Fetco TBS-2121 Service Manual

www.fetco.com

Model

®

User’s Guide

:

f TBS-2121

TBS‐2121 Iced Tea Brewer

ITD-2135 3.5 gallon Dual Slim dispenser [ 3 gallon-in use] are available separatel

NOTICE TO INSTALLER: Please leave this User Guide with the brewer.

Table of Contents

Contact Information ........................................................2

Description & Features ...................................................2

Specifications..................................................................3

Requirements .................................................................3

Weights Capacities and Measurements.........................3

Electrical Configuration and Brewing Efficiency .............3

Installation.......................................................................5

Final Setup......................................................................7

Three position brewbasket and touch screen display. ...7

FETCO®, LUXUS®, EXTRACTOR®, INTERMITTENT BREW, and Driven To Innovation™

are trademarks or trade names of Food Equipment Technologies Company.

© 2013 Food Equipment Technologies Company

TBS‐2121 Iced Tea Brewer with dual‐ 3 gallon slim dispensers

Accessing batch and programming menu screens ........8

Operating Instructions...................................................10

Programming- operator access programming..............12

Programming-category screens: Menu Tree...............14

Test, Calibration and Flow Rate adjustment.................15

List of Error codes for TBS-2121: .................................18

Optional tea dispenser instructions and cleaning.........20

Parts diagrams, bill of materials lists ............................22

Wiring diagrams............................................................26

P-121 NEW June 2013

Contact Information

FETCO

®

Food Equipment Technologies Company

600 Rose Road

Lake Zurich • IL • 60047-0429 • USA

Internet: www.fetco.com

Phone: (800) 338-2699 (US & Canada)

(847) 719-3000

Fax: (847) 719-3001

Email: sales@fetco.com

techsupport@fetco.com

Description & Features

The TBS-2121 Iced Tea EXTRACTOR® series brewer features our universal spray over technology.

The following variables are programmed for each of nine menus (3 batches Left, Center, Right positions)

Brew volume Prewet percent (Percentage of the brew volume)

Brew time Prewet delay (The time between prewetting and the brew cycle.)

Adjustable number of pulses

Dilution volume & time in cycle Expandable separately available base platform system

Drip delay (The time between the end of the brew cycle to

empty the brewbasket and end of the brewing cycle.)

Using these variables, the software calculates how much water to use for prewetting, brewing, and dilution. The

total brew time is divided into several cycles. Within these cycles, the software calculates how long to spray

water over the tea, and how long to pause before the next cycle begins.

