita la Macchina.

Software Overview

The way that light reflects off of a thin film is determined by the characteristics of the film, such as its thickness, optical constants, and roughness. The F20 is able to determine thin-film characteristics by first carefully measuring the amount of light reflected from the thin film over a range of wavelengths (i.e., by measuring the reflectance spectrum), and then analyzing this data by comparing it to a series of calculated reflectance spectra. Most of the features of the FILMeasure software that runs the F20 can be divided into reflectance acquisition and reflectance analysis functions. The following pages outline the main features of the FILMeasure software.

The basic steps for any F20 measurement are selecting and editing the film structure, taking a baseline measurement, and then making and evaluating the measurement. The details of each of these steps are explained below, followed by descriptions of other FILMeasure functions.

Measure Tab

1. Standard Windows File menu for saving and retrieving data, printing, etc.

2.The Edit menu is used for viewing and editing the material library.

3.Used to Setup various parameters and the graphic display.

4.For starting and stopping continuous reflectance acquisition and data measurement.

5.Used to access the Help, Diagnostic and Support functions of the software.

6.Shows that the Measure tab is currently selected.

7.Used to select the History tab.

8.This is the thickness result from the measured spectrum.

9.This button causes spectra to be acquired and analyzed.

10.The baseline measurement sequence, which is required before measurements are made, is initiated by pressing the Baseline button.

11.This button analyzes the selected spectra.

12.This is used to select Recipe settings that correspond to different samples to be measured.

13.This is where the Recipe (the film stack definition and data acquisition and analysis settings) is set. Hundreds of recipes can be saved and later recalled.

14.This box provides more details about the calculated thickness, as well as any additional parameters that were solved for, including Roughness, n and k, and Non-Uniformity as well as the

Goodness of Fit (GOF).

15.Graphical display for spectra. A click of the right mouse button while the cursor is within the graphical display activates a blue line (one click for measured curve) for easy reading of cursor values in the main FILMeasure window. Keyboard up/down and right/left arrows move the line to a desired location.

The graph limits can be changed by double-clicking on the graph display. The Horizontal Axis Minimum and Maximum fields are used to control the wavelength range displayed on the screen. Use the Vertical Axis Minimum and Maximum fields to control the vertical-axis display. Check the Autoscale Maximum checkbox to activate y-axis autoscaling. The lower value is always 0 for autoscaling; the maximum y-axis upper limit is 5000. Changing the Vertical Axis will change the reflectance axis, the Vertical Axis 2 will change the transmittance axis. The axes can be set to display in percent or as a decimal value (100% = 1).

Graph Options can be accessed and edited by double-clicking on the main graph window.

16. This allows the user to enter information about the Operator and Sample for tracking purposes.

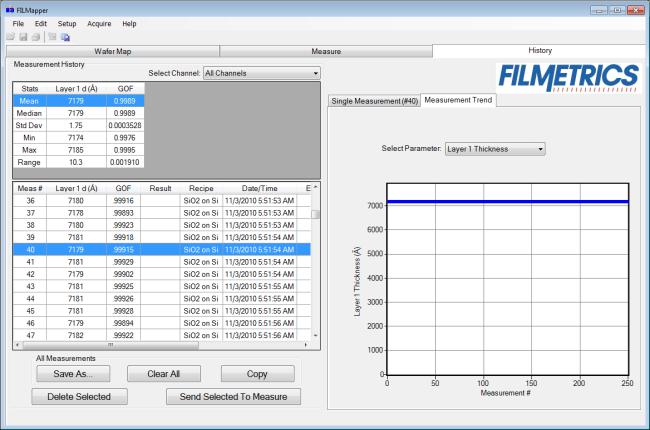

History Tab

1.Standard Windows File menu for saving and retrieving data, printing, etc.

2.The Edit menu is used for viewing and editing the material library.

3.Used to Setup various parameters and the graphic display.

4.For starting and stopping continuous reflectance acquisition and data measurement.

5.Used to access the Help, Diagnostic and Support functions of the software.

6.Used to select the Measure tab.

7.Shows that the History tab is currently selected.

8.Selecting the Measurement Trend tab will allow the user to see a plot of the measurement results versus measurement number.

