Page 1

www.fetco.com

Model:

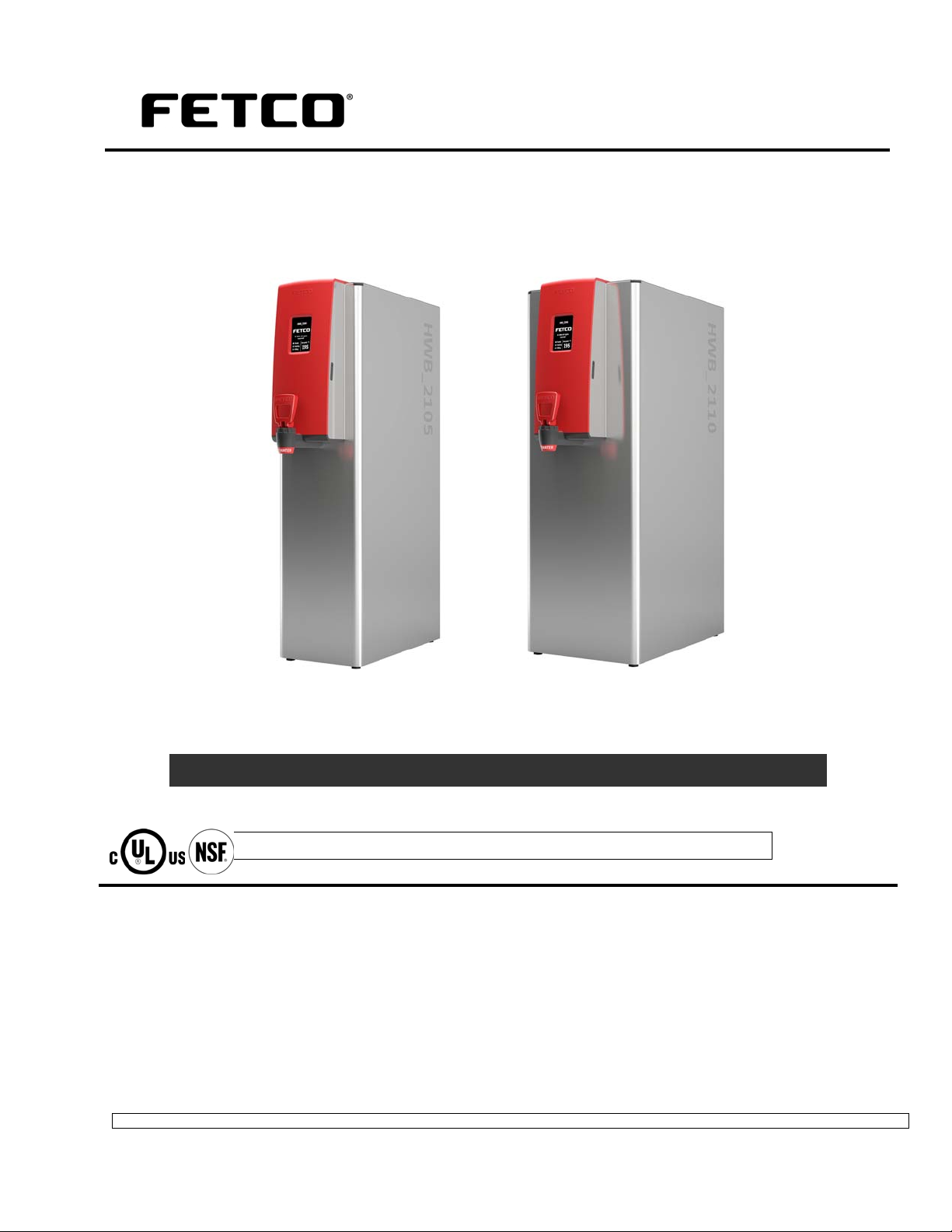

f Touchscreen Hot Water Dispenser HWB-2105XTS & HWB-2110XTS

User’s Guide

HW

B-2105 and HWB-2110 5 & 10 gallon per hour heavy-duty commercial hot water dispensers

HWB-2100XTS USERS GUIDE-North America Edition

NOTICE TO INSTALLER: Please leave this book with the machine.

Table of Contents

Contact Information ........................................................2

Description & Features ...................................................2

Specifications..................................................................2

Electrical Rating Chart....................................................2

Dimensions & Utility Connections...................................3

Operating Instructions ....................................................4

Accessing Service Screens and Controls ......................5

Error Codes ..................................................................10

Installation Instructions .................................................11

Safety Notes .................................................................12

Parts and Service drawings..........................................14

Wiring Diagrams ...........................................................23

FETCO®, XTS are trademarks or trade names of Food Equipment Technologies Company.

© 2014 Food Equipment Technologies Company P134 – North America Edition December 2014

Page 2

Contact Information

FETCO®

Food Equipment Technologies Company

600 Rose Road

Lake Zurich • IL • 60047-0429 • USA

Internet: www.fetco.com

Phone: (800) 338-2699 (US & Canada)

(847) 719-3000

Fax: (847) 719-3001

Email: sales@fetco.com

techsupport@fetco.com

Description & Features

The following are the factory settings—and range of variables that are adjustable:

Temperature Control:

(Temperature selectable 50-97°C/122°-208°F)

HWB-2105 Output Capacity:

HWB-2110 Output Capacity:

Commercial electrical requirements below

Water temperature is factory set at maximum 96°C/205°F

At least 19 liters/ 5 gallons of 96°C/205°F temperature hot water per hour

At least 38 liters/10 gallons of 96°C/205°F temperature hot water per hour

Specifications

FETCO HWB-2105 and HWB-2110 5 & 10 gallon per hour heavy-duty commercial hot water dispensers

Capacities & Measurements

Dispenser Height Width Depth

HWB-2105

HWB-2110

31½”

800mm

31½”

800mm

8”

203mm

11”

279mm

22¼”

565mm

22¼”

565mm

Empty

Weight

29 lb

13.2kg

47lb

21.3kg

Filled

Weight

55 lb

25 kg

92lb

41.7kg

Hot Water

Tank Capacity

4.4 gal

17.6 l

8.0 gal

30 l

Shipping

Weight

44lb

20kg

59lb

26.8kg

Shipping Dimensions

35inx11inx25in

889mmX279mmX635mm

35inx15inx27in

889mmX381mmX686mm

Electrical Rating Chart

Configuration

Code

5 gallon

B210551 1 X 3 kW 208-240 single 2+G Terminal Block-Hardwire 3.1 12.9 5 Gal/19 liters

B210552 1 X 4 kW 208-240 single 2+G Terminal Block-Hardwire 4.1 17.1 5 Gal/19 liters

10 gallon

B211051 2 X 3 kW 208-240 single 2+G Terminal Block-Hardwire 6.1 25.4 10Gal/38 liters

B211052 2 X 4 kW 208-240 single 2+G Terminal Block-Hardwire 8.1 33.8 10Gal/38 liters

Heater

Configuration

Voltage Phase Wires

North America Configuration -UL, cUL, NSF approved

*Flow rate based on 65°F/18.3°C water mains supply and dispensing from (““ "READY” status)

