Page 1

O

Field Manual

Models: HG1 & HG2

Field Manual

W.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.C

Page 2

I

I

O

TM

HVAC GUIDE

Tester

Field Manual

HG1 & HG2

Do it right the rst time!

Minimize call-backs. Reduce testing and diagnosis time. Improve the technician’s technical capability.

Minimize reliance on outside technical help. e HVAC

TM

Guide

the most common HVAC tests. It then makes a diagnosis and recommends action. e HVAC Guide

makes the service call or installation faster, easier, cleaner, and more complete.

reasons for call-backs. It can cause compressor noise,

shorten compressor life, and lower capacity. Using the

built-in Superheat and Subcooling tests, the HVAC

Guide

step procedure to determine if the refrigerant charge

is correct. With the proper accessory heads, no calculations, charts, or data entry are needed.

that they are too hot or too cold. Once you’ve checked

the duct system for restrictions and leaks, adjust the air ow with the Target Evaporator Exit Temperature procedure that’s built into the HVAC Guide

cause your customers to call you and complain about

the temperature being too cold or the hot water not being hot enough. Use the Combustion test built into the

HVAC Guide

air/fuel mixture by analyzing the combustion products.

You can then make adjustments to make sure the equipment works as it should.

more sophisticated air conditioner test procedure that

will help diagnose more complex problems by looking

at the air conditioning system as a whole.

it more completely and avoid call-backs in the process.

WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.F

Guided Probe Tester can do all that and more.

e display leads the technician step by step through

TM

tester

Improper refrigerant charge is one of the primary

TM

tester leads the technician through a step by

Improper air ow can cause customers to complain

TM

tester.

An improperly adjusted furnace or water heater will

TM

tester to determine if you have the right

e CheckMe!® test (model HG2 only) is a much

Do it right the rst time, do it faster, do it easier, do

2

Table of Contents

Do it Right the First Time! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Table of Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

HVAC GuideTM Tester Controls . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Select the Test (Switch Positions). . . . . . . . . . . . . . . . . . . . . . . 6

Fill in the INPUT FORM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Read the OUTPUT FORM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

What Accessory Heads Do I Need? . . . . . . . . . . . . . . . . . . . . 10

How to Connect an Accessory Head. . . . . . . . . . . . . . . . . . . 11

Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Target Evaporator Exit Temperature . . . . . . . . . . . . . . . . . 12

Superheat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Superheat and Subcooling FAQ part 1 . . . . . . . . . . . . 21

Subcooling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Superheat and Subcooling FAQ part 2 . . . . . . . . . . . . 27

Combustion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

“CheckMe!®” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Advanced Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Memory (MEM). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Customer ID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Clearing a single input or INPUT FORM . . . . . . . . . . . . . . 52

Saving Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Recalling Saved Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Contrast Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

PC Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Installing the PC Software . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Communicating with a PC . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Transfer Tests from the HVAC GuideTM Tester to a PC . . 56

Transfer Tests From the PC to the HVAC GuideTM Tester. . 58

Looking at Downloaded Data. . . . . . . . . . . . . . . . . . . . . . . 60

Other Operations with PC Software . . . . . . . . . . . . . . . . . . . 61

Air Conditioning Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Combustion Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Product Speci cations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Obtaining Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Disclaimer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

John Proctor and Title 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

ELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.C

© Copyright Fieldpiece Instruments 2007

Page 3

I

I

O

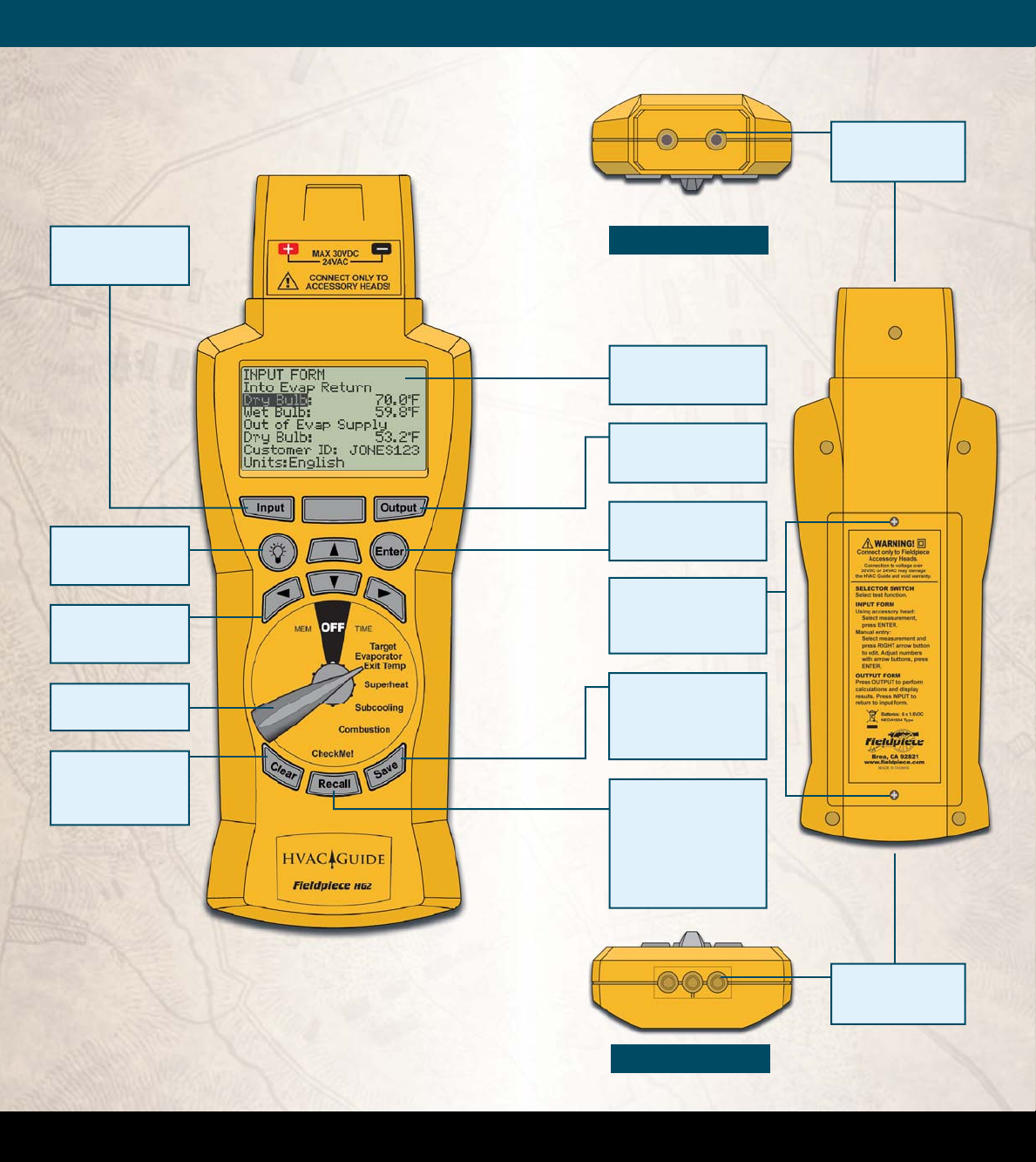

HVAC GUIDETM Tester Controls

Input Jacks

Connect accessory heads

here.

Input Button

Returns you to the INPUT

FORM.

Backlight Button

Turns on the backlight for

30 sec.

Arrow Buttons

Navigate within FORMS

and screens.

Switch Position Dial

Rotate to select test.

Clear Button

Clears a single input or

the entire INPUT FORM by

holding for 3 seconds.

Top View

Dot Matrix LCD Display

Displays INPUT FORMS and

OUTPUT FORMS.

Output Button

Triggers calculations and takes

you to the OUTPUT FORM.

Enter Button

Makes a selection or enters

data.

Battery Cover

After "POWER OFF" clears,

unscrew the two screws to

replace the 6AA batteries.

Save Button

Saves the current INPUT FORM.

Inputs are saved with Customer

ID and Time Stamp. See Saving

Data section for details.

Recall Button

Recalls previous tests within

each switch position. Previous

tests can only be accessed

through the switch position in

which they were performed

and are sorted by Customer ID

and Time Stamp.

WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.F

4

PC Cable Interface

PC cable plugs into the

bottom to transfer data.

Bottom View

ELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.C

Page 4

I

I

O

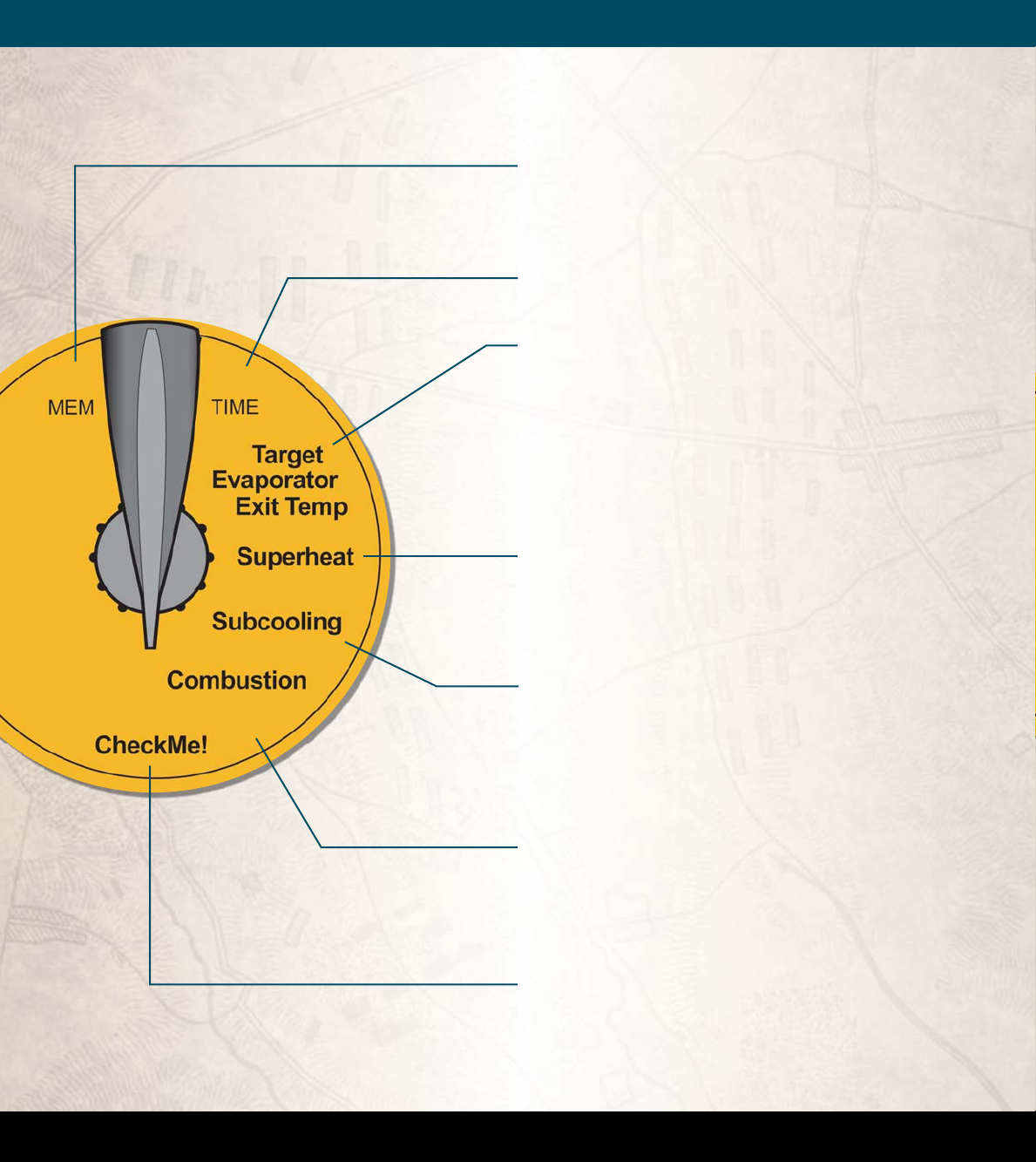

Select the Test

Switch Positions

MEM: Erase a single test, an entire customer’s set of

tests, or all data. MEM also allows you to check

memory status, rmware version, and communicate with a PC for data transfer.

TIME: Set current time and date for internal clock. All

tests are time stamped and cannot be changed later.

Target Evaporator Exit Temperature: By mea-

suring the return wet bulb and dry bulb, the HVAC

TM

Guide

temperature. To ensure that the A/C system has the

proper air ow per tonnage, the actual evaporator

exit temperature must be within ±3°F of the target

evaporator exit temperature as outlined in CA title

24.

Superheat: For a xed restrictor air conditioning sys-

tem, the HVAC Guide

bulb and outside dry bulb to calculate a target superheat and uses the suction line temperature and

pressure to calculate actual superheat.

tester calculates a target evaporator exit

TM

tester uses the indoor wet

WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.F

6

Subcooling: For a TXV/EXV air conditioning system,

the HVAC Guide

ture and pressure to calculate actual subcooling. If

the manufacture’s target subcooling is not available,

the HVAC Guide

estimate.

