Page 1

Tools for the

toughest demands

Powerful extraction.

The dust extraction turbine

TURBO for efficient working

Page 2

3

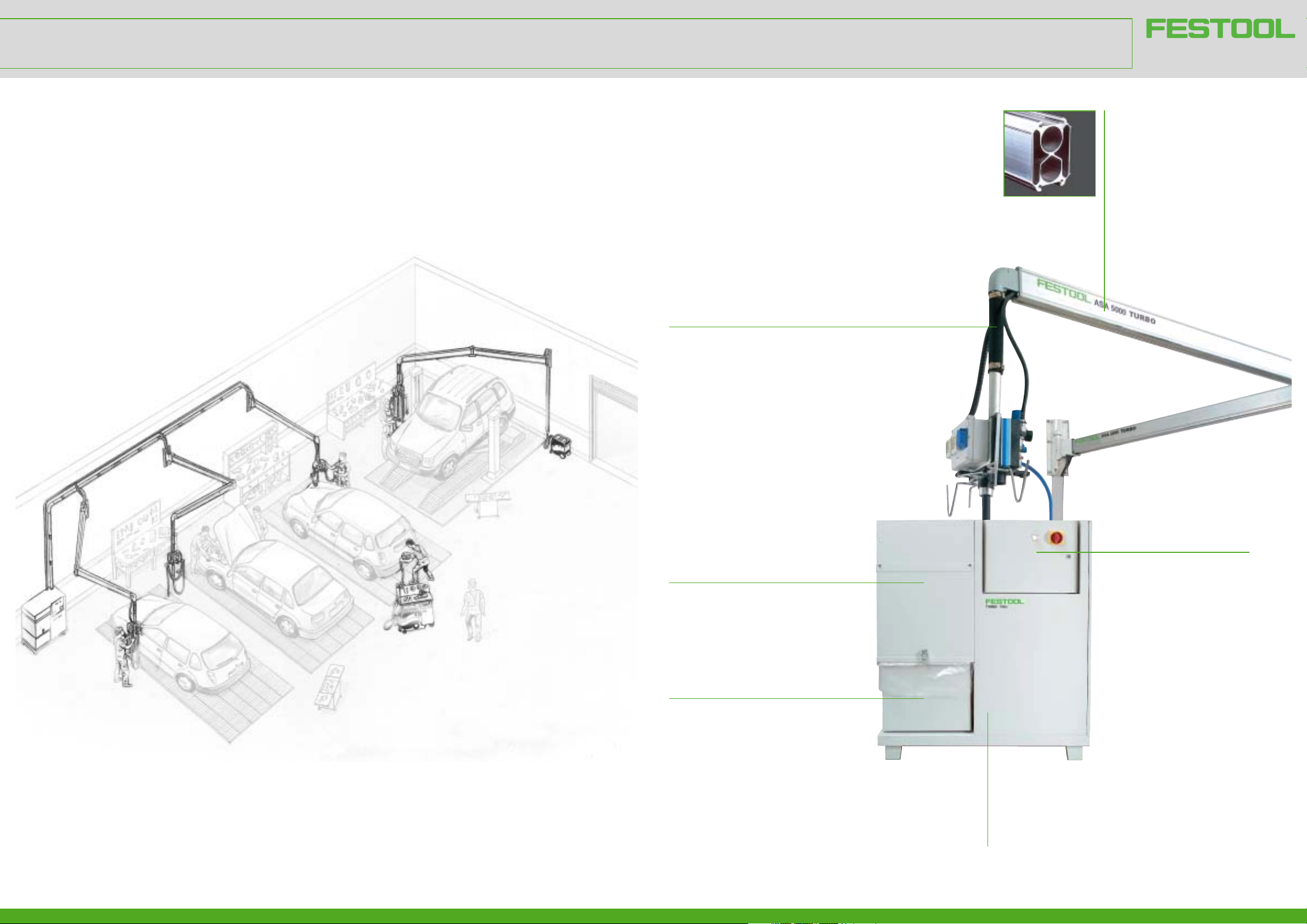

The dust extraction turbine TURBO

Central module of a stationary dust extraction system

2

Professional solutions for dust extraction

in the workshop.