Features

Touchscreen Operation Batch and dilution sizing for volume and ratio

Recipe copy Digitally adjustable brew mechanism

Up to nine fully programmable menus/batch sizes Customizable batch name

Color coded handle insert for brewbasket handle Brew at temperature protection

Three position brewbasket/dispenser Totalizing counters for brewer functions

Magnetic flux brew basket sensor Cascading Spray Dome-no holes to clog

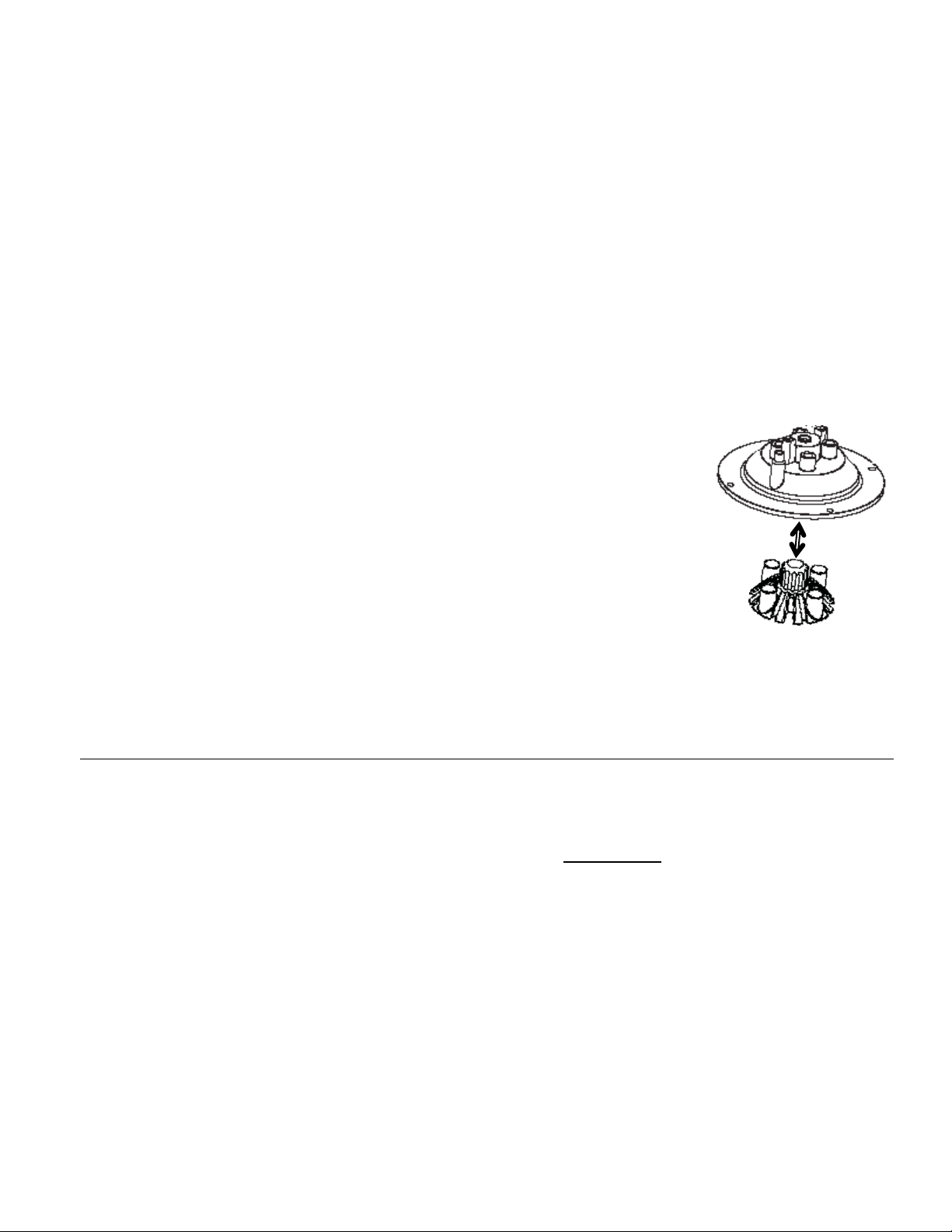

7 pc Interchangeable brewbasket orifice set Save and load programs from SD cards

Shipped ready to operate out of the box

SD card firmware program and upgrade

2

Specifications

Requirements

Water Requirements: Coffee Filter Size:

TBS-2121: 35-50 psig (241-345kPa) 1½gpm/(5.7lpm) 15” X 5 ½ ” – standard FETCO # F001

Factory calibrated for 45 psi water supply to inlet

Water inlet fitting is a 1/4 inch male flare. Temperature:

Brew Volume: 3-5 gallon [3 gallon factory set]

Ratio: TBS-2121 (user adjustable) factory setting automatically adds 2 gallons of cold water for a 1:2 ratio Iced Tea (one third hot / two thirds cold).

Water Supply Pressure: Unit is factory calibrated to a stable, non-fluctuating water supply at 45 psi.

Unit may require calibration for other water pressures. See “Dill. Volume” setting in “PROGRAMMING” menu

Designs, materials, specifications, physical dimensions, firmware and software protocol for equipment or replacement parts are subject to change by FETCO without notice.

Weights Capacities and Measurements

Weights and Capacities & Measurements-TBS-2121—Without Sweetener Option

Height Width Depth

33 7/8 in

859mm

13.5 in

343mm

19 1/2 in

495mm

Empty

Weight

35 lbs

15.9 kg

*Measurement made with a single ITD-2135 Iced Tea Dispenser

Filled

Weight

43.7 lbs

24.6 kg

Hot Water

Tank Volume

10.4 liter

2.75 gallon

Electrical: See electrical configuration chart.

200°F (93°C) inside water tank (at sea

195°F (91°C) ± 5° at sprayhead

level)

Total Weight-

Brewer &

Filled Dispenser

77.8lb

40.3 kg

*

Shipping

Weight

46 lbs

20.9 kg

Shipping

Dimensions

24” x 15” x 38”

