Page 1

high style plus utility in a

contemporary zigzag

y d av i d d u n d a s

70

proect numer

It was a revolutionary design in the 1930s, but not everyone can

afford to sit on a piece of art. We work the best features of the original

Zigzag chair into a stylish and completely accessible chair

you can actually pull up to the dinner table.

T

he original Zigzag chair designed by Dutch architect Gerrit Rietveld in the 1930s is an iconic

piece of artwork. The cantilevered, Z-shaped chair looked deceptively simple but employed

masterful joinery and was hailed as a sublime example of minimalist design. It was not a chair you

would want to use for, say, everyday dining.

Nevertheless, with modern adhesives and joinery techniques, it is feasible to build a com-

fortable upholstered dining chair both reminiscent of Rietveld’s Zigzag and strong enough for

everyday use. Our chair’s cantilevered frame also gives it a slight comfortable

springiness.

To withstand structural stresses, the chair’s

side assemblies must be made from a strong

hardwood such as jarrah, maple or white

oak. The seat cross-rails and the slip-seat

frame can be made from a secondary

hardwood. The chair’s miter joints are

reinforced and locked with floating

tenons, epoxied, and pinned with brass

screws. We designed this chair to be built

using the Festool Domino tenon joiner.

Getting started

The visible parts of the chair can be made from an

8' board of 6"-wide 6/4 hardwood. Plane the board to a

thickness of 13/8" and rip it into three lengths 1¾" wide. For

ease of handling, cut the three lengths in half to yield six 4'

lengths. Plane and joint each 4' piece so as to finish 13/8"x

19/16" ensuring that all the faces are square to one another.

Crosscut the parts for the feet, legs, seat side rails, back stiles, and back rails

from the 4’ lengths according to the cut list. It is easier to achieve a consistent

length for the matching parts if you clamp a stop to a crosscut sled or use a miter

gauge with a long fence and an adjustable stop. Mark

out 38" radius curves on the top edges of the back

Page 2

rails, and bandsaw away the waste from

their front faces. Use a random-orbit

sander with progressively finer sanding

disks to smooth and fair the curves.

The hidden parts, the seat rails and

the seat frame components, are made

from an 8' board of ¾" x 2½" secondary hardwood. Since the angle to be cut

for the miters is 67.5°, you will need

to make a supplementary 22.5° jig to

achieve the correct angle (see sidebar).

Cutting the miters

Make the 22.5° jig for cutting the

miters on the feet, legs, and the front

end of the seat side rails. Before starting the cut, ensure that the broader

(19/16" ) face of the workpiece is flat on

the saw’s table (Fig. 1). Set aside the

22.5° offcuts for later use as wedges to

facilitate clamping at the glueup stage.

The 49° miters for the back stiles are

cut without the jig by setting the miter

gauge to 41° and clamping the rear face

of the back stiles and the bottom face

of the seat side rail against the miter

gauge fence.

Marking out and milling

the mortises

It is important to remember, when

marking out the positions of the mortises on the components of the side

assemblies, that the assemblies are

mirror images rather than identical.

It is worth laying out the parts and

marking the matching miters before

marking the mortise centers on the

reference face (the face on which the

Domino’s fence will rest).

You are now ready to mill the mortises in the side assembly components

except for the miter locking tenons,

which will be milled after the leg miters

have been glued up. All of the chair’s

mortises are milled using the narrow

width setting on the Domino joiner.

Also, all of the chair’s mortises are

cut with the 6mm-diameter Domino

cutter, except those that reinforce the

miter at the bottom of the back stiles,

for which the 10mm cutter is used.

The height of the Domino’s fence is set

using the dimensions given in millime-

ters in the figures, so that the mortises

are cut at the required distance from

their respective reference faces. All the

chair’s mortises are 20mm deep, except

for those for the locking tenons, which

are 28mm deep, and those for the back

stile miter, which are 25mm deep.

In order to achieve a perfect joint,

the Domino’s fence must lie perfectly

flat on the workpiece, so that the mortise is milled exactly perpendicular

to the face. To help ensure that the

machine’s fence remained flat during

the cut, I clamped a cleat behind the

workpiece so the fence would have

a broad surface to rest on (Fig. 2).

Although this procedure slows the milling of the mortises a little, it is essential

to avoid the risk of cutting any mortise

at the wrong angle.

