Page 1

User’s Guide

www.fetco.com

Hot Water Dispenser

Table of Contents

Contact Information ........................................................2

Specifications..................................................................2

Dimensions & Utility Connections...................................2

Installation.......................................................................3

Operating Instructions ....................................................4

FETCO®, and Driven To Pioneer Innovation™ are trademarks or trade names of Food Equipment Technologies Company.

© 2009 Food Equipment Technologies Company Part # P108 REV. 000

Programming ..................................................................5

Error Codes ....................................................................6

Wiring Diagram...............................................................7

Parts ...............................................................................8

Model HWB-2

Page 2

FETCO®

Food Equipment Technologies Company

600 Rose Road

Lake Zurich • IL • 60047-0429 • USA

Website: www.fetco.com

Service & Support:

Hours: 7:00 AM - 6:00 PM Central, Monday - Friday

Phone: (800) 338-2699 (US & Canada)

(847) 719-3000

Fax: (847) 719-3001

Email: techsupport@fetco.com

Specifications

Contact Information

Water Requirements:

Pressure: 20-75 psig Weight: 16.8 lbs. (empty)

Minimum Flow Rate: ½ gpm 33.4 lbs. (filled)

Tank Capacity: 2.0 gallons

Electrical Configuration

Electrical Heater Voltage Maximum Hourly Heating

Config. Code Configuration (AC) Phase Wires KW Amp draw Capacity (gallons)

