Page 1

Chapter 1

Routine maintenance & servicing

Contents

Air fitter renewal 19

Automatic transmission fluid level check 5

Auxiliary drivebelt check and renewal 21

Auxiliary drivebelt tension check 7

Battery electrolyte level check 6

Brake fluid renewal 26

Braking system pipes and hoses check 11

Clutch cable adjustment 22

Coolant renewal 31

Engine management system fault code check 25

Engine oil and filter renewal 3

Evaporative emission control system check 29

Exhaust emissions check 24

Exhaust system check 12

Front brake pad check 4

Fuel filter renewal 20

Handbrake adjustment 23

Hinge and lock lubrication 16

Hose and fluid leak check 9

Introduction 1

Lights and horn operation check 15

Manual transmission oil level check 27

Pollen filter renewal 8

Rear brake shoe check 28

Regular maintenance 2

Road test 17

Spark plug renewal 18

Steering and suspension check 13

Timing belt renewal 30

Transmission and driveshaft gaiter check 10

Underbody protection check 14

1-1

Degrees of difficulty

Easy, suitable for

novice with little

experience

Fairly easy, suitable

for beginner with

some experience

Fairly difficult,

suitable for competent

DIY mechanic

Difficult, suitable for

experienced DIY

mechanic

Very difficult,

suitable for expert DIY

or professional

Page 2

1-2

Servicing specifications

Lubricants and fluids Refer to end of Weekly checks on page 0-17

Capacities

Engine oil (including filter):

1.2 litre engine ......................................................................................... 2.8 litres

1.4 litre engine ......................................................................................... 4.1 litres

1.8 litre engine ....................................................................................... 3.8 litres

1.8 litre engine ....................................................................................... 4,3 litres

Cooling system (approximate);

1.2 and 1.4 litre engines ......................................................................... 6.0 litres

1.6 and 1.8 litre engines .......................................................................... 7.0 litres

Transmission (approximate):

Manual transmission:

1.2 and 1.4 litre engine models ........................................................ 1.65 litres

1.6 and 1.8 litre engine models ......................................................... 2.0 litres

Automatic transmission (fluid change) ................................................. 4.3 litres

Fuel tank (approximate):

Except 1.8 litre models ......................................................................... 50 litres

1.8 litre models ....................................................................................... 60 litres

Washer reservoir:

Models with headlight washers ............................................................ 6.4 litres

Models without headlight washers ....................................................... 5.0 litres

Engine

Oil filter:

1.2, 1.4 and 1.6 litre engines ............................................................... Champion F107

1.8 litre engine:

Up to March 1996 ............................................................................ Champion F107*

April 1998 onwards .......................................................................... Champion F133*

*Note: This is the latest information available; if in any doubt, contact Champion on 01274 848283,

Cooling system

Antifreeze mixture:

40% antifreeze ...................................................................................... Protection down to -25°C

50% antifreeze ...................................................................................... Protection down to -35°C

Note: Refer to antifreeze manufacturer for latest recommendations.

Fuel system

Air filter element:

Except 1.2 litre engine ........................................................................... Champion U564*

1.2 litre engine .......................................................................................... Champion type not available*

Fuel filter .................................................................................................... Champion L225*

*Note: This is the latest information available; if in any doubt, contact Champion on 01274 848283.

Ignition system

ignition timing ........................................................................................... Refer to Chapter 5B

Spark plugs:

Except 1.2 litre engine ......................................................................... Champion RC8BYC or RC7YC*

1.2 litre engine ..................................................................................... Champion RA4HCX or RA4HC*

Electrode gap**:

Champion RC8BYC .............................................................................. Not adjustable

Champion RA4HCX .............................................................................. 0.8 mm (0.032 in)

Champion RC7YC or RA4HC ............................................................. 0.7 mm (0.028 in)

*Note: This is the latest information available; if in any doubt, contact Champion on 01274 848283,

**The spark plug electrode gap is as quoted by Champion for their recommended plugs. If spark plugs of any other type are to be used, refer to

their manufacturers specifications.

Clutch

Clutch pedal stroke (see Section 22):

1.2 and 1.4 litre models (where applicable) .............................................. 155 ± 10 mm

1.6 and 1.8 litre models .............................................................................. 170 ± 10 mm

Brakes

Brake pad/shoe friction material minimum thickness.................................. 1.5 mm

Torque wrench settings Nm lbf/ft

Manual transmission drain plug .................................................................... 46 34

Manual transmission filler/level plug ............................................................. 46 34

Roadwheel bolts ............................................................................................ 86 63

Page 3

Servicing specifications

1-3

Spark plugs:

All except 1.6 litre engine ..................................................................... 25

1.6 litre engine .......................................................................................... 27

Sump drain plug:

1.2 litre engine .......................................................................................... 10

1.4 litre engine ..................................................................................... 25

1.6 litre engine ....................................................................................... 50

1.8 litre engine ....................................................................................... 20

Maintenance schedule

The maintenance intervals in this manual are

provided with the assumption that you, not the

dealer, will be carrying out the work. These are

the minimum intervals recommended for

vehicles driven daily. If you wish to keep your

Every 250 miles (400 km) or weekly

Refer to Weekly checks

Every 12 000 miles (20 000 km) or

12 months

in addition to the items listed in the previous services, carry out the \

following:

Renew the engine oil and filter (Section 3)

Check the front brake pad-thickness (Section 4)

Check the automatic transmission fluid level

(Section 5}

Check battery electrolyte level - where applicable

(Section 6)

Check the tension of the auxiliary drivebelt(s)

(Section 7)

Renew the pollen filter element (Section 8)

Check alt underbcmnet/undertsody components

and hoses for fluid leaks (Section 9)

Check the transmission and driveshaft gaiters for

leaks and damage (Section 10)

Check the brake pipes and hoses for teaks and

damage (Section 11)

Check the condition of the exhaust system and its

mountings (Section 12)

Check the steering and suspension components

for condition and security (Section 13)

Check Underbody protection for damage (Section 14)

Check operation of all lights and horn (Section 15)

Lubricate all hinges, locks and door check straps

(Section 16)

Carry out a road test (Section 17)

Every 24 000 miles (40 000 km) or

In addition to the items/fisted in the previous services, carry out the

following:

Renew the spark plugs (Section 18)

Renew the air filter element (Section 19)

Renew the fuel filter, where applicable (Section 20)

vehicle in peak condition at all times, you may

wish to perform some of these procedures

more often. We encourage frequent maintenance, since it enhances the efficiency,

performance and resale value of your vehicle.

Nm Torque wrench settings (continued)

When the vehicle is new, it should be

serviced by a dealer service department, in

order to preserve the factory warranty.

Ibf/ft

18

20

7

18

37

15

Every 24 000 miles (40 000 km) or

Check the condition of the auxiliary drivebelt(s),

and renew if necessary (Section 21)

Check clutch cable adjustment, where applicable

Check handbrake adjustment (Section 23)

Check exhaust gas emissions (Section 24)

Check engine management system for fault codes

Every 36 000 miles (60 000 km) or

In addition to the items listed in the previous services, carry out the-

following:

Renew the brake fluid (Section 26)

Check the manual transmission oil level (Section 27)

Check the rear brake shoe lining thickness

Every 48 000 miles (80 000 km) or

In addition to the items listed in the previous services, carry out the

Check the evaporative emissions control system

Every 72 000 miles (120 000 km)

in addition to all the items listed above, carry out the following:

Renew the timing belt (Section 30)

Note: It is strongly recommended that the interval is halved to

36 000 miles (60 000 km), particularly on vehicles which are

subjected to intensive use, ie. mainly short journeys or a lot of stopstart driving, The actual belt renewal interval is therefore very much

up to the individual owner, but bear in mind that severe engine

damage will result if the belt breaks.

Every 2 years (regardless of mileage)

Renew the coolant (Section 31)

