Page 1

FOOD EQUIPMENT TECHNOLOGIES COMPANY

640 Heathrow Drive • Lincolnshire • IL • 60069 • USA

Phone: (800) 338-2699 • (847) 719-3000 • Fax: (847) 821-1178

E-mail: techsupport@fetco.com • Internet: http://www.fetco.com

3

Hot Water Dispensers

Installation

(For Qualified Service Technicians Only)

Keys To A Successful Installation

Electrical: All FETCO dispensers require NEUTRAL. Ground is not an acceptable substitute. Installation

without neutral may cause damage to the electronic components.

The power connection to L1 on the terminal block must be at least 105 volts. Less than 105 volts will cause

erratic behavior.

The power switch has a built-in circuit breaker. To reset it, turn to the “off” position, and then back to the “on”

position.

The wiring diagram for the dispenser is located on the inside of the cover.

Plumbing: This equipment is to be installed to comply with the applicable federal, state, or local plumbing codes.

The water line must be flushed thoroughly prior to connecting it to the dispenser to prevent debris from

contaminating the machine. An in-line water filter is strongly recommended.

Verify that the water line will provide at least 2 gallons per minute before connecting it to the dispenser.

General: Utilize a qualified beverage equipment service technician for installation.

Do not adjust the thermostat settings unless absolutely necessary. They are set at the factory for optimum

performance.

HWB-2000 Series

Installation Check List

The installation must comply with applicable federal, state, and local codes having jurisdiction at your location. Check

with your local inspectors to determine what codes will apply to the installation and operation of FETCO products.

1. Verify that the actual voltage at the electrical service connection is compatible with the specifications on the

dispenser’s serial number plate. Make sure the electrical service includes neutral. Ensure at this time that the

circuit breaker to the dispenser and the power switch on the dispenser are in the off position

2. The temperature and the water tank fill level are pre-set at the factory. There is no need to turn off the heaters

during the installation process. The heaters are disabled by the liquid level control board until water is sensed.

The heating process will start automatically when the tank has filled with water

3. Place the dispenser on a suitable counter or stand.

4. When the dispenser is in position for use, level the dispenser front to back as well as side to side by adjusting

the legs.

5. Remove the cover.

6. Water connection:

• Water inlet is a 3/8 inch compression fitting on HWB-25, 1/4 inch compression fitting on all other models.

• The dispenser can be connected to a cold or hot water line. Cold water is preferred for best flavor, but hot

water will allow for faster recovery times. Use of an in-line water filter is strongly recommended.

• Install a water shut off valve near the dispenser to facilitate service. If an in-line water filter is used, it should

be installed after the water shut off valve and in a position to facilitate filter replacement.

• Flush the water supply line and filter before connecting it to the dispenser.

• Verify that the water line will provide at least 2 gallons per minute and that the water pressure is between 20

and 75 psig.

• Use a wrench on the factory fitting when connecting the incoming water line. This will reduce stress on the

internal connections and reduce the possibility of leaks developing after the installation has been completed.

7. Vent tube connection:

Page 2

• Vent tube connection is a 3/8 inch hose barb.

• The end of the vent tube should be open to the air, not connected or submerged.

8. Power connection:

• A fused disconnect switch or circuit breaker on the incoming power line must be conveniently located near

the dispenser, and its location and markings known to the operators.

• All dispensers require neutral. Damage to the dispenser may result if neutral is not present.

• The body of the dispenser must be grounded to a suitable building ground. A ground lug is provided in the

dispenser next to the power terminal block. Use only 10 gauge copper wire for grounding.

• Electrical connections must be secured in-place within the unit to meet national and local standards.