H02011 1 X 2.1 KW 120 single 2 + ground 2.2 18.0 5.4

Weights and Capacity

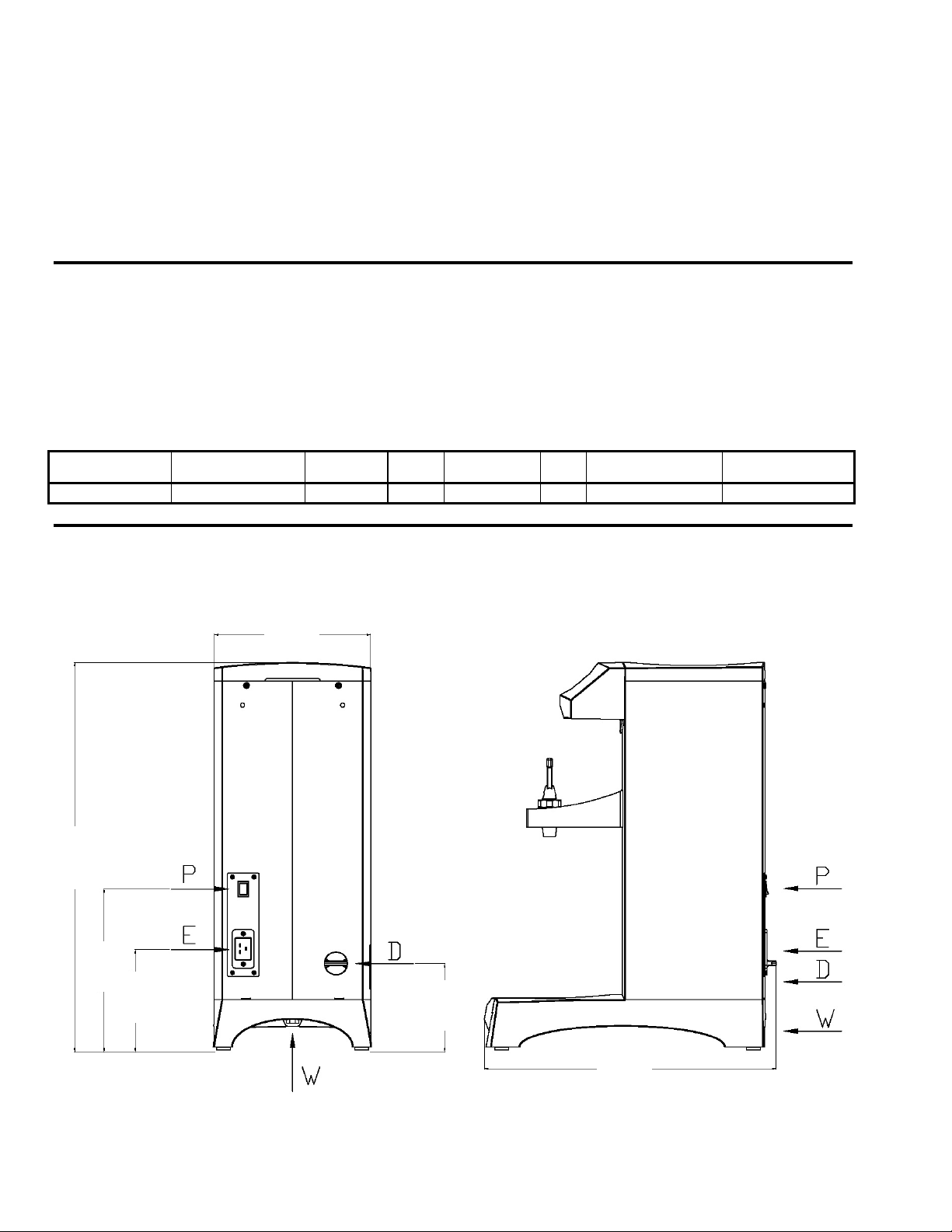

21 1/4”

540 mm

8 7/8”

225 mm

5 1/2”

141 mm

Dimensions & Utility Connections

8 5/8”

220 mm

4 3/4”

121 mm

P- MAIN POWER SWITCH

E- ELECTRIC INPUT

D- DRAIN FITTING

W- WATER CONNECTION

17 7/8”

402 mm

2

Page 3

Installation

The installation must comply with applicable federal, state, and local codes having jurisdiction at your location.

Utilize only qualified beverage equipment service technicians for installation.

A Service Company Directory may be found on our website, http://www.fetco.com.