Page 4

Maintenance - component locations

1-4

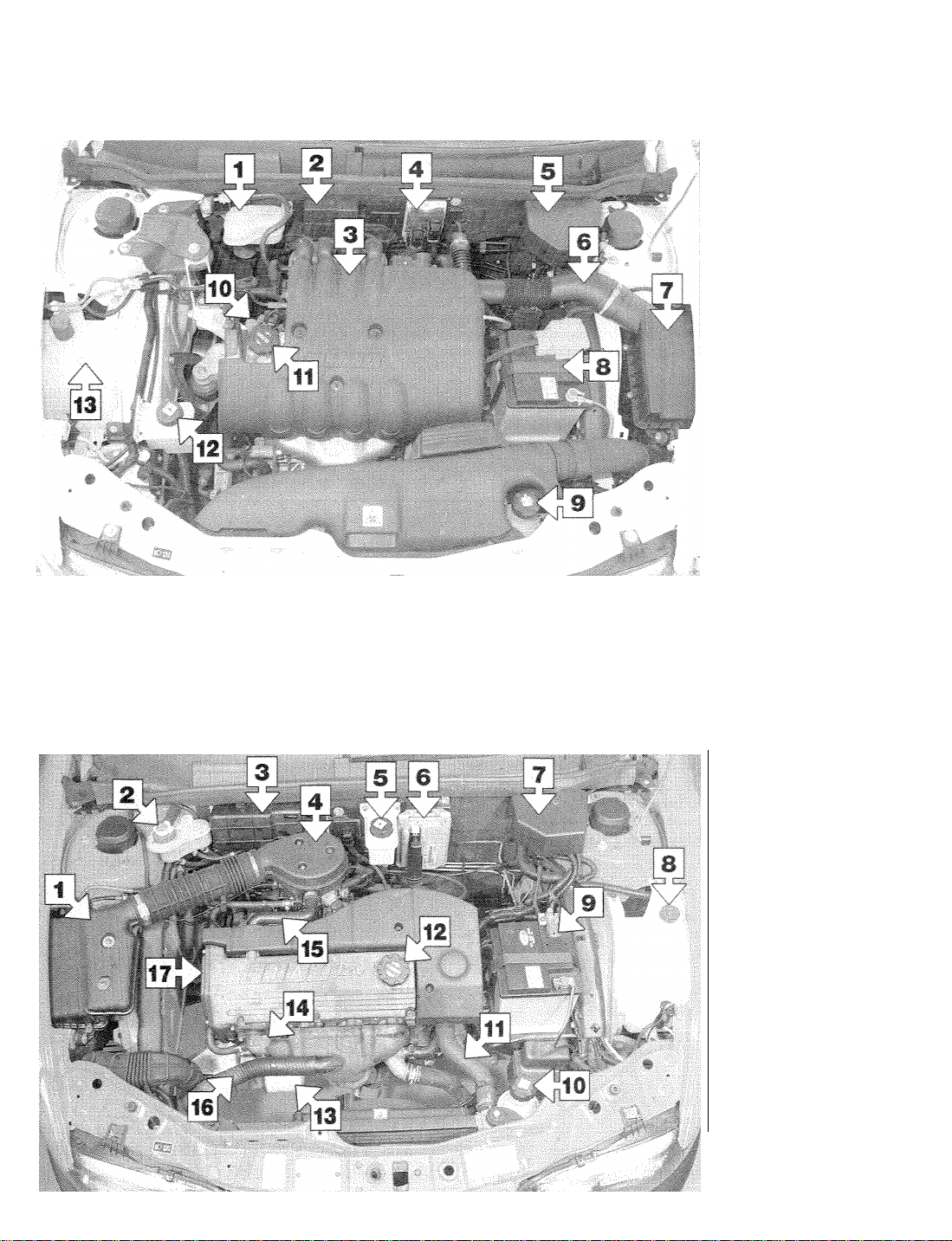

Underbonnet view of 1.2 litre model

Brake and clutch fluid

1

reservoir

Fuse and relay box

2

Engine top cover (remove

3

for access to coils and

spark plugs)

Engine management

4

system ECU

Auxiliary fusebox

5

Air inlet duct

6

Air cleaner

7

Battery

8

9

Cooling system expansion

tank

Engine oil dipstick

10

Oil filler cap

11

Power steering reservoir

12

Washer reservoir

13

Underbonnet view of 1.4 litre model

Air cleaner

1

Brake and clutch fluid

2

reservoir

Fuse and relay box

3

4

Throttle body airbox

5

Power steering reservoir

Engine management

6

system ECU

Auxiliary fusebox

7

Washer reservoir

8

Battery

9

10

Cooling system expansion

tank

Radiator top hose

11

12

Oil filler cap

Oil filter

13

Engine oil dipstick

14

15

Crankcase breather hose

Warm-air inlet duct

16

17

Timing belt cover

Page 5

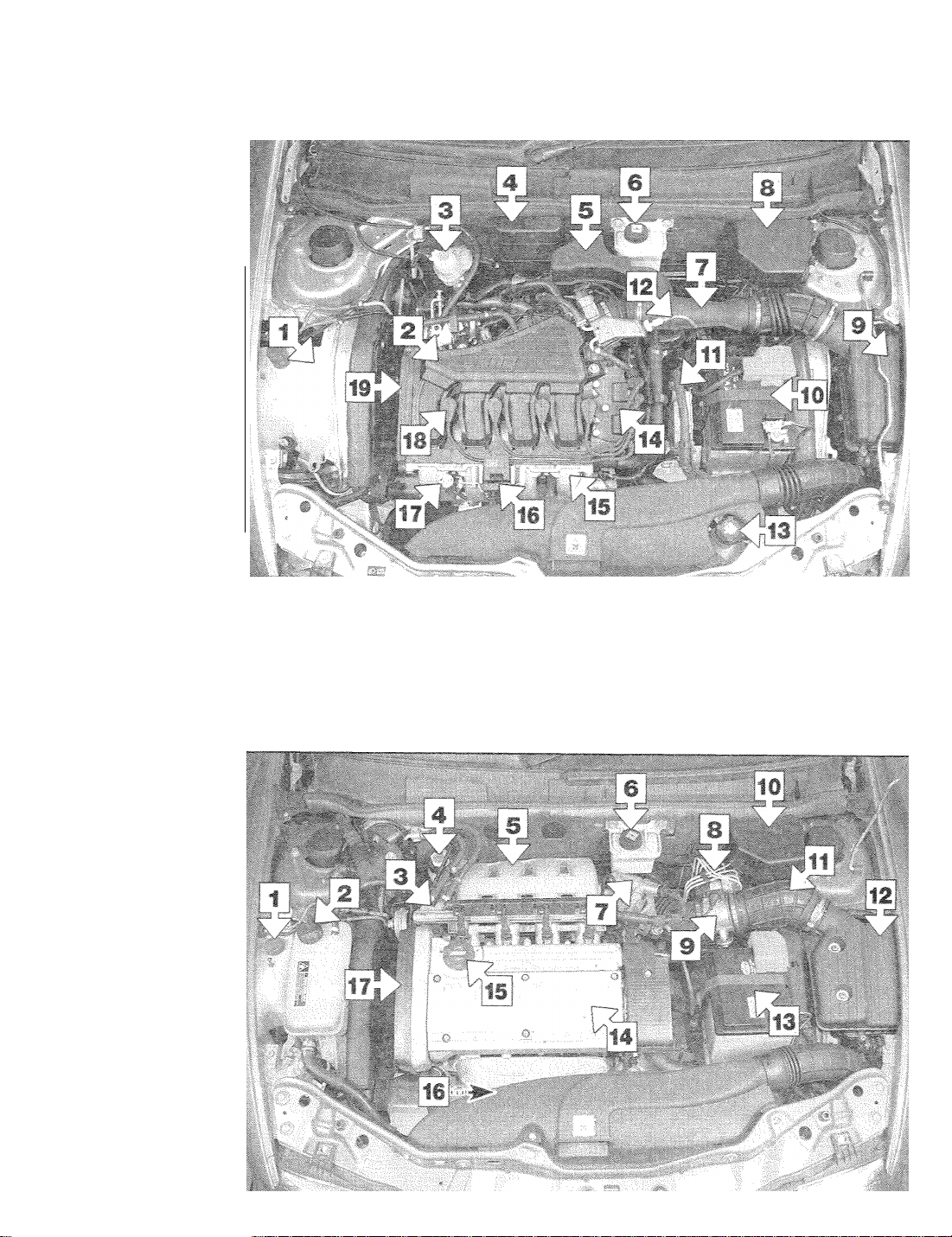

Washer reservoir

1

Inlet manifold (upper section)

2

Brake and clutch fluid

3

reservoir

Fuse and relay box

4

Inlet air resonator box

5

Power steering reservoir

6

Air inlet duct

7

Auxiliary fusebox

8

Air cleaner

9

Battery

10

11

Engine management

system ECU

Accelerator cable

12

Cooling system expansion

13

tank

14

Ignition coil

15

Inlet manifold (lower

section)

18

Oil filler cap

17

Engine oil dipstick

18

No 1 spark plug HT lead

19

Timing belt cover

Maintenance - component locations

Underbonnet view of 1.6 litre model

1-5

1 Washer reservoir

2 Cooling system expansion

tank

3 Fuel hoses, fuel rail and

injectors

4 Brake and clutch fluid

reservoir

5 Inlet manifold

6 Power steering reservoir

7 Idle speed control valve

8 Anti-lock braking system

(ABS) modulator

9 Airflow meter

10 Auxiliary fusebox

11 Air inlet duct

12 Air cleaner

13 Battery

14 Engine top cover (remove

for access to coils and

spark plugs)