591 x 268 X 943mm

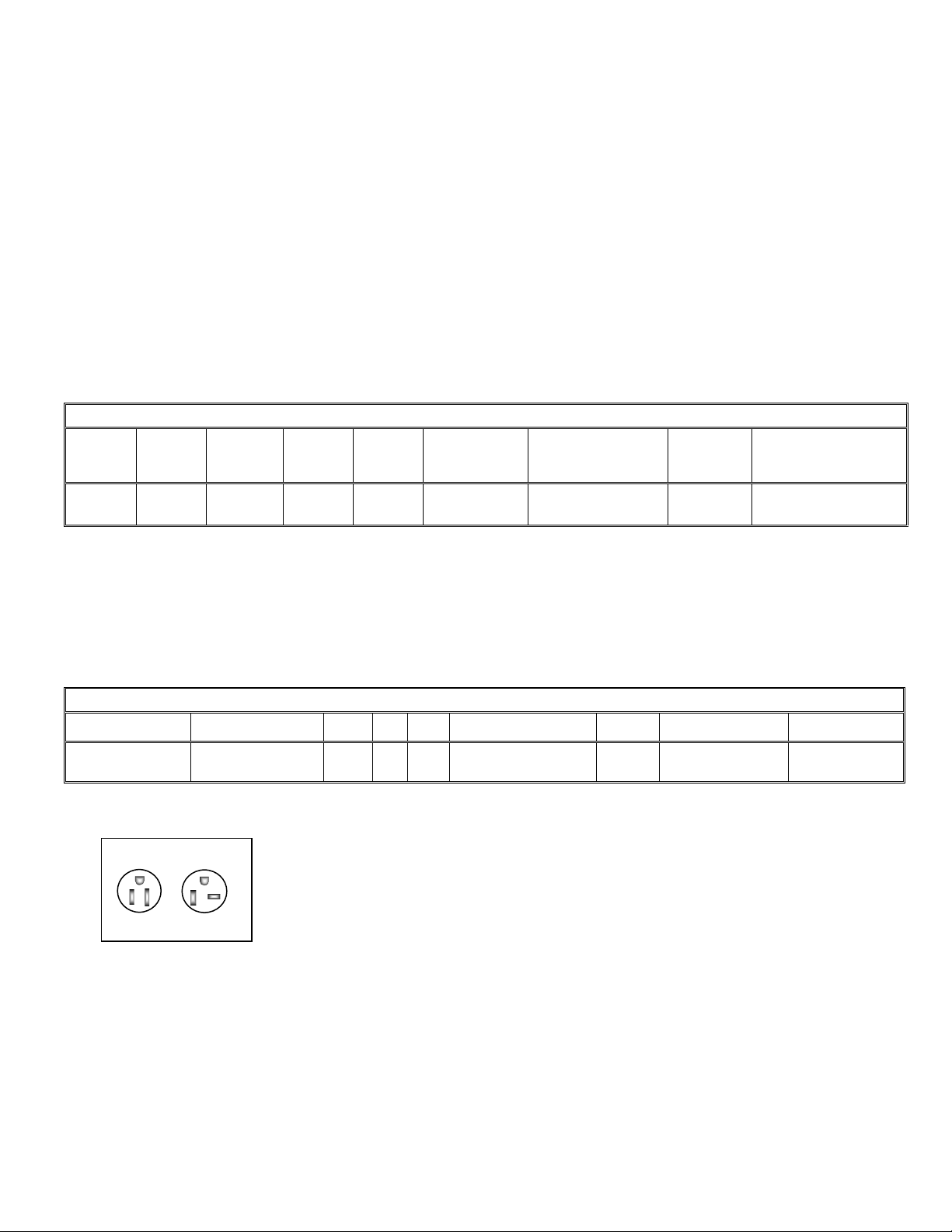

Electrical Configuration and Brewing Efficiency

Electrical Configurations TBS-2121-3 gallon brewer without Sweetener Option

Configuration Code Heater Configuration Voltage

T212101

1 X 1680 120 1 2+G NEMA 5-15P/5-20P-c 1.7 14 4

Phase

Wires

NEMA PLUG CONFIGURATION

G

W

NEMA 5-15P NEMA 5-20P

G

Designs, materials, specifications, physical dimensions, firmware and software protocol for equipment or replacement parts are subject to review and change by FETCO without notice

Electrical Connection

US/Canada

3

KW Maximum Amp Draw

Batches per Hour

(3gal/11.4L per batch)