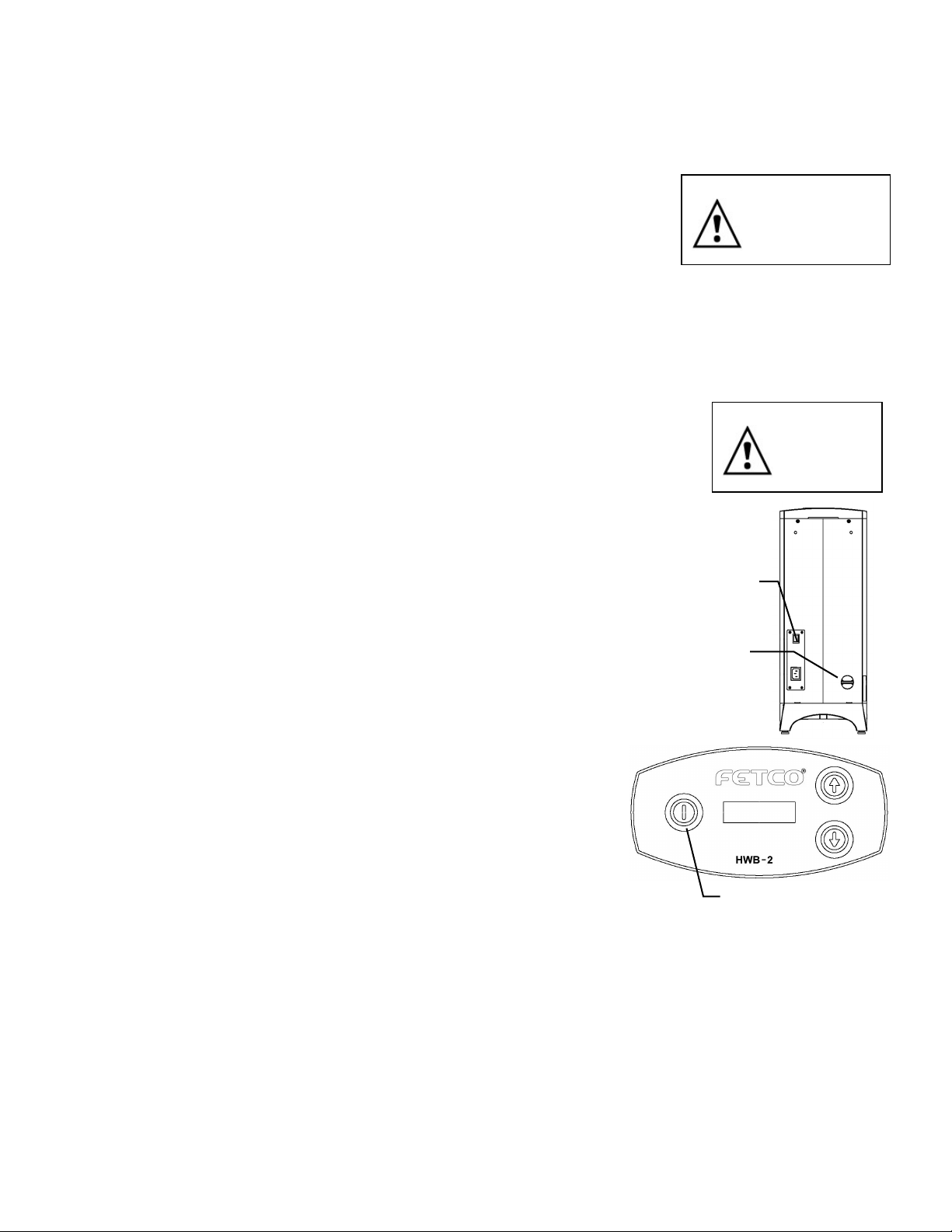

Setup

1. Before placing the unit, verify that it will fit in the space intended for it, and that

the counter or table will support its’ weight.

2. When the unit is in position, use a bubble level to level it front to back and side

to side by adjusting the legs.

Warning: Legs are to be

adjusted only for

leveling the unit.

Do not extend them

higher than necessary.

Water Connection

1. Water inlet is a ¼ inch female pipe fitting.

2. Install a shut off valve near the unit to facilitate service. If an in-line water filter is used, it should be installed

after the water shut off valve and in a position to facilitate filter replacement.

3. Flush the water supply line and filter before connecting it to the unit.

4. Verify that the water line provides at least ½ GPM, and that the water pressure is between 20 and 75 psig.

Electrical Connection

1. Verify that the actual voltage at the electrical outlet is compatible with the unit’s

specifications. The temperature and water tank fill level are pre-set at the factory

and there is no need to turn off the heater during the installation process. The

heating process will start automatically when the tank has filled.

Warning: To prevent

electrical shock,

this unit must be

properly

grounded

Final Setup

1. Turn on the incoming water supply line and inspect both inside and outside

of the unit for leaks in all fittings and tubes.

2. Plug the unit into the appropriate electrical outlet.

3. Turn on the unit’s main power switch (located on the back).

The ON/OFF switch will begin flashing, indicating it is in the OFF position.

The display will read “PRESS KEY”.

4. Press the ON/OFF switch so it is in the ON position (lit, not flashing).

MAIN

POWER

SWITCH

(Note: The switch must be pressed and held momentarily.)

5. Within 6 seconds, the water tank will begin filling until the probe at the top of

TANK

the tank senses the water. The display will read “FILL”. The control board will

disable the heaters until the tank is full.

6. While the water is heating, the display will read “HEAT” and the actual water

temperature will be displayed. After the water has reached the set

temperature, the display will read “READY”.

7. Re- inspect for leaks.

Operator Training

Review the operating procedures with everyone who will be using the

unit. Pay particular attention to the following areas:

1. Demonstrate the hot water faucet and drip tray, paying particular

attention to the safety warning.