TM

tester uses liquid line tempera-

TM

tester provides a conservative

Combustion: For combustion equipment, the HVAC

TM

Guide

temperature and CO ppm to calculate %CO

tester uses %O2, ue temperature, primary

, % Ex-

2

cess Air, CO (air free), Net Temperature, Standard

E ciency and Siegert E ciency.

CheckMe!® (model HG2): is is a more advanced

test for determining the overall state of an air conditioning system. e CheckMe!® test will give you a

diagnosis of the system in plain English and a list of

potential problems in the system.

ELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.C

Page 5

I

I

O

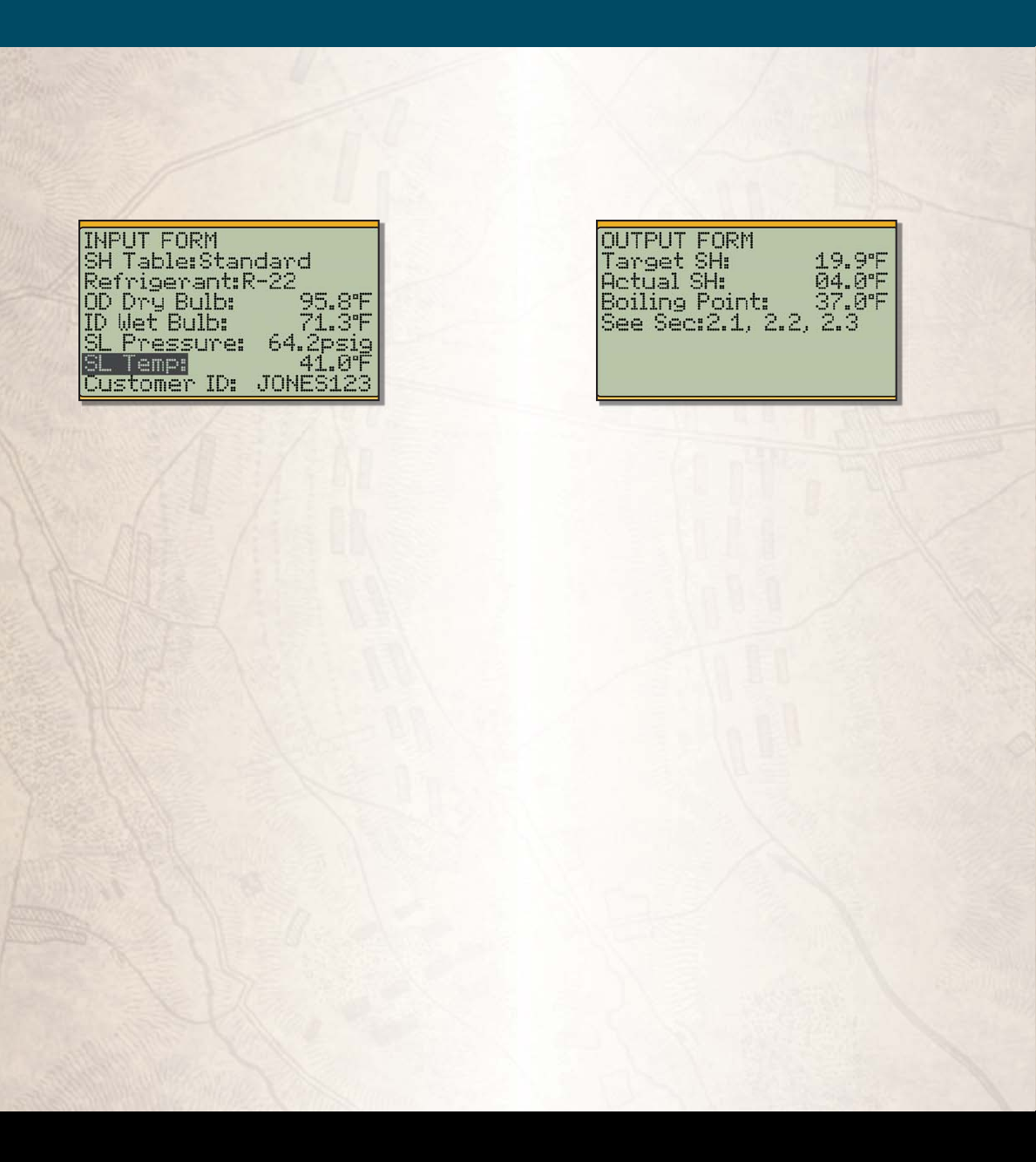

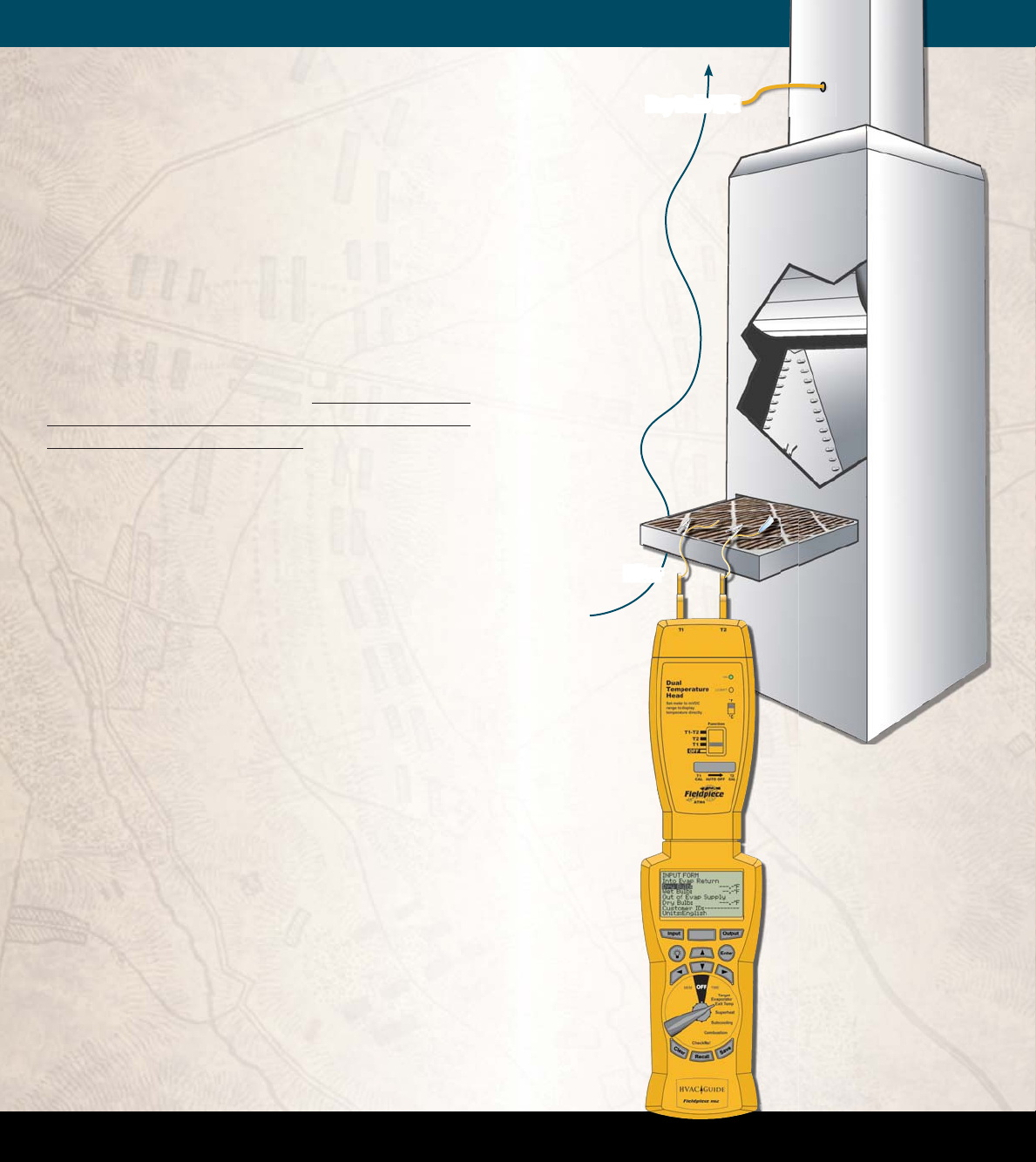

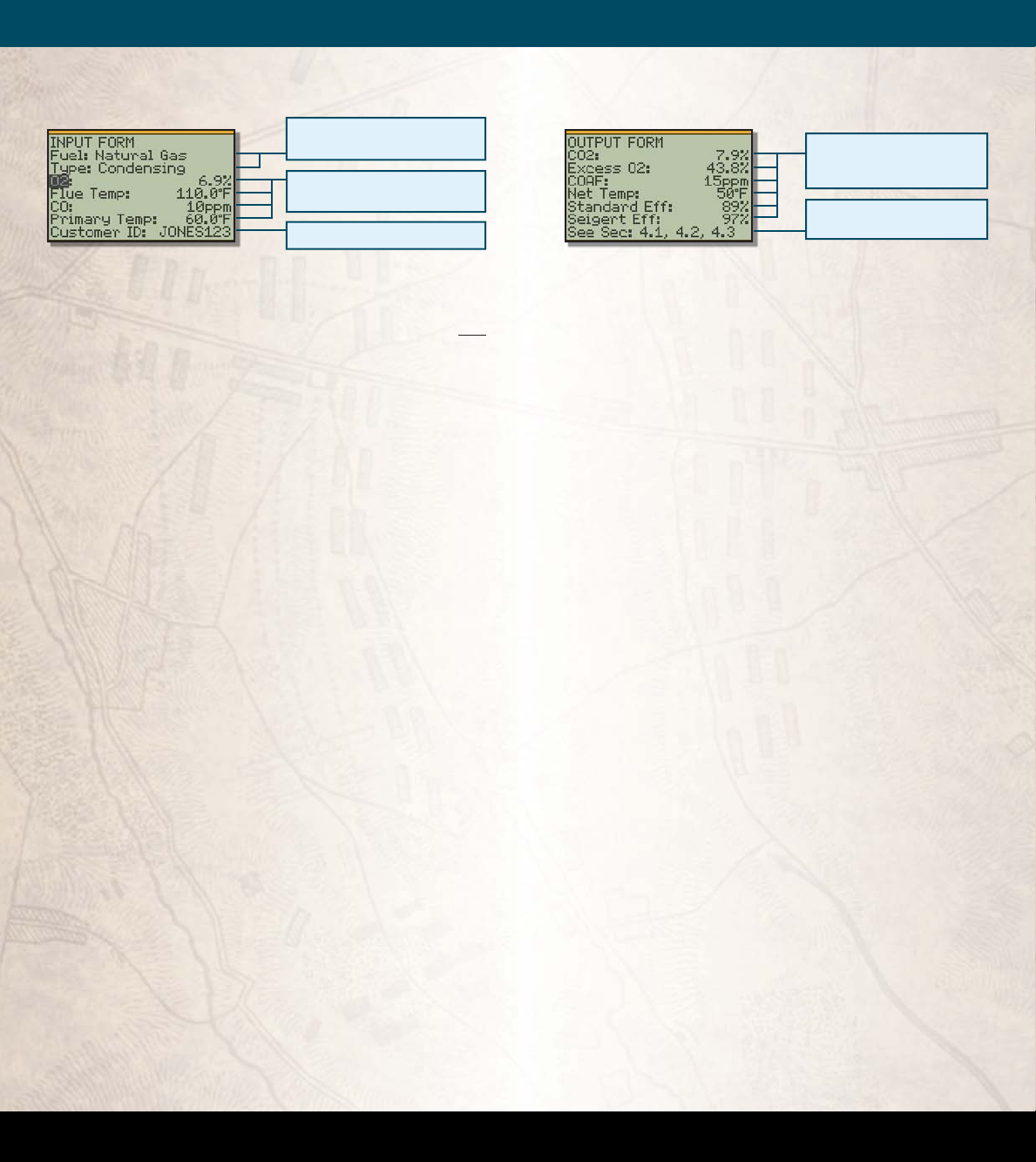

Fill in the INPUT FORM

Read the OUTPUT FORM

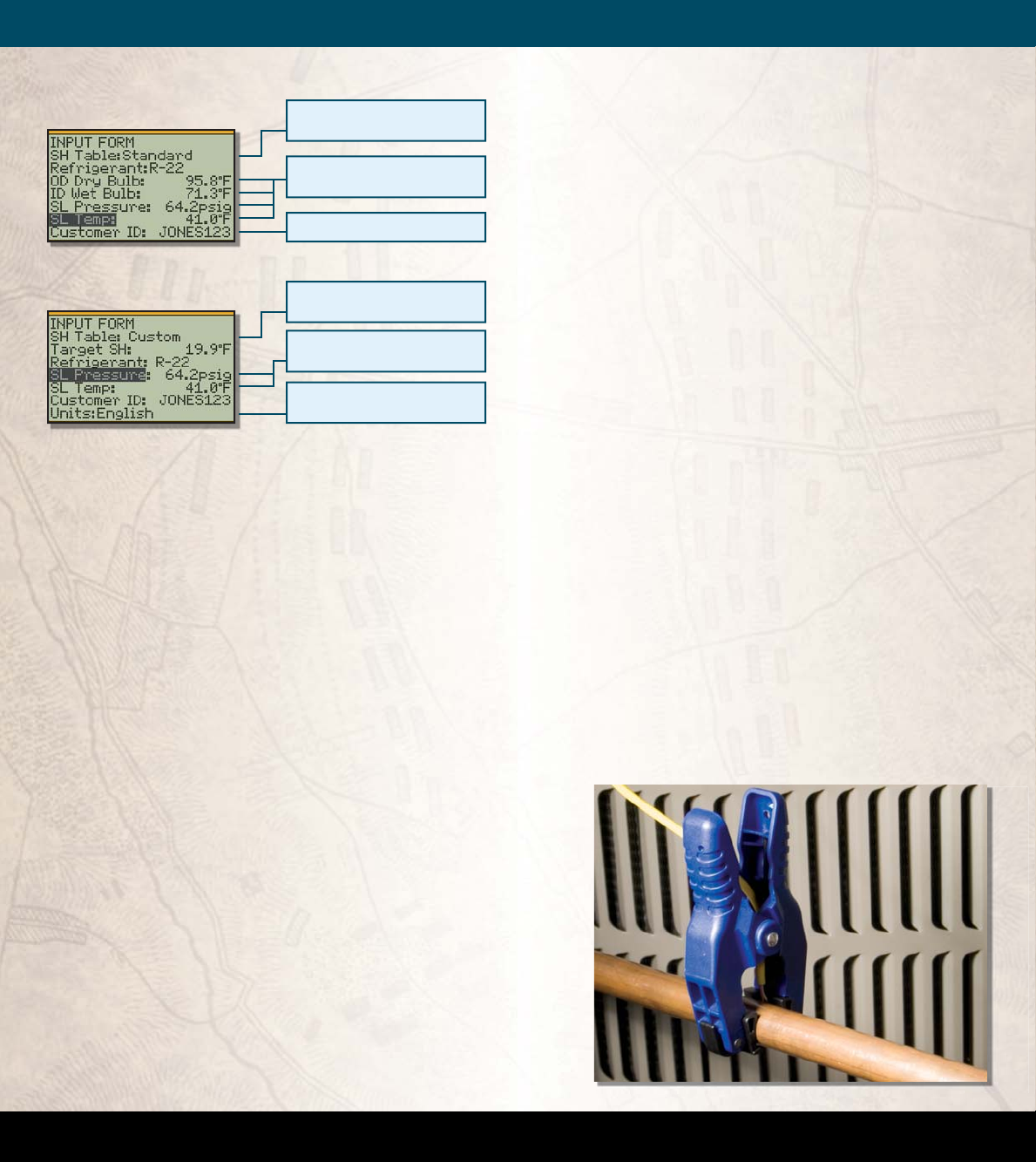

Figure 1. INPUT FORM for the Superheat test.

e INPUT FORM lists parameters in the order of

expected entry.

ree ways to enter data:

1. Automatic: Attach appropriate head, select ap-

propriate line with the UP/DOWN arrows, press

ENTER to start measuring, and press ENTER

again to lock in the value.

2. Drop down menu: To change a parameter that

has a default, press RIGHT arrow or ENTER, use

UP/DOWN arrows to scroll through the drop-

down list, and press ENTER again.

3. Manual: Enter system data (or to enter test data

not taken with an accessory head) by pressing the

RIGHT arrow and then, character-by-character, use

the UP/DOWN arrows and the RIGHT arrow to

‘type in’ the value. When nished press ENTER. Tar-

get Evaporator Exit Temperature test has no system

data to enter.

Figure 2. OUTPUT FORM for the Superheat test.

To display the OUTPUT FORM, ll in the INPUT

FORM correctly and press the OUTPUT button or

