Fiat Agri 411R Service manual

X.

5

§

‘=;.f

"=»&e1\~:==e".’_

g_N<';¢

‘Q15?-mi”

<;:;<€~_{a<2r*<:>

"

@‘\€_“">~=:."@...

Q

1‘¢*;1v<‘\-T

‘

1\‘?5?§i‘

'~-

¢§~

.

~

‘

‘

-»..

__1""4

-13:L%1!<;-

21$

W

--,_,

'-

wfifigfifi

Q"->‘=.=:»~':;"'

T?{x¢:1rEf.~.;1;:»

<:t>:-\*».;~—s

1-<

141

‘

:,._

‘iggn.

1;‘

‘#1,:3T31;.,;1’€

$/12:14

§>~“lt:»

»|

Q!

.

If

Qgfiaagfig

'3'?

.

»

T

'9

E:

ii

~,__

..._....,».w..-»..,-¢_~».-

SEEWEE

_.,,

NEMQQM,

Service

Via

Canap,;;1,3-8tupinigiA-Torino

Fm.-n

ED3_5d.5B~3-Aprfl,

nenartmeni

{Q63..2000~5.

(Rely)

A.N.-‘Fcrino

1

I

WT?

v¢___

_

w“

‘(

_

_

\V

i

flMA_Mfl\‘_i@

fit

f_§_

_%_

I;

@

“

P1];

I't.{‘!“'|‘1‘it

_|

H‘1l_|E

ii!

Iii;is_

Irma

_______

=_M_M__H%1_wH}HEHMHHVH»

A

lm%!d

/‘if:AWI

1

¢

J

b

A)

>

E

_fi__

W

M

Wm

gm

J

*

l‘_

___

‘:_|_'_'__‘”_E5)1I'_J_vV“

_'*__‘1_'_“

‘_ ‘_

__m,_,__’_fi_

__v

,

_qw_p

_

1*‘IJM6A

“‘M

||||

1‘7__

/as_A_"__‘______

H‘E"__

N

\‘“lgQK

___$

\uK5%agfimfikpfi

IWah“:'E

~\_

flaw

_

_?_A

K3H\_

fig“

‘In.Ii[AW

“kg

gm“;

m

~__

}_i_§

‘mv

__‘”1/

___

M

F

‘~‘~‘_Aw$4“_‘ffi’‘i

X

‘X_i__£!_HJL~|M|VHu{Vfi_’_,/6km")

I

E4”//I

qllédfllj1H/1%’?

‘_____,

N

‘HA_‘___ ____

R

P‘,J9E1_l>F’

1:111‘J'fLa

'_h/VF...’

_

‘ll‘;I}

__

E

///

%

\

_

{A

5

W

éasumm

"uE_U3mm"_°_

¢°mmm_____w_:w___P

am

‘

___w

|_

~m$‘)>‘_'I>_.E¥s|l

_>m:_>;v

mVv_>v__>:_

fill

_‘||£|;__||‘;_i;;_||;i||__

h

_

fix

%\

_RuiiM

/_Q

/I

M

\

t\

\

2

5

»-.=

‘in

(1

l

5...

9.;

;.

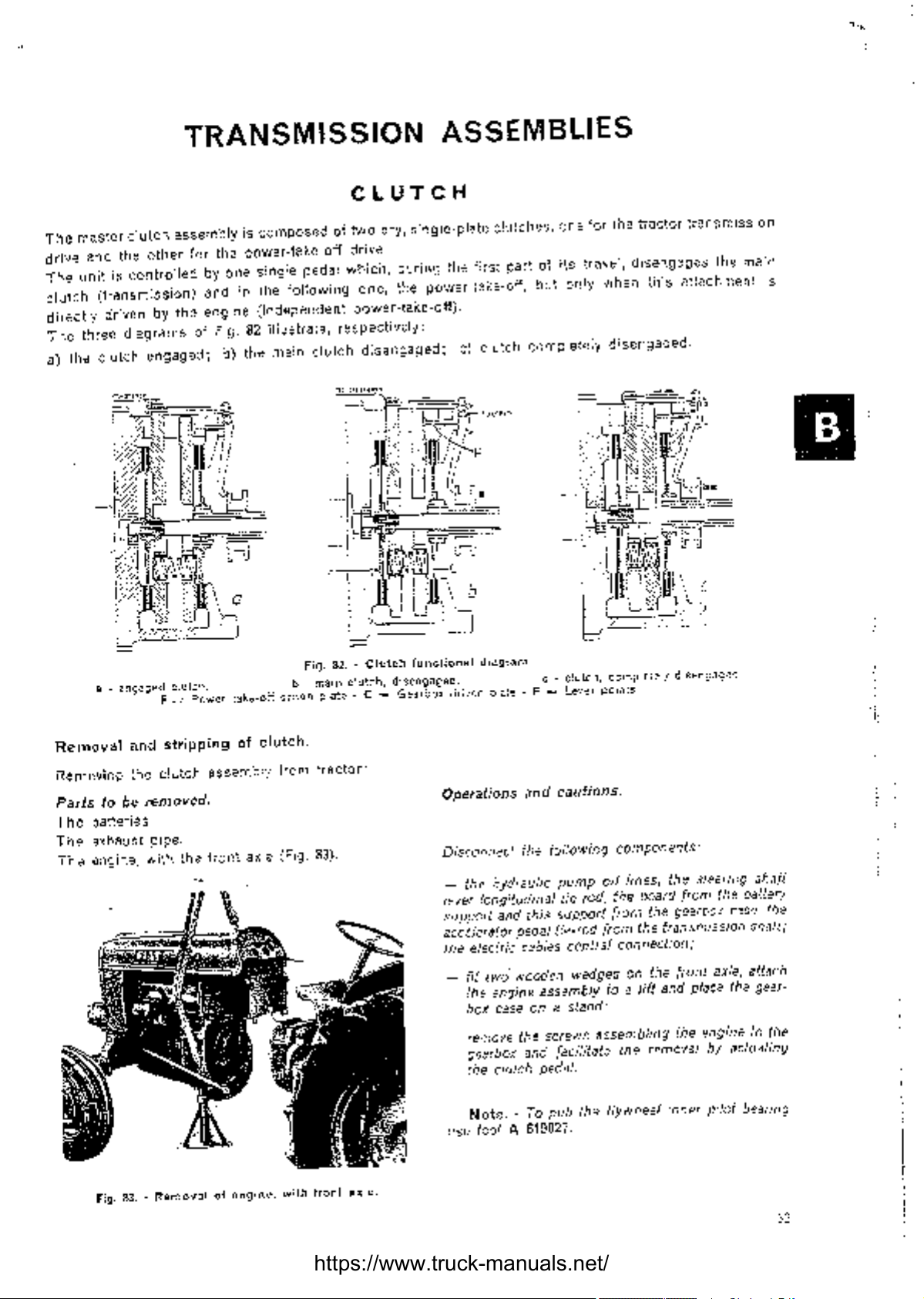

The

master

drive

The

unitiscontrolledbyone

clutch

directly

The

a)

the

clutch

and

the

other

(transmission)

drivenbythe

three

diagrannsofFig.82illustrate,

clutch

€l¢i{}[$£t_

engaged;

‘

L

».

~'

‘*

Q.

X

'

a-engaged

Removal

:~\\\§-:l;L

5

)7

./fr

2'2/f

\_»»-I

-_*'fC<//

//./1::

,

__

r

‘;\.\§§\.-E

_

§

at

//.0

//",/*__/'

FwePower

and

strippingofclutch.

TRANSMISSION

CLUTCH

assemblyiscomposed

for

the

power-take-off

single

andEnthe

engine

'

»

Ali!

*

1;;

aI:~—~

*-

.,

,,

ii)

’

“‘*--

_§}

K:

-_

..

______,,__

'

following

(independent

the

main

H

'

,

Q

\

"M

-'

clutch.

take-off

dm-en

oi two

drive.

pedal

which,

one,

powewtake-oh).

respectively:

clutch

Fig.

bAmain

disengaged;0}clutch

Nu

<l:zrin::

i

'

i

l

L

'

|

;

,_=w-.

_

—

"n

_,

'

82.-Clutch

clutch.

plate-C=Gearbox

ASSEMBLIES

dry,

single-plate

during

the

power-take-off,

III

..

F‘

~

-

1"?

eI-I,

\il

'

.

ifi

kl’".’//;_/,.-'z'*'=:e:ff

-41

I

JH

‘

'

-I1.

2%;

\

imlli

s

1""

,1

,

functional

disengaged.

clutches,

the

first

'0

'@"

Fuureuu

|

P

iv;

('3

/Tit;

D‘

diagram.

driven

plate-P=Lever

one

partofits

but

completely

-

c-clutch,

for

travel,

only

when

,--—-i

l-—""

3»,-,=

,<;L".\

.'..'

5

//'l

,

1-

-“F

gig,

.1:2‘

~‘-*i'_‘

§_,i

,

‘

IAT

points.

the

tractor

disengeges

this

attachment

disengaged.

,_..1_

,,__.-'

!:.,...._;\

».

"1;§‘

‘

..

I

-

W

L

/W//)3?/”J<”‘

o

~

. .

Maul?

'

completely

1

_

.;m'~

é:

disengaged.

transmission

ihe

main

is

I

__\v:L@(

.>‘

F)

~-1

.l.-.-W-._».,~,_

.

a

,L_

i‘

.

I

;

1

;

1

4

I

I

l

I

>

I.

-1

\

1

Removing

Paris

toberemoved.

The

batteries.

The

exhaust

The

engine,

Fig.

the

clutch

assembly

pine.

with

the

front

axle

‘

B3.-Removalofengine,

from

tractor:

(Fig.

83}.

Operations

Disconnect

»~—

the

lever

support

accelerator

the

electric

~»—

firf

the

box

¢—

remove

gearbox

the

and

the

hydraulic

longitudinal

and

pedal

cables

two‘

wooden

engine

caseona

the

and

clutch

Nofie.-To

use

foolA619827.

with

front

axle.

cauiions.

following

pump

iie~rod,

this

support

fife-rod

central

wedgesonthe

assemblytoa

stand;

screws

pedal.

pull

assembling

facilitate

the

components:

oil

lines,

the

from

from

the

board‘

the

the

transmission

connection;

lift

and

{he

removalbyacfuatlng

"

flywheel

inner

steering

from

the

gearbox

froni

axle,

place

the

enginetothe

pllol

shaft

bailery

case,

shaft;

attach

the

gear-

bearing

the

'

53

i

1

1

J

I

.

._-.<-\-.-<»,......,......_.-i

-_......i..~..-.--

._....-0....

._..

-..-.

‘W

,§‘i"?

~

ilfi

5'".-'

7::-*

‘

'

-

|‘

.

.

E_-_

;-:'

'~

"

'

’

15$

‘=5

;-.--;'

all

,;.-‘/-"0=2"5L:Ki’;-;$i"e.1=‘="'<:§2.':"2’1‘l11'

_:-.-L:;.2‘ii=¥'.%'s¢;*1»;@=.¢&~1f5“*%!1¥=*f-A".fi;;€:#

'

"~“"5'-.'fi"L'¢?i5€?"'*=’%€‘@;£1.&v*‘.‘§*u_%1€3"‘

Y_.a;<1

'7?

J’-?Y_<:'1‘.T","!f':‘,5’?

- -

~

:»,=-

.

\

-

-

"-=.:-.¢‘,‘—":**=‘.-.-:.‘*f:‘-=‘:?‘.:"@a~2@;‘

~*'».

1,\-____

“vi.

“‘~.£;a_§~ii"

@:_-_-;\.;=‘.~.V‘-'-E-,AV,--

>

‘-"‘'‘-'1=>-:'§={<

..

;~.‘_<-

.'

;-.1.-,--.’:~

§"~§='-‘».—‘»‘="'==-.="'--"~'-‘:-5'-'1‘.

.1V.!i=‘-1-"

\''_

:

-

=1

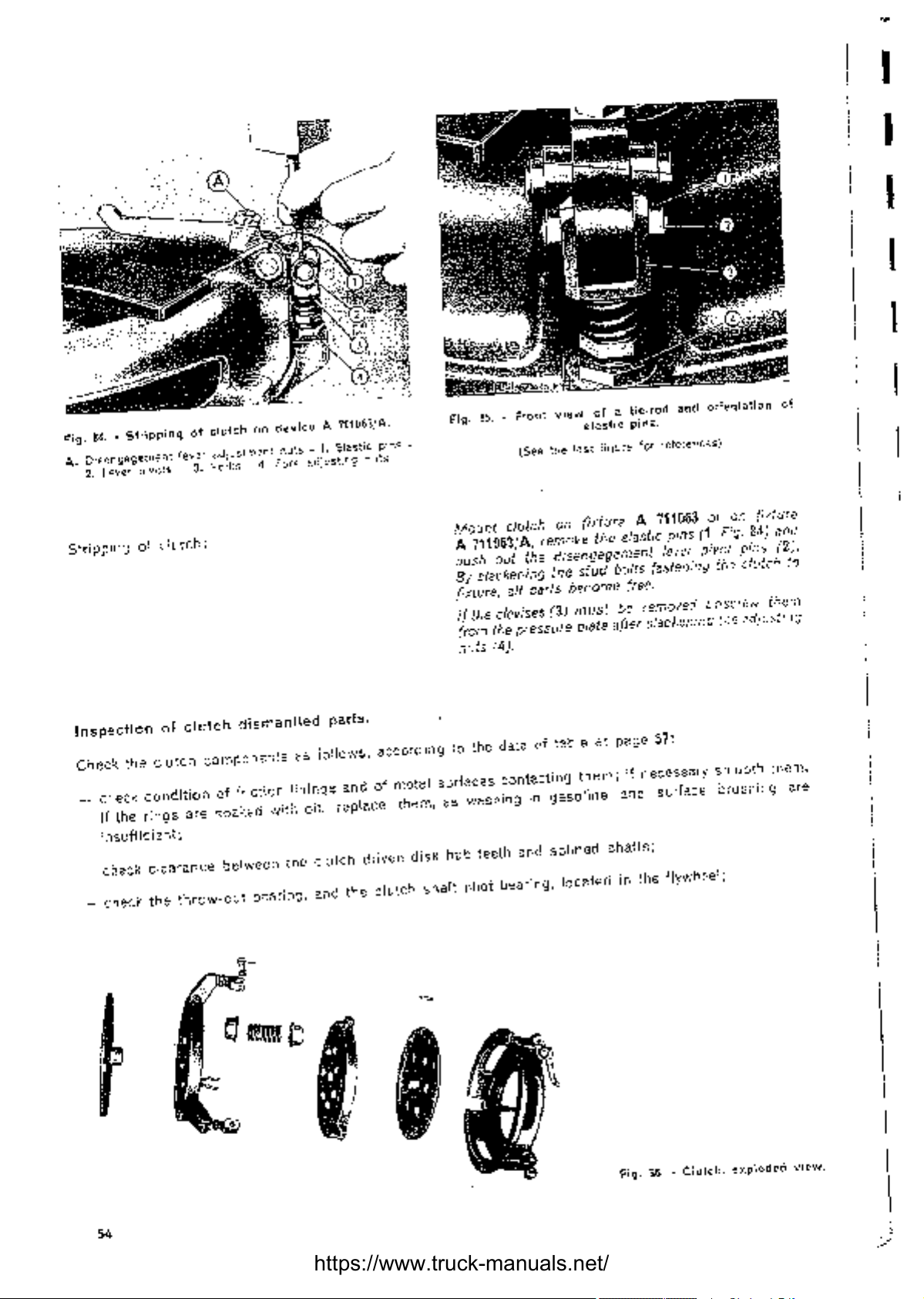

Fig.a-

A.

Disengagemeni

2.

Lever

w

‘

_~.

‘=

b

'

v

.2”.‘i3

"A:

-'1.=j=

1-)1-'—::"~‘i-;:Z,1=1r,;<:.

=-"~<-

-.-=.==<~>:==

4;;

,

--=:@.,¢w~>=:*-;-';;=.~--»"

~

‘.'1;=iL-.‘\.;—_‘fl-'

-;-,V;,-_¢_-

7,.-.

.&:~~»,..._4'$7-31.-,¢~s'~-V

_%_;L;..l=3_fl.;'-_,___

_fi~**_;,,..-.,-

-"

Si’

‘i

"pp

pivots-3.

A

_

‘

.

‘_V_.7_

_~'_:

2

~~

‘

'~

'

~'I

>~-4

:='&»''-

‘- ‘~5?:1*-:

ac:-;;¢=.-";I=—-‘i;:1~.*."§We-1*'

,

I-.

-

»~

~

.‘

.

~-

-a

’

.

-~

\.‘'

,¢11.' '

‘.1

..._.'-'-

l_41_".:?1’-‘Hr'~

-,':I~<;'lv='-:":'T:<*I_,=

in

of

Q

{ever

_

"\

I

"""'€,£s<

p---

1.

1-

'¥=

"‘‘-...3.-

,4?“

‘

1»-X-~:—‘-

41,

._-.

H

\

L‘

_

A

=

..-=-

'

¢'

_.-,.~4

»

'

."'?v.';.-i.;".1"-- -._

'

_,»_.~.'.?I_‘:-'--;".§1,,‘z-__

-f===;41.""‘.:-.

‘

.