2. Demonstrate the cleaning procedures listed on the following page.

3. Show the location and operation of the water shut off valve and the circuit

breaker for the unit.

Tank Drain

ON/OFF

Flashing = OFF

Lit = ON

Dark = Main Power Off

The water tank must be drained before certain maintenance procedures, and whenever the unit is to be relocated

or shipped.

1. Disconnect power to the unit.

2. Move the unit near a sink or obtain a container to hold the 2 gallons of water from the tank.

3. Remove the tank cover and allow the tank to cool to a safe temperature.

4. The tank drain is located on the back of the unit. Turn the drain plug one-quarter turn in either direction.

5. Pull the plug out far enough to expose the silicone tube.

6. Using pliers, loosen the hose clamp and move it back over the tube.

7. Crimp the tube an inch or two away from the drain plug to prevent water from flowing.

8. Use the other hand to pull the drain plug out of the tube.

9. Release the crimped tube and allow the water to flow into the sink or container.

3

Page 4

Operating Instructions

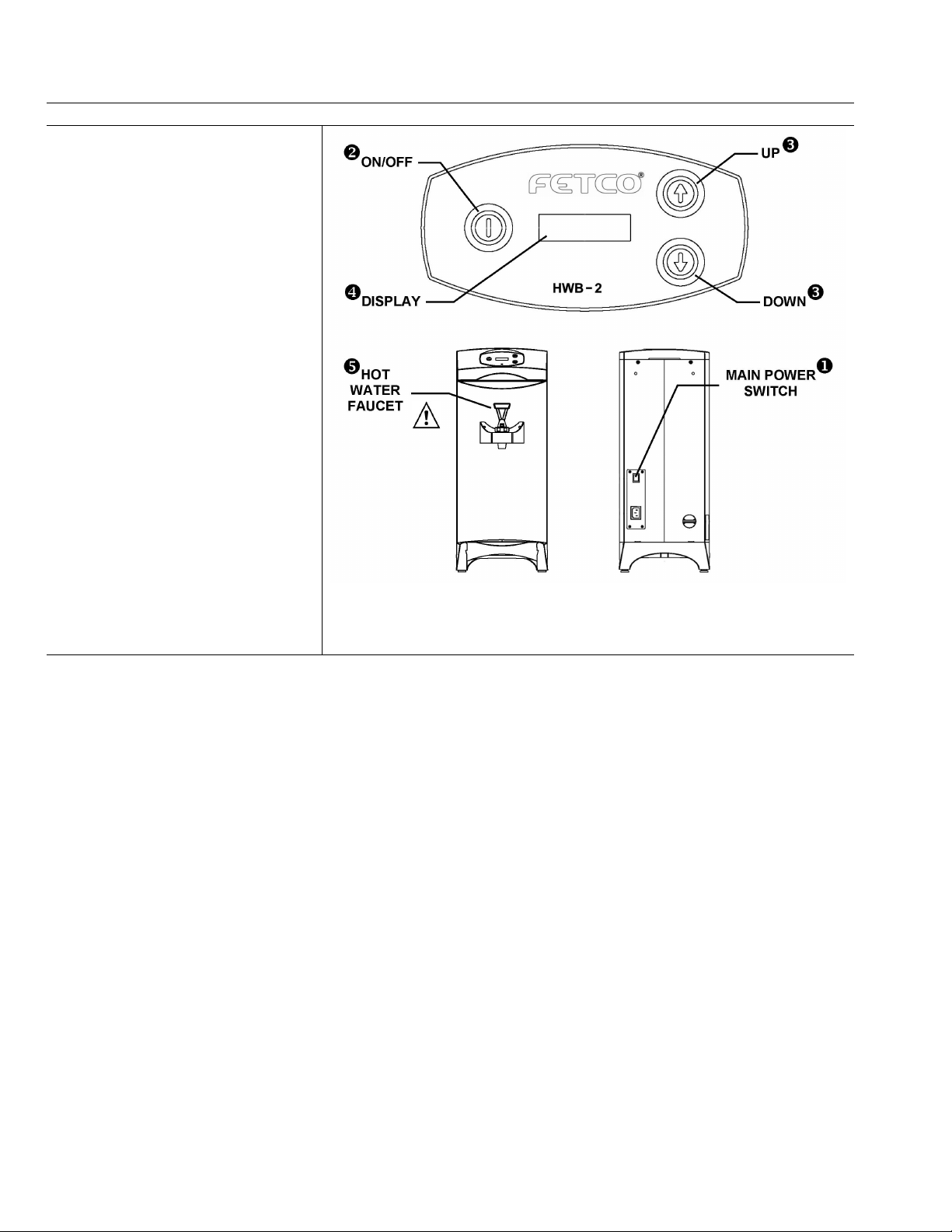

Controls

X Main Power Switch

Controls all power to the unit.

Located on the back of the unit.

Y Control Panel On/Off Switch

Affects only control panel. Does not

disconnect main power.

Flashing = OFF

Lit = On

Z UP and DOWN Switches

Used only during programming.

Switches flash if water temperature

is low (Not READY).

[ Display

Displays the following messages:

PRESS KEY – Control panel is off.

FILL – Water tank is filling.

HEAT (followed by water temp)

–Water is heating after power turned ON.

HEATING – Water is heating during

normal operation.

READY – Water temperature is at the

correct setting.

ERROR – Incorrect setup or settingsmachine will not function.

\ Hot Water Faucet

Pull handle forward to dispense water.

WARNING! Extremely hot water – may

cause serious burns.

Instructions

1. Make sure the drip tray is in place before turning the unit on. Steam and condensation from the water tank is

released into the drip tray whenever the unit is on.

2. Turn the main power switch and control panel switch on.

3. When the diplay reads “READY”, the unit has heated to the proper temperature.