scroll down. If the INPUT FORM is missing inputs, the

appropriate lines on the OUTPUT FORM will be blank.

If the data entered on the INPUT FORM is out of range

or physically impossible, an error message is displayed.

e OUTPUT FORM displays the results of the calculations.

• e “See Sec:” at the bottom of the OUTPUT FORM

tells you what section in the manual has more infor-

mation about how to perform the speci c test and

what the results mean.

• To ensure that your changes have optimized the sys-

tem, retest a er the system is stabilized.

e CheckMe!® test (model HG2) has a more detailed OUTPUT FORM. If everything on the INPUT

FORM is lled out properly, the CheckMe!® OUTPUT

FORM will rank the possible problems in order of likelihood and describe how to x them. If you haven’t taken

all the necessary measurements, the rst line will tell

you what you need to do for a complete diagnosis.

WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.F

8

ELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.C

Page 6

I

I

O

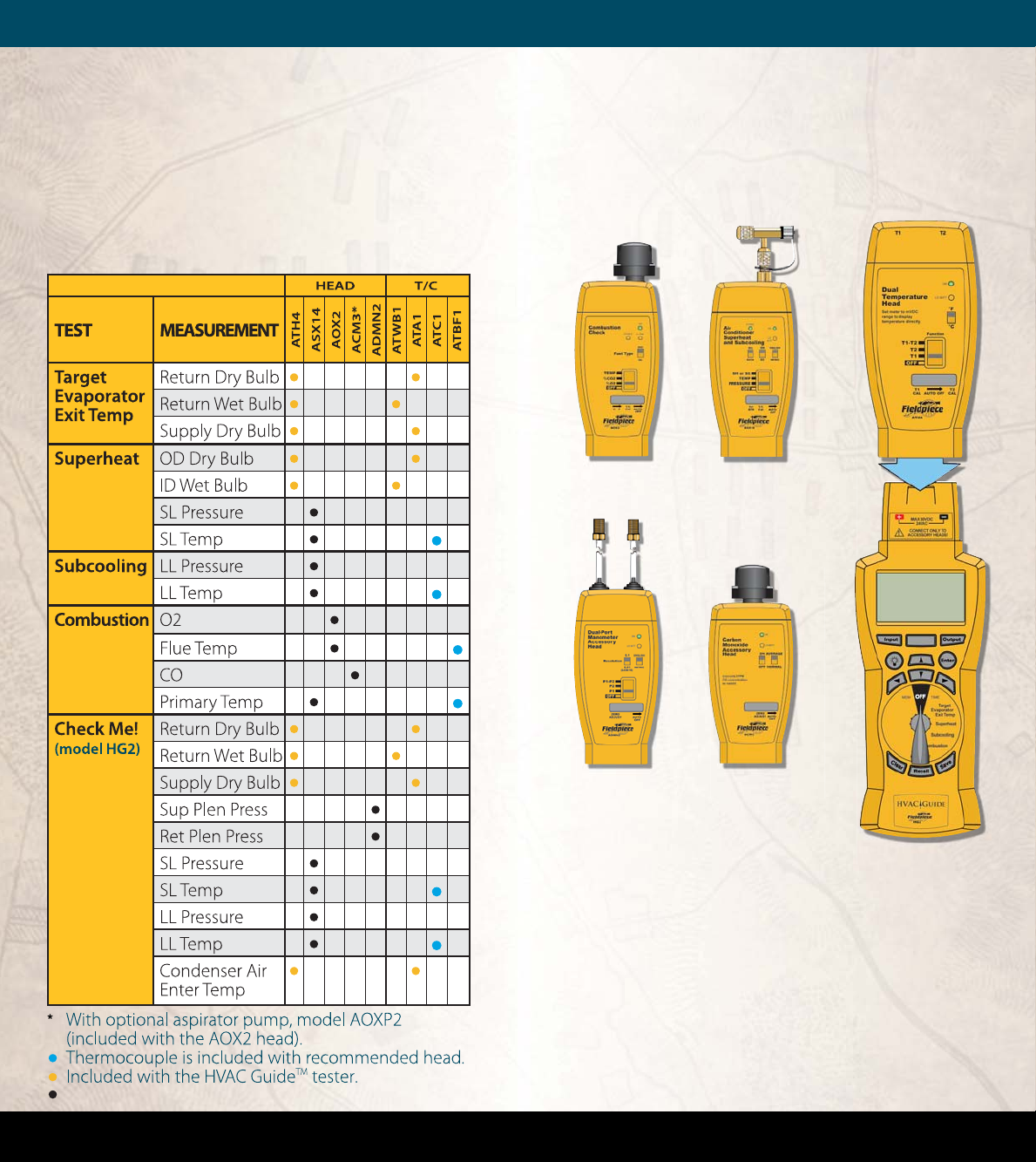

What Accessory Heads

Do I Need?

Refer to the chart below to nd the recommended accessory head and thermocouple for each measurement. Automatically input measurements with

Fieldpiece accessory heads for maximum accuracy, or

manually input from non-Fieldpiece test equipment.

How to Connect an

Accessory Head

AOX2

ADMN2

ASX14

ACM3

ATH4 on

HVAC Guide

TM

tester

WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.F

10

ELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.C

Page 7

I

I

O

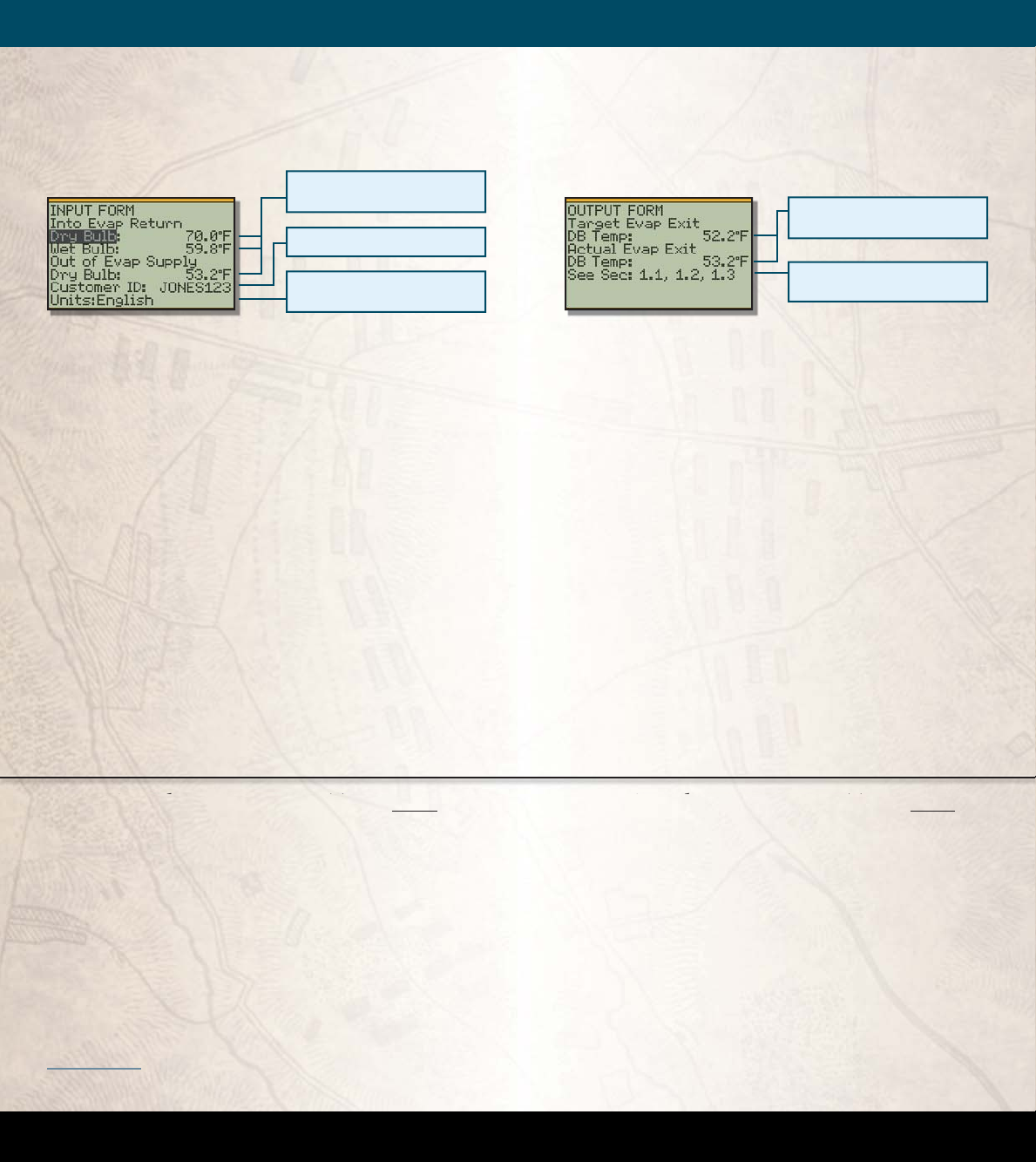

Tests

A-Coil

Fan

Dry Bulb and

Wet Bulb T/C

Supply Plenum

C

WWW.FIELDPIECE.CO WWW.

FIt.