Electrical

Connection

kW

Maximum

Amp draw

Flow Rate

Per hour*

2

Page 3

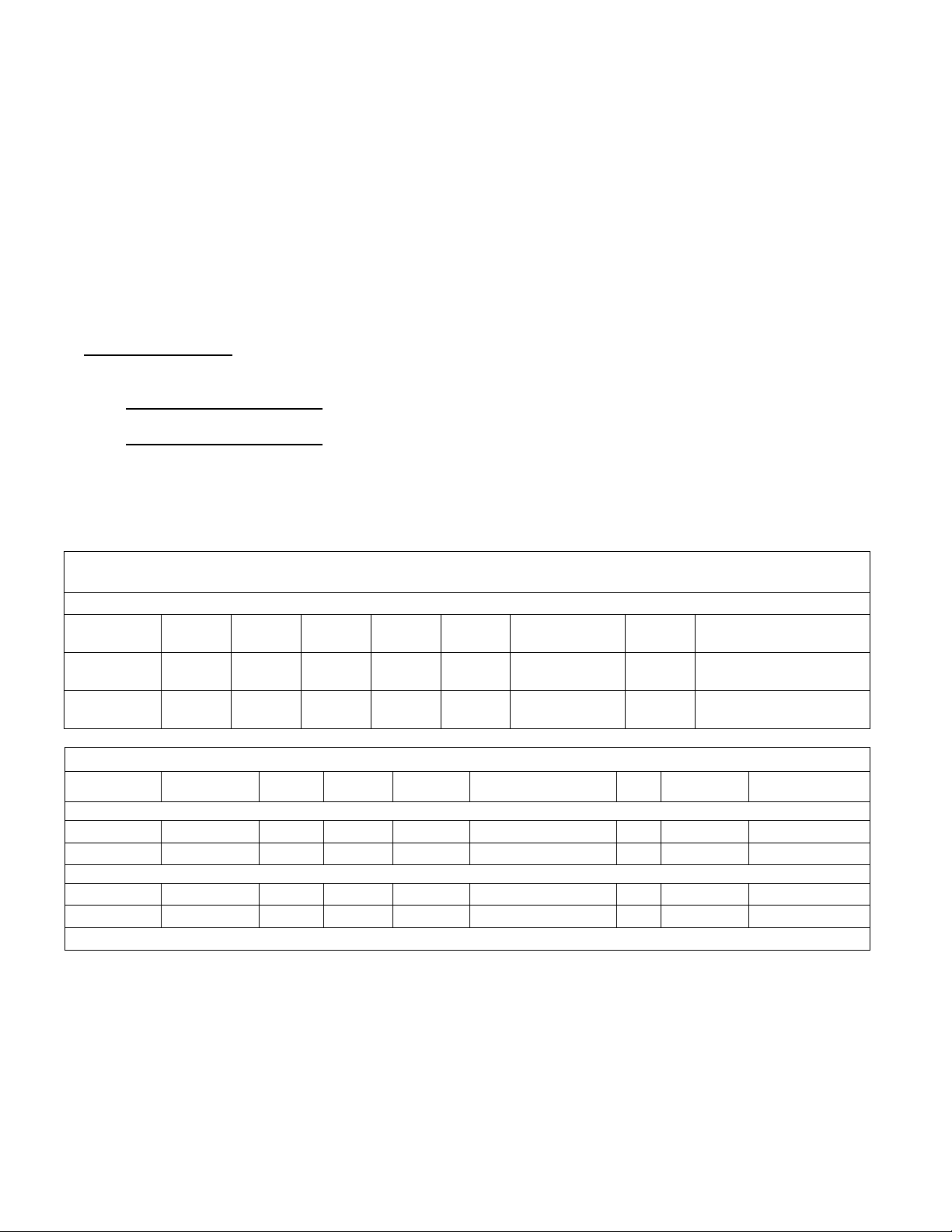

HWB-2105

Dimensions & Utility Connections

HWB-2110

DRG 1201.00015.00

3

DRG 1201.00016.00

Page 4

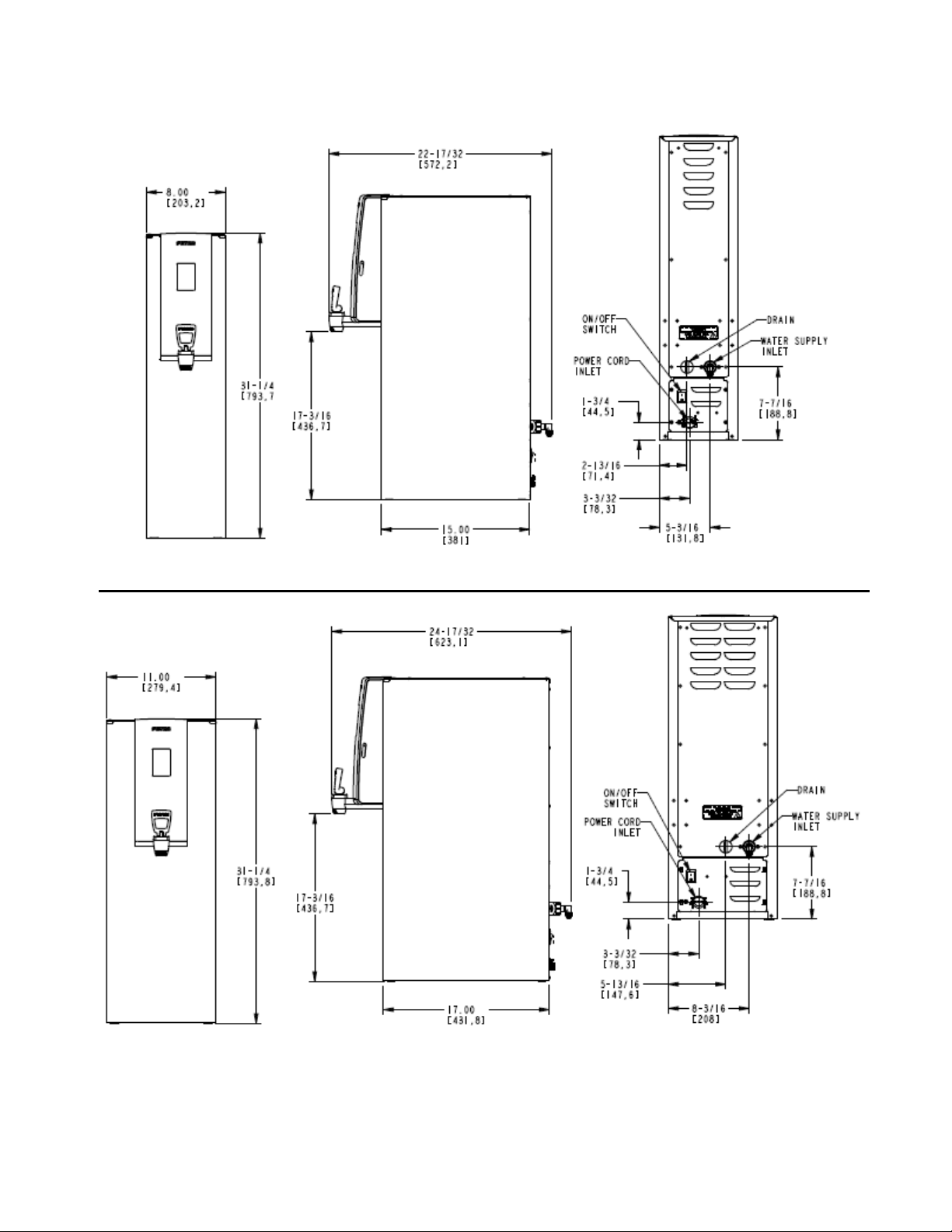

Operating Instructions

Follow instructions on pages 11-13 to install electrical and plumbing utilities. Turn on water supply.

Turn rocker switch “ON”. Switch is on the back of the equipment, at lower right.

The HWB will begin filling and heating taking 15-30 minutes to complete and the READY Icon to display.

The HWB may need to be turned “OFF” and restarted from the power switch if initial fill is too slow.