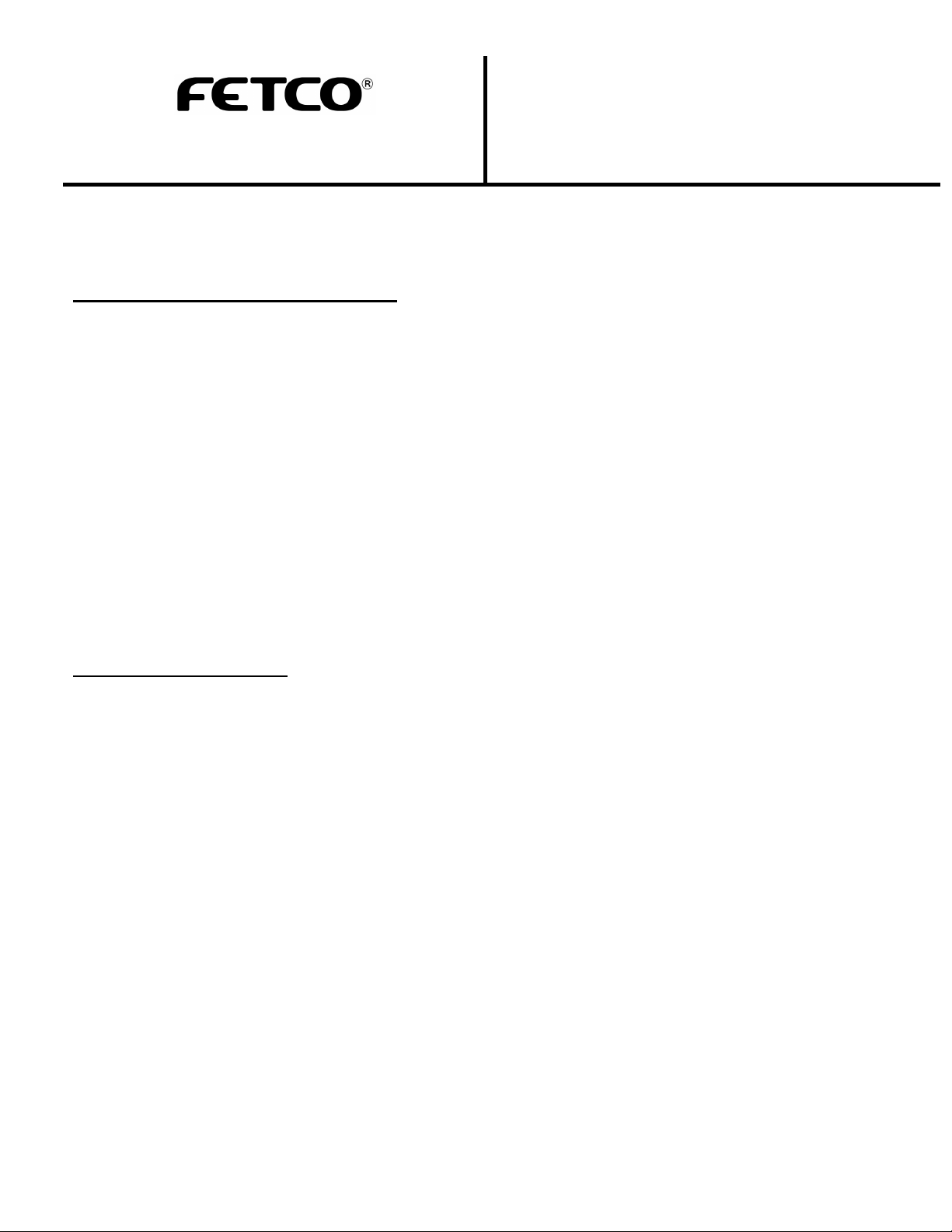

SINGLE PHASE

TERMINAL BLOCK

L1L2N

120V 120V

N

208-240V

GROUND LUG

GROUND

WIRE

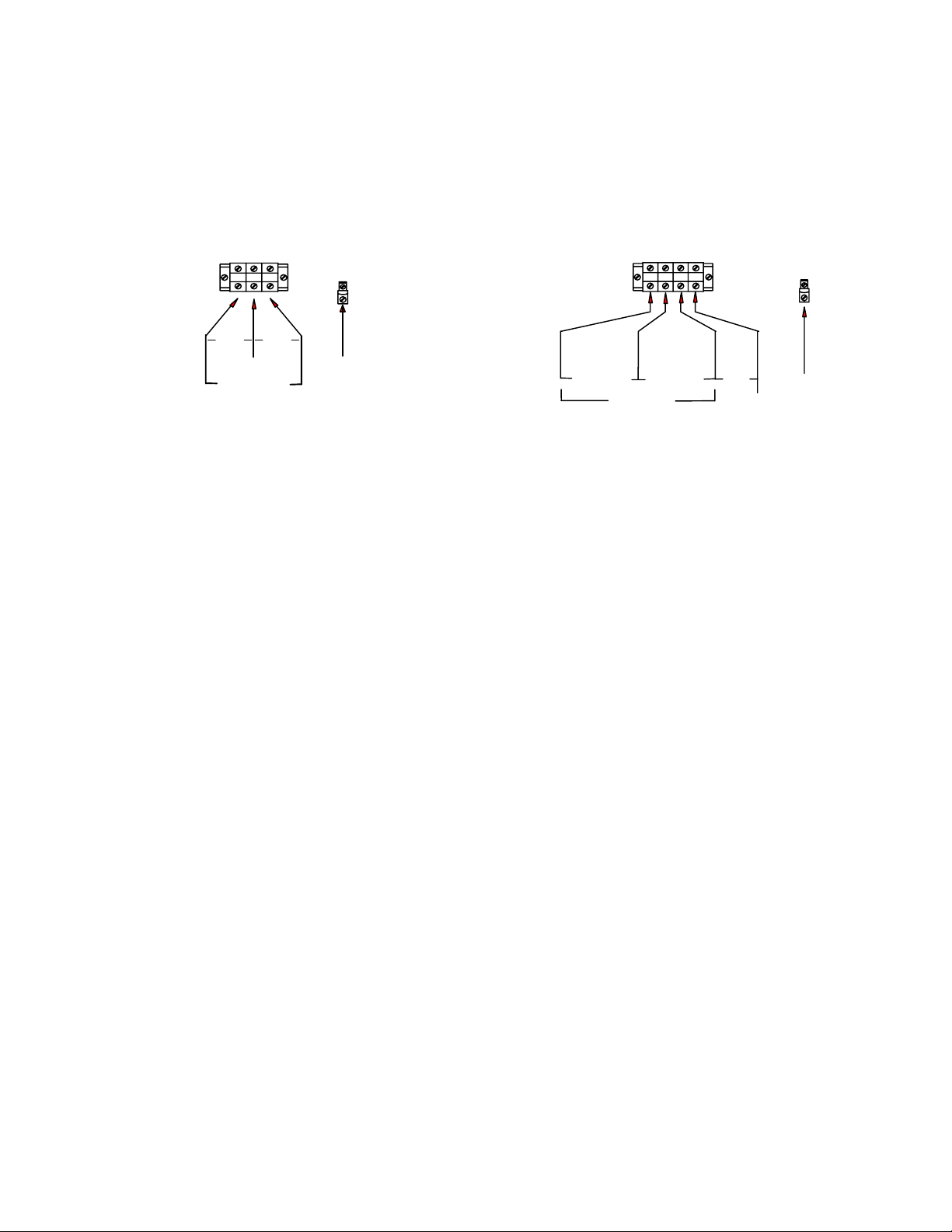

3 PHASE

TERMINAL BLOCK

208-240V 208-240V

L1L2L3

208-240V

N

120V

GROUND LUG

N

Domestic Electrical Configurations

9. Turn on the incoming water supply line and inspect both inside and outside of the dispenser for leaks in all

fittings and tubes.

10. Turn on the incoming power line and the dispenser’s on/off switch.

• Within 6 seconds, the hot water tank will begin filling until the water is sensed by the water probe at the top

of the tank.

• The heaters will be disabled until the water probe at the top of the tank senses water.

11. Review the programming instructions and make any necessary adjustments.

12. Re-attach the cover after one final inspection for leaks.

GROUND

WIRE

Operating Procedures

Turn the dispenser power switch to the on position The power switch will illuminate to indicate that the dispenser has

power and is operating.

When the ready light illuminates, the dispenser is fully up to temperature and ready to dispense hot water through

the faucet. The amount of time required to gain full operating temperature will vary depending on the electrical

configuration that was ordered, and the temperature of the incoming water.

Safety Precautions:

• Do not hang containers or any other object from the faucet or faucet guard.

• Do not disassemble the faucet without closing the shut-off valve located behind the faucet.

2

Page 3

HWB Series Programming Instructions

The display shows the current tank temperature

in ° Celsius when in normal operating mode.

Programming:

Temperature may be set in either Celsius or Fahrenheit.

1. Remove the top cover of the unit.

The control board is located on the left side near the front.

2. Turn the power switch ON.

