Fiamma Combi series, Elektra series, C series, HE series Use And Maintenance Manual

US E A N D M AI NT EN AN CE M A NU AL

E

LECTRIC COMBI WALL BOILER

FOR HEATING AND SANITARY HOT WATER PRODUCTION

INSTANTANEOUS

Combi.

Elektra. .. C

HE series

EQUIPMENT COMPLIANT CE DIRECTIVE 2006/42 - IEC 60335-2-21:2012 with IEC 6033560335-2-21:2003+A1:2005+A2:2008 - EN 60335-1:2012 - EN 62233:2008.

®

2

ELECTRIC WALL BOILER

Series

ELEKTRA. … C HE

Presentation

T

hank you for choosing an electric wall boiler FIAMMA, built with the most modern

technologies, safe and tough materials, so as to ensure maximum efficiency of use, total

quality of the device and extreme safety for the user.

The series Elektra .. is built according to European standards dir. machines 2006/42 - IEC

60335-2-21:2012 IEC 60335-1:2010 and EN 60335-2-21:2003 + A1 : 2005 + A2 : 2008 EN 60335-1:2012 - EN 62233:2008 .

The obtained results can be summarized in the following key points:

- Noiseless functioning, thanks to maximum insulation of the device by means of

innovative special materials that ensures minimum heat loss.

- High degree of reliability, thanks to a careful choice of materials and to sever tests

carried out during production for each unit built.

- High performance with maximum efficiency, thanks to a modulation of electrical power to

the heating elements, according to the actual need of energy by the system or the need of

sanitary water. The system D.E.S. manages the device with temperature probes

positioned in each sensitive point of the boiler, so as to manage both comfort and

economy functioning, in order to reduce power consumption when the device is not used

at the maximum capacity or demand.

- The appliance is fully adjustable both in water temperature of the heating system (with

the possibility to choice of system at high and low temperature for underfloor systems) and

in the domestic hot water temperature.

- The assembly of the components has been realized in order to allow an easy access to

them, all from the front of the unit, for ordinary and extraordinary maintenance.

We recommend you to follow our instructions, and we suggest to contact the area

authorized service FIAMMA in order to prepare a planned maintenance contract which can

ensure suitable operation at maximum efficiency and safety, so that your machine use can

go a long way.

In renewing our thanks, our technical department and our sales network, are at your

disposal for any further information

FIAMMA GIRO s.r.l.

Company group

The company F

IAMMA GIRO s.r.l. declines all responsibility for possible inaccuracies contained in this pamphlet, if due to printing

errors or inadvertent errors. However, reserves the right to make changes to its products that it deems useful or necessary, without

affecting the essential characteristics of the products manufactured and marketed.