_;.__.5—-4;

15‘

.._-.‘_~<~-

A

-"'

7;"-='-.-"‘\'\::B?':7‘~PWh'rl>\‘§

~

.;_-_;-‘:.1=:.¢~1-»

_~....,

-

53::-=

1-_=..

afia

=?,-;;<@-;.=;_;.~

clutch

adjustment

Forks-4.

-*

—

,.

Q.»

_.,-‘

,

=1

:51,J

'

'~I='i-"

'*£:i£"-.'.:'§:

’

7-

.=

-‘“"’%:=;

"""‘<

~

'

"Q

-.

.~.

.

_,-,

'

-

12

H

-4

‘A-**.

,

r.

K

~_.,_-

gm

"

'

"

‘*~’

-‘$1‘.m

-,__

1..

'

F.

M

..

‘

-,1

"

.

F

-~

cm

deviceA“I'HOE3fA

nuts-1.

Fork

adiusfing

3:J‘‘

"!§;L

"

’

1'

.

'

A

‘,4"“

5"--.~~

‘=‘

1--,1

’»

1..

~

;~+._

.‘i’-;'--

‘:1-,»

,,,,-..;;,;r\>,

, _

.

L

I

-r:.\;§---

-<4-»;=-<.

6

*‘_

‘BL!

wag

.

2-.

"

=

‘______

_

._~3;_»

,

;~,~_

1-'=~~

‘5‘"-'*'i':>f-

,

::_,_r_.;;_;;;§”_._~:,;;§;;_4,§

,

_

:,=

-.'5'.~

7--V'§§.§:"a‘L‘,‘

'

Q

:11

=1“-'#;{ZIi(’§-g§-x

1-_la'

1;

_.-

.-<-::.~=»;:{;'=_:"-_=-"--.=;.-arr:

Elastic

'

.,"

“'?$‘:::“

‘.

.

_‘

K

.

,

,

;

'*

-»‘

:

Ffiggaq

p_,'“,:;

_ .

3

r

_1;£5

I;-1,11»,

-

J=*~~.~=~“-“-~-

__

",..~.,_-v-avzt

-H5

Q

'="I3w-J;

S

=-J'~

.,:~»-

.-.

'

“‘

I

i

pins

nuis.

“

--

'*.w,.;"-J

»;,_

-s-.,

‘

M.:‘.':"""‘5".§:I>-L"3:="=‘_I‘‘'“

.

:1,.;%,=':1.<:=¢,r1:‘.-2;:..=§.=;1.47‘

L

-‘$=£:'-‘>1-..',;‘:“,i-;fi'~'_f3a2‘-:5,

.~_;_

-1,.1%a..-,:=..~

'

_..,. .

-l-)-A"

-‘-.»':'

*""'-“"'

‘J;-.

:".=..;,-.12.

=»¢*.'+-.:.*.'.¢:w4:-;':¢:;:--,2

>'f‘-—_—,:-e;'+.:$;-

:1-=1:--.~-.

_

-=p~',1"\1;---.~<~.-

=-.

L5

_.r,

_

-__‘.~h

_

..=.§g

_,_:_¢.,,_¢;_2_,,.,

K

»

‘

.._.=-.

¢-~--..-

a»--.,..

_

ix‘,

.

_

. 1?.

--~-\

"‘:“-=.~.

i‘?

5:-.-gé''F-1_

'4-’

_‘,__

__

_Q‘J

~..~

"“*='i;.-E?-.;_-_

-L.

Fig.

85.-Fro

-

7'»

,1;

:5‘

-

~~=-'=;~'-'-_>;"-'-‘ ‘-~='¢-‘'*=._-'.1-‘

~_-a

.=."-='_‘'-'"'V

"'--

"-"-»j

;;.’;,.,Q.I‘..‘,""'"

‘

"ii

~--V—-‘

"

h~-

_.l.;__._-_,._§»

;@_'.;—

>

Alli“

‘W’

»~,.;4

-

-.~..

2.-;*2=:~‘

+1;1~;.“<:=£&~.‘,¢--

F

‘

-E

--*-a,,::=;'1.‘;—T,k».,r='.:»-"3*~'---'

wk

<11-_'~<,>11;,

"‘*-"=¢.-§‘?~3~

L-"

"

'1".

ta:-.Yz.:..-‘.‘~_~-->.-:

;_-.;~*-~.=_. .-.~'-

:-

-.7_...-_...,._._

;

_

_.

=:‘n-£_-=-.‘-‘:;:'-‘.-=.-

—

_;:E

‘__‘‘L

“

'

;"'_.I‘_

Y"

I,-.;~<_;_'..-

.-z-§.=~.—\

"‘=."'v'L‘-"

='¢,1{<}

*'

.

*1

nt

(See

~;1,_-=:‘__:'_‘

,_._=_._7,,=11-.-.

-»‘

'

...--.

'~.=.»=.;.-

'-l

1;;-.

‘'"

};=='=.p.

¢..;~

?:i'IT-“v‘iirifla?-‘~1:;¢%._»a.2:

i-I

=-I-2

=‘»;’-'3.-'=

."

|

-".=‘.1'-JITT.\l

,--

—

"

'._{,___.;_“,1¢.,-._

K

=1.,-t

1,...

,_

... . .

_

the

='

2-,-;

s‘.-';‘=,\

.'

view

3*

last

.

“"'

'

"='''

'°*~a=.=.-

__

ofatie-rod

elastic

figure

1'".-"F‘...-V--ml--‘.--_'-,=;

_

‘

-1''

&,~~'

1'

':=;.-|..»

"

.

.‘

_._-.,

3‘L‘£:_

.-

..

..

..-''.

.

‘

'

_’

:1-..>

'

_-...—___.,,.,

F

-

*~

--..1»*1

1'4‘.'-

1‘-;l_."..¢::;

;‘.":‘11"»as.-r—,=;'-..-:='\.;;-"l';'<-3.8“.

WW

=

_:_~

'-'

1-

J

_.-.:r—,.'-.

.:.-_~.

,

\_;,~_

. _ .,'_.

.._

-

>6

-.

L

‘ -

(4

J5,

'

_

.

'--.-

“

2

-

-

<:ii-'-'.=7¢‘

..,tf».‘.~,-_

:‘;'-1"‘.--"-3.1‘15,,_--F§'=<:§§l'r:¢

1»

;._._¢;:_.§’~

é

v...:5;.=_.-I':‘~

pins

for

references).

-

:~.;,;..,..,.

;'-'-5-‘_.

;.<‘::'1'¢"—»;,.'-}=a*.£-;¢;“

-;’f'§..

.___1~*-~;

-'___.4§'vm_:-_1;:1-&<{5;t~

‘2:;=r.~~"-.'-2;-_#=1:,

"K....

=;;;‘~:~::.

=,"_-J-',.:-—;

=

1:‘

=-'¢;‘i;;

a--"~

..

~.--ar:-

,

.-.

L'_r_—_=,-1,.-=.—¢.-»

.

.—_*\,‘.0.-.-<

~

‘_=

“

.-.'.=_-~.1."=.;<”:-a-111:2-'_:,§'..=i-

_'

‘fly.

~ =A’I

__:_‘;.F_‘,_:,%€;_:i,;,:€M_..E..

.

~i=

,1

.»-1;--‘-'._:-'

._e'=--a=7p¢;.;:-‘=.='''-

1

-,,;Z'3‘**:

I,-.'..-

“':-‘Q2"

,.-1-‘1=K_<‘»""5-:r‘f;.‘=L'§§=j&l§_?'

=

.

and

oriemaiion

1-I.-‘-:11‘W47,,

_

K1“-'.‘;‘..-=.‘;!,f;~

’_e4»,-'ri

Fug,

'-sii?“

_\w;.1

-.,.

-_:J\_|h-‘»-

rd"-36

,_.‘

'

.9‘-V

;;;

,~:;

-

.

;:=

~,:.

;

-TF1‘-1.'€.‘.:

=

-‘

F

-.'

*

..

~

,

'».-1::=.=.:a§=.—.;.:;=.:

Lt:

,1

.

'-'—'"-".

.‘;-':-

LI

a_-.-=.~w-a-

"

V7‘.;;

.

.,

"'.,_.

'

of

i

[

>

i

l

1

Strippingofciuirchz

Inspection

Check

-

check

lf

the

of

clutch

the

oiutch

conditionoffriction

rings

are

insufficient;

-—

check

cléarance

-—

check

the

throvwout

dismantled

parts.

componentsasfollows.

soaked

between

bearing,

linings

with

the

andofmetai

oii,

replace

clutch

and

the

Mount

A

push

By

fixture,

If

from

nuis

accordingtothe

surfaces

ciuich

711063_lA,

out

remove

the

siackening

a1!

parts

the

clevises

the

(3)

pressure

(4).

dataoffableatpage

contacting

them,aswashinginQ0150mea

driven

clutch

disk

shaft

hub

teeth

piiot

and

bearing,

splined

on

fixfure

the

A

elastic

disengagement

the

siua‘

boffs

fasiening

become

free.

mustberemoved

plate

after

slackening

-

I‘

them;iinecessary

nd

shafis;

locatedinthe

711063oron

pins

(1,

Fig.

lever

pivot

the

urzscrew

the

S7:

surface

brushing

smooth

flywheei;

fixture

84)

and

pins

(2).

cluich

£0

them

adjusting

them.

i

i

1

l

are

54

‘

“.5

1-La.»

~‘;';;,-“i.

-

am

w

&

%

_=,\~:"

E

.\

J:-,

V-I

1

a

“'‘

»

'

».__

\

.

._‘1.:._.

*3‘

Fig.

as.-Ciuich,

exploded

view.

;

s

1'3

VI’

ii

-

check

-

-

I

ii

ciearance

check

piate

check

the

the

shaft

can

drips

duetoexcessive

between

spring

throw-out

be

mounted

bushes

characteristics;

coiiar

working

again

clearance.

and

disengagement

siiding

after

surface.Ifwear

rotatingit‘i8G°;ifnecessary

lever

pins;

does

not

replace

exceed

the

permissible

the

parts

when

iimiis.

grease

‘

ii

i

i

i

i

i

1

Assembling

and

1_;_,i;,;i¢a1§Qn_

.-.-

$

i_i

-

'l_:_f:T

*'_~i~<—---

'£-2.~¢-'=I-*-

=—»

T.‘_T.'.'_

\

‘

i,

‘

I3

adiusting

*

,....._.._

i.

l:I{'*'—‘$_“"

W

rams.

~._

the

\

s

._;.._-r;-“.'\

»'==‘-FI

,-

r

1

M

_

.._C,;x_>,;y_~<cw

*"

'1‘<1'”"

i

_

W

1

155%,

C4

in

.33»).

W‘

'

’

cluich.

1”‘

\__._.....a-

_,

'f.'-~’/

__

'

3"

‘.__¢_

xxvu-

—

._‘_

'

-

-,fi~!4.‘»§

was

i

i

*

Smear

assembling

—

.

'

iighiiy

the

clutch

ends

Fig.

34),

iaise-off

levers

confaciing

service

'-

..e.

—

'

-

i-1.->.$'1,_

1-‘7'?l7g":T'.‘-5-'Z:~:

the

foiiowing

using

quaiity

disengagement

confaciing

the

shaft

(P,

the

”‘7"-“'21{YT

''_.-1:?-E§~\"‘€'-‘w

.'\';=""..,=\_-‘

¥;'-'_"

-"7

'_.;§'1.;<.-.;E;ii;i==.=i‘;

__

-=.:=~.‘~:—

:;_.“.'-':=l1;"‘a.i!“;',-;

_i_;.7?Ԥ

".i:_.f'_§:'-‘

.i'

the

c1uZcn~gearb-ox

splines,

Fig.

88),

the

disengagement

bearing

v

~

51;‘-Lei".-:-'='_l

-.-1-Y». . .

,.

.':.;-..-.

oomponenis

chassis

lever

grease:

pivots,

disengagement

and

the

the

the

baii

ciei/is

fever

collar;inaddition

housinginengine

vi."~.=.

':,-

'1'e.'§-";?.-'i“-'§‘-‘§»'=_**-‘Q=~'~*

__—

“:7

-.1

.,

_.;_-1-.‘I

‘f-"1

T‘

f.}.

1:1.—‘1:.-es.w.

-._._-

P

ca:

-_

.e¢;::‘=v‘"

,

'1'-':

'§:;'-§]L;i=T%¢fifi1-j§»""

_..v

.

“'-"’39::§'7;F

531,‘-;Tf§;f“-;7;'*___=,

‘

:,;jij;u;-;—\;-

..

before

the

cievis

fevers

clutch

endsofpush

ends

(3.

power

where

fiywneei.

.

II“--\.,_\

"ro-

""<I=i_»:w,"r"-.=

5":

‘P’.

V."_'\

_;?.'§_Z

*_,

;_=.=-~"_»1.‘=_=+e3~...'.'

.\

.-

-,

_

.,

|

I

1

_\

:§

F.

ii

'-

.-

J.

IA

1-

.1

‘

I

X

.

4/

,,

‘

,

}

,1--—m-I‘--\

_--.'

'_T..._._."'_.

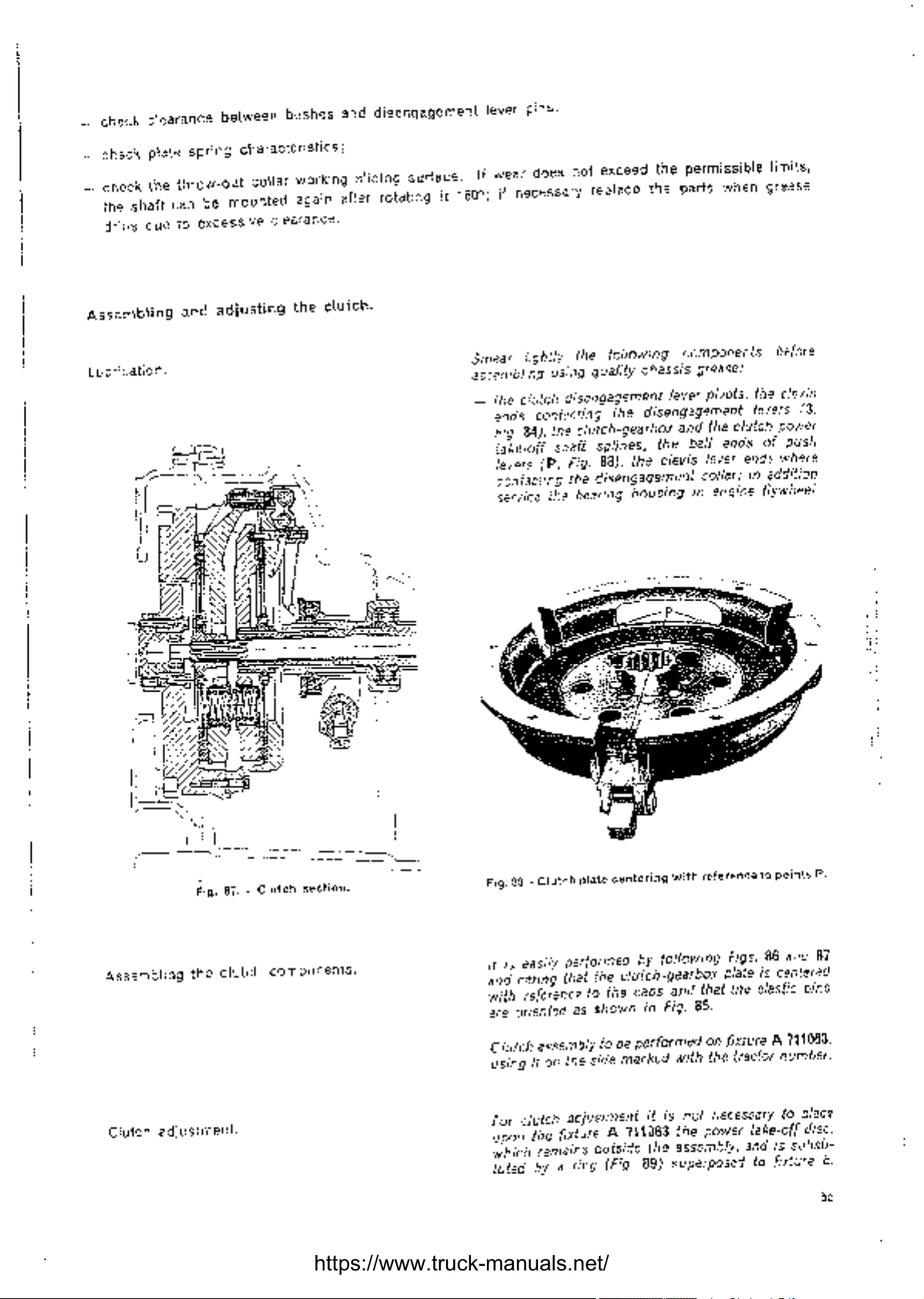

Assembling

.__.

“Fag.

av.1Cluich

the

ciutch

"-"'

s__

*

~

section.

components.