With the dust extraction turbines TURBO 3091, 4001, 7501,

you can benefit from our many years of experience. The dust extraction turbines we have developed have been used successfully

in individual European countries for over 20 years. Our knowledge

in the field of dust extraction technology and our experience as

a system provider make us a competent partner when it comes

to equipping your workshop with an efficient, individual dust extraction solution.

Here we will show you how the application of the Festool

dust extraction turbine TURBO in combination with the

boom arm ASA could look in practice. The dust extraction

turbine TURBO can be housed in the direct vicinity of the

workplace or separately in another room because it does

not require much space thanks to its compact design.

The layout of the pipe system is individually dependent on

the on-site workshop conditions, the number of workplaces

where dust extraction is to be carried out and the electric

power tools and pneumatic tools used in parallel.

For single workplaces or mobile dust extraction, the combination of CT mobile dust extractor with boom arm ASA or

with Toolcenter TC is still the proven solution for an optimum

dust extraction result.

Flexible working.

With the boom arm, the compressedair supply and power supply can be

positioned conveniently and easily

wherever work is currently be carried out. And this without obstacles

because the power supply is fed in

from above. The lengths of 5 m or

6 m and the double-jointed system

make operation extremely flexible

while simultaneously allowing for a

large action radius.

Power for any

requirement.

The dust extraction turbines

are offered in three versions.

They differ only in their suction

performance – their sturdy,

technical construction and their

reliability in daily continuous

operation are identical.

Cleaning with high pressure.

On a jet-air cleaning system, a rotating

pneumatic nozzle clears the filter by

blowing in air. The automatic cleaning

that is performed cyclically prevents the

dust from baking and ensures a long filter

service life.

Simply clean.

The sanding dust that is sucked in is collected in the dust container. With a plastic

dust bag, the dust can be disposed of

practically and conveniently.

Light and stable.

This cross-section shows the stable interior. The profile structure gives the boom

arm made of light aluminium its stability

and high torsion resistance. The smoothwalled extraction channel integrated into

the profile prevents dust deposits.

If you want to achieve an optimum paint result when carrying out

sanding work, the accumulated sanding dust has to be extracted

quickly and efficiently. The reliable extraction of dust is therefore a

central theme in car body and paint workshops. In addition to singleplace dust extraction with one of the proven Festool CT mobile dust

extractors, the powerful, interlinked dust extraction of several

workplaces is also required. Festool now offers a central, professional

solution: the Festool dust extraction turbine TURBO. This allows for

virtually dust-free working, even if you sand with several tools

simultaneously.

Constant dust extraction.

Its high suction performance allows for

optimum evacuation of the sanding dust,

even over long pipe distances.

Page 3

Your reliable partner in practice.

Josè Vargas, Motor Mallorca, Spain:

"It is important to us that we can rely on our tools at all times

because we often have to perform continuous operation. The

Festool dust extraction turbine is always ready for operation

and it is also easy to operate."

Christine Rapp, Gewerbe Akademie Lahr, Germany:

"We are continuously teaching new apprentices who are not

always familiar with dust extraction systems. Therefore, a

reliable and easy-to-operate dust extraction system is a must

in our workshop. The powerful Festool dust extraction turbine

has also proven itself in permanent operation thanks to its easy

cleaning system. For this reason, this turbine in combination

with the Festool system accessories represents an effective

problem solution for us."

5

The dust extraction turbine TURBO

Powerful, sturdy, reliable

4

Brings system into extraction.

Car body companies, paint workshops and companies in the automobile industry are dependent on efficient workplace dust

extraction when performing painting work. The dust extraction

turbine has been developed especially for these requirements.