3

P

H

L

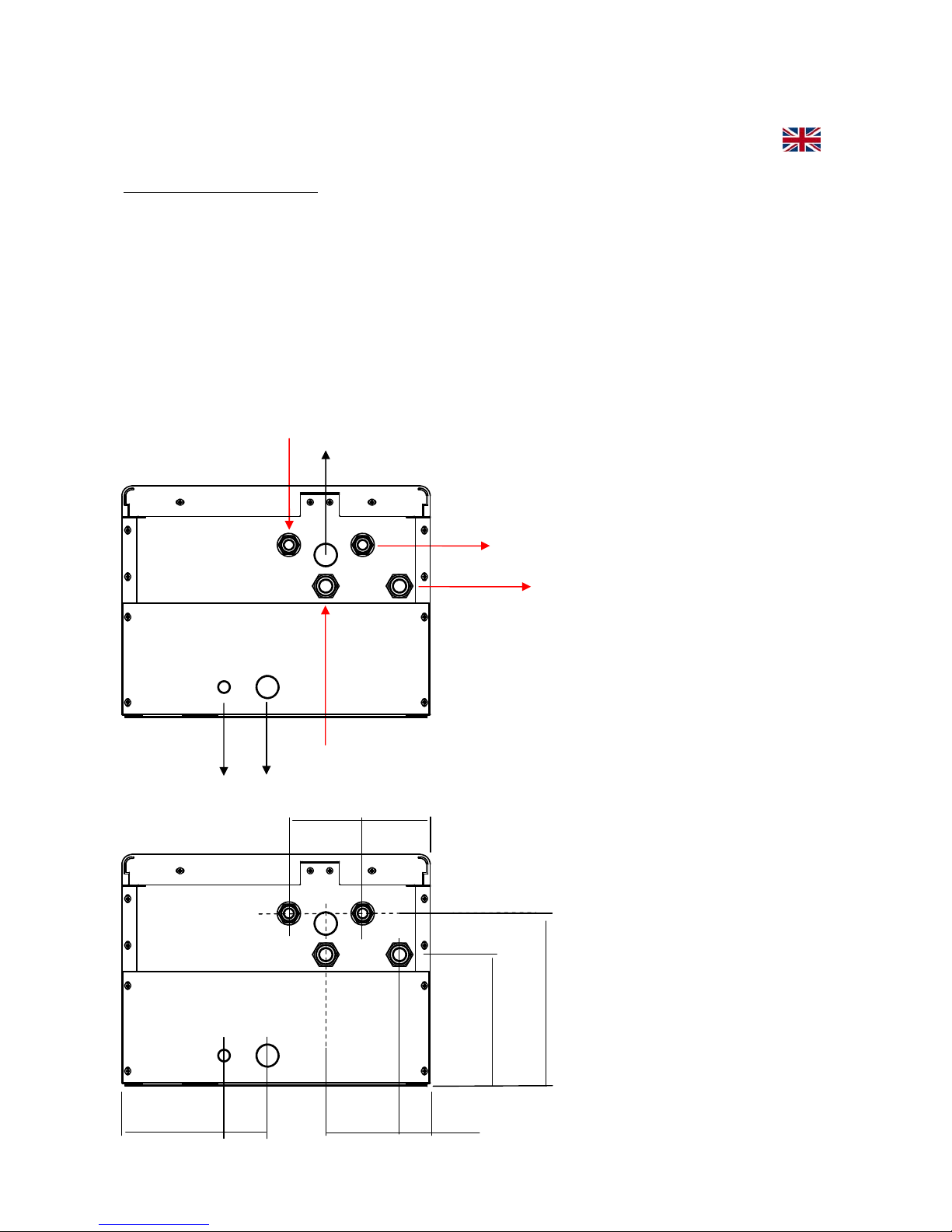

Dimensions

T

he series Elektra. .. C has four power levels, but the same overall

dimensions:

Elektra.12 C HE 12 kW maximum electrical output

Elektra.18 C HE 18 kW maximum electrical output

Elektra.24 C HE 24 kW maximum electrical output

App

liance dimension

Packaging dimension

L (Width) :

400 mm Width : 440 mm

H (Height) :

875 mm Height : 940 mm

P (Depth) : 300 mm Depth : 390 mm

Weight : 41

kg Weight : 44 kg

4

AF

VSR

AC

M

R

Electrical

supply

95

220

165

4095 80

120

Hydraulic connections – Dimensional of connection arrangement.

Hydraulic connections

M Heating delivery : ¾” M

R Heating return : ¾” M

AF C

old sanitary water inlet : ½” M

AC Hot sanitary water output: ½” M

V

SR Heating safety valve (3 bar) : ½” F

RC Manual Filling tap (restoring water pressure)

Bottom view (under the boiler)

87

5

Main technical features

Elektra.12 C HE 12 kW maximum electrical output

Single-phase electrical supply 230 V - 50 Hz.

Weight : 41,5

kg.

Electrical / heat power available at heating: 12 kW obtained by n°.2 resistance

group (n°.2 3x2 kW).

Maximum head available at the pump 5 m H

2

O

Expansion vessel capacity of 10 lt.

Safety valve of heating circuit: 3 bar.

Maximum heating operating pressure: 2.5 bar.

Maximum sanitary operating pressure: 5.5 bar.

Minimum operating pressure in the heating circuit: 0.6 bar.

Minimum operating pressure in the sanitary, comfort system: 0.25 bar.

Minimum operating pressure in the sanitary, economy system: 0.05 bar.

Maximum limit of thermal safety heating circuit - boiler body: 100 °C.

Elektra.18 C HE 18 kW maximum electrical output

Single-phase electrical supply 230 V - 50 Hz.

Weight :

4

2,5 kg.

Electrical / heat power available at heating: 18 kW obtained by n°.3 resistance

groups (n°.3 3x2 kW).

Maximum head available to the pump 5 m H

2

O

Expansion vessel capacity of 10 lt.

Safety valve of heating circuit: 3 bar.

Maximum heating operating pressure: 2.5 bar.

Maximum sanitary operating pressure: 5.5 bar.

Minimum operating pressure in the heating circuit: 0.6 bar.

Minimum operating pressure in the sanitary, comfort system: 0.25 bar.

Minimum operating pressure in the sanitary, economy system: 0.05 bar.