.COM

O

M

W

er

1.1

Evaporator Exit Temperature gives you an indication of

the proper indoor air ow. is test can be easily performed simultaneously with superheat or subcooling

tests.

3°F above or below the Target Evaporator Exit Temperature, an air ow problem may exist. Ensure that lters are

clear, dampers are adjusted properly and the fan speed

is set correctly if it can be varied. e Target Evaporator Exit Temperature switch position uses the table from

California Title 24.

Target Evaporator Exit Temperature

For given return plenum air conditions, Target

If actual evaporator exit temperature is more than

Supply Plenum

Direction

of Air ow

Dry Bulb and

Wet Bulb T/C

Filter

Dry Bulb T/C

Fan

A-Coil

WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.F

12

Figure 3. Setting up the ATH4 and

HVAC Guide

TM

tester to measure dry

bulb and wet bulb temperatures

between fi lter and coil.

ELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.C

WWW.FIELDPIECE.C

W

Page 8

I

I

O

1.2 Target Evaporator Exit Temperature

1.3 Target Evaporator Exit Temperature

INPUT FORM

Can be measured automatically with

Fieldpiece accessory heads.

Customer ID is useful for record keeping.

Units can be changed to either English

or Metric.

Figure 4. INPUT FORM for Target Evaporator Exit Temperature.

Into Evap Return Dry Bulb and Wet Bulb: Take

measurements as close to the inlet of the air handler

as possible. If the lter is just before the air handler,

the easiest way is to clip an ATWB1 and ATA1 to the

lter on the side facing the evaporator and take the

measurements. If the lter is not before the evaporator, make small holes in the return plenum just big

enough for the probes. Seal any holes before leaving

the jobsite.

Out of Evap Supply DB (dry bulb temp leaving

the evaporator): Measure in the center of the supply

plenum. Punch a small hole in the supply plenum

and insert a calibrated dry bulb thermocouple such

as the ATA1 or ATB1. Make sure the thermocouple

is in the center of the plenum cross-section. Seal the

hole when nished.

OUTPUT FORM

If Target and Actual are more than 3°F

apart a modification is needed.

Sections of manual with more

information about this test.

Figure 5. OUTPUT FORM for Target Evaporator Exit Temperature.

Press OUTPUT for the Target Evaporator Exit Tem-

perature OUTPUT FORM.

Target Evap Exit DB Temp (Target Evaporator

Exit Dry Bulb Temperature): is is the target exit

temperature based on the measured indoor conditions.

Actual Evap Exit DB Temp (Actual Evaporator

Exit Dry Bulb Temperature): is is the measured

temperature of the air in the supply.

e

Actual Evap Exit DB Temp should be

within ±3°F of the

the temperature is outside of this range, the technician

should make modi cations to correct the problem.

Target Evap Exit DB Temp. If

An Actual Evap Exit DB Temp below the

Target Evap Exit DB Temp indicates low air ow.

Increasing air ow can be accomplished by eliminating restrictions in the duct system, increasing blower

speed, cleaning lters or opening registers. A er corrective measures are taken, repeat measurement procedures as o en as necessary to establish adequate air ow

range. Allow system to stabilize for 15 minutes before

repeating measurement procedure.

1 2005 Residential ACM Manual, Page RD-5, (#5-7)

WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.F

1

14

An Actual Evap Exit DB Temp above the

Target Evap Exit DB Temp usually indicates low

capacity. Occasionally air ow is higher than expected.

Look for causes of low capacity such as refrigerant mischarge or dirty condenser coil. If the air ow is high,

correct by lowering the fan speed.

Because everything within the system is inter-dependent, one adjustment can a ect other parts of the

system. For example, increasing air ow increases the

superheat, which may require adding refrigerant. A er

modi cations, allow 15 minutes to stabilize and then

retest.

ELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.C

Page 9

I

I

O

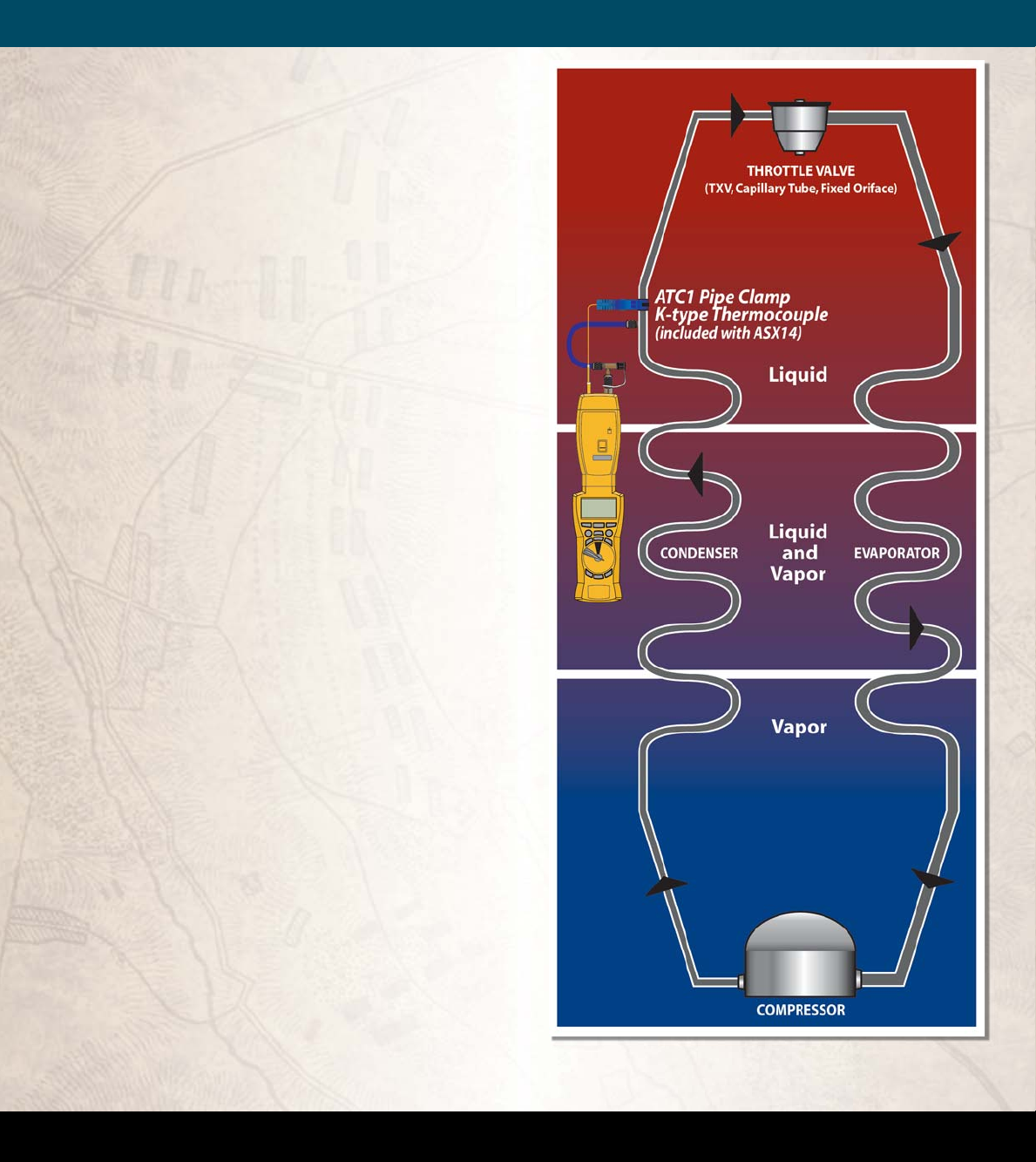

2.1 Superheat

Superheat is the temperature rise above the boiling

point of the refrigerant a er the evaporator. Too high,

and the refrigerant boils o early in the evaporator and

‘wastes’ most of the capacity of the evaporator. Too low,

and you risk liquid going into the compressor.

Using superheat is the best way to obtain proper

refrigerant charge for a xed restrictor metering device

system.

If the air conditioner is in good working order and

the air ow is adjusted properly, comparing the actual

and target superheat will tell you if refrigerant needs to

be added or recovered. Ensure the pressure never exceeds the manufacturer's maximum overload pressure

guidelines.

On a xed restrictor system, the target superheat is

determined based upon the indoor wet bulb and outdoor dry bulb temperatures. Proper superheat ensures

the compressor doesn't ood under a low indoor load

and that the maximum e ciency and capacity are maintained.

WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.F

16

Figure 6. Using the ASX14 Superheat/Subcooling Head to gather suction line

temperature and pressure for the HVAC Guide

ELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.C

TM

tester Superheat Test.

Page 10

I

I

O

2.2 Superheat INPUT FORM

Standard table uses the Title 24 target

superheat table.

Can be measured automatically with

Fieldpiece accessory heads.

Customer ID is useful for record keeping.

Figure 7. INPUT FORM for Standard Table Superheat Test.

Custom table allows you to enter your

own target superheat value.

Can be measured automatically with

Fieldpiece accessory heads.

Units can be changed to either English

or Metric.

Figure 8. INPUT FORM for Custom Table Superheat Test.

SH Table: Default: “Standard” uses the target super-

heat table from Title 24 for xed restrictor systems.

Other selection: “Custom” allows you to enter your

own target superheat by displaying the

input.

Target SH

air reaches the indoor coil). Wet the wet bulb sensor

(ATWB1) and insert it a er 15 minutes of continuous running. Clip downstream of the lter if the

lter is just before the air handler. Clip on the side

facing the evaporator and take the measurements.

If the lter is not before the evaporator, make small

holes in the return plenum just big enough for the

probes. Seal any holes before leaving the jobsite.

Watch the wet bulb temperature; it will drop and

then stabilize. e wet bulb temperature is the stabilized reading. If the sensor starts to dry out, the

reading will rise and the wrong temperature will be

recorded.

SL Pressure (suction line pressure): Connect the

ASX14 to the suction side service port. Select pressure mode on the ASX14 head. e system must be

stabilized before taking the measurements. Enter

data manually if you want to get pressure from your

gauges. e analysis is only as good as the measurements. e Fieldpiece ASX14 has better resolution

than most gauge sets.

Target SH (Custom SH Table): Change the SH Ta-

ble to Custom and enter the manufacturer’s recom-

mended superheat in the

Target SH input.

Refrigerant: Default: R-22. Other selections: R-410A,

R-134A, R-404A, R-407C, R-409A, R-408A, R-507A,

R-414B (Hotshot

(NU222B

TM

TM

), R-422C (OneshotTM), R-422B

) or R-12.

OD Dry Bulb (outdoor dry bulb, Standard SH Ta-

ble): Clip a calibrated ATA1 to the inlet of the con-

denser ns (typically on the side of the condenser),

in the shade if possible. Note that the temperature of

the air entering the outdoor coil can be considerably

di erent than the ambient temperature due to recir-

culation of air exiting the unit. Determine the aver-

age temperature of the air entering the condenser.

ID Wet Bulb (indoor wet bulb, Standard SH Table):

Take measurements very close or within the return

air side of the inlet to the air handler (not at the re-

WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.F

turn grill since temperatures change by the time the

18

SL Temp (suction line temperature): Measure near SL

service port (within 6 inches). Use the ATC1, ATC2

or ATC3 to get a good pipe temperature. e clamp

should be perpendicular to the pipe and should be

securely seated with the sensor in contact with the

suction line. If working on a package unit make sure

you are at least 6 inches away from the compressor.

Figure 9. ATC1 pipe clamp thermocouple attached to a pipe correctly.

ELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.C

Page 11

I

I

O

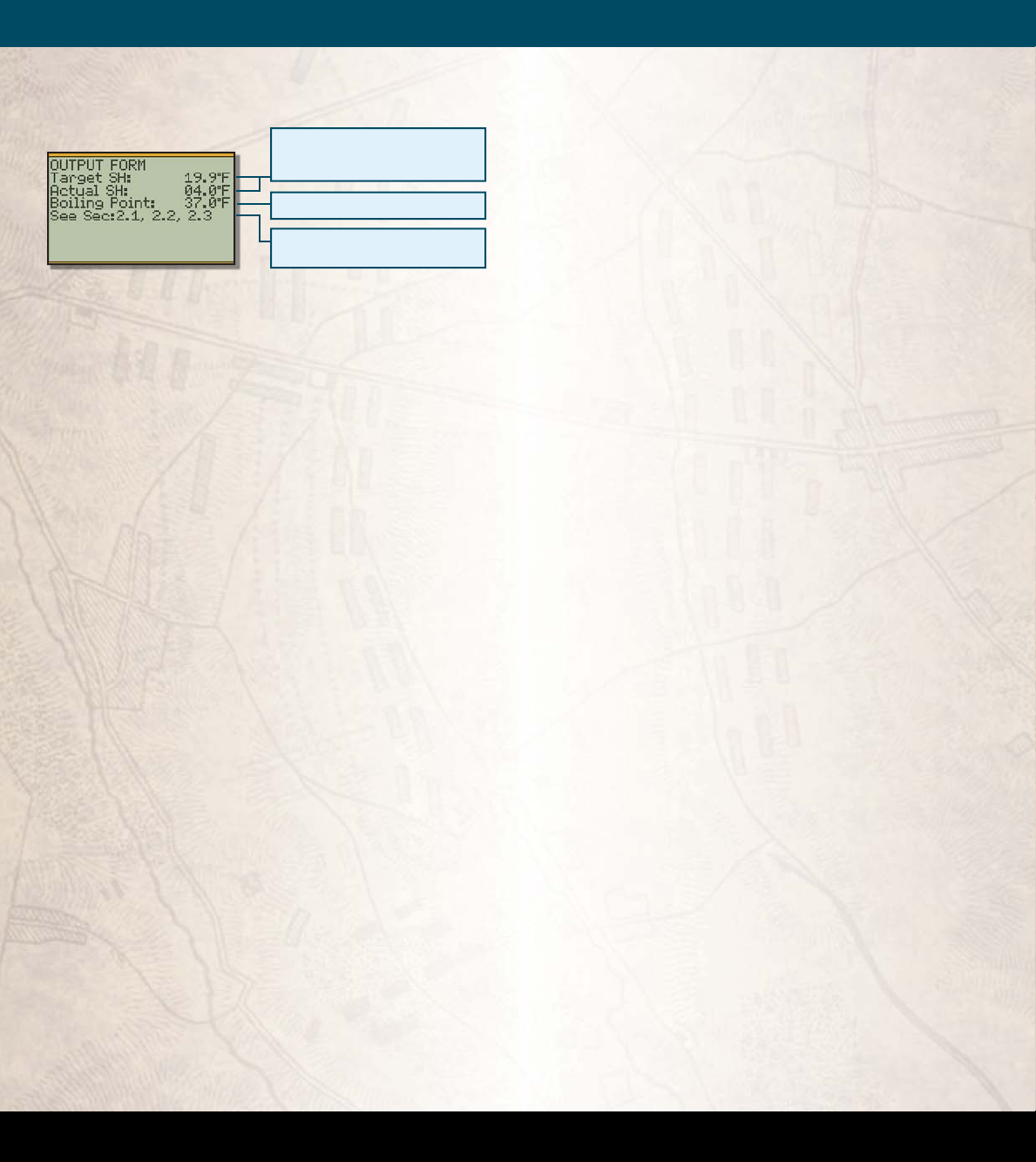

2.3 Superheat OUTPUT FORM

Superheat and Subcooling FAQ

If Target SH and Actual SH are more than

5°F apart, as in this example, you need to

make adjustments to the system.

Boiling point is used to calculate Superheat.

Sections of manual with more information

about this test.

Figure 10. Superheat Test OUTPUT FORM.

Press OUTPUT for the Superheat OUTPUT FORM.

Target SH (Superheat): Indicates what the superheat

should be as calculated from outdoor dry bulb and

indoor wet bulb

Actual SH (Superheat): Shows the superheat calculated

from the measured suction line temperature and suc-

tion line pressure.

Boiling Point: is is the saturation temperature of the

refrigerant in the evaporator coil. It is one of the tem-

peratures from which superheat is calculated.

e

Actual SH (superheat) should be within ±5°F of

the Target SH to ensure optimum performance. If the

ac-

tual SH is outside this range, modi cations to the charge

or adjustments to the restrictor (TXV) are necessary.

Adding refrigerant lowers your Actual SH. Recovering refrigerant increases your Actual SH. e amount of

refrigerant necessary to add or recover will vary based on

the size of the system and the di erence between the Actual and Target SH.

Because everything within the system is inter-dependent, one adjustment can a ect other parts of the system.

For example, increasing air ow increases the superheat,

which may require adding refrigerant. A er modi cations, allow 15 minutes to stabilize and then retest.

Q: How do superheat/subcooling tools work?

A: Superheat tools measure suction line pressure and

suction line temperature, and calculate the actual superheat. Subcooling tools measure the liquid line pressure and liquid line temperature and calculate actual

subcooling. e refrigerant charts for calculations are

incorporated into the so ware of the HVAC Guide

tester.

TM

Q: When should I take my actual and target

superheat/subcooling?

A: Superheat and subcooling readings must be taken

when the system is in a steady state. Typically a residential system will be in a steady state a er 10-15 minutes. Turn the system on and set the thermostat low to

ensure that the system doesn’t turn o during your

testing. Once the system’s temperatures and pressures

are not uctuating, the system is in a steady state.

Wet bulb temperature, outdoor dry bulb, suction line

pressure and suction line temperature must be taken

within a short time period to ensure valid results.

Conditions that a ect your target superheat and target subcooling can change by the minute.

Q: What do I do with my ACTUAL superheat

or ACTUAL subcooling measurements?

A: Compare actual readings against the target superheat/

subcooling. As a general rule, if superheat is too high,

add refrigerant. If too low, remove refrigerant. If subcooling is too low, remove refrigerant. If subcooling is

too high, add refrigerant. Consult the manufacturer’s

speci cations before adding or recovering refrigerant

as further diagnostic tests may be needed

Continued on page 27

WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.F

20

ELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.C

Page 12

I

I

O

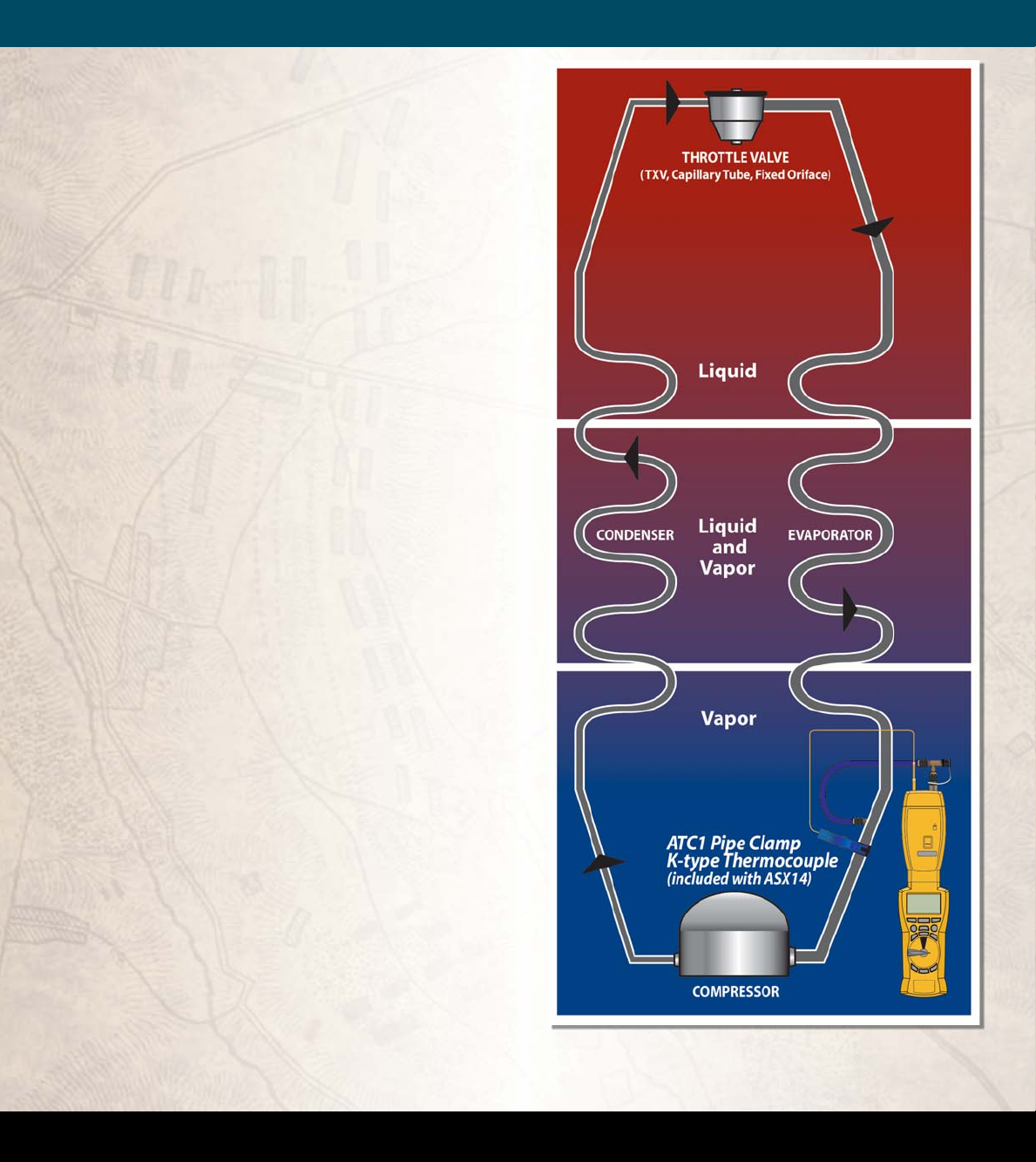

3.1 Subcooling

Subcooling is the temperature decrease below the

boiling point (same as the condensing point) in the condenser. Too high, and refrigerant condenses too early in

the condenser and ‘wastes’ most of the capacity of the

condenser. Too low, and a mixture of gas and liquid can

be delivered to the expansion valve, reducing e ciency.

Subcooling is the best way to obtain proper refrigerant charge for a TXV/EXV system.

If the air conditioner is in good working order and

the air ow is adjusted properly, comparing the actual

and target subcooling will tell you if refrigerant needs

to be added or recovered (ensure the pressure never exceeds the manufacturer's maximum overload pressure

guidelines).

In a properly working TXV/EXV system, the superheat is held constant. Ensure the TXV/EXV bulb is installed properly, there is proper refrigerant to obtain target subcooling, and there are no liquid line restrictions.

Adjust refrigerant charge so that the actual subcooling is

within ±3°F of target subcooling.

WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.F

22

Figure 11. Using the ASX14 Superheat/Subcooling Head to gather liquid line

temperature and pressure for the HVAC Guide

ELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.C

TM

tester Subcooling Test.

Page 13

I

I

O

3.2 Subcooling INPUT FORM

Target SC (WITH Manufacturer’s Data): Man-

ually input the manufacturer’s target subcooling.

Answering Yes or No takes you to a

different INPUT FORM. Always use

the manufacturer's recommended

subcooling when available.

Figure 12. Subcooling Test INPUT FORM question.

Target SC must be entered from the

equipment specifications.

Can be measured automatically with

Fieldpiece accessory heads.

Units can be changed to either English

or Metric.

Figure 13. Subcooling Test INPUT FORM with Manufacturer's Data.

Without manufacturer's recommended

subcooling data, the HVAC Guide

tester makes a conservative Target SC

estimate.

Can be measured automatically with

Fieldpiece accessory heads.

LL Pressure (liquid line pressure): Connect the

ASX14 to the liquid line service port. Set the accessory head to measure pressure and ensure the reading stabilizes before locking in the reading. Enter

data manually if you want to get pressure from your

gauges. e analysis is only as good as the measurements. e Fieldpiece ASX14 has better resolution

than most gauge sets.

LL Temp (liquid line temperature): Measure near the

same location LL Pressure was taken. Use the ATC1,

ATC2 or ATC3 to get a good pipe temperature. e

clamp should be perpendicular to the pipe and

should be securely seated with the sensor in contact

with the liquid line. If working on a package unit

make sure you are at least 6 inches away from the

compressor.

TM

Current time is set within TIME switch

position (see page 52).

Figure 14. Subcooling Test INPUT FORM without Manufacturer's Data.

Does the manufacturer have a recommended

subcooling? Default: Yes. Always answer "YES" if

you have a manufacturer’s recommended subcooling.

Other selection: "NO" will use a conservative estimate

for Target SC (Subcooling).

Refrigerant: Default: R-22. Other selections: R410A,

R-134A, R-404A, R-407C, R-409A, R-408A, R-507A,

R-414B (Hotshot

(NU222B

WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.F

TM

TM

) or R-12.

), R-422C (OneshotTM), R-422B

24

Figure 15. ATC1 pipe clamp thermocouple attached to a pipe correctly.

ELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.C

Page 14

I

I

O

3.3 Subcooling OUTPUT FORM

Superheat and Subcooling FAQ

Part 2 (continued from page 21)

If Target SC and Actual SC are more than

3°F apart, as in this example, you need to

make adjustments to the system.

Boiling point is used to calculate Subcooling.

Sections of manual with more information

about this test.

Figure 16. Subcooling Test OUTPUT FORM.

Press OUTPUT for the Subcooling OUTPUT FORM.

Target SC (Subcooling): Indicates what the subcool-

ing should be from the manufacturer’s speci cations.

e HVAC Guide

estimate when manufacturer’s speci cations are not

available.

TM

tester uses a built in conservative

Actual SC (Subcooling): Displays the subcooling calcu-

lated from the measured liquid line temperature and

liquid line pressure.

Boiling Point: is is the saturation temperature of the

refrigerant in the condenser coil. It is one of the tem-

peratures from which subcooling is calculated.

e

Actual SC (subcooling) should be within ±3°F

of the

Target SC for correct refrigerant charge. Tem-

peratures outside of this range indicate that you need to

make adjustments.