'

i

“mi

/'

W

'Cf.._‘\"

,_

_

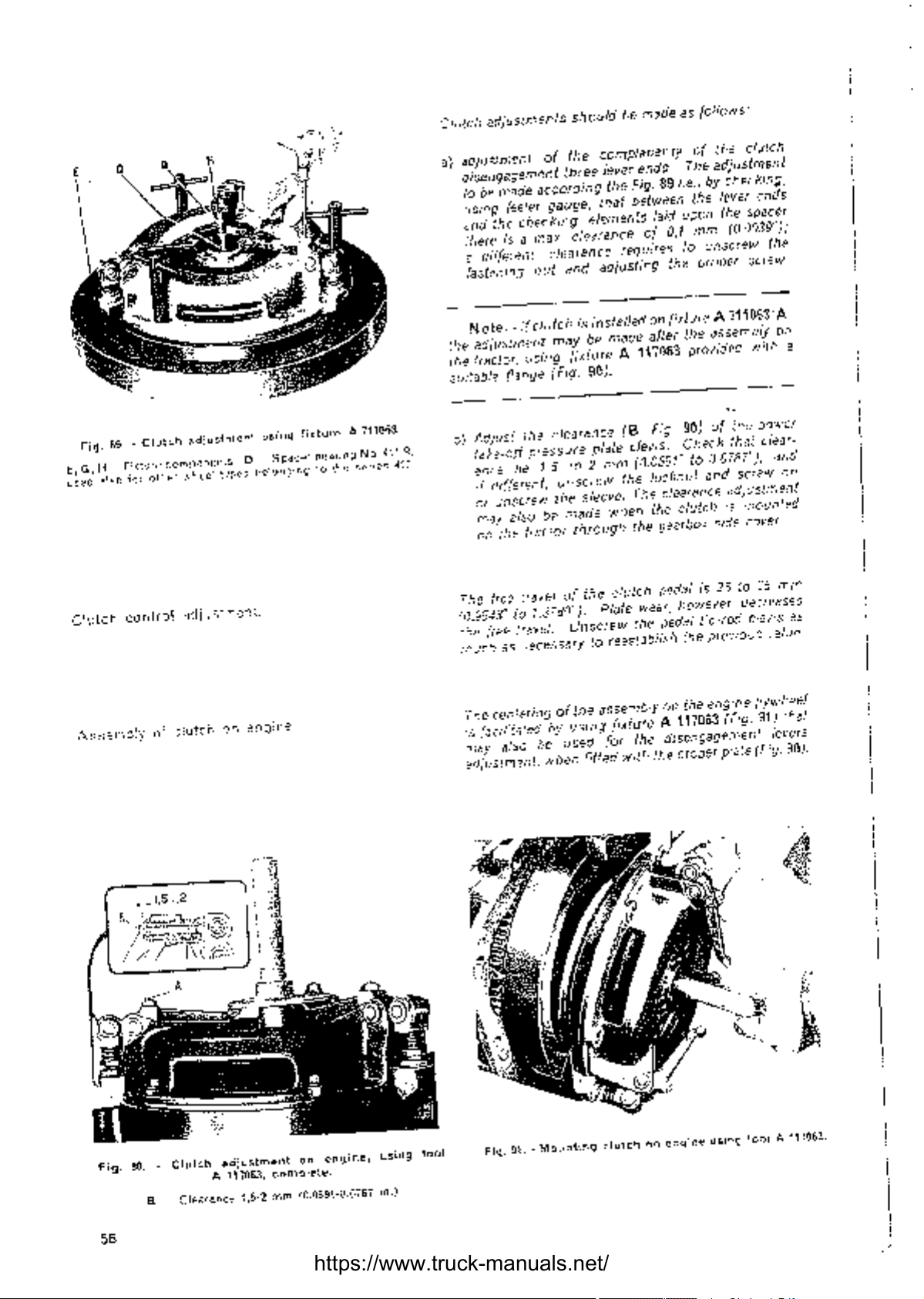

Fig.

83.-Clutch

itiseasiiy

and

caring

with

referencetothe

are

orientedasshowninFig.

Clutch

assembly£0be

usingifon

For

Ciutch

adiustment.

upon

which

iuted

clutch

the

fixtureA'I11i}63

remains

byaring

i‘

2

piaie

centering

with

referencetopoints

performedbyfoiiowfng

that

the

ciuich-gearbox

caps

and

that

35.

performedonfixtureA711063,

the

side

marked

adjustmentiiis

outside

(Fig.

with

noi

the

power

the

assernbiy,

89)

superposedtofixture

P.

Figs.86and

8?

piateiscentered

the

eiasific

pins

the

tractor

number.

necessaryioplace

take-off

andissubsu-

disc,

E.

56

E

'

G

H

E

-

D

-r--"

__

-:5-<2;-2-~,»..=

"

§'='v'-'5

X

7:‘l'-‘7'T:‘-F-

J

.1;-.§A‘;:jg,_I-"=1‘,’E;'_7‘_'T;-':.t_,__

‘-"-

L‘%€:.:-l‘:‘§-‘:2£:|:§E‘£)hI-7‘'"“'"‘-+-=~

..=

V;-¢

*'=:¢

K1’

-‘-""

*

Fig.

89.-Clutch

5,6,1»-I

used

also

Fixture

for

v__,,

i

l_I'f.';_;:"""~‘-‘Q

'-1:‘;

‘~"::‘I¢."-‘_E

V

"

‘I“"

"

-

~

cornpcnenis-D

other

wheel

/____

‘

'

‘I-

'—---\—*""“'.'I.-r

.»§:4_A':w.».¢--swl

adjusiment

types

‘

3-,,

qr"

“-.-._~»

33

ll

r;-y

.-s

Q’

_~..

,'."/_;=

'»,;':v:

_

_

1,1

.

_;.=,;l,'::-‘

V

_k__I

-"-"fi'-‘*~*.-

.-

Y-:11;

1er..1F4;glhr-

:_'_wfl

using

belongingtofihe

.

\

r

"]'T

_-

F.

;._Li-=1

-f‘.--‘

»'.:—1‘—~>-.rLl_,_

.

¢

'

'v—~

'.'l.'-57!

‘-PE-.":".»:»§rv'"=.

-

"

!_‘£v__°1;i_-é,;_:.‘-_‘:‘,___H=‘=‘_-

.3‘_|.§_-¥3’k,'§j;1;::‘;‘>’-.':|?:;,:'_P

.~_'r1fi'i1_1==~.5.';i@»:r~

-7'

Spacer

-

..“7:fi'_=3'‘V"V

.,;:_:‘i;;5;-_;;i~":g;‘=j

'=-;.=€r'-'3-""'.irr‘"‘

-“‘~

fixtureA711863

bearing

'_=-

:»1~“’

7‘-

No.M1R,

series

1-=__

,6

4'

s.

:1

?

490.

Ctutch

adjustments

a)

adjustment

disengagement

tobemade

using

feeler

and

the

thereisa

a

different

fastening

of

three

according

gauge,

checking

max

clearance

nut

and

shouldbemadeasfollows:

the

complanarily

lever

ends.

the

Fig.89:'.e.,bychecking,

that

between

elements

clearanceof0,1

laid

0;’

The

adjustment

the

upon

mm

the

lever

the

requirestounscrew

adjusting

the

proper

Mote.-lfclutchisinstalledonfixtureA'l1‘l063lA.

the

adjustment

the

tractsr,

suitable

b)

Adjust

lake~off

ance

if

or

may

on

flange

different,

unscrew

the

maybemade

using

fixtureA117683

(Fig.

96).

the

clearance

pressure

be

1.5to2

unscrew

the

sleeve.

alsobemade

tractor

through

after

(E,

plate

mm

Fig,

clevis.

(0.059'l"'to0.0787"),

the

loclmui

The

clearance

when

the

the

gearbox

the

assembly

provided

QB}ofthe

Check

and

clutchismounted

side

clutch

ends

spacer

(0.0039”);

the

screw.

on

with

in->

power

that

clear-

and

screw

on

adjustment

cover.

i

‘—"

“"”"'

~'—*--=-'--=1<—:-W»:-.-1-1'5.-I

1

a

ll

Clutch

contro!

Assembiy

,.;;,_

B“i-~,~r-E-J:-¥l~.n

/‘\

\_______,,_.,..----—--'

adiusirneni.

of

clutch

1.5

+.2

»_~~

on

PS5

engine.

The

free

travelofthe

M19843"to7.37190").Plate

fine

free

travel.

clutch

Unscrew

pedalis25to35

wear,

the

pedal

muchasn€cessa1'ytoreestablish

The

centering

is

facilitatedbyusing

may

also

adjustment,

be

when

oflhe

assemblyonthe

used

for

tilted

fixtureA117083

the

disengagement

with

the

however,

lie-rod

the

previous

engine

(Fig.

proper

plate

mm

decreases

clevis

as

value.

flywheel

91)

that

levers

(Fig.

90).

_

H

§>‘_‘{~

lg;

i

l

l

I

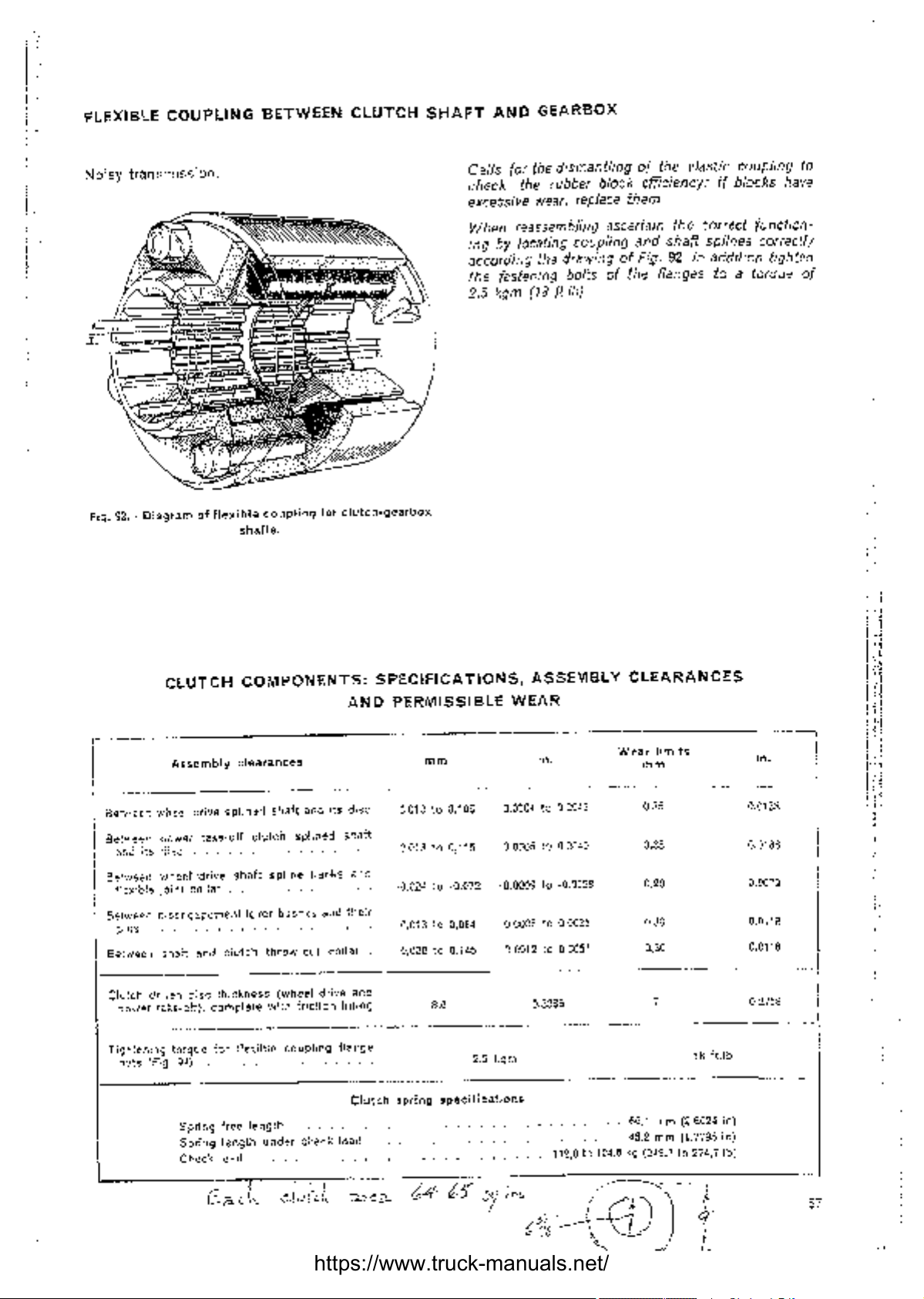

Fig.

56

Q0.-Clutch

B

Clearance

adjustmeni

A

11'£fi63,

€,5-2mm(0.059!-0.078‘?

on

complete.

Fig.

Bi.-Mounting

engine,

using

in.).

ioul

clutchonengine

using

tool11‘.1'l0fi3.

l

l.

‘

_r"

>-

FLEXIBLE

Noisy

I

l

I

IT

.

.L|-

rm3*:

I

2

COUPLING

transmission.

.-_,_

.I

“‘~'1’

:

.

L

1.--=.3~-.:~‘.i~i-'_'~_--

"“.-}{:_'E>.\;':k;;_-'fy-__‘-

___.r

~_—

"'

V’

....-.

\\

-'

T

I

.

BETWEEN

.'.'_".-_v‘_

1~'-.1

--4

-

_.='-‘-

7,21_1._.

_l1:¢

~:»-_-

Riff

_

\.

mun

\

AW“-‘l-’“*'--__

~....,,_.,.---~-K.’

“

"Q;

"'-_.'1~’3‘:':E';'.€'

QT‘\"-7

1

\

,/%'%_\;f;1._‘3

_.M/W

A

':'-}>?=,_-2"-‘--.*-3:

3.1,».-_»‘.J"i]:;vPfl_—

._‘,-¥=,_¢~_§.

.-".1

-:-

.~z='_:

ina

7'

Z

—\_

"III

jg

u

\n1~*_$\_“-“-

1

__Q\\

Q3

/1;?

..~..

>:‘l§;"

,,,;.:.»~

“Ti”

‘

,_;-:\::-

CLUTCH

._

.

.,__.

:_-»

,

-_~.=n_._-:

_

..,.“\

.*‘

-$5

.,

..-T

‘

II;

1':-fill-5.‘-I

5-J-'1.-'I‘.=‘---,

"*':‘.>3",-'4'.E-Z"'.':'-‘J

'_'?.1‘:

""-‘lhw’I

,=;'.'.'.-

1'.-2'-'

‘._.

1'2.

-:~E-‘--

SHAFT

Calls

check

excesslve

When

ingbylocating

according

the

2,5

\‘

1‘.

AND

GEARBOX

for

the

dismantlingofthe

the

rubber

wear,

reassembling

ihe

fastening

kgm

(18

ff./la).

block

e;‘i‘7ciancy,'ifblocks

replace

them.

ascertain

coupling

and

drawingofFig.

boltsof{he

elastic

the

correct

shaft

splines

92,inaddition

flangestoa

coupling

function-

correctly

iighien

torque

to

have

of

I

l

1

H11

Fig.

52.-Diagramofflexible

'

tolxpfing

shafts.

for

clutch-gearbox

CLUTCH

Assemby

Between

Between

Between

Setween

Between

Clutch

wheel

powe:

and

its

disc.,...... .......

wheei""drive

€1exib!ejoim':

disengagement

glns

. . ... .._. . ...

shaft

driven

power

take-off),

I

drive

splinad

take-off

collar..

and

ciuich

disc

thickness

complete

COMPONENTS:

e

ce

cl

aran

s

shaft

and

clutch

spiined

shfiaftvspline

. .........

lever

flanks

bushes

. , . . .

throw-out

(wheel

whh

friction

and

drive

SPECIFICATEONS,

ANDPERM1SS1BLE

mm

.

-0,024

.

.

.

0,010to0,105

0,013To0,115

‘£0

-0,072

0,613to0,064

0,930to0,145

B,6

its

disc

shaft

their

. .

collar

fining

and

and

ASSEMBLY

WEAR

.

.

In

0.0004to0.0042

0.0005to0.0045

-0.0809in-0.0028

CLOUDStol3.fiG25

0.8912to0.005?

0.3386

CLEARANCES

Wear

iimits

mm

0,35

0,35

0.20

0,30

0,30

T

m,

0.6138

0.0138

0.0079

0.0113

0.9118

0.2755

v

I

I

“'4

1.4

H

-as

I

-I

;

I

I

K’

'[

Iii

_=_

.2

I

_,.>

M

E

I

'25?

!

Em

I

1

;

2'3

I

§§

:

E

E;

I?

1:

1:3‘

I

1155

I

2‘?-;

.

LIE

£2”

II

1:-»_

§._.,

11

..

}

if

I

I

Tightening

nuts

.

(Fig.

torque

for

92)

Spring

Spring

Check

flexibie

. ... . . . . . . .....

free

{ength

load

€'-\-

l...-J»

coupling

length

under

. .-. .

c..J'.:;

flange

Clutch

spring

. .......

check

load

. ......... ... ... ....112,810

ll.

. ......... . ....... ...

. , . ...

-‘w

Elva‘,

4/IL

2.5

kgm

speciiiazafions

. .

. .

, .

'

‘

/"ifs.

45

,7

. ... . .....

».._’_

:1"/.