Depending on the version, up to 16 tools or 8 boom arms

can be operated parallel to each other using this turbine.

Its features make it a real professional for workshop applications:

the stable housing and the well-engineered cleaning system ensure a long service life and constant high suction power. Long pipe

distances do not take the wind out of this turbine because low

loss of circulation in the pipe system ensures consistent suction

power at any workplace.

Larger installations can also be achieved easily and without

problems via separate dust extraction circuits. In this way, a

gradual extension can also be implemented later on. At the

same time, this increases the availability of the dust extraction

if repair work or maintenance has to be carried out on a dust

extraction circuit.

Performance

Doesn’t give dust a chance.

Using compressed air against dust – this is the principle of jet-air

technology. The filter is cleaned by being blown clear with clean

air that is sucked in rather than being shaken as is the procedure

in mechanically pneumatic systems.

The pneumatic cleaning is effective and produces little noise.

And this is how the principle works: the compressed-air nozzle

is located in the centre of the filter. It begins to rotate as soon

as the compressed air is introduced. The dust is loosened, which

prevents the filter from baking or getting clogged up.

For filter cleaning, the jet-air system works in two stages: if the

turbine is in operation, cleaning is carried out for 6-7 seconds per

minute. After the turbine is switched off, a subsequent cleaning

cycle is also carried out for 10 seconds, in order to clean the

filter and to prevent dust particles depositing on the filter.

The filter has a degree of filtration of virtually 99.9% and ensures

that the exhaust air guided out is practically free of dust.

Cleaning

Guarantees fast working – anywhere.

On a stationary dust extraction system, the simple combination of

boom arm ASA with energy box EAA and the individually adapted

pipework ensure a large degree of mobility.

The boom arm consists of a light aluminium construction, which

is reinforced with struts on the inside. This enables it to remain

stable, even with boom extensions of up to 6 m.

The integrated energy box EAA ensures efficient and flexible layout of the workplace. This is because it offers connections for the

power supply, compressed air and exhaust air. Here, you can

quickly find a connection for all tools used for working on the paint,

both pneumatic and electric. Two tools can be operated parallel

to each other. The turbine is switched on and off by remote control via sensors in the interlocking bar system of both suction

spouts. And because the entire supply is fed in from above, there

are also no cables and hoses that could cause someone to trip up.

Flexibility

The jet-air system ensures a long operating

time without maintenance pauses.

The filter is easily and quickly inserted.

The profile structure on the inside of the

boom arm gives it its stability.

The boom arm with joint: for more flexibility

and range.

With a suction power of up to 8,500 l/min,

the workspace is kept virtually clean.

Reliability

Page 4

7

The dust extraction turbine TURBO

Technical data

The dust extraction turbine TURBO

The system concept

6

Interface pad

Stickfix

sanding pads

Pneumatic eccentric

sander LEX 2

Pneumatic

orbital sander

LRS

Pneumatic

mobile dust

extractor CT

Performance description

Powerful dust extractors.

• Constant high suction power even when several pneumatic

tools or electric power tools are used simultaneously thanks

to three-phase drive, which can withstand continuous

operation.

• Easy and application-oriented operation.

•Unique jet-air cleaning system with self-cleaning filter.

Technical Data TURBO 3091 TURBO 4001 TURBO 7501

Supply voltage/

Frequency [V/Hz] 400/50 400/50 400/50

Power consumption [kW] 2.2 3 5.5

Compressed-air supply

Jet-Air cleaning

(flowing pressure)

max.