4. Hold a cup or other container under the faucet and pull the faucet handle forward to dispense hot water. Larger

containers such as carafes, pitchers, or large mugs may be placed directly on the drip tray.

Operating Principles

When hot water is drawn from the faucet, the fill valve pulses on and off every few seconds to slowly refill the tank.

(See #60 - Fill Duty Cycle in the Programming section.)

By controlling the flow of incoming water, the amount of cold water entering the tank is synchronized with the rate

at which the water can be heated. This ensures an uninterrupted supply of hot water. When dispensing water at a

rate that exceeds the unit’s capacity to heat, the flow of water out of the faucet will be diminished to maintain the

proper temperature.

Cleaning & Maintenance

Daily: Check the drip tray and empty if necessary.

Quarterly:

• Inspect all fittings and hoses for leaks.

• Inspect inside of tank for lime deposits. De-lime tank and probes if necessary. This procedure should be

performed by a qualified service technician.

4

Page 5

Programming

• To enter Programming mode, first turn the main power switch OFF.

• Press and hold the UP button while turning the main power switch ON.

• Release the UP button as soon as the software version is displayed.

Example: (actual version may vary)

VER 0.7B

• Press the DOWN button to advance

to the first setting – Water Temperature.

7 201 F

• Press the UP button to adjust the value of the setting. After the maximum value has been reached, the value will

loop back to the beginning of the range. The DOWN button cannot be used to decrease the value.

• Continue to use the DOWN button to go to the next address and the UP button to change the value until all

settings are programmed.

• To exit Programming and save changes, press and hold the DOWN button for approximately 2 seconds.

• The POWER switch may be used to exit programming without saving new settings.

Address Name Range Default Comment

7

Water Temp. (°F) 176°F - 204°F 201°F Temperature inside tank. To display in ° Celsius,

see # 58 in Advanced Settings.

10 Enter Advanced

Settings

On / Off Off OFF = Skip Advanced Settings and go back

to 7 – Water Temperature.