65.?mm(26024

45.2mm(£3795

124,6kg(248.7to2':'4',7

/

’

Léw

_‘

-4

,

I

18

_

ft.Ib

in’

f

-

in)

in)

lb)

57

I

I

Z

4

1

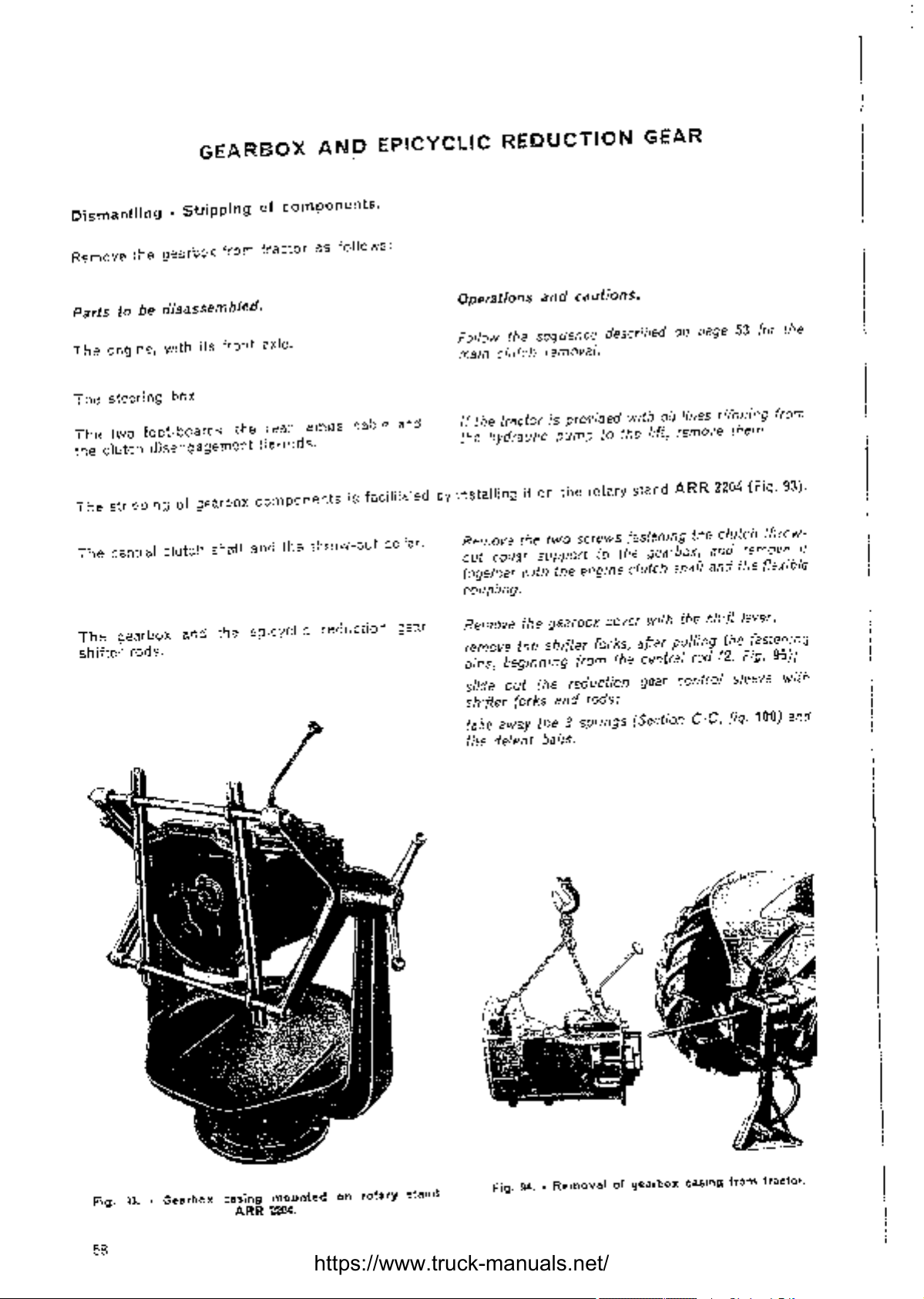

Dismantling

Remove

Pgrtstobe

The

The

The

the

The

The

the

gearbox

disassembled.

engine,

steering

two

dutch

with

foot-boards,

disengagement

strippingofgearbox

centrai

clutch

GEARBOX

-

Stripping

its

box.

shaft

from

of

components.

tractor

AND

as

EPECYCLKC

toilows:

Operations

from

axle.

Follow

main

if

the

rear

temps

cable

and

the

tie-rods.

componentsis’§aci§itaiedbyinstaiiingiton

and

the

throw-out

collar.

Remove

out

together

coupling.

REDUCTION

and

the

sequence

clutch

the

hydraufic

collar

removal.

tractorisprovided

pumptothe

the

the

two

.5UppOI"itothe

with

the

GEAR

cautions.

describedonpage53for

with

oil

lines

lift,

remove

rotary

stand

ARR

screws

engine

fastening

gearbox,

clutch

shaft

the

rfiihning

them.

2284

(Fig.

clutch

and

remove

and

the

I

I

the

from

I

5

93).

throw-

it

fie-xI'bie

The

shifter

gearbox

rods.

"-.:—--.

and

the

epicyciic

reduction

r

gear

Remove

remove

pins,

beginning

siide

out

shifter

take

the

forks

away

detent

'./-'~

I

";;£

Q"/ZS

__

t'*i'?"

51?-*:,..T1‘,"

the

gearbox

the

shifter

from

the

reduction

and

the3springs

balls.

\

4.

"

=i»a

,

3'?‘

:\‘\

o...-..

cover

forks,

the

rods;

-

_.

";’

“L;g;.

with

the

after

puliing

central

gear

control

{Section

shift

rod

C-C,

the

(2,

sleeve

fig.

lever;

Fig.

fastening

95);

with

108)

and

1

I

I

I

I

I

I.

1

Fig.

93.-Gearbox

58

casing

ARR

-..1.

mounted

2204.

an

rotary

stand

Fi.Q4.-Removalofgearbox

Q

.I"-"**¢"-‘.'_'<f"""",“9""

.41;

;__;,;1.

casing

from

tractor.

i

E

£1

l

l

v

Fig.

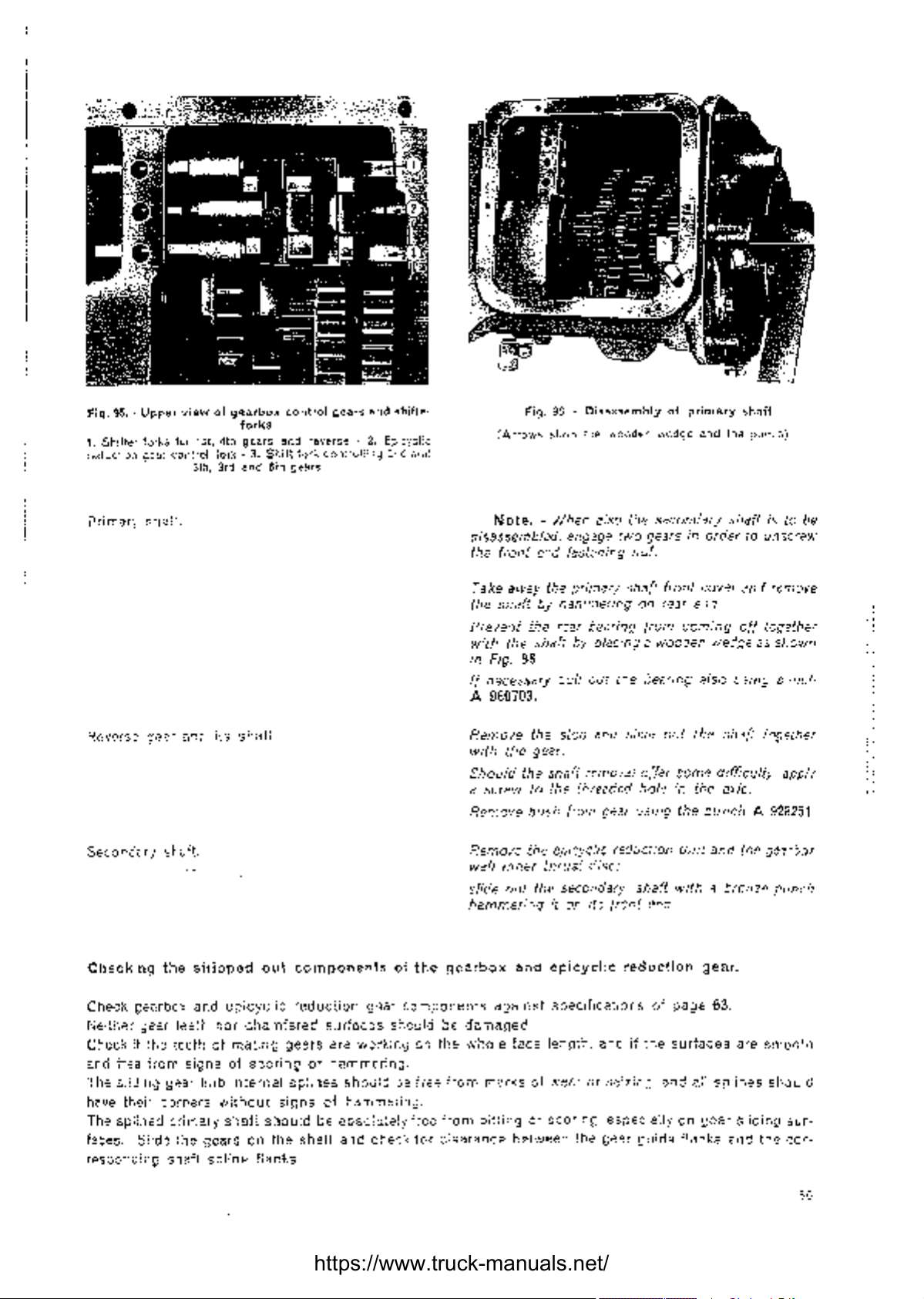

95.-Upper

1.

Shifter

reduction

viewofgearbox

forks

for

gear

control

1st,

5th,

forks.

4th

gears

fork-3.

3rd

and

Shili

Sih

control

and

fork

gears.

gears

reverse-2.

controlling

and

Epicyclic

2nd

shifter

and

Fig.

(Arrows

96.-Disassembly

show

the

wooden

of

wedge

primary

and

lhe

shaft.

punch).

l

l

Primary

Reverse

shalt.

gear

Secondary

and

shaft.

-04-.

its

shaft.

Note.-When

disassembled,

the

fronf

end

Take

away

the

the

shafébyhammeringonrear

Prevenl

with

in

lf

A

Remove

wifh

Should

a

Remove

Remove

wall

slide

the

the

shaftbyplacingaw0oo’en

Fig.

98.

necessary

9613703.

the

ihe

gear.

fhe

shall‘

screwtothe

bush

ihe

lnner

thrust

out

the

hammeringllon

also

engage

fasrfening

primary

rear

bearing

pull

out

slop

and

removal

threaded

from

gear

epicycllc

disc;

secondary

its

front

reducllon

{he

secondary

lwo

gearsinordertounscrew

shaftisto

nut.

shaft

front

cover

and

end.

from

the

hearing

slide

offer

holeinthe

using

shafl

coming

out

some

the

unit

withabronze

off

wedgeasshown

also

using

the

shaft

dlfiiculty,

axle.

punchA928251.

and

fhe

end.

be

remove

together

punch

together

apply

gearbox

punch

»

I

Checking

Check

Neither

gearbox

gear

Checkifthe

and

free

from

The

sliding

have

their

The

splined

faces.

Slide

responding

the

stripped

and

eplcycllc

teeth

nor

teethofmating

signsofscoring

gear

hub

internal

corners

primary

shaft

without

shaft

the

gearsonthe

spline

out

components

reduction

chamfered

gears

splines

signs

surfaces

are

workingonthe

or

hammering.

shouldbefree

of

hammering.

shouldbeabsolutely

shaft

and

flanks.

of

the

gearbox

gear

components

shouldhedamaged.

whole

from

free

from

check

for

clearance

and

against

face

epicyclic

specificationsofpage

length,

reduction

andifthe

marks0%wearorseizing,

pittingorscoring.

between

especiallyongear

the

gear

and

guide

gear.

63.

surfaces

ali

splines

flanks

are

sliding

and

smooth

should

sur-

the

cor-

59

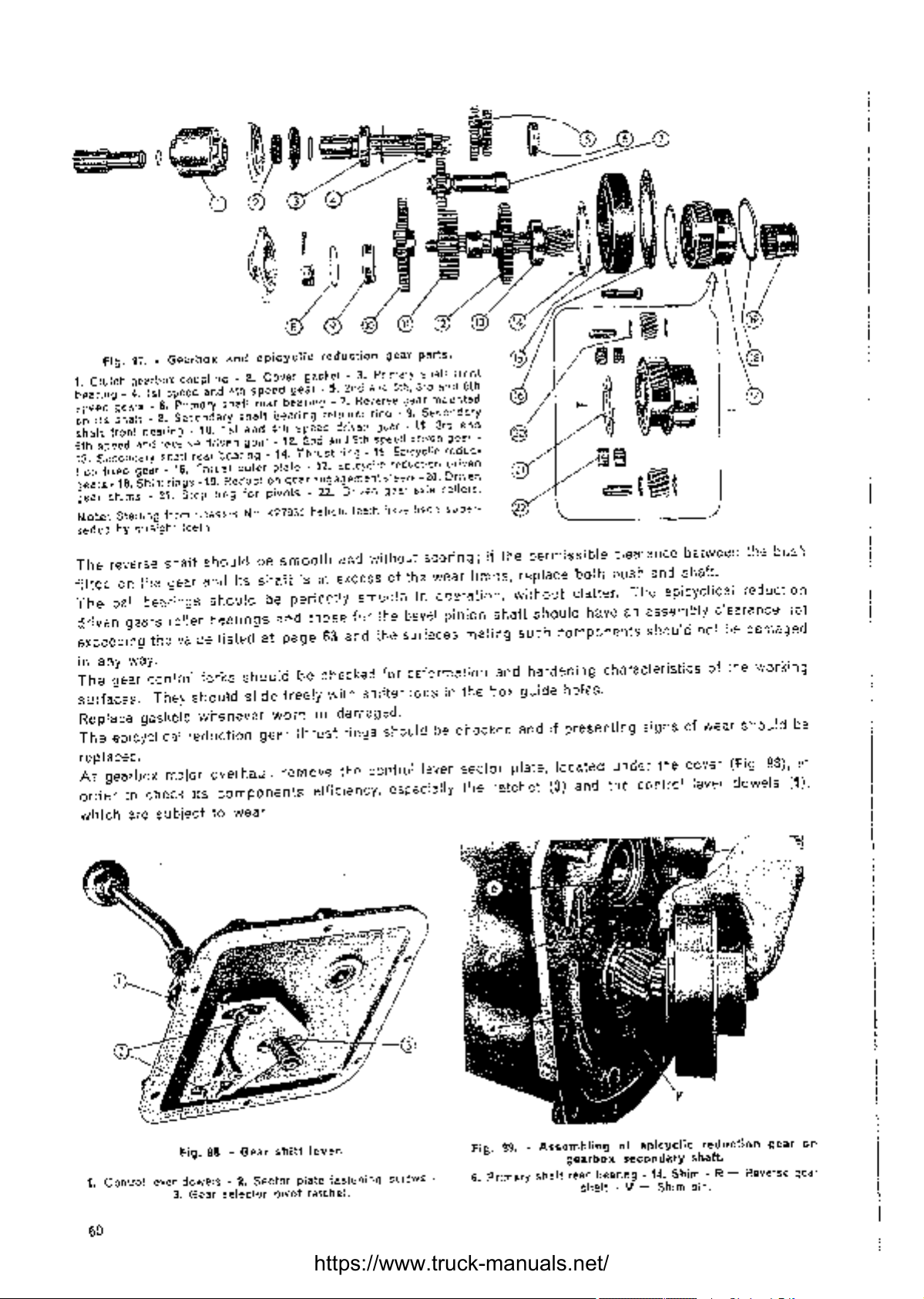

Fig.

9'1.-Gearbox

1.

Clutch~ge-arbox

bearing-4.

speed

on

its

shat?

6th

speed

13.

Secondary

lion

gears

gear

Note:

sededbystraight

The

1st

gears~6.

shaft-B.

front

bearing-19.

and

fixed

gear-16.

-18.

Shim

shims-21.

Starting

reverse

reverse

she'll

from

shaft

tittedonthe

The

bail

bearings

driven

exceeding

in

The

surfaces.

Replace

The

replaced.

At

gears

the

any

way.

gear

control

They

gaskets

epicyclicai

gearbox

ordertocheck

which

are

subjecttowear.

F

.&f:A§;?¢‘I.“

and

coupling-2.

speed

and

Primary

Secondary

4th

shaft

1st

shaft

driven

rear

bearing-14.

Thrust

-19.

ring

outer

Reduction

for

rings

Stop

chassis

teeth.

shouldbesmooth

gear

and

its

should

roller

bearings

value

listedatpage63and

forks

shouldbechecked

should

whenever

reduction

major

overhaul,

its

components

‘I

epicyciic

Cover

speed

rear

bearing

and

4th

gear-12.

plate-17.

pivots-22.

No.

#27935

__-~':'1I-_T‘V‘V

@£1M

%

reduction

gasket-3.

gear~S.

bearing-7.

retainer

speed

driven

2nd

and

Thrust

Epicyciic

gear

engagement

helical

2nd and

ring

Driven

and

shaftisin

be

and

slide

freely

excessofthe

perfectly

those

with

wornordamaged.

gear

thrust

remove

rings

the

efficiency,

lb’?