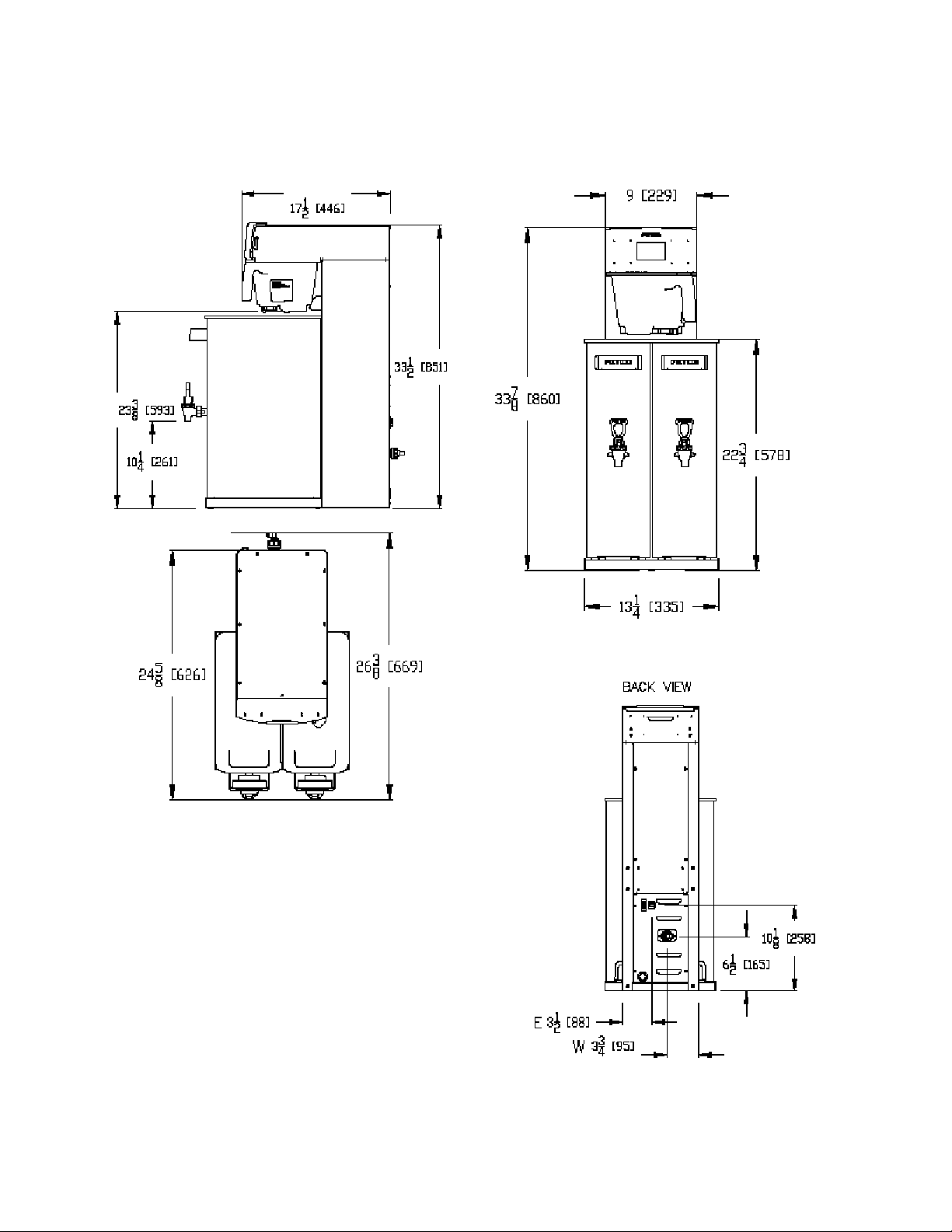

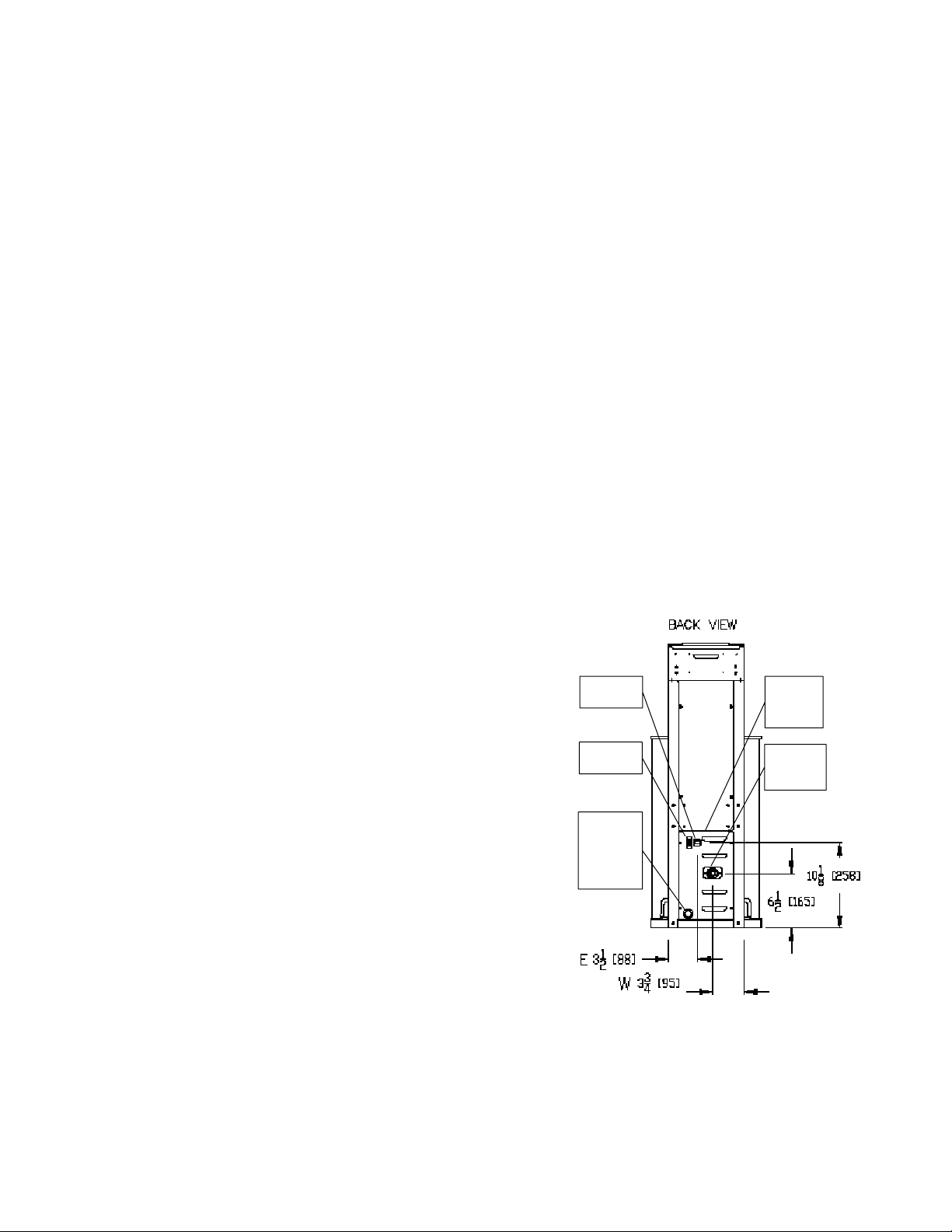

Dimensions & Utility Connections—Rough-in drawings

shown with two ITD-2135 3.5 gallon Dual Slim dispensers

Rough-in TBS-2121

Utility Connections—TBS-2121

4

Installation

(For Qualified Service Technicians Only)

Guide to A Successful Installation

If not installed correctly by qualified personnel, the brewer will not operate properly and damage may result.

Damages resulting from improper installation are not covered by the warranty, and will void the warranty.

Here are the key points to consider before installation:

Electrical:

All FETCO brewers require an electrical ground wire. Installation without grounding is dangerous.

Verify voltages, polarity, circuits, and circuit breaker access before attaching equipment.

The electrical diagram is located in the Users Guide and online at www.fetco.com.

The installation must comply with applicable federal, state, and local codes having jurisdiction at your

location. Check with your local inspectors to determine what codes will apply.

Plumbing:

All installations must comply with applicable federal, state, or local plumbing codes.

An inline water filter is highly recommended. It should be installed after a water shutoff valve and in a

position to facilitate filter replacement.

The water line and newly installed filter cartridge must be flushed thoroughly prior to connecting it to the

brewer to prevent debris from contaminating the machine.