ON = Enter Advanced Settings.

50 Water Resistance

(KΩ)

0 - 200 Displays the electrical resistance of the water in

kilohms as measured between the water level

probe and the tank.

51 Water Level

Sensitivity

LO - HI LO

LO – 50 KΩ +/- 5KΩ

HI – 130 KΩ +/- 5KΩ

If water resistance (address 50) is greater than

25 KΩ, set on HI to prevent unwanted filling of the

tank.

55 Tank Temperature

XXX°X

Displays current tank temperature in °F or °C.

57 Reload Defaults 0 - 1 0 Changes all settings to default factory settings.

0 = Do not reload defaults

1 = Reload all default settings

If 1 is selected, you must advance to the next

address for this change to take effect.

58 Temperature Scale F or C F F = Fahrenheit C = Celsius

60 Fill Duty Cycle 5 – 50% 15% This setting controls how fast the tank fills with

cold water. It is designed to ensure that water

dispensed from the faucet will be at the correct

temperature. For a full explanation, see the

Operating Instructions section.

5

Page 6

Error Codes

Code Description Possible Cause Corrective Action

050

Shorted temperature

probe.

051 Open temperature probe.

Initial Fill Error. Initial fill

100

time was more than 6

minutes.

101

200

Error on refill. Tank did

not refill within 7 minutes.

Flat Line Temperature

(Water is boiling).

201 Not heating.

Heater Short.

202*

System is not calling for

heat, but temperature

rises more than 5°F.

255** Keyboard error. Stuck button. Replace control board.

Probe failure. Replace probe.

Bad probe connection,

or probe failure, faulty

wire, connectors,

contacts, etc.

Water supply flow rate is

too low.

Water supply flow rate is

too low.

Triac failure, bad output

on control board, or

temperature is set too

high for altitude.

Failure of heating

element, triac, triac

control board*, or main

control board.

Possible triac failure, or

bad output on triac

control board* or main

control board.

Check all connections and

possible failing parts

Replace probe if

necessary.

Investigate cause of low

flow rate. (Clogged water

filter, etc.)

Investigate cause of low

flow rate. (Clogged water

filter, etc.)

Check triac, check control

board output, or adjust

temperature for altitude.

Check and replace heating

element if necessary.

Check triac, triac control

board*, and main control

board.

Check triac, triac control

board*, and main control

board.

How to Clear Error

Codes

Turn main power

switch off and on.

Turn main power

switch off and on.

Press the control

panel power switch.

Error message is

cleared

automatically.

Turn main power

switch off and on.

Turn main power

switch off and on.

Enter programming

mode, then exit

programming mode.

Turn main power

switch off and on.

6

Page 7

Wiring Diagram

7

Page 8

Figure 1 – HWB-2 – Main Assembly

Parts

ITEM # QTY PART # DESCRIPTION

1 1 1057.00002.00 VALVE, COLD WATER INLET, 120VAC

2 1 1102.00013.00 ADAPTER ASSEMBLY, 3/4" BSP x 1/4" NPT

3 2 1082.00010.00 SCREW, M4x10 ZINC PLATED PAN PHILLIPS MACHINE

4 1 1086.00004.00 BUSHING, SNAP. 1" MOUNTING HOLE

5 1 1104.00005.00 TANK ASSEMBLY, HWB-2 2100W/120V (SEE FIG. 3)

6 1 1086.00007.00 SPACER, PVC, 1.315"ODx1.033"IDx.590"LG

7 1 1003.00007.00 BRACKET, GASKET, HWB-2

8 1 1024.00004.00 GASKET, "U" CHANNEL, 6.75" LONG

9 1 1102.00005.00 COVER ASSEMBLY, POWER INLET

10 1 1102.00016.00 FRONT, ASSEMBLY, HWB-2 (SEE FIG. 2)