Adding refrigerant increases your

covering refrigerant decreases your

amount of refrigerant necessary to add or recover will

vary based on the size of the system and the di erence

between the Actual and Target SC.

Because everything is inter-dependent, changes in one

part of the system a ect other parts of the system. For example, increasing air ow decreases the subcooling, which

may require adding refrigerant. A er modi cations, allow

15 minutes for the system to stabilize and then retest.

Actual SC. Re-

Actual SC. e

Q: What if my ACTUALS are far di erent from

my TARGETS, but the system seems to be

running properly?

A: Many poor performing systems have actual super-

heat/subcooling measurements well outside the target. e system may be drastically overcharged or

undercharged. Comparing actual superheat/subcooling readings with the manufacturer’s equipment speci c target superheat/subcooling o en con rms the

system’s condition. Sometimes there is something else

wrong.

Make sure the system has been in operation for at least

15 minutes and is stable. Make sure it continues to

operate throughout the test. Take your readings in as

short of a time period as possible. ings can change,

even for a system that appears stable.

Make sure your test equipment is calibrated. Refer to

the manual of the accessory head for calibration instructions. Make certain the unit selected corresponds

to the reading you are taking. For superheat on accessory heads (ASX14, ASX24), make certain the large

switch on the face of the head is switched to superheat and small switch is in the “SH” position. Make

certain that you are testing for superheat/subcooling

at the proper location in the system. Test the evaporator/suction line side of the system for superheat. Test

the condenser/high side of the system for subcooling.

If you still get readings that don’t seem right, you can

perform a manual test using your gauges, a wet sock

for wet bulb (ATWB1 wet bulb thermocouple), thermometer, refrigerant chart, and manufacturer’s target

superheat chart. If it still appears your unit is reading

superheat/subcooling incorrectly, call Fieldpiece technical support.

Q: Where can I nd more info on Superheat

and Subcooling?

WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.F

26

A: Visit www. eldpiece.com

ELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.C

Page 15

I

I

O

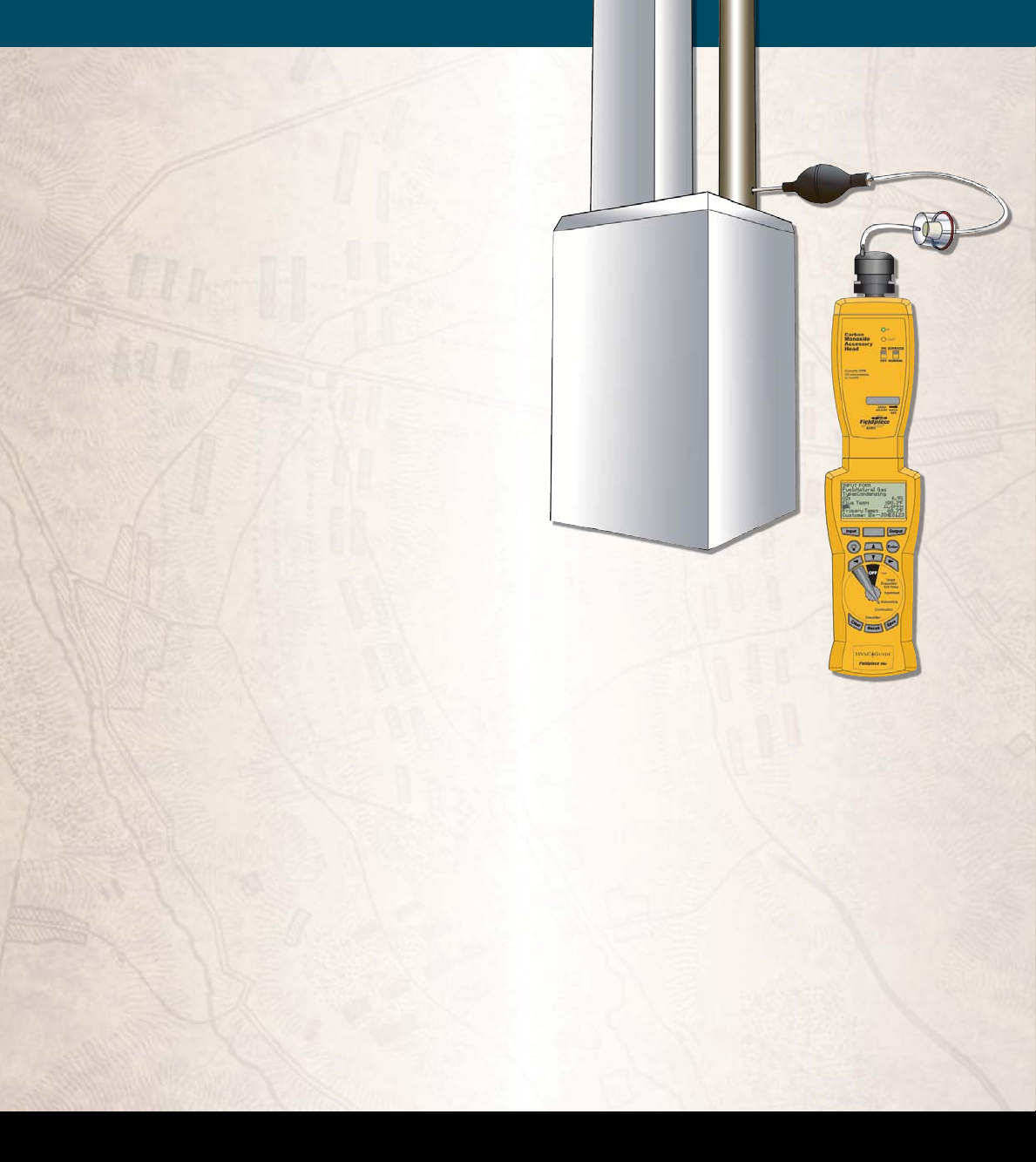

4.1 Combustion

Supply

Plenum

Flue

Combustion Test helps you determine the e ectiveness of the combustion by analysis of combustion products and temperature.

e Combustion Test will only tell you about combustion and does not take into account any losses from

poor insulation, or cycling and standby losses. It does

not measure any losses in the distribution system such

as uninsulated hydronic piping, air duct leakage or insulation levels.

Properly tuned gas combustion equipment will

produce little or no carbon monoxide, no soot, and will

consume less fuel.

Supply

Plenum

Flue

WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.F

28

Figure 17. CO measurement of fl ue gas for the Combustion Test using an

ACM3 Carbon Monoxide Head and the pump that’s included with the AOX2

Combustion Check Head.

ELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.C

Page 16

I

I

O

4.2 Combustion INPUT FORM Overview

Select the Fuel and what type of

equipment you are working on.

Can be measured automatically with

Fieldpiece accessory heads.

Customer ID is useful for record keeping.

4.3 Combustion OUTPUT FORM Overview

Modify combustion equipment

to bring these calculations to the

manufacturer's specifications.

Sections of manual with more

information about this test.

Figure 18. Combustion Test INPUT FORM.

Combustion gases should be sampled close to the exit

from the heat exchanger within an area where all gasses

would be well mixed and before dilution air enters the

venting systems i.e., dra hoods, barometric dampers, etc.

Testing within 18 inches of the breech is a typical location

for most oil- red equipment. If the appliance is an atmospheric gas with a dra hood, the test would be taken in

the top ue passage prior to mixing with dilution air.

A er testing is complete, the hole in the ue/stack

must be patched with temperature silicone or a comparable plug.

Fuel: Select Natural Gas, Oil #2 or Propane for the fuel

type of the system or appliance.

Type : Default: Condensing. Other selection: Non-Con-

densing. e presence of a condensate line indicates

a condensing unit, otherwise it is a non-condensing

unit.

O2: Connect the AOX2 with the switch on %O

and take

2

a sample of the combustion products in the ue/stack

(within 18 inches from the start of the ue).

Flue Temp: Connect the ATR1 temperature probe to

the AOX2. Set the AOX2 on TEMP and measure the

temperature of the combustion products in the ue/

stack (18 inches from the start of the ue).

CO: Connect the ACM3 and take a sample of the com-

bustion products in the ue/stack in the same location

as the O2% measurement (within 18" from the start of

the ue).

Primary Temp: Measure the temperature of the air

being introduced to the combustion process. Measure

the air temperature as close as possible to the entry

point of the appliance.

Figure 19. Combustion Test OUTPUT FORM.

Press OUTPUT for the Combustion OUTPUT

FORM.

CO2: e %CO

Excess O2: e amount of O

in the combustion products.

2

above the minimum

2

theoretical amount needed for complete combustion. For complete and e cient combustion, excess

O

must be adjusted to manufacturer’s speci ca-

2

tions.

COAF (carbon monoxide air free): e amount of CO

in the combustion products taking into account the

dilution e ect of excess O

.

2

Net Temp: e stack (vent) temperature minus the

primary air temperature.

Standard E (E ciency): e actual e ciency of the

combustion equipment calculated by analyzing the

losses up the exhaust.

Siegert E (E ciency): e European standard for

combustion e ciency.

WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.F

30

ELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.C

Page 17

I

I

O

e following tables show acceptable results from

the Combustion Test for di erent types of equipment

For all combustion equipment, ANSI Manufacturing

Standards recommends

carbon monoxide (CO)

2

.

should be below 400PPM in the ue. Technical

Standards and Safety Authority recommends repair

above 100PPM in the ue.

Erik Rasmussen

Atmospheric Fan Assisted Natural Gas or LPG

Oxygen (O2) 6-9%

Stack Temperature 325-500°F

Condensing Natural Gas or LPG

Oxygen (O2) 6-9%

Stack Temperature 90-140°F

Natural Gas/LPG Power Burners

Oxygen (O2) 3-6%

Stack Temperature 275-500°F

Fuel Oil Flame Retention Power Burners

Oxygen (O2) 3-7%

Stack Temperature 325-500°F

Fuel Oil Non-Flame Retention Power Burners

Oxygen (O2) 6-9%

Stack Temperature 400-600°F

Condensing Oil

Oxygen (O2) 3-7%

Stack Temperature 90-140°F

Erik Rasmussen has been an expert in the combustion analysis eld for over 20 years. Rasmussen has

helped Fieldpiece in providing much of the tables and

contents of the combustion section in this manual to

re ect the best real-world practices and knowledge of

today. Rasmussen has also authored and coauthored

several books on combustion analysis which go into

much greater depth on the fundamentals of the operation and diagnosis of combustion equipment.

• Sixteen 16 years as a service and installation

specialist of:

* Natural gas

* Propane

* Oil heat

* Air conditioning

• Contractor

• HVACR Instructor

• Co-author, "Carbon Monoxide: A Clear and Pres-

ent Danger", ESCO Press

• Author, “Combustion Analysis and Fuel E cien-

cy”, ESCO Press

• International Programs Director for COSA, the

Carbon Monoxide Safety Association

• Board Member HVAC Excellence

• President of ESCO press international, (Canada)

2 From Carbon Monoxide a Clear and Present Danger Third Edition, Dwyer,

Leatherman, Manclark, Kimball, Rasmussen, ESCO Press 2003.

WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.F

32

• Rasmussen continues to stay current on all tech-

nologies and procedures through the operation of

his own service organization.

ELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.C

Page 18

I

I

O

5.1 “CheckMe!®” (HG2 Only)

5.2 CheckMe!® INPUT FORM Overview

3

“CheckMe!®” is the most advanced real-world

method for troubleshooting A/C systems. It looks at the

big picture to diagnose problems. Superheat, Subcooling,

and Target Evaporator Exit Temperature tests look at individual performance indicators to determine if they are

within proper range.

a whole to give a more complete diagnosis.

CheckMe!® looks at the system as

CheckMe!®

saves time and money by quickly diagnosing a range of

problems or even multiple problems.

CheckMe!® rec-

ommends actions to tune the air conditioning system

to its optimum with minimal retests. is leads to even

fewer call backs.

e algorithms built into CheckMe!® are based

on the real world servicing of over 150,000 air conditioners. e testing procedure and accuracy of the

diagnosis have been re ned over many years by Proctor Engineering. e CheckMe!® switch position is a

real time-saver because it can give you a more accurate

diagnosis than looking at individual aspects of the air

conditioner.

e CheckMe!® has 35 diagnoses which will help

you pinpoint the problem with the air conditioning

system. In addition to giving you better diagnoses, the

CheckMe!® test will ensure that you have lled in the

form completely and warns you if conditions are unlikely to exist or impossible. In these cases, you will

want to retake some measurements.

CheckMe!® will analyze the system with almost any

amount of data. e more information supplied to the

program, the more accurate and comprehensive the diagnosis. CheckMe!® determines the current state of the

equipment. erefore you can pretest equipment prior

to any repairs.

General Information: The type of

system and the nominal tonnage.

Can be measured automatically with

Fieldpiece accessory heads.

True Flow: The measurements are

only visible if you select Yes for True

Flow. These are manual inputs.

Customer ID is useful for record

keeping.

Grant: These are all manual inputs

which are used for record keeping

when participating in a grant

program or third party verification.

Units can be changed to either

English or Metric.