[bar] 6 6 6

Volume flow

max. [l/min] 4,670 4,833 8,500

Underpressure max. [Pa] 28,000 28,000 23,500

Noise level [db(A)] 68 70 78

Dimensions 500 x 1,000 500 x 1,000 600 x 1,100

(DxWxH)[mm] approx.x 900 x 900 x 1,200

Weight [kg] approx. 107 109 200

Filter surface area [cm

2

] 50,000 50,000 50,000

Hose spout

Intake air/exhaust air

Outer diameter [mm] 75 75 75

Protection class [IP] 55 55 55

Dust bag STB-TURBO

Plastic

Contents: 10 bags

Order No. 492 730

Main filter HF-TURBO

Filter surface area 50,000 cm

2

,

Filter degree of filtration 99.9%

Contents: 1 filter

Order No. 492 731

Accessories Description and application

System components Description and application

Energy box

EAA 2/3 EW/DW TURBO

Scope of delivery: power box with 2 x 230V

connections and complete compressed-air

supply unit with 3 connections, in a box

Order No. 583 808

Boom arm ASA 5000 TURBO

Scope of delivery: double-jointed arm

with wall bracket, in a box

Order No. 273 382

Boom arm ASA 6000 TURBO

Scope of delivery: double-jointed arm

with wall bracket, in a box

Order No. 273 434

Toolcenter TC 3000

Scope of delivery: TC 3000, 1 hose holder,

in a box

Order No. 583 285

Rear panel TC 3000 RW

for Toolcenter TC 3000 including 10 hanger

hooks, Dimensions length x width:

990 x 340 mm

Order No. 452 986

Eccentric sander

ETS

Boom arm ASA

and Energy box EAA

Stickfix abrasive

Titan2 and Platin 2

Dust extraction

turbine

TURBO

Sanding and extraction with the

Festool system.

Versions

Dust extraction Dust extraction Dust extraction

turbine turbine turbine

TURBO 3091 TURBO 4001 TURBO 7501

Order No. 273 555 Order No.: 273 394 Order No.: 273 395

Scope of delivery: dust extraction turbine, 1 dust bag,

1 absolute filter (mounted), on a pallet

Quick and perfect work results when sanding with dust extraction – naturally, the Festool dust extraction turbine TURBO

offers this too. Of course, Festool again offers a system solution in which all components are completely coordinated with

each other as a fundamental component of a stationary dust

extraction system and in combination with Festool boom arms

ASA, Festool pneumatic tools and electric power tools, Jetstream

®

sanding plates, sanding pads and Stickfix sanding discs

and abrasive strips.

With the Festool product range, we are in a position to deliver

custom-made dust extraction solutions for nearly any workshop

requirement.

A well-designed system approach – very impressive.

Rotex

RO

Page 5

FESTOOL

Minden Industrial Ltd.

Saxham Business Park

Saxham

Bury St. Edmunds

Suffolk IP28 6RX

England

Telephone: 01284 760791

Facsimile: 01284 702156

E-mail: info@minden.co.uk

http://www.festool.co.uk

www.festool.com

www.festool.com

Online product catalogue

Service

Online shops

News and special offers

Dealer search

Test reports

Example applications

3D animation

Your link to more information...

On our current Festool site you can, for example,

find information about

• the complete product range

• interesting new products

• countless product animations

• many helpful application examples or

• our comprehensive service offer.

And all of this at your leisure.

Do you want to be able to order around the clock?

This is possible under www.festoolshops.com.

Simply visit the online shops of our system

partner dealers and place your order.

Subject to alterations and errors. All illustrations are non-binding. Created for TTS Tooltechnic Systems AG & Co. KG, Wendlingen, 12/2003, Parts-No. 057 314, DE and AT

1)

Within the EU in accordance with the operating manual.

2)

For current terms and conditions please see our Internet site or contact us.

Regardless of how long the warranty

period is set by law, with Festool you’re

guaranteed to be better off. Festool

grants a 1 year guarantee from the

date of purchase, as long as the tool

has been used correctly. This guarantee

is automatically extended by a further

two years provided that the guarantee form that is

enclosed with every new tool, is filled in completely and

returned to Minden Industrial Ltd within 30 days from the

date of purchase.

Art.-No. 057 314

Loading...

Loading...