3. Press and hold SET for 3 seconds.

Temperature setting in °C will be displayed and °C indicator lamp will be lit.

To adjust, press and release SET quickly to advance one degree at a time.

Range: 82-98 °C

4. Press and hold SET for 3 seconds.

Temperature setting in °F will be displayed and °F indicator lamp will be lit.

To adjust, press and release SET quickly to advance one degree at a time.

Range 180-208 °F

Only the last 2 digits of the temperature will be displayed.

Example: 185

°

F is displayed as 8 5 205°F is displayed as 0 5

5. Press and hold SET for 3 seconds. The fill valve % will be displayed and the %FV

indicator lamp will be lit.

To adjust, press and release SET quickly to advance one percent at a time.

Refer to the chart below for the proper setting for your model and voltage.

Range: 15% – 100%.

6. The unit will return to normal operating mode after 30 seconds without programming

activity.

Select the model and actual voltage to determine the correct %FV setting for step 5.

Heater Actual %FV

Model Configuration Voltage Phase Setting

HWB-5 (-1) 1 X 3000 watt 120/208 1 ph. 15

120/220 1 ph. 15

120/240 1 ph. 17

HWB-10 (-1) 2 X 3000 watt 120/208 1 ph. 25

120/220 1 ph. 28

120/240 1 ph. 33

HWB-15 (-1) 2 X 3000 watt 120/208 1 ph. 25

120/220 1 ph. 28

120/240 1 ph. 33

HWB-15 (-2) 3 X 3000 watt 120/208 3 ph. 37

120/220 3 ph. 42

120/240 3 ph. 50

HWB-25 (-1) 6 X 3000 watt 120/208 3 ph. 74

120/220 3 ph. 83

120/240 3 ph. 99

HWB-25 (-2) 6 X 4000 watt 120/208 3 ph. 99

120/240 3 ph. 100

120/220 3 ph. 100

TEMPERATURE CONVERSION

°C °F

82 180

83 181

83 182

84 183

84 184

85 185

85 186

86 187

87 188

87 189

88 190

88 191

89 192

89 193

90 194

90 195

91 196

92 197

92 198

93 199

93 200

94 201

94 202

95 203

95 204

96* 205*

97 206

97 207

98 208

*factory setting

Loading...

Loading...