When the READY Icon displays, the machine in operation will dispense hot water at displayed temperature.

Equipment in now ready to use.

NOTE: For best results-leave the HWB “ON”. FETCO hot beverage equipment is well insulated and is designed to be left

“ON” overnight. An optional, automatic digital power saver ECO Mode may be activated if desired

Temperature is factory set for 205°F/96°. Setting may be changed from Programming Screens, or as below.

Operator controls, if activated, may be accessed by touching and holding lower part of screen.

-Hot water tank temperature may be selected using slider

-Equipment may be turned off and on from touch screen, touch screen will display “OFF” status.

.

Starting Screens

© 2015 All Rights

Ready

Heating

Filling

First Screen: Unit started:

And is Filling and Heating

-

Reserved

Tank Set Temp. °F

205

© 2015 All Rights

Ready

Heating

Filling

Unit “READY” to dispense

-

Reserved

Tank Set Temp. °F

205

Operator Access Screens

Set Tank Temp.

_____________[]_|

|

140

Operator Access is disabled. To

enable, go to PROGRAMMING,

OTHER, ALLOW EDIT TEMP

If Operator Access is disabled (

Energy Saving “ECO” Mode may be activated by touching“140” icon. Touch: EXIT” icon to turn off ECO Mode.

205 °F

140 208

EXIT

OFF

© 2015 All Rights

ECO

Heating

Filling

ECO mode icon displayed

Unit is in ECO mode after being

idle for more than four hours

-

Reserved

Tank Set Temp. °F

140

+ & - icons are dark), temperature will display, but cannot be adjusted.

© 2015 All Rights

Ready

Heating

Filling

Hold finger on lower touch screen

to access OPERATOR ACCESS

SCREENS and programming menu

Set Tank Temp.

_____________[]_|

|

140 208

140

“Operator Access Controls” Are

enabled, (the -&+ icons show)

-

Reserved

Tank Set Temp. °F

205

screens

205 °F

EXIT OFF

4

Page 5

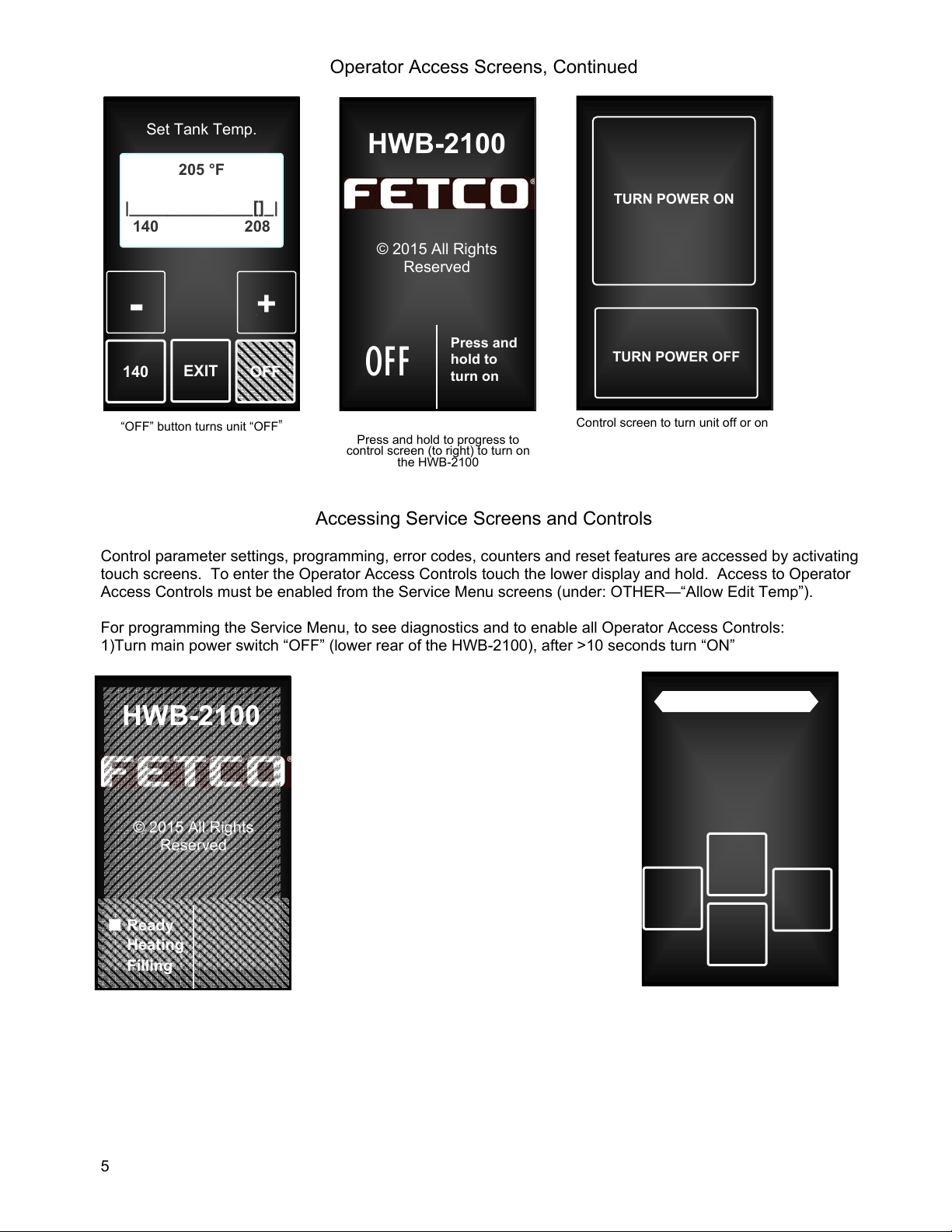

Operator Access Screens, Continued

Set Tank Temp.

_____________[]_|

|

-

140

“OFF” button turns unit “OFF

205 °F

140 208

\

+

EXIT

OFF

”