Figure 20. CheckMe!® INPUT FORM.

e quickest way to an optimized system will be to

clean coils and lters prior to the initial test. en completely ll out the the CheckMe!® INPUT FORM for a

more comprehensive and accurate diagnosis of the system.

3 CheckMe!® is the registered trademark of Proctor Engineering Group, Ltd.

WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.F

34

ELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.C

Page 19

I

I

O

CheckMe!® INPUT FORM

Sys Type (System Type): Default: AC (Air Condition-

ing). Other selections: H Pump Heat (heat pump in

heating mode), H Pump Cool (heat pump in cooling mode) or Geothermal.

Nom Ton: Nominal tonnage of the A/C system.

INDOOR UNIT

All temperature and pressure measurements must

be taken a er the unit reaches steady state (generally 15

minutes of continuous operation).

Metering Device: Default: TXV/EXV. Other selec-

tion: Fixed.

ID Volt (indoor unit voltage): Default: 120V 1 phase.

Other selections: 240V 1 phase, 240V 3 phase, 460V

3 phase or 575V 3 phase.

Return DB (dry bulb) and Return WB (wet bulb):

Take measurements very close or within the return

air side of the inlet to the air handler (not at the re-

turn grill since temperatures change by the time the

air reaches the indoor coil). Wet the wet bulb sen-

sor (ATWB1) and insert it a er 15 minutes of con-

tinuous running. Insert the dry bulb sensor (ATA1)

through the same hole. ey can be clipped together

on the downstream side of the lter if the lter is

just before the air handler.

Watch the wet bulb temperature; it will drop and

then stabilize. e wet bulb temperature is the sta-

bilized reading. If the sensor starts to dry out, the

reading will rise and the wrong temperature will be

recorded. If the lter is not directly upstream of the

air handler, make small holes in the return plenum

just big enough for the probes. Seal any holes before

leaving the jobsite.

WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.F

36

Supply DB (dry bulb leaving the indoor coil): Mea-

sure in the center of the supply plenum. Make a

small hole in the supply plenum and insert a calibrated dry bulb thermocouple such as the ATA1 or

ATB1. Determine the average air temperature in the

supply plenum.

OUTDOOR UNIT

Refrigerant: Default: R-22. Other selections: R410A,

R-134A, R-404A, R-407C, R-409A, R-408A, R-507A,

R-414B (Hotshot

(NU222B

TM

Rated Amps (Rated amperage of the outside unit):

is can be found on the nameplate along with the

outdoor voltage and the refrigerant.

OD Volts (outdoor unit voltage): Default: 240V 1phase.

Other selections: 120V 1 phase, 240V 3 phase, 460V

3 phase or 575V 3 phase.

Target Subcool: Manufacturer’s recommended

subcooling for TXV/EXV systems. is varies by

manufacturer , and may also change depending on

weather conditions. Always charge to the equipment manufacturer’s speci cations when available.

If no target subcooling is available then the HVAC

TM

Guide

tester will make a conservative estimate.

SL Pressure (suction line pressure): Connect the

ASX14 to the suction side service port. Select pressure mode on the ASX14 head. e system must be

stabilized before taking the measurements. Enter

data manually if you want to get pressure from your

gauges. e analysis is only as good as the measurements. e Fieldpiece ASX14 has better resolution

than most gauge sets.

SL Temp (suction line temperature): Measure near SL

service port (within 6 inches). Use the ATC1, ATC2

or ATC3 to get a good pipe temperature. e clamp

should be perpendicular to the pipe and should be

ELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.C

TM

) or R-12.

), R-422C (OneshotTM), R-422B

Page 20

I

I

O

securely seated with the sensor in contact with the

suction line. If working on a package unit make sure

you are at least 6 inches away from the compressor.

TrueFlow®: Default: NO. If NO, skip ahead to the

Grant section. Answering YES unlocks the inputs

for this section.

LL Pressure (liquid line pressure): Connect the

ASX14 to the liquid line service port. Set the acces-

sory head to measure pressure and ensure the read-

ing stabilizes before locking in the reading. Enter

data manually if you want to get pressure from your

gauges. e analysis is only as good as the measure-

ments. e Fieldpiece ASX14 has better resolution

than most gauge sets.

LL Temp (liquid line temperature): Measure near the

same location LL Pressure was taken. Use the ATC1,

ATC2 or ATC3 to get a good pipe temperature. e

clamp should be perpendicular to the pipe and

should be securely seated with the sensor in contact

with the liquid line. If working on a package unit

make sure you are at least 6 inches away from the

compressor.

Condenser Air Enter Temp (Condenser Air En-

tering Temperature): Clip a calibrated ATA1 to the

inlet of the condenser ns (typically on the side of

the condenser), in the shade if possible. Note that

the temperature of the air entering the outdoor coil

can be considerably di erent than the ambient tem-

perature due to recirculation of air exiting the unit.

Determine the average temperature of the air enter-

ing the condenser.

Cond Amps Draw (Condensing unit amp draw):

Actual amperage of the outdoor unit. For a package

system this will be the total amp draw of the unit.

is measurement must be taken with another me-

ter with an AC Amp clamp (such as the SC77) and

then input manually.

Supply Plenum Press Without Grid: TrueFlow®

system operating pressure with the lter installed

and no TrueFlow® grid. is is the NSOP and is

measured using the static pressure probe included

with the TrueFlow® plate.

Grid Size: Default: 14 inches. Other selection: 20 inches.

Choose the grid size you are using.

Grid Pressure: is is the TFSOP and is measured

using the TrueFlow® plate.

GRANT

If you are working under a grant you must add additional information about the system to qualify for the

grant. In parts of the United States,

to qualify for tax rebates and/or nancial incentives.

ese programs have speci c requirements that will be

available in the HG2.

Residential and commercial air conditioning constitutes about 15% and 33% peak of the electricity consumed in this country. Utilities or regulatory committees o en o er grants to motivate consumers to save

energy.

In order to participate in these grants a technician

will usually have to work through a third party veri er.

Contact your local utility to learn on how to become a

grant participant.

Te s t : Default: Initial. e other selection is A er Re-

pair.

CheckMe!® is used

TrueFlow®

e TrueFlow® meter measures the air ow directly

via a grid installed in place of the lter (or other location

that has all the indoor unit air ow through it).

4 TrueFlow® is the registered trademark of The Energy Conservatory.

WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.F

4

38

Grant: Default: None. Other selections will be avail-

able as grants are included. Some grants require different calculations.

ELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.C

Page 21

I

I

O

5.3 CheckMe!® OUTPUT FORM Overview

5.401 Air ow OK: e indoor coil air ow was di-

rectly measured using the TrueFlow® grid and is

OK.

The diagnosis are displayed in order

of likelihood.

Shows you where in this manual

you can get more information about

what the diagnosis means and how

to correct the problems.

Figure 21. CheckMe!® OUTPUT FORM.

Press the OUTPUT for the CheckMe!® OUTPUT

FORM.

e diagnoses and recommendations are listed in

order with the most likely diagnosis rst.

Because all parts of an A/C system are inter-dependent, changes made to one part of the system can affect other parts of the system. For example, increasing

air ow may increase the superheat, which may require

adding refrigerant. To be e cient, continually check the

superheat and/or subcooling as you make refrigerant

charge adjustments. A er nal modi cations, allow 15

minutes to stabilize before your nal test.

5.402 Probable OK air ow: e indoor coil air-

ow was tested by an indirect means (temperature

split) and is probably OK.

5.403 Air ow unknown, check air ow: e

measurements are insu cient to diagnose the indoor coil air ow. Either measure the Return Plenum Dry Bulb, Wet Bulb and Supply Plenum Dry

Bulb or use a True Flow Plate.

5.404 Low air ow, increase air ow until actual temp split matches target temp split: e

indoor coil air ow is low based on the temperature

split. Check the lter and coil, inspect for any restrictions and blockages. Make sure all registers are

open. If the air ow remains low, consider increased

blower speed and duct system modi cations. Supply and return plenum static pressures can be used

to diagnose the causes of low air ow.

5.405 Low air ow, increase air ow: e indoor

coil air ow was directly measured using the TrueFlow grid and is low. Check the lter and coil, inspect for any restrictions and blockages. Make sure

all registers are open. If the air ow remains low,

consider increased blower speed and duct system

modi cations. Supply and return plenum static

pressures can be used to diagnose the causes of low

air ow.

5.4 Indoor Coil Air ow

Low air ow across the inside coil is one of the most

common problems and should be corrected before nal

decisions are made about refrigerant charge or many

other issues. Air ows in moist and wet climates should

usually be between 300 to 350 cfm per ton. Air ows in

Dry climates are limited by the rapidly increasing watt

draw of the fan motor at higher air ows.

WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.F

40

5.406 Low capacity or possible high air ow,

measure air ow directly: e temperature

split is low. is usually means that the capacity of

the system has been reduced due to incorrect refrigerant charge. Higher than expected air ow is rare,

but does occur occasionally. Measuring the air ow

directly would identify if high air ow is the cause of

the low temperature split.

ELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.C

Page 22

I

I

O

5.407 High air ow, possibly reduce air ow: e

indoor coil air ow was directly measured using the

TrueFlow grid and is higher than expected. Consider

reducing the air ow particularly if the unit is in a

damp climate. In heat pumps high air ow causes uncomfortably low delivery temperatures.

5.408 Possible plenum temperature measurement error, retake plenum temperatures:

e reported wet and dry bulb temperature readings

from the return and supply plenums are unlikely. Retake the measurements in the INPUT FORM. See Return DB and Return WB sections for detailed instructions on how to take these measurements properly.

5.501 Charge OK: Refrigerant charge was tested us-

ing the appropriate method and it is OK.

5.502 Possible OK charge: e primary indicator of

refrigerant charge (subcooling for TXV/EXV or superheat for non-TXV) indicates the refrigerant level

was OK. However, a secondary indicator reduces the

con dence in that diagnosis. Check out any other potential problems indicated.

5.503 Charge unknown, check charge: e mea-

surements are insu cient to diagnose the refrigerant

charge. For best results, measure both the suction line

temperature and pressure as well as the liquid line

temperature and pressure and press the OUTPUT

button again.

5.5 Refrigerant Charge

Incorrect refrigerant charge is the most common

problem with air conditioners and heat pumps. ere are

widespread poor practices and misinformation regarding

refrigerant levels.

e primary method speci ed by major manufactur-

ers for non-TXV ( xed metering device) systems is superheat. e superheat needs to be matched to the target

superheat, which changes with indoor and outdoor conditions. e optimum refrigerant charge as indicated by superheat is a ected by the air ow across both coils. Repair

any air ow problems before setting the nal refrigerant

charge.

e primary method for TXV or EXV systems is

subcooling. e subcooling needs to be matched to the

target subcooling. e target subcooling is usually on the

manufacturer's ID plate along with the model and serial

numbers.

For heat pumps, it is best to set the refrigerant levels

in the summer in the cooling mode. e HG2 can also

check the capacity of heat pumps in the winter as an indicator of correct refrigerant charge.

5.504 Possible undercharge, possibly add refrigerant: If no other conditions are triggered, con-

sider adding refrigerant to correct. ere is possibly

insu cient refrigerant in the system. e amount of

refrigerant necessary to add will vary based on the

size of the system and the di erence between Target

and Actual superheat/subcooling.

5.505 Probable undercharge, add refrigerant:

It is very likely that there is insu cient refrigerant in

the system. Add refrigerant to bring the superheat or

subcooling to within the target.

5.506 Undercharged, add refrigerant until actual superheat reaches target superheat: is

non-TXV system is low on refrigerant. Add refrigerant until the superheat is within the proper range

(usually ±5°F) of the target superheat. e closer the

superheat is to the target, the better.

5.507 Undercharged, add refrigerant to obtain

6°F of superheat: is non-TXV system is low on

refrigerant. Since the test conditions are hot outside,

dry inside, or both, the exact target superheat cannot

be determined. Because the superheat is greater than

6°F the unit is undercharged. Add refrigerant until the

superheat is 6°F.

WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.F

42

ELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.C

Page 23

I

I

O

5.508 Charge unknown, raise indoor temperature to obtain a target superheat ≥ 5°F and

retest: Since the test conditions are hot outside, dry

inside, or both, the exact target superheat cannot be

determined. is non-TXV system may be correctly

charged or overcharged. It may be possible to open

windows or run the furnace to change the indoor

conditions enough to obtain a target superheat.

5.509 Possible overcharge, possibly remove refrigerant: If no other conditions are triggered, con-

sider recovering refrigerant to correct. e amount

of refrigerant necessary to recover will vary based on

the size of the system and the di erence between Target and Actual superheat/subcooling.

5.510 Overcharged, remove refrigerant until

superheat reaches target superheat: ere

is too much refrigerant in this non-TXV system. Remove refrigerant until the superheat is within ±5°F of

the target superheat. e closer the superheat is to the

target, the better.

5.511 Overcharged, remove refrigerant until

subcooling reaches target subcooling: ere

is too much refrigerant in this TXV/EXV system. Remove refrigerant until the subcooling is within ±3°F

of the target subcooling. e closer the subcooling is

to the target, the better.