When the Measurement Trend tab is selected in the History window, the right side of the screens graphs the results.

9.Displays the measurement results for the currently selected measurement number.

10.Displays the spectra for the currently selected measurement number.

11.Saves the history file.

12.Deletes the currently selected spectra.

13.Clears the history file.

14.Copies the selected data to the clipboard.

15.Sends the selected spectra and the associated recipe back to the measure tab.

16.Displays the statistics of all past measurements.

17.Shows all measurements numbers. Selecting a measurement number will cause the associated spectrum and measurement results to be displayed on the right side.

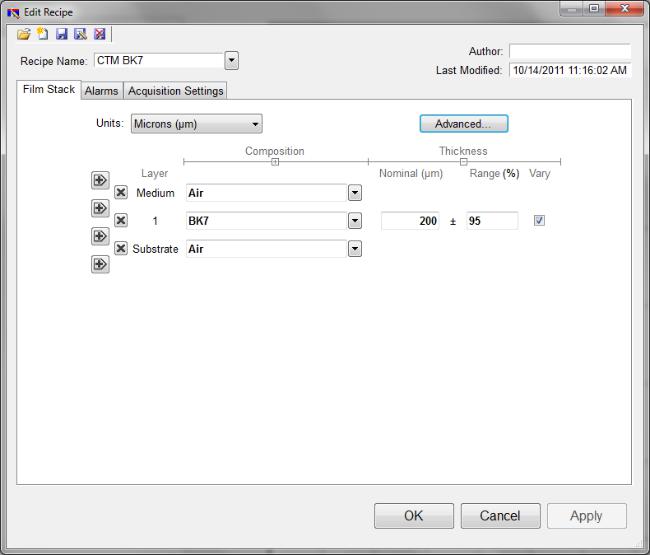

Edit Recipe Window

The Edit Recipe Window is used to define the film stack and to set analysis and acquisition parameters.

A recipe defines the film to be measured and its approximate thickness, any other films present, and the quantities to be measured:

1.Open a saved Recipe file.

2.Clear all settings and start a New Recipe.

3.Save the current recipe settings.

4.Save the current recipe settings as a new file.

5.Delete the current recipe.

6.Select from different recipes saved under the Recipes folder.

7.Author, as defined by user login name and recipe modification date are indicated here.

8.Additional solving options for Composition, Thickness, and Non-Uniformity can be hidden or revealed by pressing the + or - buttons.

9.Constraints on the possible measured values are selected here.

10.OK closes the Edit Recipe box, retaining any changes made.

11.The Cancel button closes the Edit Recipe box without retaining changes.

12.Apply will not be permanently saved unless Save or Save As New… is selected.

13.These tabs allow the users to navigate to the various other recipe settings.

14.The thickness units are chosen here. The choices include angstroms (Å, 10e-10 m), nanometers (nm, 10e-9 m), kilo-angstroms (kÅ, 10e-7 m), microns (µm, 10e-6 m), mils and microinches.

15.Adds a new layer.

16.Deletes the selected layer

17.This pulldown menu allows the user to select the desired material file. Also, left-clicking on the text will open the Search Materials dialog box.

Editing Film Structures

The description of the nominal film structure, as well as the measurement parameters, is specified in the Edit Recipe dialog box. Dozens of different film structures and their measurement specifications may be saved using the Edit Recipe dialog box.

The Edit Recipe dialog box is accessed with the Edit Recipe button on the Measure Tab. The Edit Recipe dialog box lists an initial guess at the specifications of the film structure to be measured. These specifications include the name of the film structure (which identifies it in the Recipe: list), the number of films in the structure, the specifications of individual films, and the quantities to be measured.

Adding, Changing, or Deleting a Structure

When the dialog box is opened, it shows the stored specifications of the structure selected from the Recipe: list, along with any changes made since the program was started. Changes to the structure selected can be permanently stored by making the desired changes and then clicking on Save

Changes. New structures may be added to the Recipe: list by opening the Edit Recipe dialog box, setting the desired specifications, and then clicking on Save As. Similarly, a structure may be deleted (removed from the Recipe: list) by clicking on the Delete Recipe button.

Edit Recipe>Film Stack window.