-

© 2015 All Rights

Reserved

OFF

Press and

hold to

turn on

Press and hold to progress to

control screen (to right) to turn on

the HWB-2100

TURN POWER ON

TURN POWER OFF

Control screen to turn unit off or on

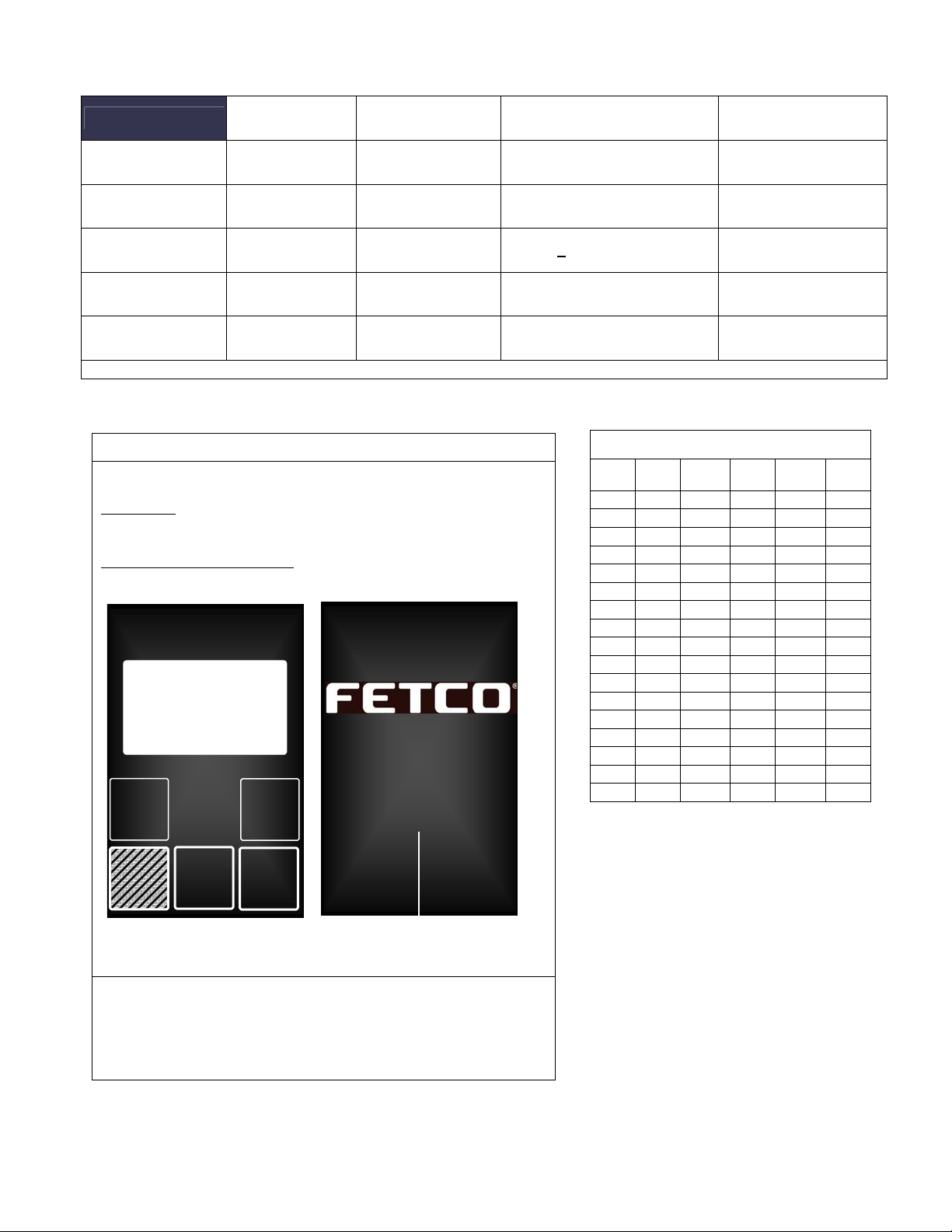

Accessing Service Screens and Controls

Control parameter settings, programming, error codes, counters and reset features are accessed by activating

touch screens. To enter the Operator Access Controls touch the lower display and hold. Access to Operator

Access Controls must be enabled from the Service Menu screens (under: OTHER—“Allow Edit Temp”).

For programming the Service Menu, to see diagnostics and to enable all Operator Access Controls:

1)Turn main power switch “OFF” (lower rear of the HWB-2100), after >10 seconds turn “ON”

2) Immediately touch upper touch the (upper) screen on: HWB-2100 display.

HWB-2100

© 2015 All Rights

Reserved

Ready

Heating

Filling

Tank Set Temp. °F

205

ÅTO ENTER PROGAMMING

From Power “OFF” state

Turn power switch “ON”

Within 5 seconds of display shown

Touch and hold to enter the

programming screens.

(

Entering Service Screen shown below)

To enter operator service screens

ÅFrom any screen, touch and hold lower

display on screen to access the

“Operator Access Controls

”

GENERAL SETUP

‹ Tank Temp. ›

◄

EXIT

▼

►

First Service Screen to show when

entering “GENERAL SETUP”

Use arrow icons to scroll through

the menu. The DOWN icon will

open the FEATURE icon below.

Scroll through the FEATURE icon

with the arrows EXIT and save

changes.

5

Page 6

Service Menu

General Service Menu, Inputs Service Menu, Outputs Service Menu and Other Service Menu.

-Enter Service Menu by accessing the power switch on back of the panel—switching into Power “OFF”

state

-After at least thirty seconds: Turn power switch “ON”

-Touch and hold Upper HWB Logo to enter the programming screens.

-When entering The SERVICE MENU: the first screen is “GENERAL SETUP”

-Use right and left arrow icons to scroll through the four main SERVICE menus.

-The DOWN icon will open the FEATURE icon below.

-Scroll through the FEATURE icon with the arrows EXIT and save changes

-A Menu Tree is below to show the main categories of the four SERVICE menus.

GENERAL SETUP

Tank Temp

INPUTS

Display Inputs

OUTPUTS

Show Summary

OTHER

Error Codes

EXIT

GENERAL

Tank Temp

Temperature Units

Volume Units

Fill Priority

ECO Mode

EXIT

INPUTS OUTPUTS

Display Inputs

Calib Touch Screen

EXIT

EXIT

Fill Valve

Heater

Screen

Allow Edit Temperature

OTHER

Error Counter

Copy Settings

Upload LOGO

Electrical Summary

Reset to Factory

Firmware

Counters

DEMO Mode

6

Page 7

First Service Menu screen: GENERAL

GENERAL

Tank Temp.

Temp Units

Vol Units

Priority

ECO Mode

Programming

Items

205°F/96°C

• Temperature

• Volume

• Temperature

• Volume

NORMAL

*Refill rate TEMPERATURE may be slower at large volume dispense, and will stay closed to set temperature

ECO Mode option, screen definitions

“ECO” mode, or digital power economy control feature may be

activated to save energy in standby state.

If selected,

after four hours of non-use—controls automatically

lower the tank temperature to 140°F/60°C, or can be selected to

turn heaters “OFF”

To restore set temperature:

Touch the screen to come out of ECO mode

Set Tank Temp.

_____________[]_|

|

205 °F

140 208

140

EXIT

TO activate ECO Mode:

FROM Operator access screen:

Press “140”

OFF

ECO

Heating

Filling

Unit is in ECO mode after being

All FETCO commercial hot beverage equipment have well

insulated hot water tanks to limit energy consumption.

Effective insulation increases equipment life and lowers

building HVAC costs. FETCO has the best energy savings of

all major suppliers.

Factory set

Default

°F

US G

Volume is default

-

© 2015 All Rights

Reserved

Tank Set Temp. °F

140

ECO mode icon displayed

idle for more than four hours

Programming Range

(display)

200 °F

|______________[]___|

140 208

|___[]____________|

|____[]

US G UK G L

|___________________[]__|

Temperature Volume

|__[]____________________|

DIS TO 140 TO OFF

°F

°F °C

U S Gallons

__________________|

Change

ECO Mode

Chart to correct for altitude for boiling point

[ft] [m]

0 0 205 212.0 96 100.0

500 152 205 211.0 96 99.5

1000 305 200 210.1 93 98.9

2000 610 200 208.1 93 97.8

2500 762 200 207.2 93 97.3

3000 914 200 206.2 93 96.8

3500 1067 197 205.3 92 96.3

4000 1219 195 204.3 91 95.7

4500 1372 194 203.4 90 95.2

5000 1524 194 202.4 90 94.7

5500 1676 193 201.5 89 94.2

6000 1829 192 200.6 89 93.6

6500 1981 191 199.6 88 93.1

7000 2134 190 198.7 87 92.6

7500 2286 188 197.8 86 92.1

8000 2438 187 196.9 86 91.6

8500 2591 185 196.0 85 91.1

in tank water temperature.