15 Oil filler cap

16 Engine oil dipstick

17 Timing belt cover

Underbonnet view of 1.8 litre model

Page 6

Maintenance - component locations

1-6

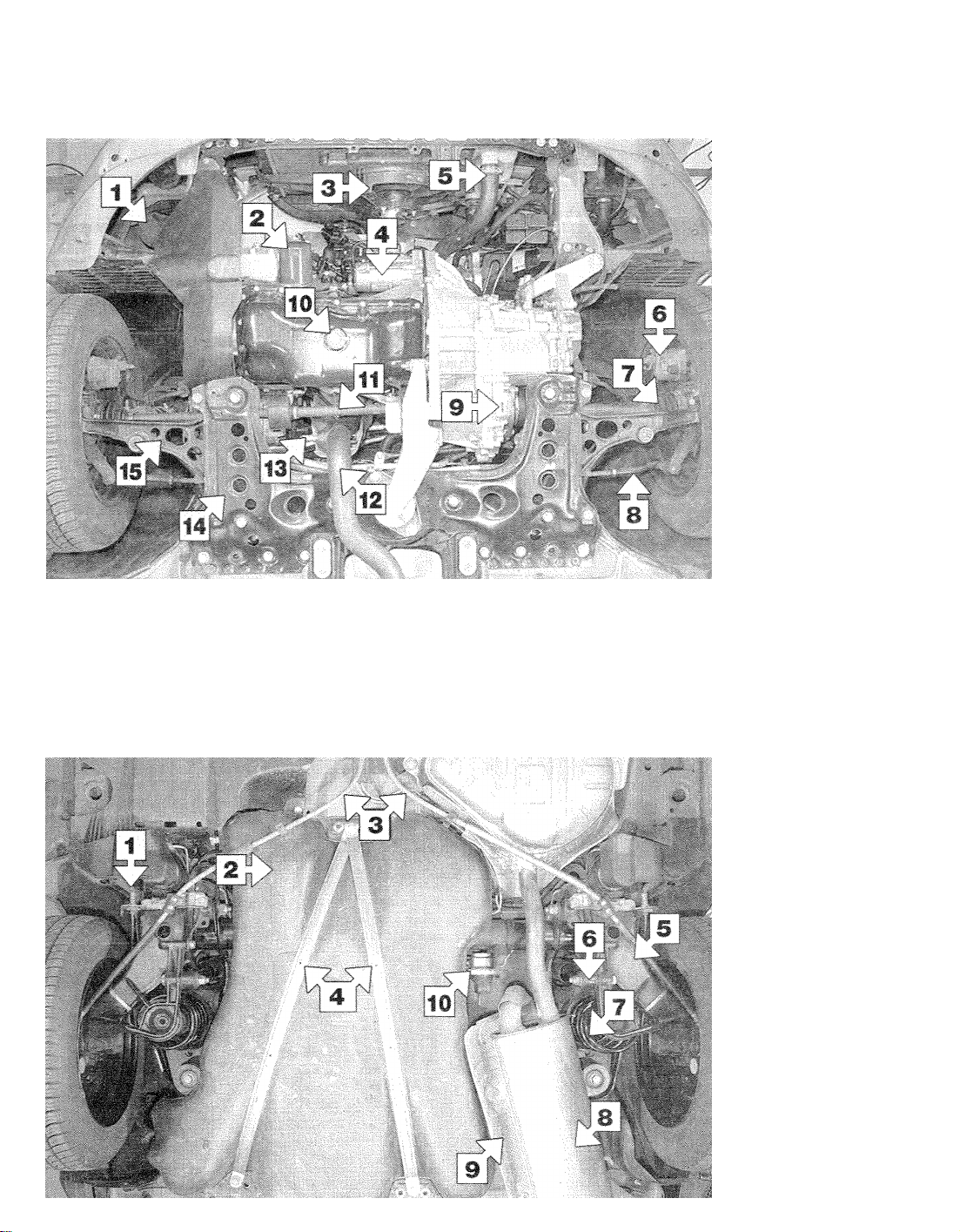

Front underside view of 1.6 litre model

1 Horn unit

2 Oil filter

3 Radiator cooling fan

4 Starter motor

5 Radiator bottom hose

6 Front brake caliper

7 Driveshaft CV joint gaiter

8 Track rod end

9 Manual transmission drain

plug

10 Engine oil drain plug

11 Right-hand driveshaft

12 Exhaust downpipe

13 Oxygen sensor

14 Subframe

15 Suspension arm

Rear underside view of 1.6 litre mode!

1 Brake pipe/hose

connection

2 Fuel tank

3 Handbrake cables

4 Fuel tank retaining straps

5 Rear suspension arm

6 Rear shock absorber

mounting

7 Rear coil spring

8 Exhaust rear silencer

9 Exhaust heat shield

10 Brake pressure

proportioning valve

Page 7

Maintenance procedures

1-7

1 Introduction

General information

This Chapter is designed to help the home

mechanic maintain his/her vehicle for safety,

economy, long life and peak performance.

The Chapter contains a master maintenance schedule, followed by Sections dealing

specifically with each task in the schedule;

Visual checks, adjustments, component

renewal and other helpful items are included.

Refer to the accompanying illustrations of the

engine compartment and the underside of the

vehicle for the locations of the various

components.

Servicing your vehicle in accordance with

the mileage/time maintenance schedule and

the following Sections will provide a planned

maintenance programme, which should result

in a long and reliable service life. This is a

comprehensive plan, so maintaining some

items but not others at the specified service

intervals, will not produce the same results.

As you service your vehicle, you will

discover that many of the procedures can and should - be grouped together, because of

the particular procedure being performed, or

because of the proximity of two otherwise

unrelated components to one another. For

example, if the vehicle is raised for any reason,

the exhaust can be inspected at the same time

as the suspension and steering components.

The first step in this maintenance programme

is to prepare yourself before the actual work

begins. Read through all the Sections relevant

to the work to be carried out, then make a list

and gather all the parts and tools required. If a

problem is encountered, seek advice from a

parts specialist, or a dealer service department.

2 Regular maintenance

1 If, from the time the vehicle is new, the

routine maintenance schedule is followed

closely, and frequent checks are made of fluid

levels and high-wear items, as suggested

throughout this manual, the engine will be

kept in relatively good running condition, and

the need for additional work will be minimised.

2 It is possible that there will be times when

the engine is running poorly due to the lack of

regular maintenance. This is even more likely

if a used vehicle, which has not received

regular and frequent maintenance checks, is

purchased. In such cases, additional work

may need to be carried out, outside of the

regular maintenance intervals.

3 If engine wear is suspected, a compression

test (refer to the relevant part of Chapter 2) will

provide valuable information regarding the

overall performance of the main internal

components. Such a test can be used as a

basis to decide on the extent of the work to

be carried out. If, for example, a compression

test indicates serious internal engine wear,

conventional maintenance as described in this

Chapter will not greatly improve the perform-

ance of the engine, and may prove a waste of

time and money, unless extensive overhaul

work is carried out first.

4 The following series of operations are those

most often required to improve the performance of a generally poor-running engine:

Primary operations

a) Clean, inspect and test the battery (See

Weekly checks and Section 6, where

applicable).

b) Check all the engine-related fluids (See

Weekly checks):

c) Check the condition and tension of the

auxiliary drivebelt (Sections 7 and 21).

d) Renew the spark plugs (Section 18).

e) Check the condition of the air filter, and

renew if necessary (Section 19).

f) Check the fuel filter, Where applicable

(Section 20).

g) Check the condition of all hoses, and

check for fluid leaks (Section 9).

h) Check the exhaust gas emissions (Sec-

tion 24).

5 If the above operations do not prove fully

effective, carry out the following secondary

operations:

Secondary operations

All items listed under Primary operations, plus

the following:

a)

Check the charging system (see Chapter 5A,

Section 4).

b) Check the ignition system (see Chapter 5B).

c) Check the fuel system (see relevant Part

of Chapter 4).

d) Renew the ignition HT leads, if applicable.

Every 12 000 miles (20 000 km)

3. Engine oil and filter renewal

1 Frequent oil and filter changes are the most

important maintenance procedures which can

be undertaken by the DIY owner. As engine oil

ages, it becomes diluted and contaminated,

which leads to premature engine wear

2 The oil change interval given in this Manual

is the same as quoted by the manufacturer,

but owners of older vehicles (or those

covering a small annual mileage) may feel

justified in changing the oil and filter more

frequently, perhaps every 6000 miles, or every

6 months. The quality of engine oil used is a

significant factor in this - the 12 000-mile

interval only applies if a high-quality

synthetic-based oil-is used.

3 Before starting this procedure, gather all

the necessary tools and materials. Also make

sure that you have plenty of clean rags and

newspapers handy, to mop up any spills,

Ideally, the engine oil should be warm, as it

will drain better, and more-built-up sludge will

be removed with it. Take care, however, not to

touch the exhaust or any other hot parts of the

engine when working under the vehicle. To

avoid any possibility of scalding, and to

protect yourself from possible skin irritants

and other harmful contaminants in used

engine oils, it is advisable to wear gloves

when carrying out this work.