Verify that the water line will provide a flow rate of 1½gpm/ (5.7lpm) per minute and water pressure is

between 35-50 psig (241-345kPa) before making any connections. A pressure regulator may be

required

Install a backflow prevention device if required. Many municipalities require a recognized backflow

preventer. Usable on all hot beverage and cold beverage equipment is a WATTS® SD-2 or SD-3.

These spring loaded double check valve models are accepted by most zoning authorities.

The check valve should be as close to the water supply inlet of the beverage equipment as possible.

General:

Utilize only qualified beverage equipment service

technicians for installation.

A Service Company Directory is available at www.fetco.com.

Power Cord

Power

Switch

[Optional]

B.I.B.

Connector

for

Sweetener

Utility slide

on back

of brewer

Water

Supply

Connection

5

Installation Instructions

Brewer Setup

1. Review the dimensions for the unit and verify that it will fit properly in the space intended for it. Verify that

the counter or table will support the total weight of the brewer and dispensers when filled (specifics-page 3).

Allow a counter for a unit that is 19 ½ inches/495mm deep from front to the wall

2. Place the brewer on the counter or stand.

3. When the brewer is in position, level it front to back as well as side-to-side by adjusting the legs.

4. For Sweetener Delivery units, provide space near the TBS-2121 for the sweetener boxes

Water Connection

1. Water inlet is a ¼ inch male flare fitting.

2. Connect brewer to a cold water supply line only.

3. Install a water shut off valve near the brewer to facilitate service. An in-line water filter should be used,

it should be installed after the water shut off valve and in a position to facilitate filter replacement.

4. Flush the water supply line and filter before connecting it to the brewer

5. Verify that the water line will provide at least 1½gpm (5.7lpm) per minute and also that the water

pressure is between 35-50 psig (241-345kPa) before connecting it to the brewer.

6. Note that during use all water filters will clog and will slow the water flow. The reduced water flow

affects the operation of the TBS-2121. Always schedule changing water filters per the manufactures

specification.

7. Unit was calibrated to a stable, non-fluctuating water supply at 45 psi. Unit may require a pressure

regulator OR calibration for other water pressures. See “Dill. Volume” setting in “PROGRAMMING”

menu

Electrical Connection

1. Verify that the actual voltage at the electrical service connection is compatible with the specifications on

the brewer’s serial number label.

2. Plug in unit into an appropriate 120v circuit. Note that the plug is either a NEMA 5-15P or NEMA 5-20P.

The NEMA 5-15P is for a minimum 15 amp circuit the NEMA 5-20P a minimum 20 amp circuit [USA].

3. The temperature and the fill level of the water tank are pre-set at the factory. There is no need to turn

off the heaters during the installation process. The control board automatically disables the heaters until

the tank is full of water. The heating process will start automatically when the tank has filled with water.