Film Stack

The Film Stack tab is used to define the film structure, as well as the starting guesses and constraints for thickness, n and k. This is also where you determine your analysis method, Grid, FFT , or None, as well as any Non-Uniformity that may be present in the sample. Additional options for Composition, Thickness and Non-Uniformity can be selected or hidden by using the + and - buttons.

Setting Up a Film Stack

When measuring a layer, the specifications (d, n, k, and roughness) of the known films (including the incident medium and substrate) must be entered into the proper fields in the Edit Recipe dialog box, as well as initial guesses for the values to be measured. The refractive index (n) and extinction coefficient (k) values for common materials can be selected automatically with the pull-down menus on the left-hand side of the Edit Recipe dialog box, or by clicking on the box and using the Search function.

If a material is being measured which is not present in the material library there are three possible approaches:

a)choose a material in the library that is similar.

b)if the material is transparent (an insulator), select “Enter Refractive Index Value” from

the material list and enter a value for the refractive index (n will automatically be varied by FILMeasure to account for dispersion effects, with the entered value being n at 632 nm).

c) in the Edit>Material Library… dialog box, enter the refractive index values for n and k as a function of wavelength and save the files so that they may be selected as in a). See Creating and Editing n and k Files for more information.

Choosing the Films to be Measured

To measure a film's thickness, check the Vary box on the right-hand side of the Film Stack field in the Edit Recipe dialog box. When no boxes are checked, the theoretical spectrum for the specified layer stack and thicknesses will be displayed.

As with most measurements, the uncertainty of the measured data increases as the number of simultaneously measured values increases. Thus it is best to provide as much information about the film structure as possible.

Constraints

By setting constraints, the user can limit the possible values of the measured film properties. The constraints are set in conjunction with the values entered in the Range dialog box for thickness. For example, if the initial guess of the measured thickness of a film is 100 nm and the thickness constraint is set at 50%, FILMeasure will only consider possible thicknesses in the range 50 nm to 150 nm. The constraints for n and k are set using the n and k dialog boxes under Composition. These boxes are only visible when the Composition option is expanded. You can select between constraining by a percent of the thickness guess, or by a selected thickness by clicking on the % or measurement unit above the constraints dialog box. Constraining the measurement range can speed up the measurements and can also help exclude non-physical solutions.

nk Model

When measuring n and k for a film, the general dependence of these values upon wavelength must be specified. This dependence is determined by the type of material to be measured. For example, insulators, semiconductors, and metals all have a unique type of n and k wavelength dependence. Dozens of models for these different dependencies have been proposed and used over the years.

FILMeasure uses a few of the most versatile and accepted of these models. For insulators, the Cauchy model is used, for semiconductors, either the Amorphous or Bridge-Lorentzian model, and for metals, the Drude model. There are also a number of special-purpose models for specific applications. These models, and starting coefficients values, are selected automatically when a material is chosen from the Material lists in the Edit Recipe dialog box. Other models may also be specified by selecting them from the nk Model pulldown menu under the Composition tab which is accessed by right clicking on the Vary checkbox.

Fourier search for thickness

The FFT option in the thickness dropdown is an alternative option to let FILMeasure choose an initial thickness for analysis. The Fourier Transform method analyzes the oscillations present in the spectrum and determines the film thicknesses based on the periodicity of those oscillations. It is somewhat less robust than the Grid method, but is better at finding the correct thickness in cases where the shape of the initial theoretical spectrum is different than the measured data (i.e., the reflectance spectrum is non-ideal in some way) or in cases where there is more than one film thickness is being measured.

Grid search for thickness

There are a number of methods that FILMeasure can use to determine thickness. None is perfect – each is a different trade-off between speed, accuracy, and robustness (i.e., the ability to find the best solution among many that are nearly as good). Because thickness can vary over many orders of magnitude and many near-solutions exist, it is often best to use a very robust method to get close to the best solution, and then let a more accurate method take over. One very robust method is the Grid method, which can be activated by selecting the Grid option in the thickness dropdown. The Grid method searches the entire allowed thickness range (as defined by the initial guess and the constraints) to find the best initial thickness. However, on some very complex multilayer spectra, it is possible for the Grid method to become confused and give the wrong answer. In such cases it is best to use the Fourier Transform method to determine initial thicknesses, or to provide them manually.