E

1

_»

_—--

llllll

lllli

mm

@

€*_.T...'3?l

@\

we

‘B

gear

parts.

Primafy

Reverse

ring-Q.

5th

speed

-15.

teeth

without

smoothinoperation,

for

shifter

control

shaft

3rd

and

mounted

Secondary

Srd

driven

gear

reduc-

driven

20.

Driver.

axle

rollers.

been

super-

from

5th

and

5th,

gear

gear-1?.

Epicyclic

reduction

sleeve-

gear

have

scoring;itthe

wear

limits,

the

bevel

pinion

the

surfaces

for

deformation

mating

rodsinthe

shouldbechecked

lever

sector

especially

the

-

=:~

-""

:_.'"""

I

-

shaft

and

box

ratchet

<-__._.___

'

Q

Q

20

®/

permissible

replace

without

should

such

hardening

guide

anditpresenting

plate,

(3)

f

r

‘

_

<,_

1

g

'

I7‘

'-

'~

ff

1

‘“"

‘l

§i:.,_W.;;..,c%-:

J

e__

j

i

clearance

both

bush

clatter.

components

holes.

located

and

The

haveanassembly

characteristicsofthe

under

the

_

E

‘gal

,i

.-

r.

gt

‘Q

1

...;._;,;

ir

5;=e?;i;"~:

between

and

shah.

epicyclical

clearance

should

signsofwear

control

notbedamaged

the

cover

lever

\

/

'@

\

62

__

the

reduction

working

should

(Fig.

dowels

,:

hush

98),

.

wt

l

ll

not

be

in

£1},

.<_j

1.

60

‘»‘~_

'=‘}'1“‘“

‘sq,

1-.

"~_

€

2

;_':¢,i<;;,*:_-‘,Y_/.-Iwkfucjw.

l

.

--<

‘."-’$T~=i'5'-;.-':"i':>*'i5

'

11¢”-5';:o';--_-=.§¢""'""'

Control

lever

'

-__;::_-,

J»,

lg,

.<=~v_=.-.1‘.

_;;~,.

-._.=_

~'

'3?

-T-ivf’5..

3,-1.';:’:u'=,="i'.

»~3_:E\E_§§_

1;

;-...=_,~."'i=_i1--K-_=~‘e_.~~

1»;-:.'.i=~I:'1u..~

.<-4~.<.

j.~.__..--

"___-133.

r‘.'é.."§‘

.i,~.-.:~

..

3

Fig.

doweis-2.

3.

l5:'f-.i’.'¢~.=."I"'.

—~‘

‘A

1-i.-re:"‘$

,'-',,_;_i,1.-.'-'.<¢f=‘-.1’..

'%:*:

»‘.;~;-

"W

-‘-.§1ifiF1:'=.‘:'.7i

=:_..<:".s~

-‘gl;—,‘;"-_f—f.L

¢;;_,-

‘

~-;'.'.="'"A:'¢.=-

-.1?.»?%zLh-1'

93.-Gear

Gear

1'-.

-..-‘l:‘—

- --1_.

.-if

5‘

..»_.‘_-_V_e.~,_;,

-_.

_-_'§_

1

'7"—"

*'

_

-".5"

_,,,,.";‘-7"lz,r'~*.-"-.5

.'£._v.l-‘V’,-,'.»

'

Sector

selector

6»;"‘*"»._~%_e;j;_e-;-‘-Id.*¢*=.~.~':I-21

M.’/'_.j_;_::-;;___:_‘-,:‘J._N."..

_.,

.

,__._

.,

,

;.-‘Y...

-?;;,.=—

""_'=_.‘u,

.5-'

.,,‘;.,,.-_'

jg

,_

f"f

"

,

.

screws

ea

I

Fig.

99.-Assembling

-

6.

Primary

i,

—_-.:_=...-;-;.;~'1F'~*--""“

-‘:2,.>1=..

'-

‘/-§.f‘“‘—‘L'1'!5§->‘!7*7T\'3’

1,~;._,;='--1...-:1

“.1-2*

_r;J;.'§z_;:~§/:.1.

‘;i:,M<.;."_--

,_~.>W-

'Ji~'-"~=“:.--'.:'§=-

's._“r;,.;-,.‘%~_...._,.'-r."{';'_.~';.»;

."i.\l':'v~;-?"".‘;':':'L'}‘

,

‘§:‘r.;:.-'=,3“;.;-3;.

7-2;‘:

='""-"."--1-’

:53.

..,;_.\~

<l‘j

1"-1?‘

.-

i

lever.

plate

ratchet.

.

fastening

-'~§--:1.;.;-

*-

shift

pivot

gearbox

shaft

rear

shaft»V=Shim

of

epicyclic

secondary

bearing-14.

reducfion

shaft.

Shim_R=Reverse

pin,

gear

on

Bea,-

‘l

e..__

.-R--m...-.-.-R-»-~.-»~..,-.

~.-.,“-..-._.-

i

l

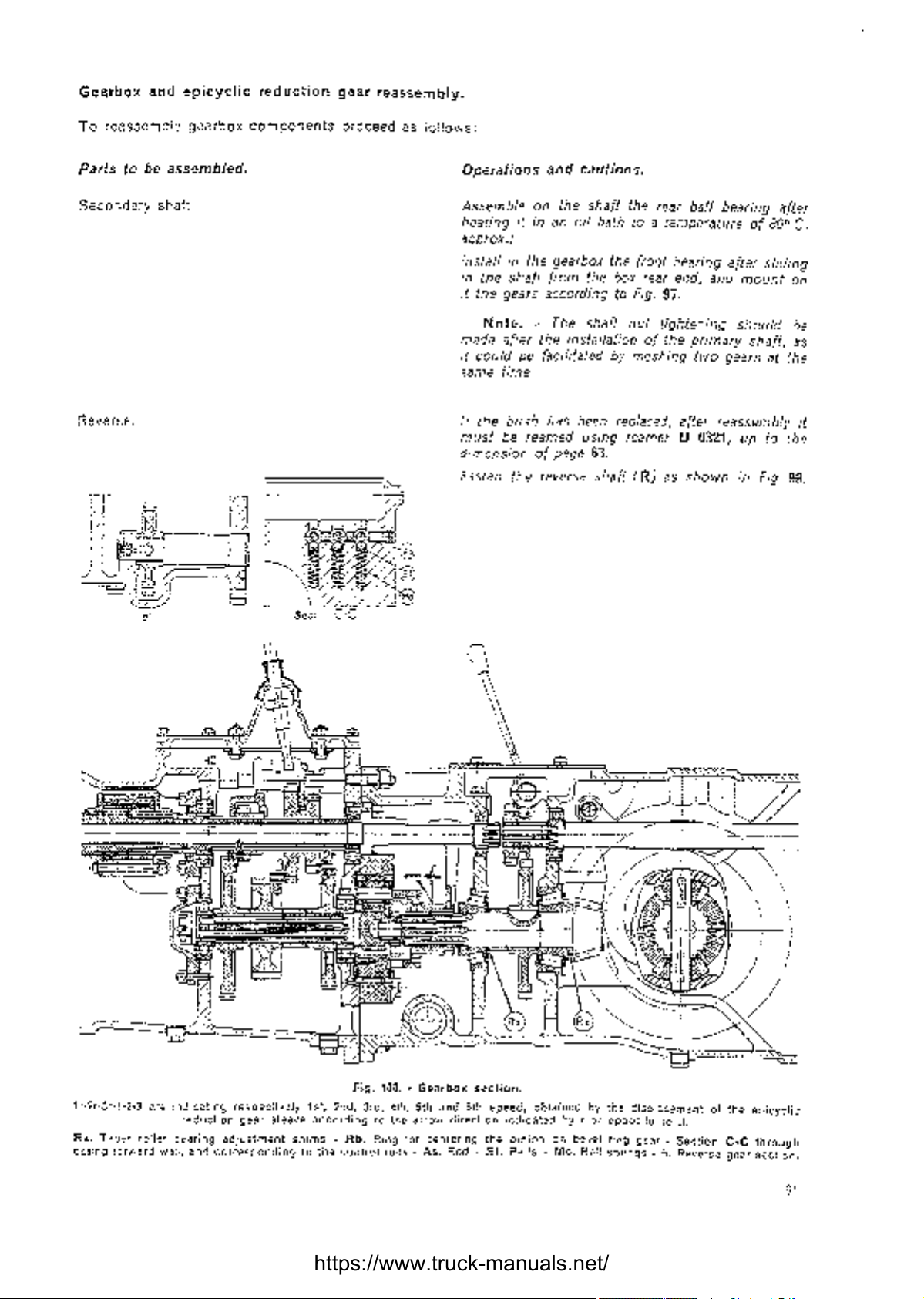

Gearbox

To

reassembfe

Paris

to

and

eplcychc

be

assembled

geaubox

reduchon

components

gear

reassembly.

proceedasroiiowsz

Operations

and

cautions.

S-=cond=ry

,_--

fiW_____.__.__

\

"~§~=¢

shaft

\\

\

\!'».:,;)€

\‘~<aq

II

I18

On

‘

Assembfeonthe

heatingiiinanoil

&ppr0X.,'

installinéhe

in

the

shaft

it

the

gears

Note.

made

if

couldbefacilitatedbymeshing

same

If

the

must

after

time.

bush

be

—

the

reamed

dimensionofpage

Fasfen

5

\§

§

(1:

_\_

fire

reverse

\

shaft

the

bathtoa

gearbox

from

the

fhe

box

front

rear

accordingtoFig.

The

shaft

nut

insfaliafic-nofthe

has

been

replaced,

using

reamerU8321,upto

53.

shaft

(R)

rear

ball

bearing

lernperature

bearing

end,

and

after

mount

97.

tightening

primary

after

as

shownin1~'ig.9B.

sjmuid

two

gearsafthe

reassembfy

01‘

80°

sfiding

shaff,

after

C.

on

59

as

it

the

‘\-=—

.L»f'~'.,

¢ypg

________

_

-

19659!

"m:."%'".;.§“**“

_

1!-21’-31

I-23ae|ndxcat|ng

Ra

Taper

CGSIFQ

ro¥lrbearmg

fflrward

was

¢*ii;.

x//

a

3‘~_

_

_

‘

$3?!‘

'

Q

fifi“

“

I

~

H.»

l|uILl;§;§;.

4

."‘

<aa's

R

ll.

filnv

_,,

§'%dLECtiUfl

wail,

adjustment

ar'd

correspondmgtotne

say

1'

W

{I

'U._~

W’

muj

I

..

2%?

ti~—

____

1%;

-

?

__

4pm»---_:~

3*‘?

--

Ea_§“________~11-.|.m-'-’-

___‘

—-

respectively

gear

_

-

sieeve

""

_(.—

shims

:4

T

_n

'°'

'/

'-1%..

F‘?

;>

'2-,_

_

mu

rm-V‘

gggfi

,

52%“.

'*

§'§°§“..'.1:-.,.,.»~mwfilm

”

‘*

1

§i‘

II

*2

QM

\.

"I

2

,,

‘ls’:

End,

accordingtothearow

Rb

control

————7——

'%%>»~=<~

F?

=

a

'

Fag

""""

‘Inn.

1

,,_W___-___!

‘Q

Far"

\,§\x

\\

163

3rd

4th

Rmg

for

rod-As

_;--E

‘$1

,:_

______

—

’

“5‘"‘?4%b_~.n.\:'k|

if

.141-'

‘

'

"“*_

~uBs2r~

\

Gearbox

5th

and

centering

Rod-Sf.

§.aw¢

‘~'\‘-\~_\'2'

Bth

lZ!H'ECfiOi"l

\.‘\

\

*

_

--

__

‘-:9-W

,

‘M

"-*

A A

=m-oz-n,' '

»

‘*

ran

:;t

_

‘*

*=—"‘

\ q

section.

speed,

indicatedbyroroppositetn5:,

the

piniononbevel

Balls-Mm

.'

“““

_,

W

i77

{\

I

'

_

Q9

V

7

"%.~/

‘

<

|

\

\_

\\

-'w-_

Bali

\.

‘

ring

sprin~b.

'"

»-;_>,___

’

».

-.=

1,’

fig?”-:&1

"—'>

v

‘

" "

:-~=v.,:>_§_,,’,;$/I

¥;~'§e

5),,

nF‘_

\,

~-

obtainedbythe

1

ELnE

/,__,_'

_;'

/

L

.

:’"‘

displacementofthe

1

I

t

\

9,9,,

{gs

g

.

V

§___

,

7‘

"14;

gear~Section

95

av)“.

P‘

"1

. ,

an

K

.

‘,‘

-E.*i=£|

F)?’

:

--

-\

R

evesegear

‘\

r

\\\\$

i

_

r

,

‘““

C-C

\

I

epicycfic

ihmugh

sechon.

"

__

_

I

\

\

)

'

‘I

-\

'

61

. .

~-

m___._=..:..-:.-..‘.._-....._-.....T_

J

‘*-.635"“"*""‘*‘-"‘"'“-

"

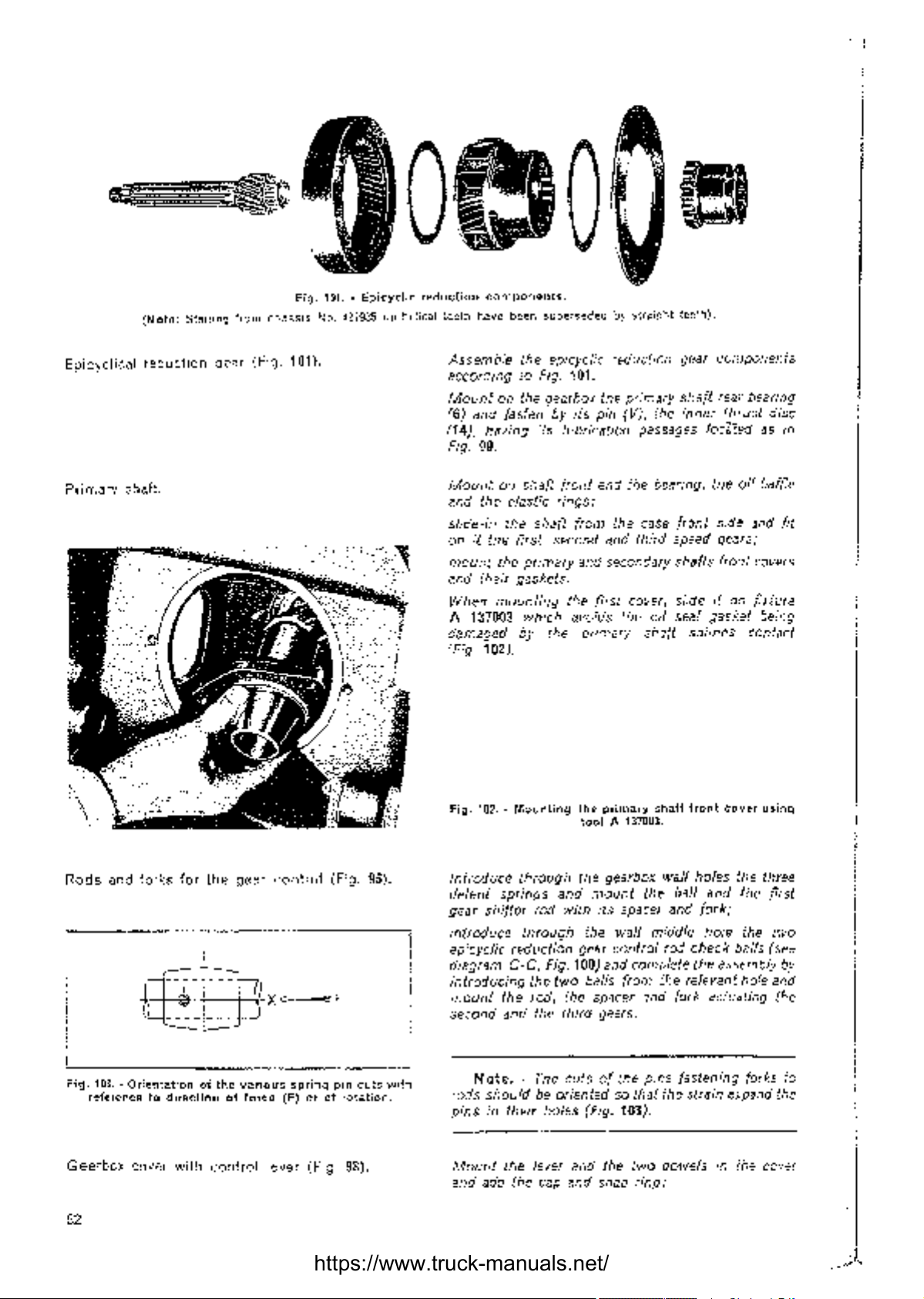

(Note:

..

Skirting

,

..__'-_._K.

from

-

Q

-

3:‘

4

*

Fig.

chassis

—~-

--';-:3,“

h;v='..1=-'1'?»

fie‘-<;;i=I<'".'I>-

-=--Y,

-..-5

:21

~~.:;-_\..

Y

‘I-..‘f_#:::

"h:~ll'-‘-,1‘

'5

‘E01.-Epicyciic

No.