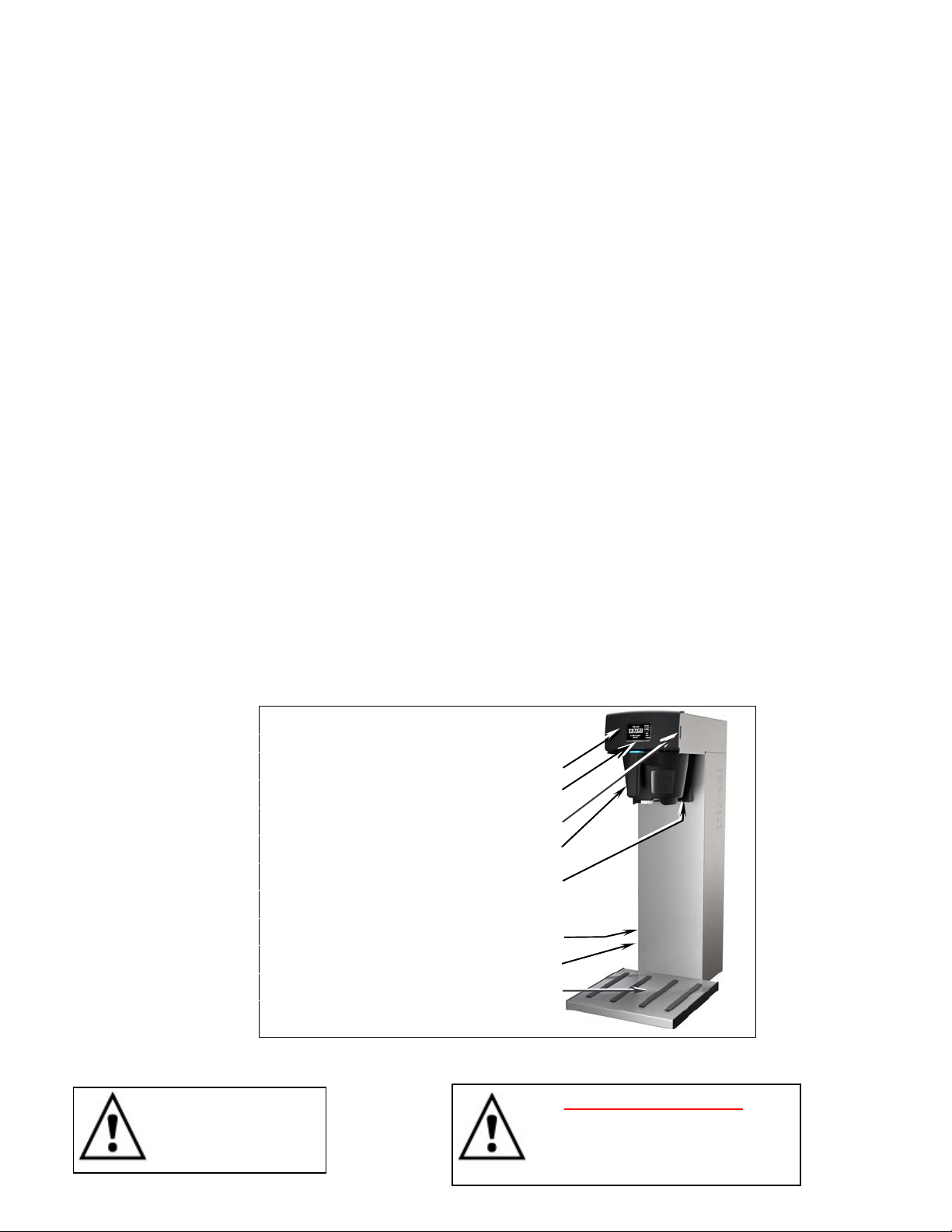

Features of your FETCO Brewer

Touch-screen for brewer operation

Brew basket sensor (not accessible)

SD card interface port (Load & Save)

Three Position Brew Basket

Dilution shelf-[behind brew basket ]

Warning : To prevent

electrical shock, this

unit must be prope rly

grounded.

Removable back panel for service

Main power switch

Platform for two slim-line dispensers

6

WARNING—DANGER

Do not plug-in or electrically

energize this equipment, or attempt

operation without all covers in place

and all screws fastened

.

Final Setup

1. Turn on incoming water supply line and carefully inspect both inside and

outside of the brewer for leaks in all fittings and tubes

2. Turn power on—by pressing the brewer’s main power switch (located on

the lower right of the back of the equipment)

3. The water tank will begin filling. FETCO Home Screen #1 will read

“FILLING”.

4. When the water level rises and is sensed by the probe at the top of the

tank the heaters will activate

5. Heaters are automatically disabled until the tank is full.

6. While the water is heating Screen #2 “HEATING” will display and the

actual water temperature will be displayed.

7. After the water has reached the set temperature Screen #3 will display

“READY”

8. Review the Operating Instructions. Brew one full batch (water only) to

confirm proper fill levels. The brewer is factory set with water only (no tea)

to dispense the correct amount of water. If the actual volume is slightly

different from the programmed volume, fine-tuning the brewer may be

necessary.

9. Re-attach the covers after one final inspection for leaks. Look closely in

the top of the brewer section at the dispense fittings during this

inspection.

Danger: Do not operate without covers in place

FETCO Home Screen #1 “FILLING”

Ready

□

□

■

Touch

screen

to unlock

Heating

Filling

TBS_2121

©2013 all rights

reserved

FETCO Home Screen #2 “HEATING”