Suggested

Setting[°F]

Notes

Correction for high

altitude below

US gallons differ from

UK (Imperial) gallons

Refill rate: Slower”

Refill rate:” Quick”

See chart below

Boiling

Suggested

point[°F]

Setting[°C]

point [°C]

Boiling

7

Page 8

Service Menu screens, continued: Second/Third Service Menu screen INPUTS & OUTPUTS

INPUTS

Display Inputs

Cal. Touch Scr

OUTPUTS

Fill Valve

Heater

Screen

Programming

Items

• Input

Summery

Programming

Items

• Fill Valve Test

• Heater Test

• Screen

Contrast

• S. Brightness

Factory set

Default

Calibrate

Factory set

Default

(Press to test)

(Press to test)

Contrast

Brightness

Programming Range

(display)

Level probe Low

Level probe High

Temp. Probe 1

Temp. Probe 1

Temp. Probe 2

Temp. Probe 2

SD Card present

Float Switch

Calibrate

________________[]____

YES NO

Programming Range

(display)

TEST

Press To Test

TEST

Press To Test

|____________[]____|

1 10

|____________[]____|

1 10

8

8

205F

158F

Follow directions on

the touch screen

Operates fill valve.

Have container under

both brewbaskets!

Energizes Heater(s)

Use for servicing.

HWB-2100

© 2015 All Rights

Ready

Heating

Filling

Reserved

Unit shown in

“DEMO MODE”

(Bottom Page 9)

Notes

If Yes

:

Notes

Tank Set Temp°F

205

Æ

8

Page 9

Service Menu screens, continued: Fourth Service Menu screen: OTHER

OTHER

Error Codes

Copy Settings

Upload Logo

Electrical

Summary

Res to

Factory

Firmware

• Update

Firmware

Counters

Allow Edit

Temp

DEMO Mode

Å (Example)

Programming

Items

• Display Errors (Codes)

• Reset Errors

• From SD to B.

• From B to SD

Factory set

Default

(Reset)

SDÆ HWB

HWBÆ SD

Upload Logo

• Firmware

Version

-Software type

UPDATE

• Display

Counters

-OR-

• Reset

Counters

• Reset

Counters

• Turns control

ON/OFF

Reset to default†

Firmware Version

UPDATE

|________________[]____|

YES NO

Counters

Display Total

Counters

Reset All Counters

Allows controls to

function without

machine in operation

Programming Range

(display)

ERRORS

Last 4 errors

202

101

200

200

(most recent at bottom)

|_______________[]____|

|________________[]____

|________________[]____|

|________________[]____|

Electrical Configuration Summary

Model Number†

Heater Power†

Heaters Number

Mains Voltage†

Tank Capacity

In. water temp.†

Valve f/r

|________________[]____|

----------------------------------------------------------------------------

Please insert SD card with the

Valve pulses

Valve-on

Water Vol.

Heater pulses

Heater-on

Energy consumed

Power-ups

ON time

Touch To Return

Reset All Counters*

|________________[]____|

|_______________[]____|

|_____[]_____________|

Reset

YES NO

SDÆ Brewer

YES NO

BrewerÆ SD

YES NO

UPLOAD LOGO

Are you sure

YES NO

4.9 (2105) (or) 9.5

(2110)

2105 (or) 2110

3.0 kW (or) 4.0 kW

1 (or) 2

208 (or) 240

62°F 0.66 GPM

Reset to Default

Are you sure

YES NO

SW ver. _ _-._._ _

HW ver

BL ver._._. _

QP ver. _._ _._ _

Firmware upload

firmware file!

Total Counters

0-∞

xxm yys

1.0 US G

5

46s

57.5 Wh

41

3h 40m 18s

Are you sure

YES NO

Enable User Mode

NO YES

Demo Mode

YES NO

Notes

Chart is below

!!Errors must be

corrected and

cleared!!

Setup upload

Please insert SD card with

the setup data!

Setup upload

Please insert SD card with

sufficient space

Please insert SD

card with logo file!

† Values must be entered

when Resetting to factory

defaults. Values displayed

(left) are most common and

generally useable.

† Values must re-enterd as

seen in “Electrical

Summary” screen (ABOVE)

Displays current

firmware version

• Update Firmware

Resetting will

restart counter

from zero

If YES, operator

adjust the tank

temperature.

Operation Display

screen shows

“DEMO”Æ

(≥2GB)

can

D

E

M

O

9

Page 10

Error Codes

Description

Recommended Corrective Action for

Service

OK 0 No error

SOFTWARE ERROR 2

EE CRC WRONG 4

There was a problem with the internal

program

The internal data memory malfunction

(EE CRC)

TEMP SENSOR SHORT 1 50 Short circuit in temperature probe T1 Check board or probe

TEMP SENSOR OPEN 1 51 Temperature probe circuit is open T1 Check board or probe

TEMP SENSOR SHORT 2 50 Short circuit in temperature probe T2 Check board or probe

TEMP SENSOR OPEN 2 51 Temperature probe circuit is open T2 Check board or probe

PREFILLING TOO LONG 100 Tank initial filling is taking too long

Tank Overflow Error - May be boiling

OVER FLOW 103

1-Hot water tank may be steaming or

boiling due to altitude.

XCHANGED 106

TANK WATER LEVEL IS

TOO LOW

EMPTY TANK OVERHEAT 114

The LLC probes' connectors have been

reversed

The tank has been drained beyond the

107

low level sensor.

Temp. probe fault - empty tank is too

hot

Temp.probe fault –

TEMP ≥100C 115

the temp is above water boiling point.

Possible bad probe

WATER BOILING 200

e.g. user set temp 90°C & water boils

at 85°C

HEATER OPEN 201 Heater circuit is open Heater open, high limit thermostat,

SSR SHORTED 202

The Solid State Relay failed

(short circuit)

Machine needs to be power cycled to

POWER CYCLE NEEDED 254

write new values to the EEPROM

memory

TOUCH SCREEN 255

A problem with the LCD Touch Screen,

touched too long (>2 min)

Display Inputs

(See “INPUTS”

Service Screen)

Use DISPLY INPUTS screen to assist in error code fault correction.

There are two Temp.Probes shown as Temp Probe1&2 Temp Probe1 is

the Hot Water Tank Temp Probe 2 is the overflow sensor probe

10

Remedy

replace board

replace board

Water turned off, clogged filter,

Turn equipment off, restore power,

clear error, and proceed

Liquid level probe fault,

Correct temperature set point for

altitude, see chart page-7.

Turn equipment off, service probes,

restore power, clear error, and

proceed

Check for Tank leakage, water turned

off.

Turn equipment off, allow to cool,

service fault, restore power, clear

error, and proceed

Turn equipment off, allow to cool,

service fault, restore power, clear

error, & proceed

Check probe position, check heaters

Also see Error Eode 103-above

Solid State Relay (SSR) fault

Power cycle the machine

(Turn OFF-Then ON)

Power cycle the machine

(Turn OFF-Then ON)

Level probe Low

Level probe High

Temp. Probe 1

Temp. Probe 1

Temp. Probe 2

Temp. Probe 2

SD Card present

Float Switch

215F

158F

Page 11

Installation Instructions

Equipment Setup

1. Read User Guide noting all instructions. Review the dimensions for the unit you are installing.

Verify that it will fit in the space intended for it.

Verify that the counter or table will support the total weight of the equipment and any dispensers when filled.

2. Place the equipment on the counter or stand.

GROUND

Illustrations above show examples of domesic terminal block and location of connections and utilities.

ÆAlways refer to the wiring diagrams when connecting equipment electrical utilities

Water Connection

1. Water supply inlet is a ⅜ inch male flare fitting.

2. The Hwb-2100 Hot Water Dispenser can be connected to a cold or hot water line.

(Cold water is preferred for best beverage flavor, but hot water will allow for greater output.)

3. Install a shut off water valve near the equipment to facilitate service. An in-line water filter should used and

installed after the water shut off valve and in a position to facilitate filter replacement.