5.512 Undercharged, add refrigerant until subcooling reaches target subcooling: is TXV/

EXV system is low on refrigerant. Add refrigerant

until the subcooling is ±3°F of the target subcooling.

e closer the subcooling is to the target, the better.

5.513 Overcharged, remove refrigerant until

actual subcooling reaches target subcooling: ere is too much refrigerant in the system. e

amount of refrigerant necessary to recover will vary

based on the size of the system and the di erence between Target and Actual subcooling.

5.514 Overcharged, remove refrigerant until

actual superheat reaches target superheat:

ere is too much refrigerant in the system. e

amount of refrigerant necessary to recover will vary

based on the size of the system and the di erence between Target and Actual superheat.

5.515 Possible low evaporator capacity: e

evaporator is suspected of being unable to deliver the

cooling load necessary to maintain the desired indoor

conditions. Check the refrigerant charge (most common), clean the evaporator and/or condenser coils

and verify that the indoor air ow is correct.

5.516 Probable oversized metering ori ce, consult manufacturer’s speci cations: e me-

tering ori ce is probably letting too much refrigerant through. Check that the ori ce is sized properly.

Find the metering device part number and obtain the

ori ce size from the manufacturer or distributor and

verify the size is appropriate for the air conditioner.

5.517 Probable undercharge, add refrigerant:

ere is probably insu cient refrigerant in the system. e amount of refrigerant necessary to add will

vary based on the size of the system and the di erence

between Target and Actual superheat/sub-cooling.

5.518 Superheat too high for TXV, check liquid

line for restriction: If there is a liquid line restric-

tion then the TXV/EXV will be unable to maintain a

proper superheat. Make sure the service shut-o valves

are open. Check the liquid line for kinks or sections

that may have been stepped on or crushed. Check for

a large temperature di erence between the liquid line

at the compressor and at the metering device.

5.519 Superheat too low for TXV, check TXV

to ensure proper functioning: If the TXV/EXV

is not set properly, then the TXV/EXV will be unable

to maintain a proper superheat. Check that the TXV/

EXV bulb is adjusted to the proper superheat, and is in

good contact with the suction line and insulated from

the environment.

WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.F

44

ELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.C

Page 24

I

I

O

5.6 Refrigerant Lines and Metering Devices

Research has shown that refrigerant line restrictions, incorrect ori ce sizes, and TXVs improperly installed are far more common than originally thought.

All of these problems can lead to premature compressor

failure.

If there are restrictions in the refrigerant lines

(pinches, dirty lter driers) the charge measurements

will provide contradictory information and getting

proper performance will not be possible. Similarly if the

ori ce of the metering device is too small or partially

blocked by foreign material in the refrigerant (such as

chips and akes from improper brazing technique) the

unit will not perform to speci cations.

If a xed ori ce is too large (not matched to the inside coil), the refrigerant will not meter properly, contradictory measurements will be obtained, and performance will su er.

A thermostatic expansion valve (TXV) only works

when the sensing bulb is in solid contact with the suction line and only senses the temperature of the suction

line. erefore it must be well insulated from surrounding air. e TXV is designed to maintain a constant superheat.

5.601 Possible oversized metering ori ce,

consult manufacturer’s speci cations: e

metering ori ce is suspected of letting too much

refrigerant through. Check that the ori ce is sized

properly. Find the metering device part number and

obtain the ori ce size from the manufacturer or dis-

tributor and verify the size is appropriate for the air

conditioner.

5.602 Probable oversized metering ori ce,

consult manufacturer’s speci cations: e

metering ori ce lets too much refrigerant through.

Check that the ori ce is sized properly. Find the

metering device part number and obtain the ori ce

size from the manufacturer or distributor and verify

the size is appropriate for the air conditioner.

WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.F

46

5.603 Check TXV to ensure proper functioning: is TXV is not maintaining proper superheat.

Check that the TXV bulb is adjusted properly and

in continuous contact with the suction line and well

insulated from the surrounding air.

5.604 Probable liquid line restriction, check

liquid line: Make sure the service shut-o valves

are open. Check the liquid line for kinks, tight

bends or sections that may have been stepped on

or crushed. Check for a large temperature di erence

between the liquid line at the compressor and at the

metering device.

5.7 Condenser Coil Performance

5.701 Condenser air ow OK: e condenser air-

ow and capacity indications are OK.

5.702 Condenser approach unknown, check

condenser approach: Liquid line temperature

and liquid line pressure measurements need to be

taken at the condenser approach. ese measurements give indications of the performance of the

air conditioner including diagnoses of compressor

problems, low capacity, and low condenser air ow.

5.703 Low condenser air ow, clean condenser, check condenser fan motor bearings:

ere is insu cient air ow going across the condenser for the needed heat transfer. Check that the

condenser coils and ns are clean, aligned and free

of nearby obstructions. Check the fan motor bearings to ensure that the fan is rotating freely.

5.8 Outdoor Unit Amp Draw

e outdoor unit amp draw gives indications of the

health of the compressor as well as overcharge and condenser coil performance.

5.801 Outdoor amp draw OK: e outdoor unit

is running at the proper amperage for the current

conditions.

ELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.C

Page 25

I

I

O

5.802 Condensing unit amps unknown, check

condensing unit amps: e outdoor unit amp

draw was not measured.

5.803 High outdoor amp draw, probable excessive compressor friction: Check other possible

causes of high amp draw (low condenser air ow and

refrigerant overcharge) before condemning the compressor. Check that condenser coils and ns are clean,

aligned and free of nearby obstructions.

5.804 Low outdoor amp draw, possible compressor valve or motor problem: Check the re-

frigerant charge before condemning the compressor.

5.9 Cooling Capacity

e heat rejection at the outside unit is another mea-

surement that gives indication of the health of the compressor as well as other potential problems.

5.901 Condesner capacity OK: e condenser is

delivering the proper capacity.

5.902 Low condenser capacity, check charge,

retest: is unit is rejecting less heat than expected.

Check the refrigerant charge, repair if needed, and retest.

5.10 Heat Pump in Heating

Test the refrigerant charge for a heat pump in the summer in the cooling mode if possible. is procedure checks

the heating capacity of the heat pump against the expected

capacity for the test conditions. In order to determine the

capacity of a heat pump, the air ow through the inside

coil must be directly measured with the TrueFlow®.

5.1001 Heating Capacity OK: e heat pump is de-

livering the proper heating.

5.1002 Capacity unknown, check capacity: e

TrueFlow inputs, outdoor unit entering temperature,

return plenum temperature, and supply plenum tem-

perature need to be measured before determining ca-

pacity.

5.1003 Low capacity, defrost outside coil or ad-

just charge and retest: Verify that the outside coil

is not frosted or iced. Frost reduces the capacity of the

heat pump. If the unit is not frosted, adjust the refrig-

erant charge per the manufacturer’s speci cation.

5.1004 High temp split, make sure strip heat is

NOT on: Check amperage to the electric strip heat-

ers to verify they are turned o .

5.903 Low condenser capacity, check compressor amps and coil saturation temperatures:

Full diagnosis of this situation requires a complete set

of data including compressor amps, high and low side

pressures, and liquid and suction line temperatures.

WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.F

48

ELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.C

Page 26

I

I

O

Advanced Operations

Time

e internal clock is the basis for the time stamps

saved with test data. e time cannot be altered once

data is taken; therefore, setting up the time before taking data is important to maintain records in the correct

order. e TIME is shown on the bottom of the LCD on

most INPUT FORMs.

• Rotate the dial to the TIME switch position.

• Press RIGHT arrow to change time if needed.

• LEFT and RIGHT arrows cycle through month,

day, year, military clock, and minutes.

• UP and DOWN arrows adjusts.

• Press ENTER to set time.

Memory (MEM)

Units

On every INPUT FORM there is a “Units” line. e

default is English units. Metric units can be used by

pressing the RIGHT arrow when “Units” is highlighted.

Scroll Up or DOWN to toggle between English and

Metric units. Press ENTER to lock in your selection. e

HVAC Guide

you have taken when units are changed mid test.

TM

tester will convert any measurements

CUSTOMER ID

On every INPUT FORM there is a Customer ID

line used for record keeping and long-term customer

tracking. Press ENTER when “CUSTOMER ID” is highlighted to select a previously saved Customer ID.

To enter a new (unsaved) Customer ID, press the

RIGHT arrow when “CUSTOMER ID” is highlighted.

Now adjust the value character-by-character using the

UP/DOWN arrows and the RIGHT arrow. When nished press ENTER to input the new Customer ID.

From the Memory switch position you can delete a

single test, entire customer le or all data. You can also

check your version of rmware to see if you are up to

date and your memory status, to see how much memory

you have le . You can also communicate with the PC

and transfer data to and from with the “Com with PC”

option. See page 56 for more details.

Figure 22. Screenshot of Memory (MEM) switch.

WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.F

50

Figure 23. Selecting a previously saved Customer ID.

ELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.C

Page 27

I

I

O

Clearing a single input or INPUT FORM

Recalling Saved Tests

Press CLEAR when an input is highlighted to erase

a single input. Hold the CLEAR button for three seconds

and select Yes to clear an entire INPUT FORM.

Figure 24. Deleting the entire INPUT FORM of a Superheat Test.

Saving Data

Press the SAVE button and press ENTER while Yes

is highlighted when in an INPUT FORM to save test

data. Test data is saved along with Customer ID and a

time stamp. You will be prompted to input a Customer

ID before saving.

While in the desired test, press the RECALL button to access previously saved test data. Highlight

the Customer ID from the list and press ENTER and

then highlight the date and time of the test you wish

to recall and press ENTER again. e INPUT FORM

for that switch position will then be populated with

the previous test’s data. No Outputs are saved on the

HVAC Guide

TM

tester, they are simply recalculated

from the saved inputs.

Figure 26. Selecting the Customer ID of the test to Recall.

Figure 25. Saving data for Superheat analysis.

WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.F

52

Figure 27. Selecting which test time to Recall.

Contrast Adjustment

To adjust the contrast level of the display hold the

BACKLIGHT button until the Contrast Adjustment

Screen shows. Press UP and DOWN arrows to adjust,

and ENTER to set.

ELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.C

Page 28

I

I

O

PC Software

Installing the PC Software

1. To install the HVAC Guide

your PC, insert the CD into the CD-ROM drive. e

installation window should pop-up automatically.

If not, manually open the CD contents through "My

Computer." Click the grey button next to "Install

PC So ware." Follow the on-screen instructions.

2. For your PC to recognize the HVAC Guide

a driver must be installed. Click on the grey button next to "Install USB Driver..." from the installation window. No new window will pop-up on your

screen.

3. Exit out of the installation screen.

TM

tester so ware onto

TM

tester

Communicating with a PC

1. Make sure the HVAC Guide

the IR2 USB cable into the bottom of the HVAC

TM

Guide

tester.

2. Plug the USB end of the IR2 USB cable into a USB

port of your PC.

TM

tester is o . Plug

Communicating with a PC (continued)

5. Launch the HVAC Guide

your Desktop or the Start menu on your PC.

6. e New Technician screen will pop-up. Fill out the

screen. Click save. is information will be printed

on work orders you generate.

7. e Data Transfer screen is displayed when the

HVAC Guide

to-Detect" on the Data Transfer screen.

TM

tester is detected. If not, click "Au-

TM

tester so ware from

3. Turn the dial to "MEM" on the HVAC Guide

TM

tes-

ter.

4. Scroll down to "Com with PC" and press ENTER.

WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.F

54

8. Click the red arrow pointing to the PC in order to

transfer data to the PC.

9. Click on desired les to transfer to the PC and click

the "Transfer to PC" button.

10. Close window when transfer is complete.

11. To open the les, go to My Documents/HVAC

Guide/Jobsite Files. e les will be listed by their

Customer IDs.

ELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.C

Page 29

I

I

O

Transferring Tests from the HVAC Guide

Tester to a PC

1. Press the Transfer arrow pointing to the right.

TM

3. If you want to change where the les are saved to,

press the "Browse Desination" button. Browse your

PC for a folder in which you would like to save the

les from the HVAC Guide tester and press "Select

Cur Dir" to assign.

2. Highlight the les you wish to transfer to the desti-

nation folder on your PC and press the "Transfer to

PC" button to transfer.

Destination folder

Click if you want to create a new folder.

WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.F

56

Click on headers to sort.

Files currently in the

destination folder on PC.

ELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.C

Page 30

I

I

O

Transferring Tests From the PC to the HVAC

Guide

1. Press the Transfer arrow pointing le .

TM

Tester

3. If you want to change where the les are located on

your PC, press the "Browse" button. Browse the PC

for a folder containing les for transfer the HVAC

Guide tester and click "Select Cur Dir" to bring

those les to the transfer screen.

2. Highlight the les you wish to transfer to the HVAC

TM

Guide

WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.F

tester and press "Transfer" to send.

Files applicable for transfer from

the destination folder on PC.

58

ELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.COM WWW.FIELDPIECE.C

Page 31

I

I

O

Looking at Downloaded Data

Other Operations

Locate the HVAC GuideTM tester les on your PC