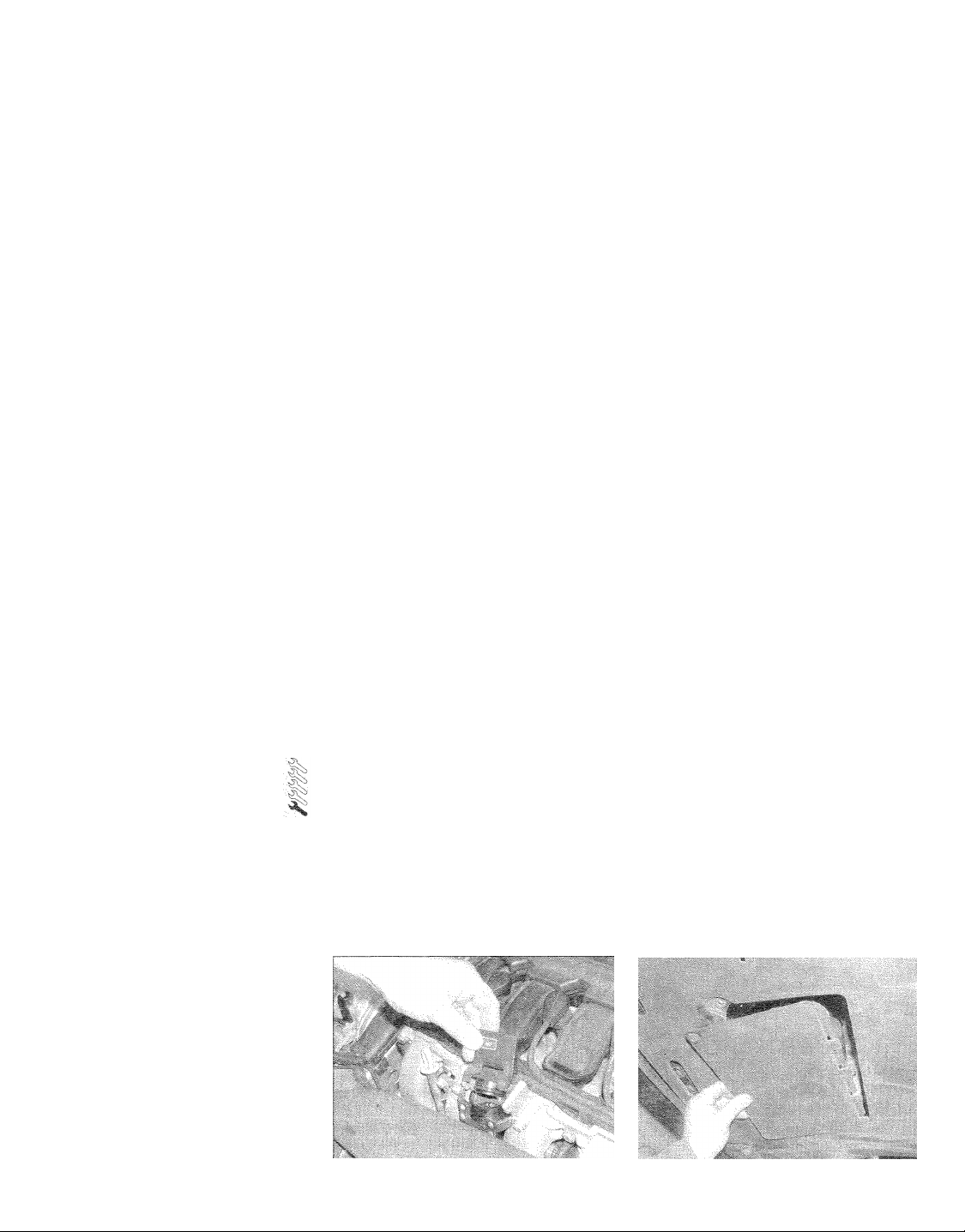

4 Remove the oil filler cap (see illustration),

and take out the dipstick.

5 Access to the underside of the vehicle will

be greatly improved if it can be raised on a. lift,

driven onto ramps, or jacked up and

3.4 Removing the oil filler cap on a

1.8 litre model

supported on axle stands (see Jacking and

vehicle support). Whichever method is

chosen, make sure that the vehicle remains

level, or if it is at an angle, that the drain plug

is at the lowest point.

6 Where applicable, unscrew the fasteners

and remove the engine undertray, for access

to the drain plug. On 1.8 litre engines, the

drain plug can be reached from the back of

the engine, and a panel is provided in the

undertray, which can be hinged down to get

to the filter (see illustration).

3.6 Removing the oil filter access panel on

a 1.8 litre model

Page 8

Every 12 000 miles (20 000 km)

1-8

3,7 On some models, a special socket is

required to loosen the sump drain plug

7 Using a special socket where necessary,

slacken the drain plug (on the base of the

sump) about half a turn (see illustration).

Position the draining container under the drain

plug, then remove the plug completely.

Recover the sealing ring from the drain plug,

8 Allow some time for the old oil to drain,

noting that it may be necessary to reposition

the container as the oil flow slows to a trickle

(see illustration).

9 After a!! the oil has drained, wipe off the

drain plug with a clean rag, and fit a new

sealing washer. Clean the area around the

drain plug opening, and refit the plug. Tighten

the plug securely.

10 Move the container into position under the

oil filter, which is located on the front of the

cylinder block,

11 Using an oil filter removal tool if

necessary, slacken the filter initially, then

unscrew it by hand the rest of the way (see

illustration). Empty the oil in the filter into the

container,

12 Use a clean rag to remove ail oil, dirt and

sludge from the filter sealing area on the

engine. Check the old filter to make sure that

the rubber sealing ring has not stuck to the

engine. If it has, carefully remove it.

13 Apply a light coating of clean engine oil to

the sealing ring on the new filter, then screw it

into position on the engine (see illustration).

Tighten the filter firmly by hand only - do not

use any tools,

14 Remove the old oil from under the car,

then refit the undertray or access panel (as

applicable). Lower the car to the ground.

3.13 Fit and tighten the new oil filter by

hand only - do not use any tools

3.8 Draining the engine oil

15 With the car on level ground, fill the

engine, using the correct grade and type of oil

(see Lubricants and fluids). An oil can spout or

funnel may help to reduce spillage (see

illustration). Pour in half the specified

quantity of oil first, then wait a few minutes for

the oil to fall to the sump,

16 Continue adding oil a small quantity at a

time until the level is up to the MIN mark on

the dipstick. Adding around 1.0 litre of oil will

now bring the level up to the MAX on the

dipstick - do not worry if a little too much goes

in, as some of the apparent excess will be

taken up in filling the oil filter. Refit the dipstick

and the filler cap.

17 Start the engine and run it for a few

minutes; check for leaks around the oil filter

seal and the sump drain plug. Note that there

may be a few seconds' delay before the oil

pressure warning light goes out when the

engine is started, as the oil circulates through

the engine oil galleries and the new oil filter

before the pressure builds up.

18 Switch off the engine, and wait a few

minutes for the oil to settle in the sump once

more. With the new oil circulated and the filter

completely full, recheck the level on the

dipstick, and add more oil as necessary.

19 Dispose of the used engine oil safely, with

reference to General repair procedures in the

Reference section of this manual.

4 Front-brake pad check

1 Firmly apply the handbrake, loosen the

front roadwheel bolts, then jack up the front of

the car and support it securely on axle stands.

Remove the front roadwheels.

2 For a comprehensive check, the brake pads

should be removed and cleaned. The

operation of the caliper can then also be

checked, and the condition of the brake disc

itself can be fully examined on both sides.

Refer to Chapter 9.

3 If any pads friction material is worn to the

specified thickness or less, all four pads must

be renewed as a set

4 Check the operation of the pad wear

warning light by disconnecting the wiring plug

3.11 Removing the oil filter on a 1.8 litre

model

adjacent to the brake caliper. With the ignition

on, touch the wiring plug to earth, and check

that the warning light comes on.

5 Automatic transmission

fluid level check

1 Ideally, the fluid level must be checked with

the engine/transmission at operating

temperature. This can be achieved by

checking the level after a journey of at least 10

miles. If the level is checked when cold, follow

this up with a level check when the fluid is hot.

2 Park the car on level ground, and apply the

handbrake very firmly. As an added precaution,

chock the front and rear wheels, so that the car

cannot move.

3 With the engine idling, move the selector

lever gently from position P to position 1, and

back to P.

4 The fluid level dipstick is located on the

front of the transmission. Before removing the

dipstick, thoroughly clean the area around it -

no dirt or debris must be allowed to enter the

transmission.

5 Extract the dipstick, and wipe it clean using

a clean piece of rag or tissue. Re-insert the

dipstick completely, then pull it out once

more. The fluid level should be between the

reference marks on the side of the dipstick

marked HOT (if the level is checked when

cold, use the markings on the COLD side of

the dipstick). .

6 If topping-up is required, this is done via the

dipstick tube. It is most important that no dirt

3.15 Filling the engine with oil

Page 9

Every 12 000 miles (20 000 km)

1-9

6.3 Topping-up the battery electrolyte

or debris enters the transmission as this is

done - use a clean funnel (preferably with a

filter) and fresh fluid from a clean container.

7 Pour the fresh fluid a little at a time down

the dipstick tube, checking the level

frequently.

8 When the level is correct, refit the dipstick

and switch off the engine.

check

Warning: The electrolyte inside a

battery is diluted acid - it is a

good idea to wear suitable rubber

gloves. When topping-up, don't overfill the

cells so that the electrolyte overflows. In

the event of any spillage, rinse the

electrolyte off without delay. Refit the cell

covers and rinse the battery with copious

quantities of clean water. Don't attempt to

siphon out any excess electrolyte.

1 Models covered by this Manual are fitted

with a limited-maintenance' battery as

standard equipment (or may have had a

'maintenance-free' one fitted as a

' replacement). If the battery in your vehicle is

marked 'Freedom', 'Maintenance-Free' or

similar, no electrolyte level checking is

required (the battery is often completely

sealed, preventing any topping-up).

2 Batteries which do require their electrolyte

level to be checked can be recognised by the

, presence of level markings and removable

covers over the six battery cells - the battery

casing is also sometimes translucent, so that

the electrolyte level can be more easily

checked. Some of the batteries fitted by FIAT

have level markings, but no means of toppingup!

3 Remove the cell covers and either look

down inside the battery to see the level web,

or check the level using any markings

provided on the battery casing. The

electrolyte should at least cover the battery

plates. if necessary, top up a little at a time

with distilled (de-ionised) water until the level

in all six cells is correct - don't fill the cells up

to the brim (see illustration). Wipe up any

spillage, then refit the cell covers.

4 On batteries where the level can be

checked but not topped-up, if the level is low,

consult a dealer or automotive electrical

specialist as to the best course of action

(likely to be fitting a replacement battery).

7 Auxiliary drivebelt tension

Note: On models with 1.4 and 1.8 litre

engines, an automatic belt tensioner is used,

and regular tension checks are not required.

Check the belt condition at the specified

intervals, however, as described in Section 21,

1 The only belt tension specifications quoted

by FIAT are for use with their dedicated belt

tensioning equipment, and are not of great

practical help. The advice given below should

be treated as a rough guide, and should be

adequate in most cases. If there is serious

concern over belt tension, refer to a FIAT

dealer for advice.