Ready

TBS_2121

©2013 all rights

reserved

□

Heating

■

Filling

□

Touch

screen

to unlock

FETCO Home Screen #3 “READY

Ready

TBS_2121

©2013 all rights

reserved

■

Heating

□

Filling

□

Touch

screen

to unlock

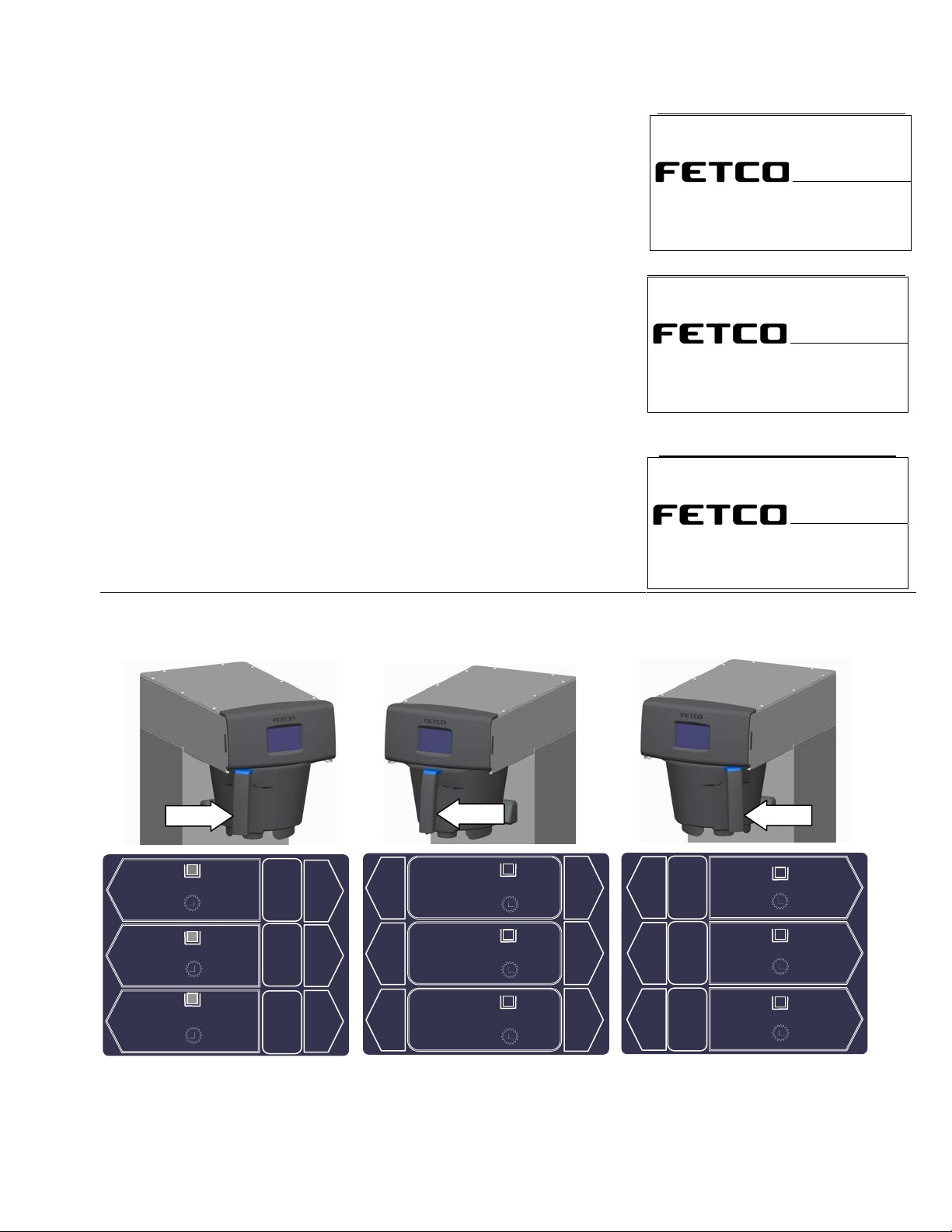

Brewbasket handle—LEFT Brewbasket handle—CENTER Brewbasket handle—RIGHT

Three position brewbasket and touch screen display.

LEFT

11:35

L 1

9:22

11:35

L 2

9:22

11:35

L 3

9:22

Left screen, L1(top) is permanent Center screen—recommended for 5 gal brews Right screen, R1(top) is permanent

CENTER

11:35

C 1

9:22

11:35

C 2

9:22

11:35

C 3

9:22

11:35

R 1

9:22

11:35

R 2

9:22

11:35

R 3

9:22

RIGHT

-Position of the brewbasket handle activates left, right, or center menu screens for nine menu settings.

-L1 and RI brew positions are permanent screen menu settings; all or any of the other seven can be deleted.

-We recommend the center menu screen for brewing into dispensers over 3.5 gallons.

-Only the center and right menu screen contains dialog and controls for the (optional) sweetener option..