To mill the mortises in the endgrain of the back rails, seat rails and

stretcher, you need to attach the narrow

frame accessory (Fig. 3) to the Domino’s fence to hold the machine steady

during the cut. The mortises in the end

0 5 . 0 7 | w oo dc ra ft m a g a z i n e 39

photos: david dundas

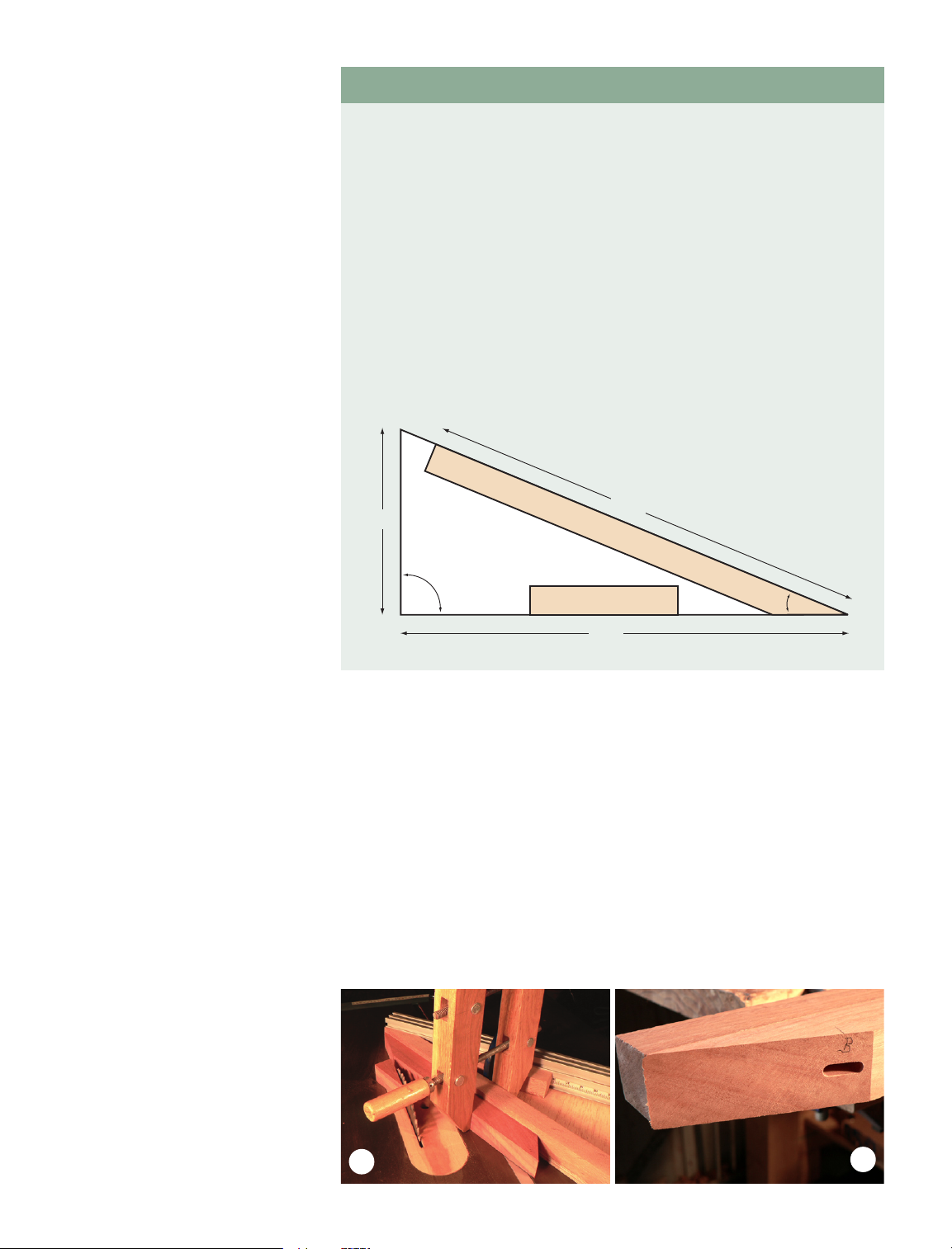

MAKE A JIG FOR CUTTING LEG MITERS

Cut a right-angled triangle from ½" plywood with a base 24" long and

a height of 9

15

/16". Mill a hardwood cleat 1½" square and 36" long. Cut an

8" length from the cleat, and glue and screw it flush with the base of the

plywood triangle. Cut 24" from the remainder of the cleat, and mark out a

22.5° miter on one of its ends. Cut away the 22.5° wedge of waste with a

backsaw, and plane the miter face to the marked line. Then glue and screw

the mitered cleat flush with the hypotenuse of the triangle. Square the outer

faces of the cleats by running the jig over the jointer with the jig’s base

against the fence.