2 If a drivebelt is set too tight, it will subject

the driven unit to excess load, resulting in

premature wear of the unit (and of the belt). If

the belt is too slack, it will not transmit drive

properly, and the belt will suffer wear due to

slippage.

1.2 litre engine

3 Two or three separate belts are used on this

engine, depending on whether or not air

conditioning is fitted.

4 For improved access to the belts, remove

the three bolts securing the engine top cover,

and lift the cover away.

7.7 Loosen the alternator mountings (arrowed) and pivot the alternator to tension the belt

5 Each of the drivebelts is checked and

adjusted in much the same way. To check the

power steering pump drivebelt, remove the

bolt securing the belt upper cover, and

remove the cover. To access the air

conditioning compressor drivebelt, refer to

paragraphs 16 to 18.

6 Press on the belt at the centre-point

between the two pulleys, and the drivebelt

should deflect by approximately 5 mm.

Alternator drivebelt

7 If adjustment is required, loosen the nuts

and bolts on the two adjuster slots, and the

lower mounting through-bolt. Pivot the

alternator as necessary using a suitable lever

to set the belt tension, then re-tighten all the

fasteners (see illustration). Take care when

levering the alternator that no damage is

caused to the alternator or surrounding

components.

8 On models with air conditioning, note that if

the air conditioning compressor drivebelt

needs adjusting, this will affect the alternator

belt tension.

Air conditioning compressor drivebelt

9 If adjustment is required, loosen the nut and

bolt on the adjuster slot, and the lower

mounting through-bolt. Pivot the compressor

as necessary using a suitable lever to set the

belt tension, then re-tighten all the fasteners.

Take care when levering the compressor that

no damage is caused to the compressor or

surrounding components.

10 Note that if the air conditioning compressor drivebelt needs adjusting, this will

affect the alternator belt tension.

Page 10

1-10

Every 12 000 miles (20 000 km)

7.11 Power steering pump adjuster bolt (arrowed)

Power steering pump drivebelt

11 If adjustment is required, loosen the nuts

and bolts on the two adjuster slots, and the

upper mounting through-bolt. The belt tension

is set by now turning the adjuster bolt at the

front of the pump mounting bracket (see

illustration), When the belt tension is correct,

re-tighten ail the fasteners and refit the belt

upper cover,

1.6 litre engine

12 Two or three separate belts are used on

this engine, depending on whether or not air

conditioning is fitted,

Power steering pump drivebelt

13 Check the power steering pump drivebelt

7,14a Loosen the pump mounting bolts

7.13 To Improve access to the power steering pump drivebelt,

first - to improve access, unbolt and remove

the drivebelt guard (see illustration). Press

on the belt at the centre-point between the

two pulleys, and the drivebelt should deflect

by approximately 5 mm..

14 If adjustment is required, loosen the pump

mountings, the nut and bolt on the adjuster

slot, and the adjuster locknut. Turn the adjuster

bolt as required to set the belt tension, then re-

tighten the locknut and the nut and bolt on the

adjuster slot (see illustrations).

15 With all fixings re-tightened, turn the belt

clockwise through one complete revolution,

using a spanner on the crankshaft pulley bolt.

Re-check the belt tension, and re-adjust if

necessary. Refit the drivebelt guard on

completion.

7.14b ... and the nut and bolt on the

adjuster slot...

remove the belt guard

Alternator/coolant pump drivebelt

16 With the car parked on a level surface,

apply the handbrake and chock the rear

wheels. Loosen the right-hand front wheel

bolts.

17 Raise the front of the vehicle, rest it

securely on axle stands and remove the right-

hand front roadwheel,

18 Unscrew and release the fasteners

securing the wheelarch inner panel, to gain

access to the belt run (see illustration).

19 Press firmly on the belt, midway between

the crankshaft and water pump pulleys (see

illustration). The belt should deflect by

approximately 5 mm,

20 Refer to the advice given in paragraph 2,

noting that the lower drivebelt drives the

alternator and coolant pump.

21 If adjustment is required, loosen the

tensioner upper and lower bolts. Using an

Allen key, turn the hex adjuster as required to

set the belt tension, then re-tighten the

tensioner bolts (see illustration).

22 Turn the belt clockwise through one

complete revolution, using a spanner on the

crankshaft pulley bolt. Re-check the belt

tension, and re-adjust if necessary.

23 On completion, refit the wheelarch access

panel and the roadwheel, and lower the car to

the ground. Tighten the wheel bolts to the

specified torque.

7,14c ... then turn the adjuster bolt as

required before tightening the locknut

7.18 Removing the wheelarch inner panel

7,19 Checking the drivebelt tension

Page 11

Every 12 000 miles (20 000 km)

1-11

7.21 Set the belt tension, then tighten the

tensioner bolts

Air conditioning compressor drivebelt

24 Press on the belt at the, centre-point

between the two pulleys, on the opposite side

to the tensioner wheel. The drivebelt should

deflect by approximately 5 mm.

25 If adjustment is required, loosen the bolt

on the adjuster slot, and the pivot bolt at the

top of the tensioner arm.

26 Loosen the locknut at the front of the arm,

and turn the adjuster bolt as required to move

the tensioner wheel and set the belt tension.

27 On completion, re-tighten all the

fasteners. With all fixings re-tightened, turn

the belt clockwise through one complete

revolution, using a spanner on the crankshaft

pulley bolt. Re-check the belt tension, and re-

adjust if necessary.

8 Pollen filter renewal

Note: A pollen filter is not fitted to all models,

and one was not actually fitted to our main

project vehicle seen in the workshop.

1 The air entering the vehicle's ventilation

system is passed through a very fine pleated-

paper air filter element, which removes

particles of pollen, dust and other airborne

foreign matter. To ensure its continued

effectiveness, this filter's element must be

renewed at regular intervals. Failure to renew

the element will also result in greatly-reduced

airflow into the passenger compartment,

reducing demisting and ventilation.

2 The pollen filter Is located in the air intake at

the base of the windscreen. Open the bonnet

for access.

3 Lift up the separate section of weatherstrip

which fits over the top edge of the pollen filter

access panel (see illustration).

4 Unscrew and remove the two retaining

bolts, and pull out the pollen filter access

panel (see illustrations).

5 Reach in through the access panel, and

release the two spring clips which retain the

pollen filter. Lower the filter out of its location,

noting which way up it fits (see illustration).

6 As far as possible, clean the inside of the

filter housing, and the inside of the access

panel.

8.3 Lift up the weatherstrip which fits over

the filter access panel

8.4b ... and lift out the access panel

7 Fit the new filter into position, and secure

with the two clips.

8 Refit the access panel, secure with the two

bolts, and clip the weatherstrip into position.

9 Hose and fluid leak check

1 Visually inspect, the engine joint faces,

gaskets and seals for any signs of water or oil

leaks. Pay particular attention to the areas

around the cylinder head, oil filter and sump

joint faces.. Bear in mind that, over a period of

time, some very slight seepage from these

areas is to be expected - what you are really

A leak in the coating system will usually

show up as white- or rust-coloured

deposits on the areas adjoining the leak.

8.4a Undo the two screws ...

8.5 Remove the pollen filter by releasing

the two clips (arrowed)

looking for is any indication of a serious leak

(see Haynes Hint). Should a leak be found,

renew the offending gasket or oil seal by

referring to the appropriate Chapters in this

manual.

2 Also check the security and condition of all

the engine-related pipes and hoses. Ensure

that all cable-ties or securing clips are in place

and in good condition. Clips that are broken

or missing can lead to chafing of the hoses,

pipes or wiring, which could cause more

serious problems in the future.

3 Carefully check the radiator hoses and

heater hoses along their entire length. Renew

any hose that is cracked, swollen or

deteriorated. Cracks will show up better if the

hose is squeezed. Pay close attention to the

hose clips that secure the hoses to the

cooling system components. Hose clips can

pinch and puncture hoses, resulting in cooling

system leaks (see illustration).

9.3 Check all hoses and their retaining

clips

Page 12

1-12

4 Inspect all the cooling system components

(hoses, joint faces etc.) for leaks. A leak in the

cooling system will usually show up as whiteor rust-coloured deposits on the area

adjoining the leak. Where any problems of this

nature are found on system components,

renew the component or gasket with

reference to Chapter 3.

5 Where applicable, inspect the automatic

transmission fluid cooler hoses for leaks or

deterioration,

6 With the vehicle raised, inspect the fuel

tank and filler neck for punctures, cracks and

other damage. The connection between the

filler neck and tank is especially critical.

Sometimes a rubber filler neck or connecting

hose will leak due to loose retaining clamps or

deteriorated rubber.

7 Carefully check all rubber hoses and metal

fuel lines leading away from the fuel tank.

Check for loose connections, deteriorated

hoses, crimped lines, and other damage. Pay

particular attention to the vent pipes and

hoses, which often loop up around the filler

neck and can become blocked or crimped.

carefully inspecting them all the way. Renew

damaged sections as necessary.

8 From within the engine compartment, check

the security of all fuel hose attachments and

9 Check the condition of the power steering

Every 12 000 miles (20 000 km)

Follow the lines to the front of the vehicle,

pipe unions and inspect the fuel hoses and

vacuum hoses for kinks, chafing and

deterioration (see illustration).

fluid hoses and pipes.

10 Transmission and

:.' driveshaft gaiter checks

1 Raise the front of the vehicle and support

on axle stands. Alternatively, drive the car

onto ramps.