Non-Uniformity

Selecting this option enables modeling of thickness non-uniformity within the measurement spot. An initial guess for Non-Uniformity must first be made, and then solving can be enabled or disabled by toggling the check box.

Search

The Search Materials dialog box is accessible by left clicking on a material name in the Edit Recipe > Film Stack tab. This feature allows the user to search for materials by using either the materials name, or a keyword for a certain class of materials. The search function will also show a brief Description of the material selected, as well as any Synonyms or Keywords related to the material file. The Similar Materials box will list any materials that may have similar optical properties.

Analysis Options

Correct setting of the following options will help ensure accurate measurements. Many of the options are set automatically when film information is supplied in the Edit Recipe dialog box, and all of them can be saved so that subsequent measurements can be made as quickly and easily as possible. If Robust (Adaptive; Thickness Only) or FFT (Thickness Only) is checked, only the

Data Selection settings will be accesible.

Data Selection

Wavelength Range

This sets the wavelength range of data that is to be analyzed. It may be either the range displayed on the current graph or a fixed range. Wavelength range may also be changed by dragging the ends of the gray bar near the bottom of the graph area.

Smoothing

This function performs wavelength-dependent boxcar averaging on the measured spectra. This can improve signal-to-noise levels and can filter out oscillations that correspond to optical thicknesses (defined as index multiplied by thickness) equal or greater than the specified value. This value should be lowered to increase smoothing, and raised to decrease smoothing. To eliminate smoothing, a very high value (for example, 1000 um) should be entered.

Source Data

If both are present, this tells the software whether to analyze the reflection data, transmission data, or both. Only possible on spectra from the F10-VC, F10-RT, and F10-PARTS.

Data Selection

Wavelength Range

This sets the wavelength range of data that is to be analyzed. It may be either the range displayed on the current graph or a fixed range. Wavelength range may also be changed by dragging the ends of the gray bar near the bottom of the graph area.

Smoothing

This function performs wavelength-dependent boxcar averaging on the measured spectra. This can improve signal-to-noise levels and can filter out oscillations that correspond to optical thicknesses (defined as index multiplied by thickness) equal or greater than the specified value. This value should be lowered to increase smoothing, and raised to decrease smoothing. To eliminate smoothing, a very high value (for example, 1000 um) should be entered.

Source Data

If both are present, this tells the software whether to analyze the reflection data, transmission data, or both. Only possible on spectra from the F10-VC, F10-RT, and F10-PARTS.

Analysis Options: Advanced

Advanced Analysis Options for Spectrum Matching.

Convergence Criteria

This sets the minimum GOF between the measured and calculated spectra that is attained before the measurement routines consider the solution final. In most cases a value of 0.999 is sufficient. For cases where the desired GOF is not attainable, the value in the Maximum Iterations field limits the number of iterations performed by the analysis routine.

Solver Cycles

This option will enable multiple solver cycles, with the number of cycles being defined by the number included in the box. When using this option, the software will run through the model for a solution once, and then try again starting from the solution previously found. A greater number of cycles will lead to a slower analysis.

Display Details

This feature controls the wavelength at which n and k are displayed in the Measurement Details portion of the main screen. These values are only displayed if solving for n or k is enabled in the Film Stack window.

Advanced Analysis Options for FFT Analysis.

FFT Analysis Window

When the FFT solver is enabled, the advanced options gives you options to help Optimize the performance of the analysis. When optimize position is enabled, The solver with check for the best possible GOF value in different areas across the spectrum as defined by the window size. For example, if a window size of 200 nm is selected, the solver will look at six different 200nm sections of the spectrum, and then select the range the provides the best GOF.

If Optimize Size is enabled, the solver will instead begin with a minimum window size as defined by the user. It will then start at the center of the analysis range, and then extend equally in both directions six times to find the best GOF. When Optimize Position and Size is selected, the software does both functions, resulting in measuring thirty-one different combinations of location and analysis range.

Exact Spectrum Matching

Unmodelled Back-Side Reflections

When measuring films in transparent substrates, reflectance off of the backside of the substrate may occur. Selecting compensate for Unmodelled Back-Side Reflections allows the software to shift the intensity of the reflectance curve to account for the additional light. This feature should not be used when measuring very thin films (< 100 nm).