Maximum limit of thermal safety heating circuit - boiler body: 100 °C.

Elektra.24 C HE 24 kW maximum electrical output

Single-phase electrical supply 230 V - 50 Hz.

Weight :

43,5 kg.

Electrical / heat power available at heating: 24 kW obtained by n°.4 resistance

groups (n°.4 3x2 kW).

Maximum head available at the pump 6 m H

2

O

Expansion vessel capacity of 10 lt.

Safety valve of heating circuit: 3 bar.

Maximum heating operating pressure: 2.5 bar.

Maximum sanitary operating pressure: 5.5 bar.

Minimum operating pressure in the heating circuit: 0.6 bar.

Minimum operating pressure in the sanitary, comfort system: 0.25 bar.

Minimum operating pressure in the sanitary, economy system: 0.05 bar.

Maximum limit of thermal safety heating circuit - boiler body: 100 °C.

6

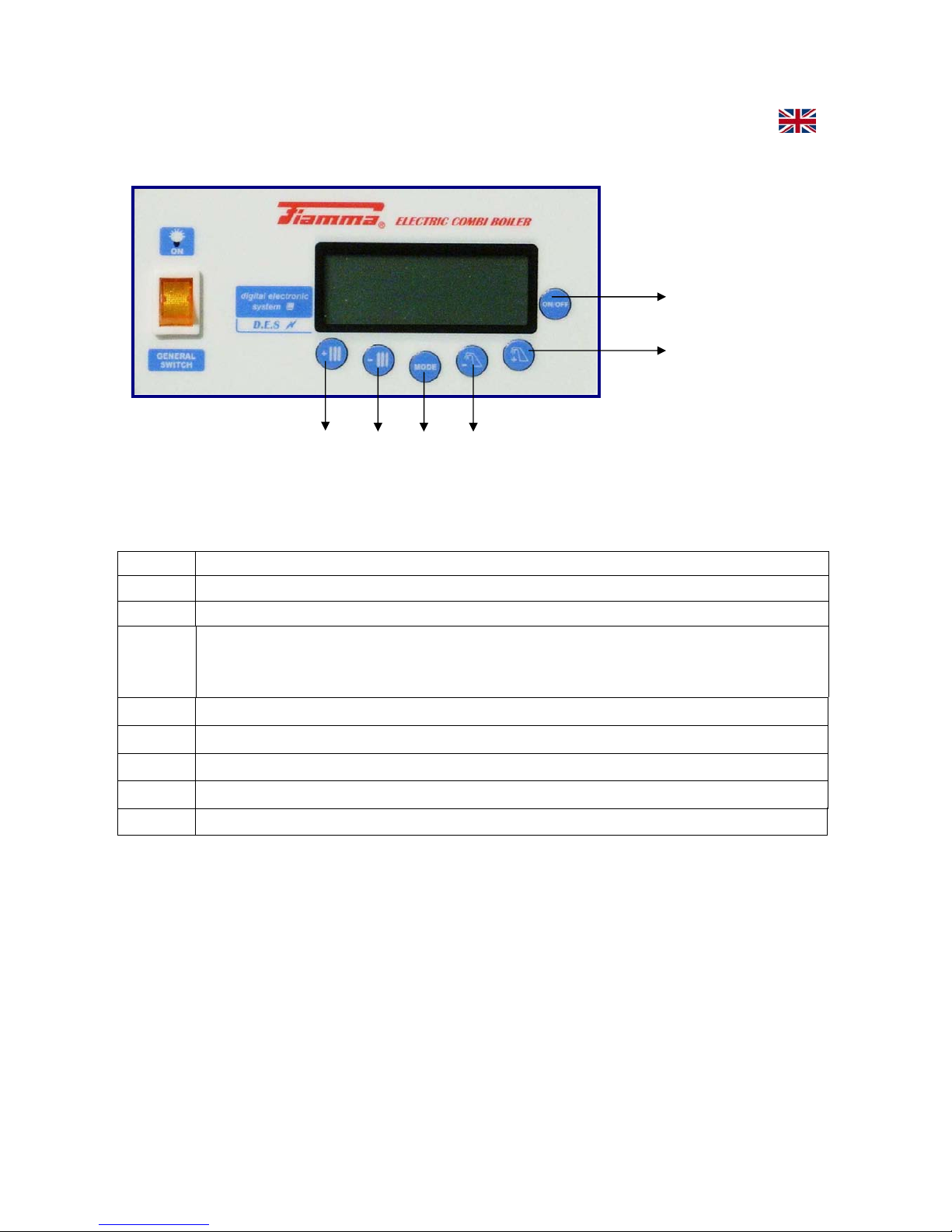

Display

General

switch

hydrometer

Switching-on the boiler

CONTROL PANEL

The control panel is composed of : display, function selection keys, general

switch and the hydrometer it is placed in the lower left corner

in front of the unit (see image above).