4. Flush the water supply line and filter before connecting it to the unit.

5. Verify that the water line will deliver a flow rate of at least 1½gpm/(5.7lpm) per minute and water pressure is

between 20-75 psig (138-517kPa) before making any connections.

6. Use a wrench on the factory fitting when connecting the incoming water line. This will reduce stress on the

internal connections and reduce the possibility of leaks developing after the install has been completed.

Electrical Connection

1. The HWB-2100 model series requires hardwired grounded service to the terminal block (illus. 1)

2. Verify that the actual voltage at the electrical service connection is compatible with the specifications on the

equipment serial number label. Make sure the electrical service match the current draw of the equipment.

3. Access the terminal block for electrical connection by removing the pullout service module on the lower back.

4. A fused disconnect switch or circuit breaker on the incoming power line must be conveniently located near the

equipment and its location and markings known to the operators.

5. The body of the unit must be grounded to a suitable building ground.

6. If Cord Connected: Do not use multiple taps for the plug. Consult local codes to determine if a single circuit is

required for the cord and plug installed. Do not use extension cords for commercial food equipment

Tank Drain

The water tank must be drained before maintenance procedures, and when the unit is to be relocated or shipped.

1. Disconnect power to the unit.

2. Move the unit near a sink or obtain a container to large enough to hold four gallons of water.

3. Remove the tank cover and allow the tank to cool to a safe temperature.

4. The tank drain is located on the back of the unit. Turn the drain plug one-quarter turn in either direction.

5. Pull the plug out far enough to expose the silicone tube.

6. Using pliers loosen the hose clamp and move it back over the tube.

7. Crimp the tube an inch or two away from the drain plug to prevent water from flowing.

8. Use the other hand to pull the drain plug out of the tube.

9. Release the crimped tube and allow the water to flow into the sink or container.

L1 L2

200-240V ac, 50-60Hz

North America

Domestic

11

Page 12

Ready

Heating

Filling

HWB-2100 display on start-up

Ready

Heating

Filling

Screens shown in Final Setup #5

Final Setup

1. Turn on the incoming water supply line and inspect both inside and outside of the equipment for leaks in all

fittings and tubes

2. Turn on the incoming power.

3. Turn on the power switch, located in the back of the unit.

4. Activate touch screen to turn equipment on.

5. The HWB-2100 display will show “Filling” and “Heating” icons (see illustration above) on start-up

6. The hot water tank will begin filling and will stop when the water is sensed by the probe at the top of the tank.

The heaters are disabled by the control board until the tank is full. Unit may need to be restarted during first fill.

7. The temperature and water tank fill level are pre-set at the factory. There is no need to turn off the heaters

during the installation process. The heaters are disabled by the control board until the tank is full of water. The

heating process will start automatically when the tank has filled.

8. Heaters will turn on when covered by water. Touch Screen displays status while the water is heating—there is

no “ready” light. After the water has reached the set temperature, the “ready” icon will turn on. (see ill. above)

9. Inspect for leaks. Look closely in the top and beneath the equipment and check all fittings during this

inspection.

Operator Training

Review the operating procedures with whoever will be using the equipment. Pay particular attention to the

following areas:

1. Show the location and operation of the water shut off valve as well as the circuit breaker for the unit.

2. We recommend leaving the power to the equipment on overnight. The water tank is well insulated and will use

very little electricity to keep the tank hot. Leaving the equipment in the “on” position will also avoid delays at

the beginning of shifts for the hot water dispenser to reach operating temperature.

Safety Notes

Professional installation is required. This appliance is manufactured for commercial use only.

Operation requirements and maintenance for commercial cooking appliances differ from household appliances.

Operators must be trained for this equipment and must understand the use, maintenance and kitchen hazards.

Do not attempt to move hot beverage equipment once it is filled. Drain equipment before moving.

The HWB-2100 Hot Water Boilers provides very hot water from the faucet when it is pulled.

HWB-2100 may continue to dispense very hot water from the mechanically operated faucet after the electronic

touchpad is completely disabled, or if the power is turned off, or by unplugging the unit.

Keep these instructions for training and future reference

HWB-2100 display” Ready”

Tank Set Temp. °F

205

Tank Set Temp. °F

205

12

Page 13

Installation safety and hygiene directions

1. Access to the service area is restricted to persons having safety/hygiene knowledge and practical experience of

the coffee brewer. This appliance must be installed in locations where it can be overseen by trained personnel.

2. For proper operation, this appliance must be installed indoors where the temperature is between 10°C/50°F to

35°C/95°F. Drain and remove al liquid from equipment and lines if exposed to freezing temperatures.

3. All commercial cooking equipment, including this unit, is not intended for use by children or persons with

reduced physical, sensory, or mental capabilities. Ensure proper supervision of children and keep them away

from the unit.

4. Children should be supervised to ensure that they do not play hot beverage equipment.

5. This unit must be installed and serviced by qualified personnel only.

6. Installation must conform to all local electrical and plumbing codes. Installation by unqualified personnel will void

the unit warranty and may lead to electric shock or burn, as well as damage to unit and/or its surroundings.

7. If the power cord requires repair or replacement-it must be performed by the manufacturer or authorized service

personnel with the specified cord only from the manufacturer in order to avoid a hazard.

8. Review the dimensions for the unit and verify that it will fit properly in the space intended for it. Verify that the

counter or table will support the total weight of the brewer and dispensers when filled (See: Technical Data).

9. Place the brewer on the counter or stand. When the brewer is in position, level it front to back as well as side-toside by adjusting the legs.

10. Do not tilt appliance more than 10° to insure safe operation.

11. Unit is for protected indoor use only. Do not steam clean or use excessive water on unit.

12. This unit is not “jet-proof” construction. Do not pressure wash or use jet spray to clean this unit.

13. The unit is not waterproof-do not submerge or saturate with water.

Do not operate if unit has been submerged or saturated with water.

Equipment exposed to flood and contaminated must not be used due to electrical and food safety.

Labels and warnings for hot beverage equipment

For FRONT of equipment (1046.00036.00) For BACK PANEL of equipment (1046.00035.00)