Tilted Sample/Lost Light

Samples with nonplanar surfaces scatter some of the light away from the collection optics. This option automatically compensates for the light lost due to nonplanarity.

Lock Identical Layers

Samples comprised of repeating layers can be more accurately measured by activating this option. By activating these options, all properties of any layers that initially have the same material or thickness are locked together.

Display Details

When solving for n and k, the values displayed in the Results Summary box of the Measure Tab will be the values determined for the wavelength entered here.

Enable Robust (Adaptive; Thickness Only)

If thickness of a single-layer film is the only property to be measured and the film is greater than 150 nm, then the Robust (Adaptive;Thickness Only) mode is often recommended. This mode can oftentimes result in successful measurements when the reflectance data is affected by non-ideal film properties, such as thickness and composition non-uniformities and birefringence. The range of thicknesses tested is constrained by the limits set in the Constraints field in the Film Stack tab. Selecting this feature will limit the Analysis Options tab settings available.

Enable FFT (Thickness Only)

If thickness is the only property to be measured and the film is greater than about 250 nm, then the FFT (Thickness Only) mode can be used. This mode is usually the most effective technique when the sample has multiple film thicknesses to be measured. Selecting this feature will limit the Anal- ysis Options tab settings available.

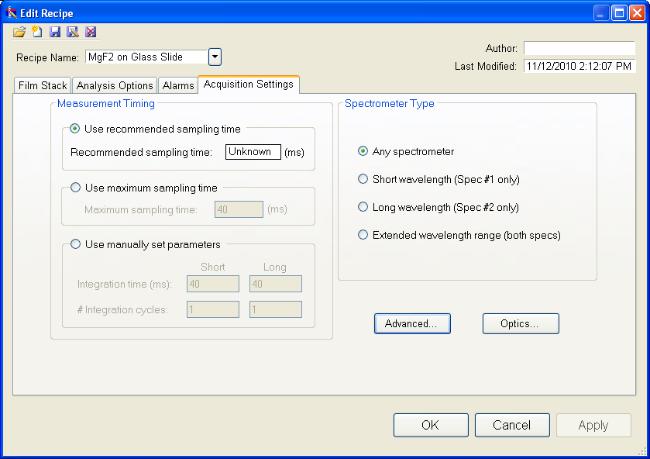

Acquisition Settings

This menu lets the user control sampling settings, active spectrometers (on EXR and UVX systems), and required baseline reference.

Measurement Timing

Use Recommended Sampling Time

Selecting this option uses the sampling time that has been automatically calculated by the software during the baseline procedure. This value is the total sampling time and not necessarily the integration time. To see the integration time and number of integration cycles go to the Help > Diag- nostics menu.

Use Maximum Sampling Time

Users can set a maximum sampling time by selecting this option. This option allows the user to tradeoff between measurement speed and improved signal-to-noise.

Use Manually Set Parameters

Users can set the integration time per acquisition cycle and set a number of integration cycles over which to average. When using this option, the total sampling time is equal to the integration time multiplied by the number of integration cycles.

To set the integration time manually, set the sample on the stage and select Setup>Raw Signal… If the proper integration time is unknown, an initial value of 40ms is a good starting guess. The vertical scale of the spectrum extends from zero to 4095. Thus, a good working level is when the peak height of the sample being measured, or the reference sample, whichever is greater, is 3000-3500 counts. (Note: if the reference measurement saturates – Detector Saturation error – then spurious final measurements will result.) If the maximum signal is too low, increase the integration time. Too large an integration time will result in excessive dark current, so it is sometimes necessary to accept a smaller signal level to limit the dark current.

* * Note * * If the integration time is changed, it will be necessary to perform the baseline procedure, or re-acquire the background and reference scans.

Spectrometer Type

EXR and UVX systems have two spectrometers (VIS/UV and NIR). Here the user can choose to use only one or both spectrometers.

Alarms

GOF Error

Constraining the GOF Error will exclude measurements where the calculated GOF does not reach the specified limit. A warning or “Invalid” result will appear if the GOF constraint is not met. Specify 0 to have all solutions reported.

Activate Alarms

When Activate Alarms is selected, an alarm will trigger if the measured thickness of the sample is outside the specified Thickness Limits.