7

p

G

OUTPUTS

O

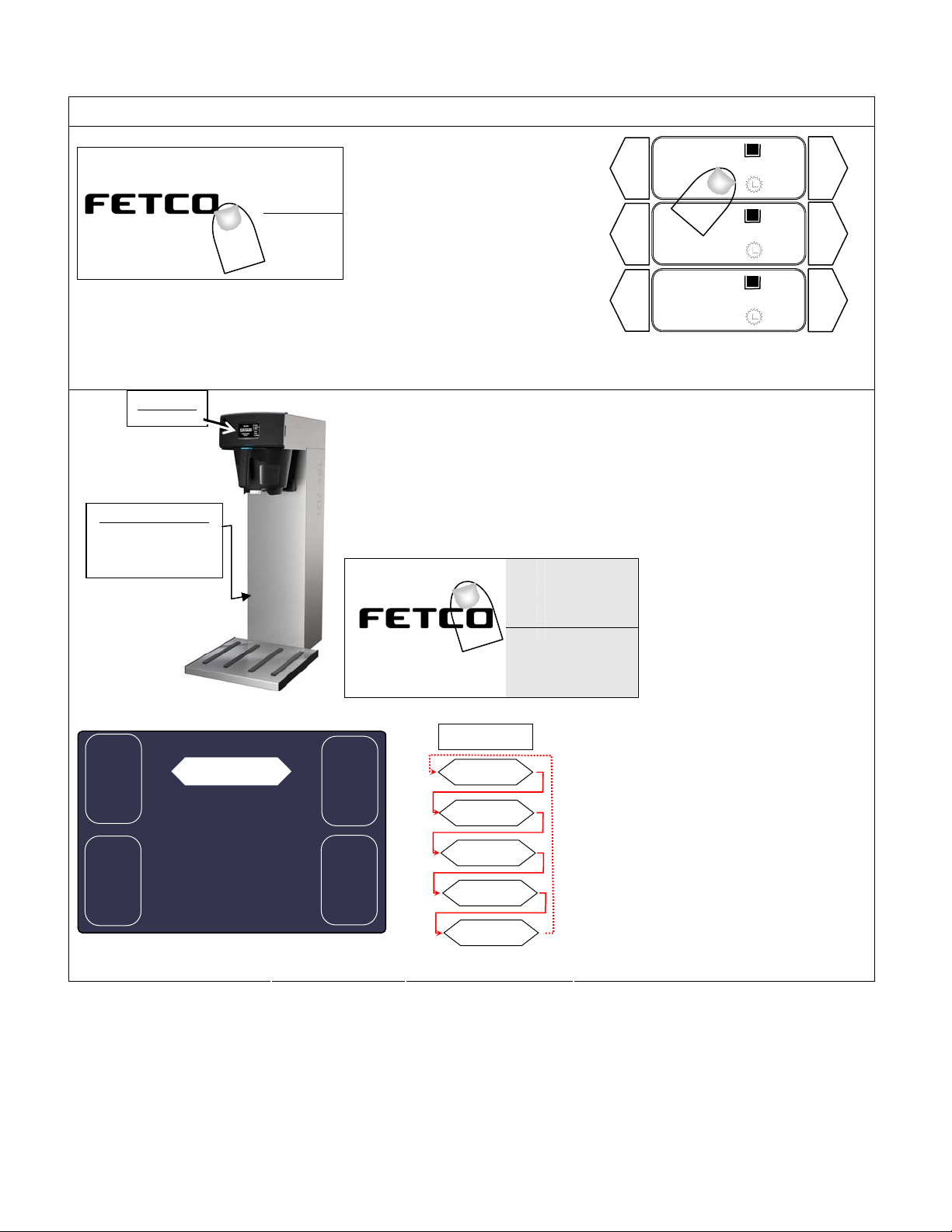

Accessing batch and programming menu screens

Batch selection and brew operation menu screens

Ready

■

Heating

□

□

Touch

screen

to unlock

Filling

TBS_2121

©2013 all rights

reserved

This screen displays when the TBS-2121

is in standby mode

Å Tap FETCO HOME SCREEN

to enter batch selection screen.

Align brewbasket handle to

select, center position batches

(center shown)Æ

Touch and hold activated top,

middle or bottom (C1, C2, C3)

recipe batch selector to begin

brew.

11:35

C 1

9:22

11:35

C 2

9:22

11:35

C 3

9:22

FETCO home screen

Programming menu screens

Touchscreen

MAIN POWER SWITCH

Located to lower left

side of back

EXIT

anel

PROGRAM

< >

< Batch 1 L >

<<

(Power off and power on the equipment-then touch and hold screen)

ÅSwitch TBS-2121 power “OFF”

Turn main power switch to “ON”—The touch screen will illuminate.

Immediately touch and hold finger to enter programming

In 5-8 seconds “PROGRAMMING” screen will appear

Illuminated touch screen-touch and hold finger for programming

TBS_2121

©2013 all rights

reserved

Programming screen

-STARTÆ

T

PROGRAM

ENERAL

>>

Operation screens

To access programming

THER

■

□

□

Ready

Heating

Filling

Touch

screen

to unlock

Screen shows the “PROGRAM” Icon

In the position shown, the unit will

access and display the recipe for batch

Left-1 (the top touch screen pennant)

By touching the right double arrows, the

PROGRAM icon will scroll through the

other control icons

PROGRAM…GENERAL…INPUTS…

OUTPUTS…OTHER......

continued scrolling returns to “PROGRAM”.

8

Operator Training

Review the operating procedures for the brewer.

Pay particular attention to the following areas:

1. Always have an empty dispenser under the brewbasket

2. Don't remove the brew basket from a brewer until it has stopped dripping.

3. Make sure the dispenser is empty before brewing into it.

4. Show how to attach covers, close, and/or secure the dispensers for transporting.

5. Show the location and operation of the water shut off valve as well as the circuit breaker for the brewer.

6. Steam from the tank will form condensation in the vent tubes. This condensation will drip into and then out of

the brew baskets. Up to 1/2 cup/118cc discharging overnight is possible. Place an appropriate container

under the brew basket when not in use.

7. We recommend leaving the power to the brewer on overnight. The water tank is well insulated and very little

electricity is used to keep the tank hot. Leaving the brewer in the “ON” position will also avoid delays at the

beginning of shifts for the brewer to reach operating temperature.

Cleaning & Maintenance

After Each Brew:

1. Dispose of used filter and rinse brew basket.

Sprayhead

2. Never strike a brewbasket or hit it against a hard surface.

This will damage the brew cone, and may damage the brewbasket support rails

3. Rinse dispensers before reuse.

Every Day:

1. Wash brew basket with hot sudsy water.

2. Pull CSD from the spray head, it is magnetically attached. Use gloves or a heavy towel. Æ

Wash off any film and reattach. Use vinegar if limescale filming is present.

3. Clean dispensers with hot suds water and a brush, rinse and air dry.

4. Use only a soft cloth and hot suds on the outside surfaces to avoid scratches.

Never use abrasives, which will scratch surface.

CSD

Weekly

1. Use a commercial coffee dispenser cleaner such as URNEX™, TABZ™, DIP-IT™ or Squeak 'n Clean™.

2. Carefully Follow the instructions supplied with the cleaning product

3. Never use spray cleaners, solvent, solvent based cleaner or petroleum based polish anywhere on dispensers

Safety notes

1. Professional installation is required. This appliance is manufactured and approved for commercial use only.

2. Operation requirements and maintenance for commercial cooking appliances differ from household appliances.

3. Operators must be trained for this equipment and must understand the use, maintenance and hazards.

4. Do not attempt to move hot beverage equipment once it is filled. IMPORTANT: Drain equipment before moving.

TBS-2121 Iced Tea brewers prepare 3-5 gallons/11.4-19 liters of tea in a single batch using very hot water.

For safety, do not attempt to remove brew basket until the brew-dilution sequence is complete. .

Warning

1. Turn off power before any cleaning procedure, including wiping the exterior for appearance reasons.

2. Dry the exterior, especially the face panel, before turning on power.

3. Do not apply any type of spray cleaner on the face panel of this equipment.

4. Never use solvent or solvent-based cleaner or petroleum based polish anywhere on this equipment.

5. Dry the face of the touch pad before turning on power

6. Do not electrically energize this equipment or attempt operation without all covers in place and all screws fastened.

7. Unplug machine before disassembly or servicing.

9

Loading...

Loading...