13

Page 14

Parts and Service drawings

Drawing 1101.00201

14

(229)(217).00 HWB-2105 Complete Parts

Page 15

Complete Parts Drawing 1101.00201

(229)(217).00 HWB-2105

# QTY PART NO DESCRIPTION

1 1 1111.00050.00 WELDMENT BODY COMPLETE, HWB-2105

2 4 1021.00018.00 LEG, TBS 2121

3 1 1104.00072.00 TANK ASSEMBLY, 3000W/240VAC, HWB-2105

3 1 1104.00078.00 TANK ASSEMBLY, 4000W/240VAC, HWB-2105

4 5 1083.00011.00 WASHER, #8 SCREW SIZE, INTERNAL TOOTH LOCK

5 5 1084.00006.00 NUT, 8-32 18-8 HEX MACHINE SCREW

6 1 1057.00059.00 VALVE, 0.66 GPM BRN FLOW REG, 180DEG/24VDC

7 2 1083.00005.00 WASHER, M4 18-8 INTERNAL TOOTH LOCKWASHER

8 2 1082.00010.00 SCREW, M4x10 ZINC PLATED PAN PHILLIPS MACHINE

9 1 1102.00243.00 ADAPTER ASSY, 3/4" BSP x 1/4" NPT x 3/8" TUBE

10 1 1023.00147.00 PLUG, TANK SERVICE DRAIN FOR 18GA AND UP BODY

11 1 1025.00061.00 TUBE, 9/16'OD X 5/16"ID X 2.75"LG

12 6 1086.00003.00 UNICLAMP, 15.9 HOSE OD CLAMP

13 1 1029.00002.00 FITTING, HOSE BARB TEE, SIZE 3/8" , NYLON

14 1 1025.00058.00 TUBE, 9/16'OD X 5/16"ID X 25.00"LG

15 1 1024.00067.00 CONNECTOR, SILICONE, TANK TO FAUCET, HWB-2100

16 10 1084.00011.00 NUT, CLIP ON (J-NUT), #6-32, 22-20 GA., BLK-PH FINISH

17 1 1102.00247.00 ASSEMBLY BACK PANEL, HWB-2105 UL

17 1 1102.00262.00 ASSEMBLY BACK PANEL, HWB-2105 CE

18 11 1082.00017.00 SCREW, # 6-32 X 1/2" TRUSS HD PHIL., MACHINE

19 1 1046.00030.00 LABEL WARNING, DISCONNECT FROM POWER SOURCE

20 2 1023.00159.00 CORNER INSERT

21 1 1023.00208.00 FAUCET BODY, HWB-2100

22 1 1102.00228.00 ASSEMBLY FRONT PANEL, HWB-2100

23 4 1082.00058.00 SCREW, # 8-32 X 5/8, FLAT HD, PH, 18-8 SS

24 1 1102.00230.00 ASSEMBLY, UPPER FAUCET, HWB-2100

25 1 1029.00029.00 FAUCET, SILICONE, HWB-2100

26 1 1024.00040.00 CARD PLUG, HWD-2100

27 1 1001.00169.00 TOP COVER, HWB 2105

28 1 1402.00067.00 HARNESS, LOW AMP, HWB-2105/2110, CE/ UL

29 1 1402.00066.00 HARNESS, HI AMP, HWB-2105 UL

30 1 1024.00050.00 GROMMET, SILICONE, 11.4mm ID

31 1 1023.00168.00 FITTING, HOT WATER, GROMMET DESIGN

32 1 1065.00009.00 GROUND LUG CONNECTOR, 14-2 AWG, ALUMINUM

33 1 1083.00016.00 WASHER, #8 SCREW SIZE, FLAT

34 1 1044.00003.00 LABEL GROUND

35 1 1025.00094.00 TUBE, 9/16 OD x 5/16 ID x 29" LG.

36 1 1086.00002.00 CLAMP, HOSE, SIZE "G" NYLON

37 1 1086.00033.00 HOSE CLAMP, NYLON BLACK, Ø1.25"-1.437" RANGE CLAMP

38 1 1025.00095.00 TUBE, 9/16 OD x 5/16 ID x 2.25 LG.

39 1 1001.00181.00 COVER FRONT, CBS-2100 XTS

40 1 1041.00021.00 LABEL FETCO, ETCHED GLASS TYPE, 10.375" L

41 1 1041.00022.00 LABEL, HWB-2105

42 1 1046.00036.00 LABEL,HOT WATER CAUTION, HWB-2100

43 1 1046.00035.00 LABEL, WARNING, HWB-2100

15

Page 16

HWB-2110 Complete Parts Drawing 1101.00202.00

16

Page 17

Complete Parts Drawing 1101.00202.00 HWB-2110

# QTY PART NO DESCRIPTION

1 1 1111.00051.00 WELDMENT BODY COMPLETE, HWB-2110

2 4 1021.00018.00 LEG, TBS 2121

3 1 1104.00073.00 TANK ASSEMBLY, 2 X 3000W/240VAC, HWB-2110

4 5 1083.00011.00 WASHER, #8 SCREW SIZE, INTERNAL TOOTH LOCK

5 5 1084.00006.00 NUT, 8-32 18-8 HEX MACHINE SCREW

6 1 1057.00059.00 VALVE, 0.66 GPM BRN FLOW REG, 180DEG/24VDC

7 2 1083.00005.00 WASHER, M4 18-8 INTERNAL TOOTH LOCKWASHER

8 2 1082.00010.00 SCREW, M4x10 ZINC PLATED PAN PHILLIPS MACHINE

9 1 1102.00243.00 ADAPTER ASSY, 3/4" BSP x 1/4" NPT x 3/8" TUBE

10 1 1023.00147.00 PLUG, TANK SERVICE DRAIN FOR 18GA AND UP BODY

11 1 1025.00061.00 TUBE, 9/16'OD X 5/16"ID X 2.75"LG

12 6 1086.00003.00 UNICLAMP, 15.9 HOSE OD CLAMP

13 1 1029.00002.00 FITTING, HOSE BARB TEE, SIZE 3/8" , NYLON

14 1 1025.00058.00 TUBE, 9/16'OD X 5/16"ID X 25.00"LG

15 1 1024.00067.00 CONNECTOR, SILICONE, TANK TO FAUCET, HWB-2100

16 10 1084.00011.00 NUT, CLIP ON (J-NUT), #6-32, 22-20 GA., BLK-PH FINISH

17 1 1102.00248.00 ASSEMBLY BACK PANEL, HWB-2110 UL

17 1 1102.00263.00 ASSEMBLY BACK PANEL, HWB-2110 CE

18 11 1082.00017.00 SCREW, # 6-32 X 1/2" TRUSS HD PHIL., MACHINE

19 1 1046.00030.00 LABEL WARNING, DISCONNECT FROM POWER SOURCE

20 2 1023.00159.00 CORNER INSERT

21 1 1023.00208.00 FAUCET BODY, HWB-2100

22 1 1102.00228.00 ASSEMBLY FRONT PANEL, HWB-2100

23 4 1082.00058.00 SCREW, # 8-32 X 5/8, FLAT HD, PH, 18-8 SS

24 1 1102.00230.00 ASSEMBLY, UPPER FAUCET, HWB-2100

25 1 1024.00040.00 CARD PLUG, HWD-2100

26 1 1001.00200.00 TOP COVER, HWB 2110

27 1 1029.00029.00 FAUCET, SILICONE, HWB-2100

28 1 1024.00050.00 GROMMET, SILICONE, 11.4mm ID

29 1 1023.00168.00 FITTING, HOT WATER, GROMMET DESIGN

30 1 1402.00067.00 HARNESS, LOW AMP, HWB-2105/2110, CE/ UL

31 1 1402.00065.00 HARNESS, HI AMP, HWB-2110 UL

32 1 1065.00009.00 GROUND LUG CONNECTOR, 14-2 AWG, ALUMINUM

33 1 1083.00016.00 WASHER, #8 SCREW SIZE, FLAT

34 1 1044.00003.00 LABEL GROUND

35 1 1025.00094.00 TUBE, 9/16 OD x 5/16 ID x 29" LG.

36 1 1086.00002.00 CLAMP, HOSE, SIZE "G" NYLON

37 1 1086.00033.00 HOSE CLAMP, NYLON BLACK, Ø1.25"-1.437" RANGE CLAMP

38 1 1025.00095.00 TUBE, 9/16 OD x 5/16 ID x 2.25 LG.