427935uphelical

1

‘-I~='

*7

‘r-.

1-

Q5

;

T.

-.

;

-

L

1

l

.

reductiun

teeth

L..,»,!

."';':‘;~';u.5<‘.,1?1"'»_€";--*:

$2-{"1==

"ii"

/I,»

-

»":.P;=-‘re

I"

l;§'~‘,

>".=»-.;<\;+;",*\

-Q3‘.

5*},-1;

Y

'

1

=

l

.

components.

have

been

supersededbystraight

1»

Y

A

.

-

'

Tel

.

its

7 2

'

§—w-,;:;

J

<

ea

-.1-~

..

.;"..'-:1.-..

-

'

'1-

.

:.;.-:'~'»3.\-:3

-A

.5-‘i"ii“'»j:I.:

teeth).

. .

..

Z

=I=

.

-.=~

fl;

i

Epfcyciical

Primary

-

_

~

-

—

__

~

_

'

»..;.»-'..

;

--

1

'

—

-

"

;;.'5.

?=-=-»'~e1=;»'-'=.

~-T

->,!\;.

E?

-‘2:1"l?<5IZ-fl‘/‘»Z!1':

.

.

ye

14

..:->’_:\.*~é\'..

‘

-

_~n

"'=

'~

‘

‘

-

.-

-

3.

P

"~:*-=~-.~.~::u='=“r~J“-'*~~

*_f;-¢.Y

-

F

reduction

gear

shaft.

<~

-_

I,—;-.

-.1i=~,"“"~~"~'1='i=-;

+

~.

-_i

..~.-

.~--».~~

'"~_

.-

._ .I-

»:->'1

1

‘;

&,;'»'-,:a;

:.

'

.

.

'

‘_>1.~.:.~-9,59;-.,»..-1:2-»:.

'

,$~‘.'we_;§",»\_-;g.g.-‘¢,-=---~=.;_~;=

es

%»‘=1"<-14;'<;:;':=*-\\‘-5:1

.

N-~.~

:‘#:1<2-:$-

<,.-

.;?‘~.

'"1%¢:'{‘1i‘.2-"A,A'2

-'1'--

-

.'+"i:I>.‘%="

,

-;

~=:—-

"-=.‘A_.‘.r.‘

;:‘*""'

-

~_,.‘.-Y.

.

-

5:

_,_

_

5‘?-£i~‘='.

'="

.-

-'1":

‘;,.;~._-2'ii.-.

'~~‘--

.~f"?.E.,—

1.

._",,.=.~.._.?,=::;;;=~

.

.

:29-,1"

(Fig.

191}.

"

I

__

11..-,

.

‘*+=-@:='.¢,=',-_

-"

--~

.__;._

;¢;,;;;-|‘;~.¢,-’_~=;.\-.,_-=;.'==

..~'-"..,..

Q-.~¢>.11&?~:,-$1.

.,1-Ȣ<,,

';,<+i=;_1;-/,€;;i5;.*.<1:.5.:

1

~.:'-@-'_";».-:5s'_i-.415

;?fi...-‘

.

~

1

.

L_-

'

-'e'11:“-=;>'

.

'*@='-‘~i=‘:‘~

.-

#1.?

‘I

.

=.4¥¢:.i.:".'-‘:*'!!:v9=@@$§-

=_=,-4-1.1?-.1-i~11'?:%=£a§§!='=>

;

.'-L';i#'*’-'—'QL'_‘.-.1‘

.FE»

iv-.‘-.4~1~-§_;-e¢;;_:,:_

*

1.1,.

~

»

‘

’i"'9'

(;1':‘;I:_'::"-';~€:;£4l;..

,,

. .

,_.,,...

=:*.-s~1-

gag.

4-

->~Z3I;="

__.;,;

<-Y

:1"

’

—,7=f5":§:c

'

r--334"’

.r@F'f.--,--

(~".L

:-

i

1.;

-'

-’*

{:-

-

‘;.==:-:-

.-

'-=-=1

__

-a:_;'¢:.-r,=fs~’1-1:-.'-

"~.'1'-."—¢‘-lo,‘

$5;

.1-,;;._.-‘J:

e?‘

.'.w..~

.-

»"‘-..‘fr

Assemble

the

epicyclic

accordingtoFig.

Mountonthe

{6}

and

(14),

having

Fig.

99.

Mount

and

the

slide-in

onitthe

mount

and

When

A

the

their

mounting

137003

damaged

(Fig.

102).

Fig.

102.-Mounting

gearbox

fastenbyits

its

on

shaff

efasiic

the

shafi

first,

primary

gaskeis.

which

by

the

101.

the

pin

lubrication

front

end

rings;

from

second

and

the

first

avoids

primary

ihe

too?A137803.

reduction

primary

(V),

passages

the

the

case

and

third

secondary

cover,

the

oil

shaft

primary

gear

shafi

the

inner

bearing,

front

speed

shafts

slideifon

sea!

splines

shaft

front

c0m,00fl8niS

rear

bearing

thrust

disc

Iocéiedasin

the

oil

baffle

side

and

fit

gears;

front

Covers

fixture

gasket

being

Confacf

cover

using

.2

.

W

1

1

1

1:

1

1

Rods

and

forks

Fig.

‘I63.-Orientafionofthe

referenceiodirection

Gearbox

cover

62

for

é_

with

the

gear

of

control

{_X F

various

force

lever

contra!

(Fig.

95).

Introduce

detenf

gear

springs

shifter

introduce

epfcyciic

diagram

reduction

C-C,

infroducing

spring

(F)orof

pin

cuts

rotation.

with

rnoum.‘

second

rods

ihe

and

Note.-The

shouldbeorientedsothaf

pinsintheir

(Fig.

93}.

Mount

and

add

the

the

through

and

rod

with

through

Fig.

{he

two

rod,

the

third

holes

lever

cap

the

gearbox

mount

its

spacer

the

waif

gear

control

106)

and

balls

from

ine

spacer

gears.

cutsofthe

(Fig.

183).

and

the

and

snap

wall

the

ball

and

middfe

roe‘

compleie

the

reievamf

and

fork

p:'ns

fastening

the

two

dowelsinthe

ring;

holes

and

fork;

no/e

check

the

aciuaiing

strain

the

three

the

first

ihe

belfs

(see

assembfy

hole

forks

expand

cover

two

by

and

the

io

ihe

\

x

I

mounttofhe

fastenitwiih

also

the

gear

Before

mounting

co-/er

the

selector

ihe

lower

two

pivot

cover,

section

screws

the

(2,

(3).

shiftinneufrai

sector

Fig.

93);

pia-fie

mount

all

gears.

and

Gearbox-ctufich

NOTE:

‘

Shift

the

the

operationoffastening

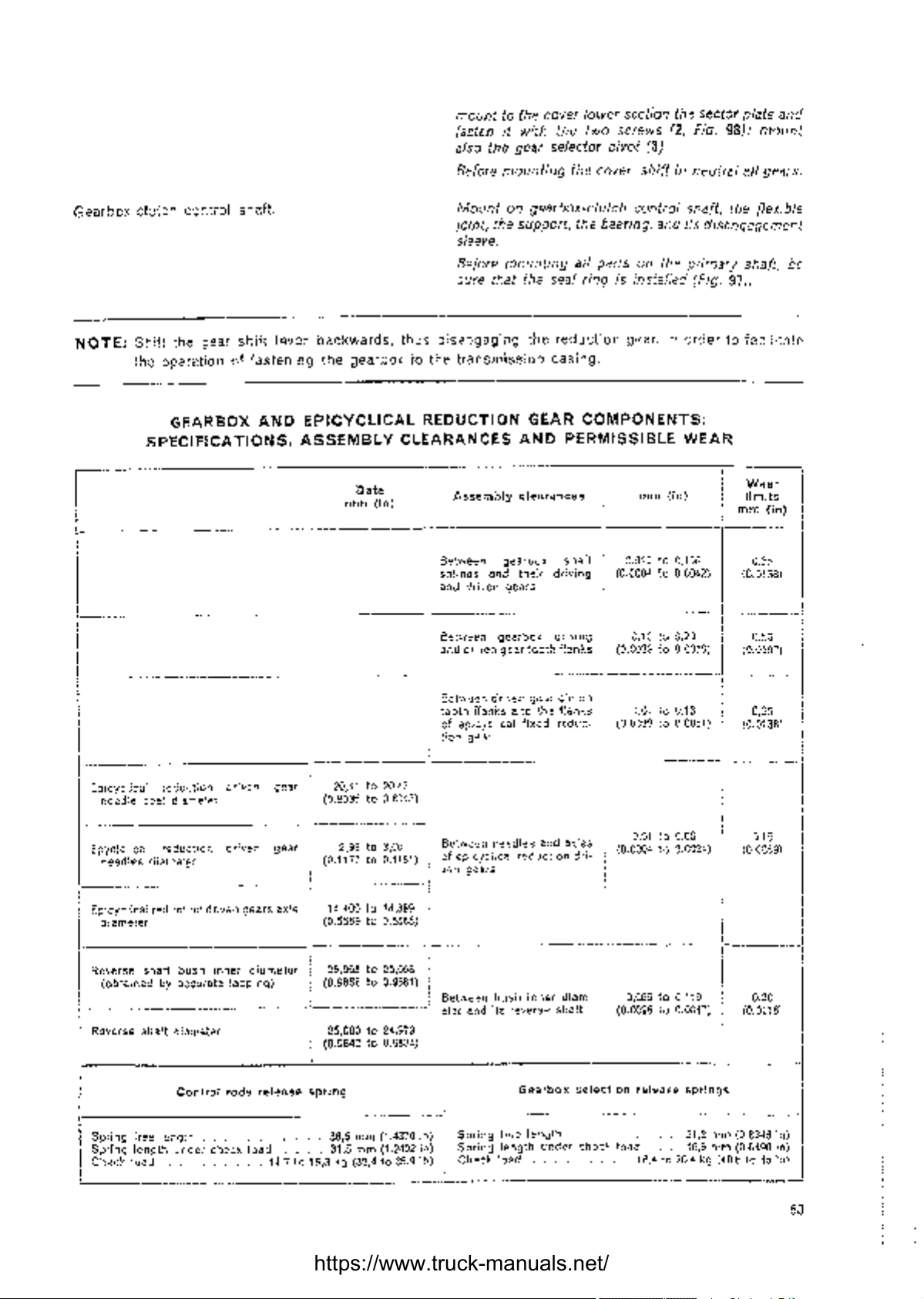

GEARBOX

SPEGFICATIONS,

control

gear

shaft.

shift

AND

fever

backwards,

the

EPKCYCUCAL

ASSEMBLY

thus

gearboxtothe

REDUUHON

CLEARANCES

mm

Bat?

(In)

_

3

Mountongearbox-clutch

joint,

the

s/eeve.

Before

sure

mounting

that

disengaging

transmission

Assembly

Between

splines

and

Beiween

and

driven

driven

gearbox

and

gears

gearbox

gear

suppcri,

the

the

GEAR

AND

ciaaranhes

their

toath

the

all

sea!

ringis1'nsz‘afied

reduction

casing.

COMPONENTS:

PERMESIBLE

shaft

driving-{Q0004to0.0042)

driving

flanks,(Q0039to0.0079)

contra!

bearing,

partsonthe

and

shaft,

its

disengagement

primary

(Fig,

gear,inordertofaciiitate

WEAR

,

T

mm

(In)

'

‘

0,010to0,105

,

w

0,10to0,20 0,50

the

flexible

shaft,

97),

Wear

limits

mm

0,35

(03133)

(O-.0197)

be

(in)

1

Epicyciical

needie

1

j

Epyciclicaf

need,“

,

E-Ipicyciicai

diameter

Reverse

reduction

seat

diameter

reduction

éiamaiel.

reduction

shaft

{obtainedbyaccurate

WV

""”""W

Reverse

_

shaft

7_

ii

5

g

Spring

free

Spring

Check

Iength

length

iuad

. . . ... . . .

‘“

driven

bush

inner

WWZ"1""

diameter

Control

_ _,,,_,,

under

check

driven

driven

gears

diameier

tapping)

rods

release

load....

gear

;

20,41to20,¢3

§

10.5035to0.8043)

gear

axis

2.99103-9°

_

(91177to93131)ofeprcychcai

'

14,-$00to14,389

(05669to0.5665)

25,065to25,098

5

(£19868to0-9881)

=

gr

7”"

=

25,000to24.979

1

(09842to0.921.243

I

spring

_ __36,5mm(14370

14,710

31,5mm(1.24CI2in],Spring

15,3kg{32,4to35.9

777‘

i

Between

‘

tooth

1ofepicyclicai

:

tion

flanks

gear

driver:

,

Y

,

1

8e‘W?en

Q

ven

gearS

I

_

I

-

Between

Bier

9-fldH5F9‘/9l'$9

E

;

'__

_____

___

1

in)‘Spring

Ib)

Check

1

gear

pinion

and

the

flanks

fixad

redu<:-

\

‘?°“°HB$

an?‘

reductlun

bush

___

Gearbox

free

length

load_...‘. . .

axie?’5(M004to0,0024)’(0.0'0§9)

dr|-

inner

diam-1;0,065to0,119

5115“

,

_

____"

seieciion

length

... . . ....21,2mm(0.8-345

under

check

.

_

0.07to0,13

(Q0028to0.0051)’(Q9135)

j

0,01mone

_

2

0,35

2

or

_

0,30

!

(919925£0Q0947)

V

release

Toad

. ..16,5mm(£16495

{SAto20,4kg[40,6to45

springs

.

'

(Q0118)

in)

in)

lb)

W

‘

E

_.

,

:

1

n

,

63

4-=-*-N-.¢=-,.~v?~.-HM-M-.,wM._i..

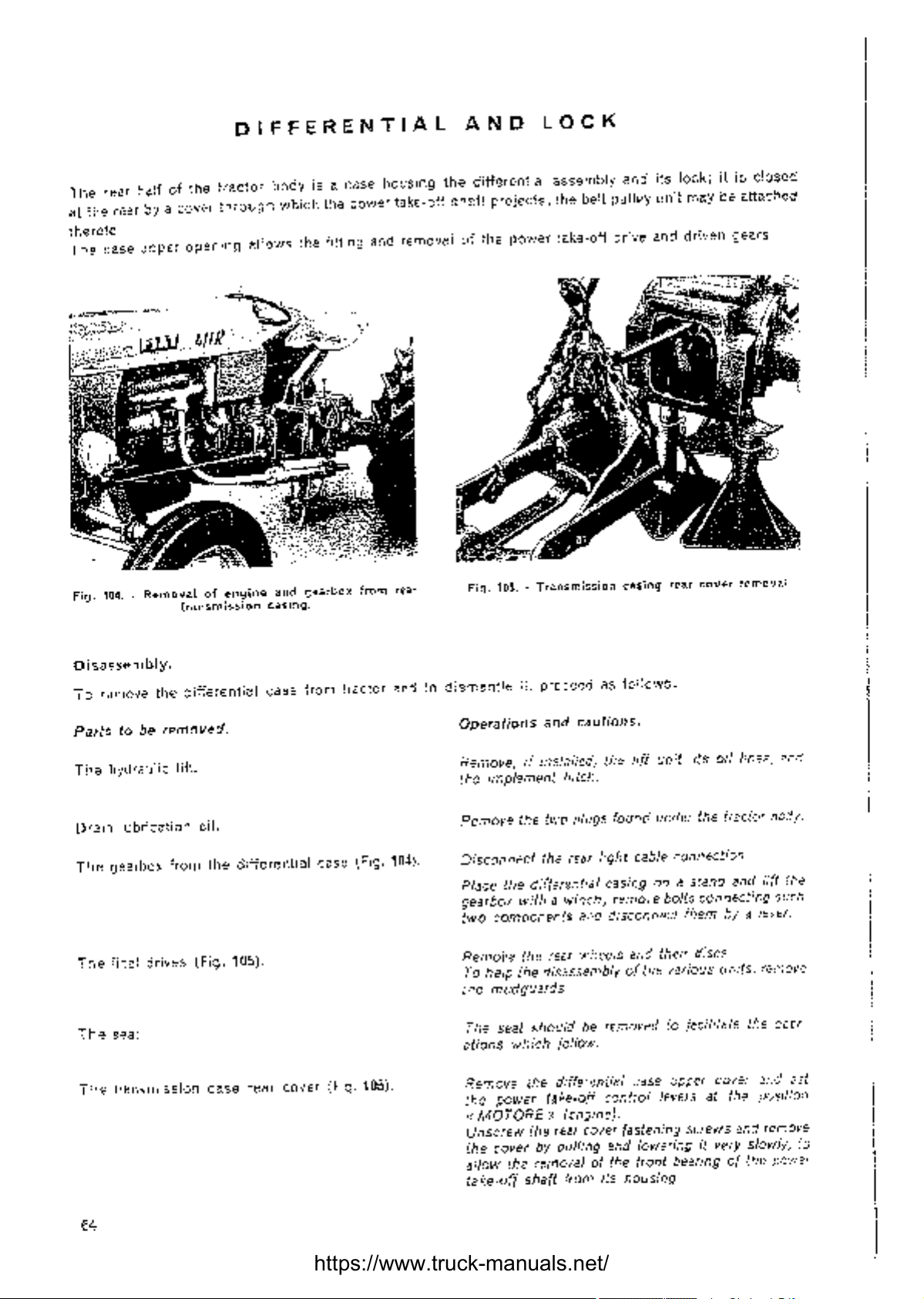

The

rear

at

the

rearbya

There/:0.