2 Inspect around the transmission for any

sign of leaks or damage. In particular, check

the area around the driveshaft oil/fluid seals

for leakage. Slight seepage should not be of

great concern, but a serious leak should be

investigated further, with reference to Chapter 7A or 7B.

3 Check the security and condition of the

wiring and wiring plugs on the transmission

housing.

4 With the vehicle raised and securely

supported on stands, turn the steering onto

full lock, then slowly rotate the roadwheel.

Inspect the condition of the outer constant

velocity (CV) joint rubber gaiters, squeezing

the gaiters to open out the folds, Check for

signs of cracking, splits or deterioration of the

rubber, which may allow the grease to

escape, and lead to water and grit entry into

the joint. Also check the security and

condition of the retaining clips. Repeat these

checks on the inner CV joints. If any damage

or deterioration is found, the gaiters should be

renewed (see Chapter 8).

9.8 Check all fuel and vacuum hoses

5 At the same time, check the general

condition of the CV joints themselves by first

holding the driveshaft and attempting to

rotate the wheel. Repeat this check by holding

the inner joint and attempting to rotate the

driveshaft. Any appreciable movement

indicates wear in the joints, wear in the

driveshaft splines, or a loose driveshaft

retaining nut,

11 Breaking system pipes

and hoses check

i Starting under the bonnet, examine the

brake fluid reservoir and master cylinder for

leaks. When a brake fluid leak occurs, it is

normal to find blistered or wrinkled paint in the

area of the leak. Check the metal pipes from

the master cylinder for damage, and check

the brake pressure regulator, servo/ABS unit

and fluid unions for leaks.

2 With the vehicle raised and securely

supported on stands, first inspect each front

brake caliper. In particular, check the flexible

hose leading to the caliper for signs of

damage or leaks, especially where the hose

enters the metal end fitting. Make sure that

the hose is not twisted or kinked, and that it

cannot come into contact with any other

components when the steering is on full lock.

3 From the caliper, trace the metal brake

pipes back along the car, Again, look for leaks

from the fluid unions or signs of damage, but

additionally check the pipes for signs of

corrosion (see illustration). Make sure the

12.2 Check ail exhaust joints for signs of

corrosion damage

11.3 Check all brake pipes and fittings for

corrosion

pipes are securely located by the clips

provided on the vehicle underside.

4 At the rear of the vehicle, inspect each rear

brake and its flexible hose, where applicable.

Examine the handbrake cable, tracing it back

from each rear brake and checking for frayed

cables or other damage. Lubricate the

handbrake cable guides, pivots and other

moving parts with general-purpose grease.

5 If any damage is found, refer to Chapter 9

for further information,

12- Exhaust system check

1 With the engine cold (at least an hour after

the vehicle has been driven), check the

complete exhaust system from the engine to

the end of the tailpipe. The exhaust system is

most easily checked with the vehicle raised on

a hoist, or suitably supported on axle stands,

so that the exhaust components are readily

visible and accessible.

2 Check the exhaust pipes and connections

for evidence of leaks, severe corrosion and

damage (see illustration). Make sure that all

brackets and mountings are in good

condition, and that all relevant nuts and bolts

are tight. Leakage at any of the joints or in

other parts of the system will usually show up

as a black sooty stain in the vicinity of the

leak.

3 Rattles and other noises can often be

traced to the exhaust system, especially the

brackets and mountings (see illustration).

12,3 Check the condition of all exhaust

mounting brackets and rubbers

Page 13

Every 12 000 miles (20 000 km)

1-13

Try to move the pipes and silencers, If the com-

ponents are able to come into contact with the

body or suspension parts, secure the system

with new mountings. Otherwise separate the

joints (if possible) and twist the pipes as

necessary to provide additional clearance,

13 Steering and

suspension check

Front suspension

and steering check

1 Raise the front of the vehicle, and securely

support it on axle stands. Where necessary

for improved access, release the fasteners

and remove the engine undertray (where

applicable).

2 Visually inspect the balljoint dust covers

and the steering rack-and-pinion gaiters for

splits, chafing or deterioration. Any wear of

these components will cause loss of lubricant,

together with dirt and water entry, resulting in

rapid deterioration of the balljoints or steering

gear (see illustration).

3 Check the power steering fluid hoses for

chafing or deterioration, and the pipe and hose

unions for fluid leaks. Also check for signs of

fluid leakage under pressure from the steering

gear rubber gaiters, which would indicate

failed fluid seals within the steering gear.

4 Grasp the roadwheel at the 12 o'clock and

6 o'clock positions, and try to rock it. Very

slight free play may be felt, but if the movement

is appreciable, further investigation is necessary

to determine the source. Continue rocking the

wheel while an assistant depresses the

footbrake. If the movement is now eliminated or

significantly reduced, it is likely that the hub

bearings are at fault. If the free play is still

evident with the footbrake depressed, then

there is wear in the suspension joints or

mountings. Before condemning any compo-

nents, however, check that the roadwheel bolts

are tightened to the specified torque.

5 Now grasp the wheel at the 9 o'clock and

3 o'clock positions, and try to rock it as

before. Any movement felt now may again be

caused by wear in the hub bearings or the

steering track-rod balljoints. If the inner or

outer balljoint is worn, the visual movement

will be obvious,

8 Using a large screwdriver or flat bar, check

for wear in the suspension mounting bushes

by levering between the relevant suspension

component and its attachment point. Some

movement is to be expected as the mountings

are made of rubber, but excessive wear

should be obvious. Also check the condition

of any visible rubber bushes, looking for splits,

cracks or contamination of the rubber, .

7 With the car standing on its wheels, have an

assistant turn the steering wheel back and

forth about an eighth of a turn each way.

There should be very little, if any, lost

movement between the steering wheel and

roadwheels. If this is not the case, closely

observe the joints and mountings previously

described, but in addition, check the steering

column universal joints for wear, and the rack-andand-pinion steering gear itself.

Suspension strut/shock

absorber check

8 Check for any signs of fluid leakage around

the suspension strut/shock absorber body, or

from the rubber gaiter around the piston rod.

Should any fluid be noticed, the suspension

strut/shock absorber is defective internally,

and should be renewed. Note: Suspension

struts/shock absorbers should always be

renewed in pairs on the same axle.

9 The efficiency of the suspension strut/shock

absorber may be checked by bouncing the

vehicle at each corner. Generally speaking, the

body will return to its normal position and stop

after being depressed, if it rises and returns on

a rebound, the suspension strut/shock

absorber is probably suspect. Examine also

the suspension strut/shock absorber upper

and lower mountings for any signs of wear.

14 "Underbody protection check

Raise and support the vehicle on axle

stands. Using an electric torch or lead light,

inspect the entire underside of the vehicle,

paying particular attention to the wheelarches.

Look for any damage to the flexible Underbody

coating, which may crack or flake off with age,

leading to corrosion. Also check that the

wheelarch liners are securely attached with any

clips provided - if they come loose, dirt may get

in behind the liners and defeat their purpose. If

there is any damage to the underseal, or any

corrosion, it should be repaired before the

damage gets too serious,

15 Lights and

horn operation check

1 With the ignition switched on where

necessary, check the operation of all exterior

lights.

2 Check the brake lights with the help of an

assistant, or by reversing up close to a reflective

door. Make sure that all the rear lights are

capable of operating independently, without

affecting any of the other lights - for example,

switch on as many rear lights as possible, then

try the brake lights. If any unusual results are

found, this is usually due to an earth fault or

other poor connection at that rear light unit.

3 Again with the help of an assistant or using

a reflective surface, check as far as possible

that the headlights work on both main and

dipped beam.

4 Replace any defective bulbs with reference

to Chapter 12.

13.2 Check the condition of the balljoint

rubber covers

Particularly on older

vehicles, bulbs can stop

working as a result of

corrosion build-up on the

bulb or its holder - fitting a new bulb

may not cure the problem in this

instance. When replacing any bulb, if

you find any green or white-coloured:

powdery deposits, these should be

cleaned off using emery cloth.

5 Check the operation of all interior lights,

including the glovebox and luggage area

illumination lights. Switch on the ignition, and

check that all relevant warning lights come on

as expected - the vehicle handbook should

give details of these. Now start the engine,

and check that the appropriate lights go out.

When you are next driving at night, check that

ail the instrument panel and facia lighting

works correctly. If any problems are found,

refer to Chapter 12, Section 5.

6 Finally, choose an appropriate time of day

to test the operation of the horn.

16 Hinge and lock lubrication

Lubricate the hinges of the bonnet, doors

and tailgate with light general-purpose oil.

Similarly, lubricate all latches, locks and lock

strikers, and the door check straps with

general-purpose oil or grease (see

illustration). At the same time, check the

10.1 Lubricate the door hinges and check

straps

Page 14

1.14

Every 12 000 miles (20 000 km)

security and operation of all the locks,

adjusting them if necessary (see Chapter 11),

Lightly lubricate the bonnet release

mechanism and cable with suitable grease.

Do not attempt to lubricate the steering lock.

17 Road test

Instruments and

electrical equipment

1 Check the operation of a!! instruments and

electrical equipment.

2 Make sure that all instruments read

correctly, and switch on ail electrical equip-

ment in turn, to check that it functions properly.

Steering and suspension

3 Check for any abnormalities in the steering,

suspension, handling or road 'feel',

4 Drive the vehicle, and check that there are

no unusual vibrations or noises.