Set your miter gauge to an angle of 45°, and clamp the jig to its fence,

adjusting the position of the jig so that the mitered end of the cleat barely

grazes the table saw’s blade as the miter gauge is moved forward in its

slot. I used a Kreg miter gauge, which has a suitably long fence, but if you

have a standard miter gauge, you will need to attach an auxiliary fence to it.

Align the end of the workpiece with the mitered end of the cleat and clamp

it to the jig with a hand-screw clamp. It is essential

to clamp both the jig and the workpiece very

firmly. If either came loose during the cut,

it could cause a nasty accident.

1

2

w w w . w o o d c r a f t M a g a z i n e . c o M

915/16"

24"

24"

90º

22½º

Page 3

iLLustration: ricK christopherson

40 w o o d c r a f t m a g a z i n e | 0 5 . 0 7

70

proect n u m er

CUT LIST

A Foot (2) 13/8" x 19/16" x 17¾"

B Leg (2) 13/8" x 19/16" x 265/8"

C Seat side rail (2) 13/8" x 19/16" x 17¾"

D Back stile (2) 13/8" x 19/16" x 181/2"

E Back rail (3) 13/8" x 19/16" x 16"

F Stretcher

7

/8" x 13/8" x 16"

G Seat rail (2) ¾" x 2¼" x 16"

Seat frame, side rail (2) - not illus.

5

/8" x 2" x 17¼"

Seat frame, back/front rail (2) - not illus. 5/8" x 2" x 11¾"

H Locking tenon stock 6mm x 19mm x 500mm

TOOLS, HARDWARE & MATERIALS

Festool Domino joiner, festool.com

6 x 19 x 40mm Domino (16)

10 x 23 x 50mm Domino (2)

11/2" #8 brass wood screws (12)

Minwax wipe-on polyurethane

G

H

E

D

B

F

C

A

Tenon center to edge

distance = 8mm

15/8"

33/8"

Page 4

13/8"

17.5mm

10mm

miter face

13/8"

5

/8"

17.5mm

miter face

0 5 . 0 7 | w oo dc ra ft m a g a z i n e 41

19/16"

FOOT

221/2˚

3"

1

/4"

173/4"

4"

15/8"

mortises 6mm x 19mm x 20mm deep

unless otherwise noted

w w w . w o o d c r a f t M a g a z i n e . c o M

13/8"

5

/8"

17.5mm

miter face

17.5mm

9

/16"

13/16"

17.5mm

10mm

miter face

End face

of back rail

19/16"

13/8"

top

5

/8"

Radius of curve 38"

17.5mm

mortises 6mm x 19mm x 20mm deep

BACK RAIL

16"

13/8"

46˚

20mm

181/2"

51/2"

23/8"

85/8"

BACK STILE

13/8"

19/16"

265/8"

221/2˚

15/8"

1315/16"

LEG

20mm

miter face

25mm

deep

19/16"

9.5mm

4"

15/8"

173/4"

221/2˚

49˚

SEAT SIDE RAIL

1"

25mm

deep

Page 5

3

5

4

7

6

8

before you apply your final finish.

First, the 22.5° miters are glued up

(Fig. 5) using a Domino in mortise B

to ensure precise alignment of the joint.

When the epoxy has set, the squeezeout is cleaned up, and mortises J and

K are milled; the locking tenons, shopmade from the same hardwood as the

chair parts, are then glued in place (Fig.

6). When the glue has set, cut away

the projecting portions of the locking

tenons and sand them level.

Drill 1¼"-deep 7/64" pilot holes

(Fig. 7) for the #8 brass screws; smear

the screws with epoxy and drive them

home, taking care not to split the wood

by driving them too hard against the

bottoms of their pilot holes. When the

epoxy has set, the heads of the screws

are sawn off and the screw shanks

are filed (wrap the tip of the file with

masking tape to prevent marring) and

sanded level.

Before gluing the 49° miters (Fig.

8), cut away the tips of the 22.5° miters,

removing about 3/8". After the sides

are glued up you can gently round

this front edge with a smooth file and

sandpaper. Make four 8° wedges out

of scrap to facilitate clamping the 49°

miters. Finally, when the 49° miter

joints have been glued up, drill pilot

holes for screws to pin their reinforcing 20 x 50mm Dominoes, and glue

them in place. Cut off the screw heads

and file and sand their shanks level as

before.