Thickness Limits

Setting the minimum and maximum allowable thickness limits will trigger an alarm if the measured thickness is outside the limits when Activate Alarms is selected.

Understand and Evaluating Measurement Results

This section covers information on the Display of Measured Spectra and a more in depth look at the Goodness Of Fit value.

Display of Measured Data

Once film stack and measurement information have been entered and baseline spectra taken, measurements may be made by clicking on the Measure button. After measurement, the measured and calculated reflectance spectra are displayed on the graph. The thickness of the films are listed in the results box. If any of the thickness values were measured, they are displayed in bold numbers.

Goodness of Fit

The accuracy of a calculation fit, and thus the reliability of the measurement, can be judged by the match between the measured and calculated spectra, which is quantified by the GOF value. GOF is a number between 0 and 1. 0 is a poor fit.

A perfect match between measured (blue) and theoretical (red) spectra will result in a GOF of 1.0. To ensure accurate results the user may set a minimum acceptable GOF value by entering a number between 0 and 1 into GOF Error on the Alarms Tab in Edit Recipe. A warning message will be displayed after each measurement where the GOF falls below the user-specified GOF Error. If the GOF is less than 1.0 there are several possible causes as follows:

a) Nonuniformity – Any variation of layer thickness, or presence of roughness, within the measurement spot will result in a reduction in reflectance. In severe cases the interference peaks may disappear entirely.

b)Incorrect Structure Definition – If the refractive index of one or more layers in the structure is different from what is described in the layer structure, then there may be some mismatch between the blue curve and the red curve.

c)Graded Interfaces – The amplitude of the peaks in the spectrum depends on both the size of the change in refractive index at each interface in the layer structure and the sharpness of the interface. In many hardcoat samples you will find that there is some degree of layer intermixing at the interface, leading to a weaker than expected reflectance at that interface. In severe cases the peaks may disappear entirely.

Window Menu Items

This section describes the various functions available through the standard Windows File Menus.

File Menu

Edit Menu

Setup Menu

Acquire Menu

Help Menu

File Menu

Open Spectrum…(Measure Tab only)

This command is used to open stored reflectance spectra, which are then displayed and can be analyzed for film properties.

Open Measured Template…(Measure Tab Only)

This command is used to open a saved Contact Probe Template Mode file.

Open History…

Previously saved history data containing measurements and statistics can be loaded with this command.

Import: Recipe…

To import recipes that were previously exported, or created with an older version of FILMeasure, use this command.

Import: Material…

Custom materials, either created by the user or provided by Filmetrics, can be imported using this command.

Import: License…

When the user purchases an upgrade for the system, Filmetrics will send a license file to the user. The license must be imported into the software before upgrades are effective.

Save Measured Spectrum…(Measure Tab only)

This command is used to save spectra for export or later analysis. All data is saved along with the corresponding wavelength data in comma-delimited format. Files can be saved in four different formats:

*.fmspe: This file can only be opened in FILMeasure 6.0 or greater. Additional information from data acquisition is stored in this file and is the preferred way to store your spectra.

*.spe: This file can be opened in all versions of FILMeasure.

*.csv: This is a comma-delimited file that can be opened directly in Excel.

*.txt: This is a tab-delimited file, and can be opened with a text editor.

Save Screen to File…(Measure Tab only)

This command takes a screenshot of the FILMeasure window.

Save n and k to files…(Measure Tab only)

This command is used to save the calculated n and k data to its own material file for use in the Edit Recipe>Material list boxes. All data is saved along with the corresponding wavelength data in comma-delimited format.

Export: Recipe…

Recipes can be exported for use on other computers running FILMeasure. The exported file will also automatically include any material files required by the recipe. To duplicate an analysis, all that is needed is the exported recipe and the spectrum being analyzed.

Export: Recipe for FILMeasure 4…

This command will convert a recipe for use with FILMeasure 4. This will not include material files or recipe features only available in FILMeasure 6.

Export: SystemInfo File…

For certain upgrade purchases that can be done through software, the user will be required to send the SystemInfo file to Filmetrics, which can be exported using this command.

Edit Menu

This Menu allows access to the Material Library.

Loading...

Loading...