The

case

halfofthe

cover

upper

opening

BiFFERENT!AL

tractor

through

bodyisa

which

allows

the

case

the

power

fitting

housing

take-off

and

removalofthe

AND

the

differential

shaft

projects;

power

LGCK

assembly

the

belt

take-ofi

and

pulley

drive

its

lock;itis

unit

maybeattached

and

driven

closed

gears.

-k

5'!-N-',a1'.'*=‘=-"""“""“""“"'

Fig.

104.-Removalofengine

Disassembly.

To

remove

Paristobe

‘

transmission

the

differential

removed.

and

casing.

case

_

gearbox

from

tractor

from

rear

and

to

dismantle

Operations

Fig.

105.-Transmission

it,

casing

proceedasfollows:

and

cautions.

rear

cover

removal.

The

Drain

The

The

The

The

hydraulic

lift.

lubrication

gearbox

final

soar.

transmission

from

drives

oil.

the

(Fig.

case

dii-Ierential

195).

rear

cover

case

(Fig.

(Fig.

165).

10¢}.

Remove,ifinstalled,

the

implement

Remove

Disconnect

Place

the

gearbox

two

components

Remoi/e

To

help

the

mudguarcls.

The

seat

ations

which

Remove

the

power

<<

MOTOREn(engine).

Unscrew

the

coverbypulling

allow

the

take-off

hitch.

the

two

plugs

the

rear

differential

withawinch;

and

the

rear

wheels

the

disassembly

shouldberemovedlofacilitate

follow.

the

dlfierenlial

fake-off

the

rear

cover

removalofthe

shaft

from

ihe

/lfl

unit,

found

under

light

cable

casingona

remove

disconnect

and

their

ofthe

case

control

and

leversatthe

fastening

loweringitvery

front

its

housing.

its

oil

the

tractor

connection.

stand

and

bolts

connecting

thembya

discs.

various

upper

units,

cover

screws

and

bearingofthe

lines,

lift

lever.

remove

the

and

position

remove

slowly,

and

body.

the

such

oper-

sei

{'0

power

l

l

l

64

l

l

\V

./‘w

."

‘-

r

"1

_.*'T\

/'

'

‘

.

-

~

.

‘

1

-

-

Y‘

. .

1,‘

.

J

-

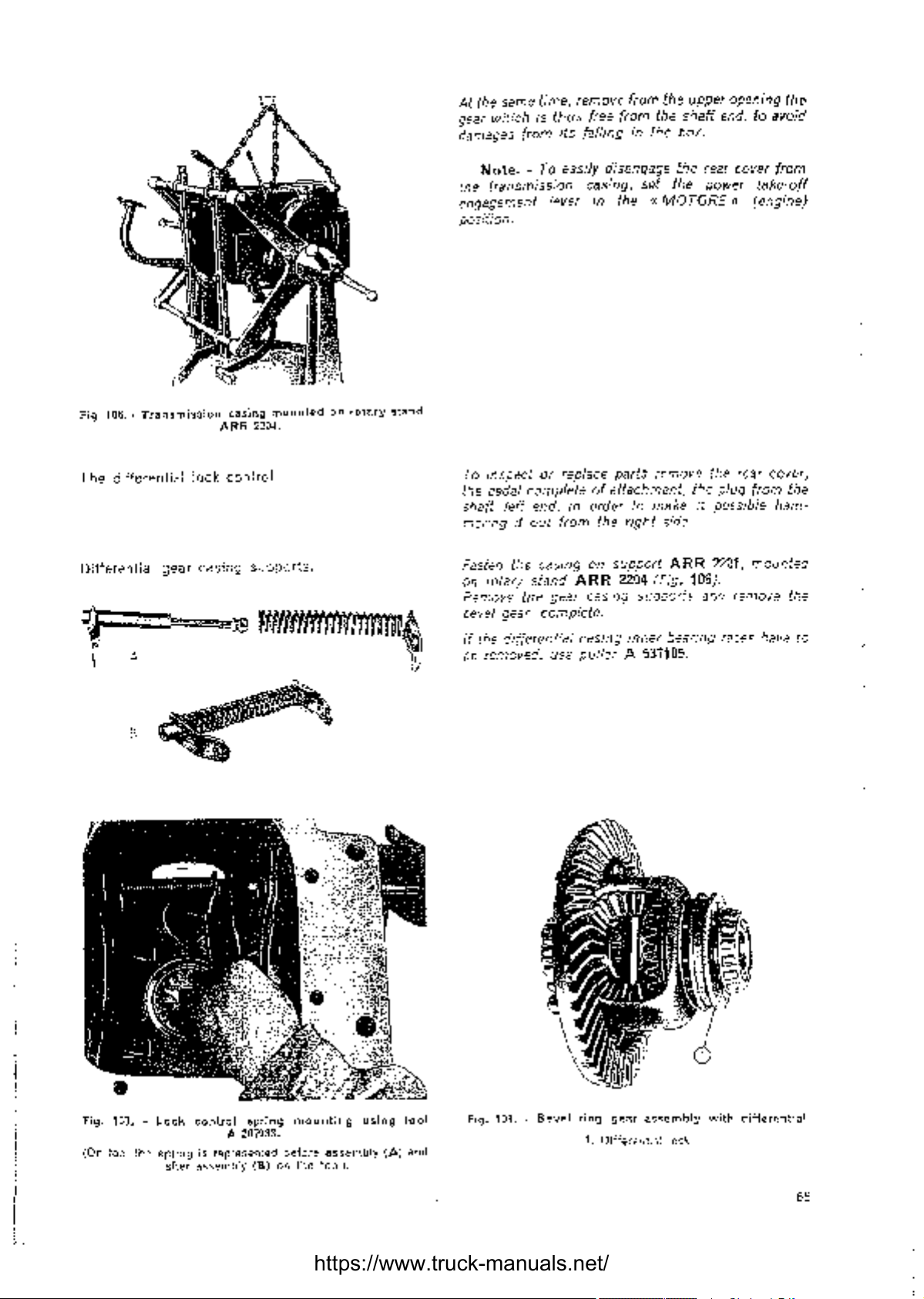

At

the

same

gear

whichisthus

damages

from

Note.-To

the

transmission

engagement

time,

its

easify

fever

remove

free

from

from

faffinginthe

disengage

casing,

in

set

the

the

upper

opening

the

shaft’

end,toavoid

box,

the

rear

cover

the

power

<1/VIOTORE»

the

from

take-Off

(engine)

posiiion.

Fig.

106.-Transmission

The

differential

Differential

L‘)

.

.--\3-‘

s'fi§§W@

,

<*rW?;

‘?:§=,i

IY-T-;yWlf;--‘

Q:

_=‘_

.V':..,_.

5%".-"

1

iock

gear

Casing

~.~~;-1“

=:c-==\=\y;ziz*-*-'~*.¢.

=

\

it

,

1

%ifi*§%““e

"

»

fit

‘-.

if:

f-="1';‘f

~

T311

‘-.-.1-‘-'_7

'

casing

ARR

mouniedonrotary

2204.

‘

;.

;-5

t‘3§;I&}

5'

V

‘ha,

_-A

-L,-J-

.'_';.;;_~_

wYmfl

,‘

-

-.

stand

controi.

supports.

‘J97

MNWWWEYMM

I}

<_-5.;

,

31‘!!!

L},

‘.

LlsihQ.

'l..:;1"

>

,___/-f“

\_'I~

To

inspectorrep/ace

ihe

pedai

compieteofaiiachmeni,

shafi

/eff

end,inordertomakeiipossibfe

meringitout

Fasfen

on

Remove

bevel

if

be

the

rotary

{he

gear,

ihe

difiereniiai

removed,

casingonsupport

stand

gear

complete.

use

parts

from

fhe

right

ARR

2204

casing

casing

supports

inner

pullerA537105.

remove

side.

ARR

(Fig.

106).

bearing

the

the

222$,

and

rear

plug

remove

races

cover,

from

the

ham-

mounieo‘

the

have

to

Y

.7‘-‘._¢,-y...

_\__

__

|

1

—,

.1_QV

‘__;;._¢:>k~_*__—:;‘

~..~

K.

gs,

..r~¢-.

.\

F~¢*fl;fi“F€'fiQ*

,5,-it-1;;

1

I

i\

\

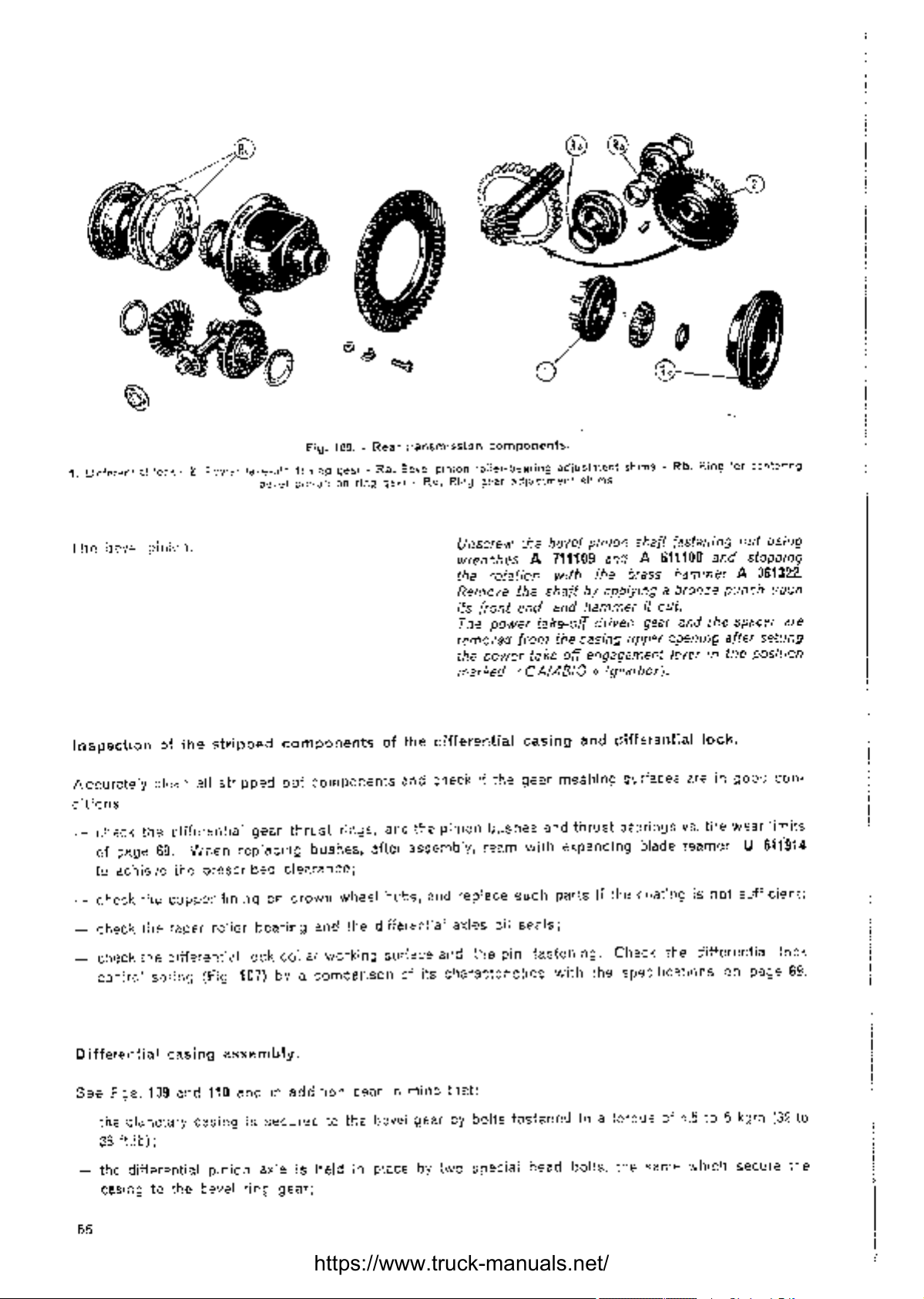

Fig.

Fig.

167.-Lock

(OFI

WP.

the

I‘

I

I

4

conirol

springisrepresented

after

assernbiy

A

spring

237033.

(B)onthe

mounting

before

assembiy

tool).

using

(A)

tool

and

108.-Beve!

ring

1.

iii-_:r?;1i;;;;;:';;~$_‘

*' _

1*,

\c_21u>»'~%:;i-§:=

I=.P’

A‘

..»~—v

.‘-

-:u—I4

_o

\‘

’Q;-.~“";r;-t-,1

. .

Differential

V

gear

,,

)3?

"’”’f‘

J

assembly

\Y'§Z'.§s,¢j§l_

,es~:'

‘§»."-‘ii;

:

1':’f':_"-“

lock.

»_;.

<51:

with

F.

“

=..

-

=

differeniiai.

65

i

i

|.

1:

1;

‘_

‘l

‘WE-s

)

'4.»

1’/®

-

'-

-

a

“T4

'

6

C0

1.

Differential

The

bevel

inspection

Accurately

clitionsi

loci.-2.

pinion.

of

the

clean

Power

stripped

all

stripped

take-off

bevel

Fig.

$59.-Rear

driving

gear-Ra.

piniononring

components

out

components

e

of

iransmission

Bevel

gear~Re,

the

and

components.

pinion

roller-bearing

Ring

gear

adjustment

Unscrew

wrenchesA711109

the

rotation

Remove

ifs

front

The

power

removed

ihe

power

marked<<CAMBIO»(gearbox).

differential

checkifthe

adjustment

shims.

the

beve!

pinion

andA611108

with

the

the

shaftbyapplyingabronze

end,

and

hammeritout.

£ake~ofi'

from

taI<e»off

casing

gear

driven

the

casing

engagement

and

meshing

"

shims-Rb.

shaft

fastening

brass

gear

upper

opening

leverinthe

differential

surfaces

i

Ring

for

centering

nut

using

and

stopping

hammerAB61322.

punch

and

the

lock.

areingood

spacer

after

upon

are

setting

position

con-

.

ll

l

,

5

i

l

I

l

»—

check

oi

page

to

achieve

-—

check

-

check

—

check

control

D

iffereniial

See

Figs.1H9

-

the

36

it.lb);

—~

the

casingisthe

66

the

diiferentiai

59.

the

the

copper

the

taper

the

difierenfial

spring

casing

and

planetary

differential.

gear

thrust

When

replacing

prescribed

clearance;

liningoncrown

roller

bearing

lock

collar

(Fig.

107)bya

asse

mbiy.

118

andinaddition

casingissecuredtothe

pinion

bevel

axleisheldinplacebytwo

ring

gear;

rings,

bushes,

wheel

and

working

comparisonofits

and

the

after

assembly,

hubs.

the

differential

suriace

bearinmind

be-vei

gearbybolts

pinion

bushes

ream

and

replace

axles

oil

and

the

characteristics

ihatz

special

and

thrust

with

expanding

such

partsifthe

seals;

pin

fastening.

with

fastenedtoa

head

bolts,

bearings

vs.

blade

{earnerU6‘lf814

coatingisnot

Check

{he

torqueof4.5to5

the

the

specifications

same

ihe

wear

differential

on

which

secure

limits

sufficient;

lock

page

69.

kgm

(32

to

the

l

l

,l

l

~>

\

~

~

it

IT*‘'

"

_

Q

\

5

‘

'

gr»

$’*%-s

l___

-_I7”’

K-\._

K

./‘T

'

l_

l~

_

i

ii

'

'

_l,

4'

w->3

'

hilfii

;:.;_;__\">

‘

I

fl

H

l

I

-*‘

1

-

,

5

l

_

r1-“*3

V

r,

‘l>——

l

l

.

z__r_';»\'i*.*‘_iv€fil-if

'

_

l

i

-"“—"“‘"""

cu

l_,4,i

,.i,.;T,,.,*T-"

1

iwi

_k_

.

s

i

.;

I:

J‘

isig

4:

2,-s»

._./

_._

-_

Tl

7

/

ii

15%

;

9

f

6

ms

3>é

.'_

"i_@"l@‘-i=-

-

_

114%

:21.

-i"'»#._l-I

_~

1%

_u'

“

‘SL154’

_~>

‘r

\

l

/_‘

ii-,=g,“

.

_.,-)

./W_/5";

F‘-1

s

A

.s

-=1-l

1*

#_

'

is

\

'

*

,

u-

\.“'

,_Q>\

,

_ _

\

_

L...

_‘_~'¢:»,‘\El;

V-:

2

*L“'.v;

-

,

*

I

'

.:i

i

=w--*='-""*'=*-*’*‘¥‘“‘~*‘*'~

_“'~\

R

‘Ear.1'

~

4

A

‘F

.“

W-

_W,

Q

1‘

.---

ls.-.;

.

.

‘ii

_

W‘,

'

‘:-

-5

~»u;,3,g5;

_

“~-

.e,§

,

én

V

li"“fl

M.-&._-1,

.

_|_

H

lg

l

W

4*

f§::-as

no

l

§

1

i

i

1

M».__.,...»...,T;4,_4

*

-

-.._>...i.4_=........

...