39 1 1001.00181.00 COVER FRONT, CBS-2100 XTS

40 1 1041.00021.00 LABEL FETCO, ETCHED GLASS TYPE, 10.375" L

41 1 1041.00023.00 LABEL, HWB-2110

42 1 1046.00035.00 LABEL, WARNING, HWB-2100

43 1 1046.00036.00 LABEL,HOT WATER CAUTION, HWB-2100

17

Page 18

HWB-2105 Hot Water Tank Drawing 1104.00072

18

(78)

Page 19

HWB-2105 Hot Water Tank Drawing 1104.00072

(78)

# QTY PART NO DESCRIPTION

1 1 1114.00107.00 WELDMENT, TANK, HWB-2105

2 2 1024.00053.00 LEVEL AND TEMP PROBE GROMMET

3 1 1102.00234.00 PROBE ASSEMBLY, TEMP. AND LLC 12" LONG

4 3 1024.00050.00 GROMMET, SILICONE, 11.4mm ID

5 1 1023.00166.00 FITTING, COLD WATER INLET, GROMMET DESIGN

6 1 1003.00005.00 BRACKET, ONE SHOT THERMOSTAT

7 1 1053.00004.00 THERMOSTAT, SINGLE SHOT, 25A

8 2 1083.00009.00 WASHER, #6 SCREW , INTL TOOTH LOCKWASHER

9 2 1084.00010.00 NUT, HEX, #6-32, UNDERSIZED, ZINC PLATED

10 2 1023.00212.00 FITTING, VENTING BOX

11 1 1112.00336.00 PROBE WELDMENT, WATER LEVEL 5.00" LG

12 1 1107.00034.00 HEATER ASSEMBLY, IMMERSION 3000W/240VAC

12 1 1107.00035.00 HEATER ASSEMBLY, IMMERSION 4000W/240VAC

13 1 1024.00007.00 O-RING, DASH #344, TANK COVER

14 1 1102.00007.00 TANK COVER ASSEMBLY

15 1 1003.00140.00 ALUMINUM BRACKET FOR SSR

16 1 1052.00033.00 RELAY, SOLID STATE, 50A/480VAC, W/BUILD IN VARISTOR

17 2 1081.00042.00 STANDOFF, 1/4" HEX

18 1 1023.00203.00 FITTING, BREW, GROMMET DESIGN

19 1 1044.00004.00 LABEL, DANGER-HIGH VOLTAGE

20 1 1102.00244.00 ASSEMBLY, VENTING BOX

21 1 1025.00022.00 TUBE, 5/8"OD X 3/8"ID X 1.25"LG, BY-PASS

22 1 1102.00242.00 ASSEMBLY, TEMPERATURE SENSOR

23 1 1025.00089.00 TUBING, 1/2ID X 3/4OD X 1/2 LG.

24 1 1022.00078.00 TANK INSULATION, HWB-2105

25 1 1023.00222.00 FITTING, FLOW RESTRICTOR, HWB-2100 TANKS

19

Page 20

20

Page 21

HWB-2110 Hot Water Tank Drawing 1104.00077

(73).00

# QTY PART NO DESCRIPTION

1 1 1114.00111.00 WELDMENT TANK, HWB-2110

2 2 1024.00053.00 LEVEL AND TEMP PROBE GROMMET

3 1 1102.00234.00 PROBE ASSEMBLY, TEMP. AND LLC 12" LONG

4 3 1024.00050.00 GROMMET, SILICONE, 11.4mm ID

5 1 1023.00166.00 FITTING, COLD WATER INLET, GROMMET DESIGN

6 2 1023.00212.00 FITTING, VENTING BOX

7 1 1112.00336.00 PROBE WELDMENT, WATER LEVEL 4.00" LG

8 1 1002.00127.00 BRACKET STIFFENER TANK TOP - 2110

9 2 1107.00034.00 HEATER ASSEMBLY, IMMERSION 3000W/240VAC

9 2 1107.00035.00 HEATER ASSEMBLY, IMMERSION 4000W/240VAC

10 1 1024.00007.00 O-RING, DASH #344, TANK COVER

11 1 1102.00007.00 TANK COVER ASSEMBLY

12 2 1003.00140.00 ALUMINUM BRACKET FOR SSR

13 2 1052.00033.00 RELAY, SOLID STATE, 50A/480VAC, W/BUILD IN VARISTOR

14 4 1081.00042.00 STANDOFF, 1/4" HEX

15 1 1023.00203.00 FITTING, BREW, GROMMET DESIGN

16 1 1044.00004.00 LABEL, DANGER-HIGH VOLTAGE

17 1 1102.00244.00 ASSEMBLY, VENTING BOX

18 1 1025.00022.00 TUBE, 5/8"OD X 3/8"ID X 1.25"LG, BY-PASS

19 1 1102.00242.00 ASSEMBLY, TEMPERATURE SENSOR

20 1 1025.00089.00 TUBING, 1/2ID X 3/4OD X 1/2 LG.

21 1 1022.00079.00 TANK INSULATION, HWB-2110

22 2 1003.00005.00 BRACKET, ONE SHOT THERMOSTAT

23 2 1053.00003.00 THERMOSTAT, SINGLE SHOT, 240V/40A

24 4 1083.00009.00 WASHER, #6 SCREW , INTL TOOTH LOCKWASHER

25 4 1084.00010.00 NUT, HEX, #6-32, UNDERSIZED, ZINC PLATED

26 1 1023.00222.00 FITTING, FLOW RESTRICTOR, HWB-2100 TANKS

21

Page 22

1102.00248.00 ASSEMBLY BACK PANEL, HWB-2110 UL

# QTY PART NO DESCRIPTION

1 1 1112.00317.00 WELDMENT BACK PANEL, HWB-2110

2 1 1086.00008.00 CONNECTOR, CABLE CLAMP, 3/4"

3 1 1058.00024.00 SWITCH, POWER, DOUBLE POLE, 16A, 125/250 VAC

4 1 1003.00170.00 BRACKET, GUARD

5 8 1081.00006.00 SPACER, 6MM OD x 3.2MM ID x 5MM LG, Z/P

6 1 1052.00001.00 POWER SUPPLY, 90-264VAC/24VDC, 1.8A

7 4 1029.00012.00 SPACER, .25" HEX X 1" LG, FEM #4-40 THREAD

8 1 1112.00246.00 WELDMENT BRACKET TERMINAL BLOCK, 3 POLE

9 1 1083.00011.00 WASHER, #8 SCREW SIZE, INTERNAL TOOTH LOCK

10 3 1084.00006.00 NUT, 8-32 18-8 HEX MACHINE SCREW

11 1 1052.00022.00 EUROSTRIP HE6 TERM. BLK., 3 POLE, 40AMP,10-20 TERM. BLK

12 1 1052.00025.00 PLATE, MARKING #BS1016E

13 1 1082.00082.00 SCREW, PHILLIP HD., 8-32 THREAD

22

Page 23

1102.00247.00 ASSEMBLY BACK PANEL, HWB-2105 UL

# QTY PART NO DESCRIPTION

1 1 1112.00313.00 WELDMENT BACK PANEL, HWB-2105

2 1 1086.00008.00 Cable Back Connector ¾”

3 1 1058.00024.00 SWITCH, POWER, DOUBLE POLE, 16A, 125/250 VAC

4 1 1003.00170.00 BRACKET, GUARD

5 8 1081.00006.00 SPACER, 6MM OD x 3.2MM ID x 5MM LG, Z/P

6 1 1052.00001.00 POWER SUPPLY, 90-264VAC/24VDC, 1.8A

7 4 1029.00012.00 SPACER, .25" HEX X 1" LG, FEM #4-40 THREAD

8 3 1083.00011.00 WASHER, #8 SCREW SIZE, INTERNAL TOOTH LOCK

9 3 1084.00006.00 NUT, 8-32 18-8 HEX MACHINE SCREW

10 1 1112.00246.00 WELDMENT BRACKET TERMINAL BLOCK, 3 POLE

11 1 1052.00022.00 EUROSTRIP HE6 TERM. BLK., 3 POLE, 40AMP,10-20 TERM. BLK.

12 1 1052.00025.00 PLATE, MARKING #BS1016E

13 2 1082.00082.00 SCREW, PHILLIP HD., 8-32 THREAD

Wiring Diagrams

Follow

23

Page 24

Page 25

Loading...

Loading...