11 1 1023.00010.00 PLUG, TANK SERVICE DRAIN

12 1 1086.00003.00 CLAMP, DRAIN PLUG

8

Page 9

13 1 1063.00001.00 CORD, POWER, IEC-320-19, 20 AMP

14 1 1029.00002.00 FITTING, HOSE BARB TEE, SIZE 3/8" , NYLON

15 1 1025.00002.00 TUBE, 5/8"OD X 3/8"ID X 11.5"LG, COLD WATER INLET

16 1 1025.00003.00 TUBE, 5/8"OD X 3/8"ID X 10"LG, TANK DRAIN

17 1 1025.00004.00 TUBE, 5/8"OD X 3/8"ID X 8"LG, TANK WATER INLET

18 1 1025.00007.00 TUBE, 1/2 OD x 1/4 ID, 18" LG, VENT

19 5 1086.00001.00 CLAMP, HOSE, .590"-.673" DIA RANGE

20 1 1001.00007.00 COVER, HWB-2

21 1 1046.00002.00 LABEL, CAUTION, "RISK OF FIRE AND ELECTRIC SHOCK"

22 1 1044.00001.00 LABEL, "FOR USE ON INDIVIDUAL BRANCH CIRCUIT ONLY"

23 1 1402.00003.00 HARNESS, HWB-2

24 1 1112.00007.00 BRACKET, WELDMENT, VENT HWB-2

25 1 1032.00001.00 VENT, ELBOW, TUBING 6 MM OD.

26 1 1025.00006.00 TUBE, VENT SUPPORT, 5/16" OD X 3/16" ID X 1/2" LG

27 1 1003.00008.00 BRACKET, VENT TUBE HOLDER, HWB-2

28 2 1084.00008.00 NUT, MACHINE, M-3 HEX

29 1 1023.00016.00 TRAY, DRIPPING, HWB-2

30 1 1008.00001.00 PLATE, DRIP TRAY, HWB-2

31 1 1102.00015.00 FAUCET ASSEMBLY, HOT WATER, HWB-2

32 1 1023.00007.00 TOP, UNIVERSAL

33 1 1071.00007.00 UPPER FAUCET ASSEMBLY, RED HANDLE, HWB-2

34 1 1071.00008.00 SEAT CUP, FAUCET HWB-2

Figure 2 – HWB-2 – Front Assembly, Part # 1102.00016.00

ITEM # QTY PART # DESCRIPTION

1 1 1108.00002.00 PC BOARD, ASSEMBLY, HWB-2

2 4 1081.00002.00 STANDOFF, 4.5MM HEX x 20MM x M3 THREAD

9

Page 10

Figure 3 – HWB-2 – Tank Assembly, Part # 1104.00005.00

ITEM # QTY PART # DESCRIPTION

1 1 1114.00012.00 TANK WELDMENT STUDS, HWB-2

2 1 1024.00007.00 O-RING, DASH #344, TANK COVER

3 1 1102.00007.00 TANK COVER ASSEMBLY

4 2 1083.00006.00 WASHER, .875"OD X .562"ID, FLAT

5 2 1025.00001.00 FITTING, COMPRESSION MALE CONNECTOR

6 1 1112.00008.00 PROBE WELDMENT, WATER LEVEL 1.875" LONG

7 1 1054.00002.00 PROBE, TEMPERATURE, 8" LONG, 50K OHM

8 2 1023.00003.00 LOCKNUT, 1/4"-18 NPT MODIFIED THREAD

9 1 1059.00001.00 TRIAC 40A, 600V

10 1 1003.00006.00 BRACKET, HEAT SINK

11 1 1003.00005.00 BRACKET, ONE SHOT THERMOSTAT

12 1 1053.00004.00 THERMOSTAT, SINGLE SHOT, 25 AMP

13 1 1107.00001.00 HEATER ASSEMBLY, IMMERSION 2100W/120VAC

14 1 1022.00006.00 INSULATION, TANK HWB-2

10

Page 11

Page 12

Loading...

Loading...