Using analogical hydrometer.

The analogical hydrometer control panel has a dial with unit of measure in a

bar, from 0 to 6 bar. The water pressure in the heating system is indicated by

the index of the black arrow.

The optimum pressure for the system is between 1 and 1.5 bar.

More than 1.5 bar you can have a maximum pressure of 2 bar (maximum

expansion of the system during the rise in temperature). More than 2 bar

pressure the system is not in the range of operation, and mechanical safety

valve (preset to 3 bar) can start to lose water.

The minimum operating pressure is 0.8 bar (+/- 0.2 bar). The differential

positive or negative tolerance is due to the operation of the water pressure

switch with fixed setting.

7

J7

J6

J5

J4 J3 J2

KEYBOARD PANEL (Control panel)

MEANING OF THE KEYS IN USER MODE

KEY FUNCTION

J5 Display / Sanitary setpoint decrease (only if JP8 = 0)

J6 Display / Sanitary setpoint increase (only if JP8 = 0)

J7 ON - OFF Switching

Display temperature output / Display setpoint output

Unlock error of safety thermostat

J4 Summer – Winter switching

J2 Display / Increase of heating setpoint (or room temperature)

J3 Display / Decrease of heating setpoint (or room temperature)

J5 + J6 Enabling function Eco/Comfort (only if JP8 = 0)

TURNING ON THE BOILER

The boiler is switched-on by means of the light General switch located on the

left of the display in the instrument panel of the boiler. Pressing the switch

upward to the ON position, it will light in the presence of single-phase supply

(230V-50 Hz). Then, it shall be pressed the ON-OFF (

J7

) on the keypad to

s

witch the power from stand-by to the operating position; the display will light

up of blue and will appear various symbols signaling function /faults etc.

At this point it shall be chosen the mode of operation, summer or winter

operation.

J4 + J7 Start function degassing

8

CHOICE OF THE OPERATION MODE (winter/summer)

Pressing the key MODE (J4), it will be chosen the mode of operation, wintry or

summery.

Pressing repeatedly each time for at least 5 seconds, you switch from WINTER

to SUMMER or from SUMMER to WINTER then.

When the device will be in WINTER mode, on the display will appear the

symbol

C

C

C

C (snow).

When the device will be in SUMMER mode, on the display will appear the

symbol

B

B

B

B (sun).

TEMPERATURE VARIATION OF THE HEATING CIRCUIT

When the apparatus has been set with the snow symbol (

C

C

C

C) for the wintry

functioning, you can change the maximum temperature of heating circuit

pressing one of the two keys with the radiator symbol located on the left of the

display (J2 and J3 keys).

The key with the symbol of the

I

+

(J2), increases the temperature, and

t

he key with the symbol of the

I

-

(J3), decreases the temperature.

TEMPERATURE VARIATION OF HOT SANITARY WATER

The temperature of hot sanitary water can be varied independently from the

mode of functioning, both wintry and summery.

The two keys with the Tap symbol on the left of the control panel,are used to

set the maximum temperature of the hot sanitary water circuit.

The key with the tap

H

+

(J6) increases the temperature, and the one with

t

he tap

H

-

(J5) decreases the temperature.

O

N-OFF KEY

Display Simbols

The ON/OFF key (J7), in addition to put the

boiler in stand-by mode, allows to reset

(unlock) the apparatus in case of high

temperature lock.

If the lock would be caused by lack of water

9

pressure alarm, the recovery will be automatic after that the hydric pressure will be

restored at the minimum operating level (0,8 bar) by means of the opening and the closure

of the charging tap placed under the boiler (black handle).

The display has several symbols, signaling in addition to operation modes, also the

various alarm or system displays:

SYMBOL MEANING

L

LL

L

Malfunction

J

JJ

J

Request of burner switch-on

I

II

I

Heating request

H

HH

H

Sanitary request

GGGG

Function sanitary Comfort activated

F

FF

F

Parameter menu activated

E

EE

E

Anti-freeze request activated

C

CC

C

Winter mode

B

BB

B

Summer mode

A

AA

A

OFF mode

Level of

modulation

Indicates the instantaneous power of the boiler from 0 to 100%

Loading...

Loading...