5 Check that the steering feels positive, with

no excessive 'sloppiness', or roughness, and

check for any suspension noises when

cornering and driving over bumps.

Drivetrain

6 Check the performance of the engine,

clutch (where applicable), transmission and

driveshafts.

7 Listen for any unusual noises from the

engine, clutch and transmission,

8 Make sure the engine runs smoothly at idle,

and there is no hesitation on accelerating.

9 Check that, where applicable, the clutch

action is smooth and progressive, that the

drive is taken up smoothly, and that the pedal

travel is not excessive. Also listen for any

noises when the clutch pedal is depressed.

10 On manual transmission models, check

that all gears can be engaged smoothly

without noise, and that the gear lever action is

not abnormally vague or 'notchy'

11 On automatic transmission models, make

sure that ail gearchanges occur smoothly,

without snatching, and without an increase in

engine speed between changes. Check that

all the gear positions can be selected with the

vehicle at rest. If any problems are found, they

should be referred to a FIAT dealer.

12 Listen for a metallic clicking sound from

the front of the vehicle, as the vehicle is driven

slowly in a circle with the steering on full-lock.

Carry out this check in both directions. If a

clicking noise is heard, this indicates wear in a

driveshaft joint, in which case renew the joint

If necessary,

Braking system

13 Make sure that the vehicle does not pull to

one side when braking, and that the wheels

do not lock prematurely when braking hard,

14 Check that there is no vibration through

the steering when braking.

15 Check that the handbrake operates

correctly without excessive movement of the

lever, and that it holds the vehicle stationary

on a slope.

16 Test the operation of the brake servo unit

as follows. With the engine off, depress the

footbrake four or five times to exhaust the

vacuum. Hold the brake pedal depressed,

then start the engine. As the engine starts,

there should be a noticeable 'give' in the brake

pedal as vacuum builds up. Allow the engine

to run for at least two minutes, and then switch

it off. If the brake pedal is depressed now, it

should be possible to detect a hiss from the

servo as the pedal is depressed. After about

four or five applications, no further hissing

should be heard, and the pedal should feel

considerably harder.

Every 24 000 miles (40 000 km)

18 Spark plug renewal

1 The correct functioning of the spark plugs is

vital for the correct running and efficiency of

the engine. It is essential that the plugs fitted

are appropriate for the engine (a suitable type

is specified at the beginning of this Chapter). If

this type is used and the engine is in good

condition, the spark plugs should not need

18.3a Remove the three screws

(arrowed)...

attention between scheduled replacement

intervals. Spark plug cleaning is rarely

necessary, and should not be attempted unless

specialised equipment is available, as damage

can easily be caused to the firing ends.

2 Before removing the spark plugs, allow the

engine time to cool.

1.2 and 1.4 litre engines

3 Remove the three bolts securing the engine

top cover, loosen the fourth bolt at the rear of

the timing cover (where applicable), and lift

18.3b ... loosen the screw behind the

timing cover ,..

away the cover for access to the spark plugs

and leads (see illustrations).

1.2, 1.4 and 1.6 litre engines

4 Release the HT leads from the retaining

clips on the top of the cylinder head as

necessary.

5 If the marks on the original-equipment spark

plug (HT) leads cannot be seen, mark the leads

1 to 4, to correspond to the cylinder the lead

serves (No 1 cylinder is at the timing belt end

of the engine).

18.3c ... and remove the engine top cover

-1.4 litre engine

Page 15

Every 24 000 miles (40 000 km)

1-15

18.6 Pull the HT leads off the spark plugs

6 Carefully pull the lead end fittings upwards

from the plugs, and (where applicable) out of

the recesses in the cylinder head. Grip the

end fitting, not the lead, otherwise the lead

connection may be fractured (see

illustration).

1.8 litre engine

7 Unscrew the oil filler cap, and remove the

two Allen screws concealed underneath.

Remove the six main cover bolts, and lift off

the engine top cover, for access to the ignition

coil assemblies (see illustrations).

8 Disconnect the wiring plugs from the

ignition coil which fits over each spark plug

(see illustration).

9 To avoid transposing the ignition coils, it is

advisable to work on one assembly at a time.

Alternatively, mark the coil assemblies for

position, noting that No 1 coil is nearest the

timing belt end of the engine.

18.7a Removing one of the Allen screws

under the oil filler cap

10 Starting with No 1 coil, unscrew the two

bolts securing the coil to the cylinder head

(see illustration).

11 Carefully pull the coil and plug connector

upwards off the plug, and withdraw it from the

cylinder head recess (see illustration).

All engines

12 It is advisable to remove the debris from

the spark plug recesses using a clean brush,

vacuum cleaner or compressed air before

removing the plugs. If this is not done, this

debris will drop into the cylinders or lodge in

the spark plug threads.

13 Unscrew the plugs using a spark plug

spanner, suitable box spanner or a deep

socket and extension bar (see illustrations).

Keep the socket aligned with the spark plug if it is forcibly moved to one side, the ceramic

insulator may be broken off. As each plug is

removed, examine it as follows.

18.7b Lifting off the engine top cover

14 Examination of the spark plugs will give a

good indication of the condition of the engine.

If the insulator nose of the spark plug is clean

and white, with no deposits, this is indicative

of a weak mixture or too hot a plug (a hot plug

transfers heat away from the electrode slowly,

a cold plug transfers heat away quickly).

15 if the tip and insulator nose are covered

with hard black-looking deposits, then this is

indicative that the mixture is too rich. Should the

plug be black and oily, then it is likely that the

engine is fairly worn, as well as the mixture

being too rich.

16 If the insulator nose is covered with lightcoloured deposits, then the mixture is correct

and it is likely that the engine is in good

condition.

17 The spark plug electrode gap is of

considerable importance as, if it is too large or

too small, the size of the spark and its

efficiency will be seriously impaired. Where the

18.8 Disconnect the wiring plug from each

coil

18.13a Unscrew the plugs using a socket

and extension bar -1.6 litre engine

18.10 Unscrew the two coil retaining bolts

18,13b ... and on the 1.4 litre engine

18.11 Pull the coil upwards off its spark

plug

1.8.13c ... and remove them from the

engine - note the twin-earth electrode plug

Page 16

1-16

Every 24 000 miles (40 000 km)

it is very often difficult to insert spark

plugs Into their holes without cross-

possibility, fit a short length of 5/16 inch

internal diameter rubber hose over the

end of the spark plug. The flexible hose

acts as a universal joint to help align

the plug with the plug hole, Should the

plug begin to cross-thread the hose

will slip on the spark plug, preventing

thread damage to the aluminium

cylinder head

gap can be adjusted, it should be set to the

value specified at the start of this Chapter,

Note: Spark plugs with multiple earth elec-

trodes are becoming an increasingly common

fitment, especially to vehicles equipped with

catalytic converters. Unless there is clear

information to the contrary, no attempt should

be made to adjust the plug gap on a spark plug

with more than one earth electrode.

18 To set the gap, measure it with a feeler

blade and then bend open, or closed, the

outer plug electrode until the correct gap is

achieved. The centre electrode should never

be bent, as this may crack the insulator and

cause plug failure, if nothing worse, If using

feeler blades, the gap is correct when the

appropriate-size blade is a firm sliding fit.

19 Special spark plug electrode gap

adjusting tools are available from most motor

accessory shops, or from some spark plug

manufacturers.

20 Before fitting the spark plugs, check that

the threaded connector sleeves are tight, and

that the plug exterior surfaces and threads are

clean. It's often difficult to screw in new spark

plugs without cross-threading them - this can

be avoided using a piece of rubber hose (see

Haynes Hint).

21 Remove the rubber hose (if used), and

tighten the plug to the specified torque using

the spark plug socket and a torque wrench. If

a torque wrench is not available, tighten the

plug by hand until it Just seats, then tighten it

by no more than a quarter of a turn further

with the plug socket and handle. Refit the

remaining spark plugs in the same manner.

22 Refit the HT leads (or ignition coils)

securely in their correct order.

23 Where applicable, refit the engine top

cover, using a reversal of the removal

procedure.

19.1 Loosen the securing clip, and pull off

the air inlet duct...

19.2b ... and remove the air cleaner lid

19.2a Loosen the securing screws

(arrowed)...

19.3 Lift out the air filter element, noting

which way round It fits

19 Air filter renewal 20 Fuel filter renewal

1 Release the metal retaining band securing

the air inlet duct to the air cleaner lid, and

separate the duct from the lid (see

illustration).

2 Remove the screws securing the air cleaner

lid, and lift the lid away (see illustrations).

3 Lift out the filter element, noting which way

round it fits (see illustration).

4 Remove any debris that may have collected

inside the air cleaner,

5 Fit a new air filter element in position, noting

any direction-of-fitting markings and ensuring

that the edges are securely seated.

8 Refit the air cleaner lid and secure with the

screws, Refit the air inlet duct, and secure

with the retaining band.

20.3 Unscrew the bolts securing the filter

cover panel

dangerous and volatile liquid, and the

precautions necessary when handling it

cannot be overstressed.

Note: On later 1.6 litre models, and all 1.2 litre

models, an in-line fuel filter is not fitted (even

though the plastic cover panel still appears

under the car). On these models, the only

filters are fitted to the base of the fuel

pump/sender unit, inside the fuel tank - these

are not routinely replaced.

1 The fuel filter is situated underneath the rear

of the vehicle, next to the fuel tank. To gain

access to the filter, chock the front wheels,

then jack up the rear of the vehicle and

support it securely on axle stands.