Gluing the rails

After sanding each of the side assemblies, lay one assembly on its outer

face and insert epoxy into the mortises

for the cross rails. Push 6 x 40mm

Dominoes into the mortises and stand

the back rails, seat rails, and stretcher

vertically in position. Insert epoxy and

Dominoes into the top end mortises

of the rails; insert epoxy into the mortises in the second side assembly, and

then get a helper to assist in fitting the

assembly onto the Dominoes projecting from the ends of the rails. When

the second assembly has been pushed

home, stand the chair upright with its

project photos: david dundas

grain of the back rails, seat rails, and

stretcher are all centered in their end

faces.

Gluing the side assemblies

Before you start to glue up the side

assemblies, bandsaw the waste from the

underside of the feet and sand all the

parts (Fig. 4) to 150-grit. Glue 100-grit

sandpaper to the 22.5° wedge offcuts to

prevent slippage when the clamps are

tightened.

The glueup is done in several stages,

using a gap-filling epoxy with a gel

consistency and a hardener that will

allow plenty of time for assembly. It’s

easy to clean up after using epoxy if

you spread carnauba wax in the areas

that you expect squeeze-out to occur.

The epoxy won’t stick to it and the wax

can be removed with mineral spirits

42 w o o d c r a f t m a g a z i n e | 0 5 . 0 7

10

9

70

proect n u m er

Page 6

0 5 . 0 7 | w oo dc ra ft m a g a z i n e 43

feet on a level surface and clamp it

until the epoxy has set (Fig. 9).

When set, clean away the epoxy

squeeze-out, give the chair a final

sanding and finish with four coats of

Minwax Wipe-on Poly. Fig. 10 shows

a close-up of a finished miter joint.

Making the seat frame

Mill mortises for 6 x 40mm Dominoes

in the ends of the front and back rails

of the seat frame and in the inner

faces of the frame's side rails. The

back and front rails of the seat frame

are glued between its side rails. I took

the frame to a professional upholsterer to get it upholstered with foam

on elastic webbing and covered with

black leather. There should be 1/8"

clearance on either side of the seat

frame to accommodate the thickness

of the leather.

In order to be certain that the chair

was strong enough to withstand the

stresses of frequent use, it was tested

by placing a board across its side rails

and having three people with a total

weight of 576 lbs. stand on the board.

The rear ends of the side rails were

depressed by ½" under the load, but

sprang back to their original position

when the load was removed, and the

joints remained intact.

w w w . w o o d c r a f t M a g a z i n e . c o M

AMAZING DETAIL WITH FREE SOFTWARE

HAVE YOU EVER HAD A HARD TIME following drawings for projects that you’d like to

build? Are there times when you would like to see hidden details? The eDrawings viewer

is a universal CAD and solid model viewer that will let you open a wide range of twoand three-dimensional files. One such file, containing the Zigzag dining chair from this

article, is available for you to download at woodcraftmagazine.com. The file includes the

viewer as well as the model file, so there is nothing more to install on your computer.

You will be able to rotate, pan, and zoom into the 3-D image with your mouse. You

will also be able to make the project explode and collapse, cut it in half with a section

view, and even take measurements directly off the model!

Navigation Tips

• When you need to return the model to its original state, click on the Home button.

• To see the parts outlined because it makes the edges more distinct, go to the View

menu and click on Show Edges When Shaded.

• To rotate your view around the model, click and hold your middle mouse button (or

mouse wheel) as you move the mouse.

• To zoom in and out, move the mouse to the center of what you want to see, and spin

the mouse wheel. If you don’t have a wheel, click on the Zoom button and click-anddrag the mouse up or down to zoom.

• If you want to see details that are obscured by another part, right-click on the part and

a popup menu will appear. You can make the part transparent or hide it completely.

Parts List, Move, Measure, and Explosion

Open the Feature Manager Tab by clicking the icon on the left side of your screen.

• The items listed are the parts and subassemblies that make up the chair. Clicking on

any of these items will highlight the part or assembly in the model view.

• To see details that are obscured by a part, click on the Move icon, then drag the part

with your mouse. Double-click on the moved part to return to its original position.

• Extract measurements by clicking the Measure icon, and clicking on a part.

• The great thing about the eDrawings viewer is that you can watch the assembly

of parts explode and collapse to match the drawing in the magazine. Click on the

Explode icon. Click it again to bring the chair parts back together.

The eDrawings viewer has many more features, so to learn more, check out the built-

in help file. To download the free viewer separately, visit solidworks.com.

Download your free copy of the Zigzag chair and viewer in the projects section at

WoodcraftMagazine.com.

David Dundas

David was an exploration geologist in Tanzania, England, and

Australia. Since retiring in 1995, he has indulged his passion

for furniture making, with a particular interest in designing and

building chairs.

Loading...

Loading...