5

_;

"

I

l

/'

.\

\.\-L_.~.

...._

-._.

._..

........

..__.W.x-.

:<M5..

AAA-AUMZZII

W.

YI£AI\AIF4

FPI'\II§1'Ii"NT-V."

J

\./K_‘

,.

>»,.1»,

,,

.-:...'t:*

~.\’<{

'\;

0

'

,

/’>‘_},';

36%

m"_

-

37

/5?"

~!"’

‘agi-i"‘Z‘»*o'+“’

A

l

;

,(-

In

-.

~

'9-r¢*".‘

‘xx

§

{fl

£74

.

“$

av‘

1...’?

F’

—

the

assembly

racesonthe

heating

peratureof80°to90°C;the

appliestotwo

off

driving

Fig.

109);

~—

the

differential

as

shownbythe

To

facilitate

casetothe

to

the

shaft

relevant

levers

of the

taper

casing

the

bearingsinan

bearings

gear,

on

the

lock

control

Fig.10'I,

the

reassemblingofthe

gearbox,wesuggest

{Font

ends

——

ihe

power

a

;s€

--

em’

‘Jar

’1:§?.2;¢;2'2'~"n

33

.

t

i

"

'

/

L.2z'&,e_

roller

bearing

should

andtothe

be

made

oil

bath

‘coatem-

same

procedure

power

bevel

pinion

springisinstalled

using

toolA23"i'lI}33.

shait

differential

placing

-—bymanoeuvering

ts5<e~0fi

very

driven

inner

after

take-

(2,

near

the

gear

and

Fig.

R:7Ring

shaft

\\

\;\

\

\

\

1

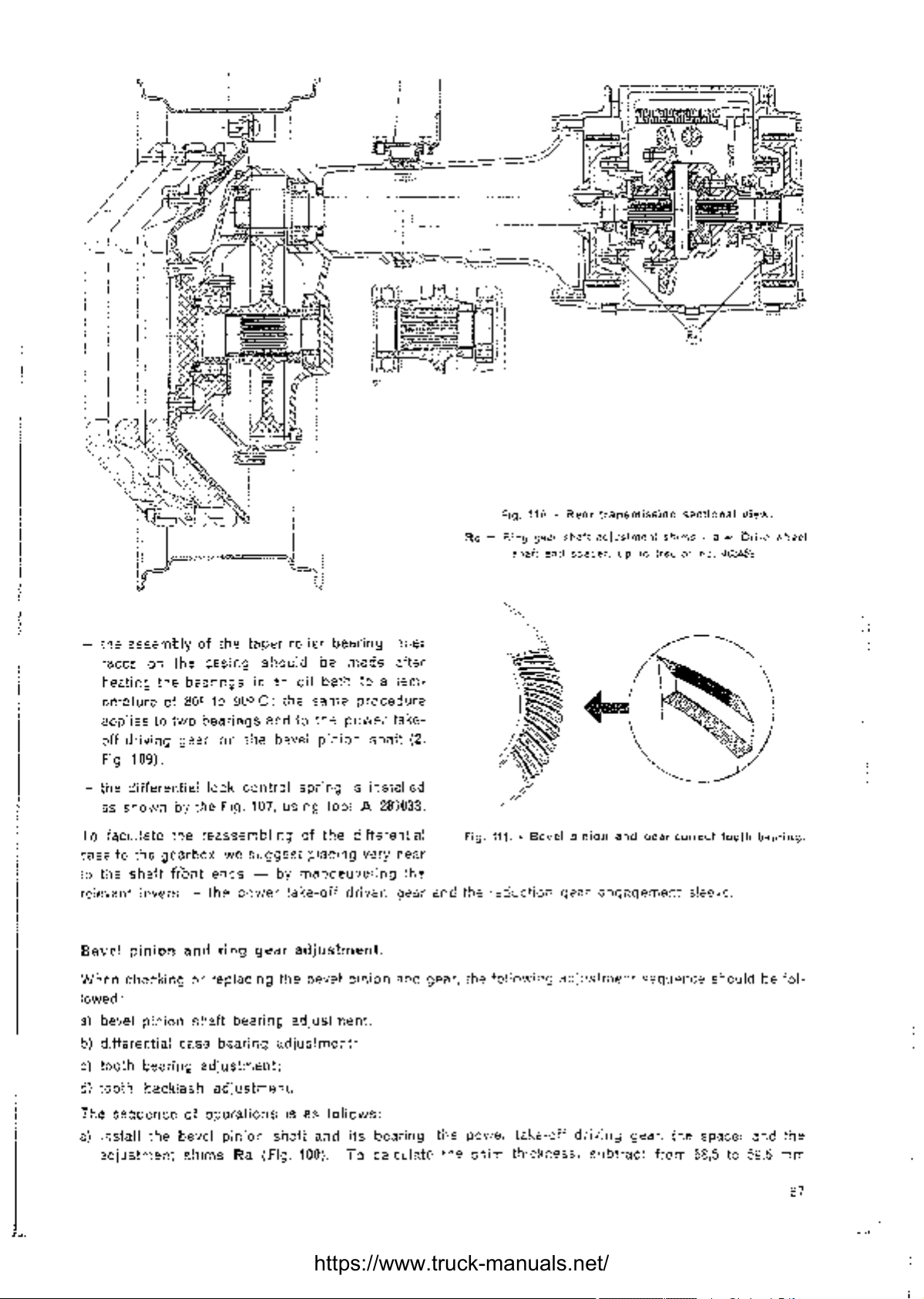

Fig.

‘E11.-Bevel

the

reduction

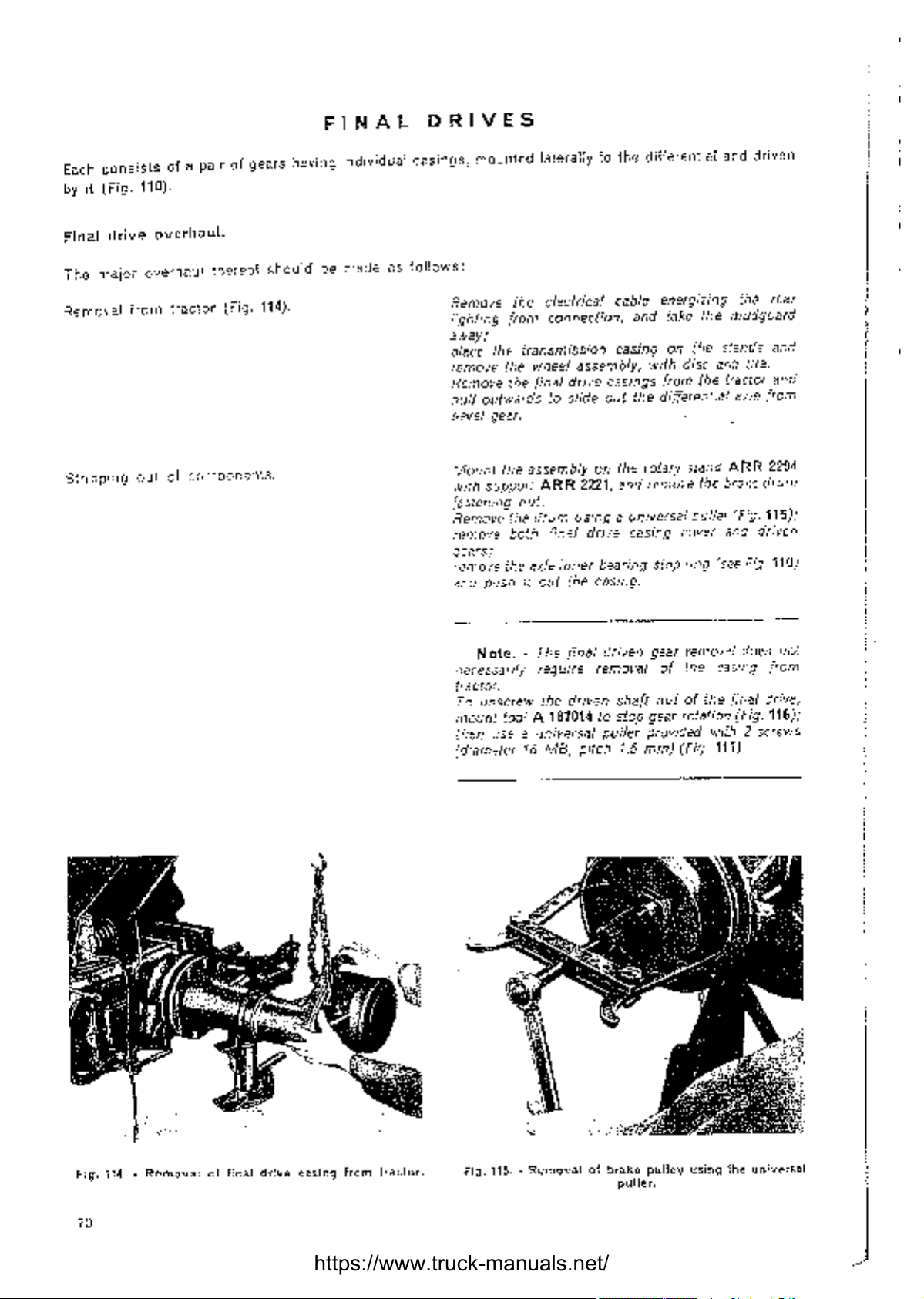

1113.-Rear

gear

and

\

.

‘\.

""

'\

L)‘

transmission

shaft

adjusirnent

spacer,upio

pinion

and

gear

engagement

sectional

shims-a=Drive

iracior

"~:»:~

.

\

no.

—.¢_¢,_;;;::

’

‘E.

view.

4-33¢S5§.

;.

%/

gear

correct

tooth

sieeve.

wheel

hearing.

sr

|

I

l

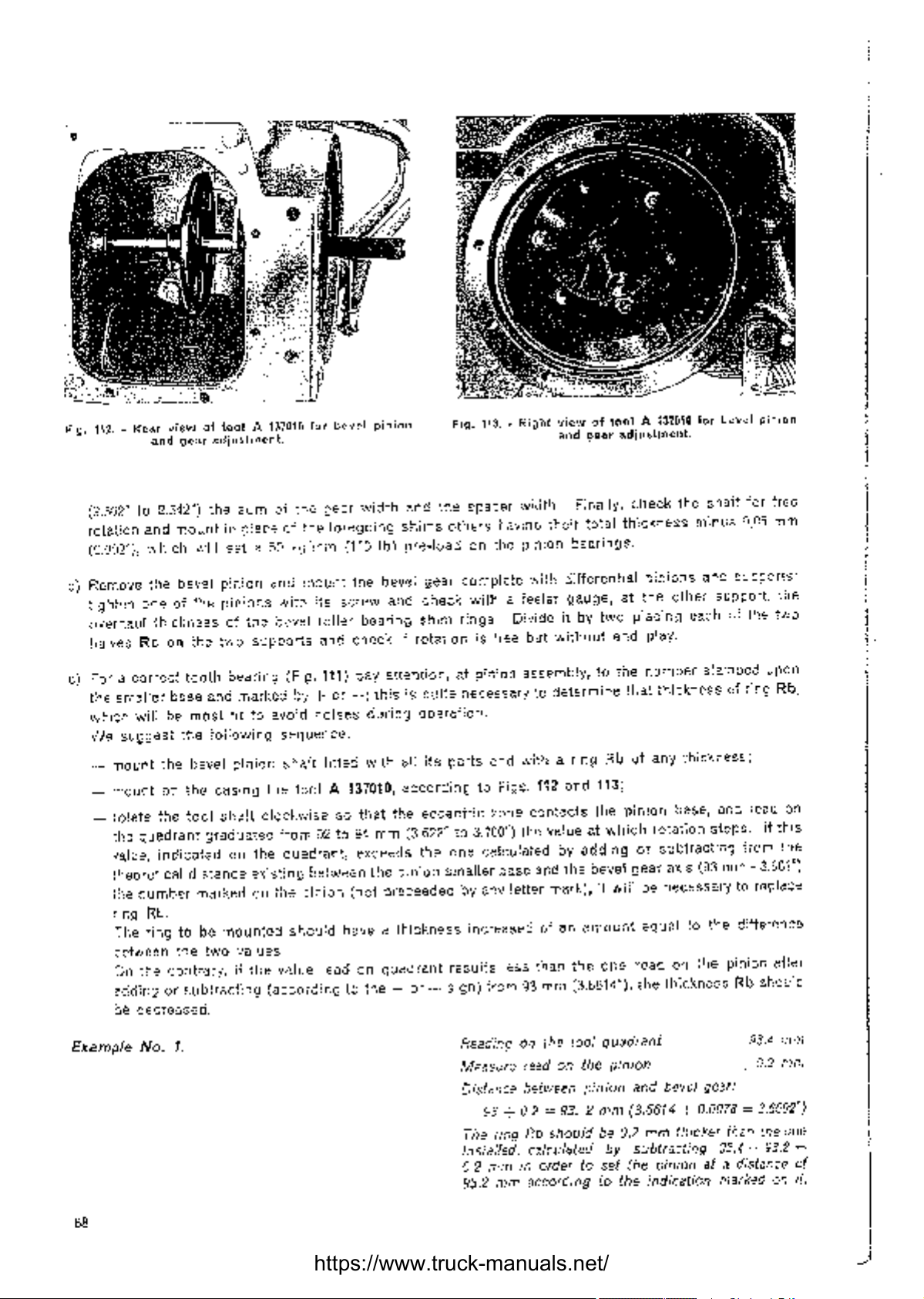

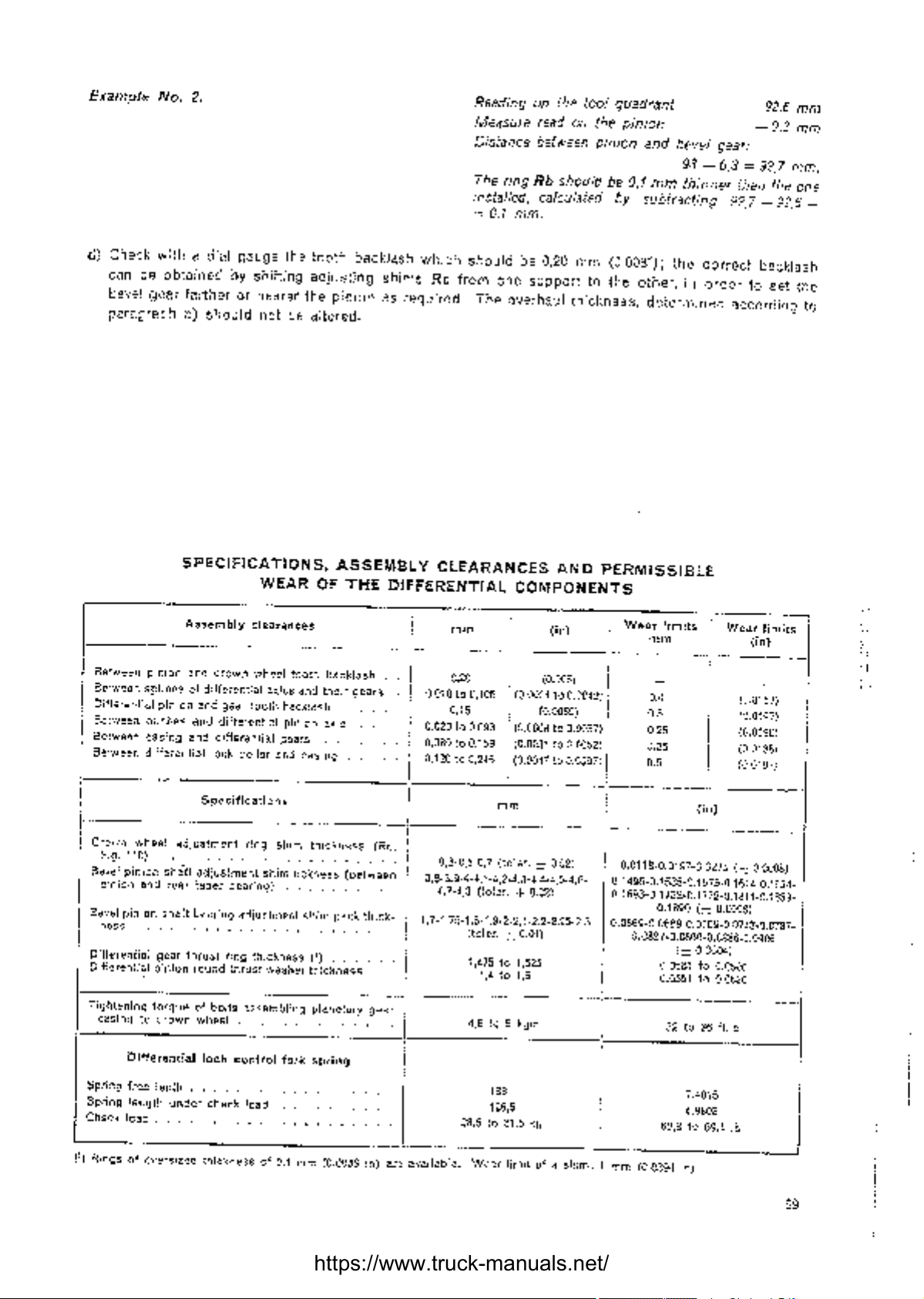

Bevel

When

lowed:

a)

1

‘

l

ll

F-

b)

c)

cl}