2 Depressurise the fuel system with reference

to the relevant Part of Chapter 4.

3 To gain access to the filter, unbolt and

remove the plastic cover panel fitted

underneath it (see Illustration).

4 If you have them, fit hose clamps to the

filter inlet and outlet hoses, These are not

essential, but even with the system

depressurised, there will still be an amount of

petrol in the pipes (and the old filter), and this

will siphon out when the pipes are

disconnected. Even with hose clamps fitted,

the old filter will contain some fuel, so have

some rags ready to soak up any spillage.

Warning: Refer to the notes in

Safety first!, and follow them

implicitly. Petrol is a highly-

Page 17

5 Before removing the filter, note any

direction-of-flow markings on the fitter body,

and check against the new filter - the arrow

should point in the direction of fuel flow

(following the hose leading to the front of the

car) (see illustration).

8 The inlet and outlet hoses are equipped

with quick-release connectors. To release the

connectors, squeeze them together at the

sides, then pull apart (see illustration).

7 Loosen the retaining clamp bolt and

remove the old filter (see illustration).

8 If the fuel hoses show any sign of damage,

or if the quick-release connectors are not

making a secure fit, seek the advice of a FIAT

dealer on renewing the hoses.

9 Fit the new filter into position, with the flow

marking arrow correctly orientated, and

tighten the retaining clamp bolt (see

illustration).

10 Reconnect the fuel hoses, ensuring that

no dirt is allowed to enter the hoses or filter

connections, and that the quick-release

connectors click together fully,

11 Start the engine (there may be a delay as

the system re-pressurises and the new filter

fills with fuel). Let the engine run for several

minutes while you check the filter hose

connections for leaks.

12 Refit the cover panel below the filter,

secure with the bolts, then lower the vehicle to

the ground.

Warning; Dispose safely of the old

filter; it will he highly flammable,

and may explode if thrown on a

fire.

1.2 litre engine

1 Remove the three bolts securing the engine

upper cover, and remove the cover for access

to the belts.

2 With the car parked on a level surface, apply

the handbrake and chock the rear wheels.

Loosen the right-hand front wheel bolts.

3 Raise the front of the vehicle, rest it

securely on axle stands and remove the right-

hand front roadwheel,

4 Unscrew and release the fasteners securing

the wheelarch inner panel, to gain access to

the belt run.

Power steering pump drivebelt

5 The power steering pump is located at the

front of the engine. Check the condition of the

pump drivebelt as follows.

6 Look for cracks, splitting and fraying on the

surface of the belt; check also for signs of

glazing (shiny patches) and separation of the

belt plies. If damage or wear is visible, the belt

should be renewed. If there is any evidence of

contamination by oil, grease or coolant, the

reason should be investigated without delay.

Every 24 000 miles (40 000 km)

20.5 Note the flow direction arrow before

removing the old filter

7 Note that it is not unusual for a ribbed belt

to exhibit small cracks in the edges of the belt

ribs, and unless these are extensive or very

deep, belt renewal is not essential.

8 Using a socket and wrench on the crankshaft pulley bolt, rotate the crankshaft so that

the full length of the drivebelt can be examined.

9 If the belt is to be removed, loosen the

fasteners described in Section 7 and slip the

drivebelt from the pulleys.

10 Refitting the belt is a reversal of removal,

making sure that the belt ribs engage properly

with the pulley grooves. Tension the belt using

the information in Section 7.

Air conditioning compressor drivebelt

11 Where fitted, the drivebelt is the 'middle'

drivebelt of three. The compressor is mounted

at the rear of the engine, below the alternator.

12 Check the belt using the information in

paragraphs 6 to 8.

13 If the belt is to be removed, first remove

the power steering pump drivebelt as

described previously. Loosen the fasteners on

the compressor as described in Section 7,

and slip the drivebelt from the pulleys.

14 Refitting the belt is a reversal of removal,

making sure that the belt ribs engage properly

with the pulley grooves. Tension the

compressor and pump drivebelts using the

information in Section 7.

Alternator drivebelt

15 The alternator is fitted at the rear of the

engine.

16 Check the belt using the information in

paragraphs 6 to 8.

20.7 Removing the fuel filter

1-17

20.6 Disconnecting one of the quickrelease hoses

17 If the belt is to be removed, first remove

the air conditioning compressor drivebelt

(where applicable) as described previously.

Loosen the fasteners on the alternator as

described in Section 7, and slip the drivebelt

from the pulleys.

18 Refitting the belt is a reversal of removal,

making sure that the belt ribs engage properly

with the pulley grooves. On models with air

conditioning, loosely fit the alternator drivebelt

first, then fit and tension the compressor

drivebelt before tensioning the alternator belt.

Tension the drivebelts using the information in

Section 7.

1.6 litre engine

19 To improve access, remove the wheelarch

inner panel as described in paragraphs 2 to 4.

Air conditioning compressor drivebelt

20 The air conditioning compressor is

mounted at the front of the engine.

21 Check the belt using the information in

paragraphs 6 to 8.

22 Loosen the fasteners on the tensioner

pulley as described in Section 7, and slip the

drivebelt from the pulleys.

23 Refitting the belt is a reversal of removal,

noting the following points:

a) Fit the belt around the pulleys as noted on

removal, with the flat side of the belt over

the tensioner wheel. Make sure that the

belt ribs engage properly with the pulley

grooves. Make sure that any slack in the

belt is adjacent to the tensioner

b) Tension the belt using the information in

Section 7,

20.9 Tighten the filter clamp bolt securely

Page 18

1-18

Every 24 000 miles (40 000 km)

21.25a Loosen the tensioner bolts ...

c) Refit the wheelarch access panel and the

roadwheel, and lower the car to the

ground. Tighten the wheel bolts to the

specified torque.

Alternator/coolant pump drivebelt

24 Check the belt using the information in

paragraphs 6 to 8.

25 If the belt is to be removed, either for

servicing work or renewal, remove the air con-

ditioning compressor belt (where applicable)

as described previously. Loosen the tensioner

bolts, and release the belt tension. Noting

how the belt is fitted around the pulleys, slip

the belt off and remove it (see illustrations).

28 Refitting the belt is a reversal of removal,

noting the following points:

a) Fit the belt around all the pulleys as noted

on removal, apart from the tensioner

pulley, making sure that the belt ribs

engage properly with the pulley grooves.

21.25b.... and remove the auxiliary

drivebelt from the pulleys

Make sure that any slack in the belt is

adjacent to the tensioner,

b) Turn the tensioner pulley fully anti-

clockwise, then slip the fiat side of the

belt over the tensioner pulley.

c) Tension the belt using the information in

Section 7,

d) Where applicable, refit the air

conditioning compressor drivebelt as

described previously,

e) Refit the wheelarch access panel and the

roadwheel, and lower the car to the

ground, Tighten the wheel bolts to the

specified torque.

Power steering pump drivebelt

27 Check the belt using the information in

paragraphs 6 to 3.

28 If the belt is to be removed, either for

servicing work or renewal, the lower belt (which

drives the alternator and coolant pump) must

be removed first, as described previously.

Loosen the pump mountings, the nut and bolt

on the adjuster slot, and the adjuster locknut.

Turn the adjuster bolt to slacken the belt

tension, then slip the belt from the power

steering pump pulley (see illustrations),

29 Refitting the belt is a reversal of removal,

making sure that the belt ribs engage properly

with the pulley grooves. Tension the belt using

the information in Section 7.

1.4 and 1.8 litre engines

30 To improve access, remove the wheelarch

inner panel as described in paragraphs 2 to 4.

Also remove the upper guard from the

drivebelt, which is secured by two bolts -

release the hose which is also clipped to the

belt guard (see illustration).

31 Check the belt using the information in

paragraphs 6 to 8.

32 If the belt is to be removed, either for

servicing work or renewal, first note how the

belt is fitted around the pulleys. Using a

spanner on the drivebelt tensioner bolt, rotate

the tensioner anti-clockwise to release the

belt tension, then slip the belt from the pulleys

(see illustration).

33 Refitting the belt is a reversal of removal,

noting the following points:

a) Fit the belt around all the pulleys as noted

on removal, apart from the tensioner

pulley, making sure thai the belt ribs

engage properly with the pulley grooves.

Make sure that any slack in the belt is

adjacent to the tensioner.

b) Turn the tensioner pulley fully anti-

clockwise, then slip the flat side of the

belt over the tensioner pulley.

c) Release the tensioner, and allow it to

tension the belt

d) Using a spanner on the crankshaft pulley

bolt, turn the belt clockwise through one

complete revolution, checking that the

belt runs true, and that the belt ribs stay

located in the pulley grooves.

e) Refit the wheelarch access panel and the

roadwheel, and lower the car to the

ground. Tighten the wheel bolts to the

specified torque.

21.28a Turn the adjuster to release the

belt tension

21.30 Removing the drivebelt upper guard

21.28b ... and remove the drivebelt from

the steering pump pulley

21.32 Release the belt tension, then slip

the belt from the pulleys

22 Clutch cable adjustment

Note: This check does not apply to models

with a hydraulicaliy-operated clutch - the

clutch on these models is self-adjusting.

Refer to Chapter 8, Section 2.

23 Handbrake adjustment

1 The handbrake should be fully applied by

the fifth click from the handbrake lever ratchet

mechanism.

Page 19

2 To fully check the operation of the handbrake, chock the front wheels, then jack up the

rear of the car and support it on axle stands.

3 Release the handbrake completely, and

check that both rear wheels are free to turn. If